Abstract

With the global trend to digitalize substation automation systems, International Electro technical Commission 61850, a communication protocol defined by the International Electrotechnical Commission, has been given much attention to ensure consistent communication and integration of substation high-voltage primary plant assets such as instrument transformers, circuit breakers and power transformers with various intelligent electronic devices into a hierarchical level. Along with this transition, equipment of primary plants in the switchyard, such as non-conventional instrument transformers, and a secondary system including merging units are expected to play critical roles due to their fast-transient response over a wide bandwidth. While a non-conventional instrument transformer has advantages when compared with the conventional one, extensive and detailed performance investigation and feasibility studies are still required for its full implementation at a large scale within utilities, industries, smart grids and digital substations. This paper is taking one step forward with respect to this aim by employing an optimized network engineering tool to evaluate the performance of an Ethernet-based network and to validate the overall process bus design requirement of a high-voltage non-conventional instrument transformer. Furthermore, the impact of communication delay on the substation automation system during peak traffic is investigated through a detailed simulation analysis.

1. Introduction

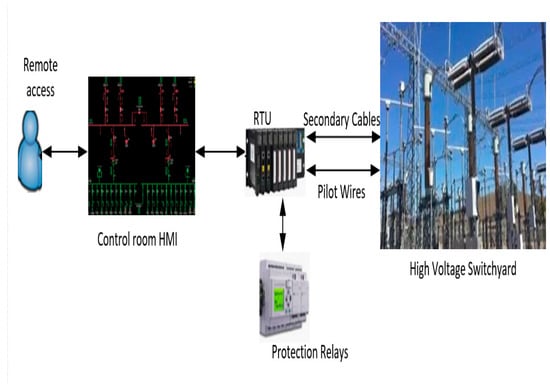

Identification and rapid isolation of faulty zones in power system networks are among the essential features of a smart protection system. A proper intelligent protection system must respond extremely fast to restore the isolated faulty zones to reduce unplanned outages and improve network reliability. The affected feeders, incomers and bus sections must be returned to a healthy state while keeping the network stability intact. This can be achieved by adopting a robust communication protocol between the protection system and the primary assets in the switchyard. Until now, most of the present high-voltage (HV) switchyard equipment communicates with the control room through a supervisory control and data acquisition (SCADA) system, remote terminal unit (RTU) and human machine interface (HMI) using a distributed network (DNP3) protocol as shown in Figure 1. RTU is a microprocessor device that acts as a gateway between the field device and control room HMI. It collates information from switchyard plants and propagates telemetry information to the control room. However, these modes of communications exhibit some short comings that limit their wider applications in future digital substation automation systems. The DNP3 communication protocol based on IEEE 1379-2000 is susceptible to poor network security which makes it more prone to hacking and is complex to implement due to the strict cybersecurity measures that should be adopted [1]. Moreover, this conventional communication is much slower than a fiber optic (FO) or Ethernet mode based on the IEC 61850 standard [2]. IEC 61850 features several advantages over the conventional protection scheme including faster data transmission, reduced secondary cables and lower engineering efforts [3].

Figure 1.

DNP3 Communication with HV apparatus in the control room using HMI.

During disturbances and fault events, the digital protection scheme publishes and subscribes data packets to trigger the intelligent electronic devices (IEDs) as per the IEC61850-9-2 standard, which is similar to a conventional relay sending analogue tripping signals to the circuit breaker (CB) in a traditional protection system [4]. Conventional instrument transformers (CITs) are prone to several types of electro-mechanical faults, which not only cause unnecessary disruption to the electricity grids, but also pose significant environmental hazards, such as fire, gas or oil leakage in the switchyard or operational plant. Original equipment manufacturers have addressed these issues by introducing non-conventional instrument transformers (NCITs). The application of NCIT in conjunction with merging units (MUs) and IEDs in the process of bus topology has provided a solution to the legacy issues of CITs to a large extent [5]. The iron core of CITs is the main source of inaccuracies due to hysteresis characteristics [6]. On the other hand, digital instrument transformers, i.e., NCITs with FO in the secondary side, offer many advantages such as rapid data communication; extensive bandwidth; reduced weight, cost and maintenance; safe and reliable performance with high accuracy; no saturation effect due to the non-existence of an iron core and ability to perform under thermal and mechanical stresses.

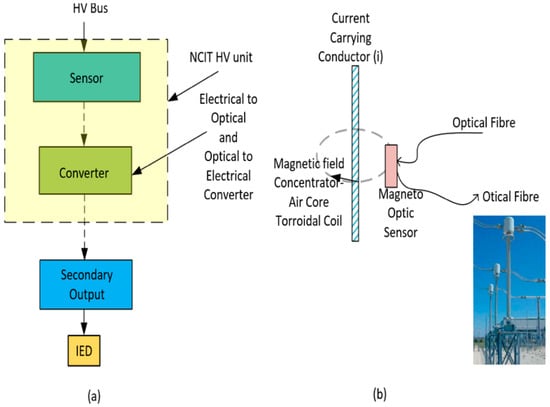

Unlike the CITs, in the event of inadvertent disconnection of secondary wirings at the NCIT terminal box, the plant does not encounter catastrophic failure. These features make NCIT suitable for future power system protection, measurement, automation and control. The basic principle of the NCIT transducer with an FO is shown in Figure 2a. In this system, the magnetic field produced around a current-carrying conductor is tapped by a sensor which propagates optical data over an FO to another sensor that re-converts the optical data to the electrical signal and feeds it to the IED actuating element. Unlike CITs, power capacity does not have an impact on the physical dimension of the NCIT. As such, the overall dimension and weight of an NCIT are approximately 30% lower than those of the CITs [7]. A typical HV NCIT in an air insulated substation (AIS) is shown in Figure 2b.

Figure 2.

(a) Block diagram of NCIT (b) Installation of a light weight NCIT in an operational switchyard [4].

Rogowski coil and NCIT technology has been successfully adopted in gas and air insulated substations. In addition, the use of FO technology reduces cables and wires in the secondary system and facilitates reliable operation and rapid fault diagnosis. With superior technology and a negligible footprint, NCIT leveraging on FO and process bus technology could potentially eliminate most of the structural, electrical and mechanical failures, which are currently attributed to the CIT physical structure. However, in order to have unwavering confidence in the technology and for its mass deployment in the transmission and distribution substations, NCIT along with the secondary peripherals and topologies needs to undergo extensive performance evaluation and validity checks.

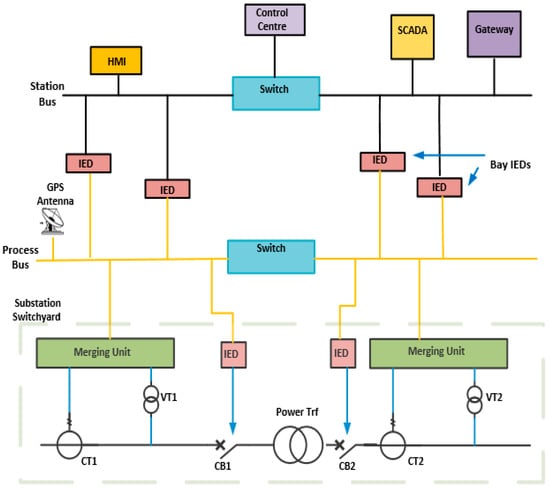

Figure 3 shows a block diagram of a process bus protection system which derives signals from current transformers (CTs) and voltage transformers (VTs) in an HV switchyard. These analogue inputs are fed into an MU, which converts it to digital data packets that are transmitted over an FO to the relay control room via switches and IEDs. Sampled values (SVs) and generic object oriented substation events (GOOSE) carry data packets with appropriate byte size under a healthy scenario. However, the status of the byte size changes in the event of a fault which activates a trip command to the CB. The SV is encrypted data in multicast mode published to multiple IEDs in a certain time interval with two dependent factors: measured signal frequency and sample per period (SPP). The two SPP values defined in IEC 61850-9-2 LE are 80 and 256. As an example, if the frequency is 50 Hz and the time interval is 80 ms, the SPP shall be recorded as 1/50/80 which is equivalent to 250 µs. The SV publishes and receives packets within a local area network (LAN).

Figure 3.

Process bus architecture encompassing NCIT and MU [10].

At the onset of the IEC 61850 standard, the utility communication architecture group developed an implementation guideline for the digital interface with instrument transformers using IEC 61850-9-2 [8].

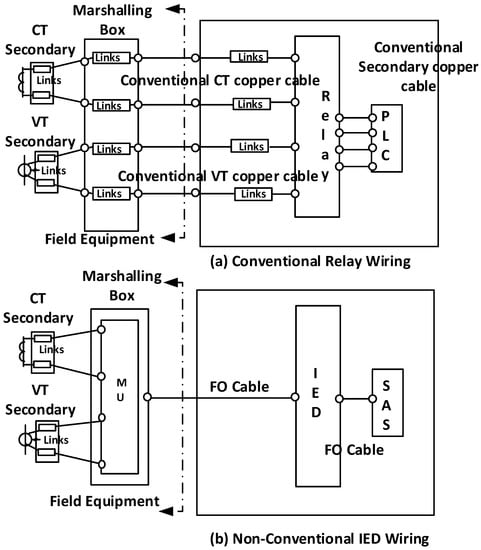

Figure 4a shows the analogue output of a CIT carried over the secondary wiring to the relay terminals (at 1 A, 110 V), which exhibits complexity in using secondary copper cables with switchyard trenches. On the other hand, Figure 4b exhibits a significant saving in copper wiring in the secondary circuit by using FO. It is possible to retrofit all conventional substations and transmit digital signals over FO and Ethernet without the need for replacing the primary asset, i.e., CIT. This not only reduces the physical dimension of the trench, but also reduces the effort in tracing physical issues arising from loose connections due to heating effects at the termination end [9]. In Figure 4b, fault finding in the loop becomes much easier due to the significant reduction in nodes and secondary wirings. Additionally, the application of MU and process bus architecture reduces the diagnostic effort by analysing data packets such as GOOSE and SV signals to IEDs passing via switches [10]. However, digital topologies suffer from some issues related to their performance, published data, end-to-end delays, latency and stripping off the trails in a virtual local area network operating in an interoperability environment and large byte size data compression. These issues need to be addressed properly by performing validation tests before the mass deployment of digital topologies. This paper is aimed at investigating some of these issues through a laboratory-based set-up analysis.

Figure 4.

(a) Parallel wiring from CITs to a relay in a conventional set up, (b) Reduced wiring in NCIT and MU to digital IED in a process bus architecture.

In a recent substation project implemented by Transgrid utility in Australia, substantial saving has been achieved in terms of decreased switchgears and protection cabinets, lower control cabling and reduction in engineering efforts. Reports indicate a cost reduction of about 11% in the process bus topology, a reduction of 93% on the secondary cable trenches and a 43% saving in the relay control panels compared with a similar relay control room in a conventional substation, besides significant savings in engineering man hours. In addition, periodic monitoring of NCITs is much easier due to the absence of mineral insulating oil and SF6 gas [11].

Table 1 exhibits the communication and data exchange architecture from a typical HV switchyard to the secondary equipment in the relay control room, routed via various stages from field devices to the control secondary assets. MU digital data packets are published and subscribed by the IEDs in a process bus architecture from Sr. No. 1 to 7 [12,13].

Table 1.

Data flow from the field to control room in an SAS topology [3].

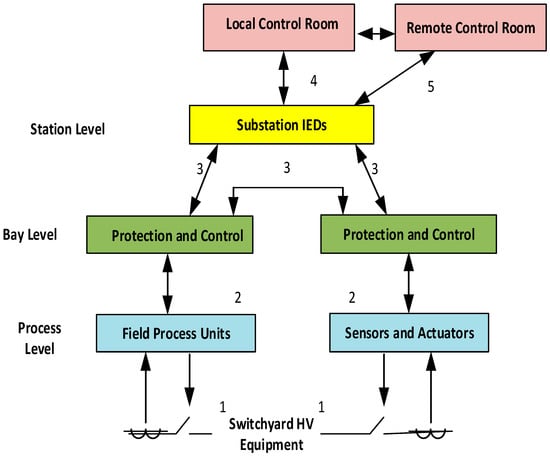

Figure 5 shows a block diagram of a typical substation automation system (SAS) in which equipment in the switchyard such as transformers, CBs, CTs and VTs communicate at the process level, i.e., function label 1. This equipment also communicates with the actuators and sensors at the process level at which the analogue signals are converted by MUs to digital signals and transmitted to the IEDs and control devices at the bay level, i.e., function label 2. Some of the SAS devices have the bay and process level functions embedded in the same device. Digital packets are then sent to substation IEDs at the station level, i.e., function label 3. Faults, trips and breaker availability signals are sent from the station level to the local control room located within the substation premise, i.e., function label 4. These events are also viewed at the remote-control room end simultaneously (function label 5). Breaker trips and isolator operations can be initiated by toggling in the local control or remote-control rooms.

Figure 5.

Functional communication in an SAS at various levels [11].

Depending on the speed and the events, messages in an SAS network are classified as:

- Fast messages—trip, start, stop, block-encompassing GOOSE (type 1)

- Medium messages—MMS message but non-time critical (type 2)

- Low speed messages—slow automation control, event record transmission such as pressure and temperature (type 3)

- Raw data message—Cyclic data message such as SV sent to IEDs (type 4)

- File transfer message—File transfer messages wherein the bulk of data messages are transferred as recorded files, information files and setting files (type 5)

- Time synchronization messages—periodic messages for the internal clocks of IEDs (type 6)

Table 2 shows the time taken for data exchange within the SAS network which can be categorized into periodic, random and burst data.

Table 2.

Message type and performance transmission duration [12].

In the periodic data transmission, the information of the switch status and analogue data are transmitted in the station level monitoring devices, and the quantity of such data varies from one topology to another. In a random data stream, the data frames are short in length. This real-time data packet contains switching operation commands and time synchronization. In a burst data stream, data messages carry information packets such as switch position, node failures and multi fault signals. The requirement of the message transmission time of frame sizes between devices and equipment is given according to IEC 61850-9-2 as summarized in Table 2 [14,15,16,17,18,19,20].

In a process bus architecture, analogue current and voltages from CIT are fed into the MUs to convert the analogue signals to digital data packets and broadcast these to the IEDs via switches. Digitized SV packets originating from MUs are carried over an Ethernet network located in the switchyard with an accuracy of ± 4 µs of the communication network with no more than a 2 µs delay based on IEC 61850-5. Considering the advantages of NCIT over CIT, it is worth evaluating the performance of this primary plant substation asset [21,22,23,24,25].

There are few shortcomings encountered when IEC 61850-9-2 is adopted, such as issues with interoperability, latency during high traffic, compressing large byte sizes and clogging of data packets at the nodes arising mainly due to the mismatch of communication technologies of different manufacturers. This has resulted in a delay of data transmission from field to control rooms which may seriously compromise the reliability of the entire protection system [26,27,28,29,30]. Although individual equipment in the network may have passed the certification requirement of IEC 61850, as a group of types of equipment in an SAS, these secondary protection assets may not perform at the desired communication level due to proprietary issues. This is mainly because different protection IEDs have non-standardized algorithms and no ability to comprehend and process large byte sizes within the stipulated time. This uncertainties and dilemma have resulted in slowing down their large-scale implementation and call for more investigations from researchers and manufacturers [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48].

2. Laboratory-Based Performance Evaluation of NCIT and CIT

Figure 6 shows the setup of the used test apparatus in an HV laboratory. The equipment was placed in the testing laboratory and cordoned off prior to testing with reduced voltage and current. A close-up view of the setup with the bus bar connected to the primary terminal is shown in Figure 7. The test condition in a real-life scenario was set up to measure the DC offset values. The NCIT equipment chosen for the test is a 132 kV voltage with a peak fault withstand capability of 63 kA for 1 sec, Class 5P.

Figure 6.

Laboratory set-up of a 132 kV NCIT.

Figure 7.

Close-up view of the 132 kV NCIT head with bus bar.

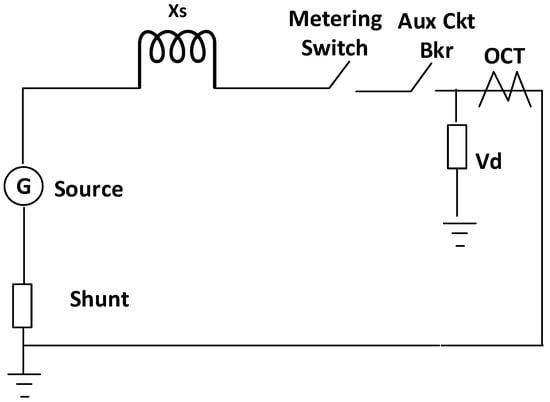

Figure 8 shows the equivalent circuit of the above setup in which the auxiliary switches were placed between the source and the NCIT/CIT. In Figure 8, Xs is the source inductive reactance and OCT is the optical current transducer. The calculated composite error is 1.42% and the peak error is 1.82%. This error aligns well with the tolerable limit stipulated in sections 3.3.4 and 13.1.3 in the IEC 60044-8 standards.

Figure 8.

Equivalent circuit diagram for the conducted experiment.

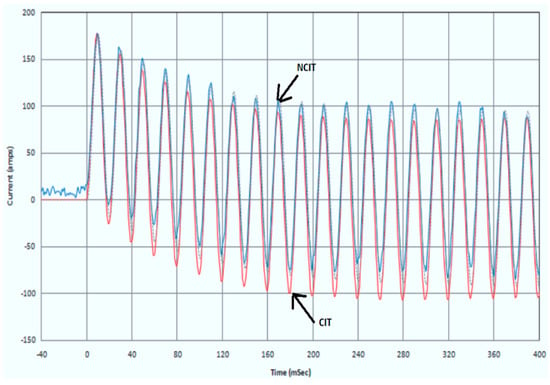

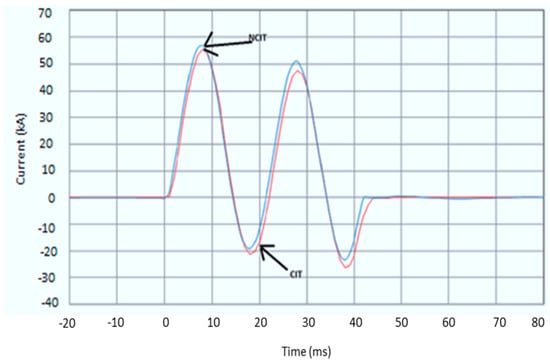

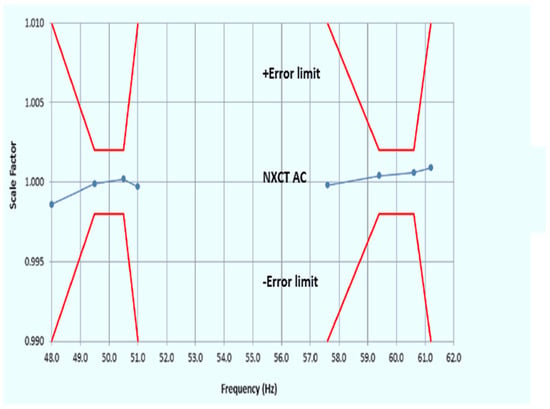

The DC offset and fault response time were plotted and compared with an equivalent 132 kV NCIT/CIT as shown in Figure 9 and Figure 10, respectively. It can be observed that the technical performance of the NCIT is marginally better than that of the CIT for the decaying DC offset with a better response time for a single-phase fault scenario. The delay time of the NCIT in a test environment is < 100 µs which complies with the IEC 61850-9-2 guidelines. Figure 11 shows the frequency response characteristic of a 132 kV NCIT is within the acceptable upper and lower band error limit when tested within a frequency band 48 Hz to 62 Hz for a 0.2 class CT.

Figure 9.

Decaying DC offset of 132 kV NCIT (Blue) vs. 132 kV CIT (Red).

Figure 10.

Comparison of 132 kV NCIT (Blue) vs. 132 kV CIT (Red) in a single-phase fault condition.

Figure 11.

Frequency response of a 132-kV NCIT.

Based on the NCIT electrical characteristics shown above and the feedback from utility operators, NCIT comprises the following features:

- Superior electrical performance in protection and measurement over CIT

- Significant reduction in project, engineering and asset management costs

- Environmentally friendly without oil or gas leaks

- Interoperable with other manufacturers IEDs and peripherals

- Reliability, availability and ease of diagnostics

- 1/3rd the weight of an equivalent CIT

3. Optimized Network Engineering Tool

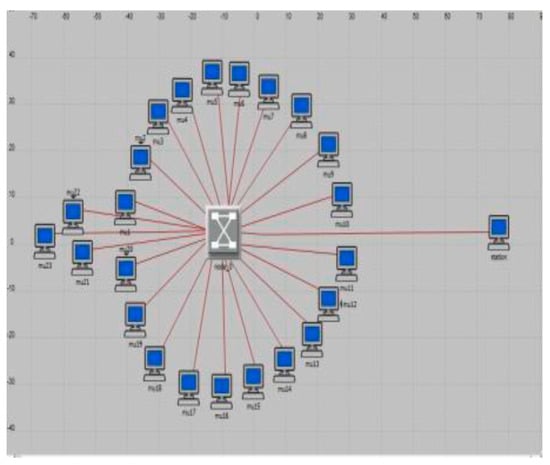

Models for the MU, IED and CB are simulated using the optimized network engineering tool (OPNET) which can simulate field devices connected by virtual FO to estimate the communication mean delay, delay variation, traffic lost, latency and traffic load of the data stacks at nodes of the device in bits/sec within an SAS scheme. The OPNET parameter, process, node and project editors are organized to achieve accurate modelling tasks.

In the parameter editor, the media access control (MAC) address, destination address, start time, inter-arrival time and packet size are determined. The process editor deals with the logic flow, behaviour, protocols, processes, application algorithm and queues and uses a finite state machine (FSM) and state transition diagrams (STD). A typical project editor shown in Figure 12 encompasses the process and interconnecting nodes that represent the electrical power equipment. The overall simulation model of a typical project in a ring topology is shown in Figure 12 with the number of IEDs connected as the case would be in a typical digital HV substation. The overall model is tested on a 100-baseT model network.

Figure 12.

Typical project editor in an OPNET environment.

IEC 61850-9-2 based communication performance is evaluated in a process bus architecture using the OPNET simulator. The evaluation of end-to-end (ETE) delay with MU, IED and CB linked up is necessary for the SAS network. This provides an indication of the latency in the transmitting and receiving of SV frames that travel from the field devices to the protection IEDs prior to practical implementation.

4. OPNET Simulation Results and Discussion

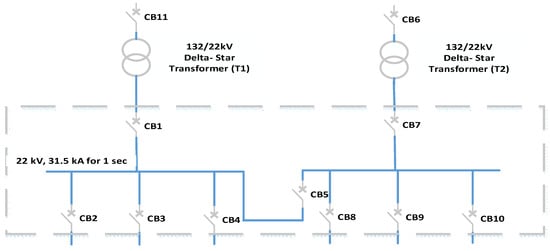

Figure 13 shows a single line diagram of a 132/22 kV High Voltage (HV) zone substation that comprises two line incomers CB11 and CB6 on the 132/22 kV transformer bays T1 and T2 respectively, 6 outgoing 22 kV feeders circuit breakers are designated CB2, CB3, CB4 for bus A and CB8, CB9, CB10 for bus B, 1 bus coupler CB5 at 22 kV. and two 22 kV line incomers respectively. The dotted line represents 22 kV switchboard in the substation HV room. The system under study have analogue voltage and current in the bus being fed into a line MU from NCIT. In these 2 x line incomers, NCIT and MU are located in the outdoor HV switchyard connected with the IEDs with FO. The SV from each MU is transmitted as a type 4 message to IEDs at a specified sampling rate at 100 baseT speed. Table 3 shows an overview of the equipment connected in the 132 kV simulated substation.

Figure 13.

Single line diagram of a 132/22 kV zone substation.

Table 3.

IED configuration in the 132 kV Substation.

The overall SAS network is connected to the HV CIT feeding current and voltage signals to the MU. The MU processes these analogue signals and converts them into digital data packets. The digital packets are transmitted over the FO network from the switchyard to the IEDs located in a local control room within the substation precinct.

Mal-operation of IEDs may cause a delay in the data transmission. The LAN speed considered in the simulation is 100 Mb/s for the ETE delay performance analysis which is widely accepted in the industry as the optimum performance speed over a digital network. It is worth noting that ETE refers to the time required for digital packets to reach the destination of a subscribing IED, from the starting point of a publishing IED. The digital protection system must undergo validation in a laboratory set up before large-scale deployment in HV and LV substations. The proposed OPNET model was tested in a laboratory set up, and the performance of the digital protection scheme with NCIT was analysed based on an actual 132/22 kV air insulated substation. The load in the communication traffic was calculated by multiplying the sampling rate, number of phases, number of data points and number of destinations.

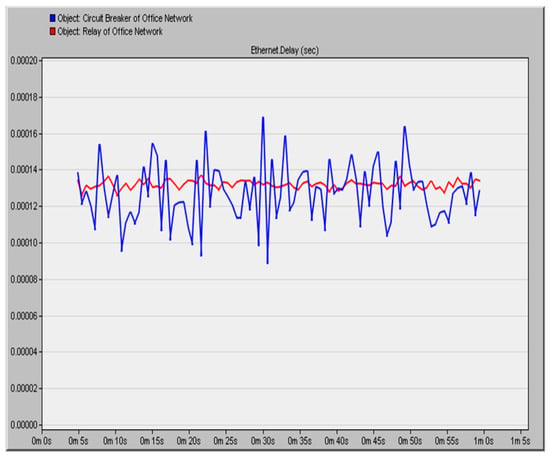

Figure 14 shows the performance of SV (red plot) versus GOOSE (blue plot) when the LAN speed is operating at 100 Mb/s speed. This was simulated for data communication capability during a peak traffic of 350 kbps. As per IEC 61850-5, a message must be ensured during all operating conditions within the substation. The SV messages from NCIT to the IEDs and GOOSE transmission within the IEDs are critical frames as these would affect protection due to latency, delay and queuing. Table 4 lists the parameters used in the OPNET simulation.

Figure 14.

Comparison of ETE delay of data packets for SV (Red) and GOOSE (Blue) messages.

Table 4.

Parameters for simulation in OPNET.

Discrete Event Simulation was run on OPNET for both SV and GOOSE. It can be observed from Figure 14 that the GOOSE messages take a longer time to broadcast and publish to the IEDs as compared to SV messages. Table 5 shows the average and maximum ETE delays of SV obtained using OPNET simulation are much lower than those of the GOOSE messaging which increases due to passage through various nodes in the SAS scheme.

Table 5.

SV and GOOSE message ETE delay in OPNET simulation.

In the studied substation communication network, the preferred data communication rate of 100 Mb/s is chosen with a sampling frequency of 4800 Hz. It is observed that SV packets encountered fewer delays travelling from the field to IEDs, while GOOSE messages were delayed due to traffic, which is mainly due to priority tagging. The losses encountered in the SV packets were negligible. Simulation results attest that ETE and latency to IEDs were well within the acceptable IEC 61850-9-2 guideline (below 4 µs) when tested with a LAN speed of 100 Mbps and sampling rate of 4800 sample/s.

The obtained results attest to the superior performance of the NCIT in future digital substations. In addition, it is envisaged that NCIT along with IEC 61850 will have wide applications in the control, protection, condition monitoring and asset management of smart grids, wind energy conversion systems and flexible ac transmission systems [44,45,46,47,48].

5. Conclusions

NCIT technology is widely gaining acceptance over CIT for a future digital substation paradigm. However, the performance of NCIT with respect to protection comprises some limitations that need to be fully addressed prior to its large-scale deployment in the industry. The NCIT and MU devices complement each other and form an integral part in the SAS digital network. Experimental results indicate the superior performance of NCITs in a process bus implementation compared with CITs. OPNET simulation software is employed to model the physical devices within the substation and evaluates their performance for latency along with the ETE delay for SV in a process bus system. Simulation results indicate that a 132 kV NCIT performs better than CIT through key performance indices such as ETE, latency, DC offset and frequency response. The model developed and results tabulated encourage the utility and industry users to replace CITs with NCITs for existing and future substations.

Author Contributions

S.K. conducted the experimental testing, simulation analysis and drafted the first version of the paper under the supervision of A.A.-S., N.D. and S.I. who analysed the obtained results, checked, reviewed and edited the final version of the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to gratefully acknowledge the support provided by ABB, GE, Siemens, Schneider, SEL and Omicron Australia for their support and contribution towards the progress to obtain these experimental results in the Curtin University IEC61850 Lab., Perth, WA, Australia.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, G.Y.; Newson, T.P. Detection of fibre-optic current sensors based on faraday effect. IET J. Mag. 2014, 50, 626–627. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Yin, Y. Modelling and Simulation for Performance Evaluation of IEC61850-Based Substation Communication Systems. IEEE Trans. Power Deliv. 2007, 22, 1482–1489. [Google Scholar] [CrossRef]

- Kanabar, M.G.; Sidhu, T.S. Performance of IEC 61850-9-2 Process Bus and Corrective Measure for Digital Relaying. IEEE Trans. Power Deliv. 2011, 26, 725–735. [Google Scholar] [CrossRef]

- Schaub, P.; Haywood, J.; Ingram, D.; Kenwrick, A.; Dusha, G. Test and Evaluation of Non-Conventional Instrument Transformers and Sampled Value Process bus on Powerlink’s Transmission network. In Proceedings of the 2011 South East Asia Protection and Control Conference (SEAPAC 2011), Sydney, Australia, 9–11 March 2011. [Google Scholar]

- UCA. Implementation Guideline for Digital Interface to Instrument Transformer Using IEC 61850-9-2; UCA International User Group: Raleigh, NC, USA, 2004. [Google Scholar]

- Schmid, J.; Schumarcher, M. IEC 61850 Merging Unit for the universal connection of conventional and Non-Conventional Instrument Transformers. Cigre, AS-306. 2008. Available online: https://e-cigre.org/publication/A3-306_2008-iec-61850-merging-unit-for-the-universal-connection-of-conventional-and-non-conventional-instrument-transformers (accessed on 20 November 2020).

- Liu, K.; Dong, X.; Bo, Z. Current differential protection based on Non-Conventional Instrument Transformer and IEC61850. In Proceedings of the 2008 43rd International Universities Power Engineering Conference, Padova, Italy, 1–4 September 2008; pp. 1–5. [Google Scholar]

- Hinkley, K.; Batger, D. Transgrid’s journey to a full digital substation. In Proceedings of the South East Asia Protection, Automation and Control Conference, Melbourne, Australia, 14–15 September 2017. [Google Scholar]

- ALSTOM Cost Comparison Spreadsheet, Private Communications/Consultations with ALSTOM Engineers. Available online: file:///C:/Users/MDPI/AppData/Local/Temp/72773_ddr.pdf (accessed on 5 June 2015).

- Das, N.; Ma, W.; Islam, S. Comparison study of various factors affecting end to end delay in IEC 61850 substation communication using OPNET. In Proceedings of the Australasian Power Engineering Conferences 2012 (AUPEC 2012), Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Pavaiya, N.; Newman, P.; Boucherit, M.; Diemer, P.; Varghese, A. IEC 61850 Process Bus Application in Energinet, Denmark. In Proceedings of the 12th IET International Conference on Developments in Power System Protection (DPSP 2014), Copenhagen, Denmark, 31 March–3 April 2014. [Google Scholar]

- Kanabar, M. Investigation Performance and Reliability of Process Bus Networks for Digital Protective Relaying. Ph.D. Thesis, The University of Western Ontario, London, ON, Canada, 2007. [Google Scholar]

- Ingram, D.M.; Schaub, P.; Taylor, R.R.; Campbell, D.A. Performance Analysis of IEC 61850 Sampled Value Process Bus Networks. IEEE Trans. Ind. Inform. 2013, 9, 1445–1454. [Google Scholar] [CrossRef]

- Moore, R.; Goraj, M. New paradigm of smart transmission substation—practical experience with Ethernet based fiber optic switchyard at 500 kilovolts. In Proceedings of the 2011 2nd IEEE PES International Conference and Exhibition on Innovative Smart Grid Technologies, Manchester, UK, 5–7 December 2011. [Google Scholar]

- Ingram, D.M.E.; Schaub, P.; Taylor, R.R.; Campbell, D.A. System-Level Tests of Transformer Differential Protection Using an IEC 61850 Process Bus. IEEE Trans. Power Deliv. 2013, 29, 1382–1389. [Google Scholar] [CrossRef]

- OPNET Modeler—OPNET Technologies. Available online: http://www.opnet.com (accessed on 21 December 2019).

- Mekkanen, M.; Antila, E.; Virrankpski, R.; Elmusarati, M. Using OPNET to model and evaluate the MU performance based on IEC 61850-9-2LE. Procedia Comput. Sci. 2014, 36, 72–79. [Google Scholar] [CrossRef][Green Version]

- Hughes, R. Considering the process bus. In Proceedings of the South East Asia Protection, Automation and Control Conference, Cigre Australia Panel B5, Melbourne, Australia, 17–18 March 2009. [Google Scholar]

- Igarashi, G.; Santos, J.C.; Junior, S.N.; Pellini, E.L. Development of a digital optical Instrument Transformer with process bus interface according to IEC 61850-9-2 standard. In Proceedings of the 2015 IEEE PES Innovative Smart Grid Technologies Latin America (ISGT LATAM), Montevideo, Uruguay, 5–7 October 2015; pp. 893–897. [Google Scholar]

- Yiqing, L.; Houlei, G.; Mingjiang, X.; Xin, W.; Peng, W.; Chunsheng, Z. Performance testing of complete digital relays based on ATP-EMTP and IEC61850-9-2. In Proceedings of the 2011 4th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Weihai, China, 6–9 July 2011; pp. 83–87. [Google Scholar]

- Cai, C.; Lu, Y.; Ding, T.; Zhu, G. A smart resampling scheme for digital substation relay protection. In Proceedings of the 2008 IEEE PES General Meeting, Providence, RI, USA, 25–29 July 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Araujo, A.; Lazaro, J.; Astaloa, A.; Zuloaga, A.; Moeira, N. Duplicate and Circulating frames discard methods for PRP and HSR (IEC 62439-3). In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013. [Google Scholar]

- Hoga, C. Seamless communication redundancy of IEC 62439. In Proceedings of the 2011 International Conference on Advanced Power System Automation and Protection, Beijing, China, 16–20 October 2011; Volume 1, pp. 489–494. [Google Scholar]

- Araujo, J.A.; Lázaro, J.; Astarloa, A.; Zuloaga, A.; García, Á. PRP and HSR version 1 (IEC 62439-3 Ed.2), improvements and a prototype implementation. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 4410–4415. [Google Scholar]

- Aghanoori, N.; Masoum, M.A.; Islam, S.; Abu-Siada, A.; Nethery, S. Improving voltage of remote connection using wind-solar farms equipped with new voltage control strategy based on virtual impedance monitoring enabled by IEC 61850 communication. IET Gener. Transm. Distrib. 2019, 13, 2199–2207. [Google Scholar] [CrossRef]

- International Standard IEC 62439-3, Edition 3.0. In Industrial Communication Networks High Availability Automation Networks—Part 3: Parallel Redundancy Protocol (PRP) and High-Availability Seamless Redundancy (HSR); IEEE: Piscataway Township, NJ, USA, 2012.

- Li, Z.; Zhang, S.; Wu, Z.; Abu-Siada, A.; Tao, Y. Study of Current Measurement Method based on Circular Magnetic Field Sensing Array. Sensors 2018, 18, 1439. [Google Scholar] [CrossRef] [PubMed]

- Aghanoori, N.; Masoum, M.A.; Abu-Siada, A.; Islam, S. Enhancement of microgrid operation by considering the cascaded impact of communication delay on system stability and power management. Int. J. Electr. Power Energy Syst. 2020, 120, 105964. [Google Scholar] [CrossRef]

- Kumar, S.; Das, N.; Islam, S. Causes and mitigation of sympathetic tripping phenomenon based on IEC 61850. In Proceedings of the Australian Protection Symposium 2014, Sydney, Australia, 12–13 August 2014. [Google Scholar]

- Kovic, L.J. Innovative Non-convention Current Transformer for advanced Substation design and improved Substation performance. In Proceedings of the CIGRE 2008, Paris, France, 24–29 August 2008. [Google Scholar]

- Nilsson, S.L.; Koenig, D.F.; Udren, E.A.; Allguren, B.J.; Lau, K.P. Pros and cons of Integrating protection and control in transmission substations. IEEE Trans. Power Appar. Syst. 1985, 104, 1207–1224. [Google Scholar] [CrossRef]

- IEC 61850-9-2 2004. In Communication Networks and Systems in Substations—Part 9-2: Specific Communication System mapping (SCSM)—Sampled Values over ISO/IEC 802-3, 1st ed.; IEC: Geneva, Switzerland, 2005.

- IEC 61850-9-2 LE. In Implementation Guideline for Digital Interface to Instrument Transformers Using IEC 61850-9-2; UCA International Users Group: Raleigh, NC, USA, 2004.

- Apostolov, A.; Auperrin, F.; Passet, R.; Guenego, M.; Gilles, F. IEC 61850 process bus based distributed waveform recording. In Proceedings of the 2006 IEEE Power Engineering Society General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- Li, Z.; Yu, C.; Abu-Siada, A.; Li, H.; Li, Z.; Zhang, T.; Xu, Y. An online correction system for electronic voltage transformers. Int. J. Electr. Power Energy Syst. 2021, 126. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Y.; Abu-Siada, A.; Lu, M.; Li, H.; Xu, Y. Online evaluation for the accuracy of electronic voltage transformer based on re-cursive principal components analysis. Energies 2020, 13, 5576. [Google Scholar] [CrossRef]

- Li, Z.; Tao, Y.; Abu-Siada, A.; Masoum, M.A.S.; Li, Z.; Xu, Y.; Zhao, X. A New Vibration Testing Platform for Electronic Current Transformers. IEEE Trans. Instrum. Meas. 2018, 68, 704–712. [Google Scholar] [CrossRef]

- Li, Z.; Xiang, X.; Abu-Siada, A.; Li, Z.; Xu, Y. Research on a Composite Voltage and Current Measurement Device for HVDC Networks. IEEE Trans. Ind. Electron. 2020. [Google Scholar] [CrossRef]

- Li, B.Z.; Xiang, X.; Hu, T.; Abu-Siada, A.; Li, Z.; Xu, Y. An improved digital integral algorithm to enhance the measurement accuracy of Rogowski coil-based electronic transformers. Int. J. Electr. Power Energy Syst. 2020, 118, 105806. [Google Scholar] [CrossRef]

- Tong, Y.; Liu, B.; Abu-Siada, A.; Li, Z.; Li, C.; Zhu, B. Research on calibration technology for electronic current transformers. In Proceedings of the 2018 Condition Monitoring and Diagnosis (CMD), Perth, Australia, 23–26 September 2018; pp. 1–5. [Google Scholar]

- Li, Z.; Du, Y.; Abu-Siada, A.; Li, Z.; Zhang, T. A New Online Temperature Compensation Technique for Electronic Instrument Transformers. IEEE Access 2019, 7, 97614–97623. [Google Scholar] [CrossRef]

- Dos Santos, A.; Soares, B.; Fan, C.; Kuipers, M.; Sabino, S.; Grilo, A.; Pereira, P.R.; Nunes, M.S.; Casaca, A.; Sabino, S. Characterization of Substation Process Bus Network Delays. IEEE Trans. Ind. Inform. 2018, 14, 2085–2094. [Google Scholar] [CrossRef]

- Alharbi, Y.M.; Yunus, A.M.S.; Abu-Siada, A. Application of STATCOM to Improve the High-Voltage-Ride-Through Capability of Wind Turbine Generator. In Proceedings of the IEEE Innovation Smart Grid Technologies, Perth, Australia, 13–16 November 2011. [Google Scholar]

- Yunus, A.M.S.; Abu-Siada, A.; Masoum, M.A.S. Effects of SMES on the dynamic behaviors of type D-Wind Turbine Genera-tor-Grid connected during short circuit. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; pp. 1–6. [Google Scholar]

- Alharbi, Y.M.; Yunus, A.M.S.; Abu-Siada, A. Application of UPFC to Improve the LVRT Capability of Wind Turbine Generator. In Proceedings of the 2012 22nd Australasian Universities Power Engineering Conference (AUPEC), Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Abdou, A.F.; Abu-Siada, A.; Pota, H.R. Application of STATCOM to improve the LVRT of DFIG during RSC Fire-through Fault. In Proceedings of the 2012 22nd Australasian Universities Power Engineering Conference (AUPEC), Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Yunus, A.M.S.; Abu-Siada, A.; Masoum, M.A.S. Improving Dynamic Performance of Wind Energy Conversion System using Fuzzy-Based Hysteresis Current Controlled SMES. IET Power Electron. 2012, 5, 1305–1314. [Google Scholar] [CrossRef]

- Masoum, A.S.; Moses, P.S.; Masoum, M.A.S.; Abu-Siada, A. Impact of Rooftop PV Generation on Distribution Transformer and Voltage Profile of Residential and Commercial Networks. In Proceedings of the 2012 PES Innovative Smart Grid Technologies Conference, Washington, DC, USA, 16–18 January 2012. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).