Positioning Algorithm of MEMS Pipeline Inertial Locator Based on Dead Reckoning and Information Multiplexing

Abstract

:1. Introduction

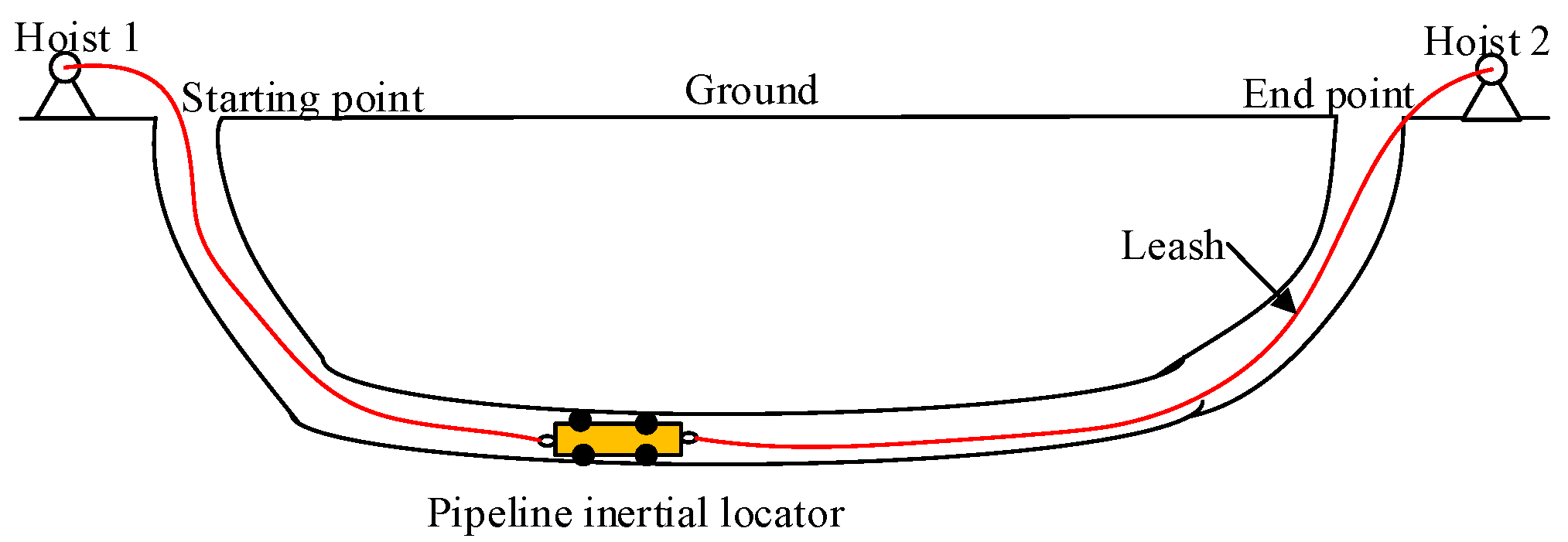

2. Mathematical Model of Dead Reckoning for Pipeline Inertial Locator

2.1. Initial Alignment Model

2.2. Dead Reckoning Model

3. Dead Reckoning Error Analysis

4. Trajectory Position Error Correction Algorithm

4.1. Forward Horizontal and Height Correction Algorithm

4.2. Inverse Horizontal and Height Correction Algorithm

5. Simulation and Experiment

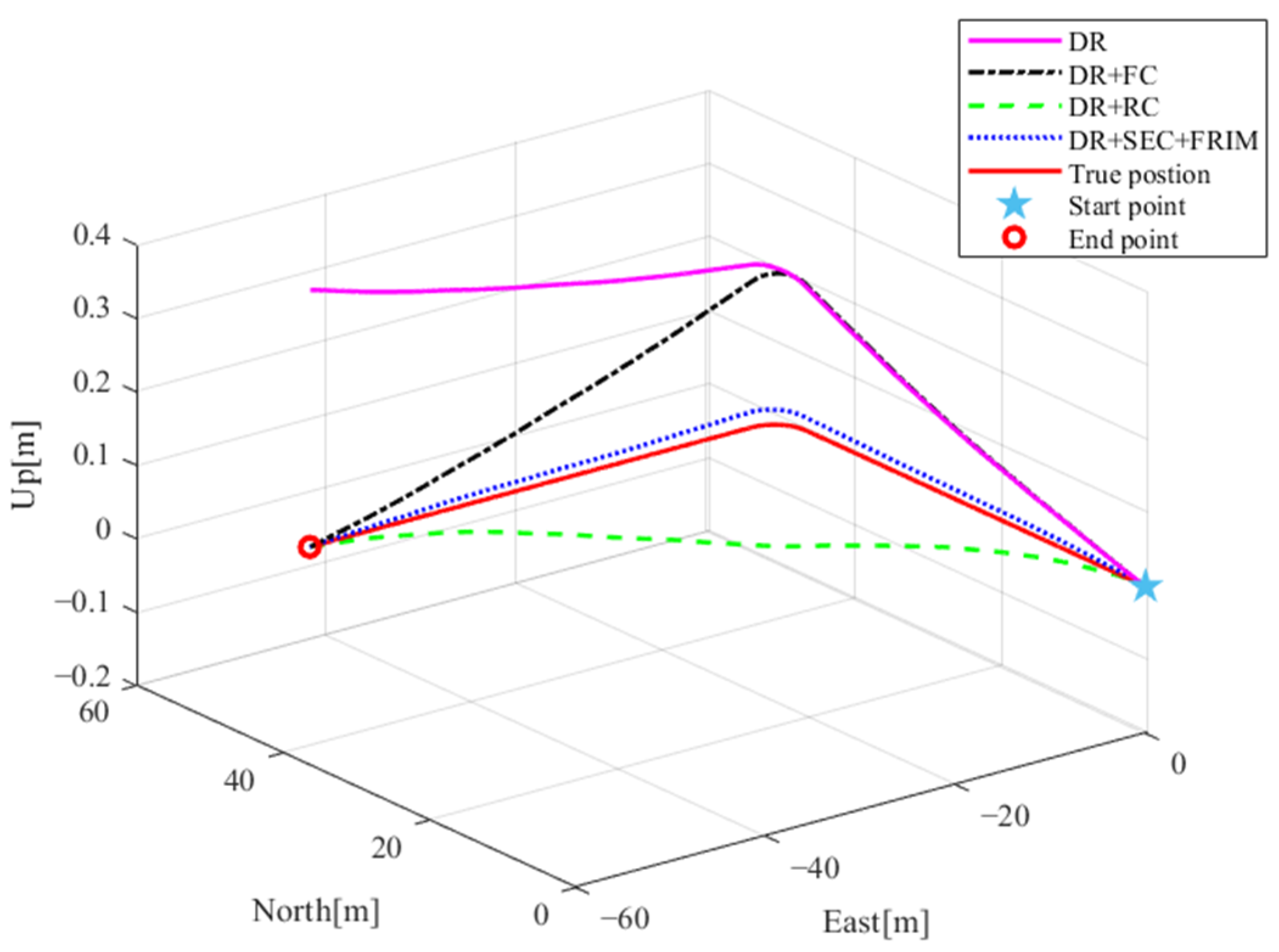

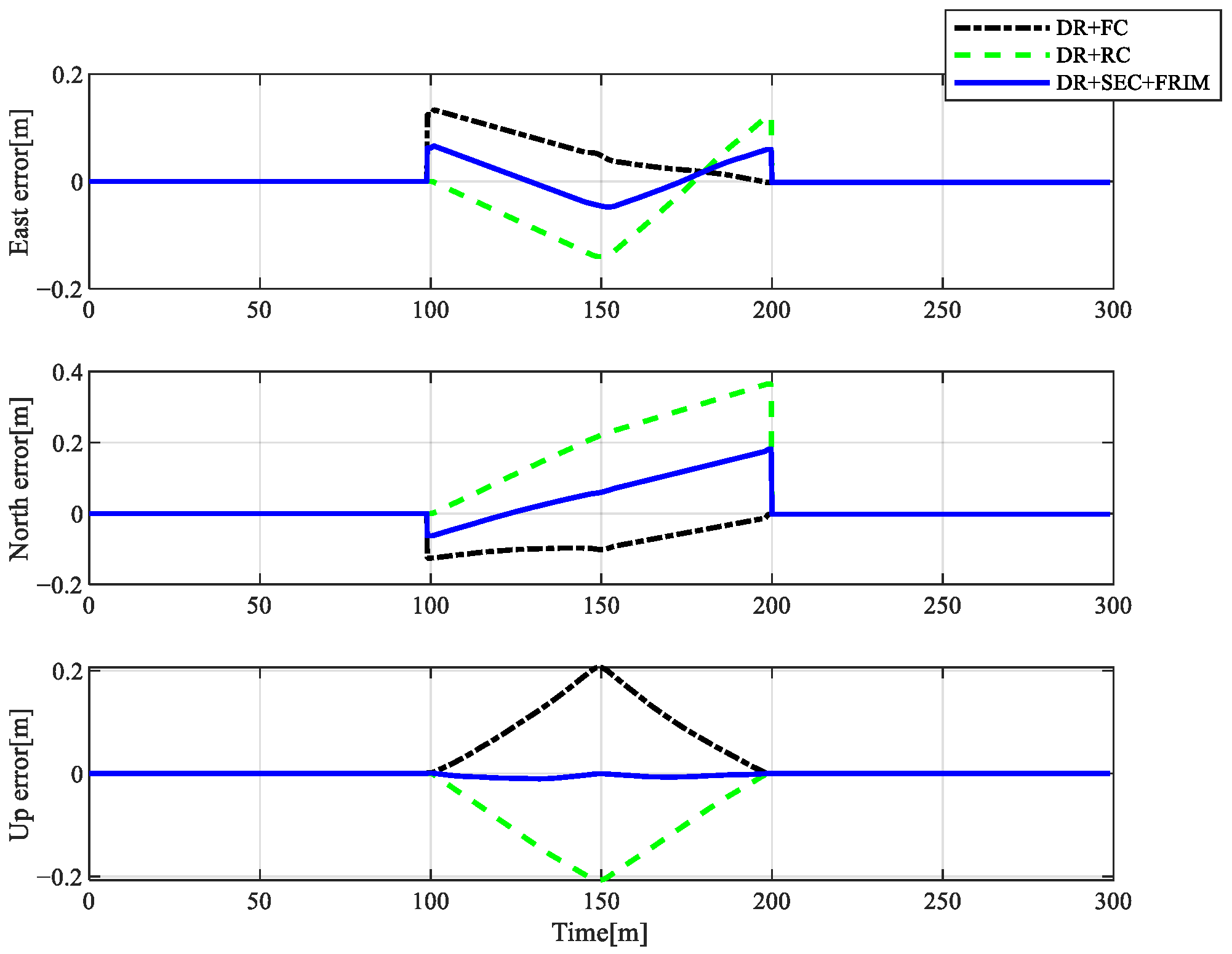

5.1. Simulation Results

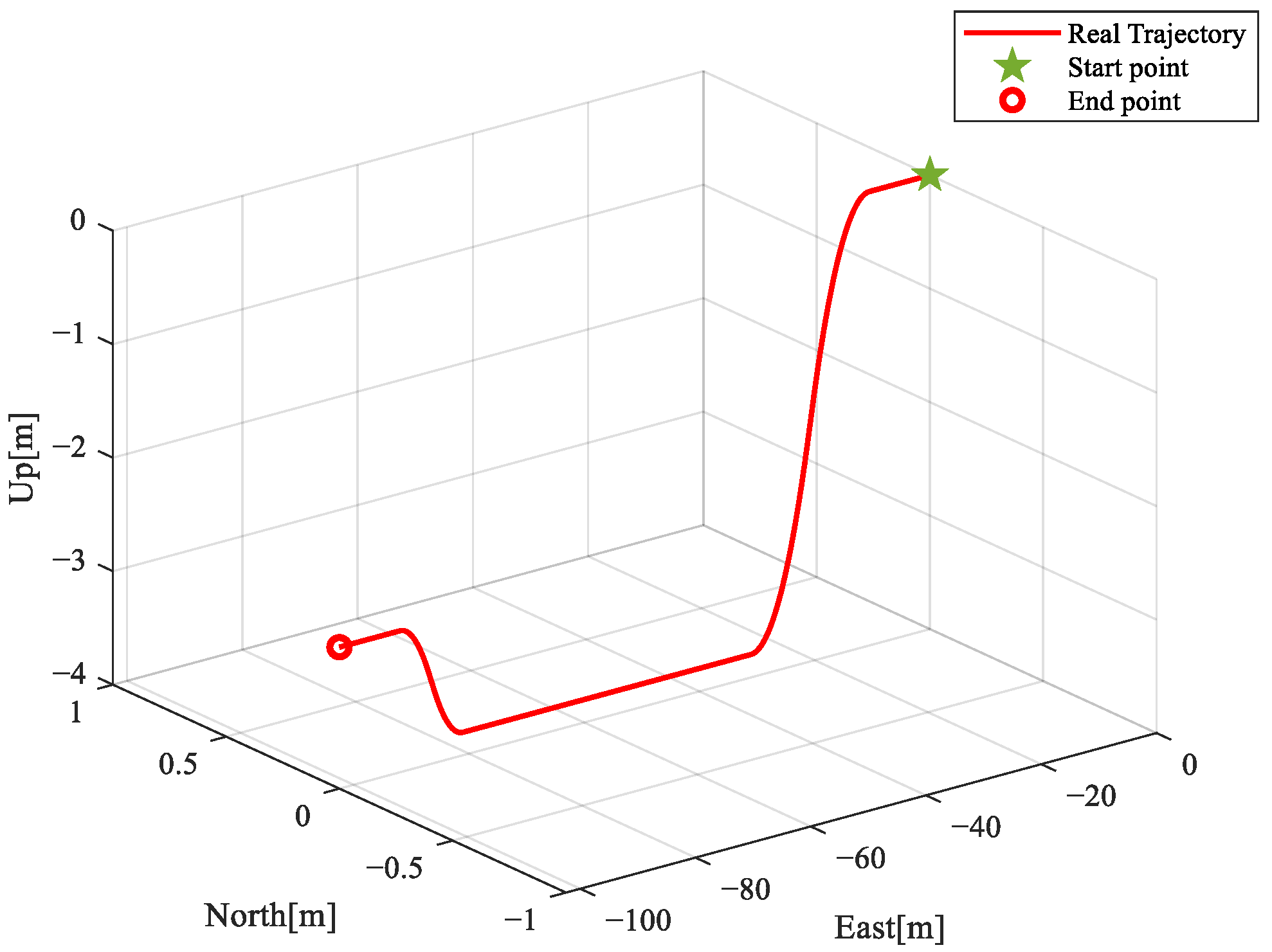

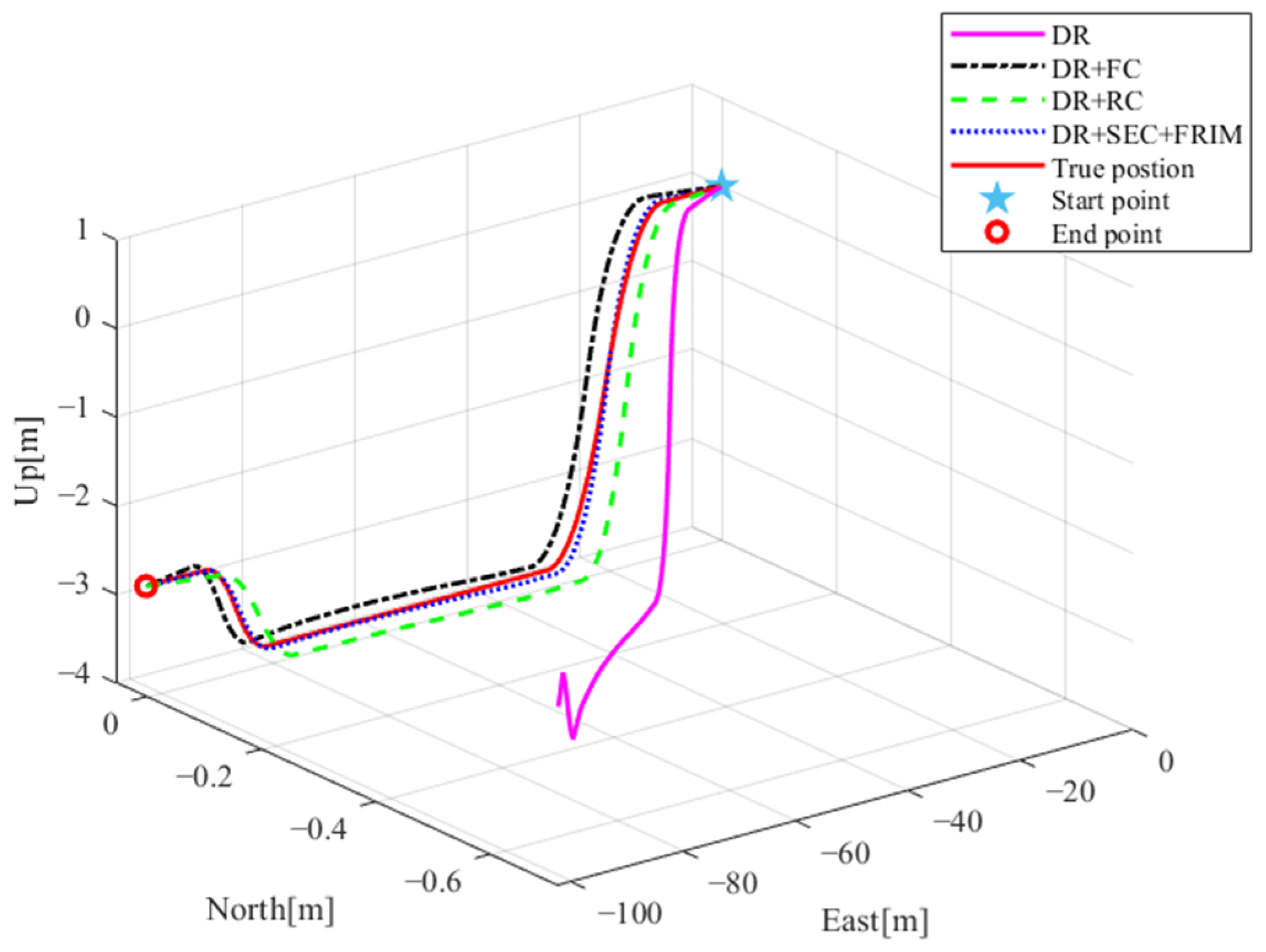

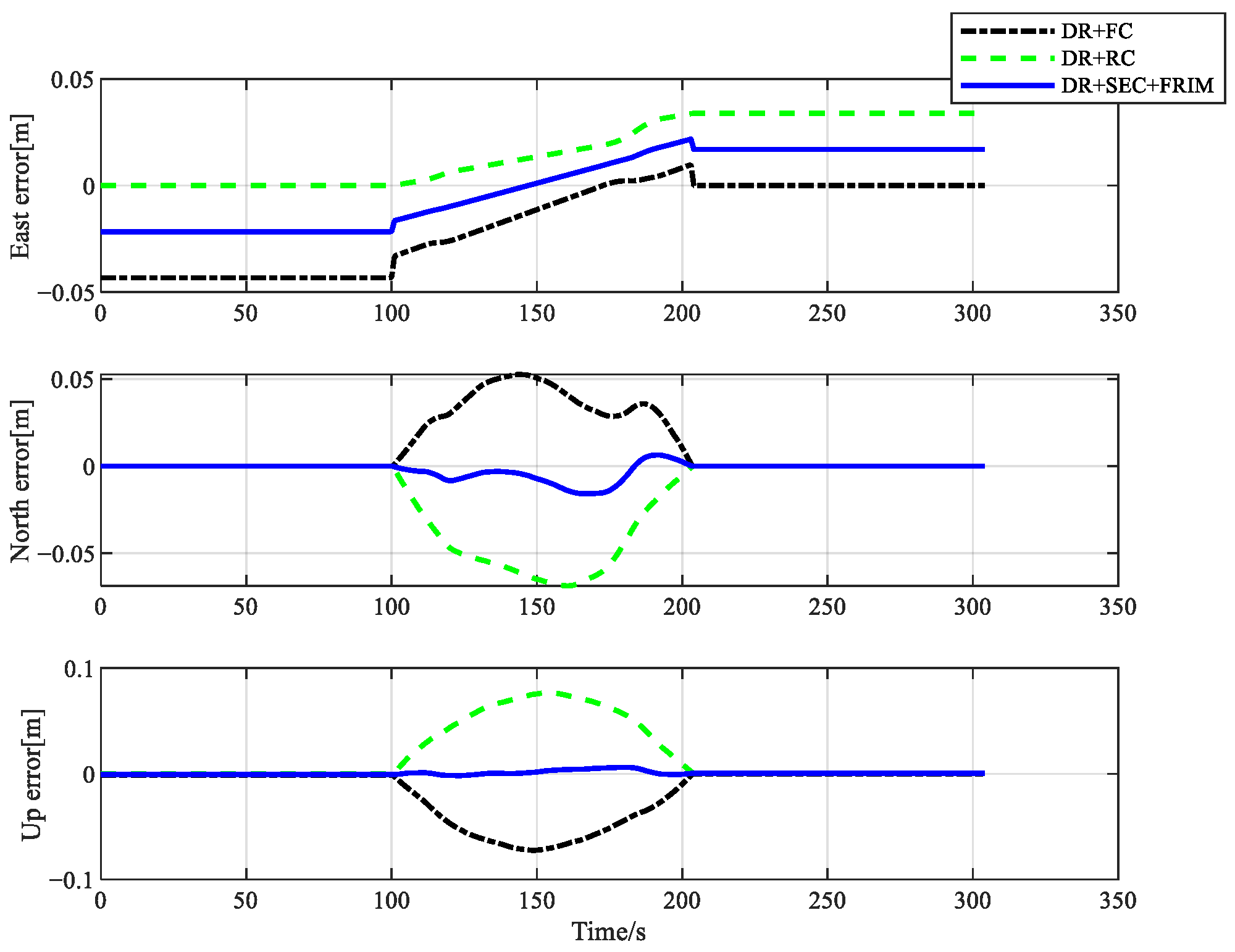

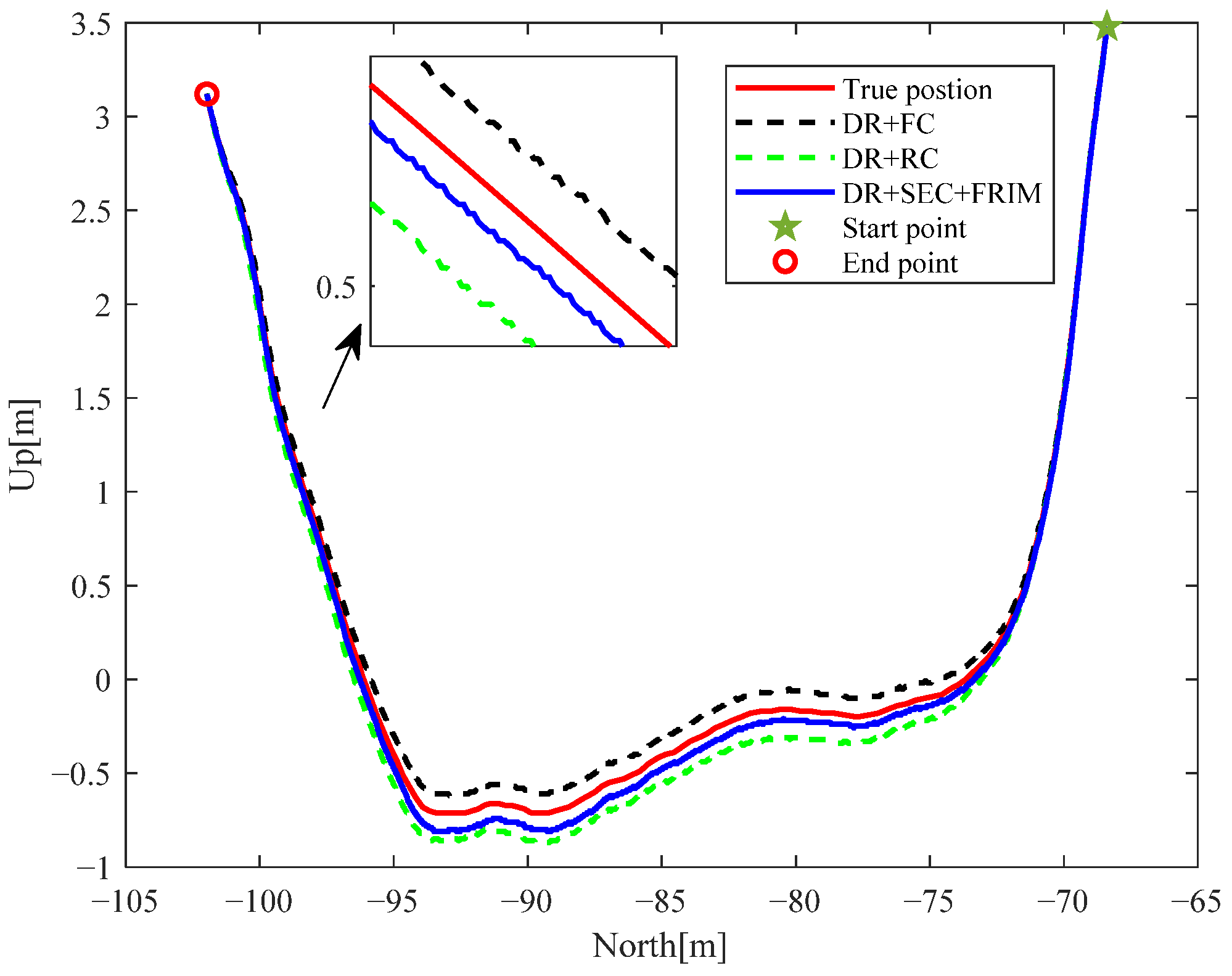

5.2. Experiment Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tan, X.; Sun, Z.; Wang, P. On Localization for Magnetic Induction-based Wireless Sensor Networks in Pipeline Environments. In Proceedings of the IEEE International Conference on Communications (ICC), London, UK, 8–12 June 2015; pp. 2780–2785. [Google Scholar]

- Huang, C.; Peng, F.; Liu, K. Pipeline Inspection Gauge Positioning System Based on Optical Fiber Distributed Acoustic Sensing. IEEE Sens. J. 2021, 21, 25716–25722. [Google Scholar] [CrossRef]

- Chen, S.L.; Wu, J.L.; Huang, X.J.; Li, J. An accurate localization method for subsea pipelines by using external magnetic fields. Measurement 2019, 147, 106803. [Google Scholar] [CrossRef]

- Allard, P.; Lavoie, J.-A. Differentiation of 3D Scanners and Their Positioning Method When Applied to Pipeline Integrity; CREAFORM: Lévis, QC, Canada, 2014. [Google Scholar]

- Maekawa, A.; Takahashi, T.; Tsuji, T.; Noda, M. Noncontact Measurement Method of Vibration Stress Using Optical Displacement Sensors for Piping Systems in Nuclear Power Plants. ASME J. Nucl. Eng. Radiat. Sci. 2015, 1, 31002. [Google Scholar] [CrossRef]

- Sahli, H. MEMS-Based Aided Inertial Navigation System for Small Diameter Pipelines. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2016. [Google Scholar]

- Lv, Z.; Wang, G.; Wang, Z.; Zhao, H.; Gao, W. Application of Weld Scar Recognition in Small-Diameter Transportation Pipeline Positioning System. Electronics 2022, 11, 1100. [Google Scholar] [CrossRef]

- Jin, S.-H.; Ping, Y. Research on the describing of trajectory for subsea pipeline based on Inertial Navigation System. In Proceedings of the 2011 IEEE Power Engineering and Automation Conference, Wuhan, China, 8–9 September 2011; Volume 2, pp. 463–468. [Google Scholar]

- Wasim, M.; Djukic, M.B. External corrosion of oil and gas pipelines: A review of failure mechanisms and predictive preventions. J. Nat. Gas Sci. Eng. 2022, 100, 104467. [Google Scholar] [CrossRef]

- Biondi, A.M.; Zhou, J.; Guo, X.; Wu, R.; Tang, Q.; Gandhi, H.; Yu, T.; Gopalan, B.; Hanna, T.; Ivey, J.; et al. Pipeline structural health monitoring using distributed fiber optic sensing textile. Opt. Fiber Technol. 2022, 70, 102876. [Google Scholar] [CrossRef]

- Al-Masri, W.M.F.; Abdel-Hafez, M.F.; Jaradat, M.A.K. Inertial Navigation System of Pipeline Inspection Gauge. IEEE Trans. Control. Syst. Technol. 2020, 28, 609–616. [Google Scholar] [CrossRef]

- Niu, X.; Kuang, J.; Chen, Q. Study on the Posibility of the PIG Positioning Using MEMS-based IMU. Chin. J. Sens. Actuators 2016, 29, 40–44. [Google Scholar]

- Chen, Q.J.; Zhang, Q.; Niu, X.J.; Wang, Y. Positioning Accuracy of a Pipeline Surveying System Based on MEMS IMU and Odometer: Case Study. IEEE Access 2019, 7, 104453–104461. [Google Scholar] [CrossRef]

- Huang, F.; Sun, L.; Guo, L.; Yang, L.I.; Qian, F. High-accuracy positioning method based on reverse navigation solution in pipeline detection. J. Chin. Inert. Technol. 2018, 26, 435–439. [Google Scholar]

- Sahli, H.; Moussa, A.; Noureldin, A.; El-Sheimy, N. Small Pipeline Trajectory Estimation Using MEMS Based IMU. In Proceedings of the 27th International Technical Meeting of the Satellite Division of The Institute of Navigation (ION GNSS+ 2014), Tampa, FL, USA, 8–12 September 2014. [Google Scholar]

- Li, R.; Feng, Q.; Cai, M.; Li, H.; Zhao, X. Measurement of long-distance buried pipeline centerline based on multi-sensor data fusion. Acta Petrol. Sin. 2014, 35, 987–992. [Google Scholar]

- Zhang, S.; Dubljevic, S. Trajectory determination for pipelines using an inspection robot and pipeline features. Metrol. Meas. Syst. 2021, 28, 439–453. [Google Scholar] [CrossRef]

- Zhang, P.; Hancock, C.M.; Lau, L.; Roberts, G.W.; de Ligt, H. Low-cost IMU and odometer tightly coupled integration with Robust Kalman filter for underground 3-D pipeline mapping. Measurement 2019, 137, 454–463. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Yang, W.; Pan, S. Investigating the survey instrument for the underground pipeline with inertial sensor and dead reckoning method. Rev. Sci. Instrum. 2021, 92, 025112. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Jia, H.G.; Chu, H.R. MEMS-SINS Transfer Alignment Based on UKF. Comput. Simul. 2015, 32, 29–33. [Google Scholar]

- Lu, J.; Lei, C.; Li, B.A.; Wen, T. Improved calibration of IMU biases in analytic coarse alignment for AHRS. Meas. Sci. Technol. 2016, 27, 075105. [Google Scholar] [CrossRef]

- Kang, G.; Ren, S.; Chen, X.; Yi, G.; Xu, Z. High precision SINS/OD dead reckoning algorithm considering lever arm effect. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar]

- Chen, Q.; Niu, X.; Kuang, J.; Liu, J.-N. IMU Mounting Angle Calibration for Pipeline Surveying Apparatus. IEEE Trans. Instrum. Meas. 2020, 69, 1765–1774. [Google Scholar] [CrossRef]

- Wang, Z.G.; Tan, J.; Sun, Z.C. Error Factor and Mathematical Model of Positioning with Odometer Wheel. Adv. Mech. Eng. 2015, 7, 305981. [Google Scholar] [CrossRef] [PubMed]

| Device | Parameter | Value |

|---|---|---|

| Gyroscope | Zero Bias (°/h) | 10 |

| Random walk (°/) | 0.5 | |

| Accelerometer | Zero Bias (mg) | 1 |

| Random walk ) | 0.3 | |

| Odometer | Scale Factor | 0.9995 |

| Algorithms | Horizontal Maximum Positioning Error (m) | Horizontal Positioning Error RMS (m) | Height Maximum Positioning Error (m) | Height Positioning Error RMS (m) |

|---|---|---|---|---|

| DR | 0.792 | 0.518 | 0.551 | 0.356 |

| DR + FC | 0.093 | 0.045 | 0.105 | 0.057 |

| DR + RC | 0.183 | 0.078 | 0.121 | 0.051 |

| DR + SEC + FRIM | 0.042 | 0.023 | 0.005 | 0.002 |

| Algorithms | Horizontal Maximum Positioning Error (m) | Horizontal Positioning Error RMS (m) | Height Maximum Positioning Error (m) | Height Positioning Error RMS (m) |

|---|---|---|---|---|

| DR | 1.380 | 0.552 | 0.325 | 0.250 |

| DR + FC | 0.271 | 0.179 | 0.086 | 0.048 |

| DR + RC | 0.422 | 0.182 | 0.198 | 0.087 |

| DR + SEC + FRIM | 0.187 | 0.096 | 0.011 | 0.009 |

| Device | Performance | Precision |

|---|---|---|

| Gyroscope | Zero bias stability | 0.5°/h |

| Zero bias stability at all temperatures | 10°/h | |

| Angle random walk | 0.2°/ |

| Different Methods | Horizontal Error (m) | Height Error (m) |

|---|---|---|

| DR + FC | 0.296 | 0.125 |

| DR + RC | 0.183 | 0.141 |

| DR + SEC + FRIM | 0.074 | 0.097 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Fan, S.; Zhang, Y.; Chang, L.; Wang, G.; Shen, F. Positioning Algorithm of MEMS Pipeline Inertial Locator Based on Dead Reckoning and Information Multiplexing. Electronics 2022, 11, 2931. https://doi.org/10.3390/electronics11182931

Wei X, Fan S, Zhang Y, Chang L, Wang G, Shen F. Positioning Algorithm of MEMS Pipeline Inertial Locator Based on Dead Reckoning and Information Multiplexing. Electronics. 2022; 11(18):2931. https://doi.org/10.3390/electronics11182931

Chicago/Turabian StyleWei, Xiaofeng, Shiwei Fan, Ya Zhang, Longkang Chang, Guochen Wang, and Feng Shen. 2022. "Positioning Algorithm of MEMS Pipeline Inertial Locator Based on Dead Reckoning and Information Multiplexing" Electronics 11, no. 18: 2931. https://doi.org/10.3390/electronics11182931

APA StyleWei, X., Fan, S., Zhang, Y., Chang, L., Wang, G., & Shen, F. (2022). Positioning Algorithm of MEMS Pipeline Inertial Locator Based on Dead Reckoning and Information Multiplexing. Electronics, 11(18), 2931. https://doi.org/10.3390/electronics11182931