Optimal Operation of a Microgrid with Hydrogen Storage Based on Deep Reinforcement Learning

Abstract

:1. Introduction

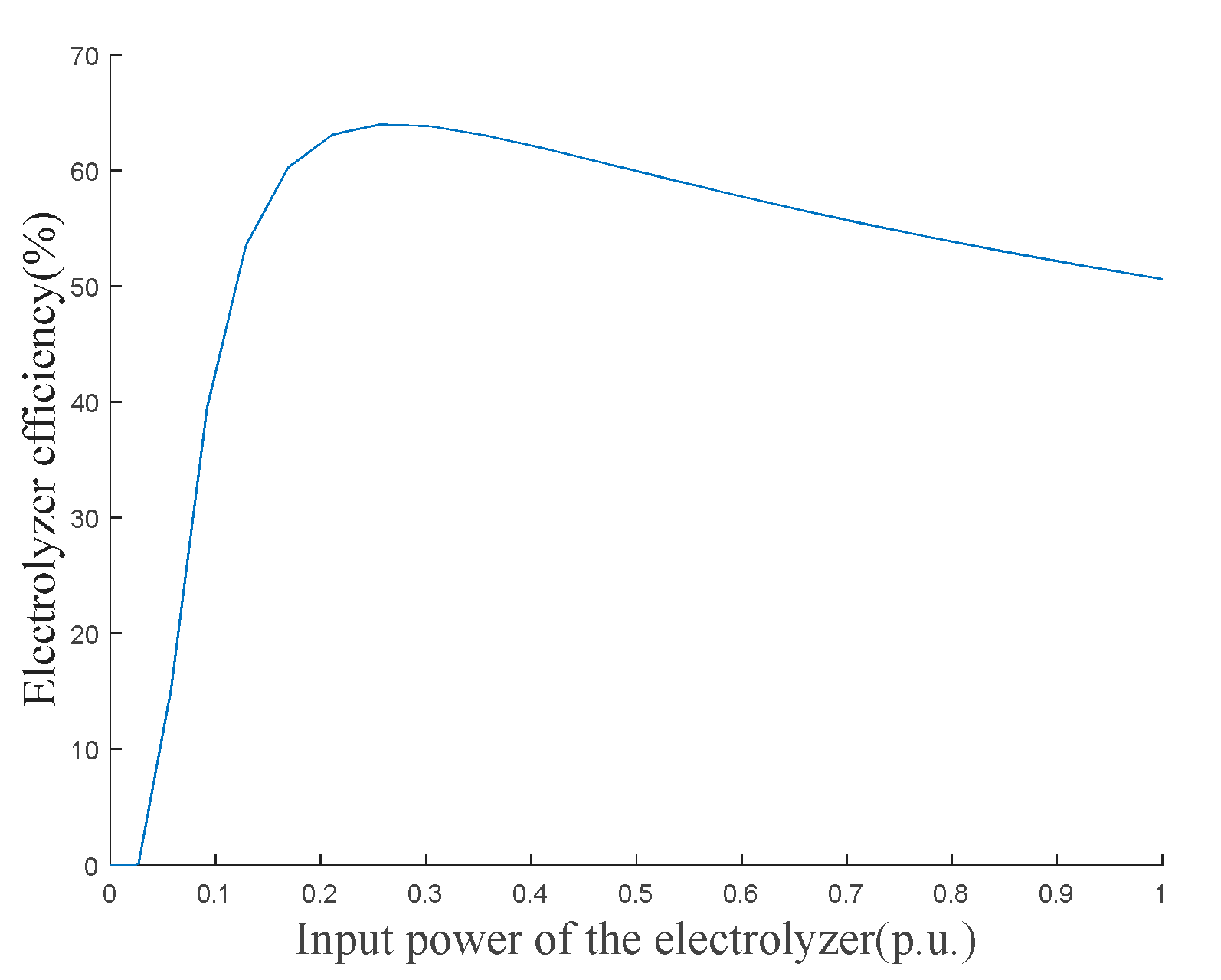

- A refined model represents the electrolyzer efficiency characteristics based on the linear interpolation method is proposed;

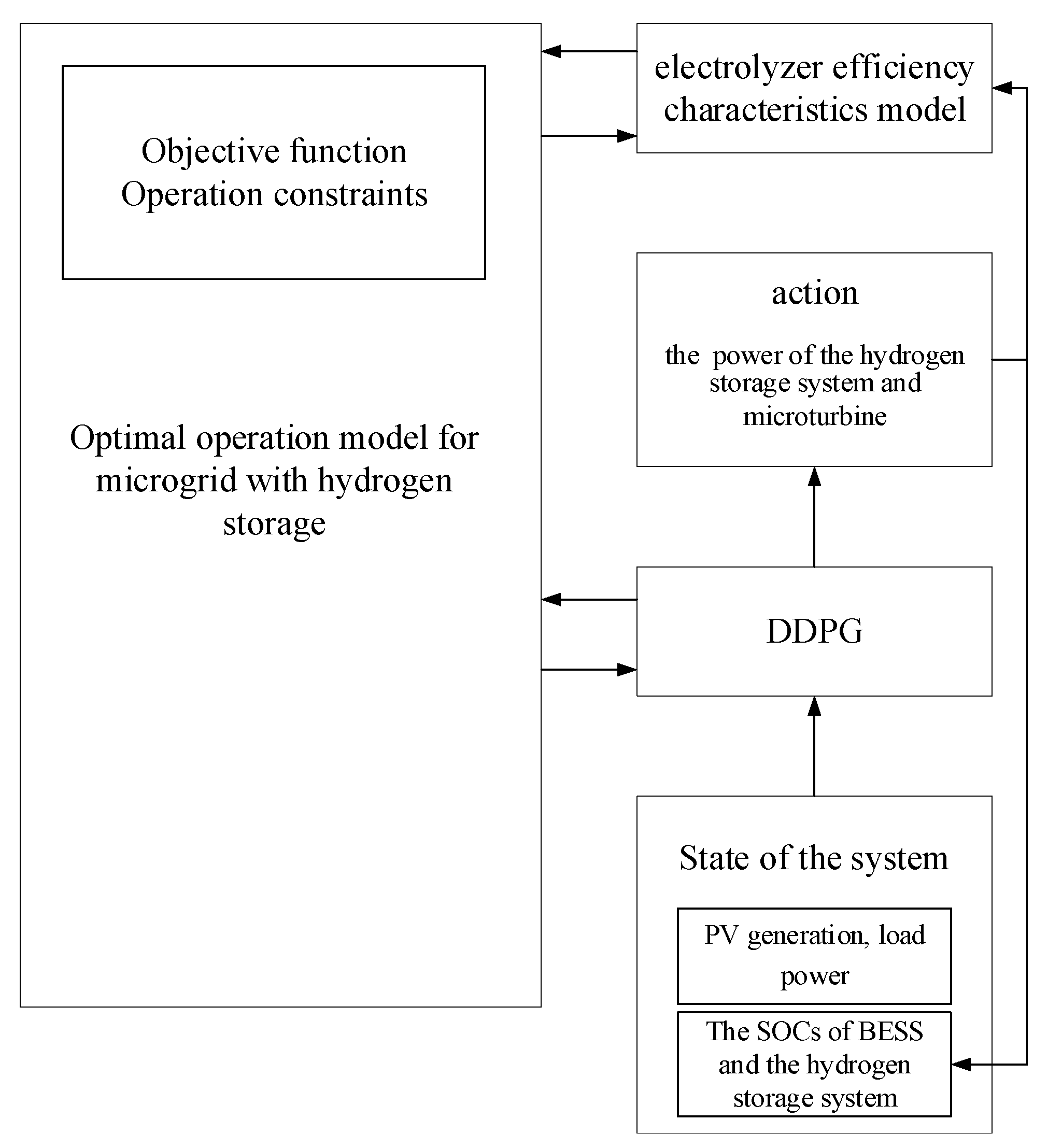

- An optimal operation model for a microgrid with hydrogen storage is proposed. The electrolyzer efficiency characteristics model is incorporated into the optimal operation model;

- The DDPG algorithm is adopted to solve the optimal operation model, which has a continuous action space.

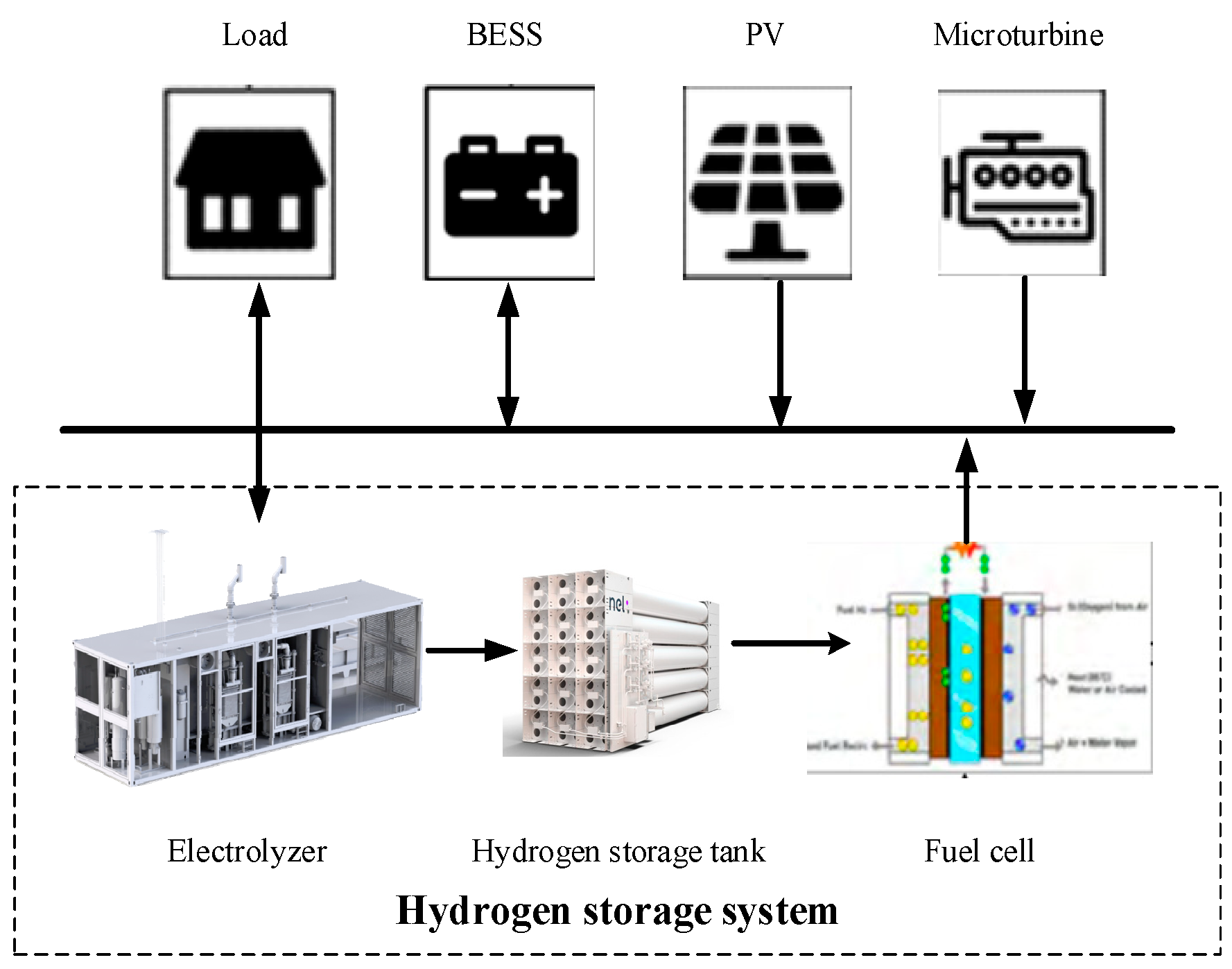

2. Model of the Microgrid System

2.1. Electrolyzer Efficiency

2.2. Economic Dispatch Model of Microgrid

2.2.1. Objective Function

2.2.2. Constraints

- Power balance

- 2.

- Operating power constraints

- 3.

- Energy storage capacity

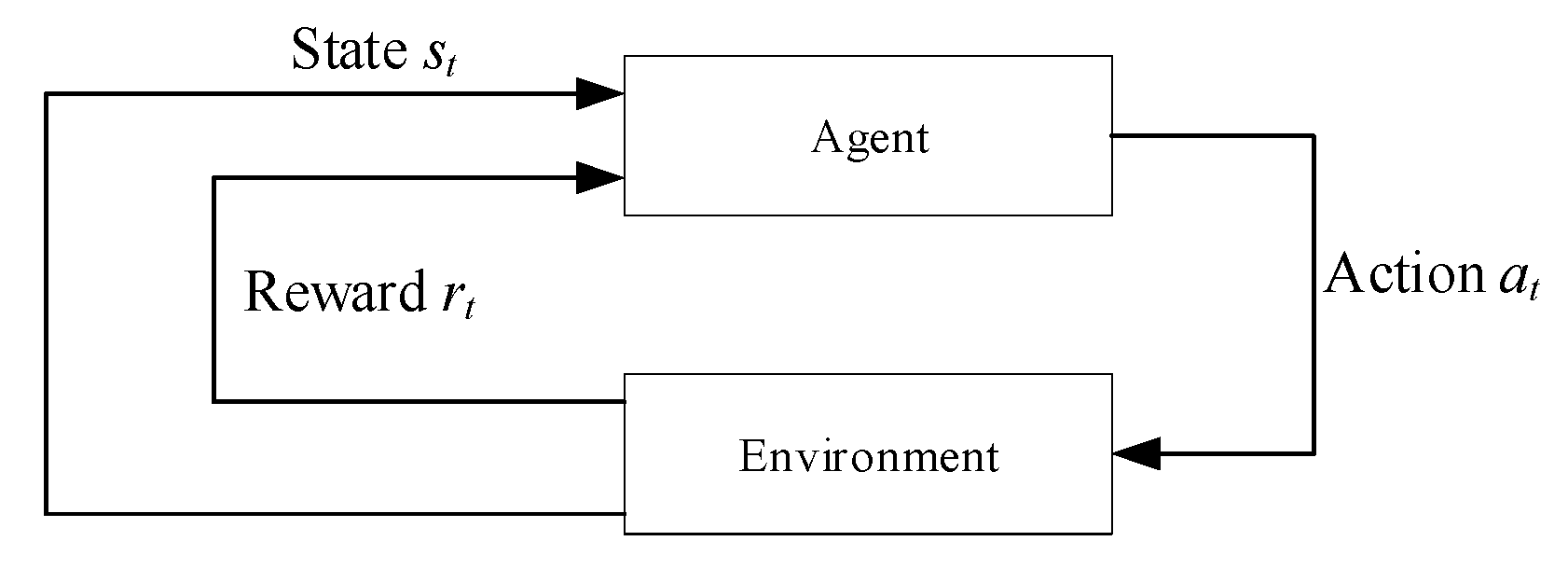

3. Deep Reinforcement Learning

3.1. Reinforcement Learning

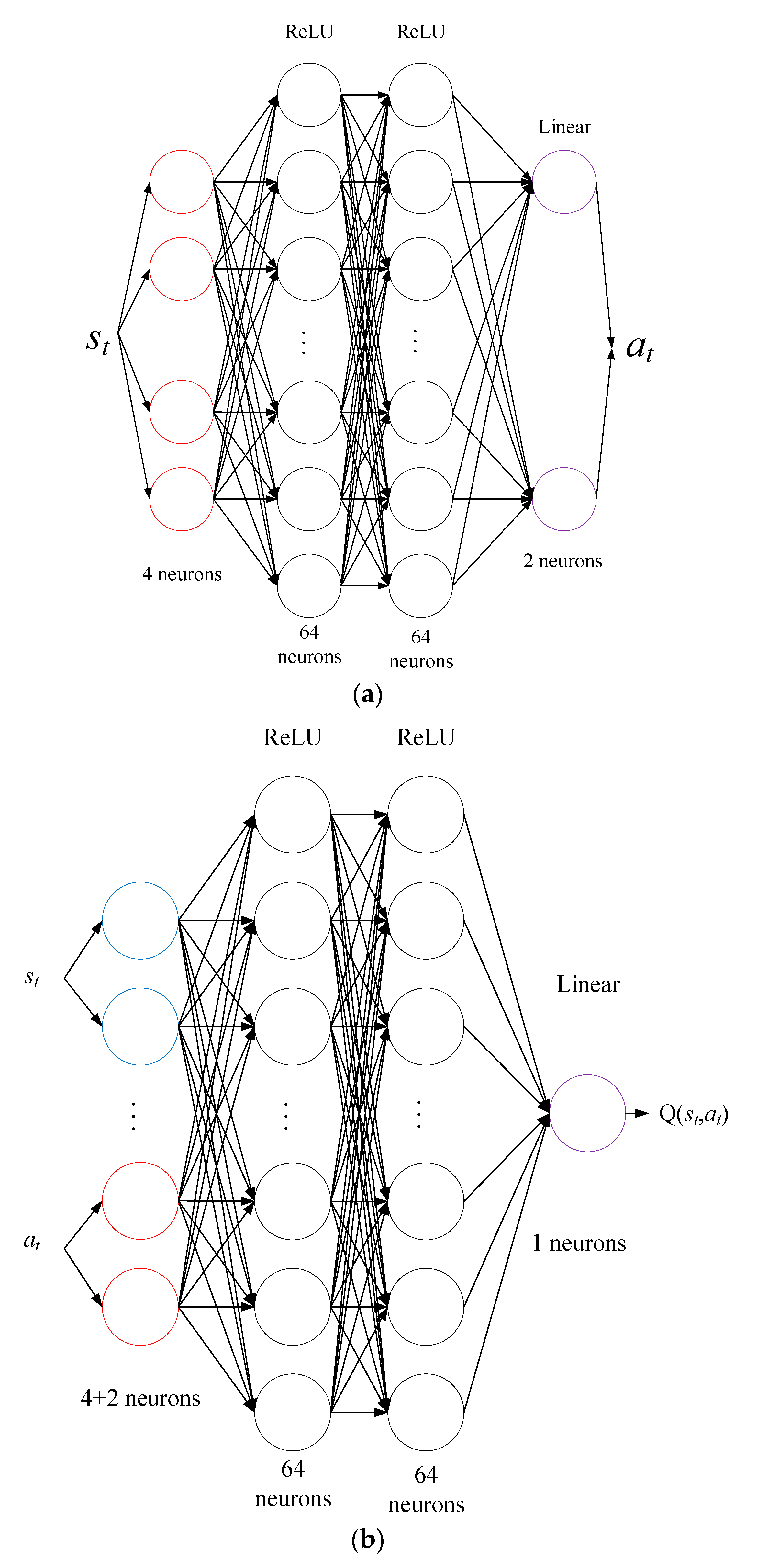

3.2. Deep Deterministic Policy Gradient Algorithm

4. Optimal Operation of Microgrid Based on DDPG

4.1. State Space

4.2. Action Space

4.3. Reward Function

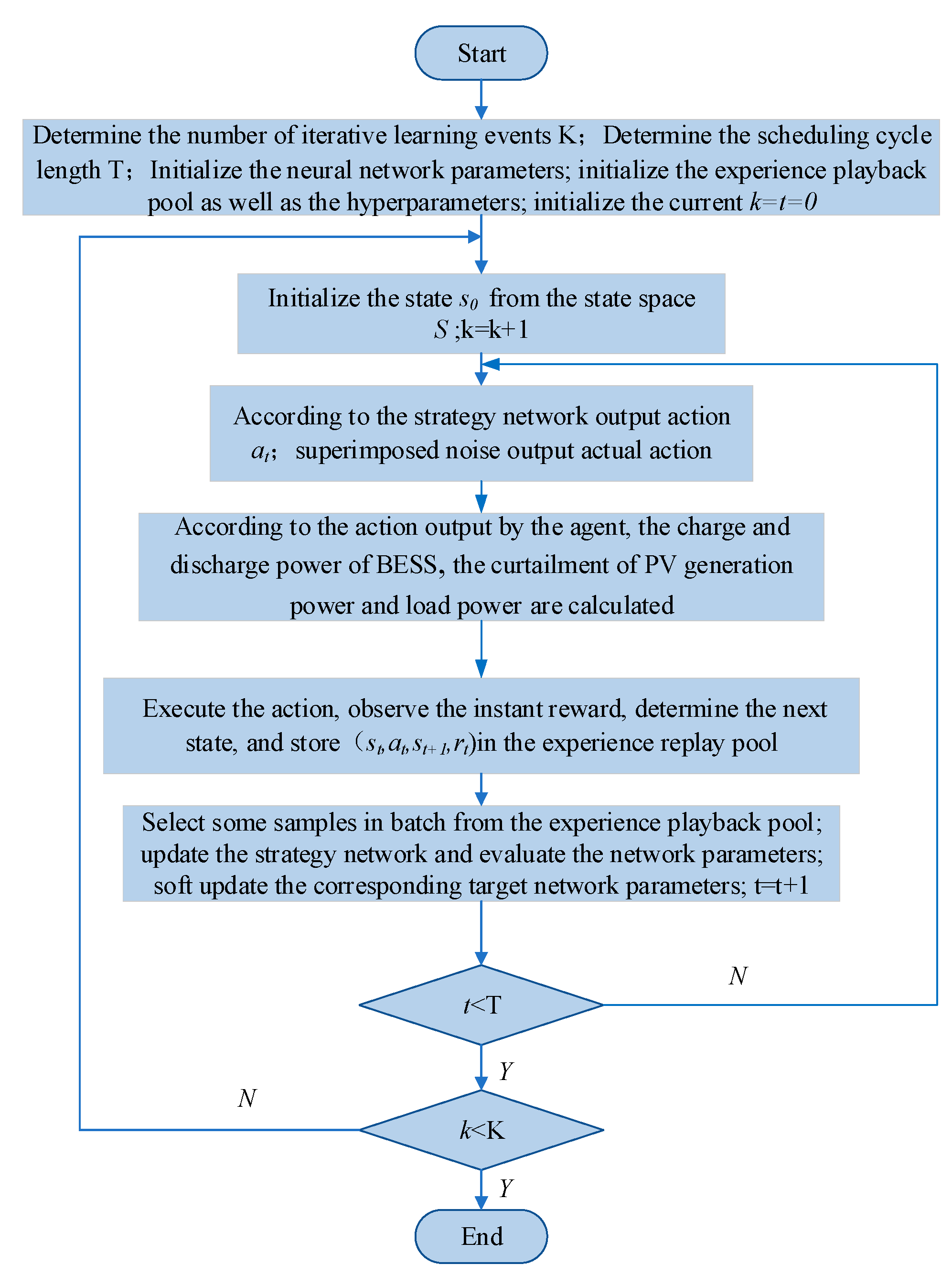

4.4. Process of the Optimal Operation Method

5. Case Studies

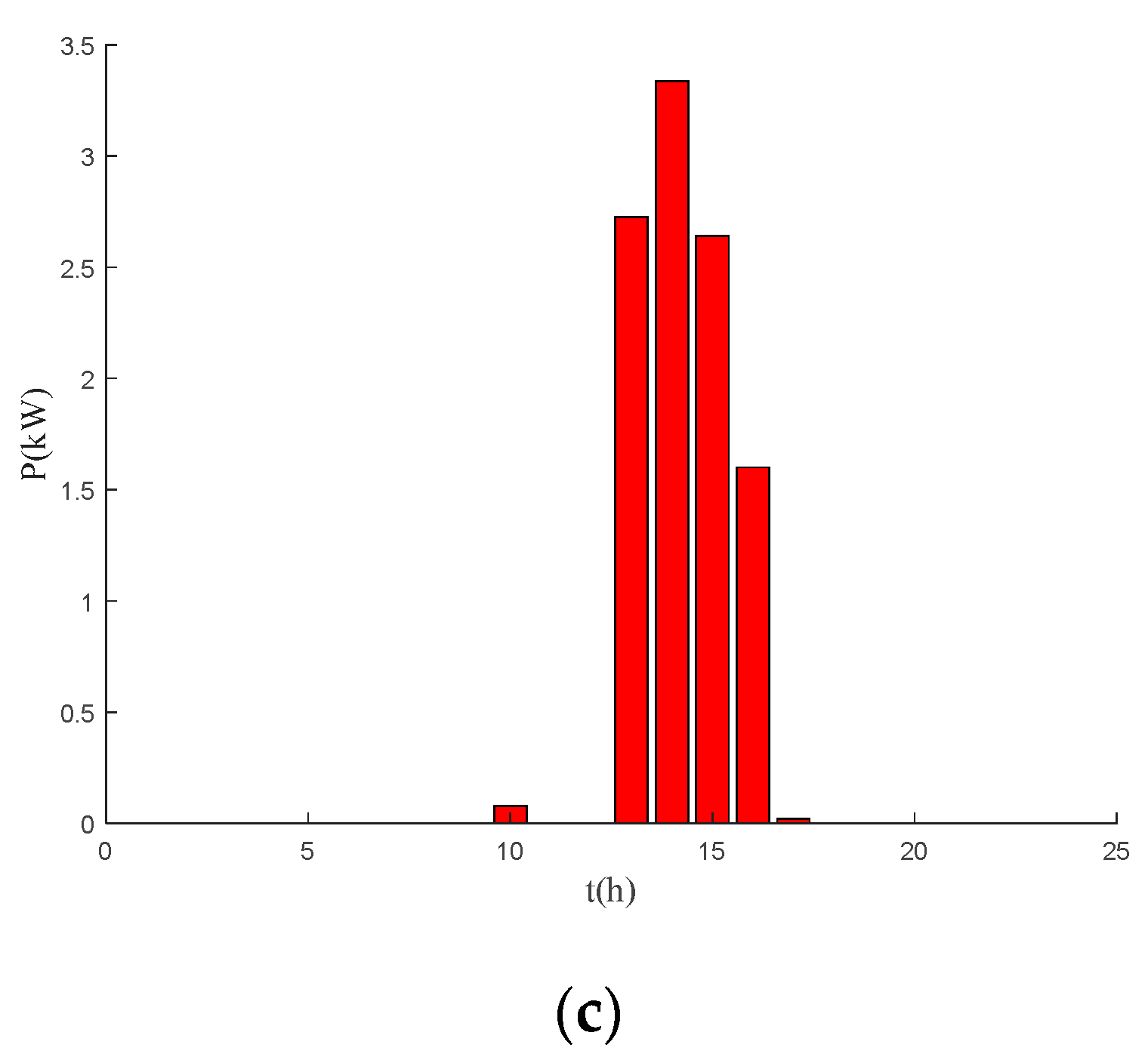

5.1. Simulation Environment

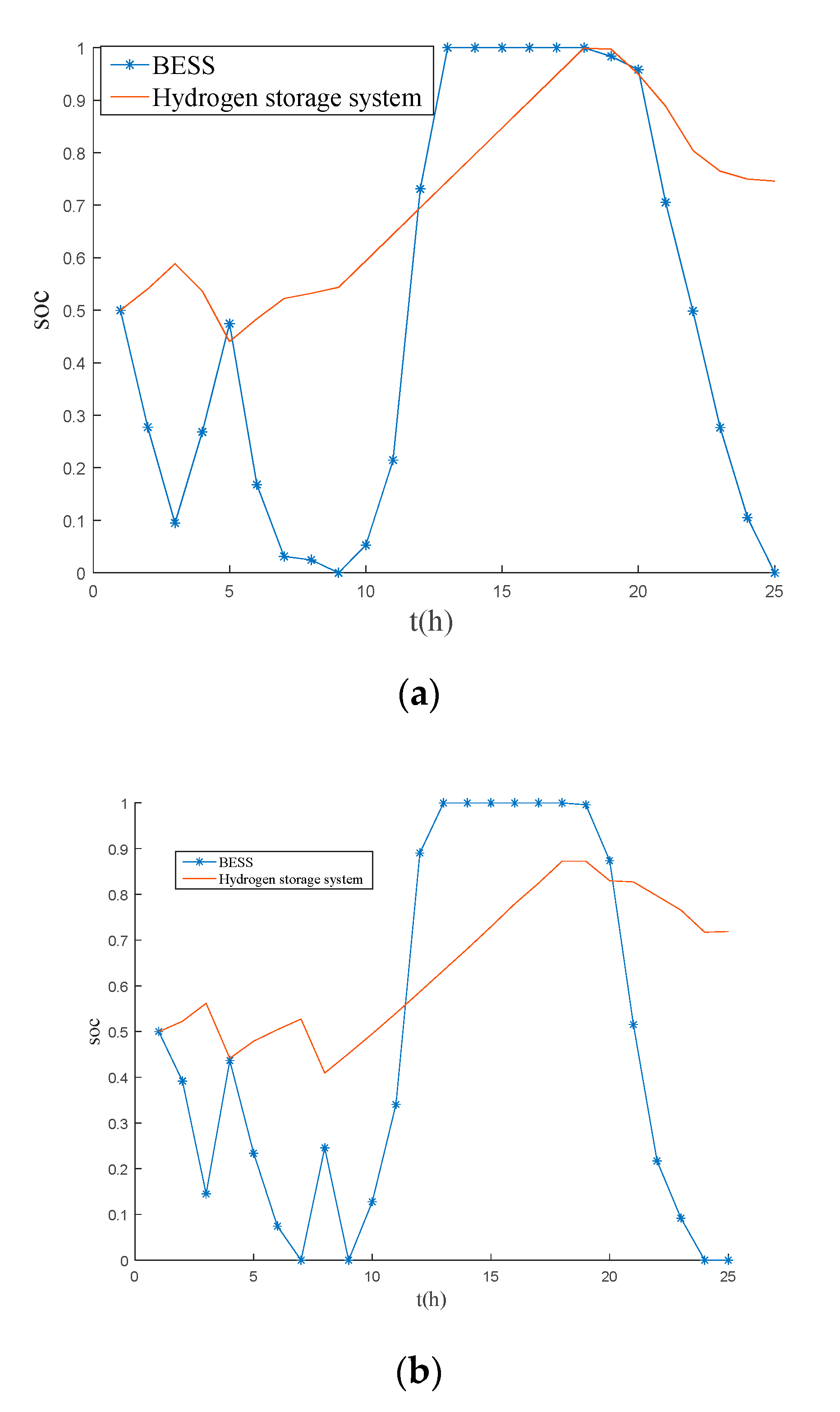

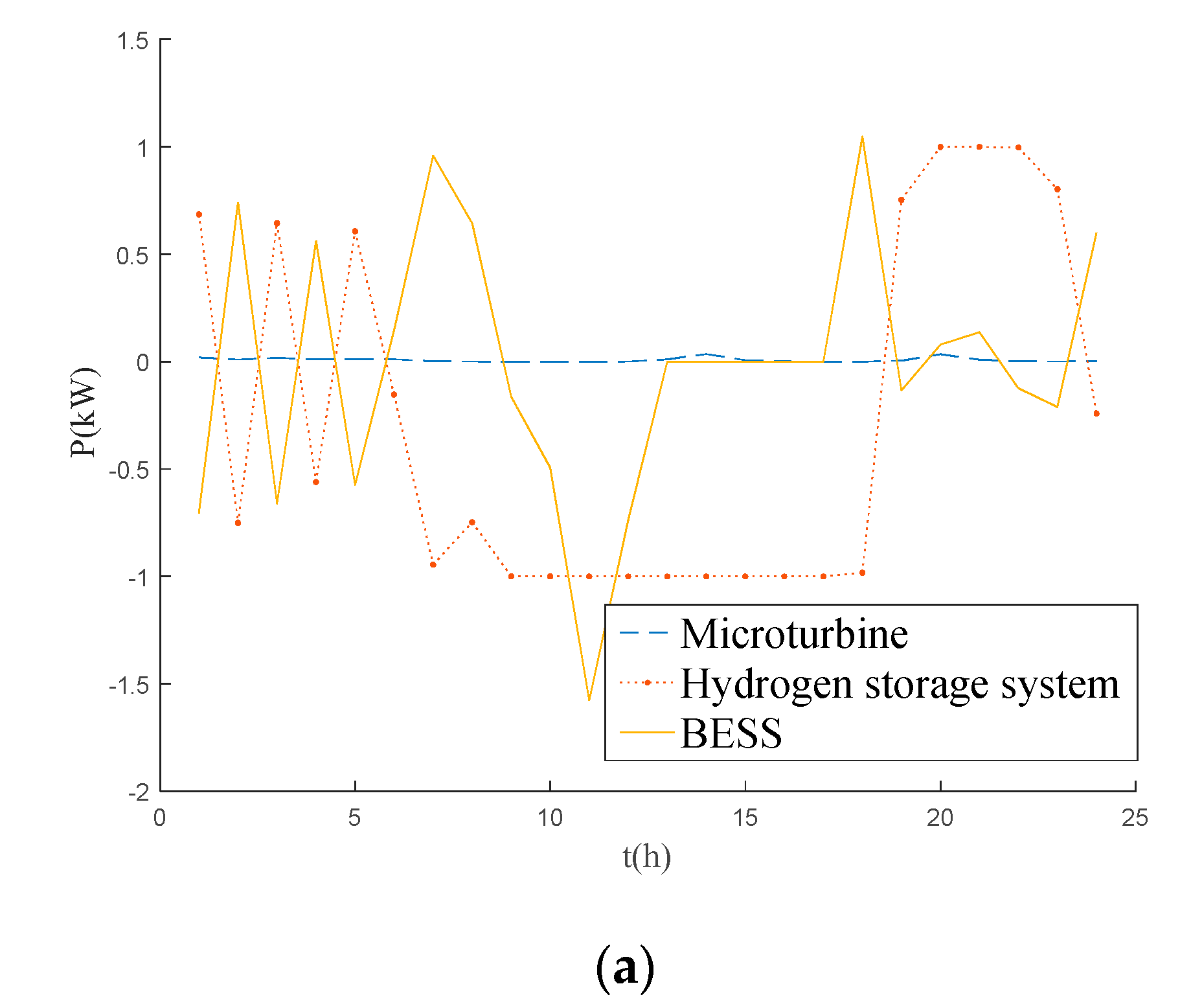

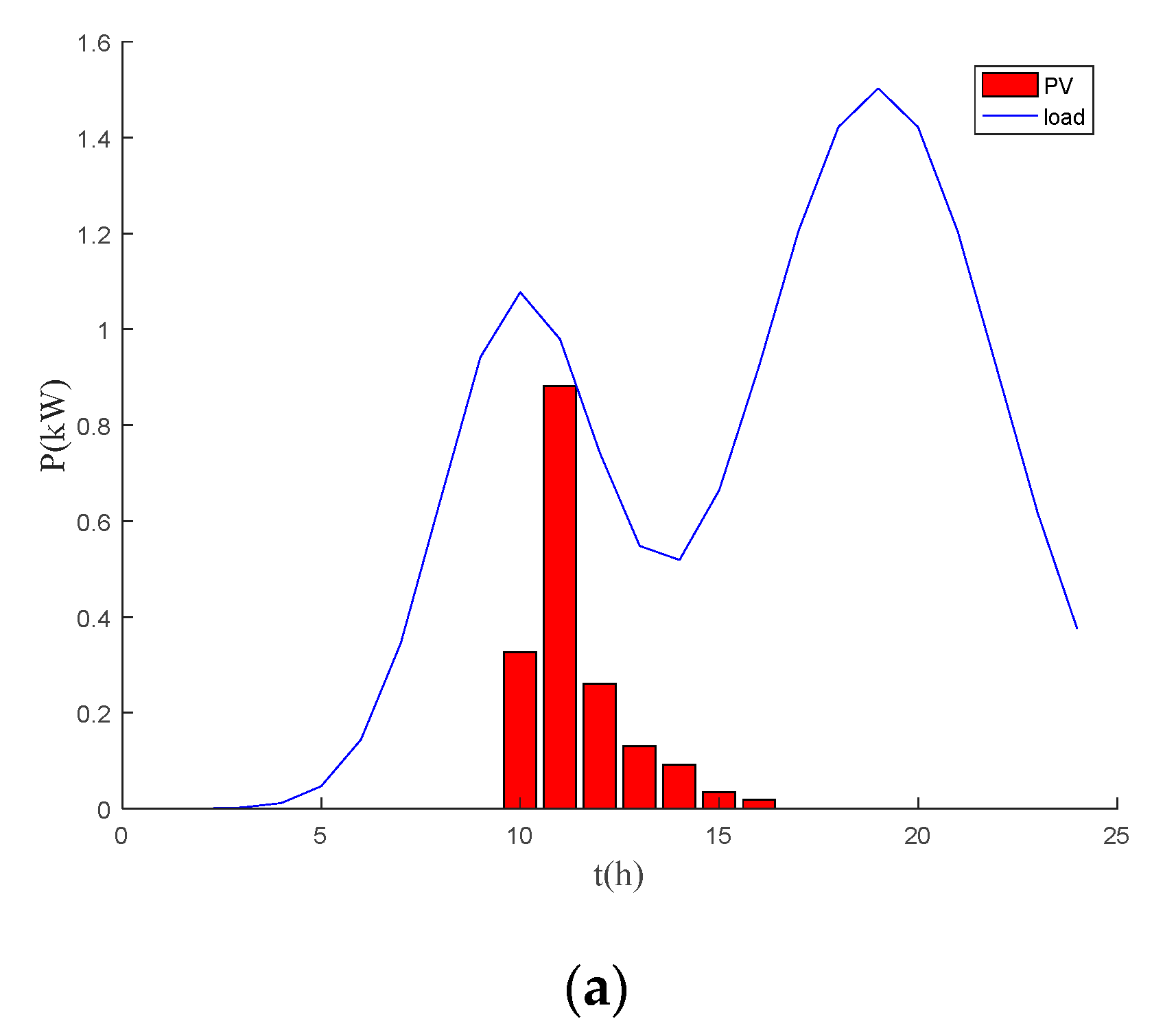

5.2. Simulation Results

5.2.1. Simulation Results of Electrolyzer Efficiency Characteristics

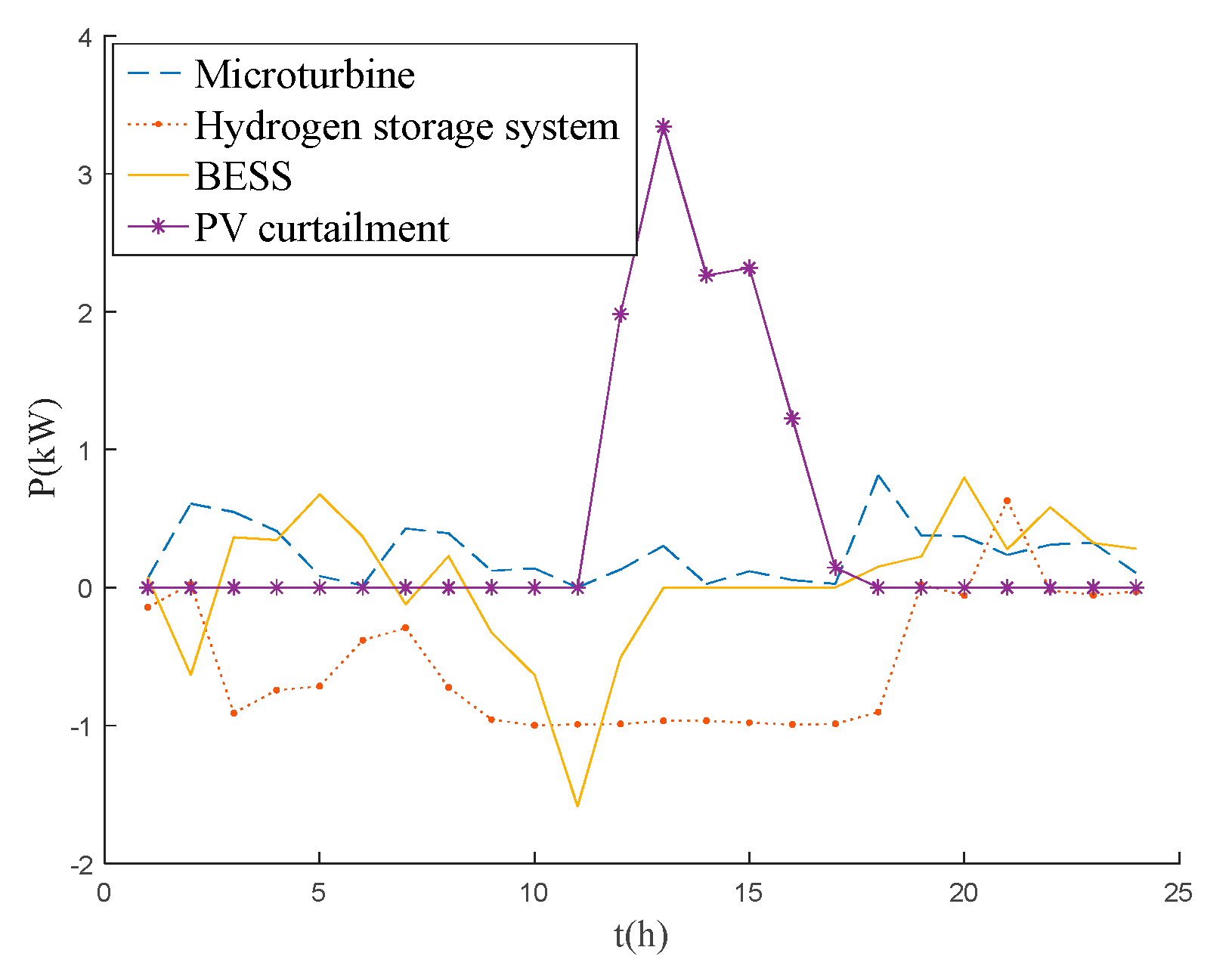

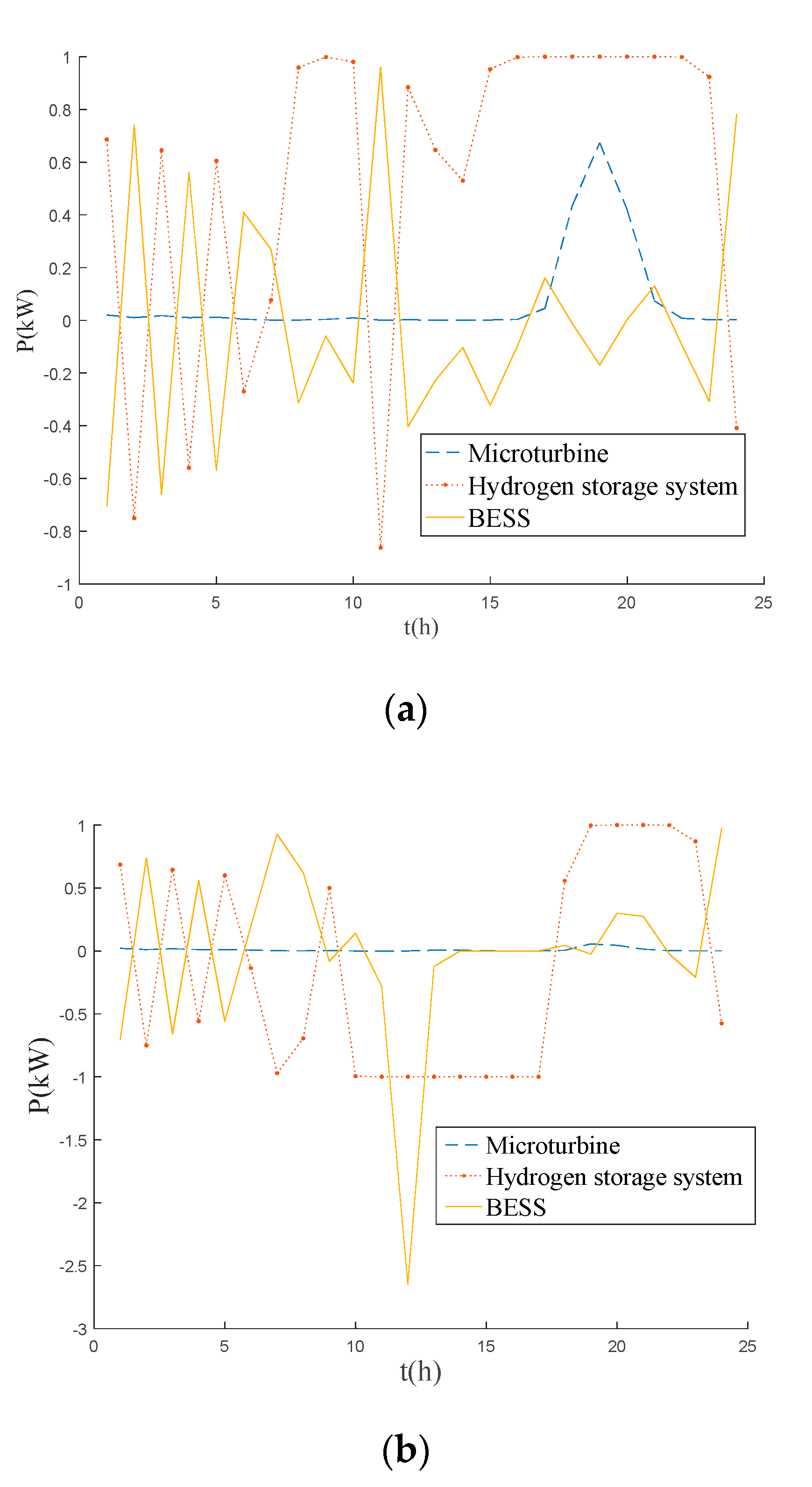

5.2.2. Simulation Results of DDPG Algorithm

5.2.3. Performance Evaluation

- Method1: Optimize the operation of microgrids using DDPG algorithm;

- Method2: Optimize the operation of the microgrid using the GA;

- Method3: Optimize the operation of the microgrid using the interior point method.

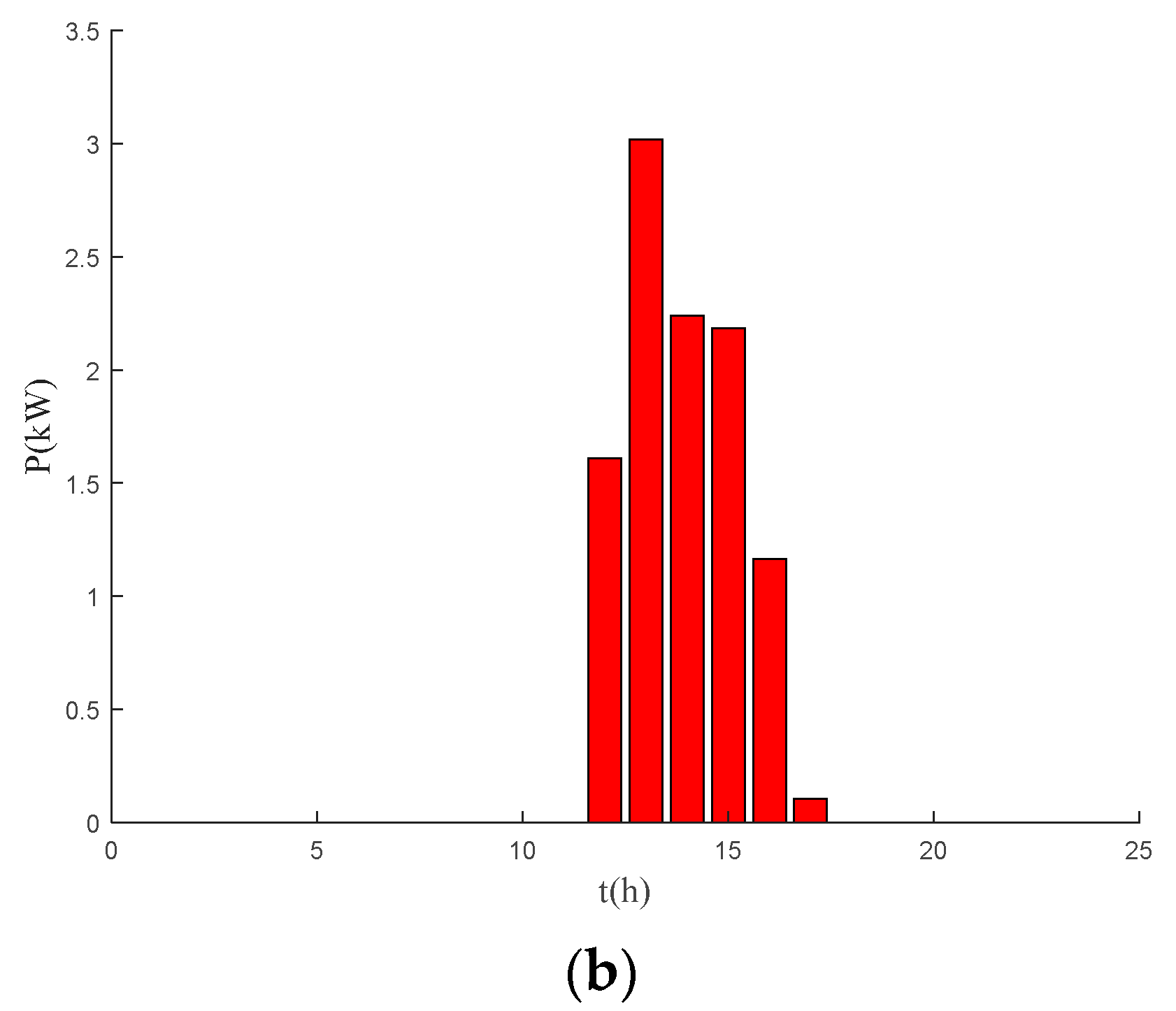

5.2.4. Generalization Analysis

6. Conclusions

- The electrolyzer efficiency characteristics model using linear interpolation method can describe the operation of electrolyzer more accurately. The proposed optimal operation method for the microgrid considering electrolyzer efficiency characteristics can reduce the PV curtailment and reduce the microgrid operation cost;

- The optimal microgrid operation method based on DDPG algorithm can effectively reduce the operation cost and improve the microgrid efficiency compared with the method based on traditional algorithms, such as the GA and interior point method;

- The optimal microgrid operation method based on DDPG algorithm has a certain generalization and can be used in in different scenarios.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Abbreviation | Description |

| GAMS | General algebraic modeling system |

| DDPG | Deep deterministic policy gradient |

| PV | Photovoltaic |

| BESS | Battery energy storage system |

| SOFC | Solid oxide fuel cell |

| SOC | State of charge |

| GA | Genetic algorithm |

References

- Mah, A.X.Y.; Ho, W.S.; Hassim, M.H.; Hashim, H.; Ling, G.H.T.; Ho, C.S.; Ab Muis, Z. Optimization of a standalone photovoltaic-based microgrid with electrical and hydrogen loads. Energy 2021, 235, 121218. [Google Scholar] [CrossRef]

- Hatziargyriou, N.; Asano, H.; Iravani, R.; Marnay, C. Microgrids. IEEE Power Energy Mag. 2007, 5, 78–94. [Google Scholar] [CrossRef]

- Shatnawi, M.; Al Qaydi, N.; Aljaberi, N.; Aljaberi, M. Hydrogen-Based Energy Storage Systems: A Review. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018. [Google Scholar]

- Ji, Y.; Wang, J.; Xu, J.; Fang, X.; Zhang, H. Real-Time Energy Management of a Microgrid Using Deep Reinforcement Learning. Energies 2019, 12, 2291. [Google Scholar] [CrossRef] [Green Version]

- Daneshvar, M.; Mohammadi-Ivatloo, B.; Zare, K.; Asadi, S. Transactive energy management for optimal scheduling of interconnected microgrids with hydrogen energy storage. Int. J. Hydrog. Energy 2020, 46, 16267–16278. [Google Scholar] [CrossRef]

- Akbari-Dibavar, A.; Daneshvar, M.; Mohammadi-Ivatloo, B.; Zare, K.; Anvari-Moghaddam, A. Optimal Robust Energy Management of Microgrid with Fuel Cells, Hydrogen Energy Storage Units and Responsive Loads. In Proceedings of the 2020 International Conference on Smart Energy Systems and Technologies (SEST), Istanbul, Turkey, 7–9 September 2020. [Google Scholar]

- Nojavan, S.; Akbari-Dibavar, A.; Farahmand-Zahed, A.; Zare, K. Risk-constrained scheduling of a CHP-based microgrid including hydrogen energy storage using robust optimization approach. Int. J. Hydrog. Energy 2020, 45, 32269–32284. [Google Scholar] [CrossRef]

- Nojavan, S.; Zare, K.; Mohammadi-Ivatloo, B. Application of fuel cell and electrolyzer as hydrogen energy storage system in energy management of electricity energy retailer in the presence of the renewable energy sources and plug-in electric vehicles. Energy Convers. Manag. 2017, 136, 404–417. [Google Scholar] [CrossRef]

- Konstantinopoulos, S.A.; Anastasiadis, A.G.; Vokas, G.A.; Kondylis, G.P.; Polyzakis, A. Optimal management of hydrogen storage in stochastic smart microgrid operation. Int. J. Hydrog. Energy 2017, 43, 490–499. [Google Scholar] [CrossRef]

- Gong, X.; Dong, F.; Mohamed, M.A.; Abdalla, O.M.; Ali, Z.M. A Secured Energy Management Architecture for Smart Hybrid Microgrids Considering PEM-Fuel Cell and Electric Vehicles. IEEE Access 2020, 8, 47807–47823. [Google Scholar] [CrossRef]

- Dufo-López, R.; Bernal-Agustín, J.L.; Contreras, J. Optimization of control strategies for stand-alone renewable energy systems with hydrogen storage. Renew. Energy 2007, 32, 1102–1126. [Google Scholar] [CrossRef]

- García-Triviño, P.; Fernández-Ramírez, L.M.; Gil-Mena, A.J.; Llorens-Iborra, F.; García-Vázquez, C.A.; Jurado, F. Optimized operation combining costs, efficiency and lifetime of a hybrid renewable energy system with energy storage by battery and hydrogen in grid-connected applications. Int. J. Hydrog. Energy 2016, 41, 23132–23144. [Google Scholar] [CrossRef]

- Wang, S.; Duan, J.; Shi, D.; Xu, C.; Li, H.; Diao, R.; Wang, Z. A Data-driven Multi-agent Autonomous Voltage Control Framework Using Deep Reinforcement Learning. IEEE Trans. Power Syst. 2020, 35, 4644–4654. [Google Scholar] [CrossRef]

- Diao, R.; Wang, Z.; Shi, D.; Chang, Q.; Duan, J.; Zhang, X. Autonomous Voltage Control for Grid Operation Using Deep Reinforcement Learning. In Proceedings of the IEEE Power & Energy Society General Meeting (PESGM), Atlanta, GA, USA, 4–8 August 2019; pp. 1–5. [Google Scholar]

- Wan, Z.; Li, H.; He, H.; Prokhorov, D. Model-Free Real-Time EV Charging Scheduling Based on Deep Reinforcement Learning. IEEE Trans. Smart Grid 2018, 10, 5246–5257. [Google Scholar] [CrossRef]

- López, K.L.; Gagné, C.; Gardner, M.A. Demand-Side Management Using Deep Learning for Smart Charging of Electric Vehicles. IEEE Trans. Smart Grid 2018, 10, 2683–2691. [Google Scholar] [CrossRef]

- Ye, Y.; Qiu, D.; Sun, M.; Papadaskalopoulos, D.; Strbac, G. Deep Reinforcement Learning for Strategic Bidding in Electricity Markets. IEEE Trans. Smart Grid 2020, 11, 1343–1355. [Google Scholar] [CrossRef]

- Xu, H.; Sun, H.; Nikovski, D.; Kitamura, S.; Mori, K.; Hashimoto, H. Deep Reinforcement Learning for Joint Bidding and Pricing of Load Serving Entity. IEEE Trans. Smart Grid 2019, 10, 6366–6375. [Google Scholar] [CrossRef]

- Ye, Y.; Qiu, D.; Wu, X.; Strbac, G.; Ward, J. Model-Free Real-Time Autonomous Control for a Residential Multi-Energy System Using Deep Reinforcement Learning. IEEE Trans. Smart Grid 2020, 11, 3068–3082. [Google Scholar] [CrossRef]

- Bian, H.; Tian, X.; Zhang, J.; Han, X. Deep Reinforcement Learning Algorithm Based on Optimal Energy Dispatching for Microgrid. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 4–7 June 2020. [Google Scholar]

- Domínguez-Barbero, D.; García-González, J.; Sanz-Bobi, M.A.; Sánchez-Úbeda, E.F. Optimising a Microgrid System by Deep Reinforcement Learning Techniques. Energies 2020, 13, 2830. [Google Scholar] [CrossRef]

- Pan, G.; Gu, W.; Lu, Y.; Qiu, H.; Lu, S.; Yao, S. Optimal Planning for Electricity-Hydrogen Integrated Energy System Considering Power to Hydrogen and Heat and Seasonal Storage. IEEE Trans. Sustain. Energy 2020, 11, 2662–2676. [Google Scholar] [CrossRef]

- Deng, Z.; Jiang, Y. Optimal sizing of a wind-hydrogen system under consideration of the efficiency characteristics of electrolysers. Renew. Energy Resour. 2020, 38, 259–266. [Google Scholar]

- Du, Y.; Li, F. Intelligent Multi-Microgrid Energy Management Based on Deep Neural Network and Model-Free Reinforcement Learning. IEEE Trans. Smart Grid 2020, 11, 1066–1076. [Google Scholar] [CrossRef]

- Yu, P.; Song, T.; Yuan, T.; Han, X. Economic Operation of Regional Integrated Energy System Considering Cogeneration of Fuel Cell. Proc. CSU-EPSA 2021, 33, 9. [Google Scholar]

- François-Lavet, V.; Taralla, D. DeeR. 2016. Available online: http://deer.readthedocs.io (accessed on 16 April 2020).

- Raghavan, A.; Maan, P.; Shenoy, A.K. Optimization of Day-Ahead Energy Storage System Scheduling in Microgrid Using Genetic Algorithm and Particle Swarm Optimization. IEEE Access 2020, 8, 173068–173078. [Google Scholar] [CrossRef]

- Valencia, F.; Sáez, D.; Collado, J.; Ávila, F.; Marquez, A.; Espinosa, J.J. Robust Energy Management System Based on Interval Fuzzy Models. IEEE Trans. Control. Syst. Technol. 2016, 24, 140–157. [Google Scholar]

| Parameters | Value |

|---|---|

| Unit current density j/A·cm−2 | 0~4 |

| Operating temperature T/K | 353 |

| Universal gas constants R/J·(mol·K)−1 | 8.31446 |

| Faraday’s constant F/C·mol−1 | 96,485.3 |

| Cathodic charge transfer coefficient αc | 0.71 |

| Anode charge transfer coefficient αa | 0.29 |

| Cathode exchange current density jco/mA·cm−2 | 24.6 |

| Anode exchange current density jao/mA·cm−2 | 24.1 |

| Electron transfer number of cathode and anode nc, na | 2 |

| Electrolyte resistance/mΩ | 20 |

| Cross-sectional area of electrolyzer/cm2 | 16 |

| Device | Maximum Power/kW | Minimum Power/kW | Operation and Maintenance Cost (USD/kWh) |

|---|---|---|---|

| Electrolyzer | 1 | 0 | 0.01262 |

| Microturbine | 1 | 0 | / |

| Fuel Cell | 1 | 0 | 0.01325 |

| BESS | 2.9 | 2.9 | 0.01311 |

| Electrolyzer Efficiency | Microgrid Operating Cost/USD |

|---|---|

| Considering efficiency characteristic | 5.24 |

| Constant efficiency 0.5 | 5.20 |

| Constant efficiency 0.6 | 5.42 |

| Constant efficiency 0.65 | 5.56 |

| Constant efficiency 0.7 | 5.94 |

| Algorithm | Method 1 | Method 2 | Method 3 |

|---|---|---|---|

| Operating cost of microgrid/USD | 5.29 | 5.75 | 5.52 |

| DDPG | GA | |

|---|---|---|

| Operating cost of winter/USD | 2.07 | 2.08 |

| Operating cost of summer/USD | 5.31 | 5.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Weng, Z.; Zheng, H. Optimal Operation of a Microgrid with Hydrogen Storage Based on Deep Reinforcement Learning. Electronics 2022, 11, 196. https://doi.org/10.3390/electronics11020196

Zhu Z, Weng Z, Zheng H. Optimal Operation of a Microgrid with Hydrogen Storage Based on Deep Reinforcement Learning. Electronics. 2022; 11(2):196. https://doi.org/10.3390/electronics11020196

Chicago/Turabian StyleZhu, Zhenshan, Zhimin Weng, and Hailin Zheng. 2022. "Optimal Operation of a Microgrid with Hydrogen Storage Based on Deep Reinforcement Learning" Electronics 11, no. 2: 196. https://doi.org/10.3390/electronics11020196

APA StyleZhu, Z., Weng, Z., & Zheng, H. (2022). Optimal Operation of a Microgrid with Hydrogen Storage Based on Deep Reinforcement Learning. Electronics, 11(2), 196. https://doi.org/10.3390/electronics11020196