Experimental Study of Thermal Management Characteristics of Mass via Arrays

Abstract

1. Introduction

2. System Description and Design Techniques

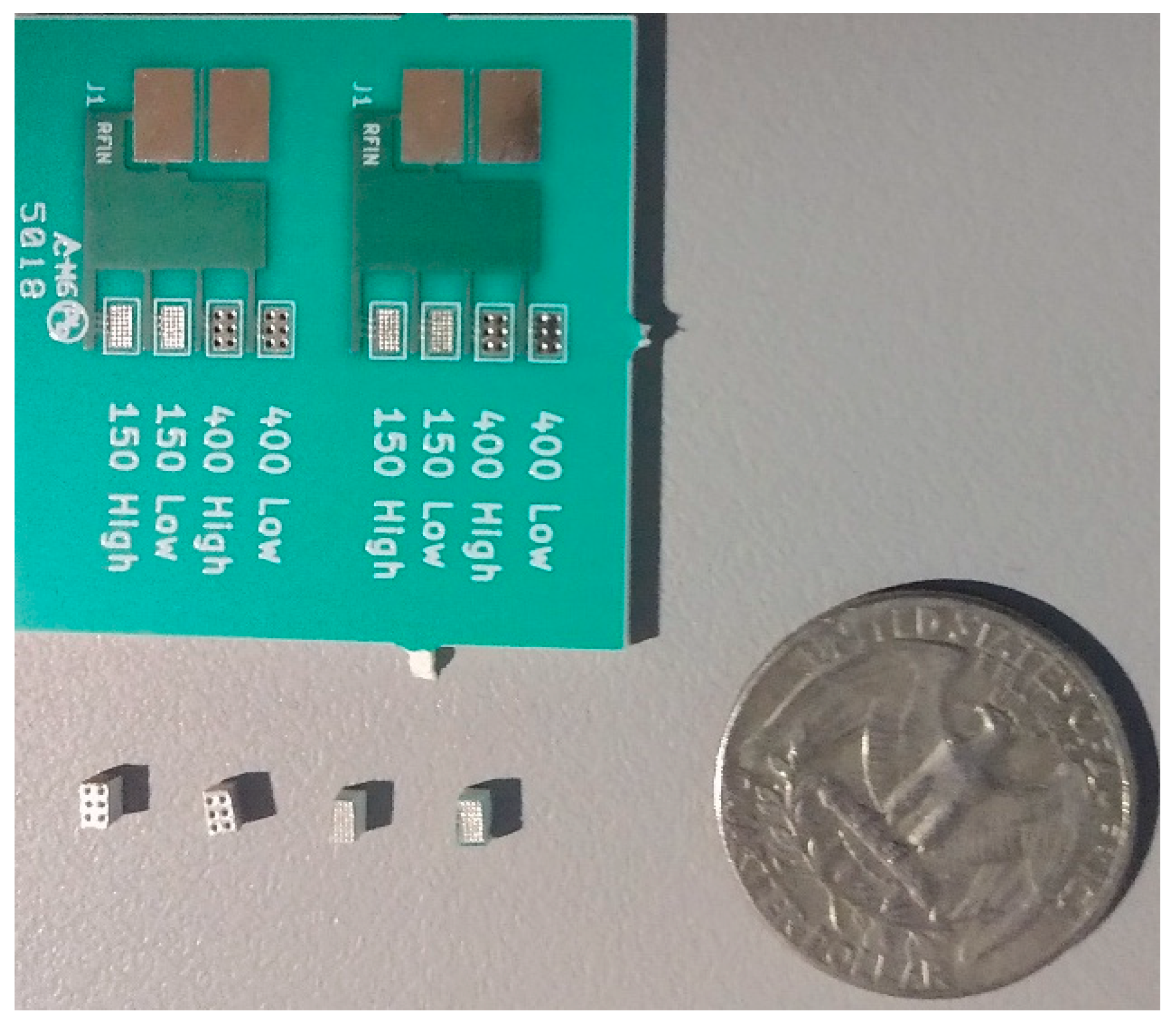

Full Factorial Design Format

3. Design Validation

3.1. Through-Plane Resistance

3.2. In-Plane Resistance

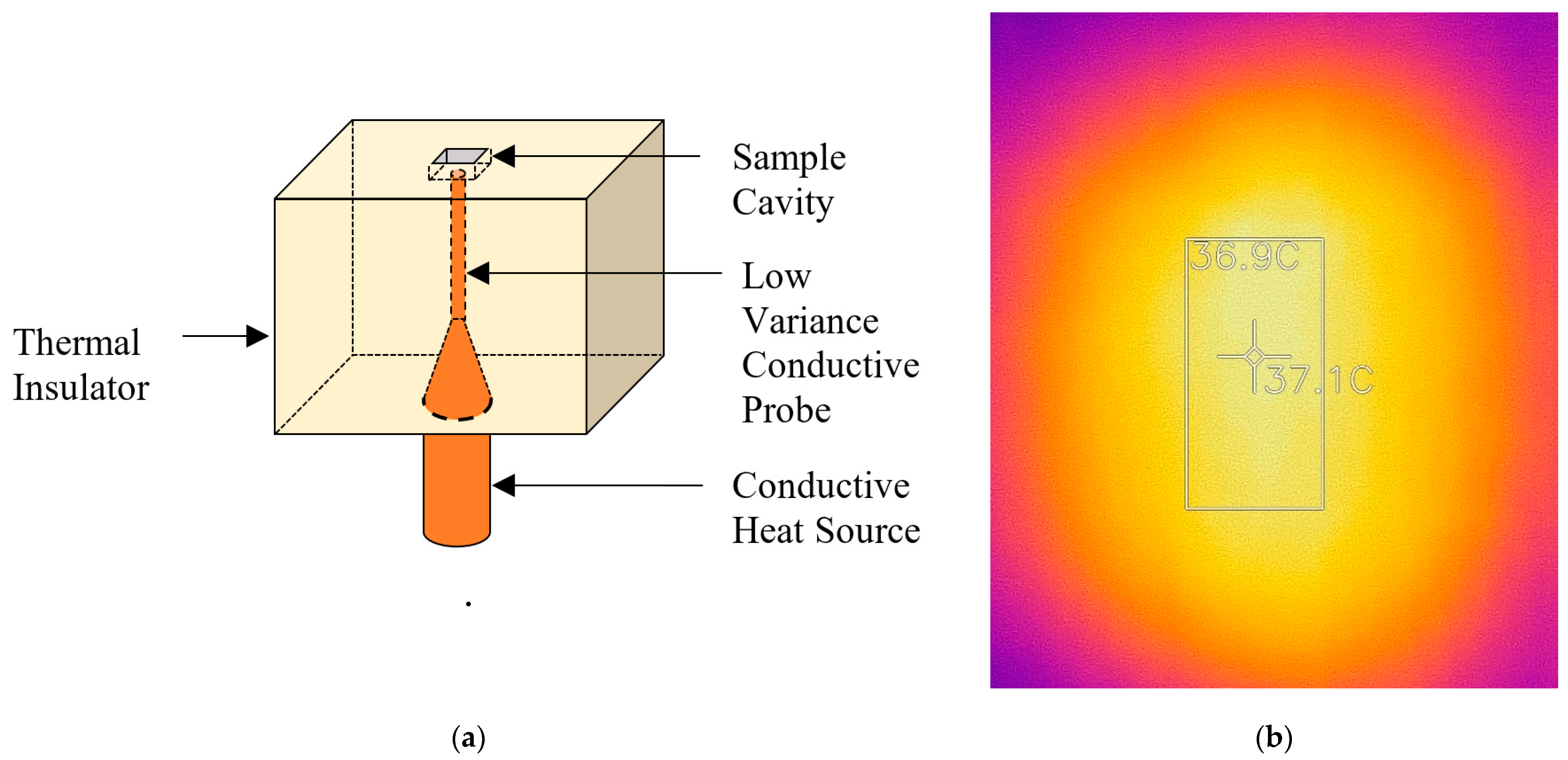

3.3. Heat Spreading Validation

4. Description of the Physical Characteristics of the Test System

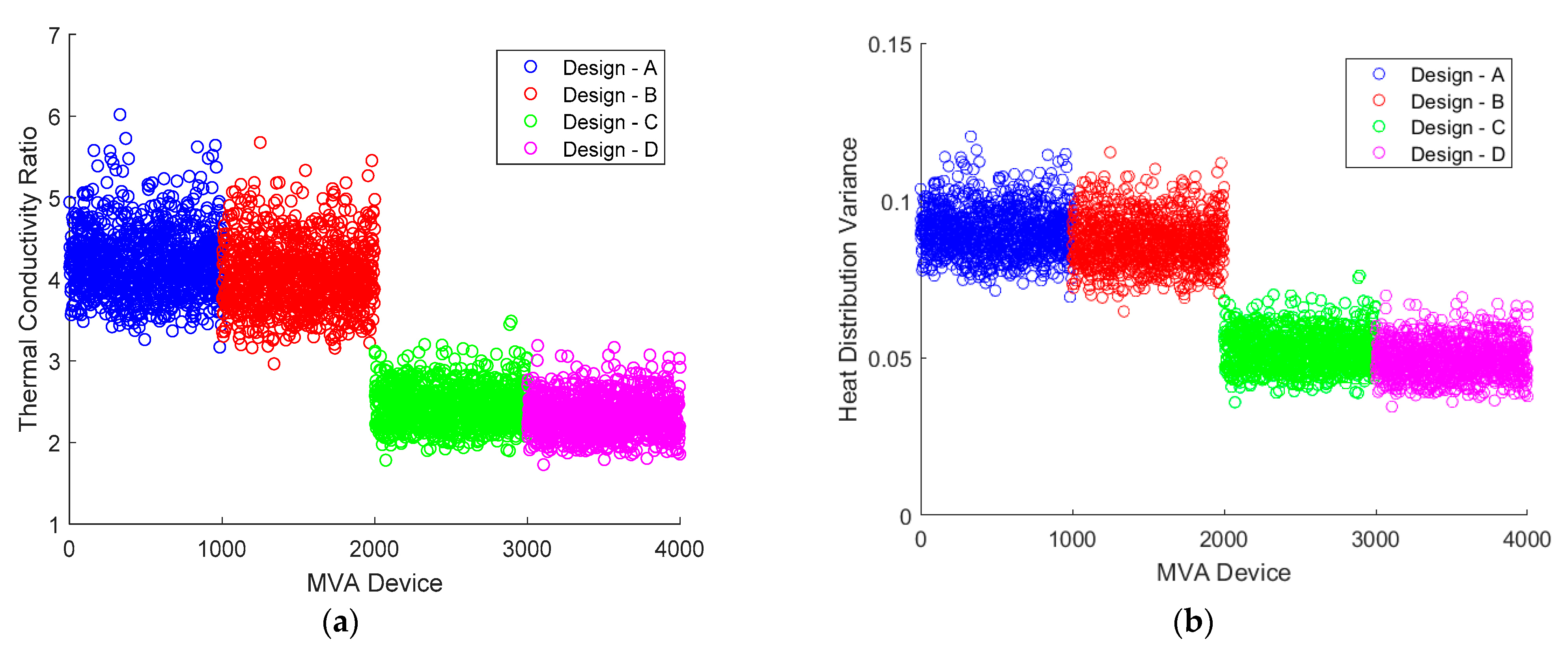

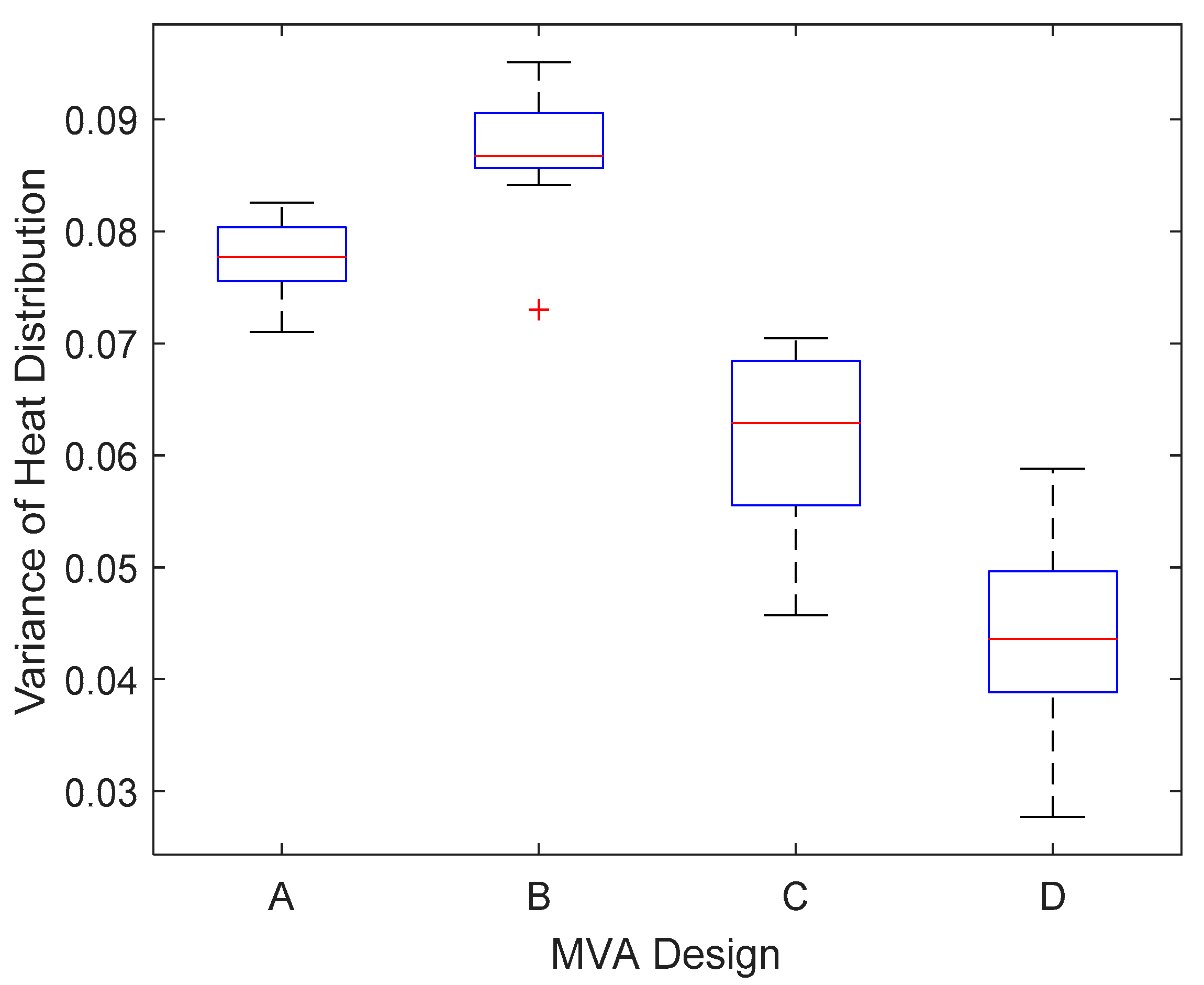

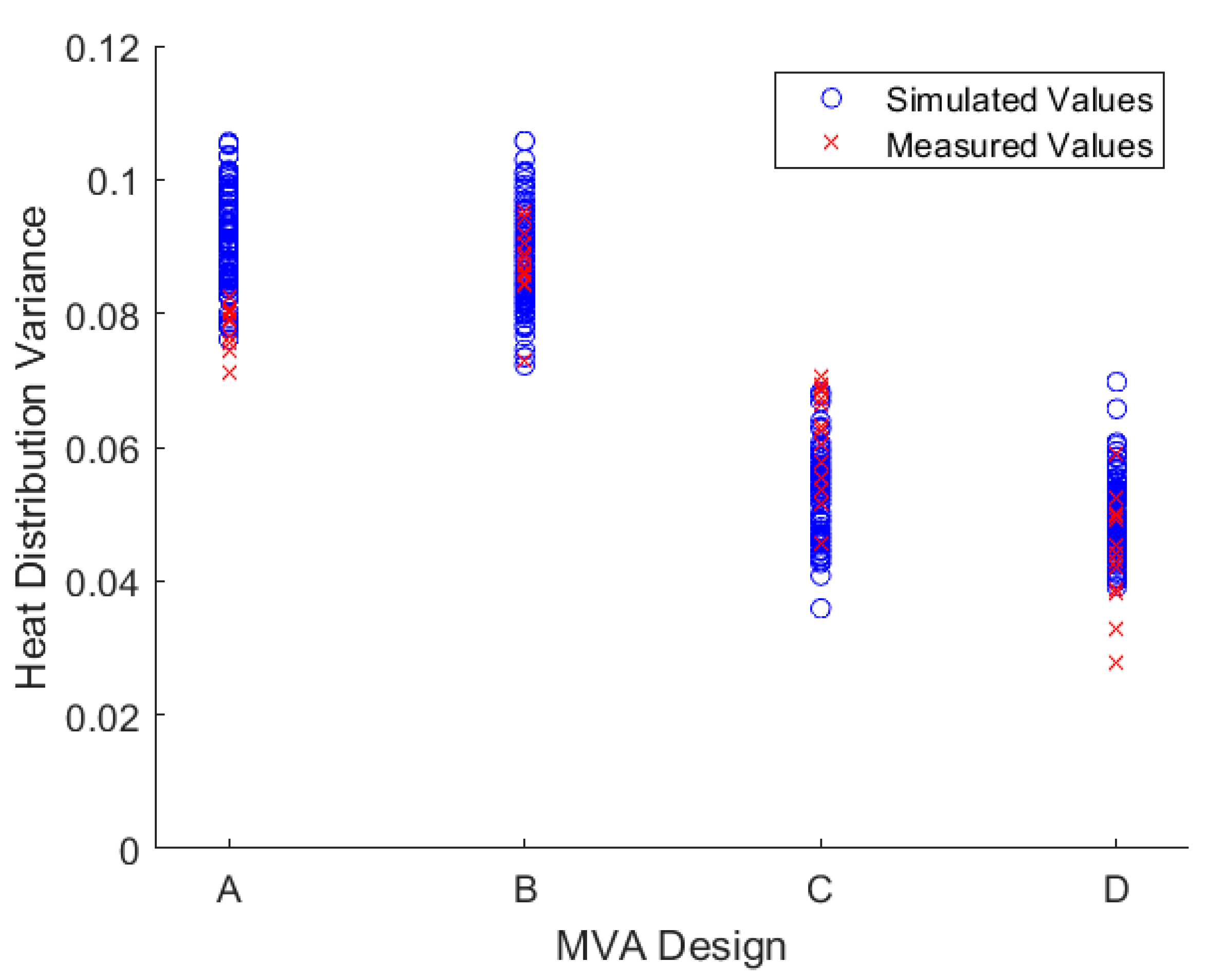

5. Results and Discussion

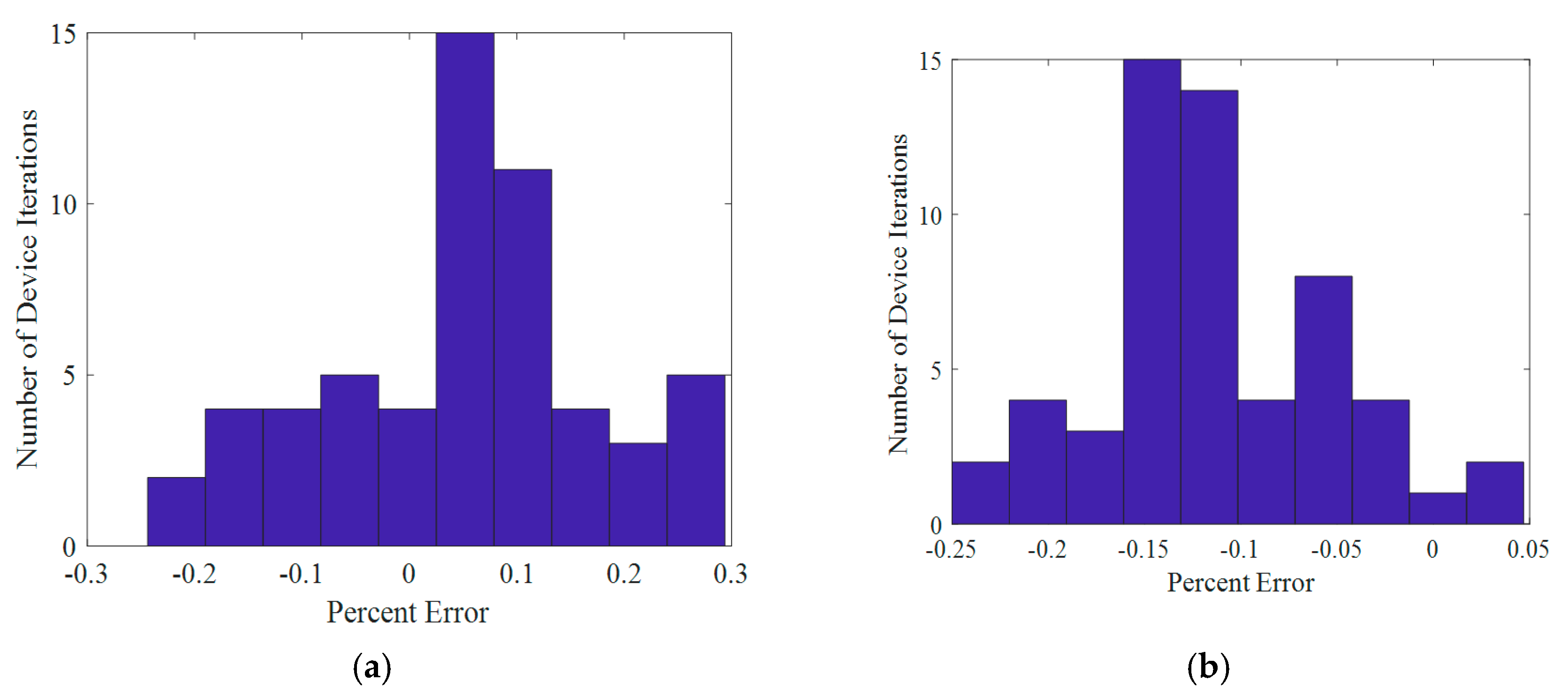

5.1. Extraction and Uncertainty Analysis

5.2. Description of the Measurement Setup

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Brillhart, M.; Xue, J. Next generation packaging technology for high performance ASICs. In Proceedings of the Sixth IEEE CPMT Conference on High Density Microsystem Design and Packaging and Component Failure Analysis (HDP ‘04), Shanghai, China, 3 July 2004; pp. 18–20. [Google Scholar]

- Tang, G.; Chai, T.C.; Zhang, X. Thermal Optimization and Characterization of SiC-Based High Power Electronics Packages With Advanced Thermal Design. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 854–863. [Google Scholar] [CrossRef]

- Kalyanam, V.K.; Mahurin, E.; Bowman, K.; Venkumahanti, S. 35.3 Thread-Level Power Management for a Current- and Temperature-Limiting System in a 7nm Hexagon™ Processor. In Proceedings of the 2021 IEEE International Solid- State Circuits Conference (ISSCC), San Francisco, CA, USA, 16–20 February 2021; pp. 494–496. [Google Scholar]

- Aiello, O.; Fiori, F. On the Susceptibility of Embedded Thermal Shutdown Circuit to Radio Frequency Interference. IEEE Trans. Electromagn. Compat. 2012, 54, 405–412. [Google Scholar]

- McNamara, A.J.; Joshi, Y.; Zhang, Z.M. Characterization of nanostructured thermal interface materials. Int. J. Therm. Sci. 2012, 62, 2–11. [Google Scholar] [CrossRef]

- Warzoha, R.J.; Zhang, D.; Feng, G.; Fleischer, A.S. Engineering interfaces in carbon nanostructured mats for the creation of energy efficient thermal interface materials. Carbon 2013, 61, 441–457. [Google Scholar] [CrossRef]

- Khodadadi, J.M.; Fan, L.; Babaei, H. Thermal conductivity enhancement of nanostructure-based colloidal suspensions utilized as phase change materials for thermal energy storage: A review. Renew. Sustain. Energy Rev. 2013, 24, 418–444. [Google Scholar] [CrossRef]

- Gholami, A.; Bahrami, M. Thermal spreading resistance inside anisotropic plates with arbitrarily located hotspots. J. Thermophys. Heat Transf. 2014, 28, 679–686. [Google Scholar] [CrossRef]

- Yang, T.; Wu, Q.; Xu, W.; Liu, D.; Huang, L.; Chen, F. A thermal ground cloak. Phys. Lett. A 2016, 380, 965–969. [Google Scholar] [CrossRef]

- Hamed, A.; Ndao, S. High anisotropy metamaterial heat spreader. Int. J. Heat Mass Transf. 2018, 121, 10–14. [Google Scholar] [CrossRef]

- Lee, J.; Thompson, S.M.; Lacy, T.E. Thermal spreading analysis of a transversely isotropic heat spreader. Int. J. Therm. Sci. 2017, 118, 461–474. [Google Scholar] [CrossRef]

- McCluskey, F.P.; Podlesak, T.; Grzybowski, R. High Temperature Electronics (Electronic Packaging); CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Smarra, D.; Wicks, M.; Chodavarapu, V. A study of the heat spreading capabilities of Mass Via Arrays. In Proceedings of the 2019 IEEE National Aerospace Electronics Conference (NAECON), Dayton, OH, USA, 15–19 July 2019. [Google Scholar]

- Kafaradova, N.; Andonova, A. PCB thermal design improvement through thermal vias. In Recent Advances in Circuits, Systems, Electronics, Control and Signal Processing; World Scientific and Engineering Academy and Society (WSEAS): Milwaukee, WI, USA, 2009; pp. 241–244. [Google Scholar]

- Shen, Y.; Wang, H.; Blaabjerg, F. Thermal resistance modelling and design optimization of PCB vias. Microelectron. Reliab. 2018, 88–90, 1118–1123. [Google Scholar] [CrossRef]

- Zampino, M.A.; Kandukuri, R.; Jones, W.K. High performance thermal vias in LTCC substrates. ITherm 2002. In Proceedings of the Eighth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2002; pp. 179–185. [Google Scholar]

- Bar-Cohen, A. Thermal management of on-chip hot spots and 3D chip stacks. In Proceedings of the 2009 IEEE International Conference on Microwaves, Communications, Antennas and Electronics Systems, Tel Aviv, Israel, 9–11 November 2009; pp. 1–8. [Google Scholar]

- Hatta, H.; Taya, M. Equivalent inclusion method for steady state heat conduction. Int. J. Eng. Sci. 1986, 24, 1159–1172. [Google Scholar]

- Smarra, D. Low Temperature Co-Fired Ceramic (LTCC) Substrate for High Temperature Microelectronics. (Electronic Thesis or Dissertation). 2017. Available online: https://etd.ohiolink.edu/ (accessed on 31 January 2020).

- Smarra, D.; Wicks, M.; Chodavarapu, V. A generalized 1-dimensional model for mass via arrays (MVA). In Proceedings of the 2018—IEEE National Aerospace and Electronics Conference (NAECON), Dayton, OH, USA, 23–26 July 2018. [Google Scholar]

- Standard Multi-Layer Construction Tables. Layer Stackup. Available online: https://www.sunstone.com/pcb-manufacturing-capabilities/layer-stackup (accessed on 16 April 2021).

- Rogers Corporation. RO4000 Laminates RO4003C and RO4350B—Data Sheet. Available online: https://rogerscorp.com/-/media/project/rogerscorp/documents/advanced-connectivity-solutions/english/data-sheets/ro4000-laminates-ro4003c-and-ro4350b---data-sheet.pdf (accessed on 16 April 2021).

- De Tommasi, L.; Magnani, A.; d’Alessandro, V.; De Magistris, M. Time domain identification of passive multiport RC networks with convex optimization: An application to thermal impedance macromodeling. In Proceedings of the 2014 IEEE 18th Workshop on Signal and Power Integrity (SPI), Ghent, Belgium, 11–14 May 2014; pp. 1–4. [Google Scholar]

- De Tommasi, L.; Magnani, A.; De Magistris, M. Advancements in the identification of passive RC networks for compact modeling of thermal effects in electronic devices and systems. Int. J. Numer. Model. Electron. Netw. Devices Fields 2018, 31, e2296. [Google Scholar] [CrossRef]

- Feng, T.; Xu, J. An analytical solution of thermal resistance of cubic heat spreaders for electronic cooling. Appl. Therm. Eng. 2004, 24, 323–337. [Google Scholar] [CrossRef]

- Thompson, S.M.; Ma, H.B. Thermal spreading analysis of rectangular heat spreader. J. Heat Transf. 2014, 136, 064503. [Google Scholar] [CrossRef]

| Category | Design Factor | Variable Type | Setting(S) |

|---|---|---|---|

| via | Diameter | Control | L: 200 um; H: 600 um |

| Material | Fixed | Copper | |

| heat spreader | Thickness | Fixed | 2 oz. |

| Density | Control | L: 2; H: 10 | |

| Material | Fixed | Copper | |

| substrate | Layers | Fixed | 9 |

| Material | Fixed | RO4350 [22] |

| Design Factor | Symbol | X | Y | Design |

|---|---|---|---|---|

| via diameter | X | 200 µm | 2 Layers | A |

| 600 µm | 2 Layers | B | ||

| heat spreader thickness | Y | 200 µm | 10 Layers | C |

| 600 µm | 10 Layers | D |

| MVA Design | (W/m-K) |

|---|---|

| A | 101.47 |

| B | 108.97 |

| C | 111.14 |

| D | 118.76 |

| MVA Design | (W/m-K) |

|---|---|

| A | 29.04 |

| B | 32.60 |

| C | 54.95 |

| D | 61.85 |

| MVA Design | K* |

|---|---|

| A | 3.49 |

| B | 3.34 |

| C | 2.02 |

| D | 1.92 |

| minimum | −24.375% | −25.000% | −0.822% | −30.598% |

| maximum | 29.375% | 4.688% | 0.822% | 20.389% |

| σ | 0.125 | 0.059 | 0.005 | 0.135 |

| μ | 5.197% | −11.447% | 0.216% | −6.133% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smarra, D.A.; Chodavarapu, V.P. Experimental Study of Thermal Management Characteristics of Mass via Arrays. Electronics 2021, 10, 1027. https://doi.org/10.3390/electronics10091027

Smarra DA, Chodavarapu VP. Experimental Study of Thermal Management Characteristics of Mass via Arrays. Electronics. 2021; 10(9):1027. https://doi.org/10.3390/electronics10091027

Chicago/Turabian StyleSmarra, Devin A., and Vamsy P. Chodavarapu. 2021. "Experimental Study of Thermal Management Characteristics of Mass via Arrays" Electronics 10, no. 9: 1027. https://doi.org/10.3390/electronics10091027

APA StyleSmarra, D. A., & Chodavarapu, V. P. (2021). Experimental Study of Thermal Management Characteristics of Mass via Arrays. Electronics, 10(9), 1027. https://doi.org/10.3390/electronics10091027