Proposal of a Decoupled Structure of Fuzzy-PID Controllers Applied to the Position Control in a Planar CDPR

Abstract

1. Introduction

2. Materials and Methods

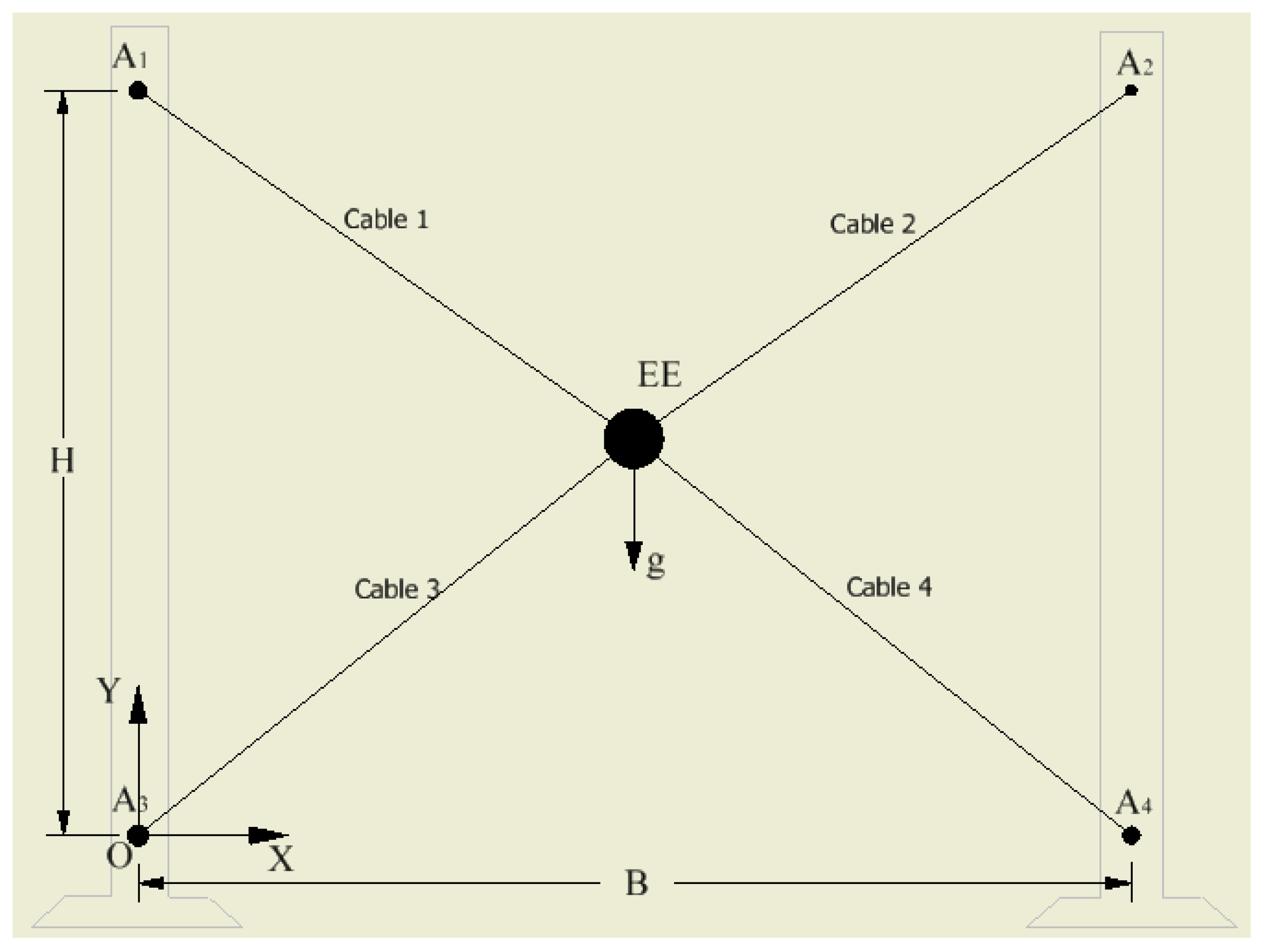

2.1. Structure of the Parallel Cable Mechanism

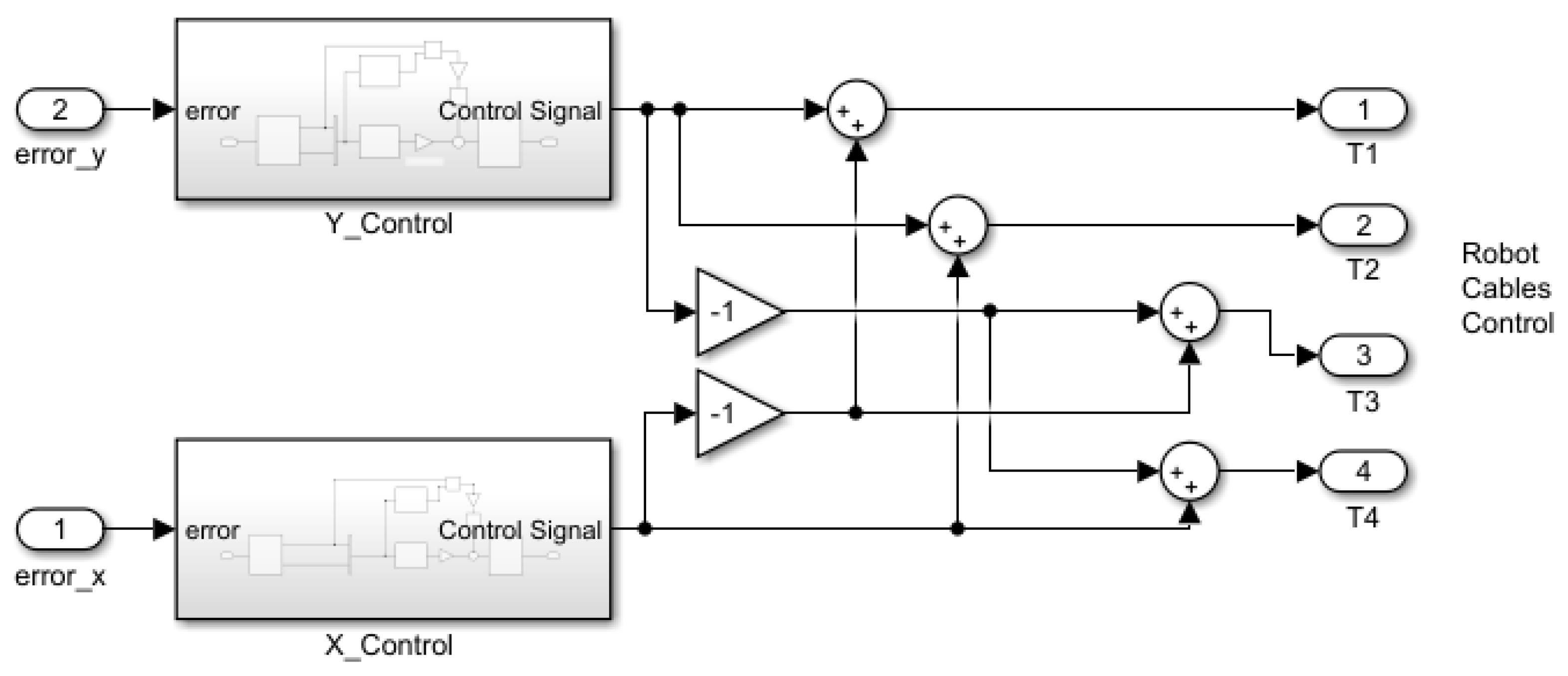

2.2. Motion Control Topology

- One controller performs the X-axis positioning control. For positive displacement, force is applied to cables 2 and 4, while for negative displacement, force is applied to cables 1 and 3.

- Another controller performs the Y-axis positioning control. For positive displacement, force is applied to cables 1 and 2, while for negative displacement, force is applied to cables 3 and 4.

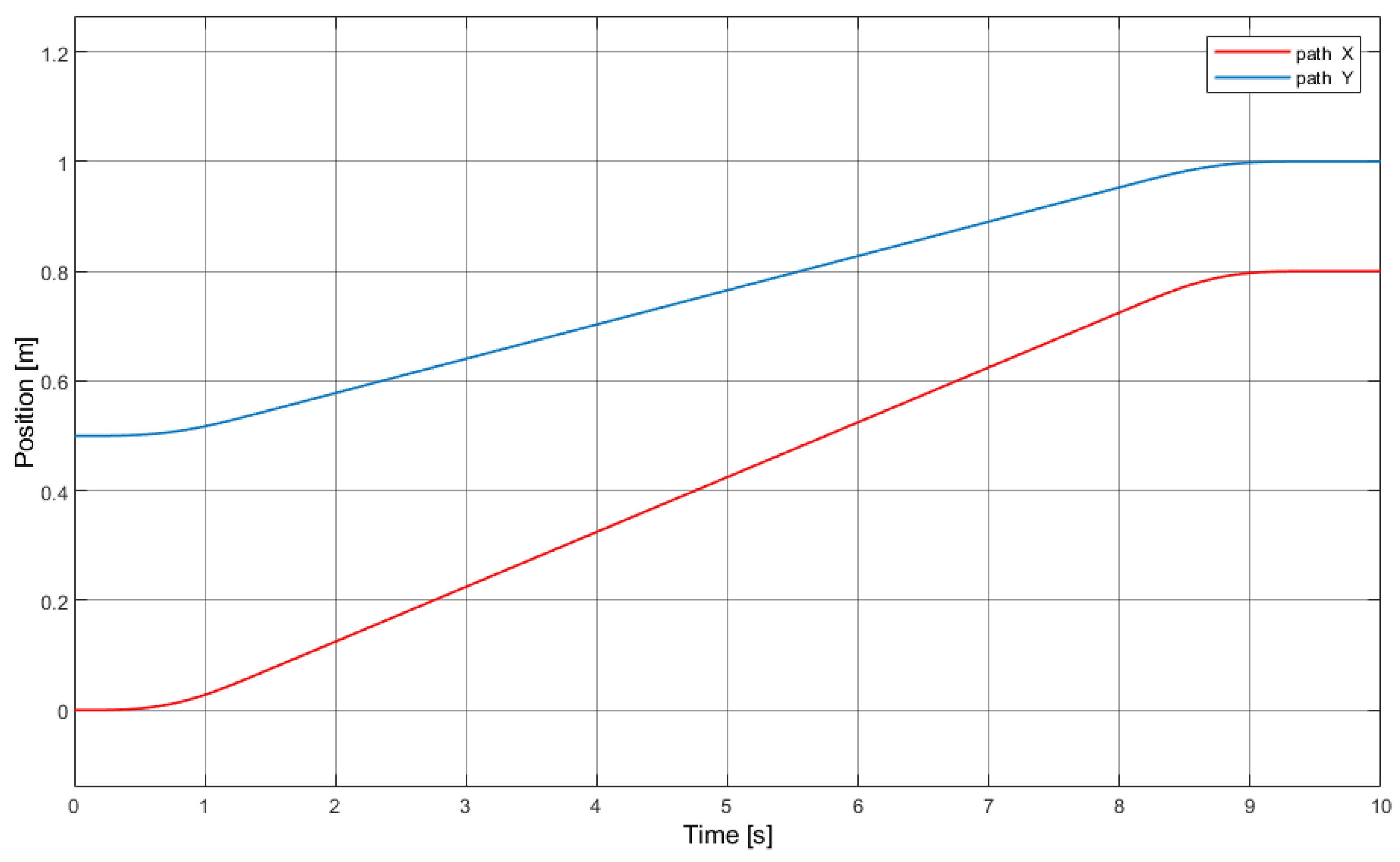

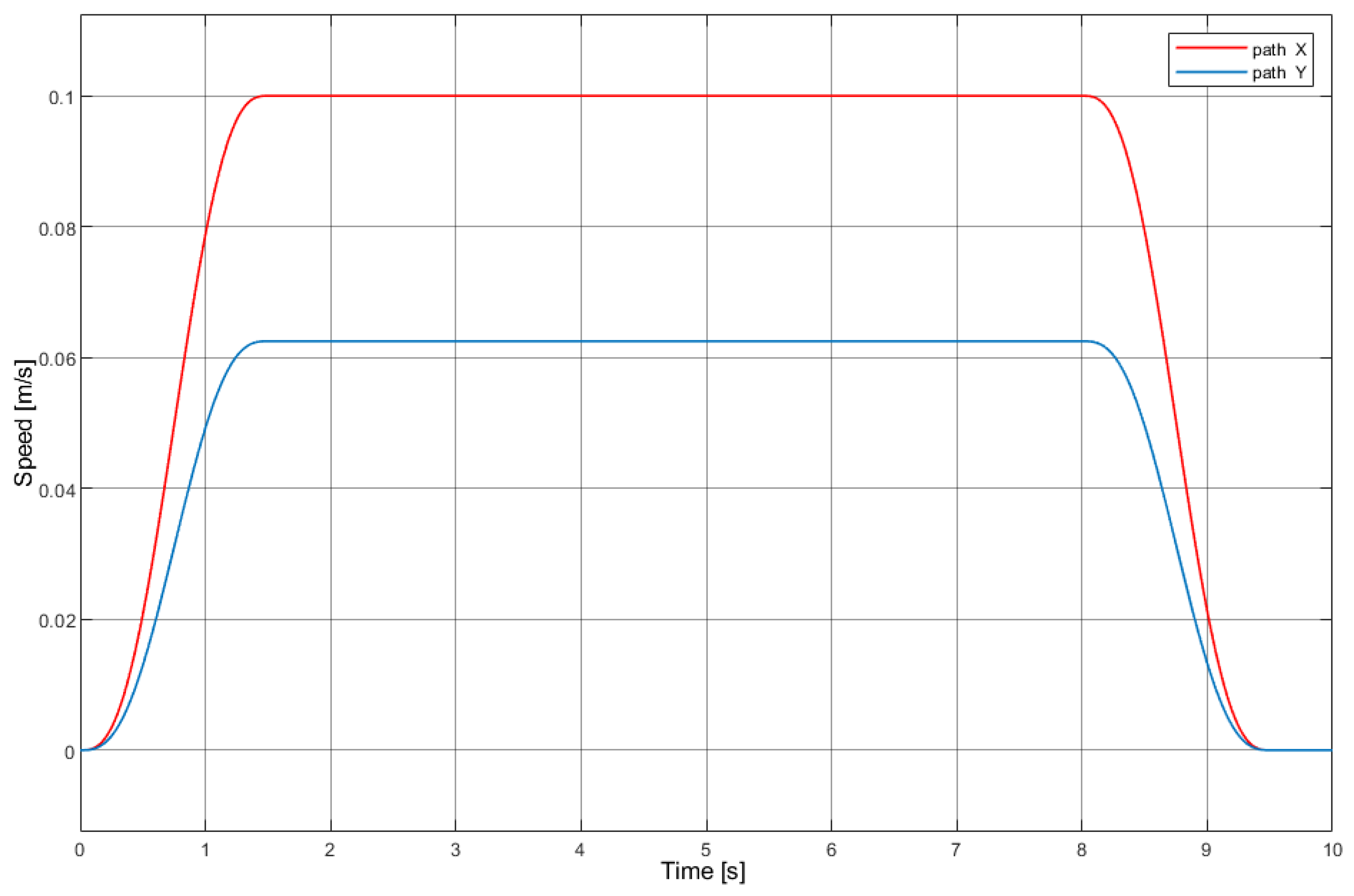

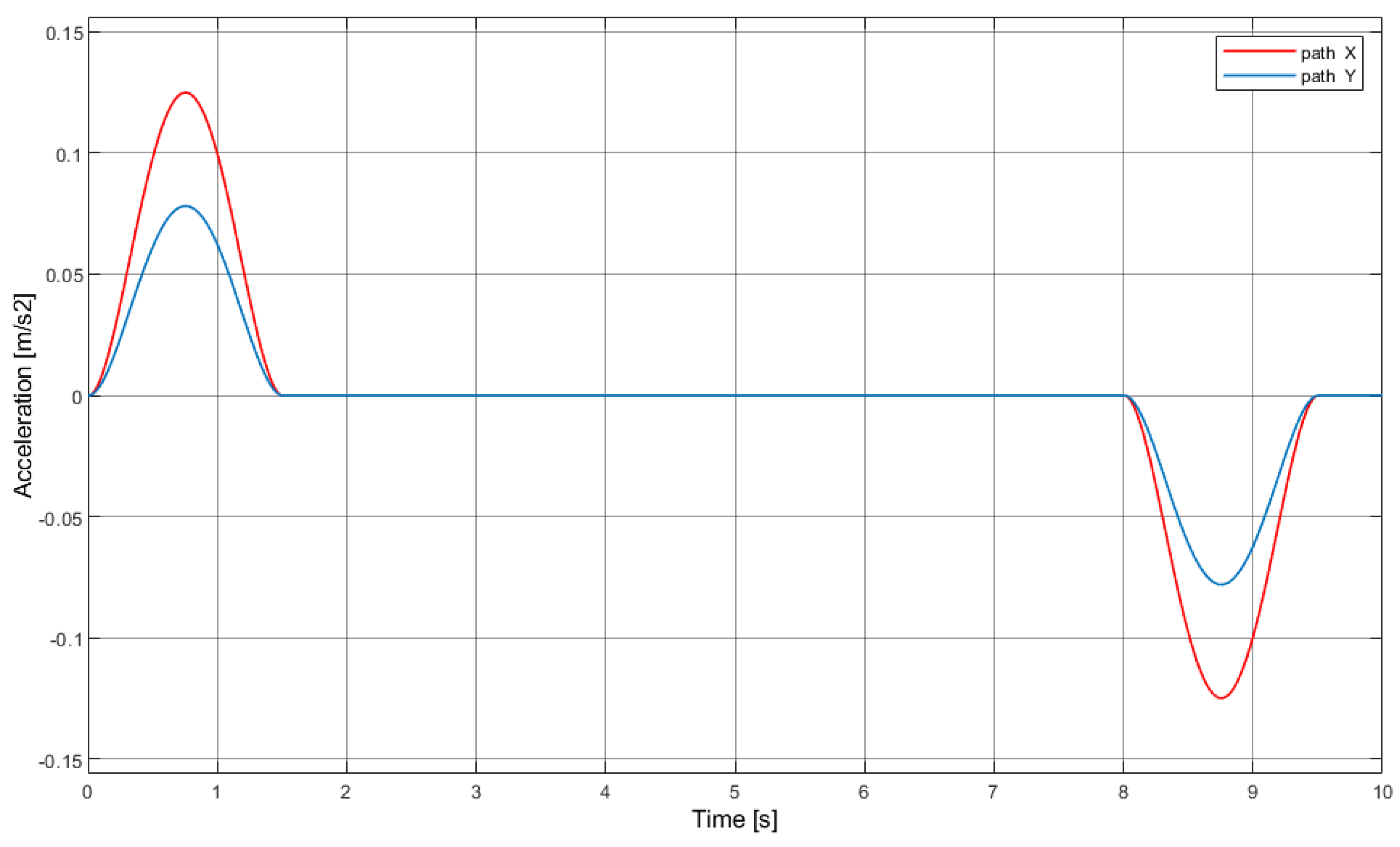

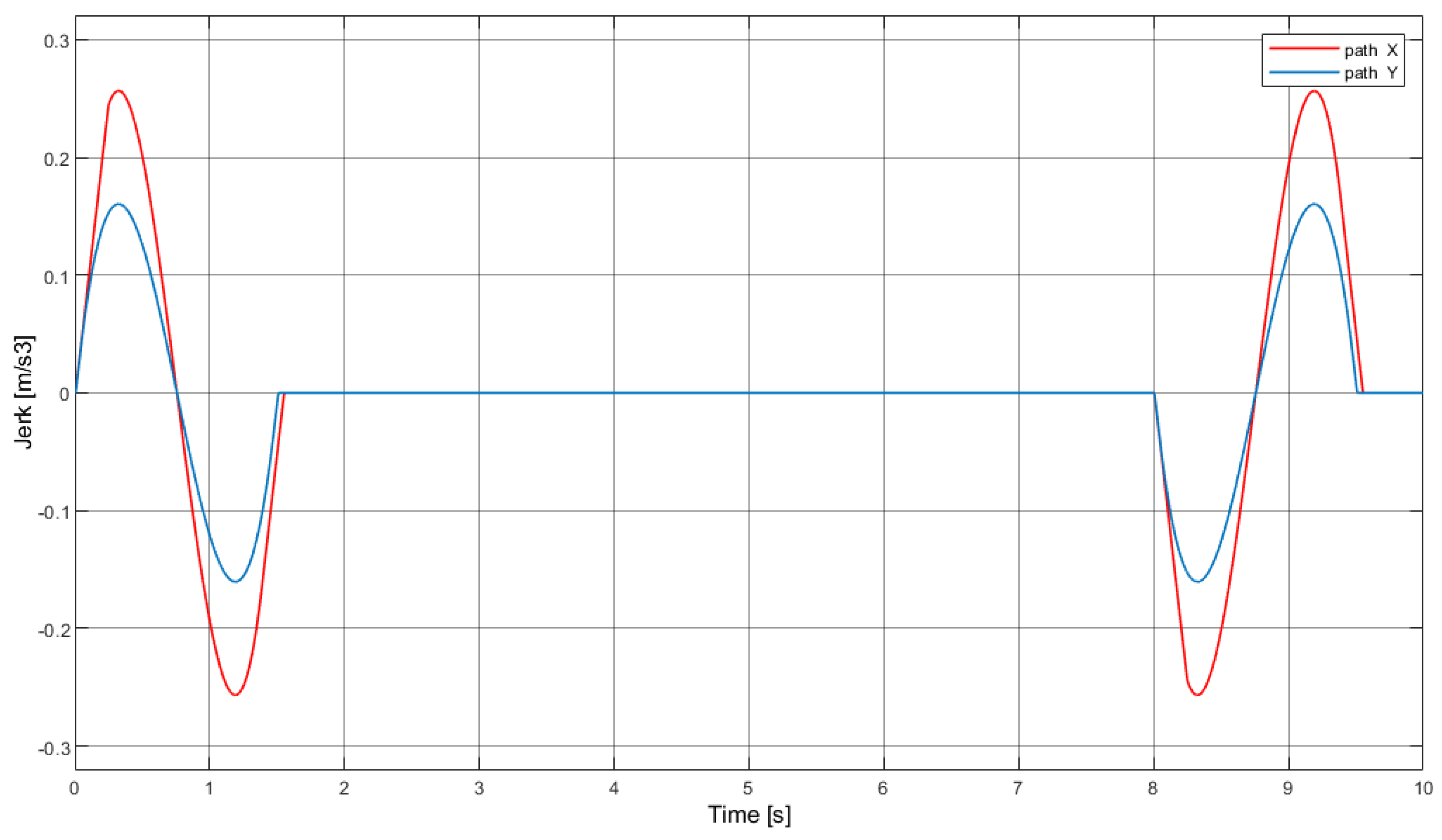

2.3. Trajectory Planning

- , , and : positions reached during the sections of acceleration, constant speed, and deceleration, respectively.

- : maximum speed that can be developed.

- : acceleration and deceleration time.

- : total time required to develop the whole trajectory.

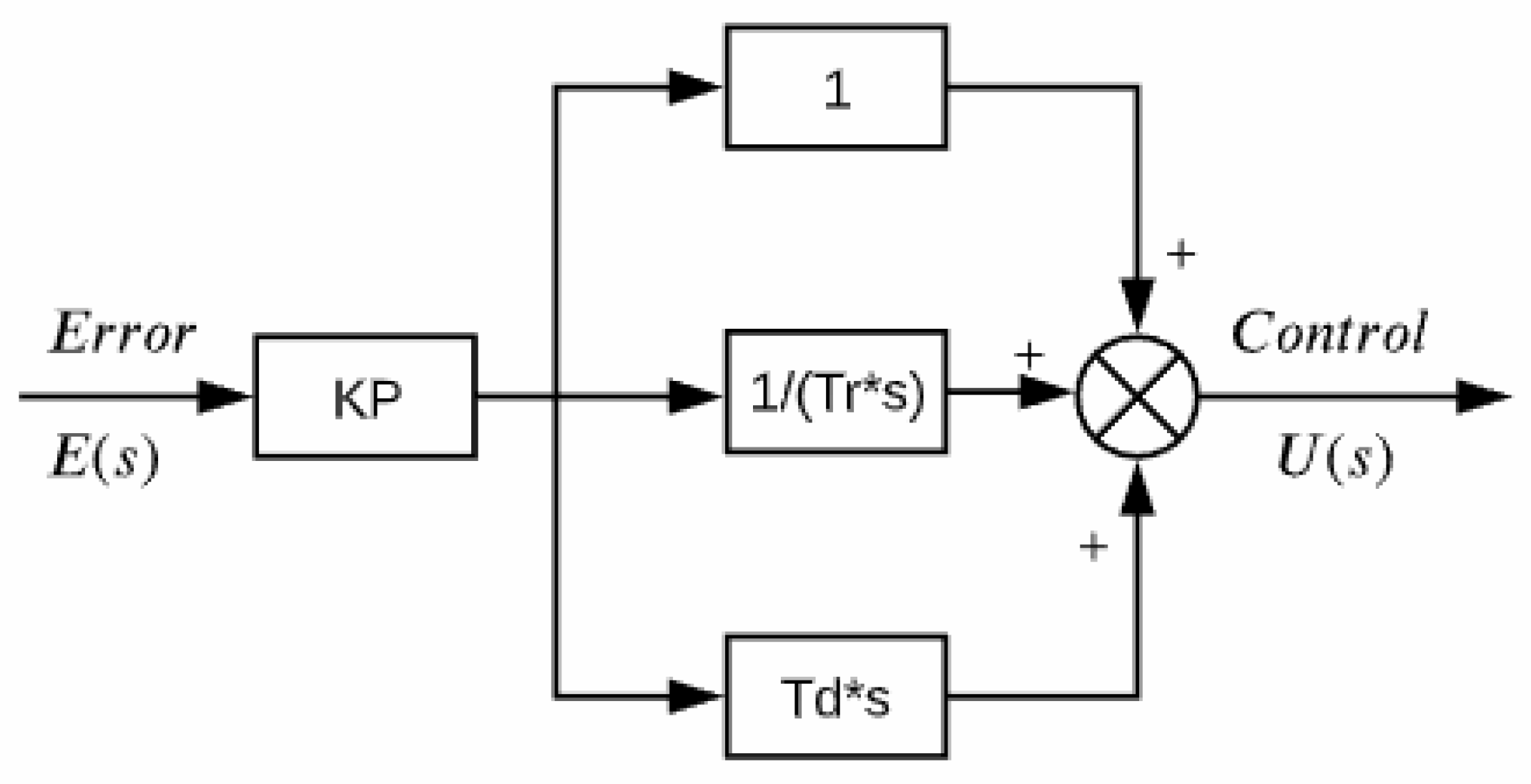

2.4. Controller Tuning

2.4.1. PID Control

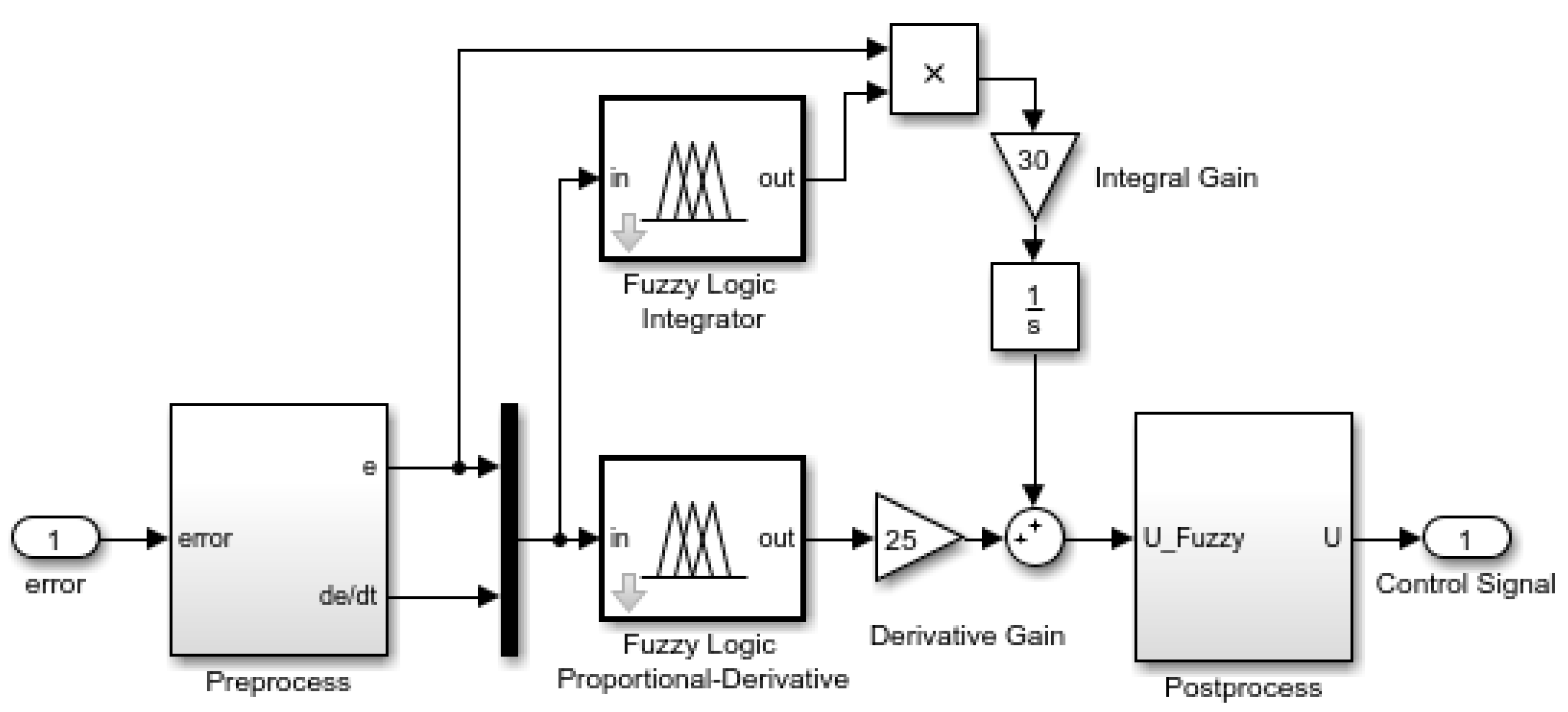

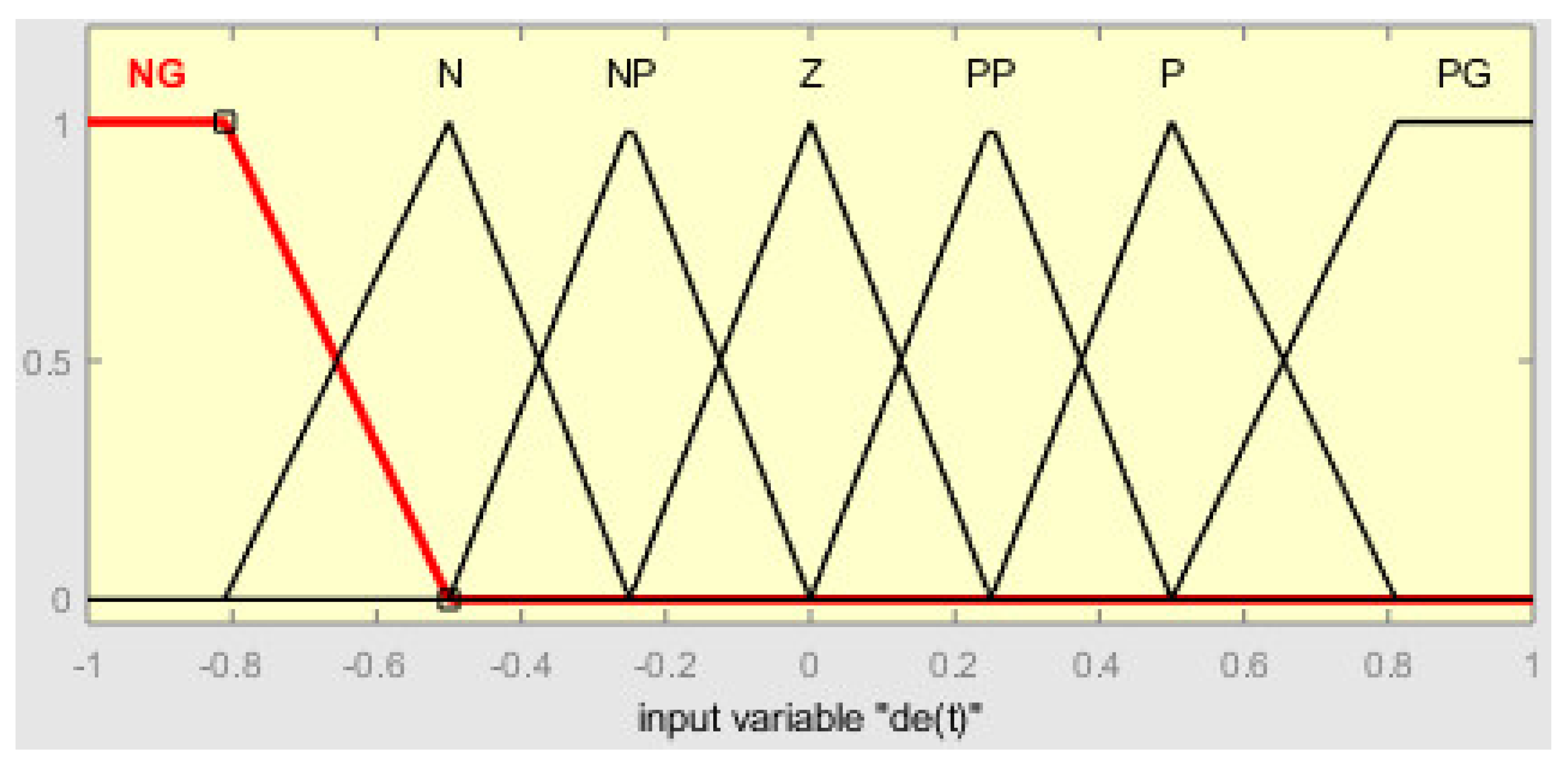

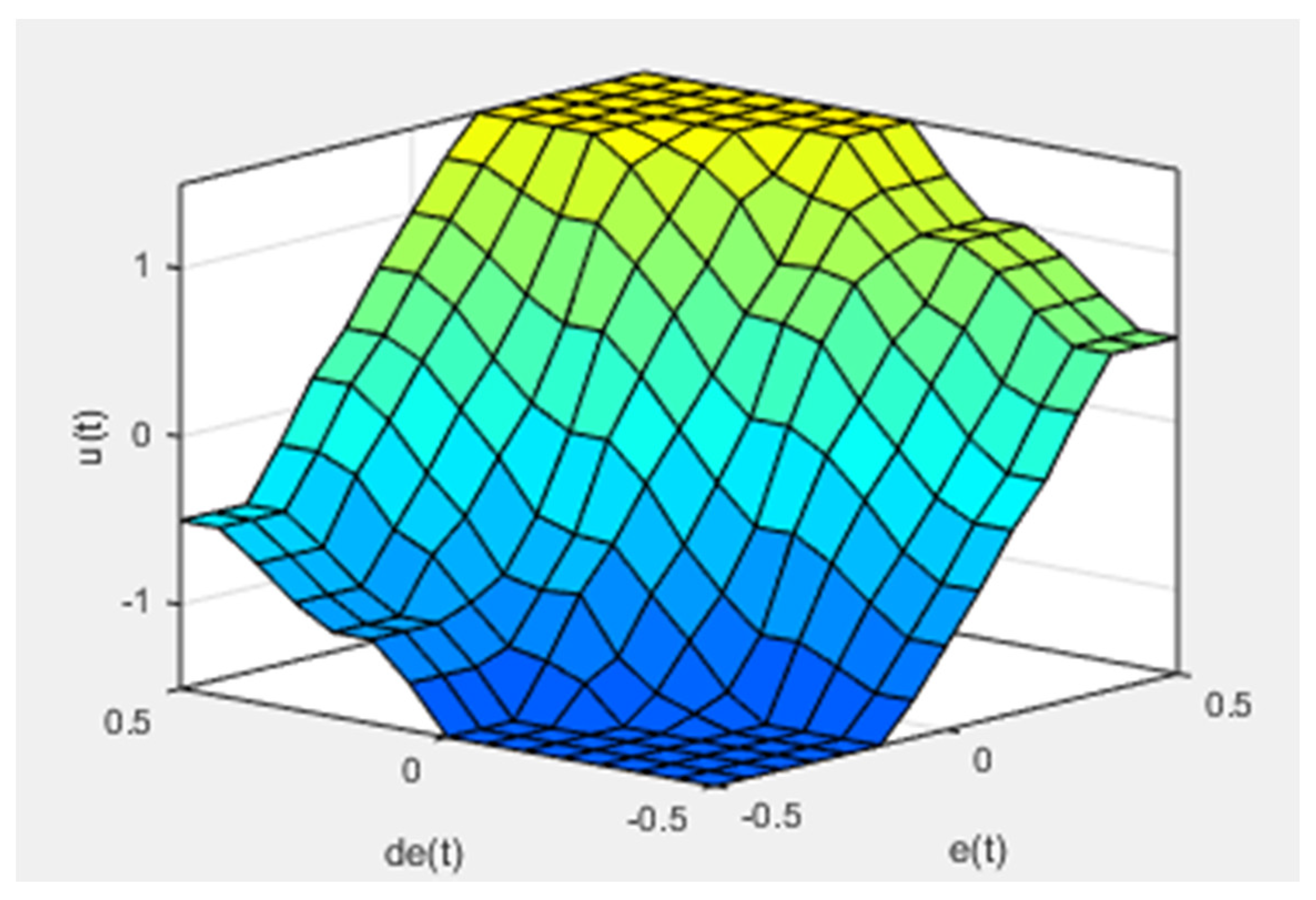

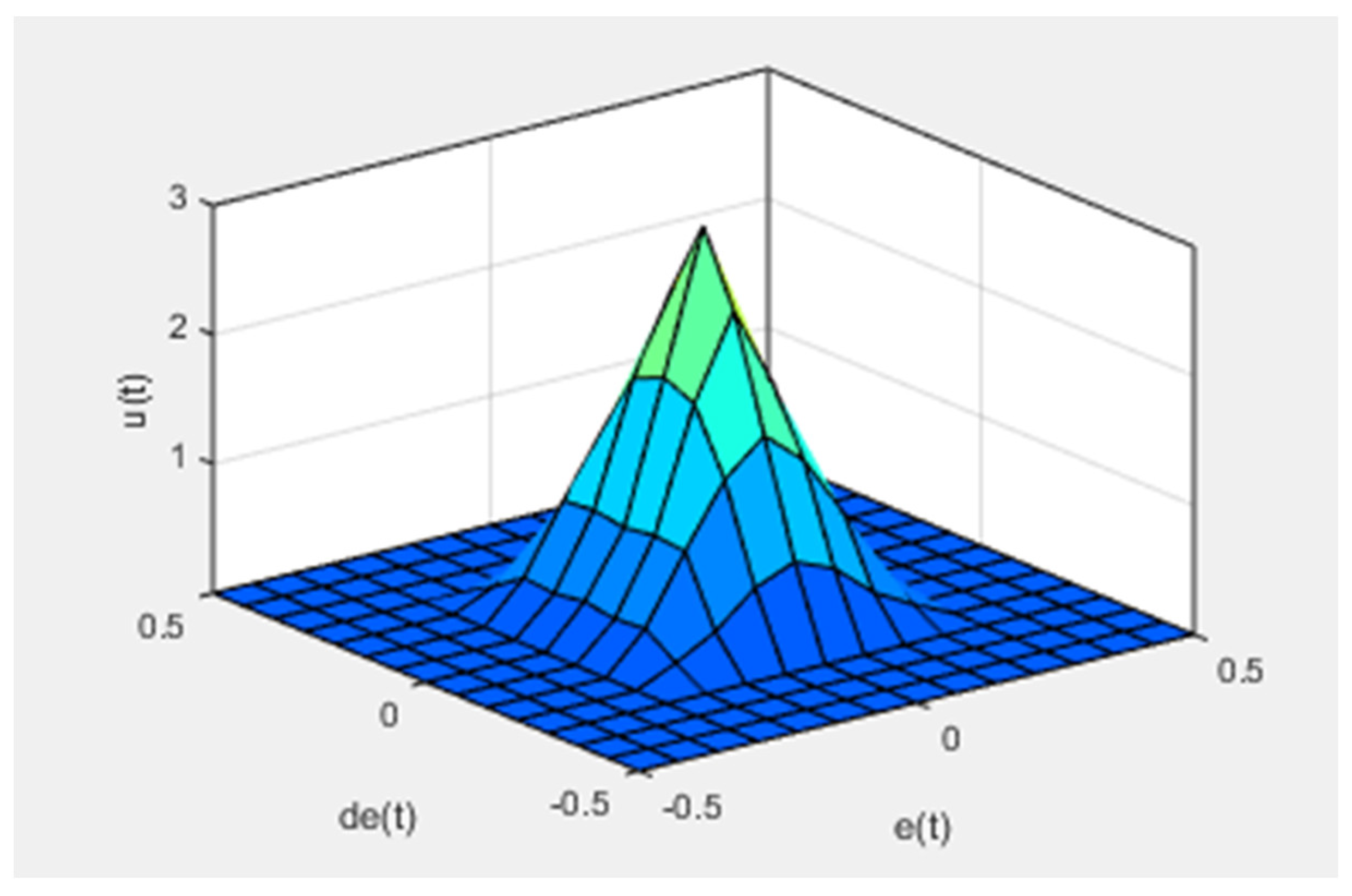

2.4.2. Fuzzy Control

- ∘

- It does not require knowledge of the mathematical model of the plant to be controlled.

- ∘

- The control output is generated by inference of the input signals based on the membership functions defined for each variable, establishing its form and respective universe of discourse.

- ∘

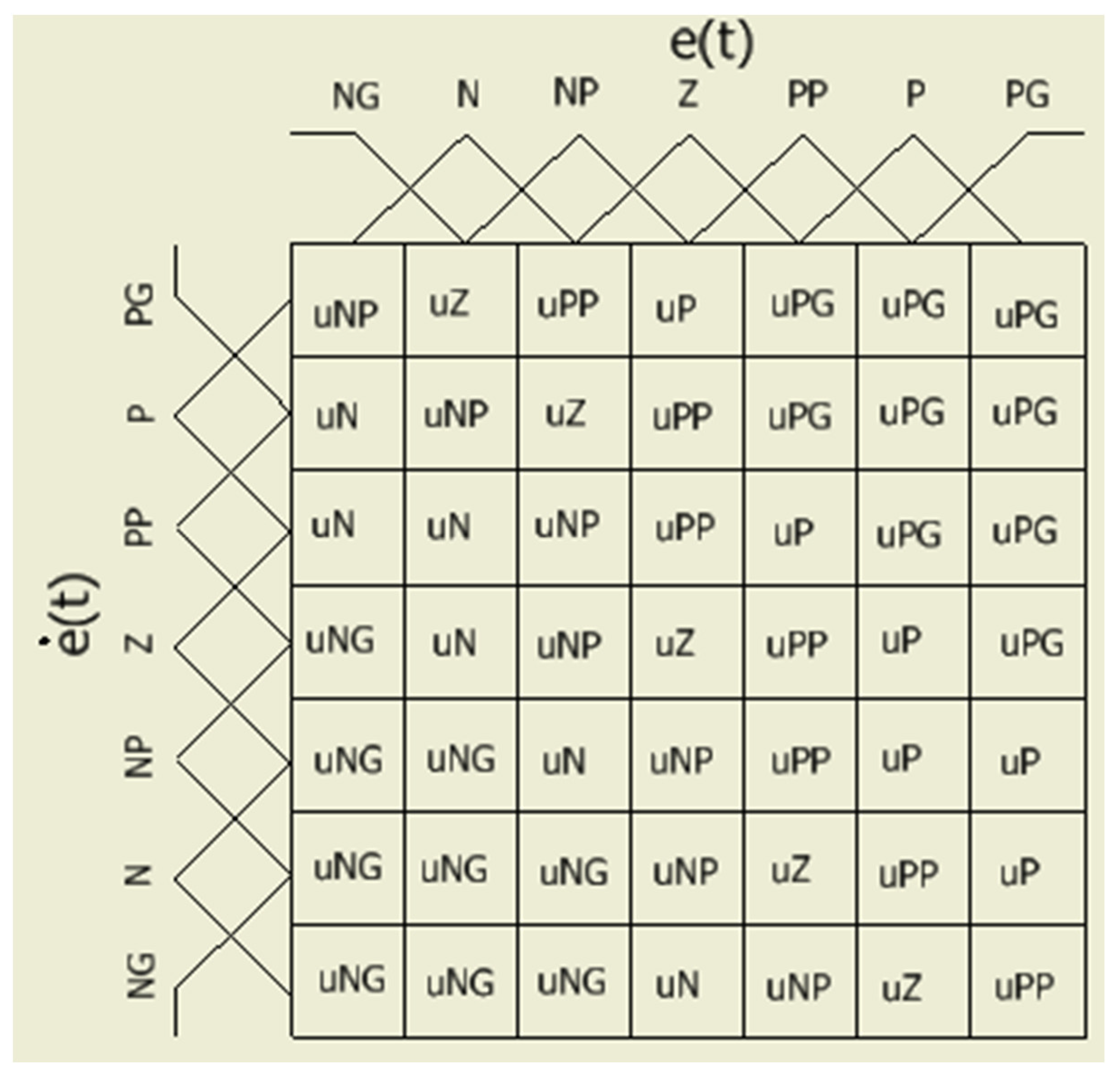

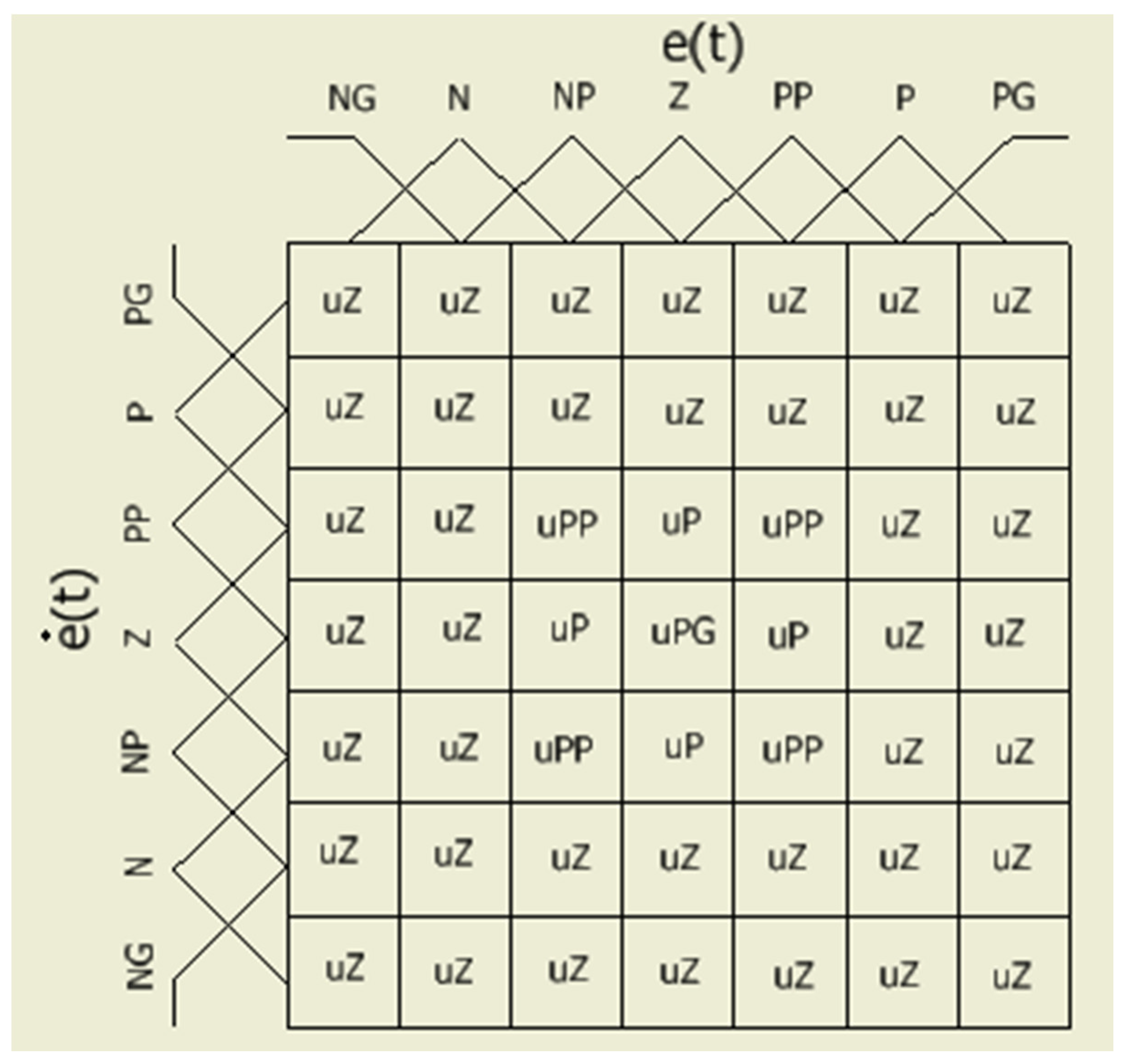

- The inference is developed through a rules table of query and decision.

- For the output of the proportional–derivative action when the error signal and the error derivative are close to zero, the rule can be stated as: IF e(t) is “Z” AND is “Z” THEN u(t) is “uZ.” The same situation for the output of the integrative action can be stated as: IF e(t) is “Z” AND is “Z” THEN u(t) is “uPG.” In this case, the idea is that the integrative action is in charge of outputting the required control signal that maintains the tracking error near zero.

- If a small positive error is now considered with a small negative error derivative, a small positive action would be required at the output of the proportional–derivative action and this rule can be stated as: IF e(t) is “PP” AND is “NP” THEN u(t) is “uPP.”

- If again, a small positive error is considered, but now a small positive error derivative is present, then the output of the proportional-derivative action must be reinforced, and this can be stated as: IF e(t) is “PP” AND is “PP” THEN u(t) is “uP.”

3. Results

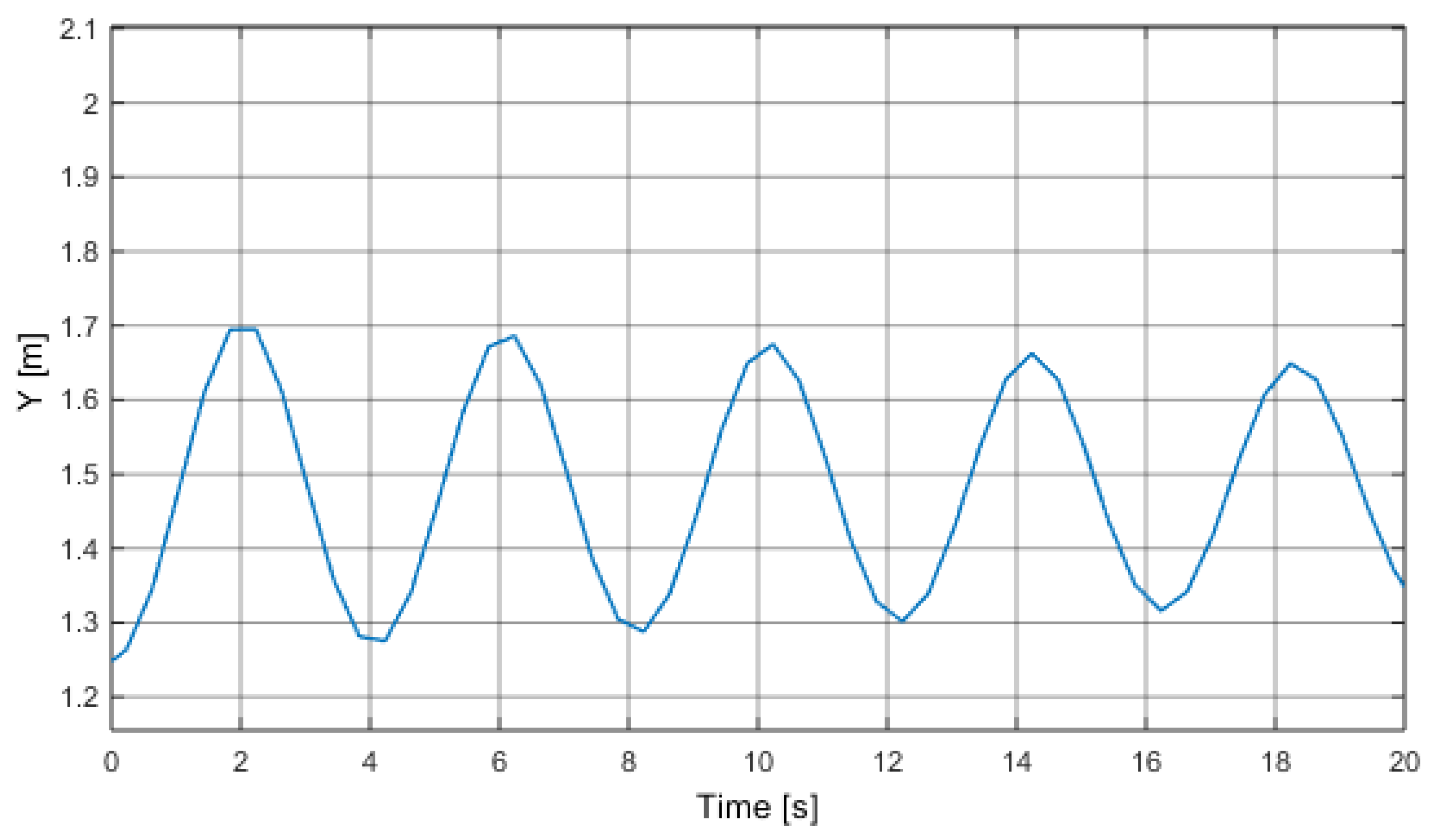

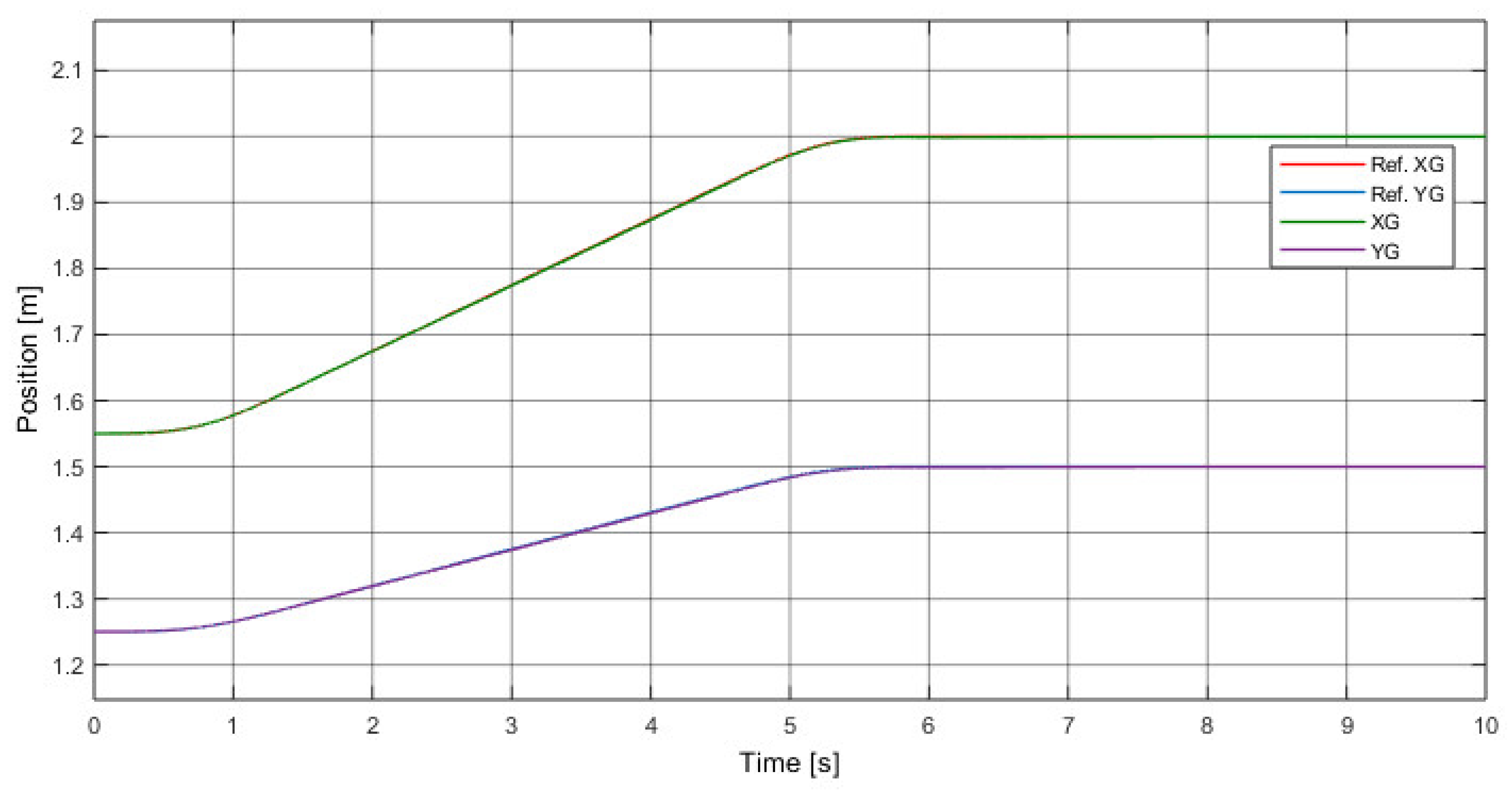

3.1. Simulation Results for a Control Structure Based on PID Controllers

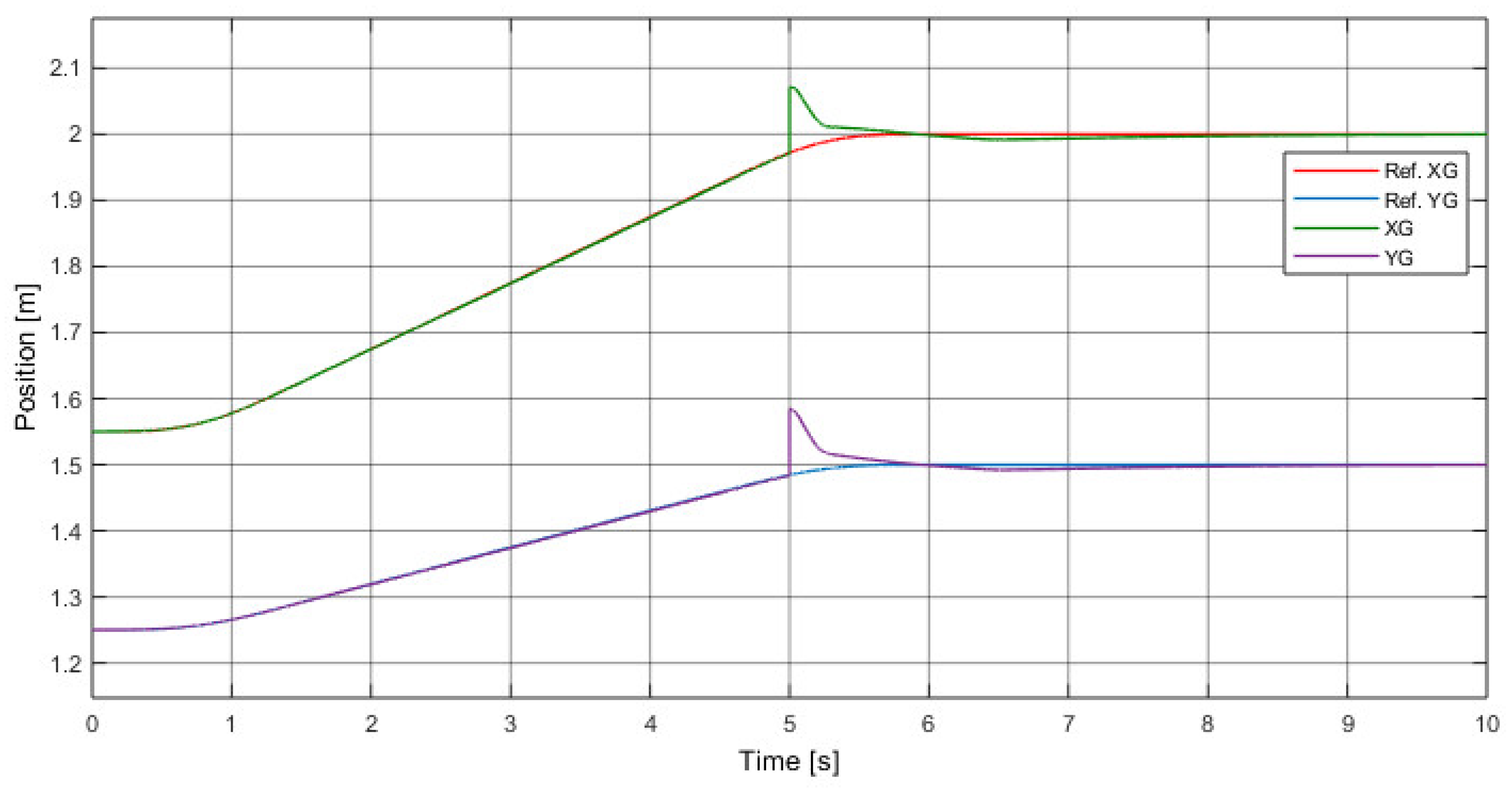

3.2. Simulation Results for Control Structure Based on Fuzzy-PID Controllers

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, H.; Tang, X.; Cui, Z.; Hou, S. Dynamic Response of Spatial Flexible Structures Subjected to Controllable Force Based on Cable-Driven Parallel Robots. IEEE/ASME Trans. Mechatron. 2020, 25, 2801–2811. [Google Scholar] [CrossRef]

- Zhang, B.; Shang, W.; Cong, S.; Li, Z. Coordinated Dynamic Control in the Task Space for Redundantly Actuated Cable-Driven Parallel Robots. IEEE/ASME Trans. Mechatron. 2020. [Google Scholar] [CrossRef]

- Picard, E.; Caro, S.; Franck, P.; Claveau, F. Control Solution for a Cable-Driven Parallel Robot with Highly Variable Payload. Mech. Robot. Conf. 2018, 5B, 26–29. [Google Scholar]

- Tho, T.P.; Thinh, N.T. Using a Cable-Driven Parallel Robot with Applications in 3D Concrete Printing. Appl. Sci. 2021, 11, 563. [Google Scholar] [CrossRef]

- Gosselin, C. Cable-driven parallel mechanisms: State of the art and perspectives. Mech. Eng. Rev. 2014, 1, DSM0004. [Google Scholar] [CrossRef]

- Merlet, J.; Papegay, Y.; Gasc, N. The Prince’s tears, a large cable-driven parallel robot for an artistic exhibition. In Proceedings of the IEEE International Conference on Robotics and Automation, Paris, France, 31 May–31 August 2020; pp. 10378–10383. [Google Scholar]

- Jung, J. Workspace and Stiffness Analysis of 3D Printing Cable-Driven Parallel Robot with a Retractable Beam-Type End-Effector. Robotics 2020, 9, 65. [Google Scholar] [CrossRef]

- Chen, Y.; Shao, L.; Liu, S.; Zhang, Y.; Wang, H. Adaptative Fuzzy Control for a Class of Nonlinear Time-Delay Systems. In Proceedings of the IEEE Data Driven Control Learn. Syst. Conf. (DDCLS), Cairo, Egypt, 14–16 December 2020; pp. 1125–1130. [Google Scholar]

- Ma, X.-J.; Sun, Z.-Q.; He, Y.-T. Analysis and design of fuzzy controller and fuzzy observer. IEEE Trans. Fuzzy Syst. 1998, 6, 41–51. [Google Scholar]

- Erenoglu, I.; Eksin, I.; Yesil, E.; Guzelkaya, M. An Intelligent Hybrid Fuzzy PID Controller. In Proceedings of the 20th European Conference on Modelling and Simulation, Bonn, Germany, 28–31 May 2006; pp. 1–5. [Google Scholar] [CrossRef]

- Dewantoro, G.; Kuo, Y. Robust speed-controlled permeant magnet synchronous motor drive using fuzzy logic controller. In Proceedings of the IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), Taipei, Taiwan, 27–30 June 2011; pp. 884–888. [Google Scholar]

- Yunong, Y.; Ha, H.M.; Kim, Y.K.; Lee, J. Balancing and driving Control of a ball robot using fuzzy control. In Proceedings of the International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Goyangi, Korea, 28–30 October 2015; pp. 492–494. [Google Scholar]

- Zabbah, I.; Foolad, S.; Chaharaqran, B.; Mazlooman, R. Design and making the intelligence assistant robot and controlling it by the fuzzy procedure. In Proceedings of the International Conference on Electronics, Computer and Computation (ICECCO), Ankara, Turkey, 7–9 November 2013; pp. 168–171. [Google Scholar]

- Sheikhalr, A.; Fakharian, A.; Adhami, A. Fuzzy adaptative control of omni-directional mobile robot. In Proceedings of the 13th Iranian Conference on Fuzzy Systems (IFSC), Qazvin, Iran, 27–29 August 2013; pp. 1–4. [Google Scholar]

- Ziegler, J.G.; Nichols, N.B. Optimum settings for automatic controllers. Trans. ASME 1942, 64, 759–765. [Google Scholar] [CrossRef]

- Li, J.; Li, Y. Dynamic analysis and PID control for a quadrotor. In Proceedings of the IEEE International Conference on Mechatronics and Automation, Beijing, China, 7–11 August 2011; pp. 573–578. [Google Scholar]

- Kelly, R. A tuning procedure for stable PID control of robot manipulators. Robotica 1995, 13, 141–148. [Google Scholar] [CrossRef]

- Cervantes, I.; Alvarez, J. On the PID tracking control of robot manipulators. Syst. Control Lett. 2001, 42, 37–46. [Google Scholar] [CrossRef]

- Lumelsky, V. Effect of kinematics on motion planning for planar robot arms moving amidst unknown obstacles. IEEE J. Robot. Autom. 1987, 3, 207–223. [Google Scholar] [CrossRef]

- Kim, J.; Jin, M.; Park, S.; Chung, S.; Hwang, M. Task Space Trajectory Planning for Robot Manipulators to Follow 3-D Curved Contours. Electronics 2020, 9, 1424. [Google Scholar] [CrossRef]

- Barroso, A.; Saltaren, R.; Portilla, G.; Cely, J.; Carpio, M. Smooth Path Planner for Dynamic Simulators Based on Cable-Driven Parallel Robots. In Proceedings of the International Conference on Smart Systems and Technologies (SST), Osijek, Croatia, 10–12 December 2018; pp. 145–150. [Google Scholar]

- Max, H. Cable Structures, 1st ed.; The MIT Press: Cambridge, MA, USA, 1981; pp. 2–255. [Google Scholar]

- Taghirad, H. Parallel Robots: Mechanics and Control, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 1–533. [Google Scholar]

- Merlet, J. Parallel Robots, 2nd ed.; Springer: Paris, France, 2006; pp. 4–320. [Google Scholar]

- Macfarlane, S.; Elizabeth, A. Jerk-Bounded Manipulator Trajectory Planning: Design for Real-Time Applications. Trans. Robot. Autom. 2003, 19, 42–51. [Google Scholar] [CrossRef]

- Kaur, A.; Kaur, A. Comparison of Mamdani-Type and Sugeno-Type Fuzzy Inference Systems for Air Conditioning System. Int. J. Soft Comput. Eng. (IJSCE) 2012, 2, 323–325. [Google Scholar]

- Carpio, M.; Orozco, W.; Betancur, M. Design and Simulation of a Fuzzy Controller for Vertical Take off and Landing (VTOL) Systems. In Proceedings of the International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 9–16 November 2016. [Google Scholar]

- Ponce, P. Artificial Intelligence with Applications to Engineering, 1st ed.; Alfaomega: Mexico City, Mexico, 2010; pp. 72–75. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carpio, M.; Saltaren, R.; Viola, J.; Calderon, C.; Guerra, J. Proposal of a Decoupled Structure of Fuzzy-PID Controllers Applied to the Position Control in a Planar CDPR. Electronics 2021, 10, 745. https://doi.org/10.3390/electronics10060745

Carpio M, Saltaren R, Viola J, Calderon C, Guerra J. Proposal of a Decoupled Structure of Fuzzy-PID Controllers Applied to the Position Control in a Planar CDPR. Electronics. 2021; 10(6):745. https://doi.org/10.3390/electronics10060745

Chicago/Turabian StyleCarpio, Marco, Roque Saltaren, Julio Viola, Cristian Calderon, and Juan Guerra. 2021. "Proposal of a Decoupled Structure of Fuzzy-PID Controllers Applied to the Position Control in a Planar CDPR" Electronics 10, no. 6: 745. https://doi.org/10.3390/electronics10060745

APA StyleCarpio, M., Saltaren, R., Viola, J., Calderon, C., & Guerra, J. (2021). Proposal of a Decoupled Structure of Fuzzy-PID Controllers Applied to the Position Control in a Planar CDPR. Electronics, 10(6), 745. https://doi.org/10.3390/electronics10060745