Modeling and Electrical Characterization of a Bilayer Pt/AlN/Sapphire One Port Resonator for Sensor Applications

Abstract

1. Introduction

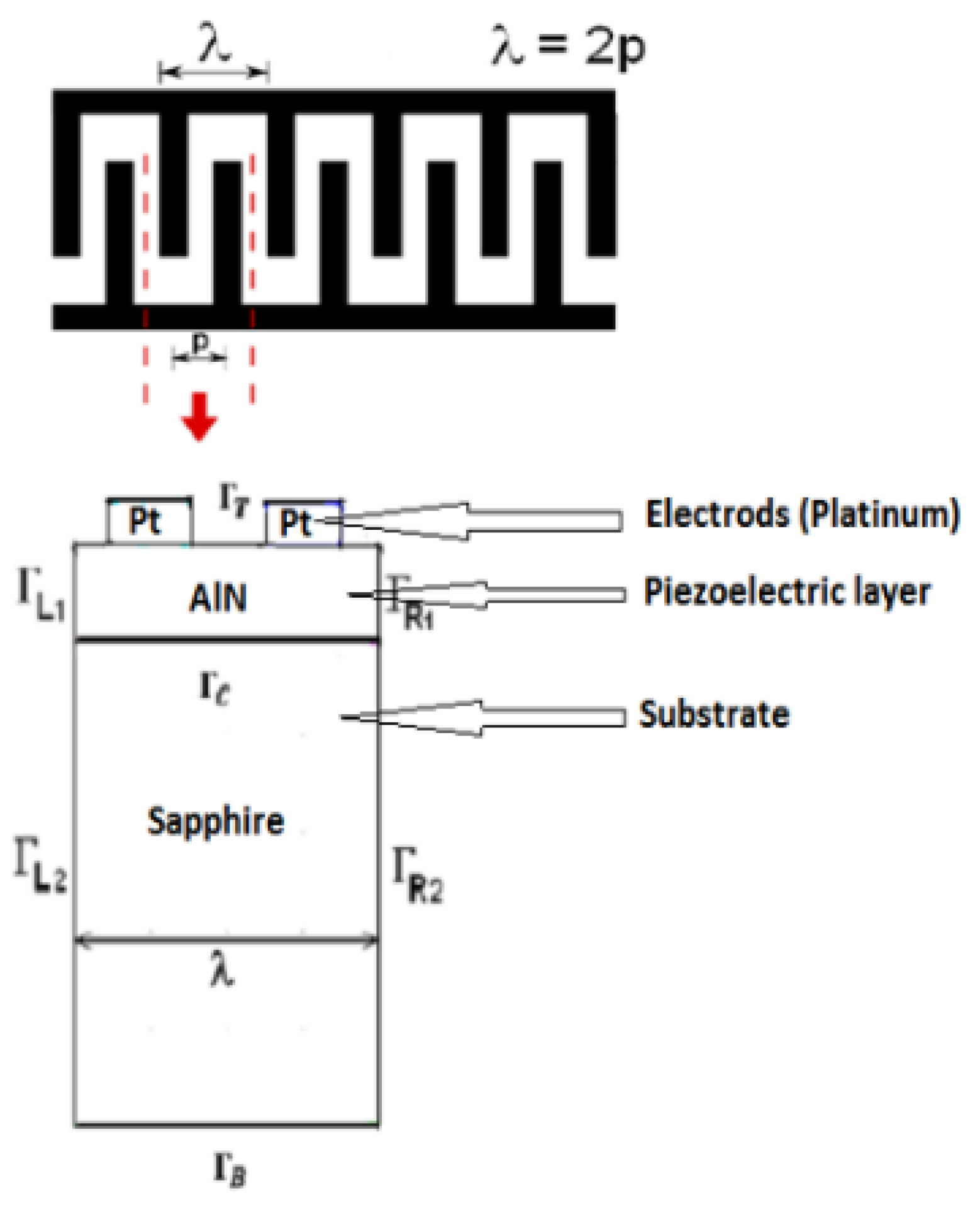

2. Mathematical Model, Device Geometry, and Materials Properties

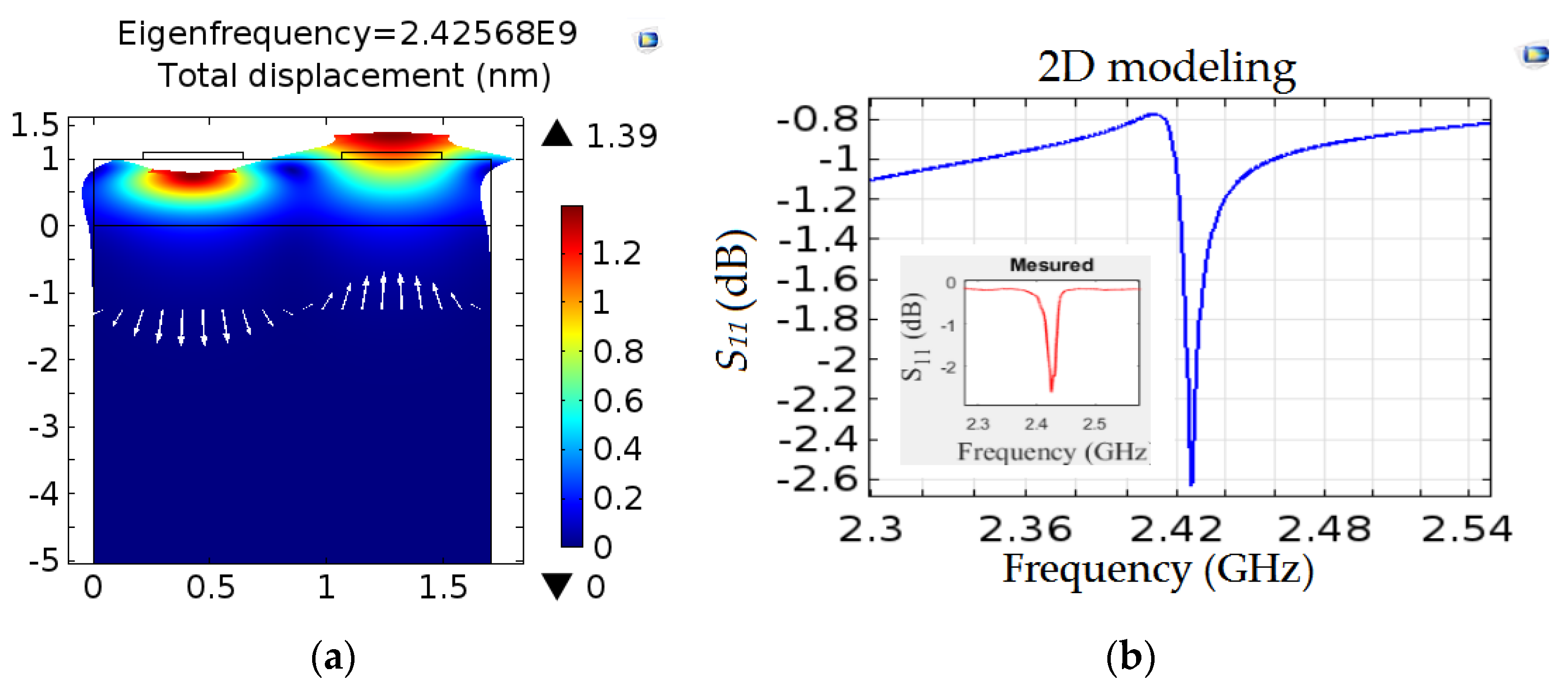

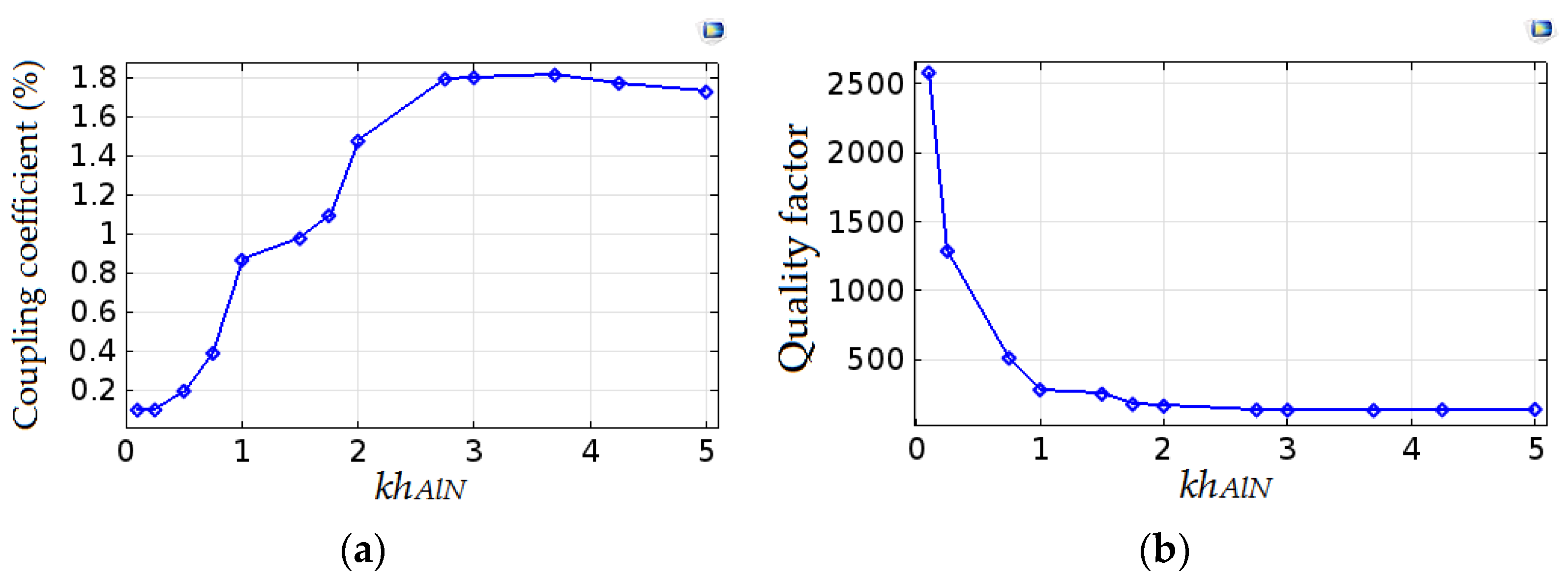

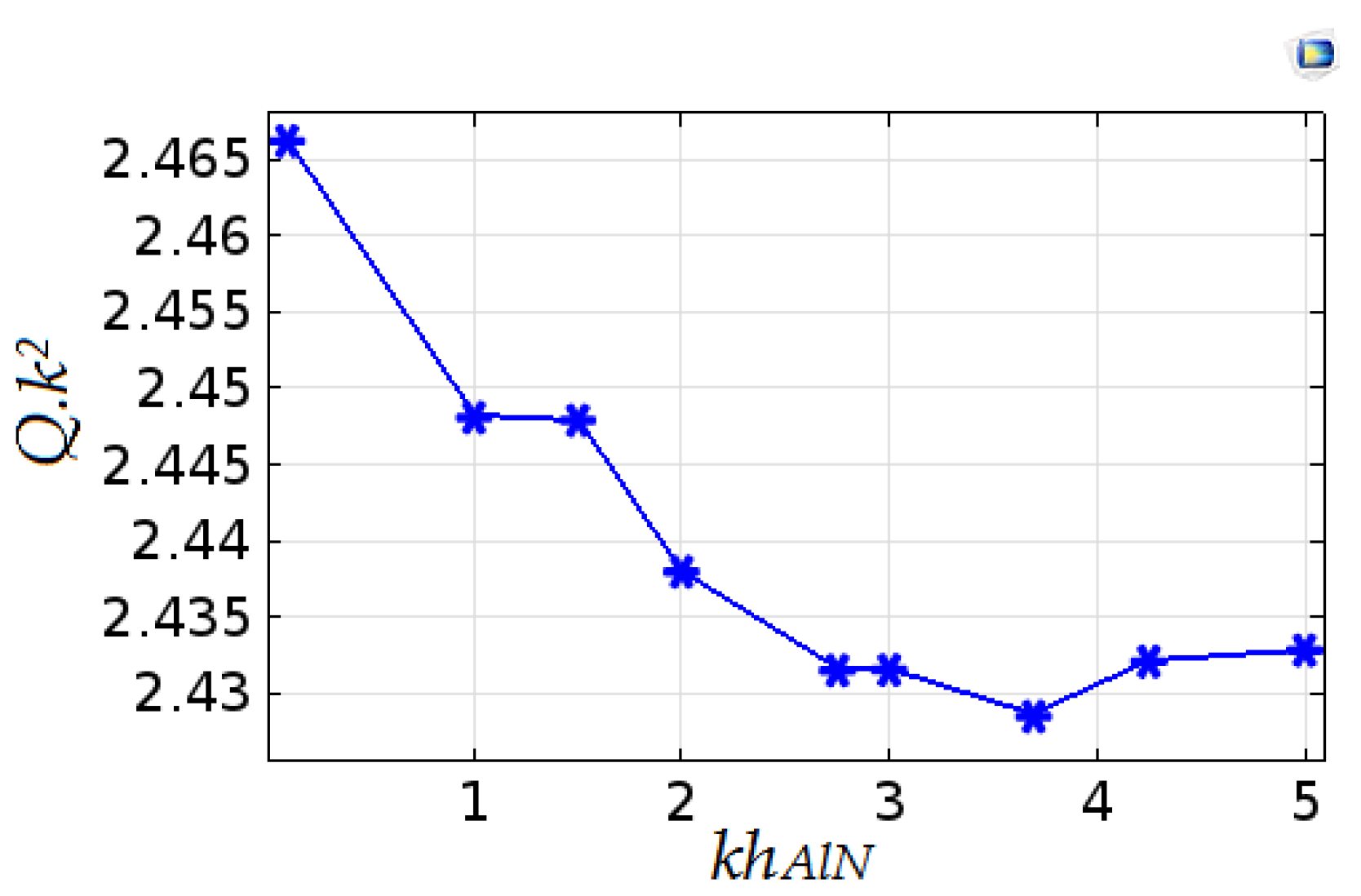

2.1. Mathematical Model

2.2. Device Geometry

2.3. Materials Properties

3. Experimental Aspects

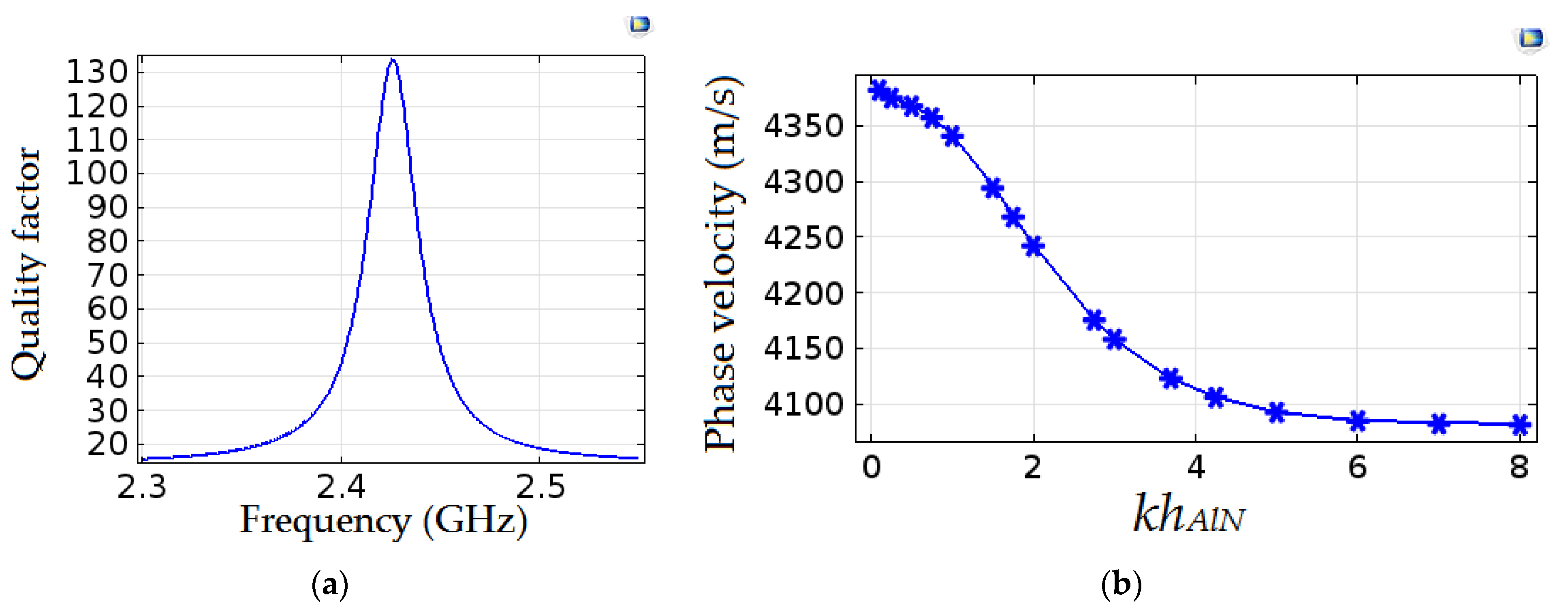

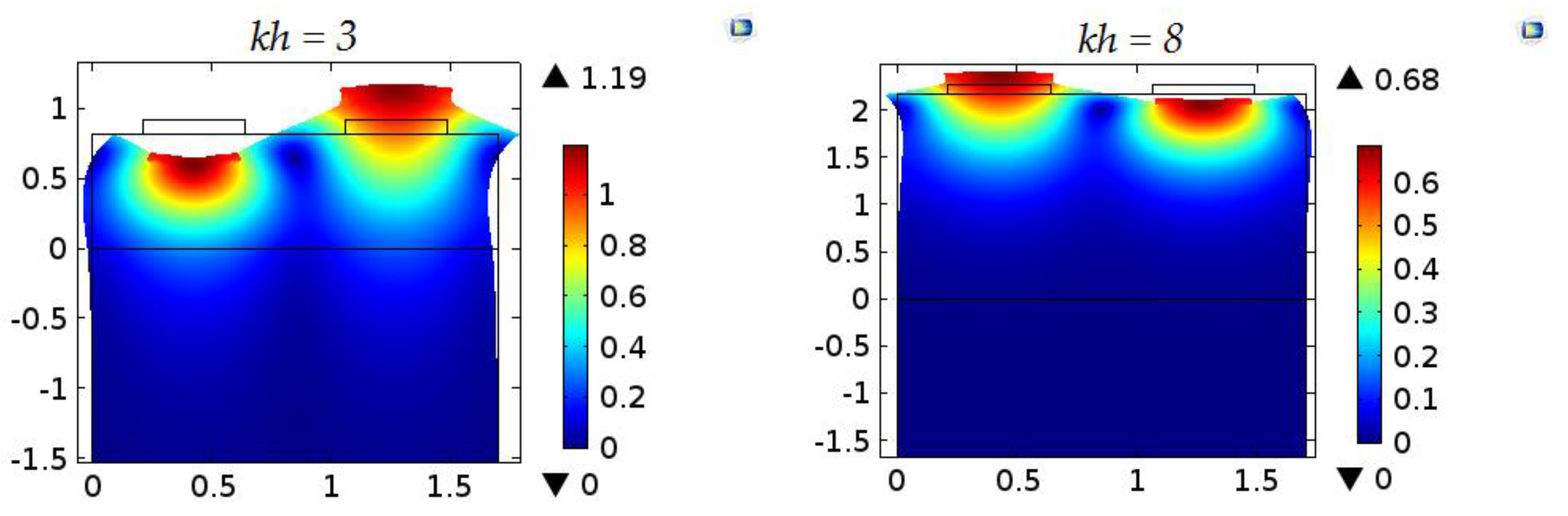

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morgan, D. Surface Acoustic Wave Filters with Applications to Electronic Communications and Signal Processing; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Shigematsu, T.; Kurosawa, M.K.; Asai, K. Nanometer stepping drives of surface acoustic wave motor. IEEE Trans. Ultrason. Ferroelectronics Freq. Control 2003, 50, 376–385. [Google Scholar] [CrossRef] [PubMed]

- Bell, D.L.T.; Li, R.C.M. Surface acoustic wave resonator. Proc. IEEE 1976, 64, 711–721. [Google Scholar] [CrossRef]

- Lange, K.; Rapp, B.E.; Rapp, M. Surface acoustic wave biosensors: A review. Anal. Bioanal. Chem. 2008, 391, 1509–1519. [Google Scholar] [CrossRef] [PubMed]

- Hoang, T.; Rey, P.; Vaudaine, M.-H.; Robert, P.; Benech, P. Effect of Mo layer on performance of AlN/Si SAW filter. In Proceedings of the IEEE International Frequency Control Symposium, Honolulu, HI, USA, 19–21 May 2008. [Google Scholar]

- Wittstruck, R.H.; Emanetoglu, N.W.; Lu, Y. Properties of transducers and substrates for high frequency resonators and sensors. J. Acoust. Soc. Am. 2005, 118, 1414–1423. [Google Scholar] [CrossRef]

- Zhang, B.; Zaghloul, M.E. Improved surface acoustic wave filter design with low insertion loss. In Proceedings of the 53rd IEEE International Midwest Symposium on Circuits and Systems, Seattle, WA, USA, 1–4 August 2010. [Google Scholar]

- Julian, W.; Gardner, V.; Varadan, K.; Osama, O. Awadelkarim, Microsensors MEMS and Smart Devices; John Wiley & Sons, Inc.: New York, NY, USA, 2002. [Google Scholar]

- Link, M.; Schreiter, W.; Pitzer, D.; Primig, R.; Assouar, O.; Elmazria, G.; Wersing, W. c-axis inclined ZnO films for shear-wave transducers deposited by reactive sputtering using an additional blind. J. Vac. Sci. Technol. A Vac. Surf. Film. 2006, 24, 218–222. [Google Scholar] [CrossRef]

- Aubert, T.; Elmazria, O.; Assouar, B.; Blampain, E.; Hamdan, A.; Genève, D.; Weber, S. Investigations on AlN/sapphire piezoelectric bilayer structure for high-temperature SAW applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 999–1005. [Google Scholar] [CrossRef] [PubMed]

- Blampain, E.; Elmazria, O.; Legrani, O.; Murtry, S.M.; Montaigne, F. Platinum/AlN/sapphire SAW resonator operating in GHz range for high temperature wireless SAW sensor. In Proceedings of the UFFC, EFTF and PFM Symposium, Prague, Czech Republic, 21–25 July 2013. [Google Scholar]

- Legrani, O.; Aubert, T.; Elmazria, O.; Bartasyte, A.; Nicolay, P.; Ghanbaja, J.; Mangin, D. AlN/IDT/AlN/sapphire SAW heterostructure for high-temperature applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 898–906. [Google Scholar] [CrossRef] [PubMed]

- Kadota, M.; Ito, S.; Ito, Y.; Hada, T.; Okaguchi, K. Magnetic sensor based on surface acoustic wave resonators. Jpn. J. Appl. Phys. 2011, 50, 07HD07. [Google Scholar] [CrossRef]

- Wang, Y.; Sha, G.; Harlow, C.; Yazbeck, M.; Khafizov, M. Impact of nuclear reactor radiation on the performance of AlN/sapphire. Nucl. Instrum. Methods Phys. Res. B 2020, 481, 35–41. [Google Scholar] [CrossRef]

- Thanner, H.; Krempl, P.W.; Selic, R.; Wallnofer, W.; Worsh, P.M. GaPO4 high temperature crystal microbalance demonstration up to 720 °C. J. Therm. Anal. Calorim. 2003, 71, 53–59. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Yamaguchi, M. Delta Function Model Analysis of SSBW Spurious response in SAW devices. In Proceedings of the IEEE International Frequency Control Symposium, Salt Lake City, UT, USA, 2–4 June 1993; p. 639. [Google Scholar]

- Royer, D.; Dieulsaint, E. Ondes Elastiques Dans Les Solides Tome 2; Elsevier Masson: Paris, France, 1999. [Google Scholar]

- Kovacs, G. A generalised P-matrix model for SAW filters. In Proceedings of the IEEE Ultrasonics Symposium, Honolulu, HI, USA, 5–8 October 2003; p. 707. [Google Scholar]

- Hachigo, A.; Malocha, D.C. SAW dispersive equivalent circuit modeling for diamond layered structures. In Proceedings of the IEEE Ultrasonics Symposium, San Antonio, TX, USA, 3–6 November 1996; p. 151. [Google Scholar]

- Thirumal, V.; Priya, B. Modelling of 200 MHz surface acoustic wave (Saw) delay line for sensor specific applications. J. Environ. Nanotechnol. 2017, 6, 68–72. [Google Scholar]

- Hu, G.; Xu, J.; Auner, G.W.; Smolinski, J.; Ying, H. Digital phase detection approach and its application for AlN dual-mode differential surface acoustic wave sensing. Sens. Actuators B 2008, 132, 272. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Luo, J.K.; Du, X.Y.; Flewitt, A.J.; Li, Y.; Markx, G.H.; Walton, A.J.; Milne, W.I. Recent developments on ZnO films for acoustic wave based bio-sensing and microfluidic applications: A review. Sens. Actuators B 2010, 143, 606. [Google Scholar] [CrossRef]

- Du, X.Y.; Fu, Y.Q.; Tan, S.C.; Luo, J.K.; Flewitt, A.J.; Milne, W.I.; Lee, D.S.; Park, N.M.; Park, J.; Choi, Y.J.; et al. ZnO film thickness effect on surface acoustic wave modes and acoustic streaming. Appl. Phys. Lett. 2008, 93, 094105. [Google Scholar] [CrossRef]

- Le Brizoual, L.; Elmazria, O. Diamond and relat. Mater 2007, 16, 987. [Google Scholar]

- COMSOL Multiphysics Reference Manual Version 5.3.a, Update. Available online: https://doc.comsol.com/5.3/doc/com.comsol.help.comsol/COMSOL_ReferenceManual.pdf (accessed on 2 February 2021).

- Ondo, J.C.A.; Blampain, E.J.J.; Mbourou, G.N.; Murtry, S.M.; Hage-Ali, S.; Elmazria, O. FEM modeling of the temperature influence on the performance of SAWSensors operating at gigahertz frequency range and at high temperature up to 500 °C. Sensors 2020, 20, 4166. [Google Scholar] [CrossRef] [PubMed]

- Hofer, M.; Finger, N.; Kovacs, G.; Schoberl, J.; Zaglmayr, S.; Langer, U.; Lerch, R. Finite element simulation of wave propagation in periodic piezoelectric SAW structures. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 53, 1192–1201. [Google Scholar] [CrossRef] [PubMed]

- Yong, Y.-K. Analysis of periodic structures for BAW and SAW resonators. In Proceedings of the IEEE Ultrasonics Symposium, Atlanta, GA, USA, 7–10 October 2001; Volume 1, pp. 781–790. [Google Scholar]

- Zhao, Y.-G.; Liu, M.; Li, D.-M.; Li, J.-J.; Niu, J.-B. FEM modeling of SAW organic vapor sensors. Sens. Actuators A 2009, 154, 30–34. [Google Scholar] [CrossRef]

- Morgan, D.P. Surface-Wave Devices for Signal Processing; Elsevier: Amsterdam, The Netherlands, 1991. [Google Scholar]

- Ballantine, D., Jr.; White, R.M.; Martin, S.J. Acoustic Wave Sensors: Theory, Disignand Physico-Chemical Applications; Academic Press: San Diego, CA, USA, 1996; pp. 83–88. [Google Scholar]

- Pradeep, D.J.; Krishnan, N.R.; Harshal, B.N. Simulation of unidirectional interdigital transducers in SAW devices using COMSOL multiphysics. In Proceedings of the COMSOL Conference, Hannover, Germany, 4–6 November 2008. [Google Scholar]

- Shu, L.; Peng, B.; Li, C.; Gong, D.; Yang, Z.; Liu, X.; Zhang, W. The characterization of surface acoustic wave devices based on AlN-metal structures. Sensors 2016, 16, 526. [Google Scholar] [CrossRef] [PubMed]

- Shvetsov, A.; Zhgoon, S.; Antcev, I.; Bogoslovsky, S.; Sapozhnikov, G. Quartz orientations for optimal power efficiency in wireless SAW temperature sensors. In Proceedings of the European Frequency and Time Forum (EFTF), York, UK, 4–7 April 2016; pp. 1–4. [Google Scholar]

- Streque, J.; Camus, J.; Laroche, T.; Hage-Ali, S.; M’Jahed, H.; Rammal, M.; Aubert, T.; Djouadi, M.A.; Ballandras, S.; Elmazria, O. Design and characterization of high-Q SAW resonators based on the AlN/sapphire structure intended for high-temperature wireless sensor applications. IEEE Sens. J. 2020, 20, 6985–6991. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jean Claude, A.O.; Eloi Jean Jacques, B.; Gaston, N.M.; Adoum, T.N.; Elysée, O.N.; Omar, E. Modeling and Electrical Characterization of a Bilayer Pt/AlN/Sapphire One Port Resonator for Sensor Applications. Electronics 2021, 10, 370. https://doi.org/10.3390/electronics10040370

Jean Claude AO, Eloi Jean Jacques B, Gaston NM, Adoum TN, Elysée ON, Omar E. Modeling and Electrical Characterization of a Bilayer Pt/AlN/Sapphire One Port Resonator for Sensor Applications. Electronics. 2021; 10(4):370. https://doi.org/10.3390/electronics10040370

Chicago/Turabian StyleJean Claude, Asseko Ondo, Blampain Eloi Jean Jacques, N’tchayi Mbourou Gaston, Traore Ndama Adoum, Obame Ndong Elysée, and Elmazria Omar. 2021. "Modeling and Electrical Characterization of a Bilayer Pt/AlN/Sapphire One Port Resonator for Sensor Applications" Electronics 10, no. 4: 370. https://doi.org/10.3390/electronics10040370

APA StyleJean Claude, A. O., Eloi Jean Jacques, B., Gaston, N. M., Adoum, T. N., Elysée, O. N., & Omar, E. (2021). Modeling and Electrical Characterization of a Bilayer Pt/AlN/Sapphire One Port Resonator for Sensor Applications. Electronics, 10(4), 370. https://doi.org/10.3390/electronics10040370