1.1. Motivation

As electrification, control theory, and advanced manufacturing technology continue to evolve, the National Aeronautics and Space Administration (NASA) has identified unmanned aerial vehicle (UAV) technology as being a critical area for future development, as illustrated in

Figure 1. Adaptive and learning systems have significantly broadened the operational designed domain (ODD) of UAVs, enabling them to function with minimal human intervention and rapidly self-tune during unpredictable weather, extreme working conditions, or even under conditions of partial damage [

1].

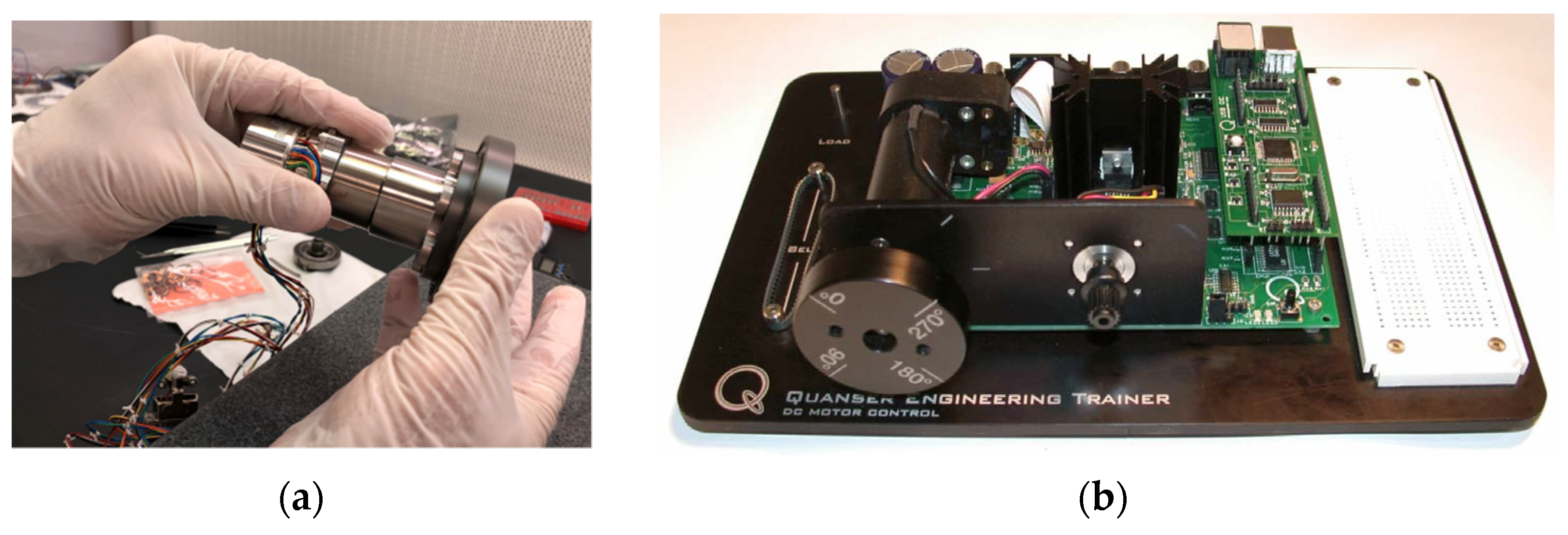

Direct current (DC) motors, illustrated in

Figure 2, are a type of rotary electrical motor that converts direct current electrical energy into mechanical energy. DC motors were the first type of motor to receive widespread usage due to their ability to be powered by existing direct-current lighting power distribution systems. As a result, they are widely used as the driving mechanism for UAV propellers.

Control of DC motors is a classic topic, with recent novel methods such as deterministic artificial intelligence (DAI), as presented here, neural networks [

7,

8,

9,

10,

11,

12], and reinforcement learning [

13], as well as other instantiations of neural network-based, stochastic artificial intelligence [

14,

15,

16] being employed.

Khomenko et al. [

9] sought optimal control of motor positioning using a combination of artificial neural network and state space methods with variable gain yielding a transient process close to optimal without overshoot. The approach proposed in this manuscript has a similar efficacy. Gesh et al. [

10] investigated a dual implementation: a neural estimator used to estimate the motor speed and a neural controller used to generate a control signal for a converter, illustrating the effectiveness and advantages of the method in comparison with conventional control schemes. Naung et al. [

11] demonstrated the improved speed and torque dynamic responses of DC motors by using a neural network parameter tuner with a classical proportional, integral controller. Yang et al. [

12] proposed neural networks with output feedback to deal with DC motor measurement noise and unknown dynamics, including friction, parametric uncertainties, external disturbances, and unmodeled dynamics. Ćirić et al. [

13] applied an adequate classifier based on a deep neural network, achieving accuracy of about 87% using only 668 data samples. Nizami et al. [

14] proposed a single-functional-layer Legendre neural network integrated adaptive backstepping control technique and favorably compared the performance to the response obtained from proportional–integral–derivative controller. Lei et al. [

15] proposed self-tuning and approximation via RBF neural networks, validating control system accuracy owing to its robustness and adaptability. Seeking to avoid corrective maintenance to reduce costs, Scalabrini et al. [

16] used an artificial neural network for the prediction of motor failure time.

Just this year, Zhang et al. [

17] appended a virtual DC motor control to the converter to effectively suppress the fluctuation of the DC bus reducing the rate to 9%, and the voltage recovery time was only 0.18 s. Tufenkci et al. [

18] proposed reinforcement learning of PI control dynamics for optimal speed control of DC motors by using the Twin Delay Deep Deterministic Policy Gradient Algorithm. Munagala et al. [

19] proposed controlling DC motor speed using a technique for identifying the system dynamics for neural network-based fractional-order proportional-integral derivative controller. With respect to computer numerical control machines, DC motors are still affected by transmission torque ripple, which mostly depends on the speed and the transient line current at the transmission interval, Prakash et al. [

20] utilized a combination of so-called golden eagle optimization and a radial basis function neural network to reduce ripple to 1.26%. Ghany et al. [

21] illustrated that an efficient interval type-2 fuzzy-based, single-neuron proportional–integral–derivative controller can improve dynamic motor response while accommodating system uncertainty. Baidya et al. [

22] utilized a sensor feedback-supported controller based on a novel dandelion optimization PID controller, achieving integral square errors, integral absolute errors, integral errors, integral time square errors, and integral time absolute errors on the order of

. Sorfina et al. [

23] illustrated that the deleterious impact on the performance of DC motors when utilized for photovoltaic cleaning system automation resulted in 14% failure rate. Mohanraj et al. [

24] illustrated many advantages, including independent variable speed and variable torque operation along with regeneration capability when using DC motor-based electric drive systems by considering road friction, aerodynamic forces and transmission in the calculation of the motor shaft torque using model predictive control and proportional integral control, while only being able to assert the scheme makes significant energy capture possible. Thus, improvements that can be validated are continually being developed. Yang et al. [

25] reported that efficiency as much as 15–20% higher was possible with a sliding-mode-based PID control, while merely asserting effectiveness. Tripathi et al. [

26] proposed a quite novel fractional order adaptive Kalman filter for sensor-less motor speed control, but only achieved robustness and accuracy improvements in state estimation in comparison with extended Kalman filter instantiations. Saini et al. [

27] claimed better performance using an enhanced hybrid stochastic fractal search controller. Rahman et al. [

28] also tried a fractional transformation, but implemented it on an H-infinity controller. The results of that 2023 study should be considered a benchmark for the comparison of the results presented In this manuscript (noting the undershoot and overshoot characteristics).

Highlighting the vulnerability of conventional direct torque control to ripple, Kumar et al. [

29] sought to achieve minimization and regulation of speed, where their novel instantiation of space vector pulse width modulation reduced the torque ripple by 63.1% when compared to conventional PI and 58.5% when compared to a second benchmark, a PSO-PI controller.

Mérida-Calvo et al. [

30] also focused on commanded trajectory tracking seeking to address both time delays (tracking lag) and overshoots. They asserted that PID controllers did not yield a good tracking performance owing to friction nonlinearity, and proposed adding a prefilter combined with a Smith predictor, an anti-windup scheme, and a Coulomb friction compensator.

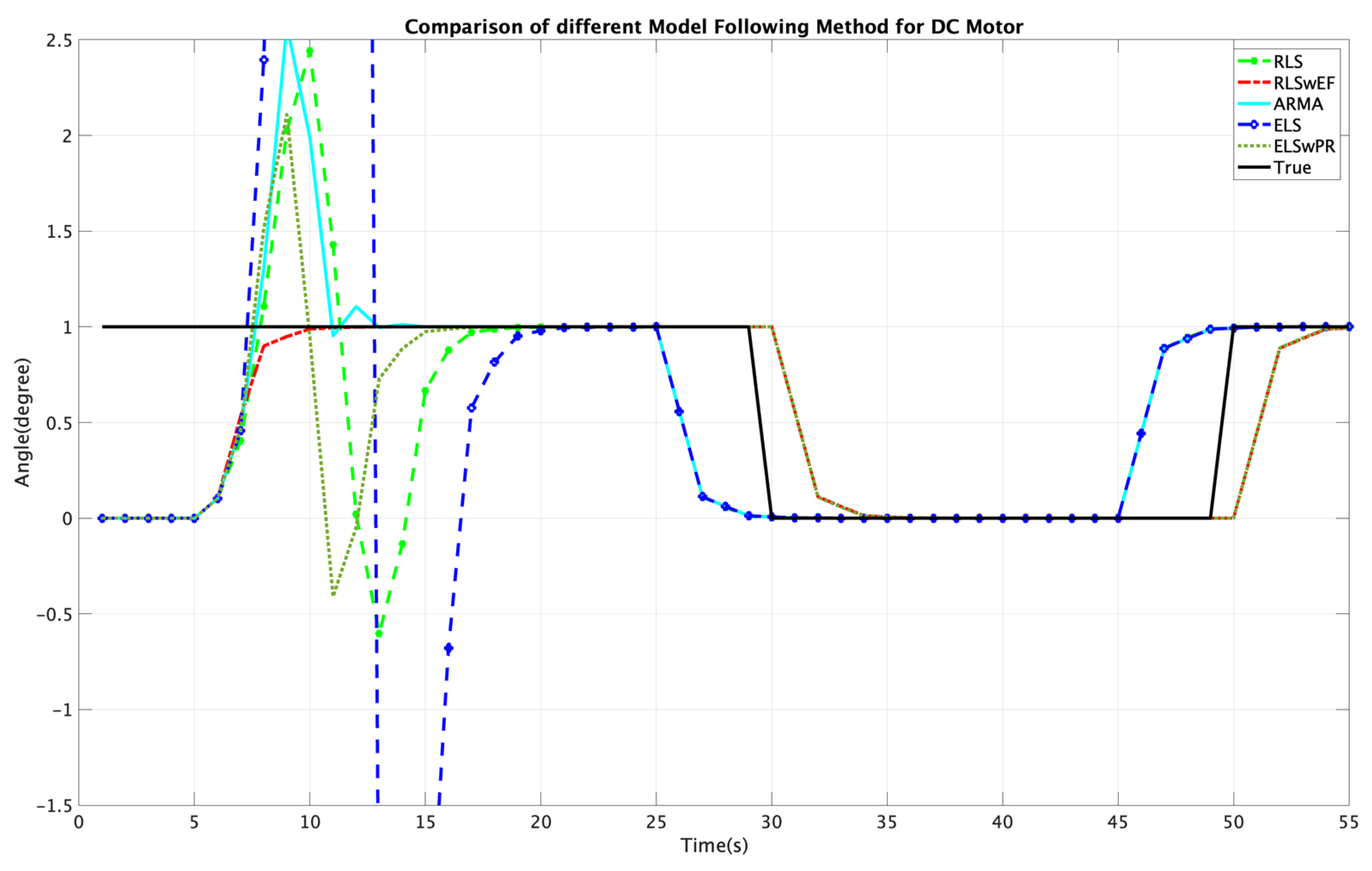

Vered et al. [

31] used digital twins to remotely update feedback controllers, and the results produced very accurate trajectory tracking of square wave commands (while the overshoots and settling (also called “ringing”) remain a residual concern. The results recently achieved by Vered in 2023 make available a high-performance benchmark for comparing the results presented in this manuscript, where such tight target-tracking is sought without the “ringing”.

Improved performance was achieved by Gurumoorthy et al. [

32], and the results modestly mimic the results presented in this manuscript, although the deleterious effects of noise remain prevalent.

Perhaps the proposals closest to those presented in this manuscript come from Stanford’s Moehle and Boyd [

33], whose methods most closely mimic the proposed work, following the Cornell University line of research, where comparisons are made for sinusoidal versus optimal instantiations akin to the deterministic artificial intelligence methods to be proposed in this manuscript. Figures 6 and 8 in [

33] illustrate the difficulty overcoming back electromagnetic force while attempting to follow a square wave. Very similar results were presented by Stanford’s Niemeyer et al. [

34,

35], and later by their colleague Diolaiti [

36], illustrating the temporal longevity of the challenge identifying cancellation-replacement approaches experience performance limits due to sensor quantization, discretization, and amplifier bandwidths, where virtual stiffness was introduced to address these limitations.

On the other hand, the deterministic artificial intelligence method proposed in this manuscript utilizes self-awareness statements that are deterministic in nature to establish governing differential equations based on either the underlying physical properties of the problem or system identification methods [

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47]. This characteristic distinguishes it from the commonly used stochastic approaches in artificial intelligence, as it primarily employs first principles whenever feasible. Utilizing deterministic artificial intelligence principles instead of commonly used methods has the advantage of a simpler approach once re-parameterization has been derived. Despite being deterministic, its optimality in terms of self-awareness and learning can be readily understood by researchers who possess basic knowledge of linear regression.

Bernat et al. [

37] proposed model-reference adaptive control, while Gowri et al. [

38] proposed direct-induction motor torque control using a discontinuous pulse width modulation algorithm, seeking to reduce current ripples. Rathaiah et al. [

39] optimized the adaptive control method, while Haghi et al. [

40] made similar proposals using extremum-seeking methods. These approaches were in parallel with one of the predominant lines of physics-based work, that of the research group of Lorenz at the University of Wisconsin [

41], and their efforts continue [

42,

43,

44,

45,

46]. Zhang et al. [

42] used an analogous three-phase motor illustrating efficacies applied to direct torque control of five phase motors. Apoorva et al. [

43] extended Lorenz’s physics-based techniques to variable flux motors. Flieh et al. [

44] illustrated loss minimization for various servo motors, in permanent magnet motor systems [

45], and self-sensing via flux injection [

46] with parallel application by Vidlak et al., illustrating ripple control [

47]. The deterministic artificial intelligence proposed here adopts the physics-based feedforward approaches of Lorenz’s group, and that adoption necessitates prescribed trajectories.

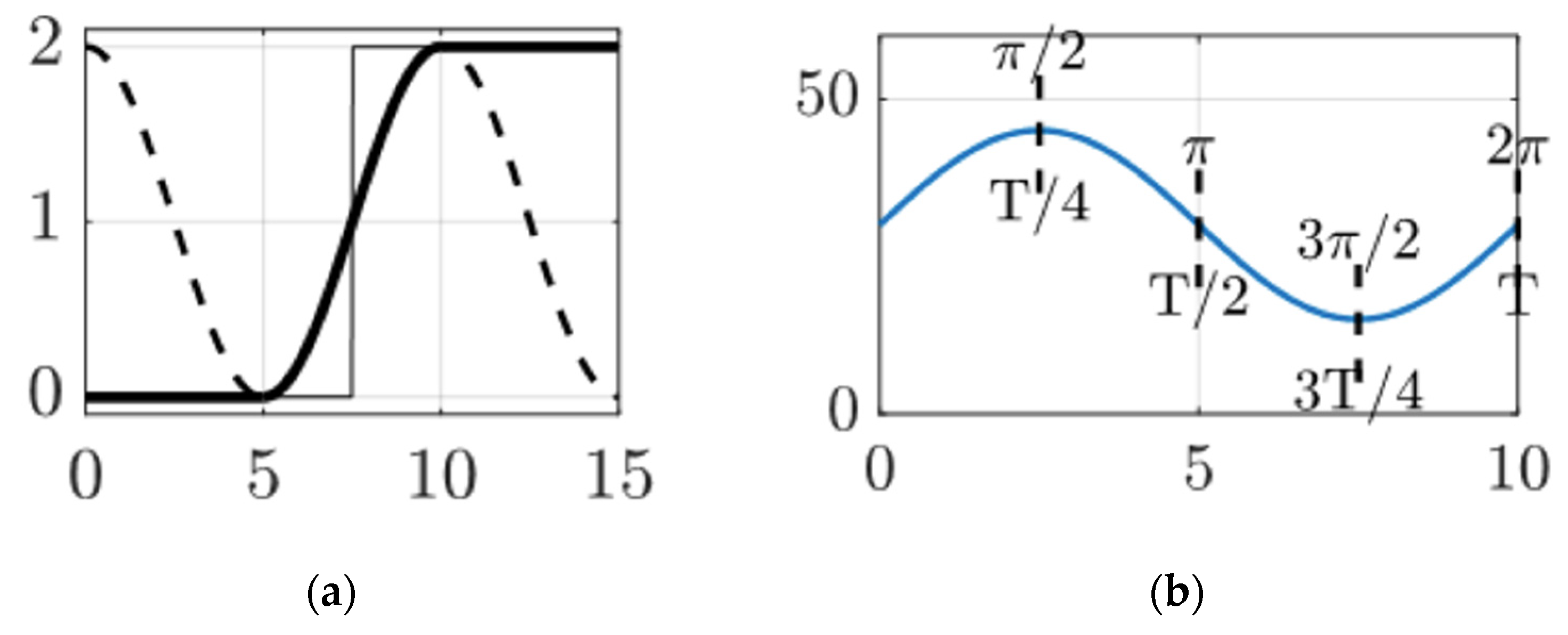

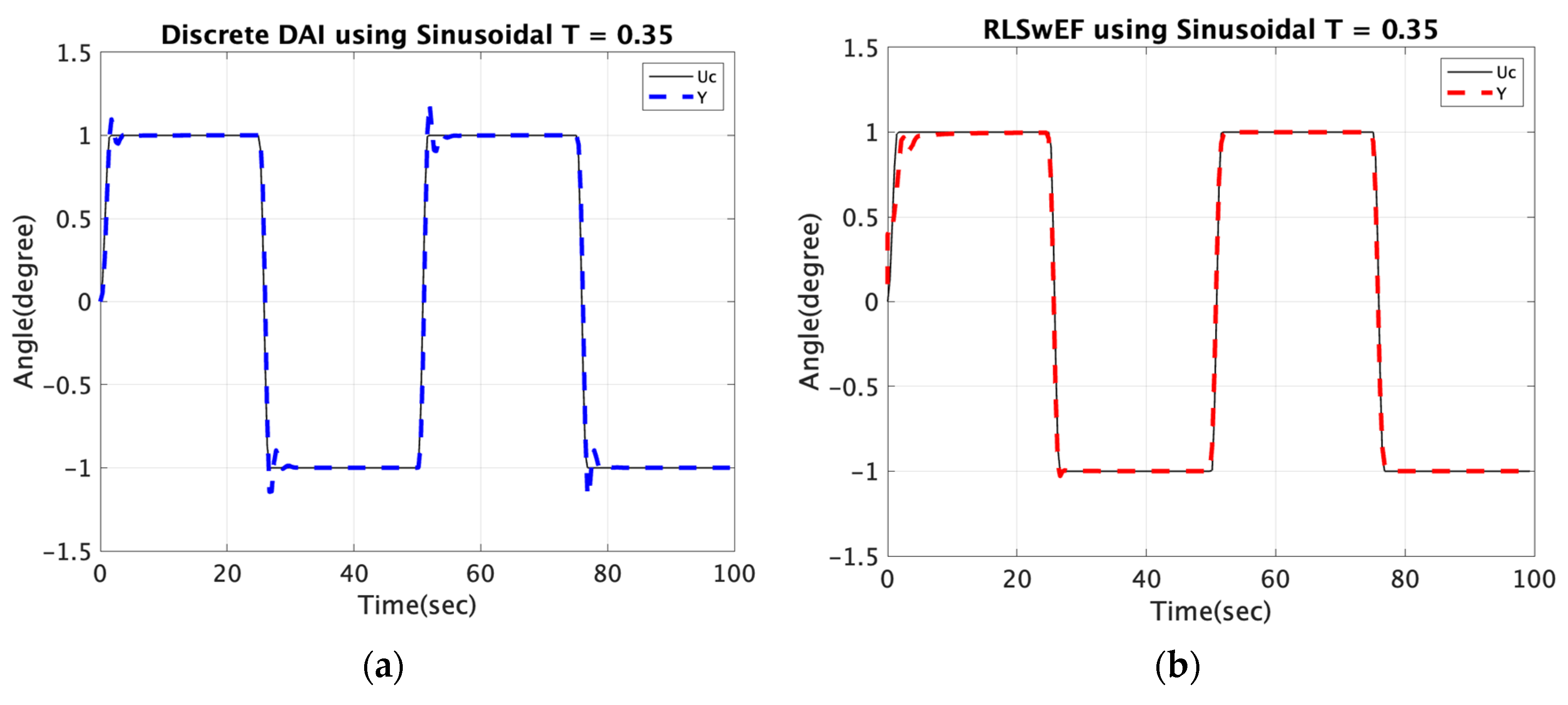

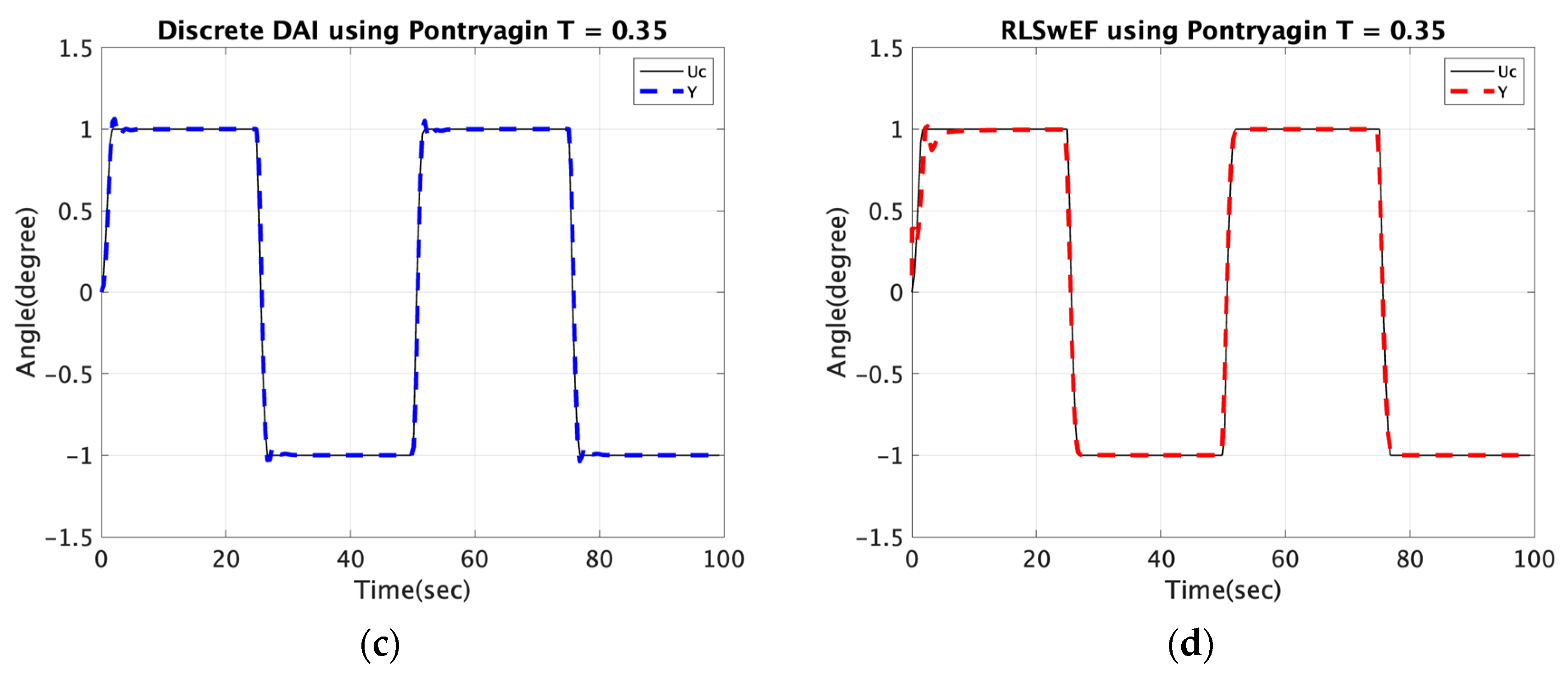

When applying deterministic artificial intelligence, autonomous trajectory generation techniques are needed to approximate non-differentiable transient changes using a smooth curve. Two of the most widely used techniques for this purpose are the sinusoidal and Pontryagin methods. The latter involves utilizing boundary conditions to compute optimal trajectories based on control cost and will be compared to the sinusoidal method, which is a simpler technique for trajectory generation.

This manuscript expands on the analysis of deterministic artificial intelligence as presented in the following literature review, with the main purpose being to advocate for the commercial use of deterministic artificial intelligence in unmanned vehicles. The primary content of this manuscript consists of a detailed comparison of both discrete deterministic artificial intelligence and a selected state-of-the-art benchmark approach, with a specific focus on their trajectory-tracking capabilities when combined with different trajectory-generation methods. The comparison aims to provide a comprehensive evaluation of the strengths and weaknesses of each approach in the context of trajectory tracking, thereby aiding in a more informed decision-making process when selecting a suitable methodology for unmanned aerial vehicle applications.