Novel Practical Life Cycle Prediction Method by Entropy Estimation of Li-Ion Battery

Abstract

1. Introduction

2. Suggestion of a Model for Predicting Battery Lifetime

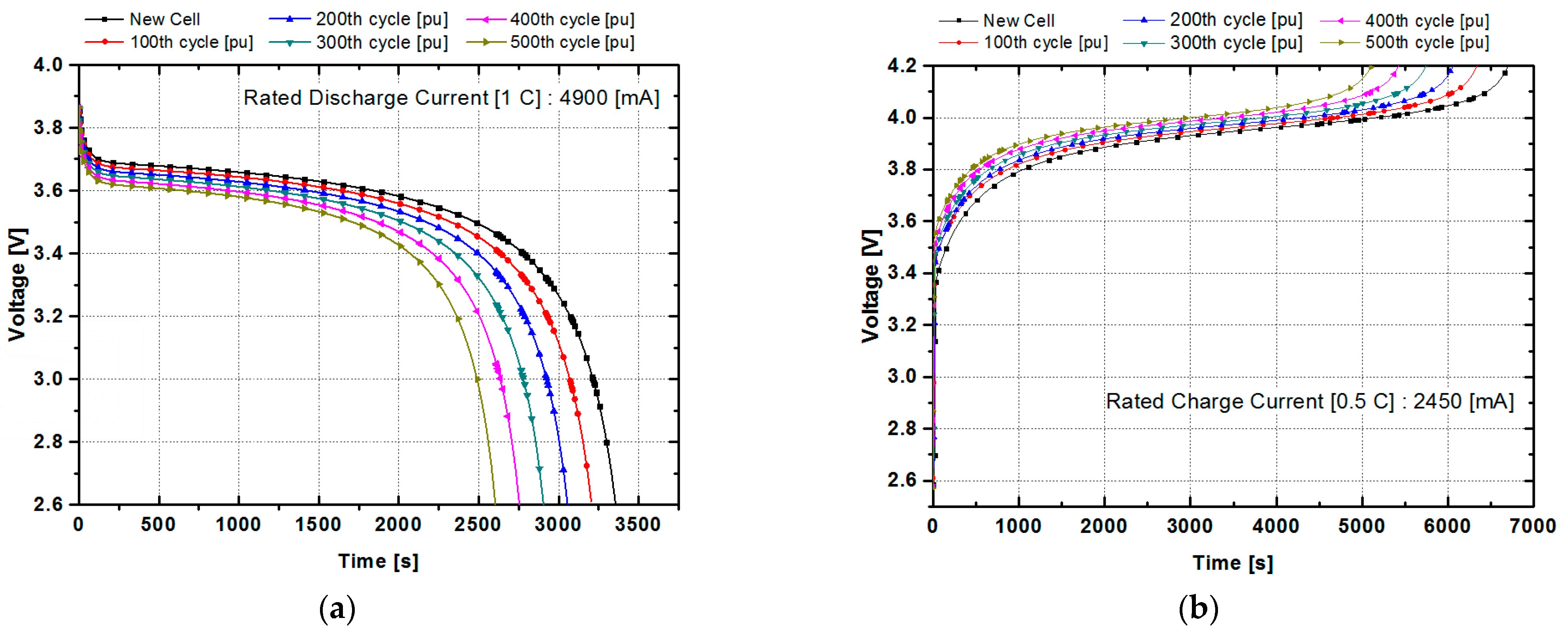

2.1. The Charging-Discharging Characteristics of Li-Ion Batteries

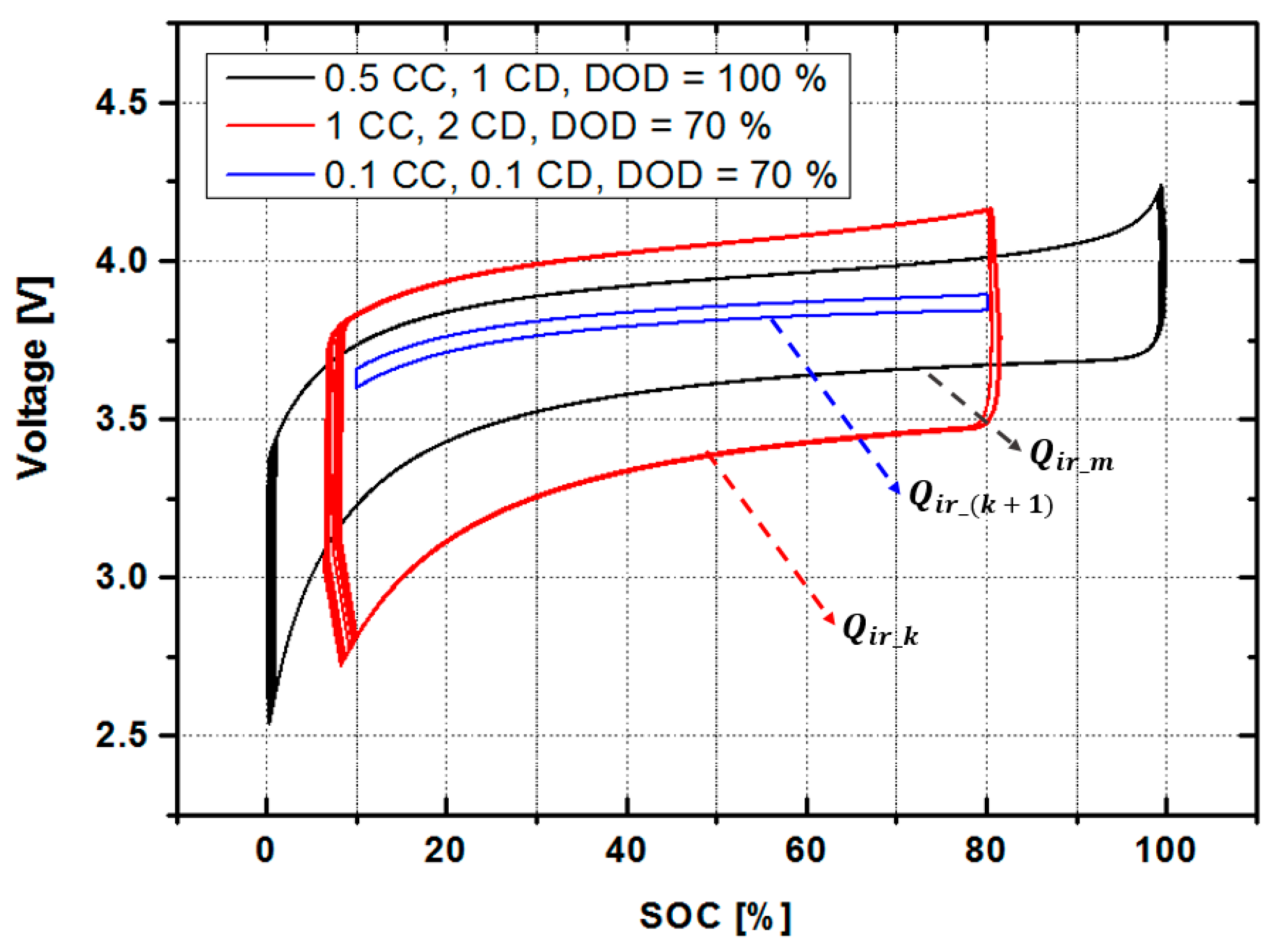

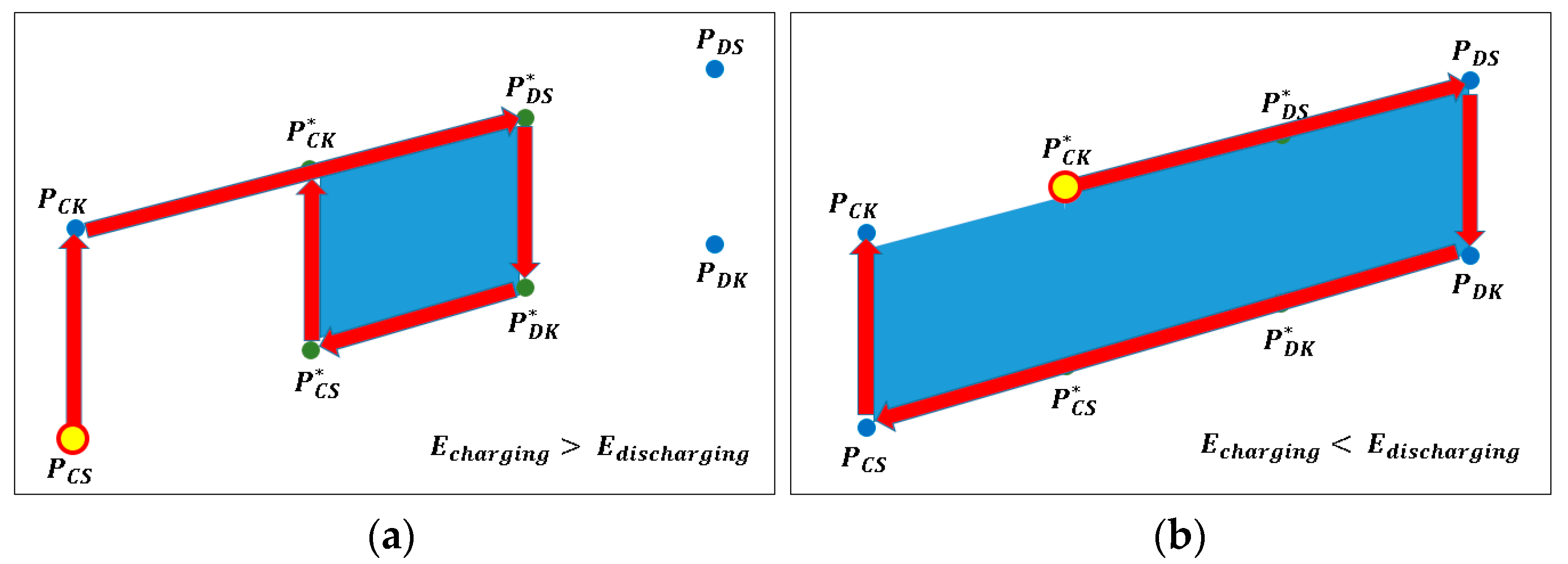

2.2. The Mathematical Model for Suggested Life Cycle Prediction

3. Experiments and Discussion

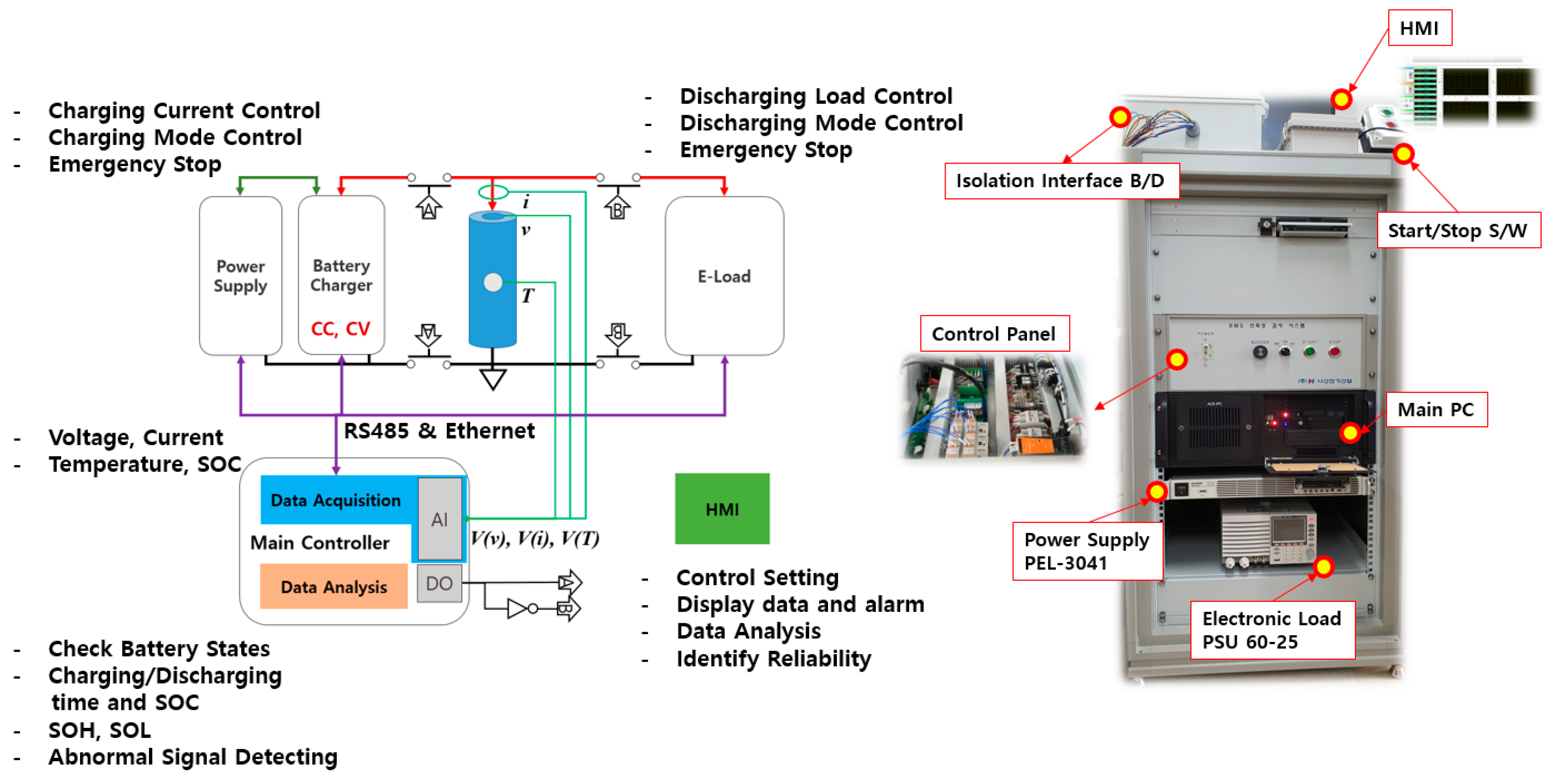

3.1. Configuration of Test System

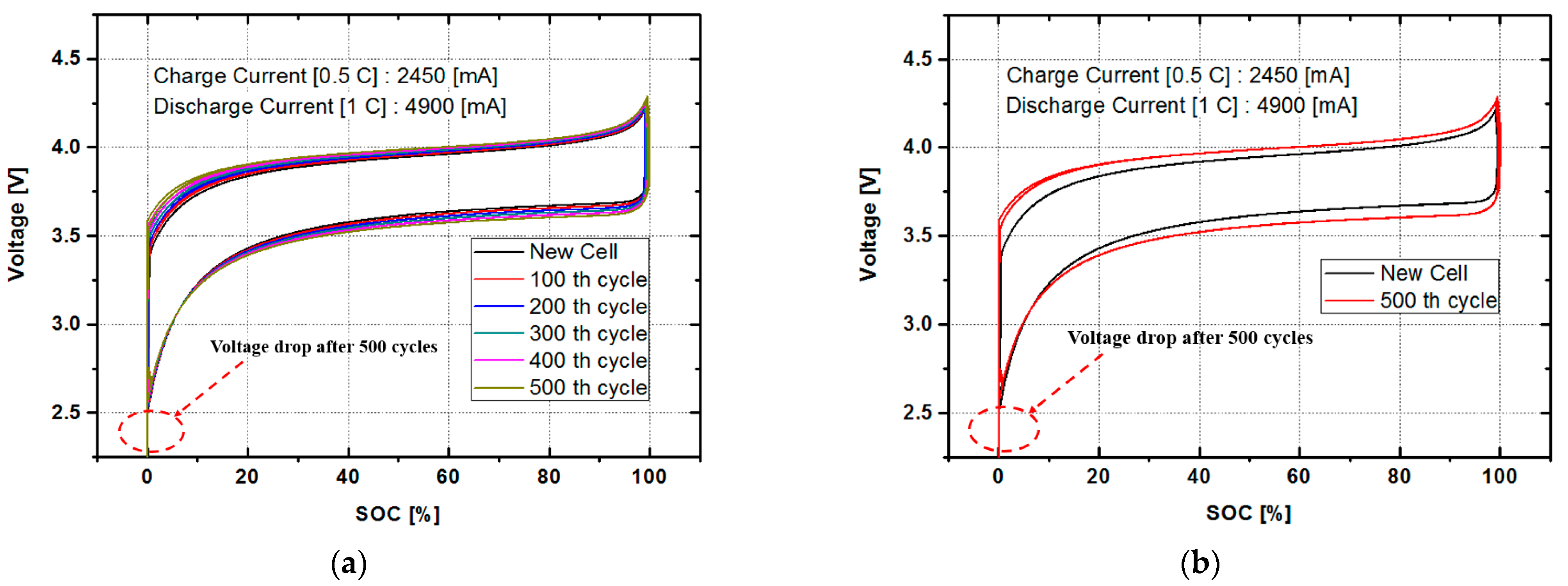

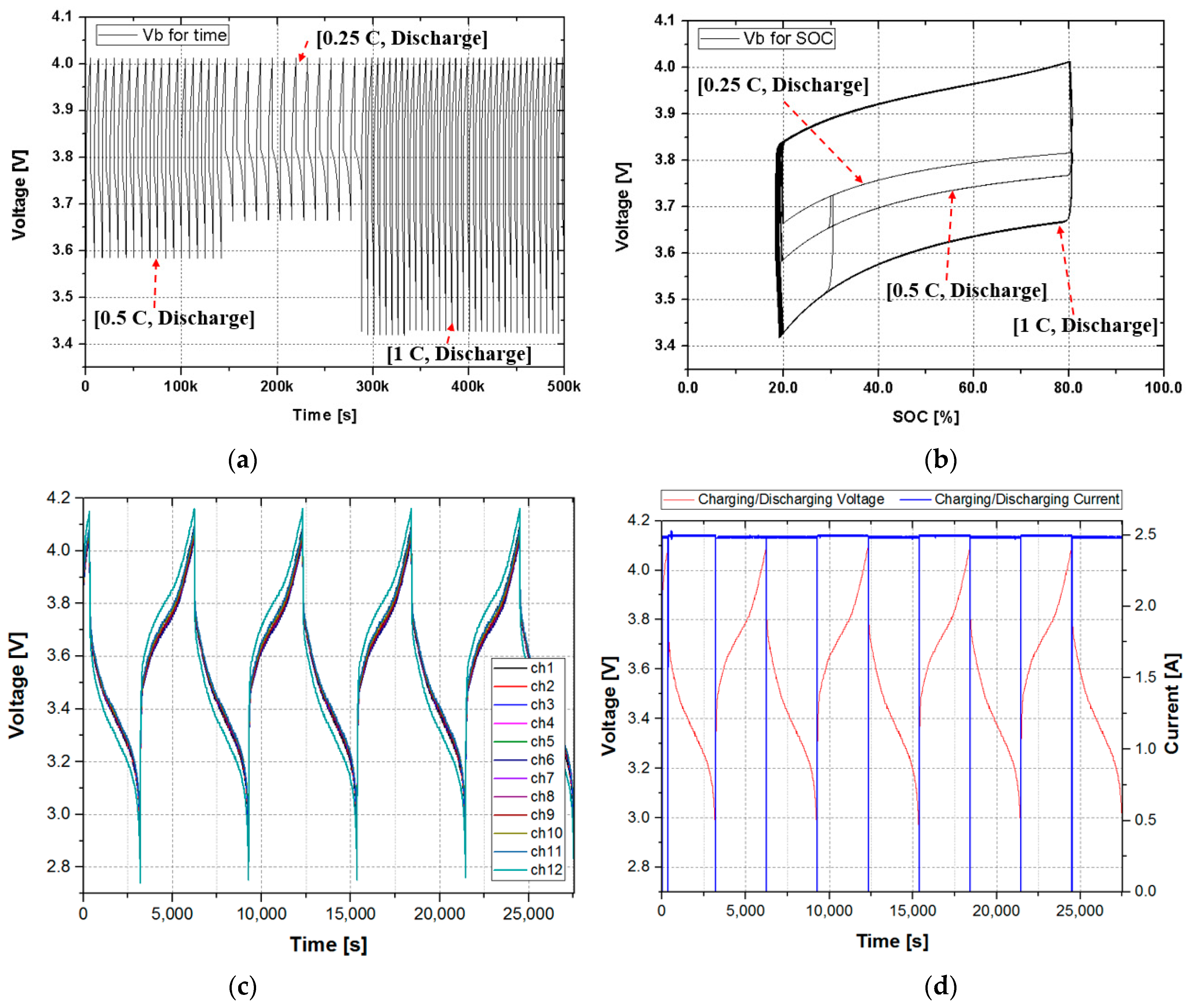

3.2. Characteristic Test of Li-Ion Batteries

3.3. Signal Processing Strategy

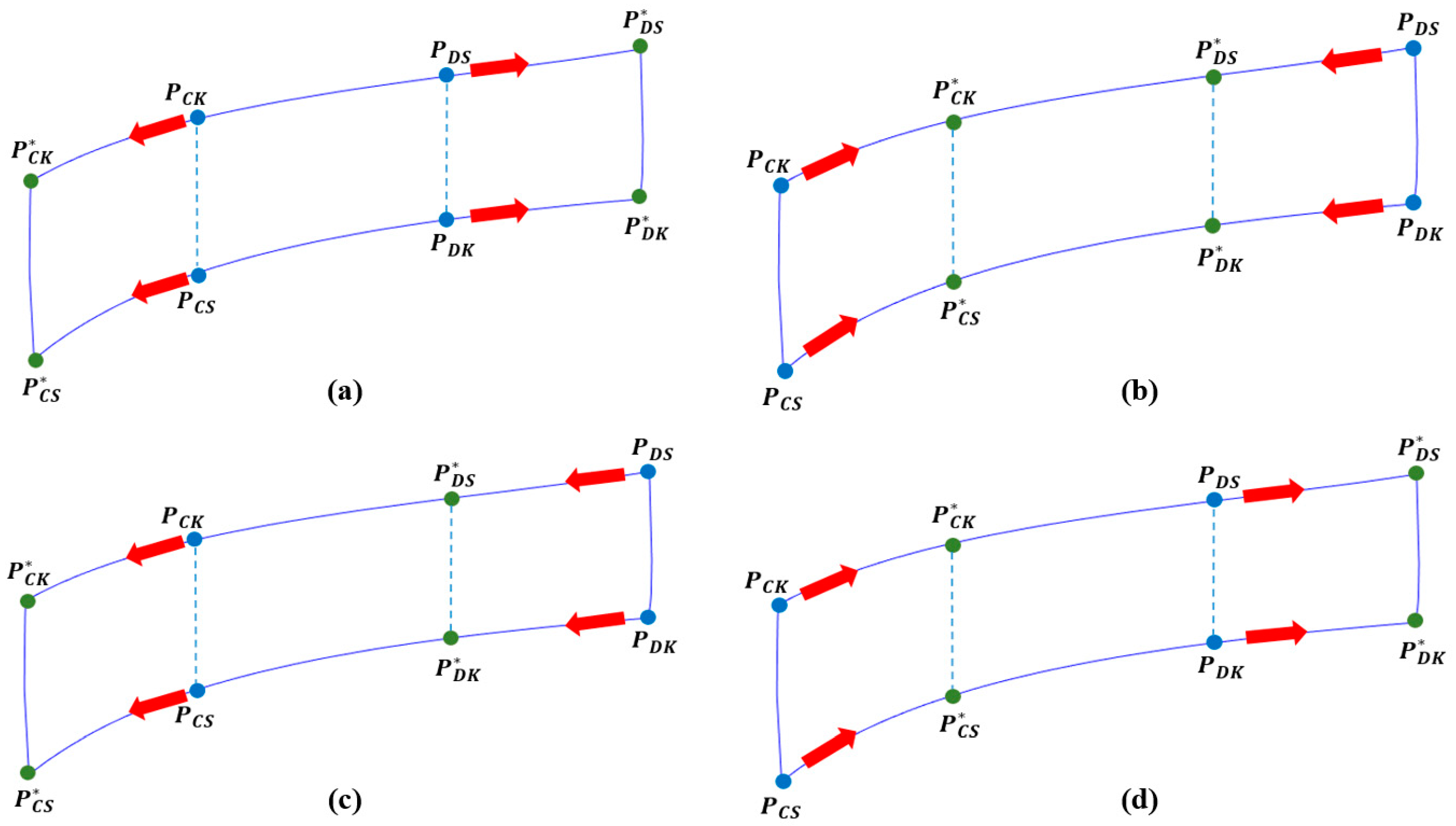

3.3.1. Point Detection Method (PDM)

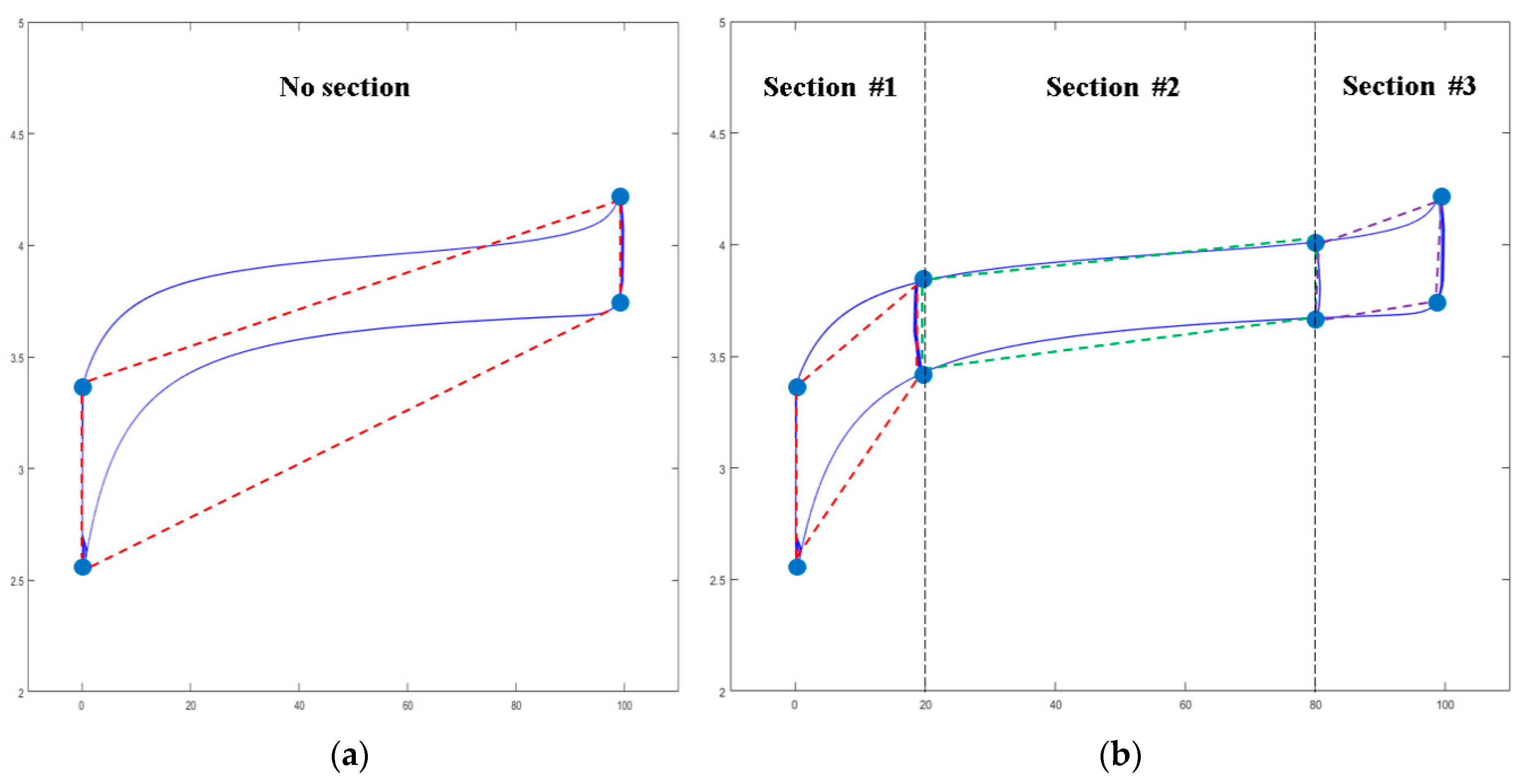

3.3.2. Section Separation Method (SSM)

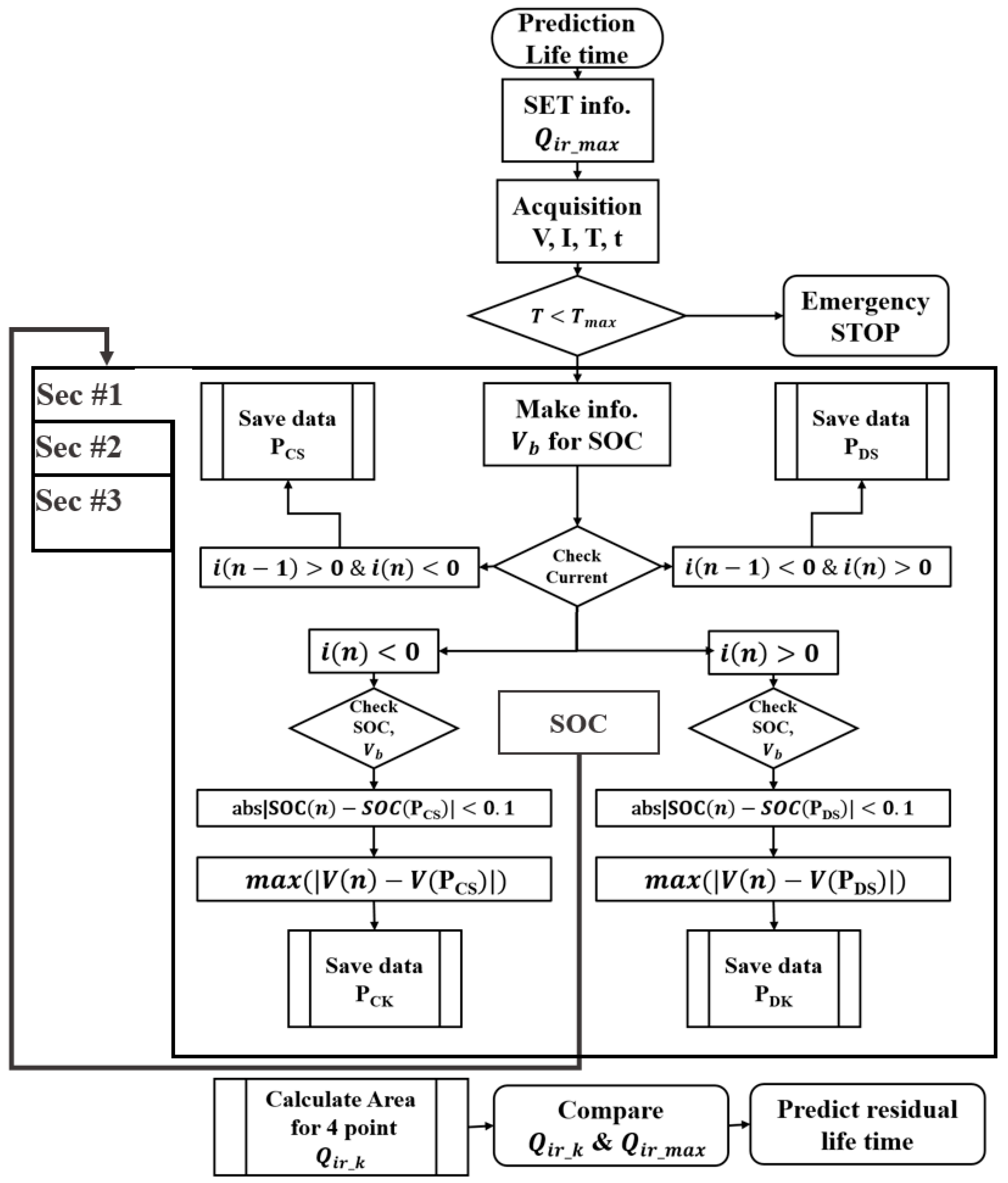

3.3.3. Algorithm

4. Results and Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| nonlinear battery voltage, V | Arrhenius rate constant for | ||

| constant voltage, V | open circuit voltage, V | ||

| internal resistance, | irreversible heat energy, , | ||

| polarization constant, | reversible heat energy, , | ||

| maximum battery capacity, Ah | heat energy of connect tab, | ||

| battery current, A | anode tab resistance, | ||

| low frequency filtered current, A | cathode tab resistance, | ||

| exponential voltage, V | current battery capacity, Ah | ||

| exponential zone time constant, | maximum cycle period at | ||

| nominal ambient temperature, K | maximum irreversible energy for 1 cycle | ||

| cell internal temperature, K | current irreversible energy for 1 cycle | ||

| ambient temperature, K | actual cycle time | ||

| Arrhenius rate constant for | predicted cycle time |

References

- Barre, A.; Deguilhem, B.; Grolleau, S.; Gerard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Doh, C.-H.; Ha, Y.-C.; Eom, S.-W. Entropy measurement of a large format lithium ion battery and its application to calculate heat generation. Electrochim. Acta 2019, 309, 382–391. [Google Scholar] [CrossRef]

- Schlueter, S.; Genieser, R.; Richards, D.; Hoster, H.E.E.; Mercer, M.P. Quantifying structure dependent responses in Li-ion cells with excess Li spinel cathodes: Matching voltage and entropy profiles through mean field models. Phys. Chem. Chem. Phys. 2018, 20, 21417–21429. [Google Scholar] [CrossRef]

- Viswanathan, V.V.; Choi, D.; Wang, D.; Xu, W.; Towne, S.; Williford, R.E.; Zhang, J.-G.; Liu, J.; Yang, Z. Effect of entropy change of lithium intercalation in cathodes and anodes on Li-ion battery thermal management. J. Power Sources 2010, 195, 3720–3729. [Google Scholar] [CrossRef]

- Zabala, E.S.; Laserna, E.M.; Berecibar, M.; Gandiaga, I.; Martinez, L.M.R.; Villarreal, I. Realistic lifetime prediction approach for Li-ion batteries. Appl. Energy 2016, 162, 839–852. [Google Scholar] [CrossRef]

- Osara, J.A.; Bryant, M.D. A Thermodynamic Model for Lithium-Ion Battery Degradation: Application of the Degradation-Entropy Generation Theorem. Inventions 2019, 4, 23. [Google Scholar] [CrossRef]

- Rahn, C.D.; Wang, C.-Y. Battery Systems Engineering, 1st ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Cordoba-Arenas, A.; Onori, S.; Guezennec, Y.; Rizzoni, G. Capacity and power fade cycle-life model for plug-in hybrid electric vehicle lithium-ion battery cells containing blended spinel and layered-oxide positive electrodes. J. Power Sources 2015, 278, 473–483. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life Cycle Environmental Assessment of Lithium-Ion and Nickel Metal Hydride Batteries for Plug-In Hybrid and Battery Electric Vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef] [PubMed]

- Sim, S.H.; Gang, J.H.; An, D.; Kim, S.I.; Kim, J.Y.; Choi, J.H. Remaining Useful Life Prediction of Li-Ion Battery Based on Charge Voltage Characteristics. Trans. Korean Soc. Mech. Eng. B 2013, 37, 313–322. [Google Scholar] [CrossRef]

- Gao, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Ma, Z.; Jiang, Y. Lithium-ion battery aging mechanisms and life model under different charging stresses. J. Power Sources 2017, 356, 103–114. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.-Y.; Tang, X. Cycling degradation of an automotive LiFePO4 lithium-ion battery. J. Power Sources 2011, 196, 1513–1520. [Google Scholar] [CrossRef]

- Li, Z.; Huang, J.; Liaw, B.Y.; Metzler, V.; Zhang, J. A review of lithium deposition in lithium-ion and lithium metal secondary batteries. J. Power Sources 2014, 254, 168–182. [Google Scholar] [CrossRef]

- Legrand, N.; Knosp, B.; Desprez, P.; Lapicque, F.; Rael, S. Physical characterization of the charging process of a Li-ion battery and prediction of Li plating by electrochemical modelling. J. Power Sources 2014, 245, 208–216. [Google Scholar] [CrossRef]

- Liu, Y.-H.; Luo, Y.-F. Search for an Optimal Rapid-Charging Pattern for Li-Ion Batteries Using the Taguchi Approach. IEEE Trans. Ind. Electron. 2010, 57, 3963–3971. [Google Scholar] [CrossRef]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.-J.; Del Duce, A.; Simons, A. The environmental performance of current and future passenger vehicles: Life cycle assessment based on a novel scenario analysis framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Blomgren, G.E. The Development and Future of Lithium Ion Batteries. J. Electrochem. Soc. 2016, 164, A5019–A5025. [Google Scholar] [CrossRef]

- Peters, J.F.; Weil, M. Providing a common base for life cycle assessments of Li-Ion batteries. J. Clean. Prod. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Zhu, C.; Li, X.; Song, L.; Xiang, L. Development of a theoretically based thermal model for lithium ion battery pack. J. Power Sources 2013, 223, 155–164. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Standard discharge capacity, mAh | min 4900 | Cycle life capacity at 500 cycles, mAh | |

| Rated discharge capacity, mAh | min 4753 | Initial internal impedance, | 28.0 |

| Charge voltage, V | 4.5 | Calculated internal impedance, | 40.0 |

| Nominal voltage, V | 3.63 | Cell weight, g | 69.0 |

| Max. charge current, mA | 4900 | Cell length, mm | 70.6 |

| Max. cont. discharge current, mA | 9800 | Cell diameter, mm | 21.1 |

| Discharge cut-off, V | 2.5 | Charge method | CC-CV 1 |

| DOD 1 [%] | No Section [%] | 3 Section Separation [%] |

|---|---|---|

| 0–100 | <70 | >89 |

| 10–90 | >88 | >92 |

| 20–80 | >92 | >94 |

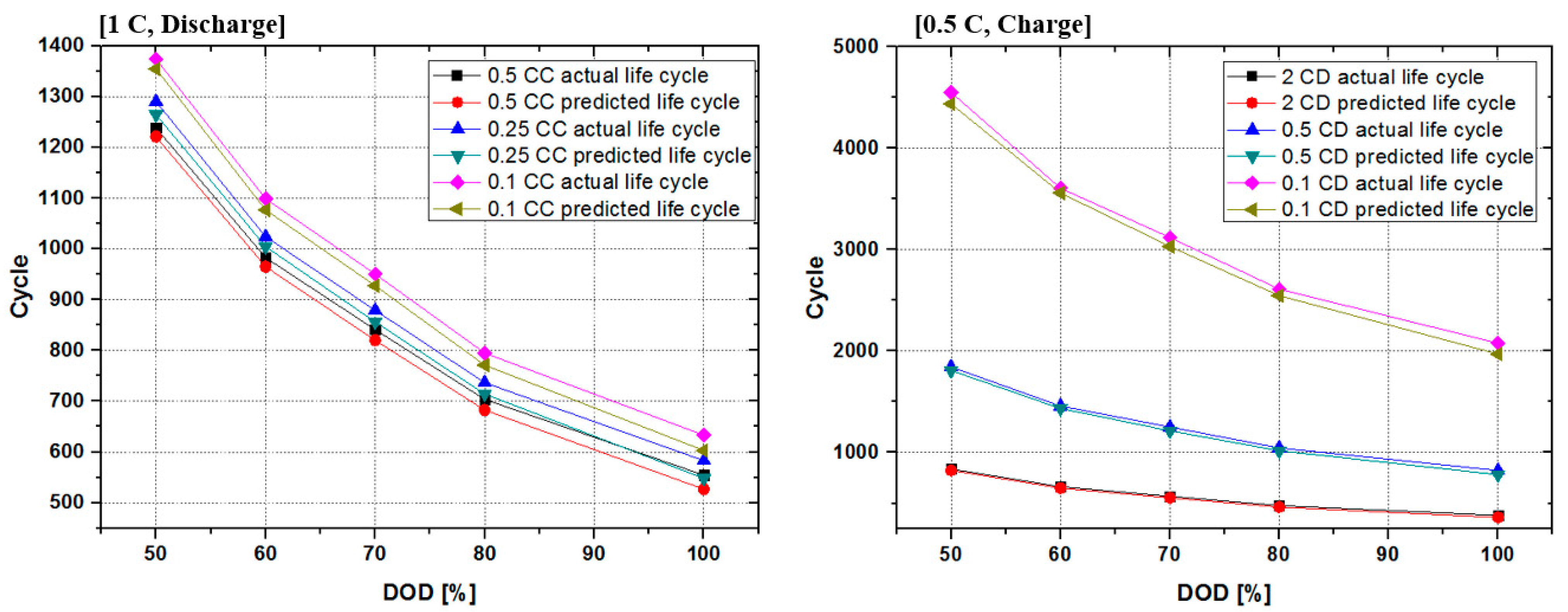

| Charging Current [C] | Discharging Current [C] | DOD [%] | Actual Cycle | Predicted Cycle | Accuracy Rate [%] |

|---|---|---|---|---|---|

| 0.5 | 1 | 100 [0–100] | 554.5 | 510 | 92.0 |

| 0.5 | 1 | 80 [10–90] | 704.0 | 650 | 92.4 |

| 0.5 | 1 | 70 [20–90] | 841.3 | 778 | 92.5 |

| 0.5 | 1 | 60 [20–80] | 983.1 | 918 | 93.4 |

| 0.5 | 1 | 50 [30–80] | 1238.8 | 1172 | 94.6 |

| 0.25 | 1 | 100 [0–100] | 583.1 | 538 | 92.2 |

| 0.25 | 1 | 80 [10–90] | 736.5 | 685 | 93.0 |

| 0.25 | 1 | 70 [20–90] | 879.3 | 815 | 92.7 |

| 0.25 | 1 | 60 [20–80] | 1024.4 | 954 | 93.1 |

| 0.25 | 1 | 50 [30–80] | 1290.8 | 1218 | 94.4 |

| 0.1 | 1 | 100 [0–100] | 633.3 | 585 | 92.3 |

| 0.1 | 1 | 80 [10–90] | 795.3 | 740 | 93.1 |

| 0.1 | 1 | 70 [20–90] | 950.7 | 890 | 93.6 |

| 0.1 | 1 | 60 [20–80] | 1099.3 | 1031 | 93.8 |

| 0.1 | 1 | 50 [30–80] | 1374.4 | 1299 | 94.5 |

| 0.5 | 2 | 100 [0–100] | 381.0 | 350 | 91.8 |

| 0.5 | 2 | 80 [10–90] | 476.4 | 443 | 92.9 |

| 0.5 | 2 | 70 [20–90] | 568.6 | 532 | 93.5 |

| 0.5 | 2 | 60 [20–80] | 663.6 | 622 | 93.8 |

| 0.5 | 2 | 50 [30–80] | 837.4 | 787 | 94.0 |

| 0.5 | 0.5 | 100 [0–100] | 822.7 | 765 | 93.0 |

| 0.5 | 0.5 | 80 [10–90] | 1045.2 | 979 | 93.7 |

| 0.5 | 0.5 | 70 [20–90] | 1251.6 | 1175 | 93.9 |

| 0.5 | 0.5 | 60 [20–80] | 1459.6 | 1376 | 94.3 |

| 0.5 | 0.5 | 50 [30–80] | 1843.9 | 1744 | 94.6 |

| 0.5 | 0.1 | 100 [0–100] | 2078.5 | 1933 | 93.0 |

| 0.5 | 0.1 | 80 [10–90] | 2612.8 | 2453 | 93.9 |

| 0.5 | 0.1 | 70 [20–90] | 3120.3 | 2936 | 94.1 |

| 0.5 | 0.1 | 60 [20–80] | 3607.9 | 3406 | 94.4 |

| 0.5 | 0.1 | 50 [30–80] | 4553.7 | 4308 | 94.6 |

| 1 | 2 | 100 [0–100] | 366.8 | 336 | 91.6 |

| 1 | 2 | 80 [10–90] | 452.3 | 418 | 92.4 |

| 1 | 2 | 70 [20–90] | 548.7 | 510 | 92.9 |

| 1 | 2 | 60 [20–80] | 640.9 | 597 | 93.1 |

| 1 | 2 | 50 [30–80] | 810.4 | 756 | 93.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-K.; Moon, S.-C. Novel Practical Life Cycle Prediction Method by Entropy Estimation of Li-Ion Battery. Electronics 2021, 10, 487. https://doi.org/10.3390/electronics10040487

Kim T-K, Moon S-C. Novel Practical Life Cycle Prediction Method by Entropy Estimation of Li-Ion Battery. Electronics. 2021; 10(4):487. https://doi.org/10.3390/electronics10040487

Chicago/Turabian StyleKim, Tae-Kue, and Sung-Chun Moon. 2021. "Novel Practical Life Cycle Prediction Method by Entropy Estimation of Li-Ion Battery" Electronics 10, no. 4: 487. https://doi.org/10.3390/electronics10040487

APA StyleKim, T.-K., & Moon, S.-C. (2021). Novel Practical Life Cycle Prediction Method by Entropy Estimation of Li-Ion Battery. Electronics, 10(4), 487. https://doi.org/10.3390/electronics10040487