A Dynamics Coordinated Control System for 4WD-4WS Electric Vehicles

Abstract

:1. Introduction

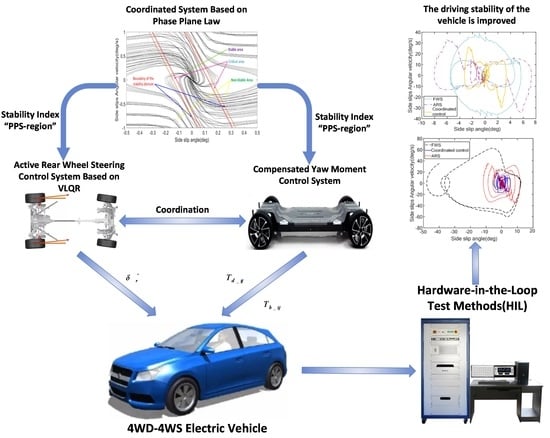

2. Segmentation of Stability Domain of the Side-Slip Angle Based on Phase Plane Law

2.1. Establishment of the Phase Plane Diagram

2.2. Division of Stability Domains in Phase Plane

- (1)

- When the vehicle speed is constant, the influence of the road adhesion coefficient on the boundary coefficient:

- (2)

- When the road adhesion coefficient is constant, the influence of vehicle speed on the boundary coefficient:

2.3. Calculation of Phase Plane Stability Index (PPS-Region)

3. Dynamics Coordinated Control System

3.1. VLQR-Based Active Rear-Wheel Steering Control

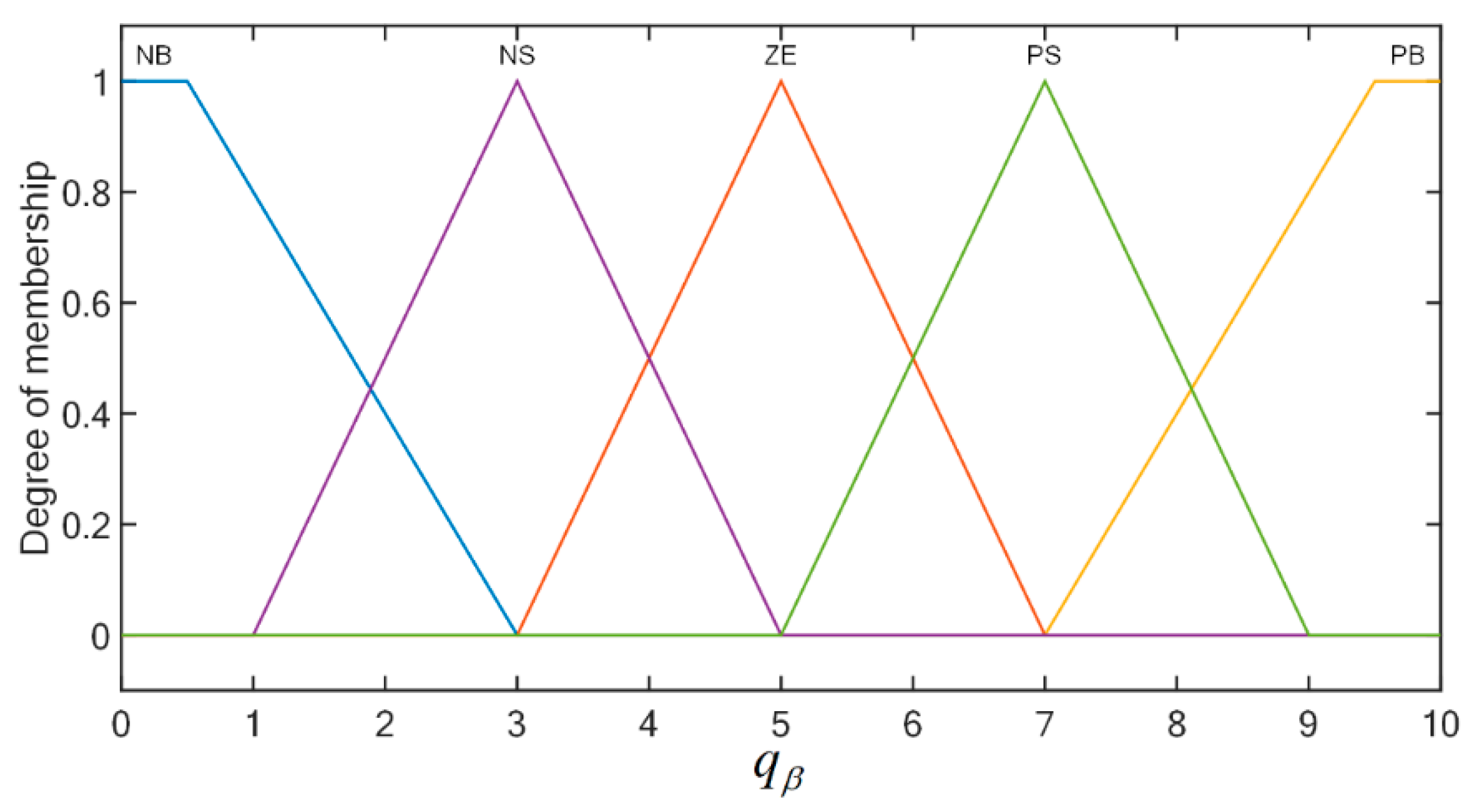

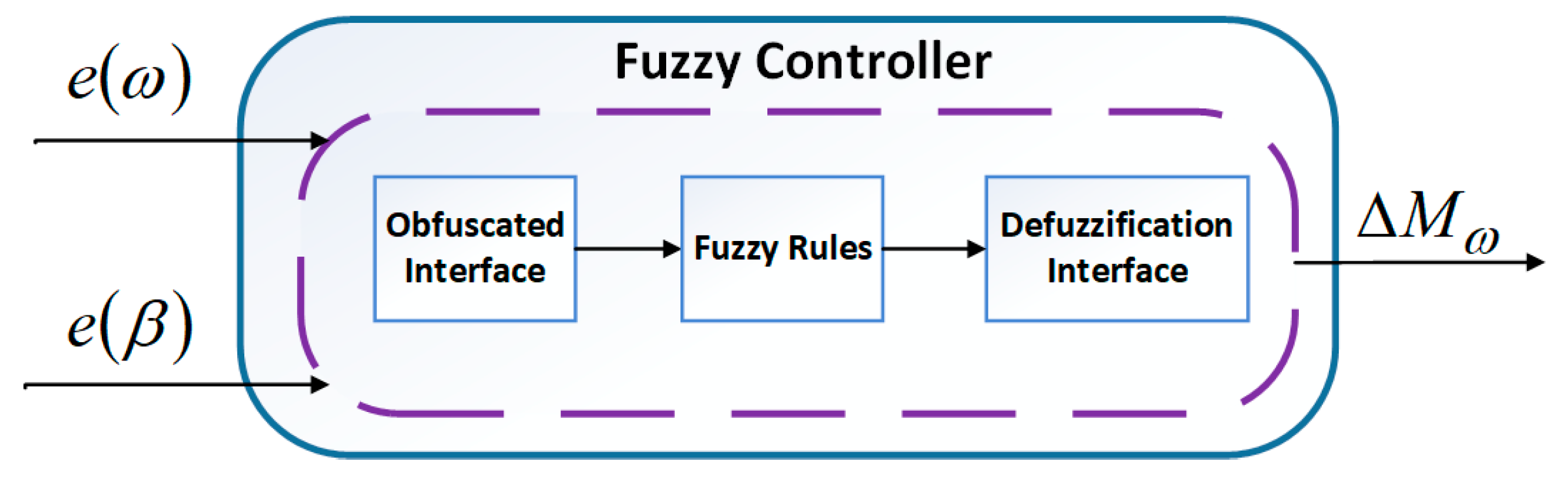

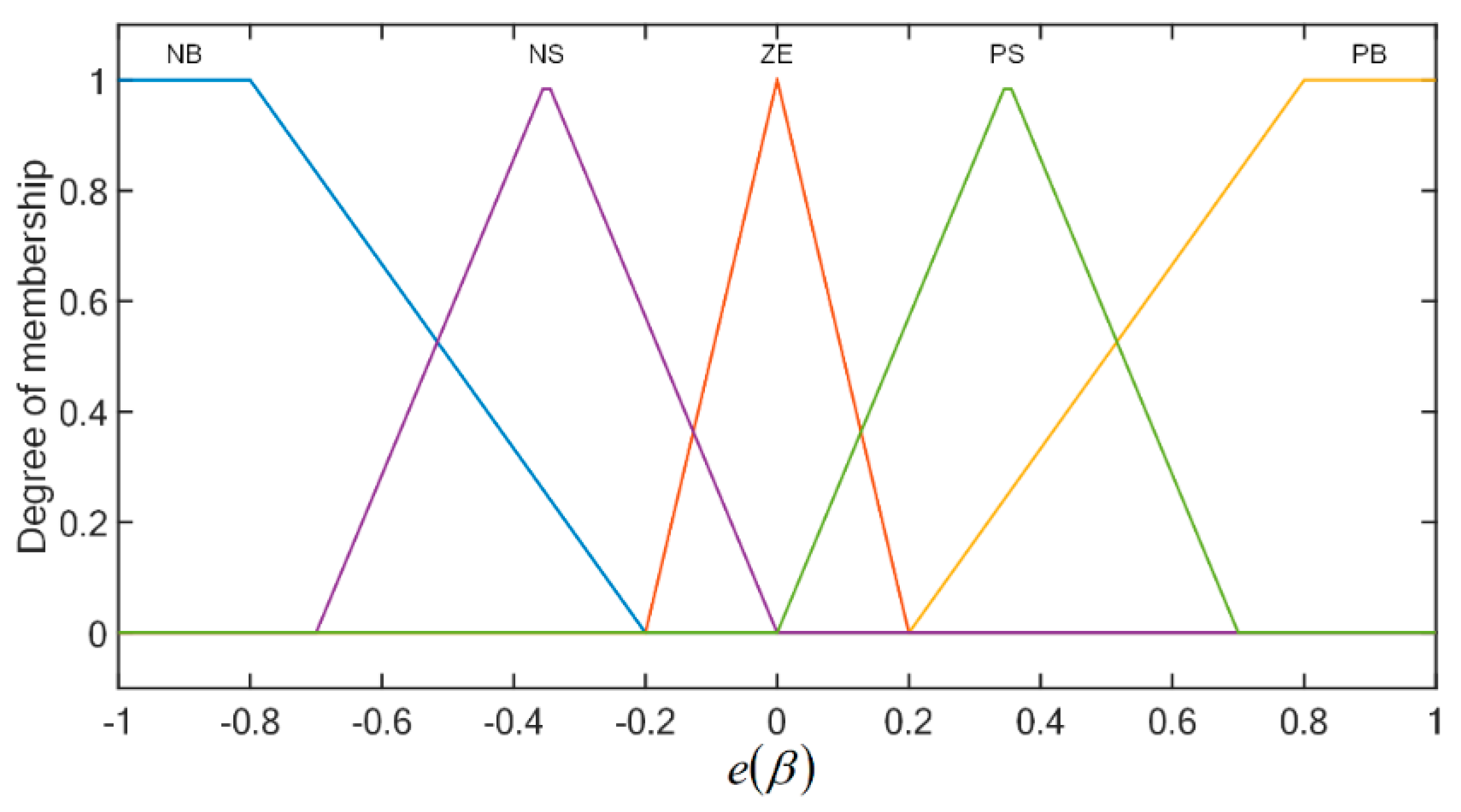

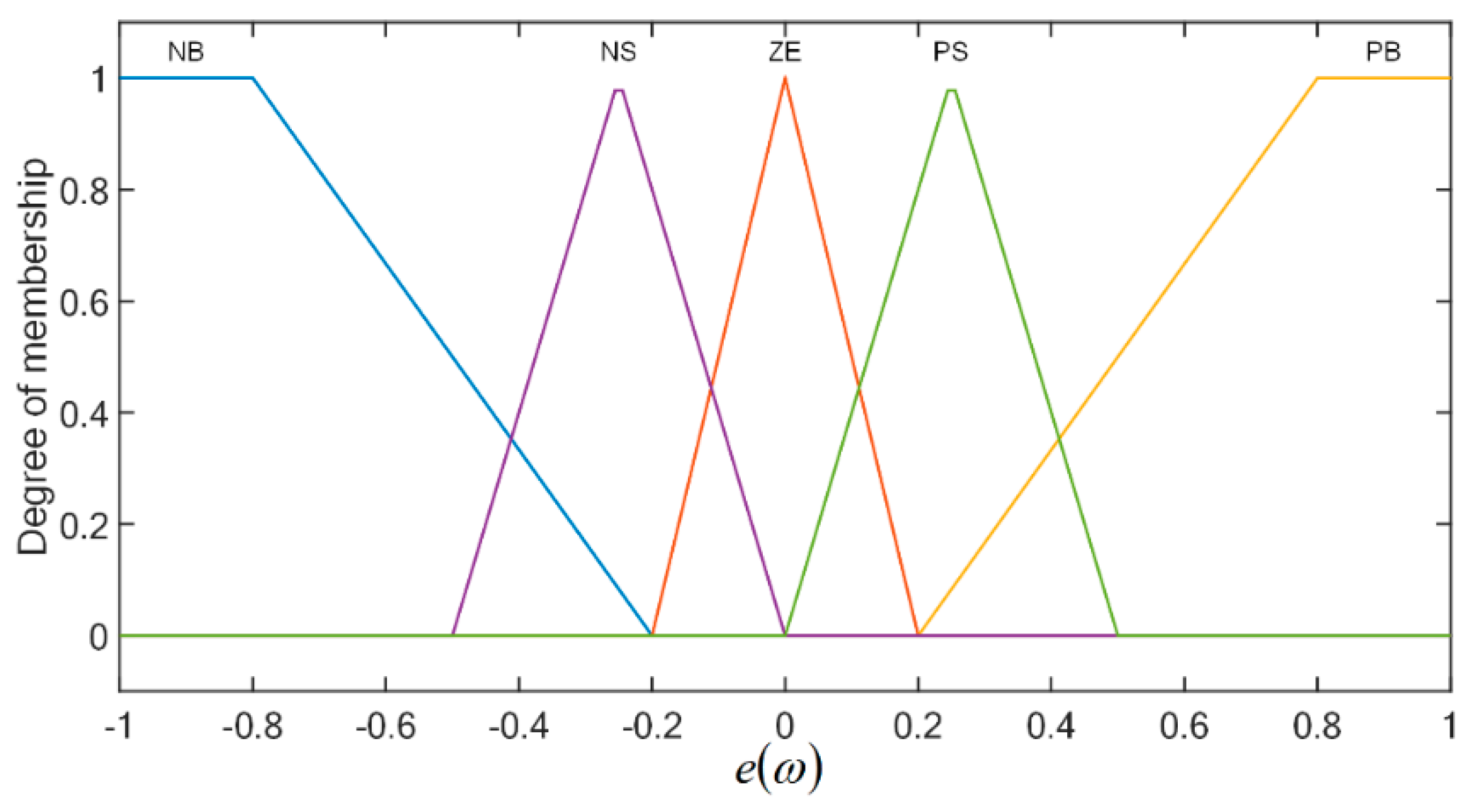

3.2. FC-Based Compensated Yaw Moment Control

3.3. “PPS-Region” Based Dynamics Coordination Controller

3.3.1. Drive Force Distribution Module

3.3.2. Braking Force Distribution Module

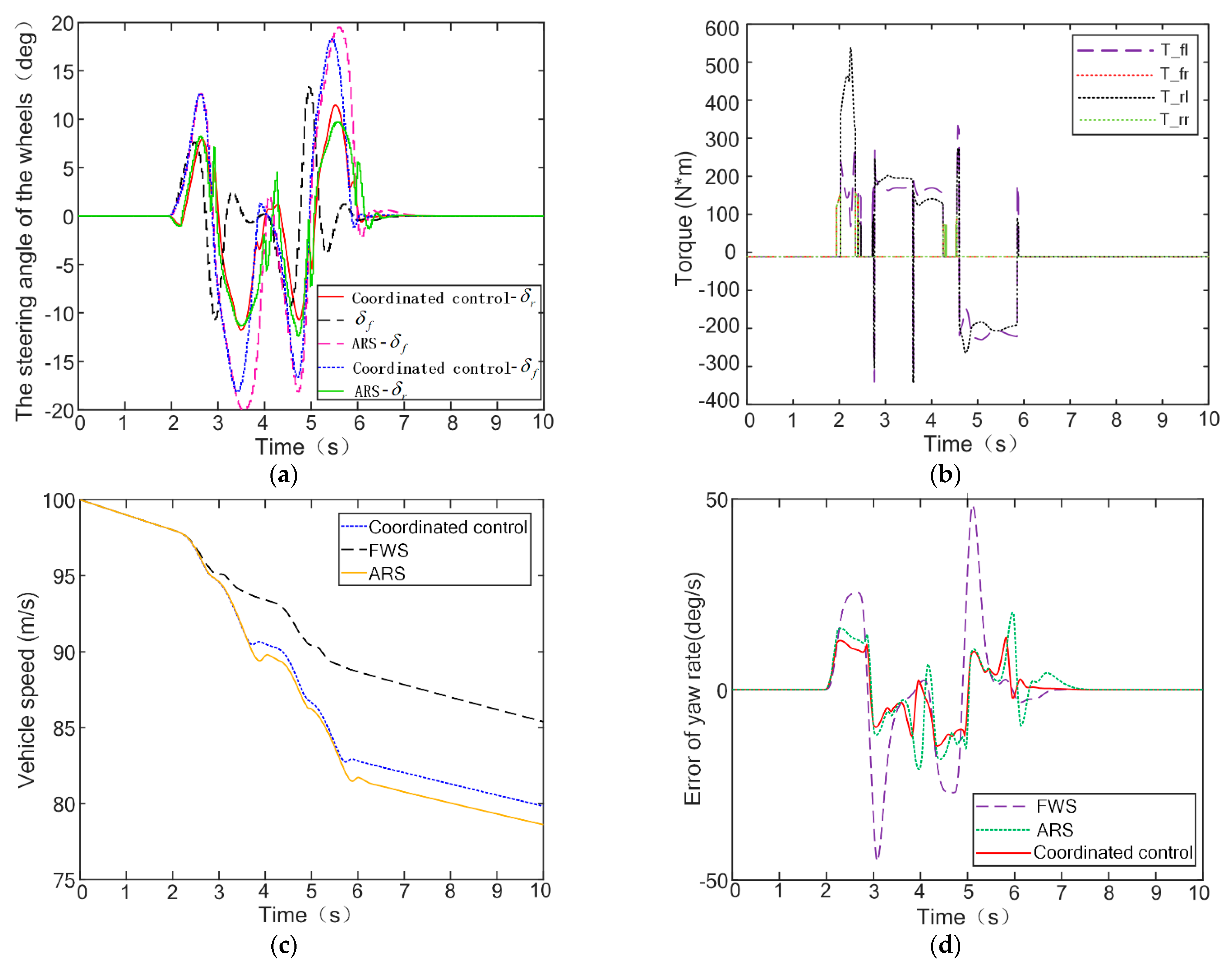

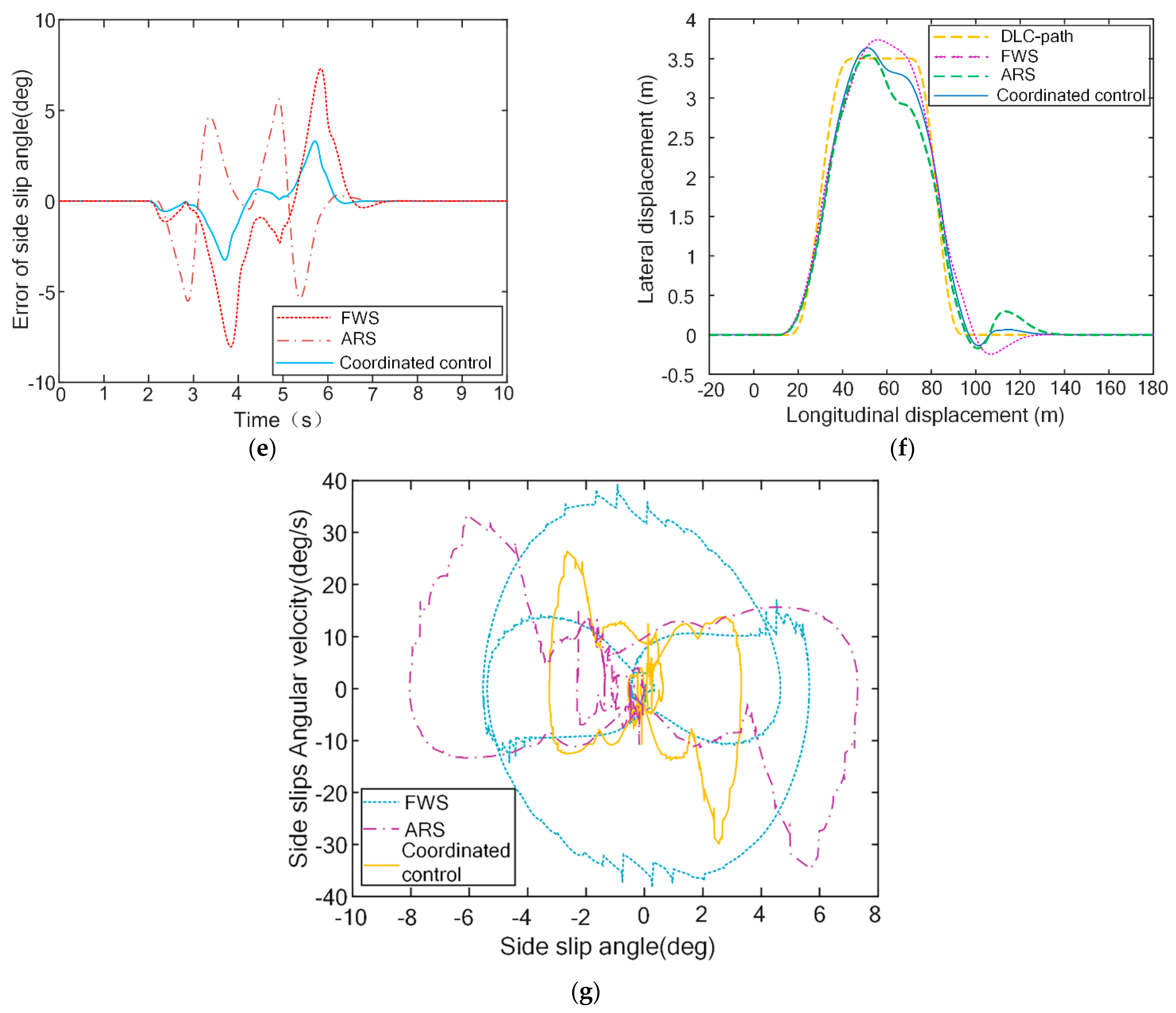

4. Hardware-in-the-Loop Simulation of Coordinated Control Strategies

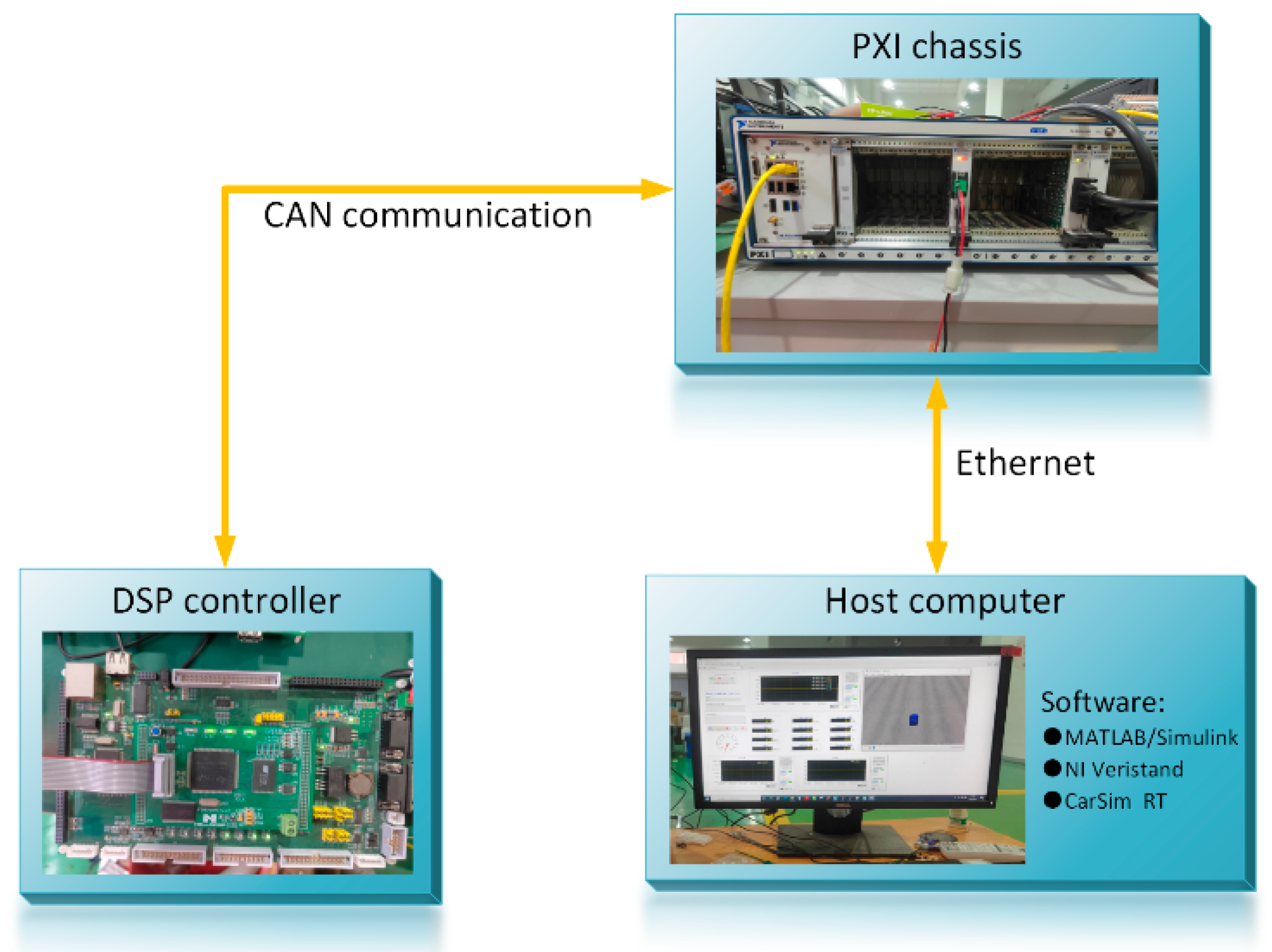

4.1. Construction of Test Platform

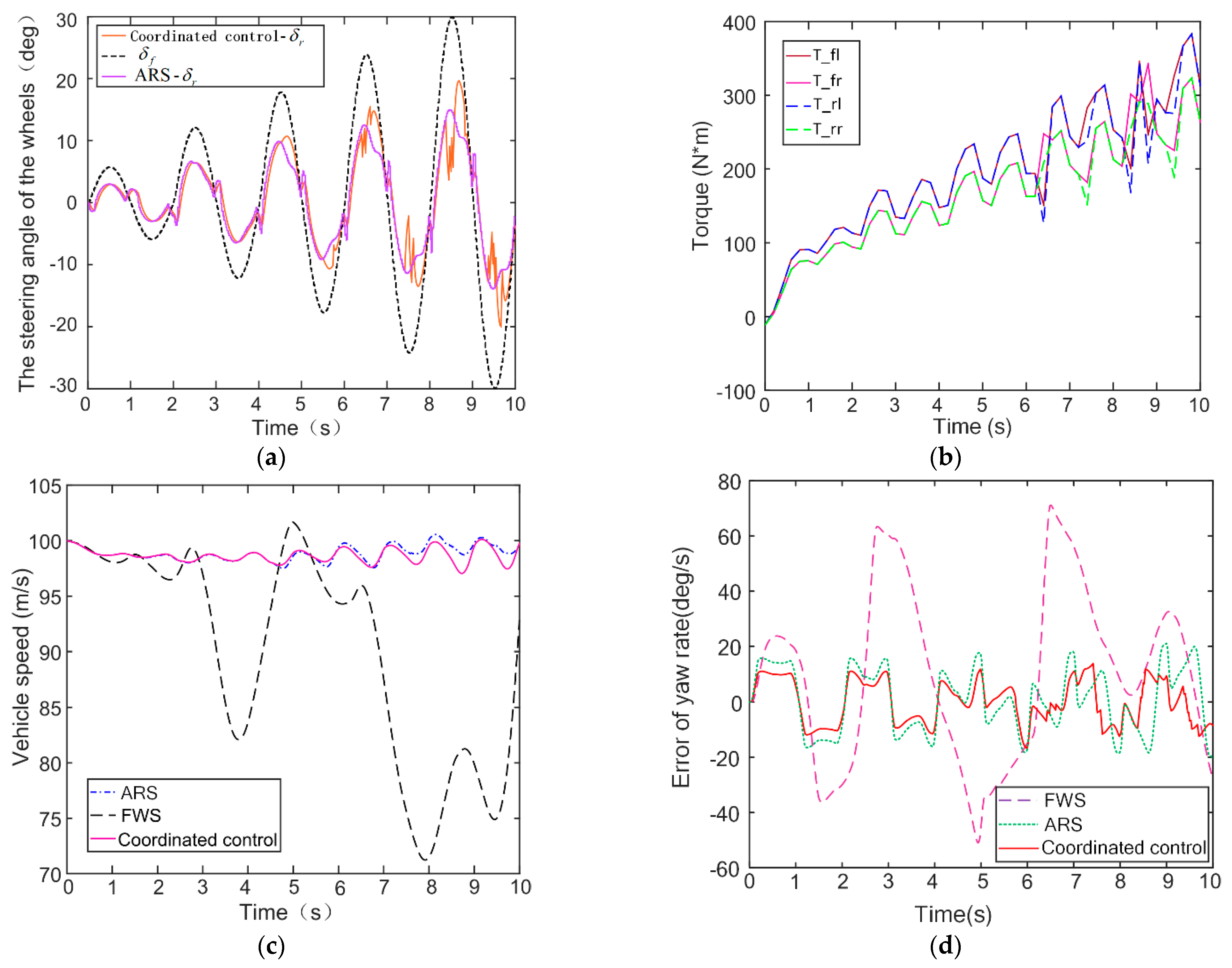

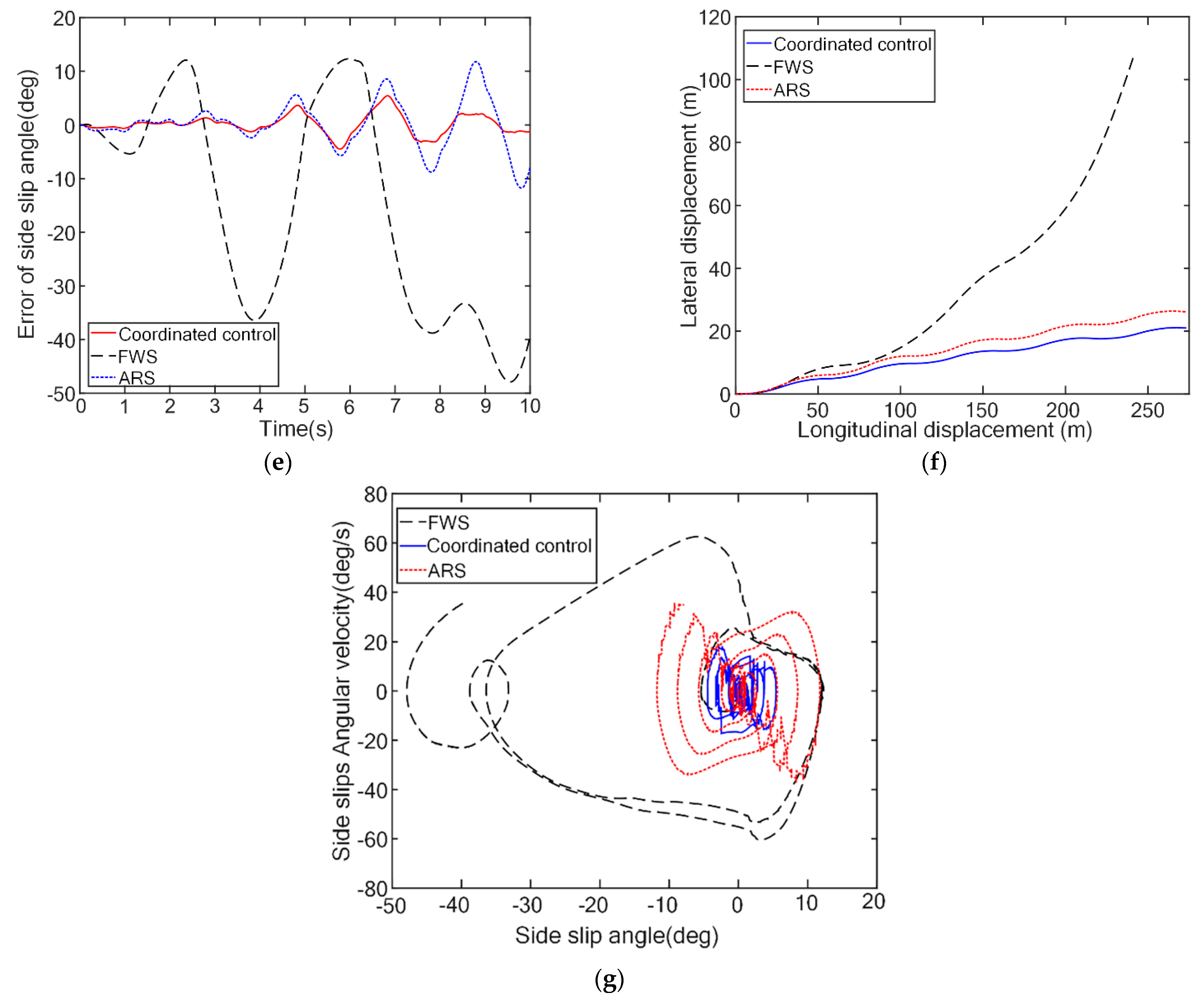

4.2. Hardware-in-the-Loop Simulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eberle, U.; Von Helmolt, R. Sustainable transportation based on electric vehicle concepts: A brief overview. Energy Environ. Sci. 2010, 3, 689–699. [Google Scholar] [CrossRef]

- Guoying, C.; Changfu, Z.; Qiang, Z.; Lei, H. The study of traction control system for omni-directional electric vehicle. In Proceedings of the IEEE 2011 International Conference on Mechatronic Science, Electric Engineering and Computer (MEC), Jilin, China, 19–22 August 2011; pp. 1590–1593. [Google Scholar]

- Xiong, L.; Yu, Z.; Wang, Y.; Yang, C.; Meng, Y. Vehicle dynamics control of four in-wheel motor drive electric vehicle using gain scheduling based on tyre cornering stiffness estimation. Veh. Syst. Dyn. 2012, 50, 831–846. [Google Scholar] [CrossRef]

- Shaopeng, Z.; Ding, L.; Bozhen, X.; Xiaoli, Y.; Song, H. Driving force hierarchical control strategy of electric vehicle. J. Zhejiang Univ. (Eng. Sci.) 2016, 50, 2094–2099. [Google Scholar]

- Ono, E.; Hattori, Y.; Muragishi, Y.; Koibuchi, K. Vehicle dynamics integrated control for four-wheel distributed steering and four-wheel distributed traction/braking systems. Veh. Syst. Dyn. 2006, 44, 139–151. [Google Scholar] [CrossRef]

- Zhang, B.; Amir, K.; Xie, H. Simulation and Test of Rollover Stability Based on Rear Wheel Pulsed Active Steering. Automot. Eng. 2016, 38, 857–864. [Google Scholar]

- Dongdong, T.; Jun, S.; Nenglian, F. μ-Synthesis Control Research of Active Rear Wheel Steering Vehicle Based on Model Matching. J. Hubei Univ. Automot. Technol. 2015, 29, 1–5+10. [Google Scholar]

- Hirche, B.; Ayalew, B. A model-free stability control design scheme with active steering actuator sets. SAE Int. J. Passeng. Cars-Mech. Syst. 2016, 9, 373–383. [Google Scholar] [CrossRef]

- Feng, D. Simulation Research on Control Strategies for Active 4WS Vehicle Based on the Steer-by-Wire Technology; Chang’an University: Xi’an, China, 2009. [Google Scholar]

- Wenzheng, P.; Yinhui, A.; Chenqi, Z.; Zipeng, L.; Sixian, W. Cooperative Control for Distributed Drive Vehicle and Active Rear Wheel Steering. Mech. Sci. Technol. Aerosp. Eng. 2020, 39, 207–213. [Google Scholar]

- Feng, D.U.; Zhiwei, G.U.A.N.; Bolin, G.A.O.; Jingang, D.A.I.; Lang, W.E.I. Vehicle stability control based on synergistic effect of active steering and differential braking. J. Automot. Saf. Energy 2018, 9, 65–73. [Google Scholar]

- Ronghui, G. Research on Stability of Distributed Drive Electric Vehicle Based on Four-Wheel Steering; Fujian University of Technology: Fuzhou, China, 2020. [Google Scholar]

- Beng, L. Research on Dynamic Coordinated Control System of 4WS-4WD Electric Vehicle; Jilin University: Changchun, China, 2018. [Google Scholar]

- Jiajia, Y.; Wei, H.; Peizhu, Z. Cooperative control of active rear wheel steering vehicle and torque distribution. Manuf. Autom. 2020, 42, 130–134. [Google Scholar]

- Saikia, A.; Mahanta, C. Integrated control of active front steer angle and direct yaw moment using second order sliding mode technique. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–4. [Google Scholar]

- Xiang, F.; Fengjun, Y.; Bin, H. Coordinated control of active rear wheel steering and four wheel independent driving vehicle. J. Jiangsu Univ. (Nat. Sci. Ed.) 2021, 42, 497–505. [Google Scholar]

- Shuen, H.; Hongyin, H.; Dongyin, J. Stability Control of Distributed Drive Electric Vehicle Based on AFS/DYC coordinated Control. J. Huaqiao Univ. (Nat. Sci.) 2021, 42, 571–579. [Google Scholar]

- Inagaki, S.; Kushiro, I.; Yamamoto, M. Analysis on vehicle stability in critical cornering using phase-plane method. JSAE Rev. 1995, 2, 216. [Google Scholar]

- Hanjie, L. Research on Handing Stability Control of Vehicle Based on Phase Plane Analysis; Hefei University of Technology: Hefei, China, 2018. [Google Scholar]

- Peng, C. Study on Vehicle Integrated Control of Active Steering and Independent Drive Control; Qingdao University of Technology: Qingdao, China, 2016. [Google Scholar]

- Wei, L. Vehicle Stability Control System Research Based on Side-Slip Angle Phase; Jilin University: Changchun, China, 2013. [Google Scholar]

- Tao, D.; Junlin, L.; Mingming, W. State estimation and lateral stability control for electric vehicles based on EKF and MPC algorithm. J. Automot. Saf. Energy 2017, 8, 287–295. [Google Scholar]

- Wei, Z. Research on Lateral Stability of Parallel Hybrid Electric Tractor. Bull. Sci. Technol. 2018, 34, 245–248+253. [Google Scholar]

- Pacejka, H. Tire and Vehicle Dynamics; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Guozhong, Z.; Yunbing, Y.; Wendian, P. Extension coordinated control of AFS and DYC for vehicles based on phase plane. J. Wuhan Univ. Sci. Technol. 2021, 44, 146–153. [Google Scholar]

- Xuecheng, L.; Jun, L.; Hanjie, L. Research on direct yaw moment control of vehicle based on phase plane method. J. Hefei Univ. Technol. (Nat. Sci.) 2019, 42, 1455–1461. [Google Scholar]

- Tianyang, G.; Xianyi, X.; HUI, R.; Wenyang, W. A Control Strategy of Vehicle Electronic Stability Based on Phase Plane Method. J. Transp. Inf. Saf. 2019, 37, 83–90. [Google Scholar]

- Zhurong, D.; Xin, Z.; Songhua, H.; Hao, Q. A Simulation Study on the Steering Control of a 4WIS EV Based on LQR Variable Transmission Ratio Control. Automot. Eng. 2017, 39, 79–85. [Google Scholar]

- Hao, Q.; Zhengbao, L.; Ping, H. Research on active steering control of rear wheels based on variable transmission ratio. J. Mach. Des. 2015, 32, 90–94. [Google Scholar]

- Honghua, W. Modern Control Theory, 3rd ed.; Publishing House of Electronics Industry: Beijing, China, 2018. [Google Scholar]

- Feng, D.; Lang, W.; Jianyou, Z. Optimization control of four-wheel steering vehicle based on state feedback. J. Chang. Univ. (Nat. Sci. Ed.) 2008, 4, 91–94. [Google Scholar]

- Xianyi, X. Research on Integrated Control Method of Handling and Stability for Distributed Electric Vehicle; Jilin University: Changchun, China, 2018. [Google Scholar]

- Chung, T.; Yi, K. Design and evaluation of side slip angle-based vehicle stability control scheme on a virtual test track. IEEE Trans. Control. Syst. Technol. 2006, 14, 224–234. [Google Scholar] [CrossRef]

- Abe, M.; Kano, Y.; Suzuki, K.; Shibahata, Y.; Furukawa, Y. Side-slip control to stabilize vehicle lateral motion by direct yaw moment. JSAE Rev. 2001, 22, 413–419. [Google Scholar] [CrossRef]

- Ishida, S.; Takei, A. Method and Apparatus for Controlling a Vehicle and Accounting for Side-Slip Angle. U.S. Patent 5,243,524, 7 September 1993. [Google Scholar]

- Zhisheng, Y. Theory of Automobile; China Machine Press: Beijing, China, 2009. [Google Scholar]

| Control Objectives | Control Method | References |

|---|---|---|

| side slip angle, yaw rate | ARS + DYC | [12] |

| side slip angle, yaw rate | ARS + DYC | [13] |

| side slip angle, yaw rate | ARS + DYC | [14] |

| side slip angle, yaw rate | AFS + DYC | [15] |

| side slip angle, yaw rate, vehicle speed | ARS + DYC | [16] |

| side slip angle, yaw rate | AFS + DYC | [17] |

| Abbreviation | Meaning |

|---|---|

| 4WD-4WS | Four-wheel driving and Four-wheel steering |

| PPS-region | An indicator of stability |

| 4WS | Four-wheel steering |

| ARS | Active rear-wheel steering system |

| DYC | Direct yaw moment control |

| ABS | Anti-lock braking system |

| AFS | Active Front Wheel Steering |

| VLQR | Varying parameter Linear Quadratic Regulator |

| LQR | Linear Quadratic Regulator |

| FC | Fuzzy control |

| FWS | Front wheel steering |

| Number | Road Adhesion Coefficient | |||

|---|---|---|---|---|

| 1 | 0.1 | 2.32 | −0.13 | 0.13 |

| 2 | 0.2 | 3.86 | −0.22 | 0.22 |

| 3 | 0.3 | 4.04 | −0.36 | 0.36 |

| 4 | 0.4 | 4.53 | −0.50 | 0.50 |

| 5 | 0.5 | 4.94 | −0.56 | 0.56 |

| 6 | 0.6 | 5.17 | −0.63 | 0.63 |

| 7 | 0.7 | 5.47 | −0.70 | 0.70 |

| 8 | 0.8 | 5.96 | −0.81 | 0.81 |

| 9 | 0.9 | 6.13 | −0.97 | 0.97 |

| 10 | 1.0 | 6.54 | −1.08 | 1.08 |

| Number | Vehicle Speed | |||

|---|---|---|---|---|

| 1 | 50 km/h | 6.11 | −0.83 | 0.83 |

| 2 | 60 km/h | 6.07 | −0.83 | 0.83 |

| 3 | 70 km/h | 6.08 | −0.81 | 0.81 |

| 4 | 80 km/h | 6.06 | −0.82 | 0.82 |

| 5 | 90 km/h | 6.02 | −0.83 | 0.83 |

| 6 | 100 km/h | 5.96 | −0.81 | 0.81 |

| 7 | 110 km/h | 6.01 | −0.84 | 0.84 |

| 8 | 120 km/h | 6.05 | −0.83 | 0.83 |

| Road Surface Adhesion Conditions | Take Value | Adjustment of Objectives |

|---|---|---|

| μ↓ | Control the side slip angle within a reasonable range | |

| μ↑ | Reducing the error between the yaw rate and its ideal value |

| μ | ||

|---|---|---|

| NB | NB | NB |

| NM | NS | NS |

| NS | ZE | ZE |

| ZE | PS | PS |

| PS | PB | PB |

| PM | ||

| PB |

| μ | ||

|---|---|---|

| NB | PB | NB |

| NM | PS | NS |

| NS | PS | NS |

| ZE | ZE | ZE |

| PS | NS | PS |

| PM | NS | PS |

| PB | NB | PB |

| NB | NB | NB |

| NM | NS | NS |

| NS | ZE | ZE |

| ZE | PS | PS |

| PS | PB | PB |

| PM | ||

| PB |

| NB | NS | ZE | PS | PB | ||

|---|---|---|---|---|---|---|

| NB | NB | NB | NB | NM | NM | |

| NS | NB | NM | NM | NS | NS | |

| ZE | NS | NS | ZE | PS | PS | |

| PS | PS | PS | PM | PM | PB | |

| PB | PM | PM | PB | PB | PB | |

| The Value Range of PPS-Region | |||

|---|---|---|---|

| (0, 0.8) | 0 | 0 | |

| [0.8, 1] | 0 | ||

| ) | 0 | 0 |

| Steering Status of the Vehicle | Wheels That Provide Braking Power | ||

|---|---|---|---|

Turn left | Oversteer | Right front wheel, Right rear wheel | |

| Understeer | Left front wheel, Left rear wheel | ||

Turn right | Understeer | Right front wheel, Right rear wheel | |

| Oversteer | Left front wheel, Left rear wheel |

| Types of Test Conditions | Initial Speed (km/h) | Input Charact Eristics of Front Wheel Steering Angle | The Road Adhesion Coefficient |

|---|---|---|---|

| Continuous gain sine test | 100 | Continuous sine gain with a period of 2 s and the maximum steering angle of 30° | 0.8 |

| Double lane-change test | 100 | After turning left back to positive, then right back to positive | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, S.; Wei, B.; Liu, D.; Chen, H.; Huang, X.; Zheng, Y.; Wei, W. A Dynamics Coordinated Control System for 4WD-4WS Electric Vehicles. Electronics 2022, 11, 3731. https://doi.org/10.3390/electronics11223731

Zhu S, Wei B, Liu D, Chen H, Huang X, Zheng Y, Wei W. A Dynamics Coordinated Control System for 4WD-4WS Electric Vehicles. Electronics. 2022; 11(22):3731. https://doi.org/10.3390/electronics11223731

Chicago/Turabian StyleZhu, Shaopeng, Bangxuan Wei, Dong Liu, Huipeng Chen, Xiaoyan Huang, Yingjie Zheng, and Wei Wei. 2022. "A Dynamics Coordinated Control System for 4WD-4WS Electric Vehicles" Electronics 11, no. 22: 3731. https://doi.org/10.3390/electronics11223731

APA StyleZhu, S., Wei, B., Liu, D., Chen, H., Huang, X., Zheng, Y., & Wei, W. (2022). A Dynamics Coordinated Control System for 4WD-4WS Electric Vehicles. Electronics, 11(22), 3731. https://doi.org/10.3390/electronics11223731