A Vibration Fault Signal Identification Method via SEST

Abstract

1. Introduction

2. Synchroextracting S Transform Method

2.1. SEST Algorithm

2.2. Algorithm Implementation

3. Comparative Analysis with Other Transforms

3.1. Comparative Analysis of Time-frequency Distribution

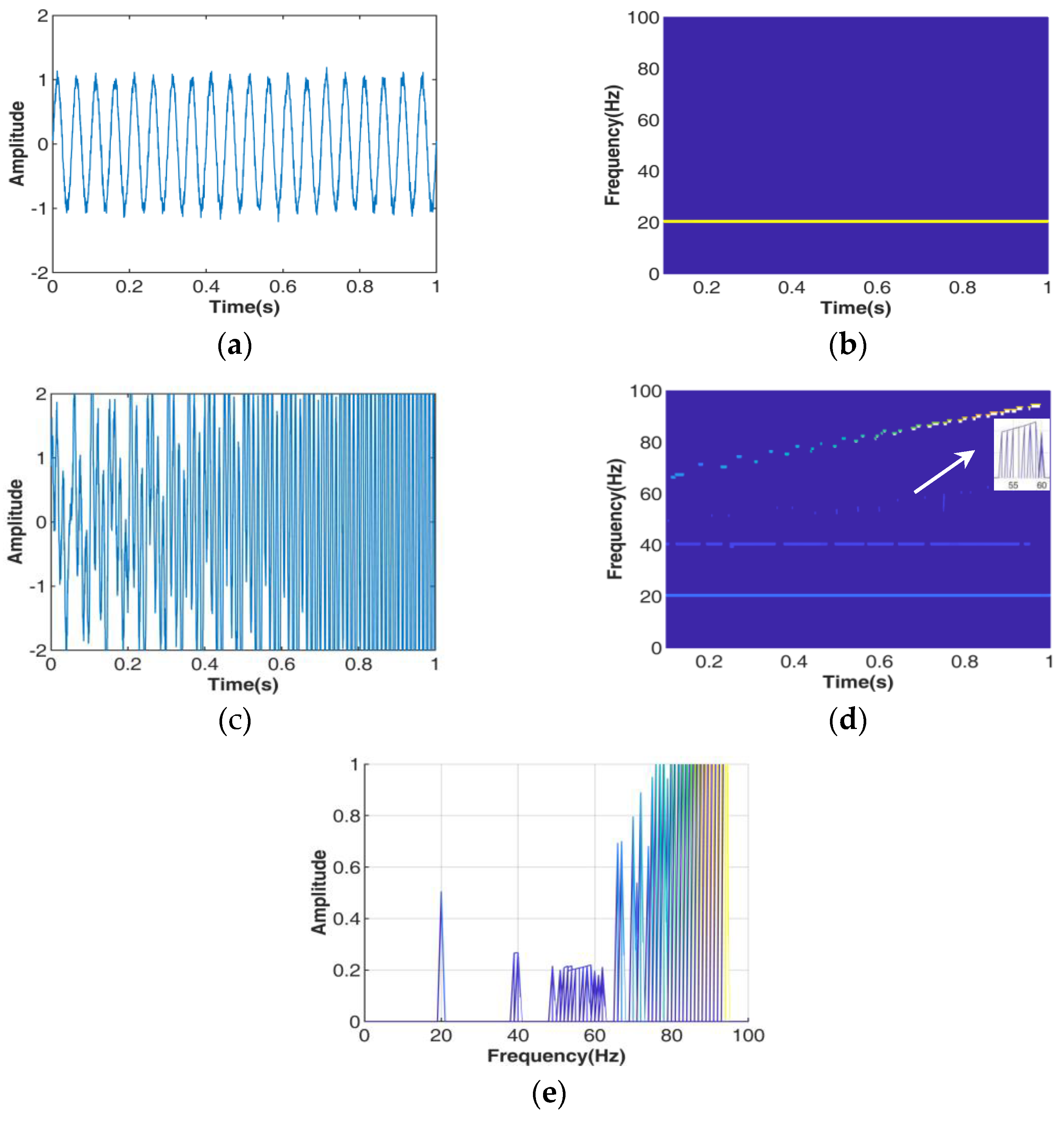

3.1.1. SEST Proposed in This Paper

3.1.2. Comparative Analysis with Other Transforms

3.2. Comparative Analysis of Time-Frequency Concentration

3.2.1. Comparative Analysis without Noise Interference

3.2.2. Comparative Analysis with Noise Interference

3.3. Comparative Analysis of Algorithm Efficiency

4. Time-Frequency Feature Extraction of Rotor Vibration Fault Signals

4.1. Rotor Misalignment Vibration

4.2. Rotor Unbalance Vibration

4.3. Rotor Bearing Wear Vibration

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xin, P.; Ge, B.; Tao, D.; Lv, P. Electromagnetic torque characteristics analysis of nuclear half-speed turbine generator with stator winding inter-turn short circuit fault. Electr. Eng. Technol. 2021, 16, 2055–2063. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Li, J.; Lu, H.; Ma, H. Feature extraction method based on nofrfs and its application in faulty rotor system with slight misalignment. Nonlinear Dyn. 2020, 99, 1763–1777. [Google Scholar] [CrossRef]

- Maheswari, R.U.; Umamaheswari, R. Trends in non-stationary signal processing techniques applied to vibration analysis of wind turbine drive train-a contemporary survey. Mech. Syst. Signal Process. 2017, 85, 296–311. [Google Scholar] [CrossRef]

- Varanis, M.; Silva, A.L.; Balthazar, J.M.; Pederiva, R. A tutorial review on time-frequency analysis of non-stationary vibration signals with nonlinear dynamics applications. Braz. J. Phys. 2021, 51, 859–877. [Google Scholar] [CrossRef]

- Żak, G.; Wyłomańska, A.; Zimroz, R. Local damage detection method based on distribution distances applied to time-frequency map of vibration signal. IEEE Trans. Ind. Appl. 2018, 54, 4091–4103. [Google Scholar] [CrossRef]

- Verma, N.K.; Gupta, R.; Sevakula, R.K. Signal transforms for feature extraction from vibration signal for air compressor monitoring. In Proceedings of the Tencon IEEE Region 10 Conference, Bangkok, Thailand, 22–25 October 2014. [Google Scholar]

- Narasimhan, S.; Nagarajaiah, S. A STFT semiactive controller for base isolated buildings with variable stiffness isolation systems. Eng. Struct. 2005, 27, 514–523. [Google Scholar] [CrossRef]

- Huang, M.; Zhu, L.; Zhang, Z.; Han, J.; Liu, B. Fault vibration signal analysis of air vehicle flying based on STFT. Equip. Environ. Eng. 2021, 18, 62–65. [Google Scholar]

- Liu, J.; Li, X.; Qiao, X.; Li, H. Time-frequency analysis of vibration signal from cylinder head of a diesel engine based on EMD and STFT. Noise Vib. Control 2013, 33, 133–137. [Google Scholar]

- Wang, Y.; Zheng, L.; Gao, Y.; Li, S. Vibration signal extraction based on FFT and least square method. IEEE Access 2020, 8, 224092–224107. [Google Scholar] [CrossRef]

- Mao, Y.; Fang, S.; Li, T.; Ma, H. Study on the vibration characteristic of turbine rotor eccentricity based on FFT. In Proceedings of the 7th International Conference on Mechanical and Aerospace Engineering, London, UK, 18–22 July 2016. [Google Scholar]

- Le, Y.; Li, H.; You, C.; Hu, X.; Liu, D.; Xiao, Z. On the Feature Extraction Method for Rotor Vibration Signal based on FFT and EWT. Hydropower New Energy 2019, 33, 34–38+65. [Google Scholar]

- Liu, J.; Yao, J.; Liu, X. Generalized S transform with adaptive optimized window and its application in seismic signal analysis. Inf. Technol. J. 2013, 12, 276–286. [Google Scholar] [CrossRef][Green Version]

- Chen, H.; Yi, Y.; Chen, W.; Chen, P.; Shen, J. Fault Diagnosis Method of Gearbox Bearings Based on Generalized S-transform. China Mech. Eng. 2017, 28, 51–56. [Google Scholar]

- Hu, Y.; Tu, X.; Li, F. High-order synchrosqueezing wavelet transform and application to planetary gearbox fault diagnosis. Mech. Syst. Signal Process. 2019, 131, 126–151. [Google Scholar] [CrossRef]

- Chen, X.; Cheng, G.; Shan, X.; Hu, X.; Guo, Q.; Liu, H. Research of weak fault feature information extraction of planetary gear based on ensemble empirical mode decomposition and adaptive stochastic resonance. Measurement 2015, 73, 55–67. [Google Scholar] [CrossRef]

- Yu, G. Research on Excavator Vibration and Sound Signal Processing Using Time-Frequency Analysis Method and Implementation. Ph.D. thesis, Shandong University, Ji’nan, China, 2016. [Google Scholar]

- Yu, G.; Yu, M.; Xu, C. Synchroextracting transform. IEEE Trans. Ind. Electron. 2017, 64, 8042–8054. [Google Scholar] [CrossRef]

- Yu, Z.; Yu, C.; Chen, X.; Huang, T. Adaptive multiple second-order synchrosqueezing wavelet transform and its application in wind turbine gearbox fault diagnosis. Meas. Sci. Technol. 2022, 33, 15110. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K.; Chen, P. Fault diagnosis for rolling bearings based on synchrosqueezing wavelet transform. China Mech. Eng. 2018, 29, 585–590. [Google Scholar]

- Welch, P. The Use of Fast Fourier Transform for the Estimation of Power Spectra: A Method Based on Time Averaging over Short, Modified Periodograms. IEEE Trans. Audio Electroacoust. 1967, 15, 70–73. [Google Scholar] [CrossRef]

- Schmidt, R. Multiple Emitter Location and Signal Parameter Estimation. IEEE Trans. Antennas Propag. 1986, 34, 276–280. [Google Scholar] [CrossRef]

- Xu, B.; Tian, S. Detection for Broken Rotor Fault in Induction Motors Combining Multiple Signal Classification Algorithm with Extended Prony. J. North China Electr. Power Univ. 2015, 42, 16–23. [Google Scholar]

- Dehina, W.; Boumehraz, M.; Kratz, F. Detect ability of rotor failure for induction motors through stator current based on advanced signal processing approaches. Int. J. Dyn. Contorl 2021, 9, 1–15. [Google Scholar]

- Roy, R.; Paulraj, A.; Kailath, T. Estimation of Signal Parameters via Rotational Invariance Techniques-ESPRIT. IEEE Trans. Acoust. Speech Signal Processing 1987, 67, 341–350. [Google Scholar]

- Capon, J. High-Resolution frequency-Wavenumber Spectrum Analysis. Proc. IEEE 1969, 57, 1408–1418. [Google Scholar] [CrossRef]

- Stoica, P.; Li, J.; Ling, J. Missing Data Recovery Via a Nonparametric Iterative Adaptive Approach. Signal Process. Lett. 2009, 4, 241–244. [Google Scholar] [CrossRef]

- Lei, L.; Zhou, J. Parameter estimation in multi-antenna system based on iterative adaptive approach. Matec Web Conf. 2018, 232, 4064. [Google Scholar] [CrossRef][Green Version]

- Guan, J. Missing Data Recovery of Frequency Hopping Signal Based on Iterative Adaptive Approach. Telecommun. Eng. 2020, 60, 791–797. [Google Scholar]

- Chen, H.; Kang, J.; Chen, Y.; Xu, D.; Hu, Y. An improved time-frequency analysis method for hydrocarbon detection based on EWT and SET. Energies 2017, 10, 1090. [Google Scholar] [CrossRef]

- Yu, G.; Wang, Z.; Zhao, P.; Li, Z. Local maximum synchrosqueezing transform: An energy-concentrated time-frequency analysis tool. Mech. Syst. Signal Process. 2019, 117, 537–552. [Google Scholar] [CrossRef]

- GLeite, N.P.; Araújo, A.M.; Rosas, P.A.C.; Stosic, T.; Stosic, B. Entropy measures for early detection of bearing faults. Phys. A Stat. Mech. Its Appl. 2019, 514, 458–472. [Google Scholar]

- Baraniuk, R.G.; Flandrin, P.; Janssen, A.J.E.M.; Michel, O.J.J. Measuring time-frequency information content using the Rényi entropies. IEEE Trans. Inf. Theory 2001, 47, 1391–1409. [Google Scholar] [CrossRef]

- He, D.; Cao, H.; Wang, S.; Chen, X. Time-reassigned synchrosqueezing transform: The algorithm and its applications in mechanical signal processing. Mech. Syst. Signal Processing 2019, 117, 255–279. [Google Scholar] [CrossRef]

| Parameters | Names | Values |

|---|---|---|

| amplitude | 1 | |

| initial frequency | 20 Hz | |

| time width | 1 s | |

| sampling frequency | 1000 Hz |

| Parameters | Names | Values |

|---|---|---|

| A1 | sinusoidal signal amplitude | 1 |

| f01 | sinusoidal signal initial frequency | 130 Hz |

| A2 | FM signal amplitude | 1.5 |

| f02 | FM signal initial frequency | 60 Hz |

| k2 | FM signal frequency modulation rate | −50 Hz/s |

| r | AM amplitude of AM-FM signal | 1.5 |

| f03 | AM-FM signal initial frequency | 280 Hz |

| k3 | AM-FM signal frequency modulation rate | 50 Hz/s |

| T | time width | 1 s |

| fs | sampling frequency | 1024 Hz |

| SNR | signal-to-noise ratio | 22 dB |

| Transform | Rényi Entropy Value | Transform | Rényi Entropy Value |

|---|---|---|---|

| STFT | 1.3404 | ST | 1.1466 |

| WVD | 2.2789 | WT | 1.3952 |

| GST | 1.1476 | SET | 1.0033 |

| HHT | 1.3059 | SEST | 0.5246 |

| Transform | Times/s | Transform | Times/s |

|---|---|---|---|

| STFT | 1.371 | ST | 3.876 |

| WVD | 4.055 | WT | 4.594 |

| GST | 4.661 | SET | 8.188 |

| HHT | 1.538 | SEST | 6.615 |

| Parameters | Names | Values |

|---|---|---|

| fundamental signal component amplitude | 1 | |

| fundamental signal component frequency | 24 Hz | |

| time width | 1 s | |

| sampling frequency | 2048 Hz | |

| SNR | signal-to-noise ratio | 20 dB |

| Parameters | Names | Values |

|---|---|---|

| fundamental signal component amplitude | 1 | |

| fundamental signal component frequency | 20 Hz | |

| AM amplitude of AM-FM signal component | 1.5 | |

| AM-FM signal component initial frequency | 64 Hz | |

| AM-FM signal component frequency modulation rate | 31 Hz/s | |

| time width | 1 s | |

| sampling frequency | 2048 Hz | |

| SNR | signal-to-noise ratio | 20 dB |

| Parameters | Names | Values |

|---|---|---|

| fundamental signal component amplitude | 1 | |

| fundamental signal component frequency | 30 Hz | |

| time width | 1 s | |

| sampling frequency | 2048 Hz | |

| SNR | signal-to-noise ratio | 20 dB |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, C.; Liu, X.; Xiao, B.; Wang, Z. A Vibration Fault Signal Identification Method via SEST. Electronics 2022, 11, 1300. https://doi.org/10.3390/electronics11091300

Li X, Wang C, Liu X, Xiao B, Wang Z. A Vibration Fault Signal Identification Method via SEST. Electronics. 2022; 11(9):1300. https://doi.org/10.3390/electronics11091300

Chicago/Turabian StyleLi, Xuemei, Chunyang Wang, Xuelian Liu, Bo Xiao, and Zishuo Wang. 2022. "A Vibration Fault Signal Identification Method via SEST" Electronics 11, no. 9: 1300. https://doi.org/10.3390/electronics11091300

APA StyleLi, X., Wang, C., Liu, X., Xiao, B., & Wang, Z. (2022). A Vibration Fault Signal Identification Method via SEST. Electronics, 11(9), 1300. https://doi.org/10.3390/electronics11091300