Implementation of DDS Cloud Platform for Real-Time Data Acquisition of Sensors for a Legacy Machine

Abstract

:1. Introduction

2. Sensing Information and Protocols

2.1. Acquisition of Motion Behavior of Machine Tool

2.2. DDS Protocol

2.3. MQTT and Node-RED

2.4. Characteristics of the Proposed DDS Platform

3. Platform Design

3.1. Problem Definition

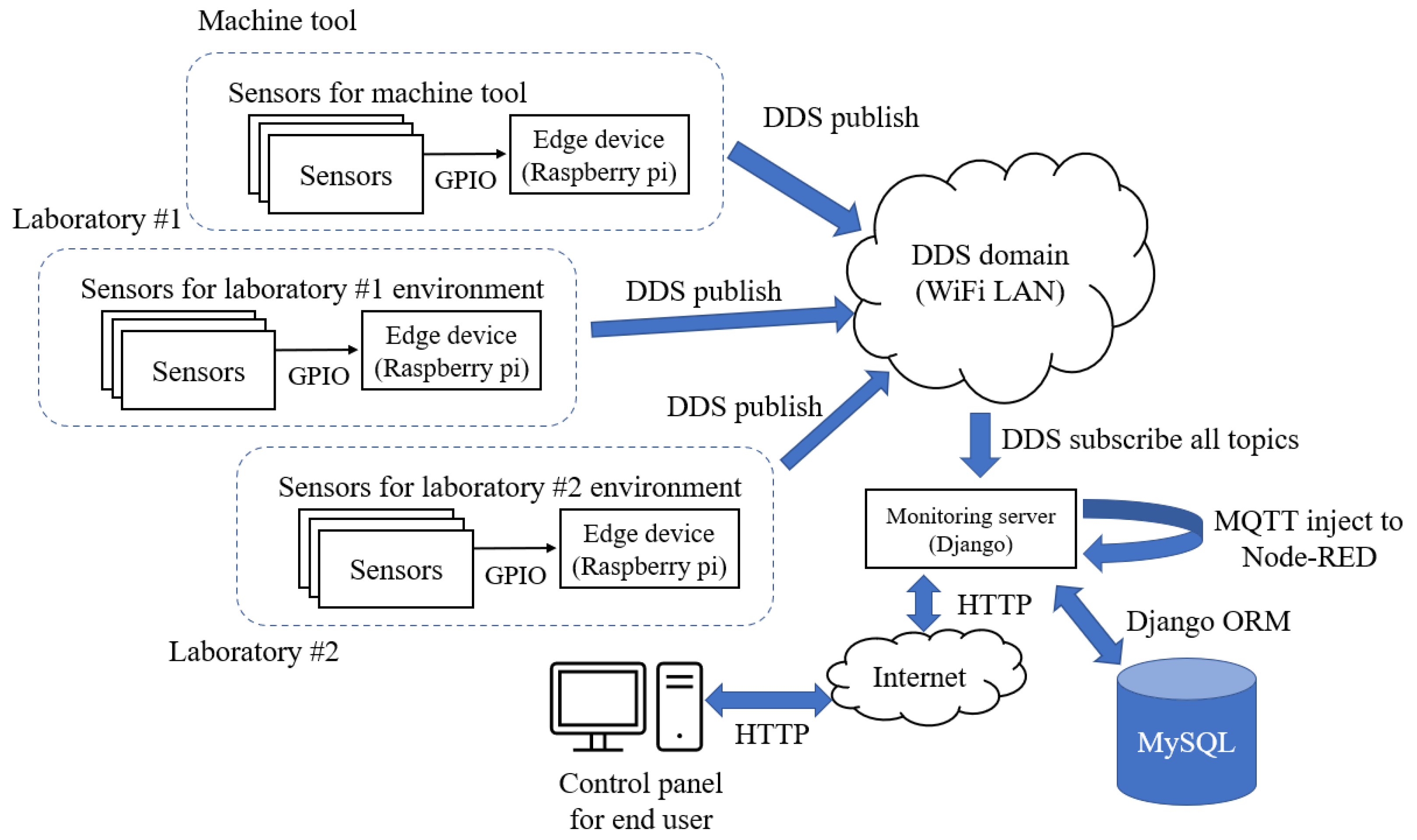

3.2. Proposed Platform Architecture

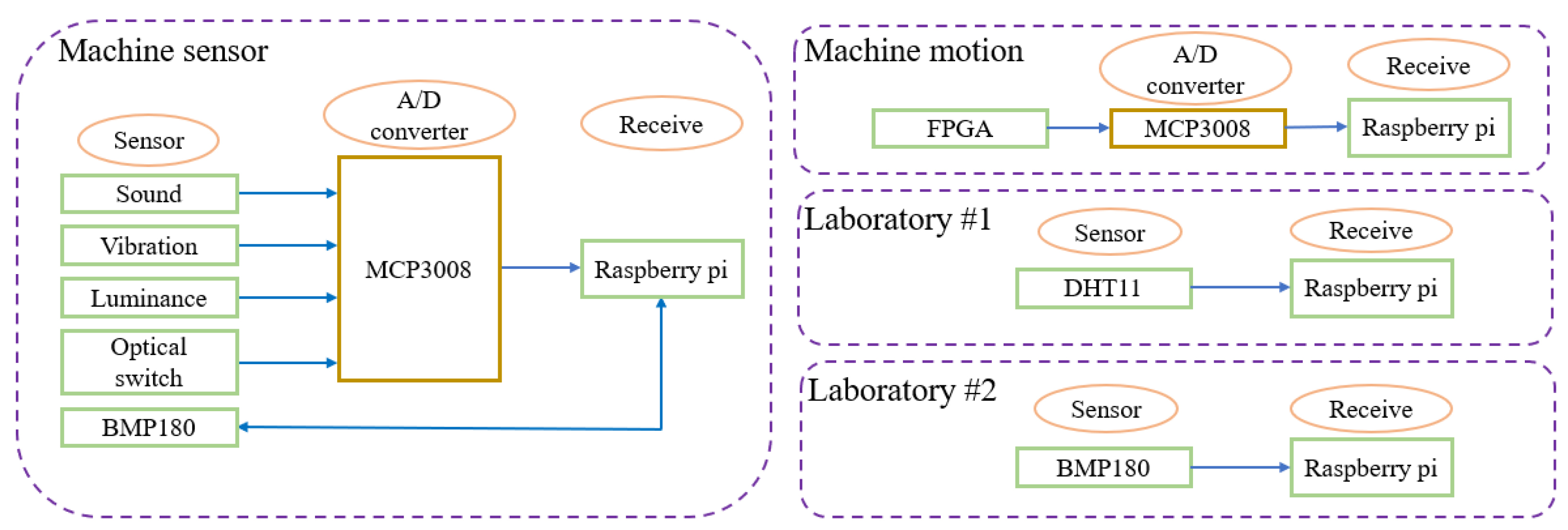

3.3. Raspberry Pi-Based Sensor Publisher

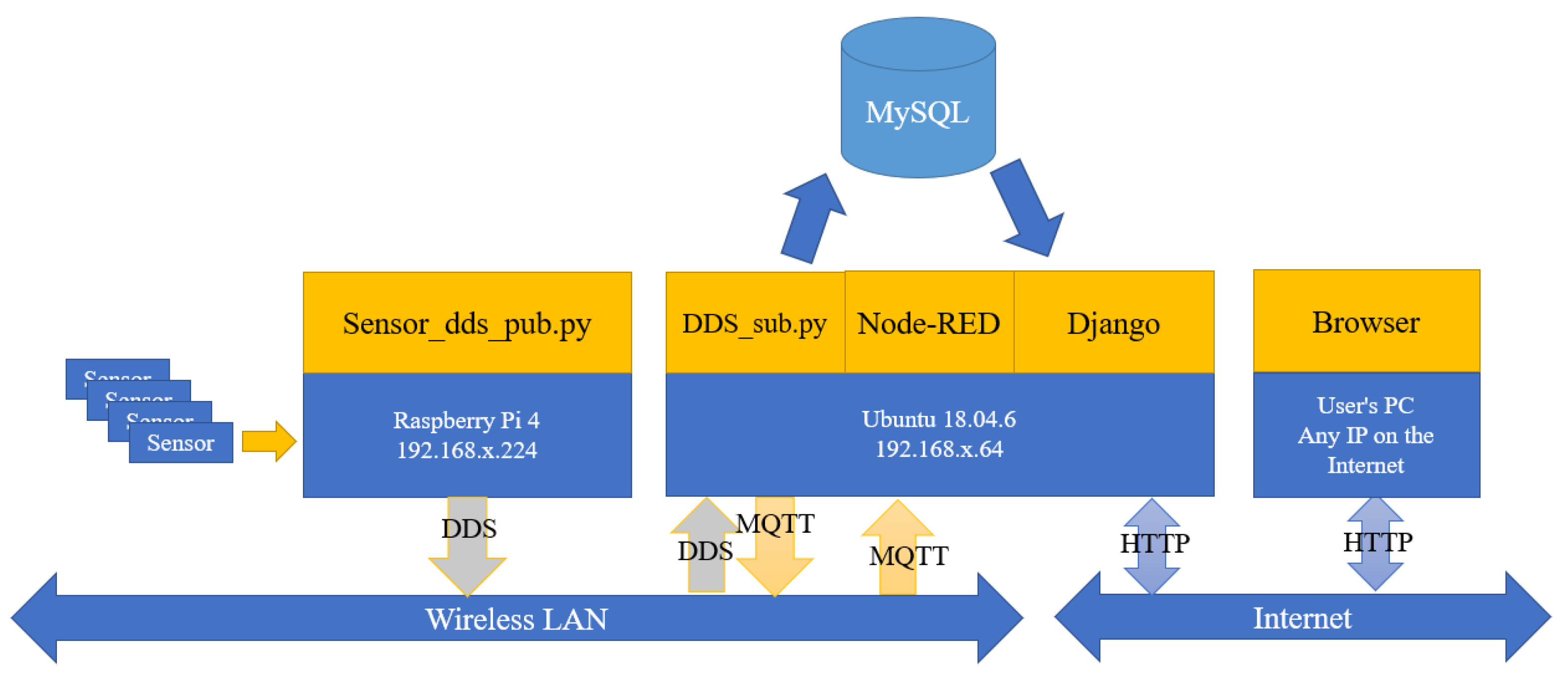

3.4. Messaging between Raspberry Pi and Server via DDS

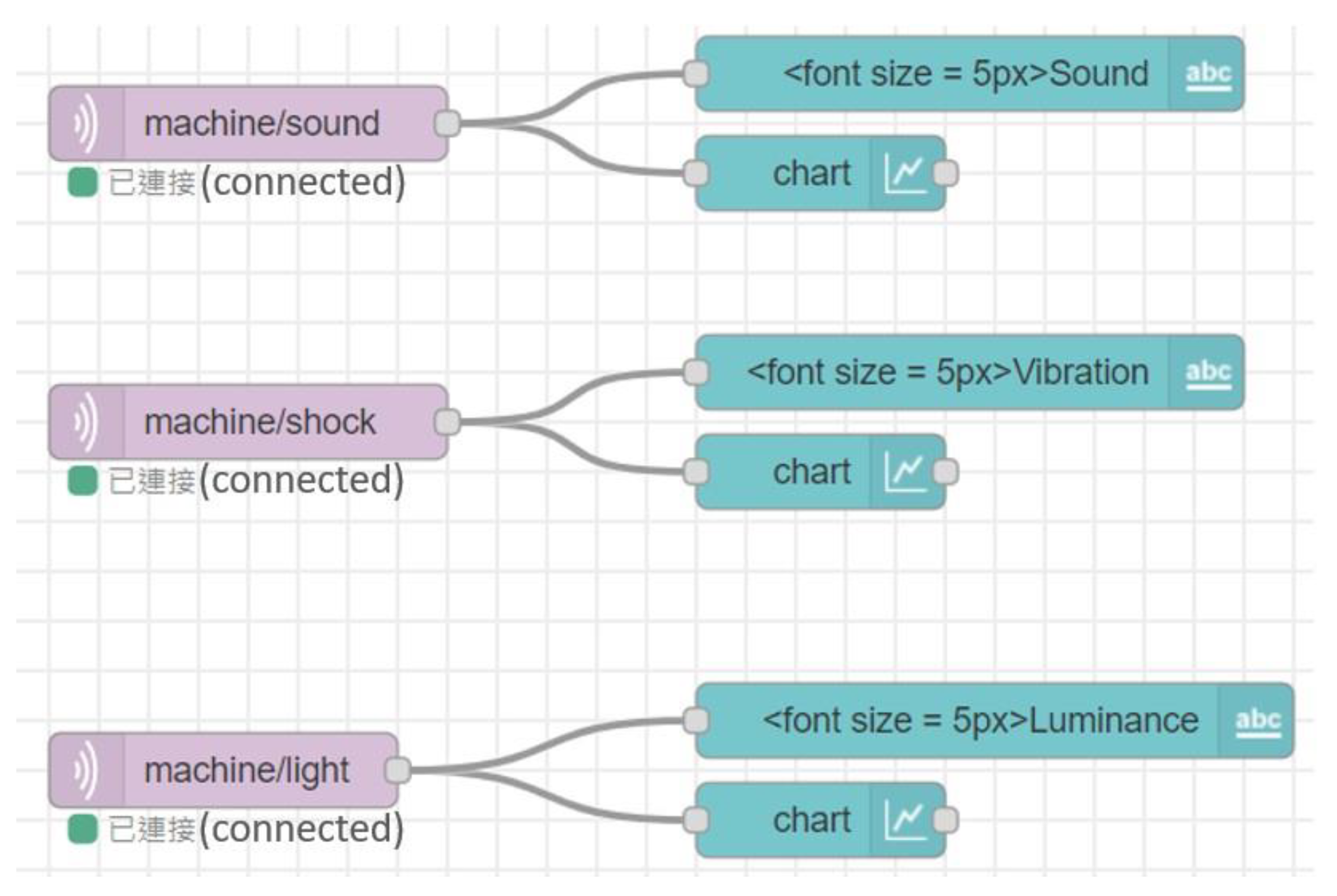

3.5. Display of Real-Time Chart with MQTT and Node-RED

4. System Implementation and Results

4.1. Implemented Platform

4.2. Sensing Module

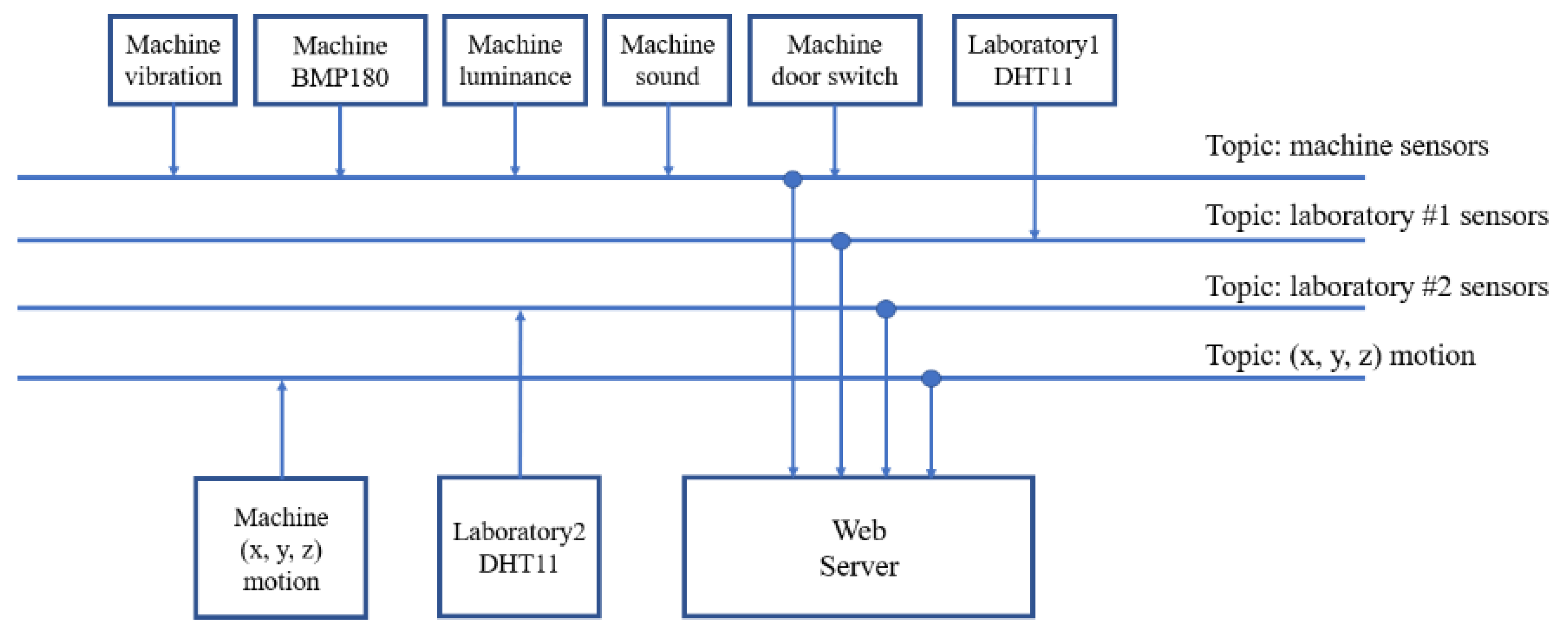

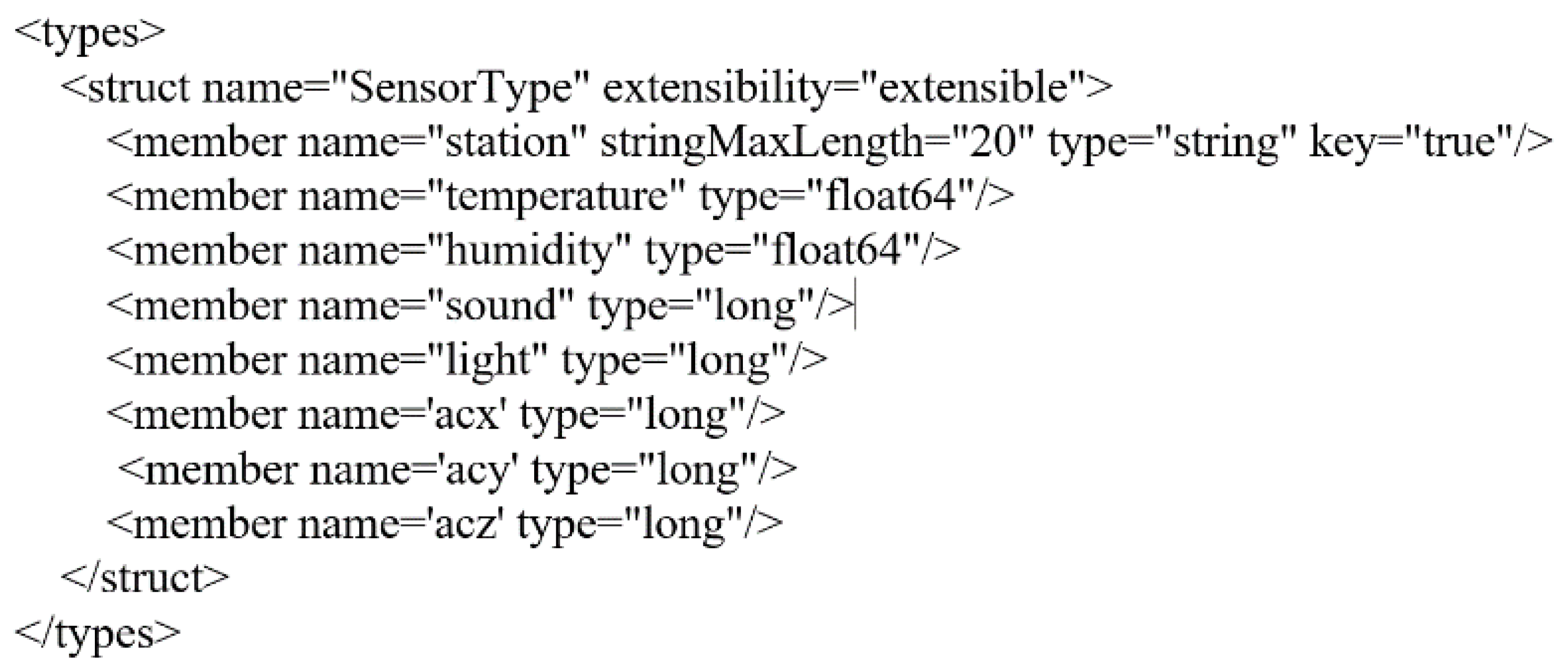

4.3. DDS Topic and Its Implementation

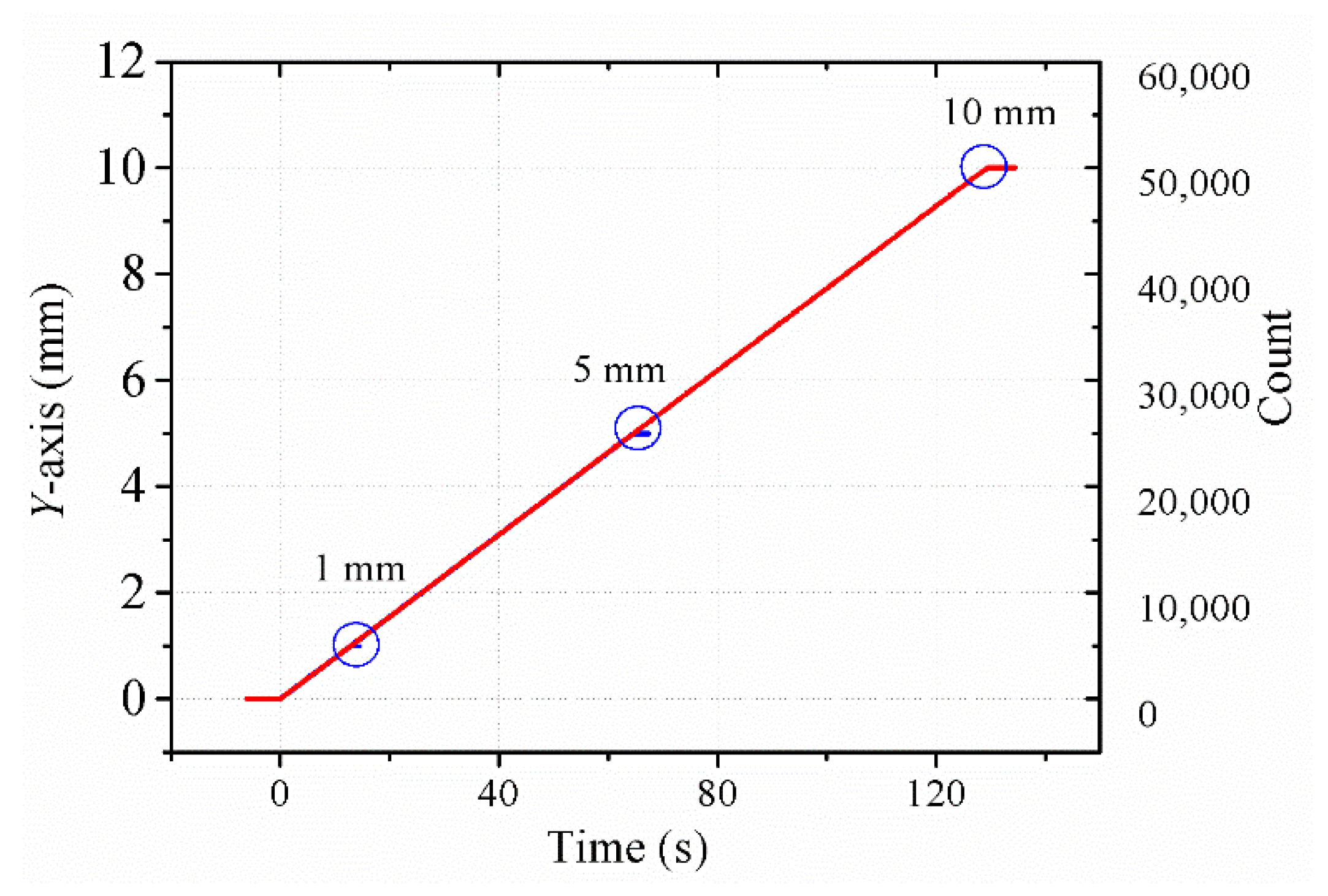

4.4. Motion Displacement Expressed by AO Signal and Sensed via Raspberry Pi

4.5. Motion Displacement Directly Sensed via Raspberry Pi

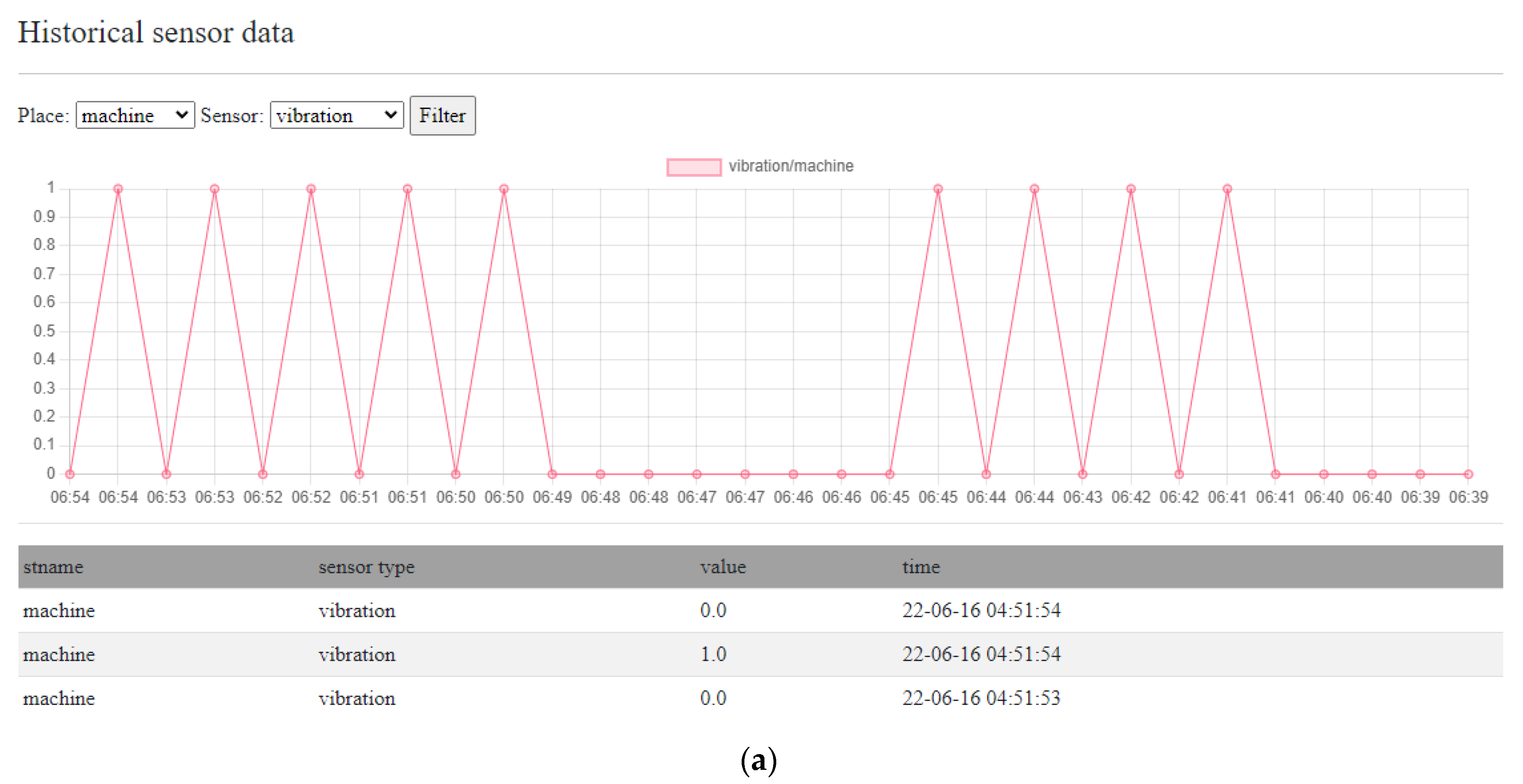

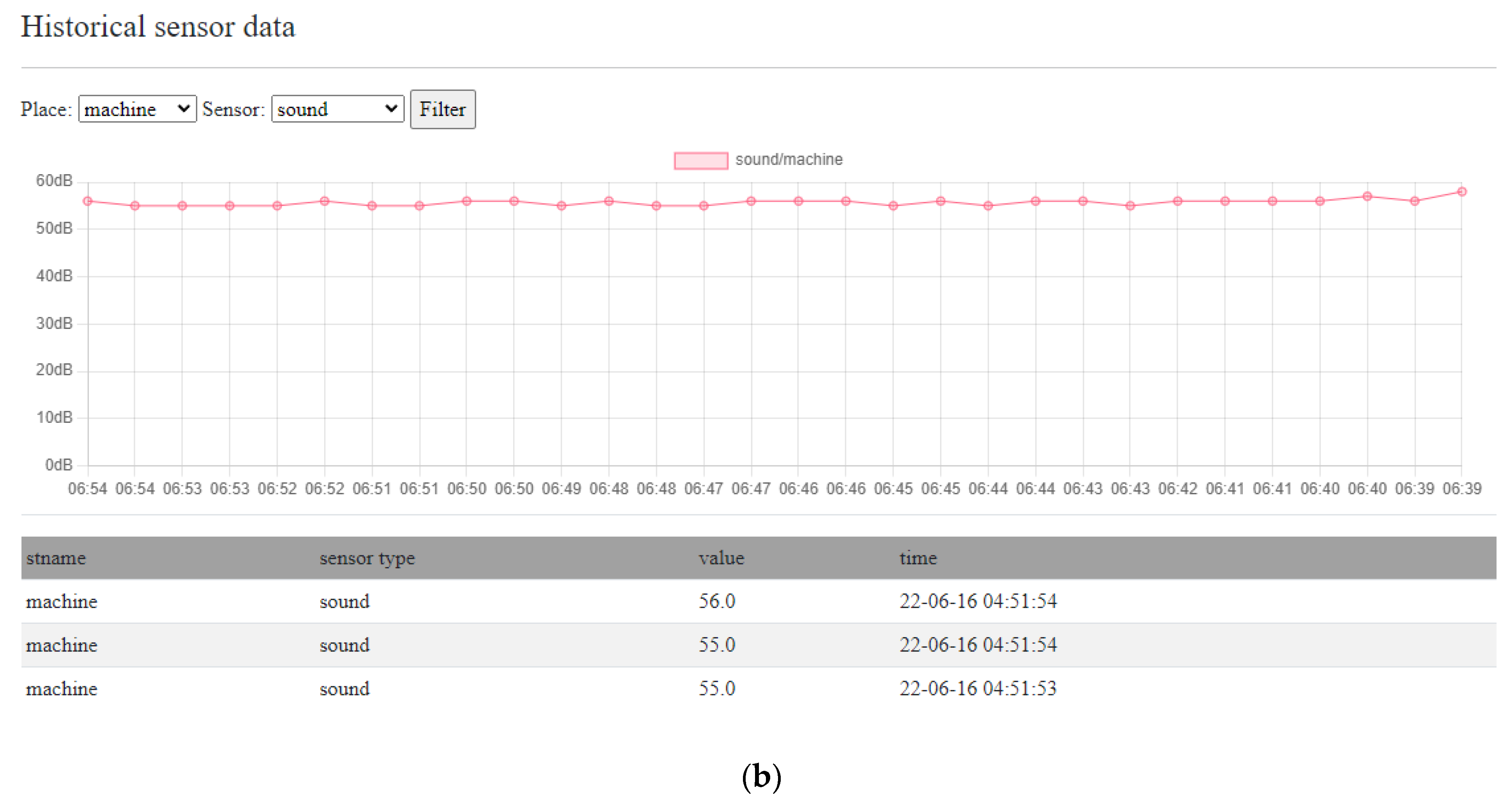

4.6. Dashboard Implementation of Sensors

5. Conclusions

- (1)

- The DDS-based platform can receive the sensor information, publish the data to a private topic, and store the information in a database.

- (2)

- The sensed information of sensors including measured values and time history charts can be shown by Node-RED via the MQTT protocol.

- (3)

- The motion displacement of the machine tool can be well acquired by the edge device of Raspberry PI.

- (4)

- A database based on MySQL is implemented for the data retrieved.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| DDS | Data distribution service |

| Django ORM | Django object relational mapper |

| FPGA | Field-programmable gate array |

| GPIO | General purpose input/output |

| HTTP | Hypertext transfer protocol |

| I4.0 | Industry 4.0 |

| IIoT | Industrial IoT |

| IoT | Internet of things |

| LAN | Local area network |

| M2M | Machine-to-machine |

| MQTT | Message queuing telemetry transport |

| OPC | Open platform communications |

| OPC UA | OPC Unified Architecture |

| PAD | Position acquisition device |

| QoS | Quality of service |

| REST | Representational state transfer |

| RT controller | Real-time controller |

| UI | User interface |

| WAN | Wide area network |

| Web API | Web application programming interface |

| XML file | Extensible markup language file |

References

- VDI/VDE-Gesellschaft Mess-und Automatisierungstechnik. Status Report: Reference Architecture Model Industrie 4.0 (RAMI4.0). 2015. Available online: https://www.vdi.de/ueber-uns/presse/publikationen/details/reference-architecture-model-industrie-40-rami40-english-version (accessed on 1 May 2022).

- Al-Fuqaha, A.; Guizani, M.; Mohammadi, M.; Aledhari, M.; Ayyash, M. Internet of Things: A Survey on Enabling Technologies, Protocols, and Applications. IEEE Commun. Surv. Tutor. 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Marcon, P.; Zezulka, F.; Vesely, I.; Szabo, Z.; Roubal, Z.; Sajdl, O.; Gescheidtova, E.; Dohnal, P. Communication technology for industry 4.0. In 2017 Progress in Electromagnetics Research Symposium-Spring (PIERS); IEEE: Piscataway, NJ, USA, 2017; pp. 1694–1697. [Google Scholar] [CrossRef]

- OPC Foundation. OPC Unified Architecture: Interoperability for Industrie 4.0 and the Internet of Things; OPC Foundation: Scottsdale, AZ, USA, 2016. [Google Scholar]

- Saxena, S.; El-Taweel, N.A.; Farag, H.E.; Hilaire, L.S. Design and Field Implementation of a Multi-Agent System for Voltage Regulation Using Smart Inverters and Data Distribution Service (DDS). In Proceedings of the 2018 IEEE Electrical Power and Energy Conference (EPEC), Toronto, ON, Canada, 10–11 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Endeley, R.; Fleming, T.; Fehringer, N.J.G.; Cammish, S. A Smart Gateway Enabling OPC UA and DDS Interoperability. In Proceedings of the 2019 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Leicester, UK, 19–23 August 2019; pp. 88–93. [Google Scholar] [CrossRef]

- Profanter, S.; Tekat, A.; Dorofeev, K.; Rickert, M.; Knoll, A. OPC UA versus ROS, DDS, and MQTT: Performance Evaluation of Industry 4.0 Protocols. In Proceedings of the 2019 IEEE International Conference on Industrial Technology (ICIT), Melbourne, VIC, Australia, 13–15 February 2019; pp. 955–962. [Google Scholar] [CrossRef] [Green Version]

- Ioana, A.; Korodi, A. DDS and OPC UA Protocol Coexistence Solution in Real-Time and Industry 4.0 Context Using Non-Ideal Infrastructure. Sensors 2021, 21, 7760. [Google Scholar] [CrossRef] [PubMed]

- Habib, K.; Saad, M.H.M.; Hussain, A.; Sarker, M.R.; Alaghbari, K.A. An Aggregated Data Integration Approach to the Web and Cloud Platforms through a Modular REST-Based OPC UA Middleware. Sensors 2022, 22, 1952. [Google Scholar] [CrossRef] [PubMed]

- Vaclavova, A.; Strelec, P.; Horak, T.; Kebisek, M.; Tanuska, P.; Huraj, L. Proposal for an IIoT Device Solution According to Industry 4.0 Concept. Sensors 2022, 22, 325. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Significance of sensors for industry 4.0: Roles, capabilities, and applications. Sens. Int. 2021, 2, 100110. [Google Scholar] [CrossRef]

- Namjoshi, J.; Manish Rawat, M. Role of smart manufacturing in industry 4.0. Mater. Today Proc. 2022; in press. [Google Scholar]

- Catenazzo, D.; O’Flynn, B.; Walsh, M. On the use of Wireless Sensor Networks in Preventative Maintenance for Industry 4.0. In Proceedings of the 2018 12th International Conference on Sensing Technology (ICST), Limerick, Ireland, 4–6 December 2018; pp. 256–262. [Google Scholar]

- Citroni, R.; Di Paolo, F.; Livreri, P. Evaluation of an optical energy harvester for SHM application. AEU-Int. J. Electron. Commun. 2019, 111, 152918. [Google Scholar] [CrossRef]

- Ho, M.-H.; Yen, H.-C.; Lai, M.-Y.; Liu, Y.-T. Implementation of DDS Cloud Platform for Real-time Data Acquisition of Sensors. In Proceedings of the 2021 International Symposium on Intelligent Signal Processing and Communication Systems (ISPACS), Hualien City, Taiwan, 16–19 November 2021; pp. 1–2. [Google Scholar] [CrossRef]

- Yang, W.; Zimroz, R.; Papaelias, M. Advances in Machine Condition Monitoring and Fault Diagnosis. Electronics 2022, 11, 1563. [Google Scholar] [CrossRef]

- Duan, H.; Hosobata, T.; Takeda, M.; Morita, S.; Yamagata, Y. Quadrant protrusion measurement of ultra-precision machine tool by real-time position capturing method. Mater. Sci. Forum 2016, 874, 531–536. [Google Scholar] [CrossRef]

- Liu, Y.-T.; Chang, P.-N. Comparison of Motion Behaviors of a Machine Tool Examined by Position Acquisition Device (PAD) and Laser Interferometry System (LIS). In Proceedings of the 24th International Conference on Mechatronics Technology (ICMT), Singapore, 18–22 December 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Available online: https://www.dds-foundation.org/what-is-dds-3/ (accessed on 1 May 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, M.-H.; Lai, M.-Y.; Liu, Y.-T. Implementation of DDS Cloud Platform for Real-Time Data Acquisition of Sensors for a Legacy Machine. Electronics 2022, 11, 2096. https://doi.org/10.3390/electronics11132096

Ho M-H, Lai M-Y, Liu Y-T. Implementation of DDS Cloud Platform for Real-Time Data Acquisition of Sensors for a Legacy Machine. Electronics. 2022; 11(13):2096. https://doi.org/10.3390/electronics11132096

Chicago/Turabian StyleHo, Min-Huang, Ming-Yi Lai, and Yung-Tien Liu. 2022. "Implementation of DDS Cloud Platform for Real-Time Data Acquisition of Sensors for a Legacy Machine" Electronics 11, no. 13: 2096. https://doi.org/10.3390/electronics11132096

APA StyleHo, M.-H., Lai, M.-Y., & Liu, Y.-T. (2022). Implementation of DDS Cloud Platform for Real-Time Data Acquisition of Sensors for a Legacy Machine. Electronics, 11(13), 2096. https://doi.org/10.3390/electronics11132096