Research on Buffer Characteristics of a New 2D Digital Buffer Valve for Vehicle Shift

Abstract

1. Introduction

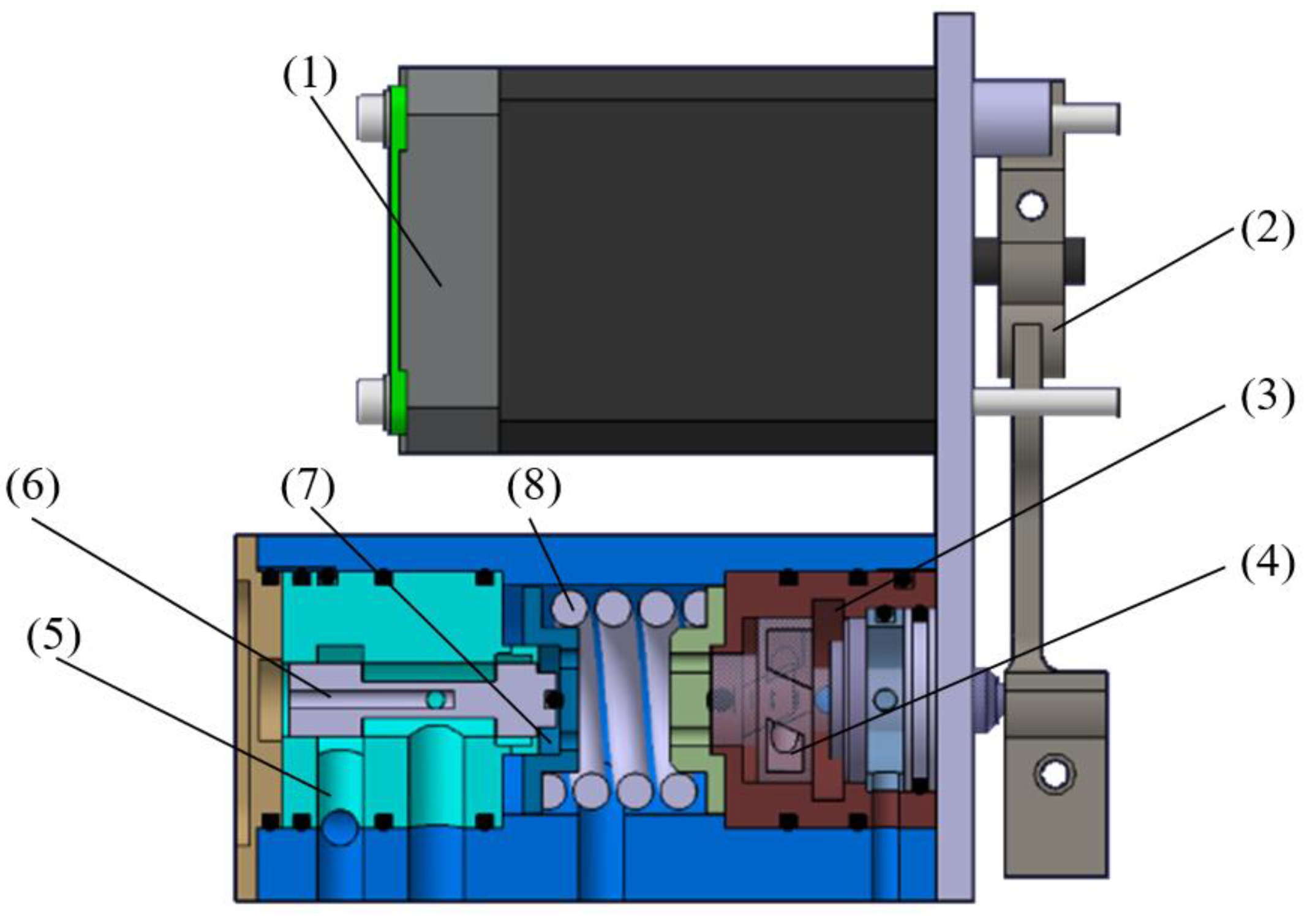

2. 2D Digital Buffer Valve’s Structure and Working Principle

3. Analysis of Buffer Characteristics of 2D Digital Buffer Valve

3.1. Model Assumption

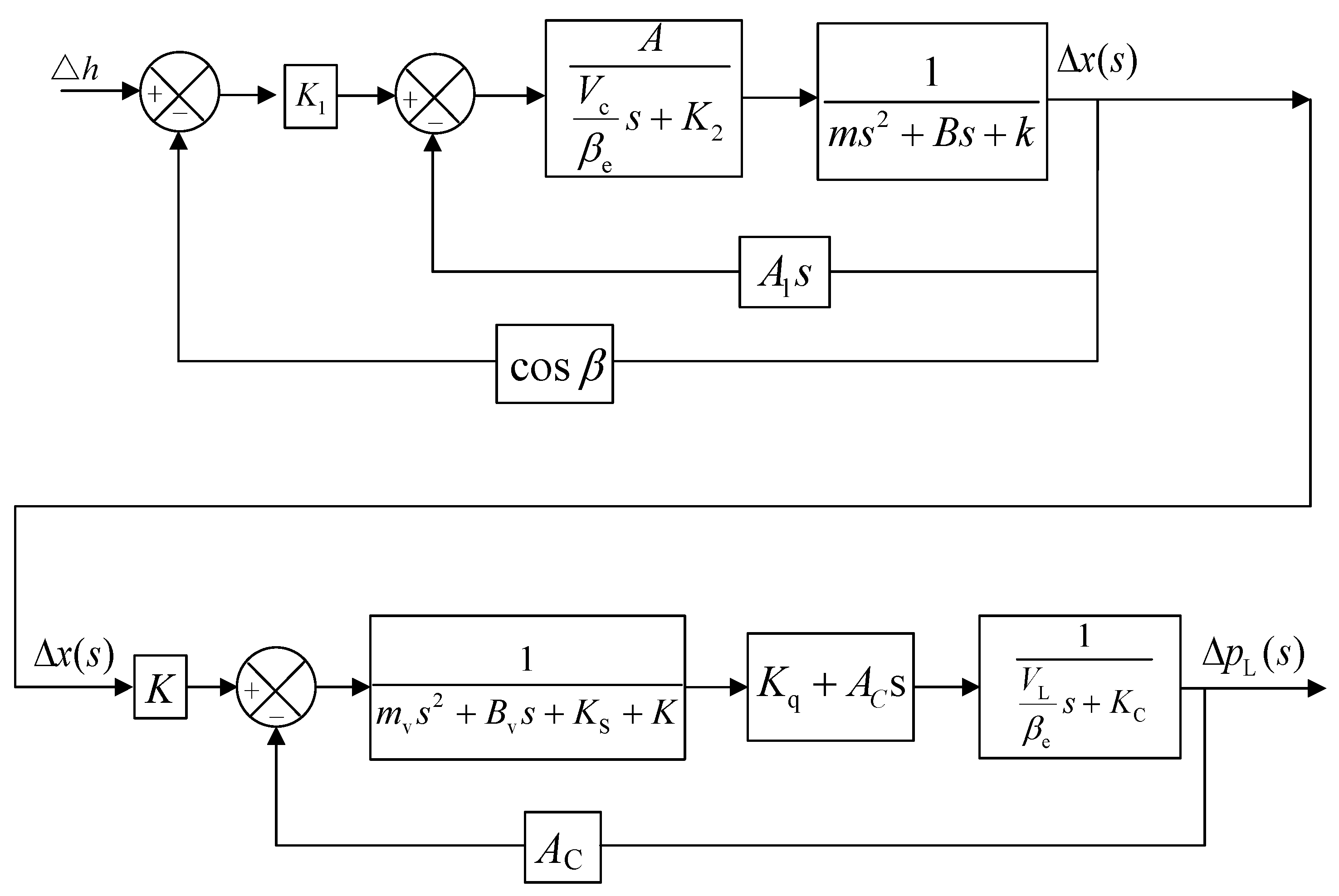

3.2. Mathematical Model of 2D Digital Valve

- (1)

- Flow equation

- (2)

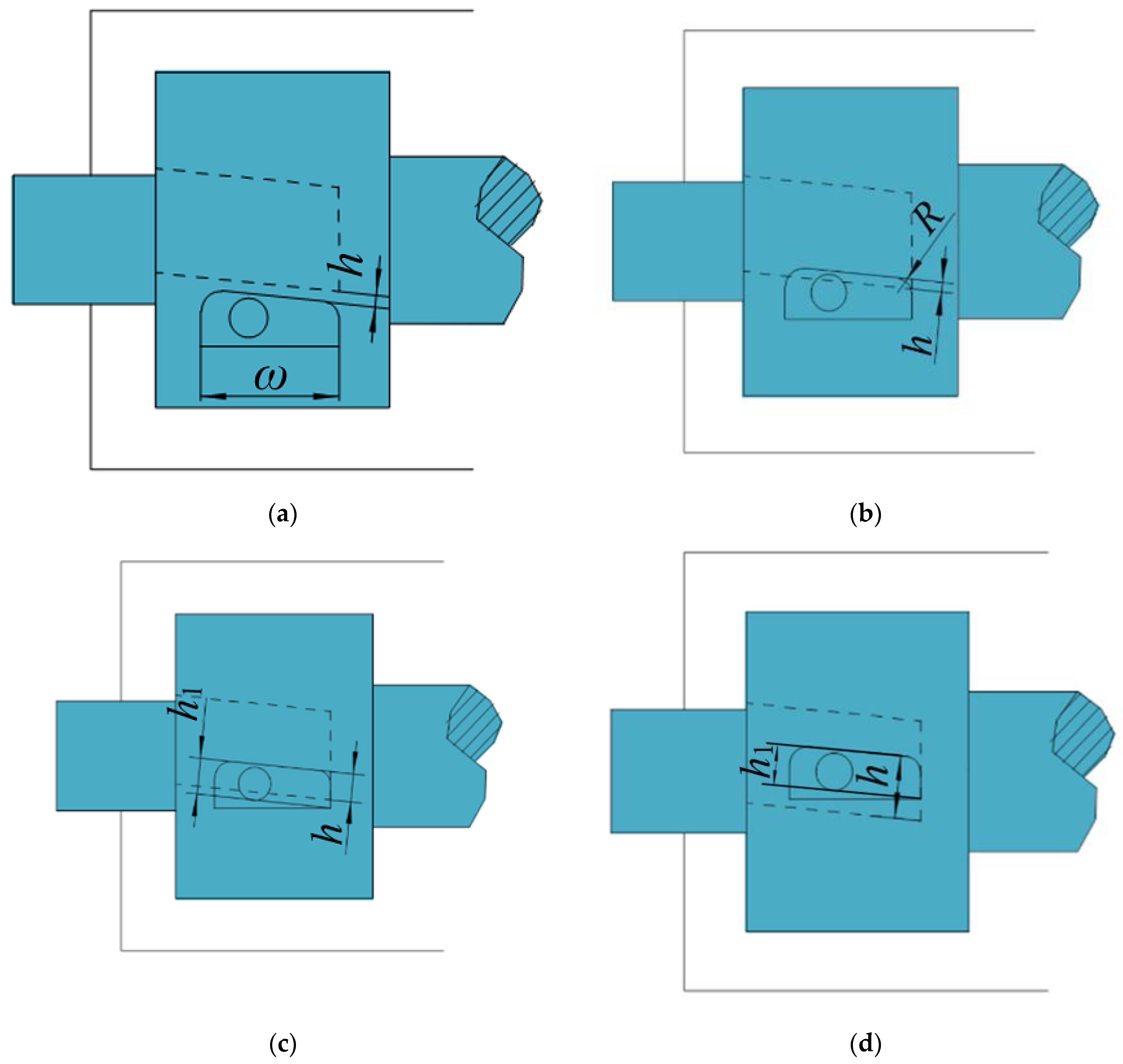

- Overlapping area calculation

- (3)

- Fluid continuity equation

- (4)

- Digital spool dynamics equation

3.3. Main Valve Mathematical Model

- (1)

- Flow equation

- (2)

- Continuity equation

- (3)

- Main spool dynamic equation

3.4. Simulation and Results

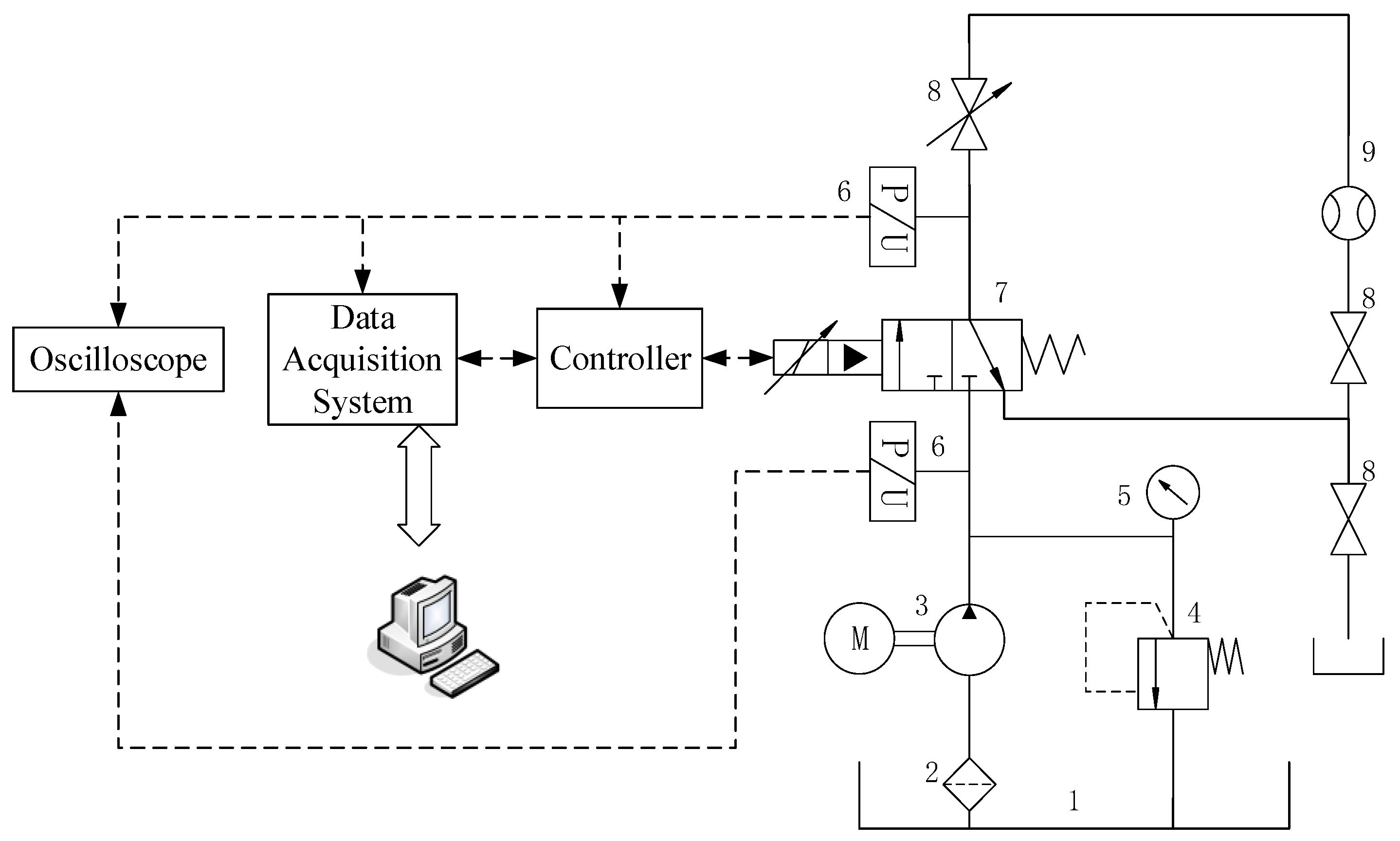

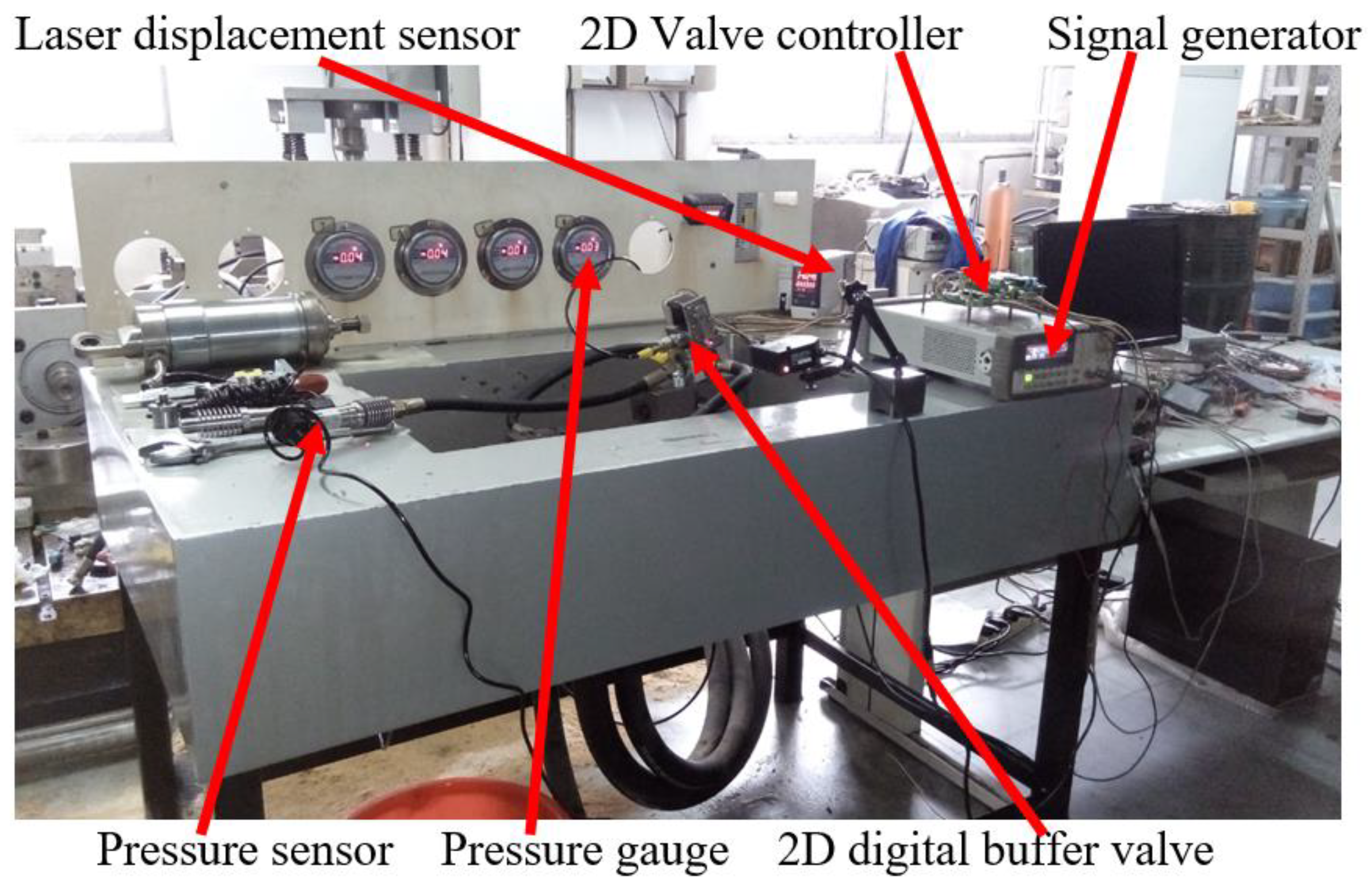

4. Buffer Characteristic Test of 2D Digital Buffer Valve

4.1. Test Platform of 2D Buffer Valve

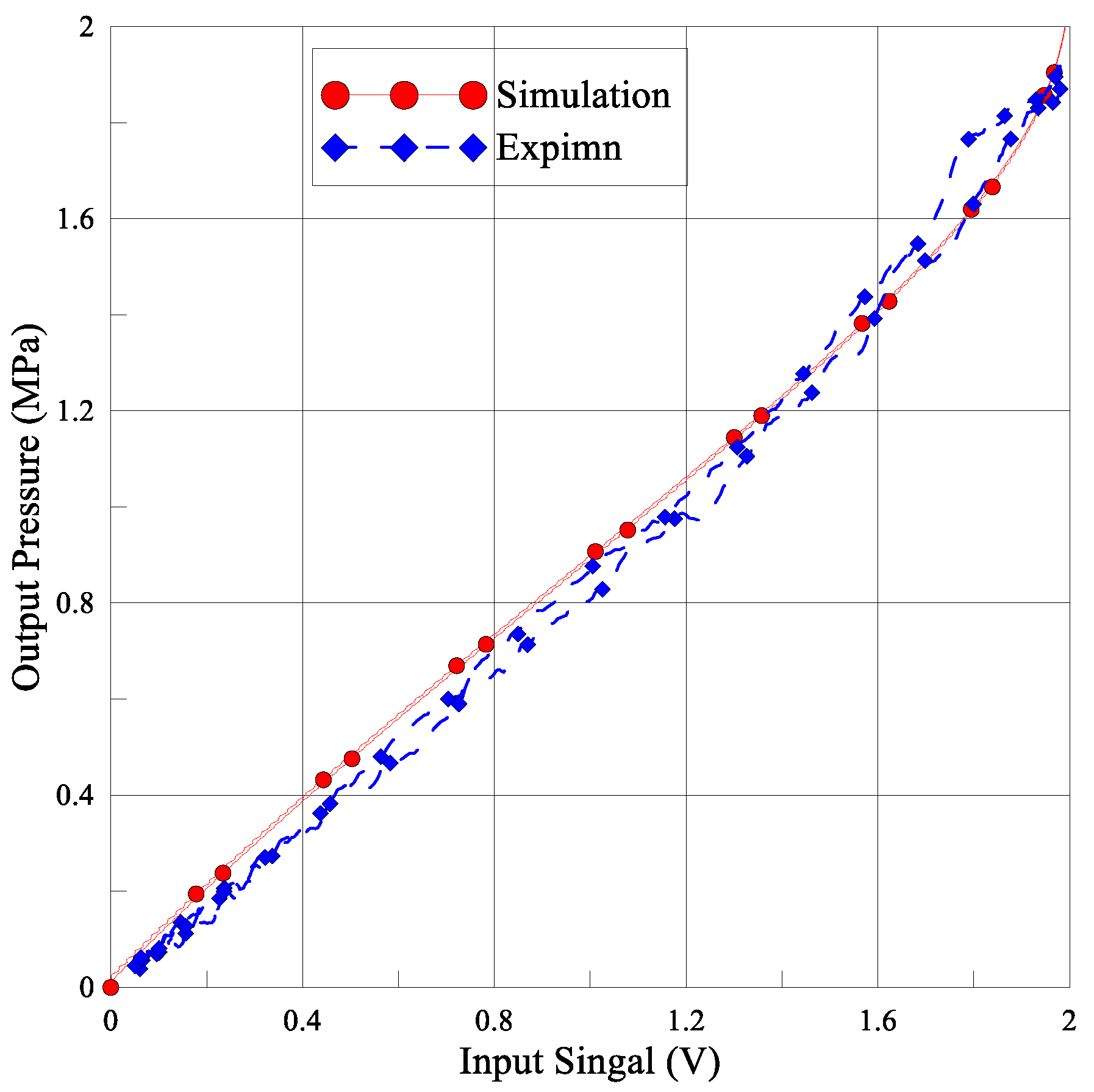

4.2. Static Characteristics of 2D Buffer Valve

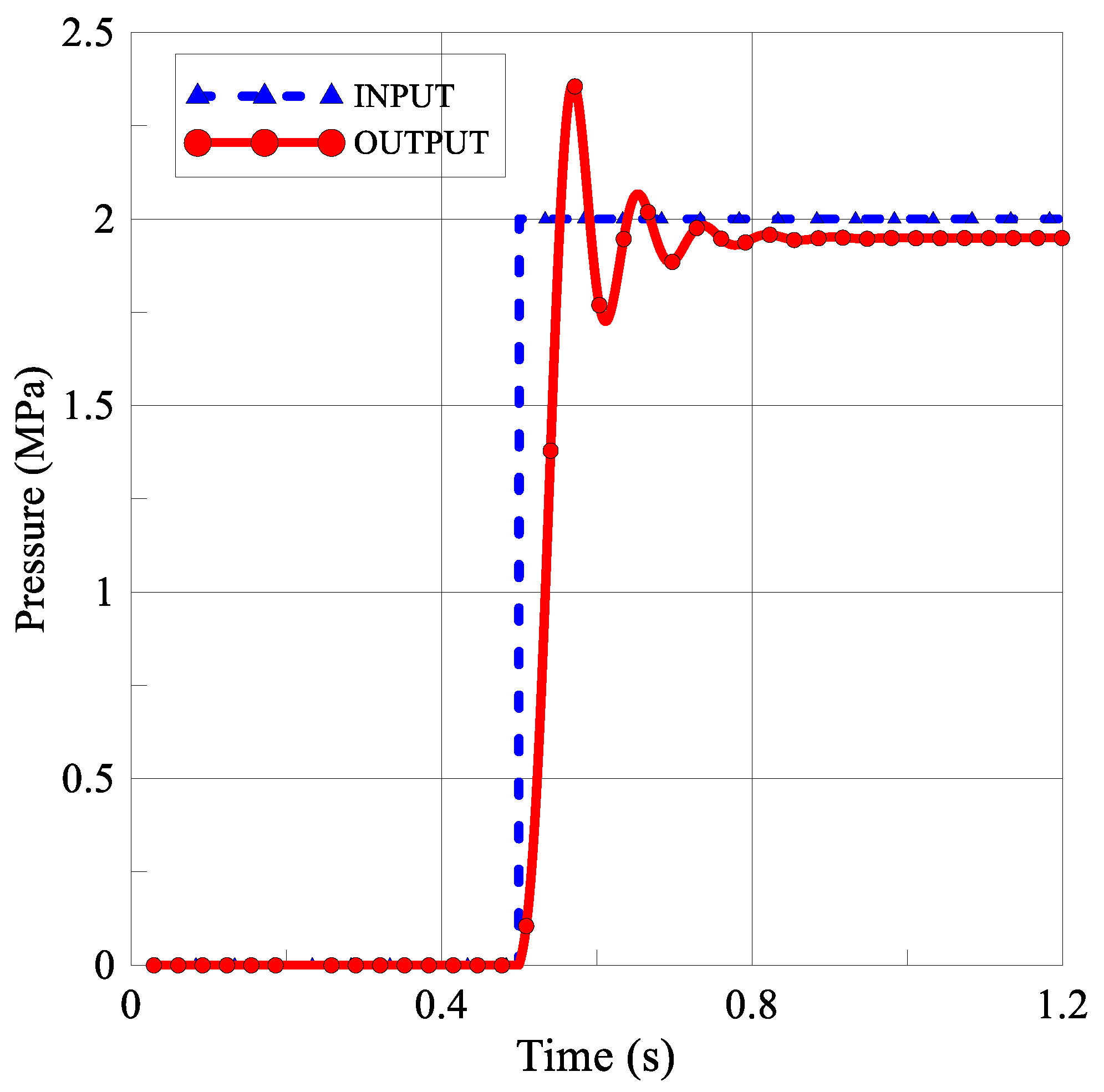

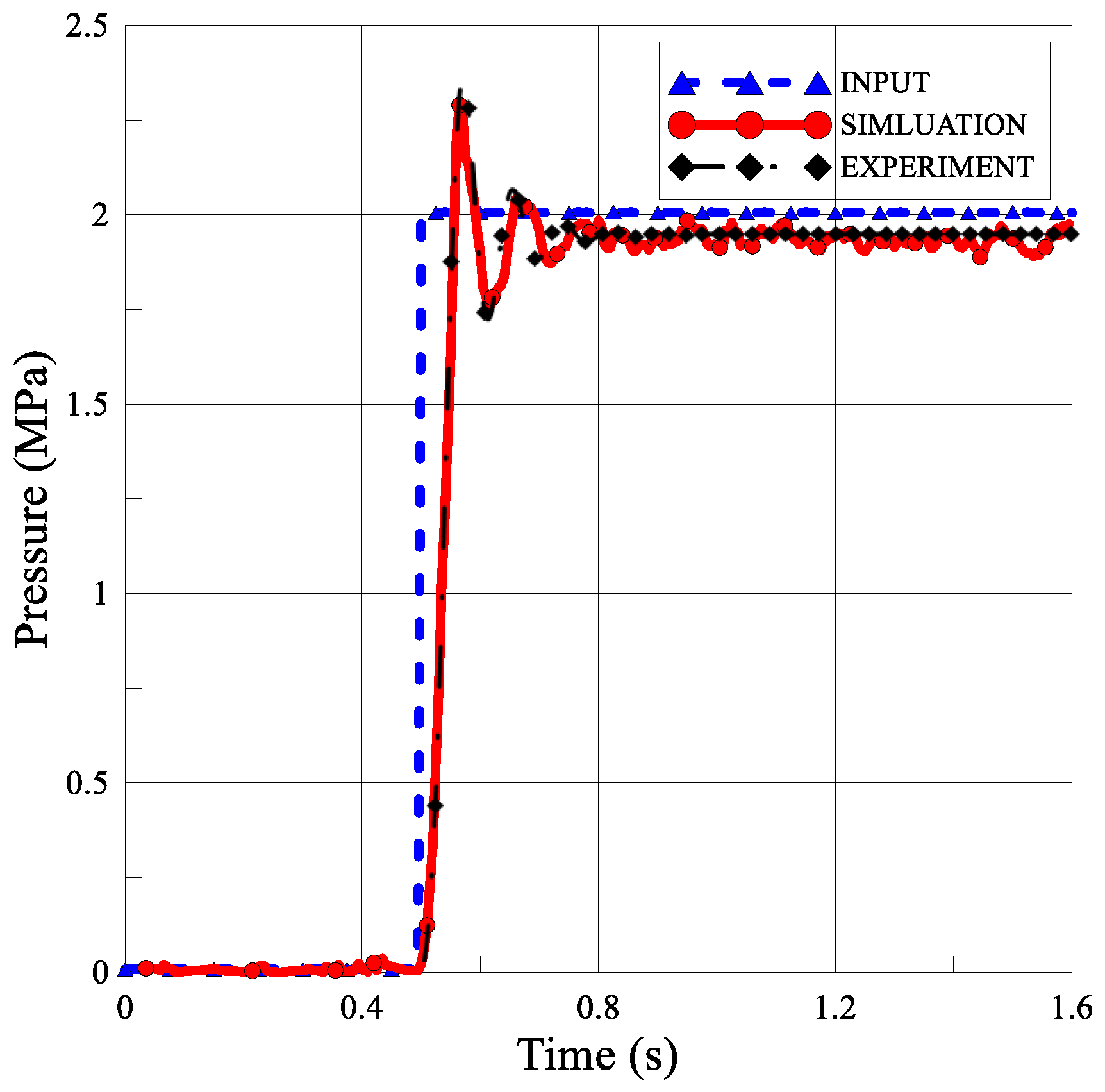

4.3. Step Characteristics of 2D Buffer Valve

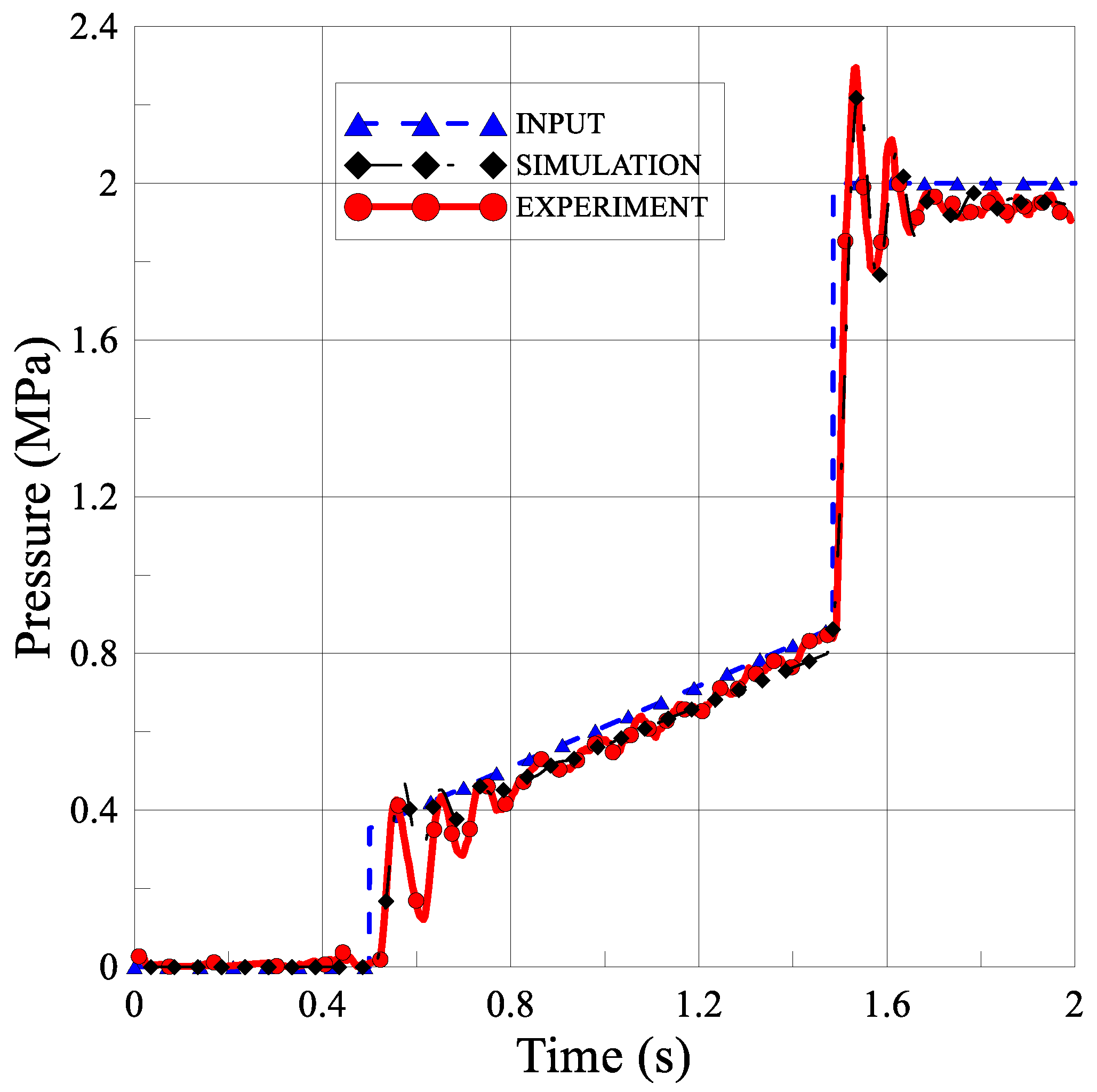

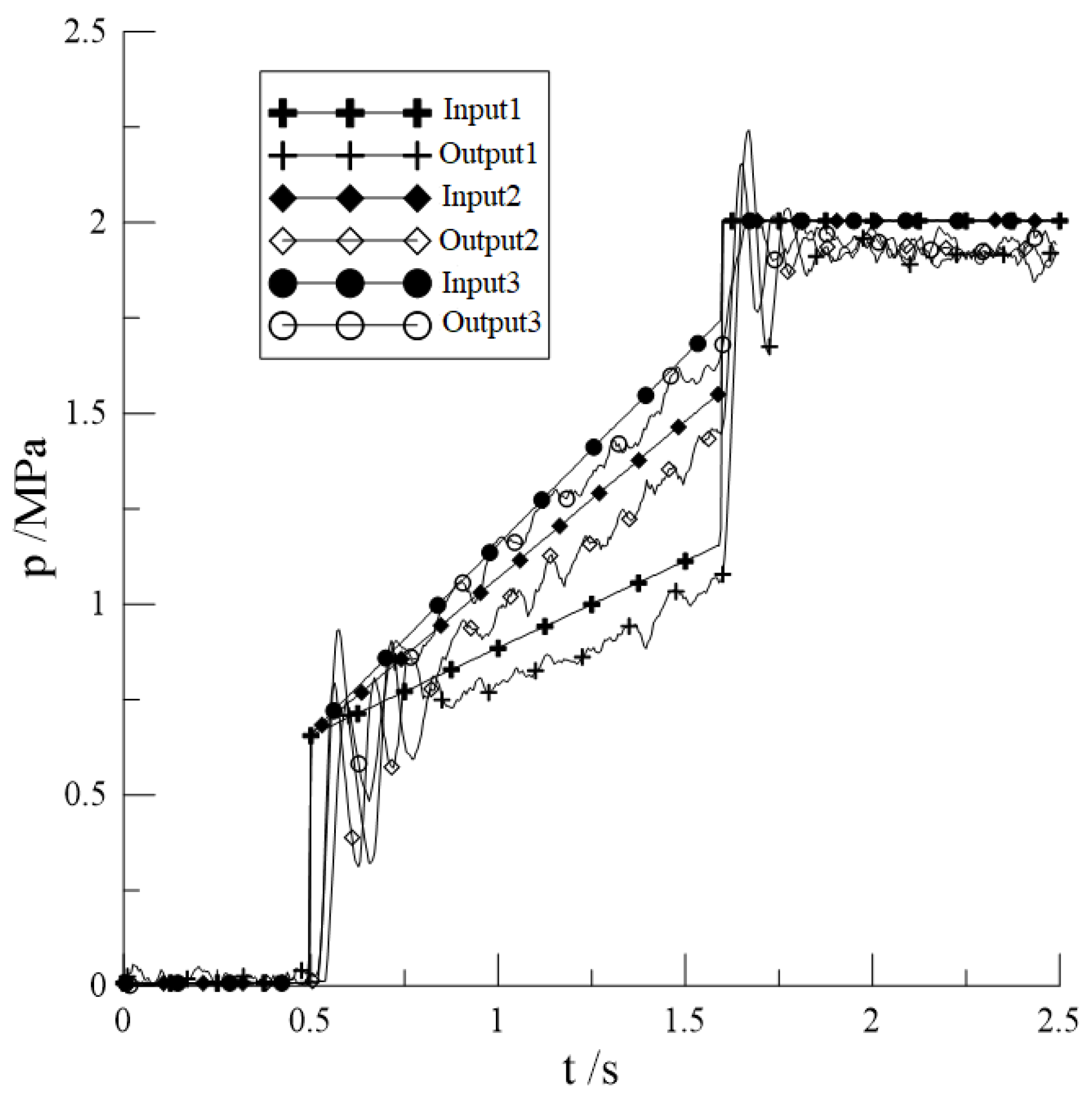

4.4. Experimental Study of Buffer Characteristics of 2D Buffer Valve

5. Conclusions

- (1)

- The 2D buffer valve can be designed using digital technology. During shifting, it can directly control the output pressure through digital technology to meet the pressure change within the clutch.

- (2)

- The step response time is about 55 ms, and the maximum overshoot is about 18.62%. The step performance of the valve is sufficient for the application.

- (3)

- In the buffering stage, the output pressure of the valve tends to be stable after 4 oscillations. The maximum deviation is 0.165 MPa, and the steady-state error is 0.056 MPa. In the step stage, the overshoot is 18.5%, and after 3.5 oscillations, it tends to be stable.

- (4)

- Different input signals can produce different buffering characteristics; the 2D digital buffer valve has better buffer following characteristics, and the output can reproduce the input, so that the vehicle can change the control signal to adapt to different operating conditions.

Author Contributions

Funding

Conflicts of Interest

References

- He, X.; Wang, Y.; Shi, Y.; Du, C.; Yu, B.; Zhang, Q.; Xie, Z.; Xie, Y.; Hou, X. Parameter Sensitivity Analysis of a Brake Pressure Control System in Aviation Using an Electro-Hydraulic Servo Valve. Electronics 2022, 11, 746. [Google Scholar] [CrossRef]

- Qian, P.; Pu, C.; Liu, L.; Li, X.; Zhang, B.; Gu, Z.; Meng, D. Development of a new high-precision friction test platform and experimental study of friction characteristics for pneumatic cylinders. Meas. Sci. Technol. 2022, 33, 065001. [Google Scholar] [CrossRef]

- Udovichenko, A.V.; Kaluzhskij, D.; Uvarov, N.; Mekhtiyev, A. Electric Motors for Variable-Speed Drive of Lock Valves. Electronics 2021, 10, 2727. [Google Scholar] [CrossRef]

- Yan, Q.D.; Zhang, L.D.; Zhao, Y.Q. Tank Construction and Design; Part 2; Beijing Institute of Technology Press: Beijing, China, 2006. [Google Scholar]

- Ma, B.; Shun, X.L.; Ju, Y.F. The analysis of smooth control methods of clutches in vehicle automatic shifting. Acta Armamentarii 1996, 2, 47–53. [Google Scholar]

- Dai, Z.K.; Xu, X.Y.; Liu, Y.F.; Wang, S.H. Closed-loop slip control of clutches in hydraulic automatic transmission. Automot. Eng. 2012, 34, 718–722. [Google Scholar] [CrossRef]

- Zhao, D.X.; Wang, Z.; Zhang, J.B. System simulation of changeable structure feed forward fuzzy control for vehicle shift. Acta Armamentarii 2003, 24, 412–415. [Google Scholar]

- Sarawoot, W.; Krishnaswany, S. Modeling and simulation of a shift hydraulic system for a stepped automatic transmission. SAE Tech. Pap. 2003, 1–14. [Google Scholar] [CrossRef]

- Horn, J.; Bamberger, J.; Michaud, P.; Pindl, S. Flatness-based clutch control for automated manual transmissions. Control. Eng. Pract. 2003, 11, 1353–1359. [Google Scholar] [CrossRef]

- Morselli, R.; Zanasi, R. Modeling of automotive control systems using power oriented graphs. In Proceedings of the Conference of the IEEE Industrial Electronics Society, Paris, France, 6–10 November 2006; pp. 5295–5300. [Google Scholar]

- Balau, A.E.; Caruntu, C.F.; Lazar, C. Simulation and control of an electro-hydraulic actuated clutch. Mech. Syst. Signal Process. 2011, 25, 1911–1922. [Google Scholar] [CrossRef]

- Walker, P.D.; Zang, N. Engagement and control of synchronizer mechanisms in dual clutch transmissions. Mech. Syst. Signal Process. 2012, 26, 320–332. [Google Scholar] [CrossRef][Green Version]

- Meng, F.; Tao, G.; Chen, H.Y. A study on the dynamic response characteristics of electro-hydraulic proportional valve for the shift of automatic transmission. Automot. Eng. 2013, 35, 229–233. [Google Scholar]

- Yang, S.J.; Zhou, Z.G.; Su, L.J. Test research of digital proportional relief valve for shifting on vehicle. Chin. Hydraul. Pneum. 2009, 2, 80–82. [Google Scholar]

- Zhang, Y.F.; Wang, Y.; Pang, H.L.; Yu, Y.; Zhan, J.Q. Solenoid valve simulation study for high-power automatic transmission based on AMESim. Chin. J. Automot. Eng. 2014, 4, 267–273. [Google Scholar] [CrossRef]

- Ruan, J.; Li, S.; Pei, X.; Burton, R.; Ukrainetz, R.; Bitner, D. 2D digital simplified flow valve. Chin. J. Mech. Eng. 2004, 17, 311–314. [Google Scholar] [CrossRef]

- Ruan, J.; Pei, X.; Li, S. 2D digital directional control valve. J. Mech. Eng. 2000, 36, 86–89. [Google Scholar] [CrossRef]

- Ruan, J.; Li, S.; Pei, X.; Yu, Z.Q.; Zhu, F.M. Electrohydraulic vibration exciter controlled by 2D Valve. J. Mech. Eng. 2009, 45, 125–132. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| System pressure ps/MPa | 2 |

| Density ρ/(kg/m3) | 860 |

| Flow coefficient Cd | 0.62 |

| Viscous damping B | 23.83 |

| Volumetric modulus of elasticity of oil βe/MPa | 700 |

| Pilot digital spool quality m/g | 15.5 |

| Pilot spool radius R/mm | 9 |

| Main spool radius Rm/mm | 4 |

| Oblique groove inclination β/rad | 1.13 |

| Spring stiffness K/(N/mm) | 115 |

| Small hole diameter r/mm | 3 |

| Small hole initial bow height h0/mm | 0.1 |

| System pressure ps/MPa | 2 |

| Density ρ/(kg/m3) | 860 |

| Flow coefficient Cd | 0.62 |

| Parameter | Value |

|---|---|

| Step response time | 55 ms |

| Peak time | 65 ms |

| Maximum overshoot | 18.62% |

| Contrast Stage | Contrast Phase | Experiment | Simulation |

|---|---|---|---|

| Buffer stage | Maximum deviation (MPa) | 0.165 | 0.105 |

| Peak time (ms) | 60 | 68 | |

| Steady-state error (MPa) | 0.056 | 0.059 | |

| Number of oscillations | 4 | 4.5 | |

| Step stage | Overshoot | 18.5% | 17.9% |

| Peak time (ms) | 65 | 69 | |

| Steady-state error (MPa) | 0.055 | 0.05 | |

| Number of oscillations | 3.5 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Liu, Y.; Xiong, W.; Ruan, J.; Tang, J.; Tan, J. Research on Buffer Characteristics of a New 2D Digital Buffer Valve for Vehicle Shift. Electronics 2022, 11, 1846. https://doi.org/10.3390/electronics11121846

Zhang Q, Liu Y, Xiong W, Ruan J, Tang J, Tan J. Research on Buffer Characteristics of a New 2D Digital Buffer Valve for Vehicle Shift. Electronics. 2022; 11(12):1846. https://doi.org/10.3390/electronics11121846

Chicago/Turabian StyleZhang, Qihui, Yi Liu, Wei Xiong, Jian Ruan, Jun Tang, and Janping Tan. 2022. "Research on Buffer Characteristics of a New 2D Digital Buffer Valve for Vehicle Shift" Electronics 11, no. 12: 1846. https://doi.org/10.3390/electronics11121846

APA StyleZhang, Q., Liu, Y., Xiong, W., Ruan, J., Tang, J., & Tan, J. (2022). Research on Buffer Characteristics of a New 2D Digital Buffer Valve for Vehicle Shift. Electronics, 11(12), 1846. https://doi.org/10.3390/electronics11121846