Enhancement of the Evaporation and Condensation Processes of a Solar Still with an Ultrasound Cotton Tent and a Thermoelectric Cooling Chamber

Abstract

:1. Introduction

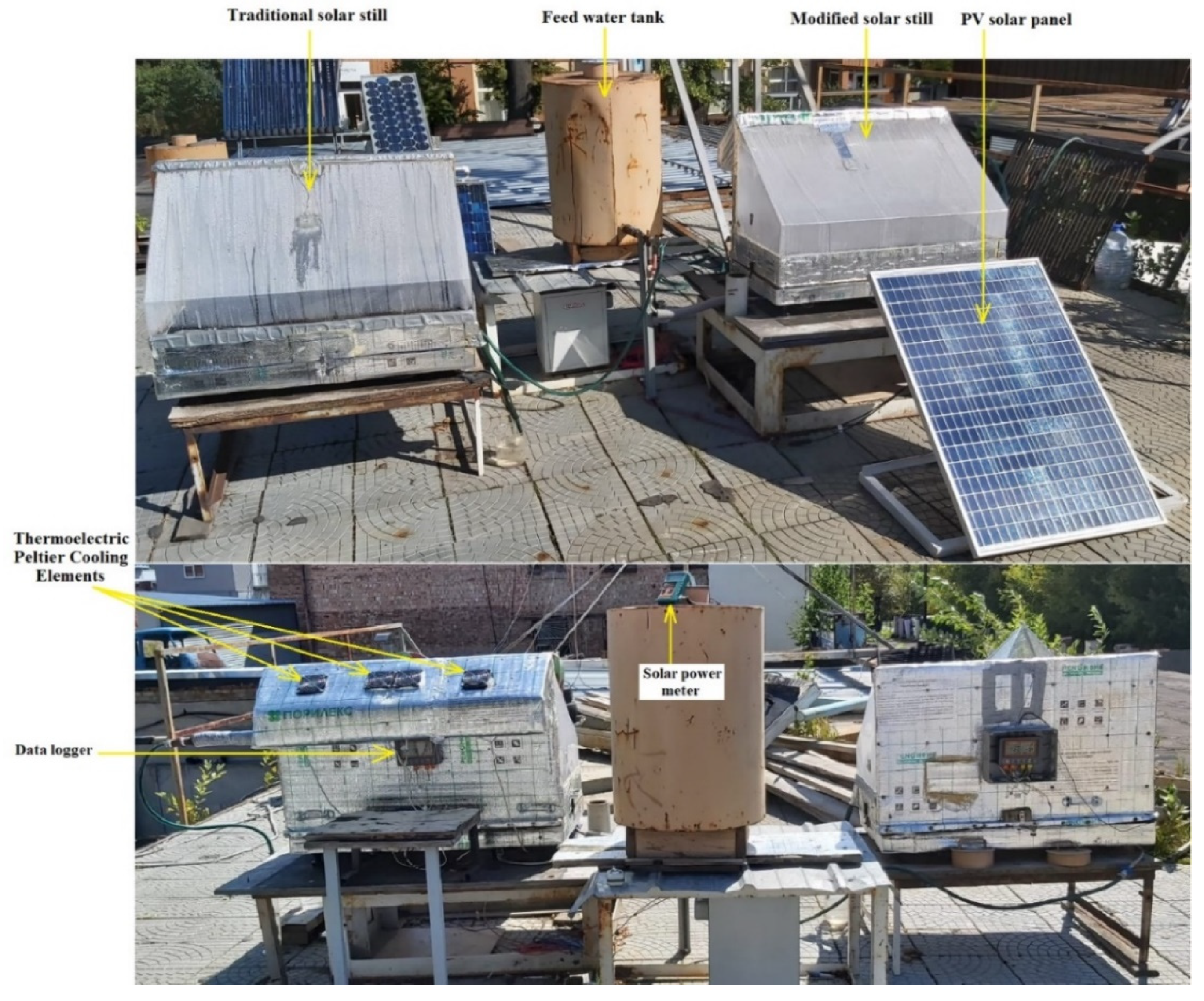

2. Materials and Methods

2.1. Scheme of a Solar Distiller System

2.1.1. Working Principle for Ultrasonic Humidifiers

2.1.2. Working Principle for Thermoelectric Coolers

2.2. Experimental Procedure

2.3. Uncertainty Analysis

2.4. Thermal Efficiency

3. Production Cost Analysis

4. Experimentation and Performance Analysis

5. Conclusions

- (1)

- The production of distilled water in the cooling chamber was enhanced by installing thermoelectric Peltier cooling elements on its walls. This set-up increased the condensation of water vapor in the channel of the cooling chamber. Productivity was also improved by placing ultrasonic humidifiers inside a cotton mesh tent in the basin water. The productivity of the modified solar still increased by 124% compared with the traditional solar still.

- (2)

- The thermal efficiency of the modified solar still was always higher than that of the traditional solar still over 12 h due to the increase in productivity, which itself was a result of improving the evaporation and condensation processes.

- (3)

- The low temperature of the cooled aluminum plate of the cooling chamber, which decreased by about 7–11 °C, compared with the plexiglass cover indicates the positive effect of the proposed cooling mechanism.

- (4)

- The productivity cost of distillate water (1 L) was approximately 0.040 and 0.042 $/L for the modified and traditional solar stills, respectively. The economic analysis shows that the proposed modification agreed with previous studies in the environmental conditions of Yekaterinburg, Russia in terms of the cost of producing distilled water.

- (5)

- Therefore, it can be concluded that the ultrasonic humidifiers and thermoelectric cooling elements were effective, considering the parameters assessed, and could be used to enhance the productivity of the solar stills in hot climatic areas where water is scarce.

- (6)

- The results showed that the temperature of the basin water in the modified solar still was lower than that of the conventional solar still. Therefore, to overcome this problem, it is recommended in the future to combine the modified still with an external solar collector to increase the temperature of the basin water under the cotton tent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Saidan, M.; Albaali, A.G.; Alasis, E.; Kaldellis, J.K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew. Energy 2016, 92, 499–505. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Palai, G.; Nayyar, A.; Manikandan, R.; Singh, B. Metamaterial based photonic structure: An alternate high performance antireflection coating for solar cell. Optik 2019, 179, 740–743. [Google Scholar] [CrossRef]

- Ghaderi, D.; Maroti, P.K.; Sanjeevikumar, P.; Holm-Nielsen, J.B.; Hossain, E.; Nayyar, A. A modified step-up converter with small signal analysis-based controller for renewable resource applications. Appl. Sci. 2020, 10, 102. [Google Scholar] [CrossRef] [Green Version]

- Fouad, M.M.; Shihata, L.A.; Morgan, E.I. An integrated review of factors influencing the perfomance of photovoltaic panels. Renew. Sustain. Energy Rev. 2017, 80, 1499–1511. [Google Scholar] [CrossRef]

- Gastli, A.; Charabi, Y. Solar electricity prospects in Oman using GIS-based solar radiation maps. Renew. Sustain. Energy Rev. 2010, 14, 790–797. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A. Feasibility study of a smart building energy system comprising solar PV/T panels and a heat storage unit. Energy 2020, 210, 118528. [Google Scholar] [CrossRef]

- Dincer, F. The analysis on photovoltaic electricity generation status, potential and policies of the leading countries in solar energy. Renew. Sustain. Energy Rev. 2011, 15, 713–720. [Google Scholar] [CrossRef]

- Moharram, K.A.; Abd-Elhady, M.S.; Kandil, H.A.; El-Sherif, H. Enhancing the performance of photovoltaic panels by water cooling. Ain Shams Eng. J. 2013, 4, 869–877. [Google Scholar] [CrossRef] [Green Version]

- Bahaidarah, H.M.; Baloch, A.A.B.; Gandhidasan, P. Uniform cooling of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2016, 57, 1520–1544. [Google Scholar] [CrossRef]

- Nižetić, S.; Papadopoulos, A.; Giama, E. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part I: Passive cooling techniques. Energy Convers. Manag. 2017, 149, 334–354. [Google Scholar] [CrossRef]

- Farhan, A.A.; Hasan, D.J. Enhancing the efficiency of Photovoltaic panel using open-cell copper metal foam fins. Int. J. Renew. Energy Res. (IJRER) 2019, 9, 1849–1855. [Google Scholar]

- Alwan, N.T.; Shcheklein, E.S.; Ali, O.M. Experimental investigations of single-slope solar still integrated with a hollow rotating cylinder. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Jumpholkul, C.; Thiangtham, P.; Wongwises, S.; Srisomba, R. Solar distillation practice for water desalination systems. J. Therm. Eng. 2015, 1, 287–288. Available online: https://dergipark.org.tr/en/download/article-file/199366 (accessed on 19 December 2020). [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Effect of hollow drum rotational speed variation on the productivity of modified solar still according to Yekaterinburg City, Russia. Appl. Sol. Energy 2020, 56, 276–283. [Google Scholar] [CrossRef]

- Tariq, R.; Sheikh, N.; Xamán, J.; Bassam, A. An innovative air saturator for humidification-dehumidification desalination application. Appl. Energy 2018, 228, 789–807. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.; Ali, O.M. Experimental investigation of modified solar still integrated with solar collector. Case Stud. Therm. Eng. 2020, 19, 100614. [Google Scholar] [CrossRef]

- Nazari, S.; Safarzadeh, H.; Bahiraei, M. Experimental and analytical investigations of productivity, energy and exergy efficiency of a single slope solar still enhanced with thermoelectric channel and nanofluid. Renew. Energy 2019, 135, 729–744. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Evaluation of the productivity for new design single slope solar still at different saltwater depth. J. Phys. Conf. Ser. 2020, 1706, 012002. [Google Scholar] [CrossRef]

- Lwan, N.T.; Shcheklein, S.; Ali, O. Investigation of the coefficient of heat transfer and daily cumulative production in a single-slope solar distiller at different water depths. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 43, 2820–2837. [Google Scholar] [CrossRef]

- Abdullah, A.; Alarjani, A.; Al-Sood, M.A.; Omara, Z.; Kabeel, A.; Essa, F. Rotating-wick solar still with mended evaporation technics: Experimental approach. Alex. Eng. J. 2019, 58, 1449–1459. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.; Ali, O.M. Evaluation of distilled water quality and production costs from a modified solar still integrated with an outdoor solar water heater. Case Stud. Therm. Eng. 2021, 27, 101216. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Experimental investigation of solar distillation system integrated with photoelectric diffusion-absorption refrigerator (DAR). Intern. Conf. Numer. Anal. Appl. Math. Icnaam 2020, 2290, 50023. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Experimental study and economic cost analysis about enhancement productivity for a conventional solar still combined with humidifiers ultrasonic. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 1–17. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O. A practical study of a rectangular basin solar distillation with single slope using paraffin wax (PCM) cells. Int. J. Energy Convers. 2019, 7, 162–170. [Google Scholar] [CrossRef]

- Majeed, M.H.; Alwan, N.T.; Shcheklein, S.; Matveev, A. Electromechanical solar tracker system for a parabolic dish with CPU water heater. Mater. Today Proc. 2021, 42, 2346–2352. [Google Scholar] [CrossRef]

- Sadeghia, G.; Nazarib, S. Retrofitting a thermoelectric-based solar still integrated with an evacuated tube collector utilizing an antibacterial-magnetic hybrid nanofluid. Desalination 2020, 500, 114871. [Google Scholar] [CrossRef]

- Nazari, S.; Safarzadeh, H.; Bahiraei, M. Performance improvement of a single slope solar still by employing thermoelectric cooling channel and copper oxide nanofluid: An experimental study. J. Clean. Prod. 2019, 208, 1041–1052. [Google Scholar] [CrossRef]

- Bahiraei, M.; Nazari, S.; Safarzadeh, H. Modeling of energy efficiency for a solar still fitted with thermoelectric modules by ANFIS and PSO-enhanced neural network: A nanofluid application. Powder Technol. 2021, 385, 185–198. [Google Scholar] [CrossRef]

- Teffah, K.; Zhang, Y.; Mou, X.-L. Modeling and experimentation of new thermoelectric cooler—Thermoelectric generator module. Energies 2018, 11, 576. [Google Scholar] [CrossRef] [Green Version]

- Duan, Z.; Muzychka, Y.S. Experimental investigation of heat transfer in impingement air cooled plate fin heat sinks. J. Electron. Packag. 2005, 128, 412–418. [Google Scholar] [CrossRef] [Green Version]

- Benghanem, M.; Al-Mashraqi, A.; Daffallah, K. Performance of solar cells using thermoelectric module in hot sites. Renew. Energy 2016, 89, 51–59. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.; Ali, O.M. Experimental analysis of thermal performance for flat plate solar water collector in the climate conditions of Yekaterinburg, Russia. Mater. Today Proc. 2021, 42, 2076–2083. [Google Scholar] [CrossRef]

- Alwan, N.; Shcheklein, S.; Ali, O. Experimental investigation of modified solar still productivity under variable climatic conditions. Int. J. Des. Nat. Ecodynamics 2020, 15, 57–64. [Google Scholar] [CrossRef]

- Samee, M.A.; Mirza, U.K.; Majeed, T.; Ahmad, N. Design and performance of a simple single basin solar still. Renew. Sustain. Energy Rev. 2007, 11, 543–549. [Google Scholar] [CrossRef]

- Shehata, A.I.; Kabeel, A.; Dawood, M.M.K.; Elharidi, A.M.; Abd_Elsalam, A.; Ramzy, K.; Mehanna, A. Enhancement of the productivity for single solar still with ultrasonic humidifier combined with evacuated solar collector: An experimental study. Energy Convers. Manag. 2020, 208, 112592. [Google Scholar] [CrossRef]

- Abdullah, A.; Essa, F.; Omara, Z.; Rashid, Y.; Hadj-Taieb, L.; Abdelaziz, G.; Kabeel, A. Rotating-drum solar still with enhanced evaporation and condensation techniques: Comprehensive study. Energy Convers. Manag. 2019, 199, 112024. [Google Scholar] [CrossRef]

- Kumar, S.; Tiwari, G. Life cycle cost analysis of single slope hybrid (PV/T) active solar still. Appl. Energy 2009, 86, 1995–2004. [Google Scholar] [CrossRef]

- Badran, O.; Al-Tahaineh, H. The effect of coupling a flat-plate collector on the solar still productivity. Desalination 2005, 183, 137–142. [Google Scholar] [CrossRef]

- El-Bahi, A.; Inan, D. Analysis of a parallel double glass solar still with separate condenser. Renew. Energy 1999, 17, 509–521. [Google Scholar] [CrossRef]

| Description | Feature |

|---|---|

| Model | AV-F9025MS |

| Name | DC12V BRUSHLESS FAN |

| Rated Voltage | 12 V DC |

| Operation Voltage | DC 6.8–12.8 V |

| Consuming Current | 0.20 A |

| Consuming Power | 1.2 W |

| Rated Speed | 3000 R.P.M. |

| Max. Air Flow | 32.28 CFM |

| Size | 80 × 80 × 25 mm |

| Weight | 40 g |

| Device | Accuracy Value | Measuring Range | Error Ratio % | Measuring Units |

|---|---|---|---|---|

| Temperature data recorder | 1 °C | from −200 to 1370 | 0.3% | °C |

| K-type thermocouple | 0.1 °C | from −100 to 200 | 0.3% | °C |

| TM-207 radiation intensity meter | 0.1% | 0–2000 | 0.1% | W/m2 |

| UT 363 BT anemometer | 0.05 | 0–30 | 3% | m/s |

| Components | Traditional Solar Still | Modified Solar Still |

|---|---|---|

| Wooden board | 14 | 14 |

| Plexiglass cover | 15 | 15 |

| Galvanized stainless steel | 11 | 11 |

| Solar panel | - | 60 |

| Peltier element | - | 20 |

| Ultrasonic elements | - | 15 |

| Cotton mesh | - | 1 |

| Various materials and accessories | 42 | 42 |

| Total cost ($) | 82 | 178 |

| Expression | Traditional Solar Still | Modified Solar Still |

|---|---|---|

| C ($) | 82 | 178 |

| FCR | 0.1769 | 0.1769 |

| FSF | 0.0569 | 0.0569 |

| FCY | 14.505 | 31.48 |

| MCY | 2.175 | 4.72 |

| SV | 16.4 | 35.6 |

| SVY | 0.93 | 2.02 |

| TCY | 15.747 | 34.17 |

| 2.095 | 4.7 | |

| 377.1 | 846 | |

| PCD | 0.042 | 0.040 |

| Study | Type of Single-Slope Solar Still Enhancement | Study Location | Daily Yield of Distillate Water (L/m2·day) | Cost of Productivity ($/L) |

|---|---|---|---|---|

| [17] | Solar still with external solar collector | Russia | 5.5 | 0.047 |

| [19] | Solar still at different water depths | Russia | 1.6 at 1 cm | 0.033 |

| [22] | Solar still integrated with hollow drum | Russia | 12.5 | 0.026 |

| [23] | Solar still combined with diffusion absorption cooling | Russia | 5.180 | 0.046 |

| [24] | Solar still combined with ultrasonic humidifiers | Russia | 4.2 | 0.0259 |

| [35] | Single-slope solar distiller | Pakistan | 3.2 | 0.062 |

| [36] | Single-slope solar still combined with ultrasonic humidifier and integrated with solar water heater | Egypt | 7.4 | 0.037 |

| [37] | Single-slope solar still integrated with rotating drum | Saudi Arabia | 11 | 0.039 |

| [38] | Hybrid (PV/T) active single-slope solar stills | India | 1.90 | 0.14 |

| [25] | Single-slope solar distiller combined with thermal storage materials (PCM) | Iraq | 2.35 | 0.035 |

| [39] | Single-basin single-slope with a solar collector | Jordan | 4.78 | 0.115 |

| [40] | Single-basin single-slope with a separate condenser | Turkey | 6 | 0.06 |

| Current study | Solar still combined with ultrasonic cotton mesh and Peltier cooling chamber | Russia | 4.7 | 0.040 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alwan, N.T.; Ahmed, A.S.; Majeed, M.H.; Shcheklein, S.E.; Yaqoob, S.J.; Nayyar, A.; Nam, Y.; Abouhawwash, M. Enhancement of the Evaporation and Condensation Processes of a Solar Still with an Ultrasound Cotton Tent and a Thermoelectric Cooling Chamber. Electronics 2022, 11, 284. https://doi.org/10.3390/electronics11020284

Alwan NT, Ahmed AS, Majeed MH, Shcheklein SE, Yaqoob SJ, Nayyar A, Nam Y, Abouhawwash M. Enhancement of the Evaporation and Condensation Processes of a Solar Still with an Ultrasound Cotton Tent and a Thermoelectric Cooling Chamber. Electronics. 2022; 11(2):284. https://doi.org/10.3390/electronics11020284

Chicago/Turabian StyleAlwan, Naseer T., Ayad S. Ahmed, Milia H. Majeed, Sergey E. Shcheklein, Salam J. Yaqoob, Anand Nayyar, Yunyoung Nam, and Mohamed Abouhawwash. 2022. "Enhancement of the Evaporation and Condensation Processes of a Solar Still with an Ultrasound Cotton Tent and a Thermoelectric Cooling Chamber" Electronics 11, no. 2: 284. https://doi.org/10.3390/electronics11020284

APA StyleAlwan, N. T., Ahmed, A. S., Majeed, M. H., Shcheklein, S. E., Yaqoob, S. J., Nayyar, A., Nam, Y., & Abouhawwash, M. (2022). Enhancement of the Evaporation and Condensation Processes of a Solar Still with an Ultrasound Cotton Tent and a Thermoelectric Cooling Chamber. Electronics, 11(2), 284. https://doi.org/10.3390/electronics11020284