Challenges and Opportunities in Industry 4.0 for Mechatronics, Artificial Intelligence and Cybernetics

Abstract

:1. Introduction

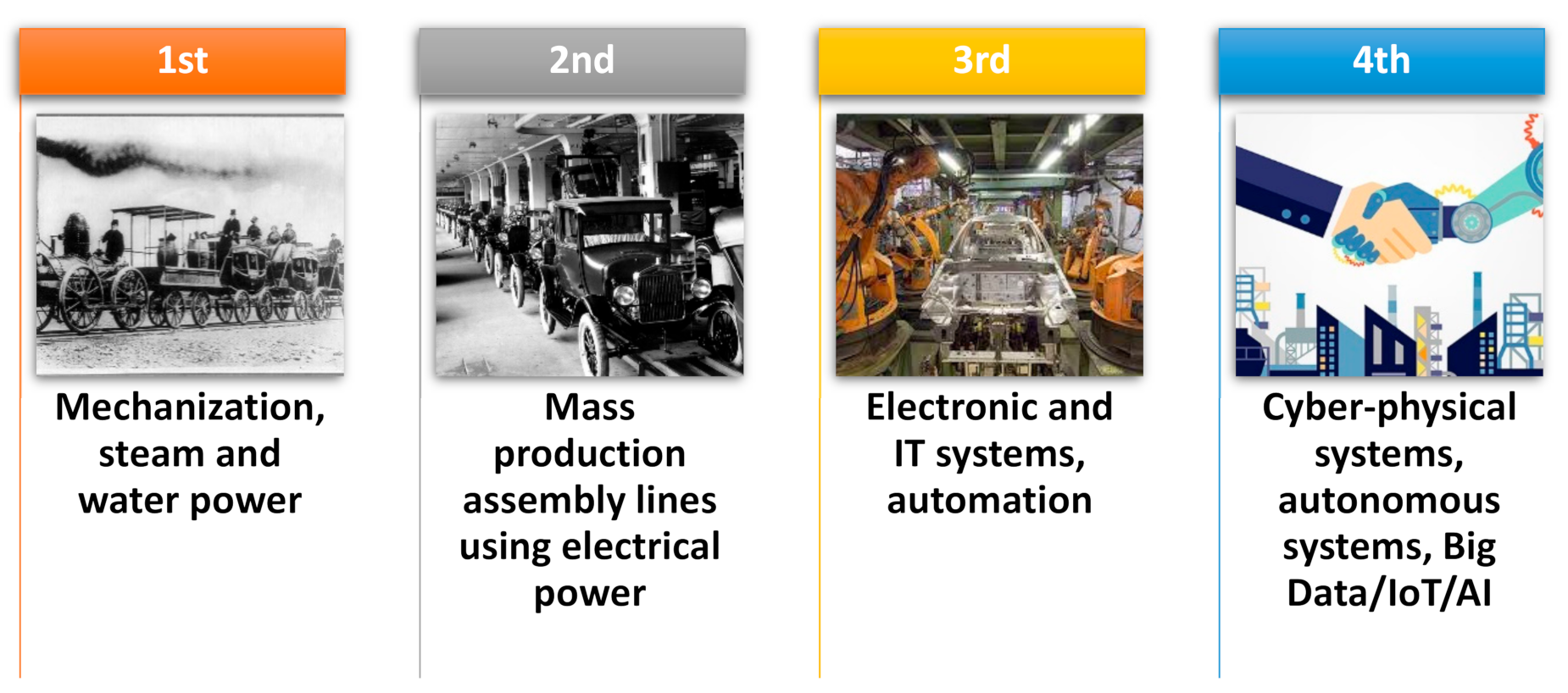

2. Main Contribution

3. Main Aspects of Industry 4.0

- Interoperability: cyber-physical systems (workpiece carriers, assembly stations, and products) allow humans and smart factories to connect and communicate with each other.

- Virtualization: a virtual copy of the smart factory is created by linking sensor data with virtual plant models and simulation models.

- Decentralization: cyber-physical systems make decisions of their own and produce locally (by using 3D).

- Real-time capability: enabling the collection and analysis of data and providing the derived insights immediately.

- Service orientation.

- Modularity: the flexible adaptation of smart factories to changing requirements by replacing or expanding individual modules.

- Convergence.

- Cost reduction and efficiency.

- Mass customization.

- The growth of automation and data technologies powered by the IoT, the cloud, advanced computers, robotics, and people.

- The seamless integration of software, equipment, and people. It extends the speed, reliability, and flow of information between all systems of a manufacturer.

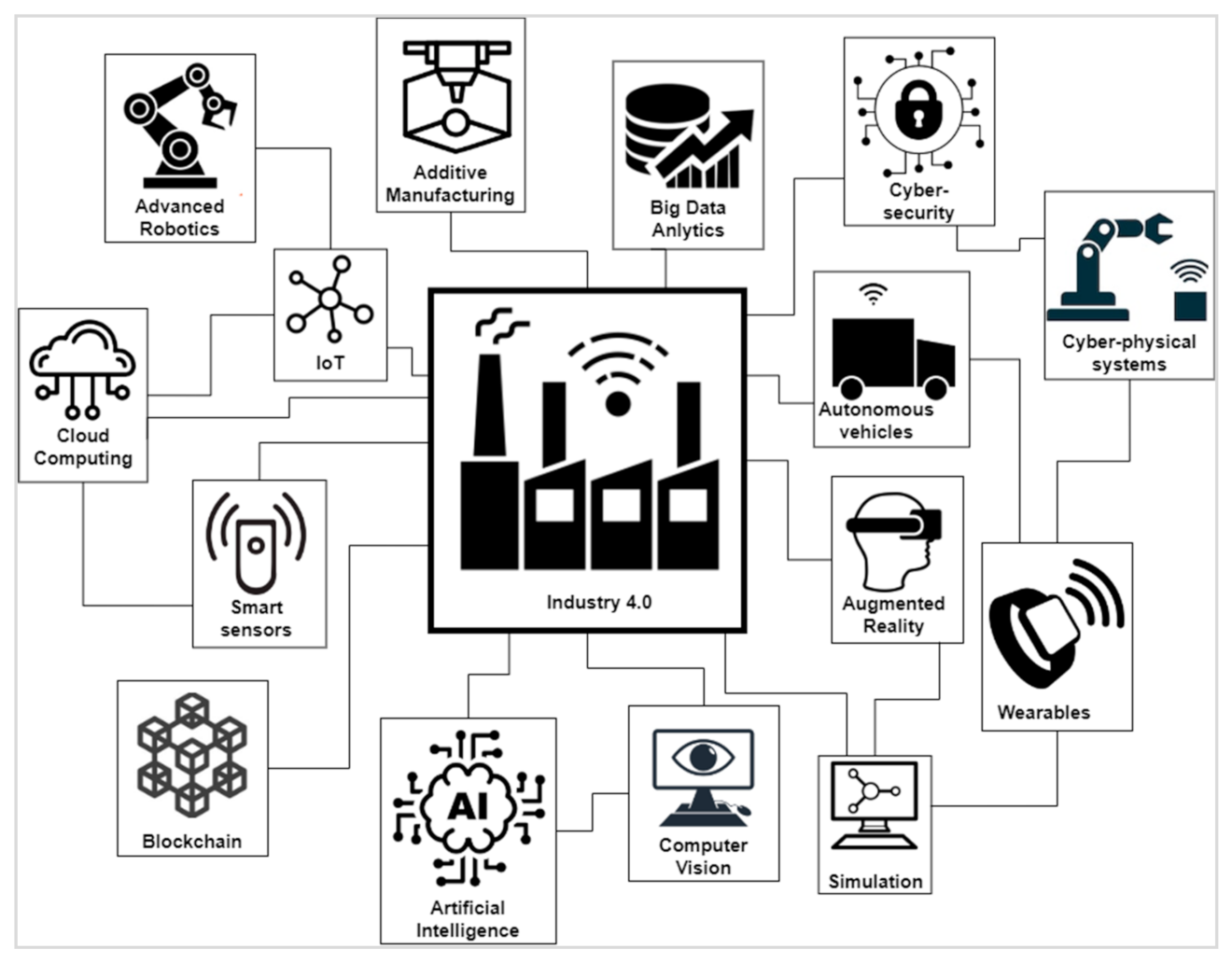

- Key technologies driving I4.0 are:

- autonomous vehicles and robots,

- additive manufacturing,

- distributed ledger systems (such as blockchain),

- big data analytics,

- mobile computing and wearables,

- cloud computing,

- augmented reality.

3.1. Industry 4.0 Effect

3.1.1. Evolution of I4.0 by Adapting Edge Technology

- digitalization and integration of manufacturing resources on cloud-based platforms as adaptive, secure, and on-demand services,

- intelligent and connected objects capable of real-time and autonomous decision-making via embedded electronics and analytical/cognitive capabilities.

- The intelligent product. The products themselves can order production resources and coordinate the manufacturing process for its accomplishment.

- The smart machine. The machines become cyber-physical production systems. Decentralized, adaptable, jointed, and self-regulating production networks substitute conventional production structures.

- The augmented operator. I4.0 project’s goal is not to create production plants without workers. It instead aims to acknowledge the crucial role of the human factor: taking advantage of technology, the human operator is the most adjustable part of the production system.

3.1.2. Evolution of I4.0 by Adapting Mechanical Advances

4. Guarding Industry 4.0 Components

4.1. Cyber-Physical Systems (CPS)

4.2. Internet of Things (IoT)

4.3. Industrial IoT (IIoT)

4.4. Big Data Analytics

- Volume (refers to the unimaginable amounts of information generated every second).

- Velocity (refers to the speed at which the data is generated, collected, and analyzed).

- Variety (entails the processing of diverse data types collected from varied data sources).

- Veracity (means the degree of reliability that the data has to offer).

- Value (refers to the ability to transform an enormous amount of data into something that brings profit).

4.5. Artificial Intelligence (AI)

- Supervised,

- Unsupervised,

- Reinforcement learning.

4.6. Advanced Robotics

- acting on environmental stimuli,

- sensing,

- logical reasoning.

4.7. Cloud Computing

4.8. Fog-Edge Computing and Mobile Cloud

4.9. Virtual and Augmented Reality (VR/AR)

- The cost of adopting VR/AR technology is not negligible and should be taken into account. Several technologies exist to get access to the virtual world, e.g., Oculus Rift, HTC Vive. The cost of each tool depends on the extent of immersion it provides. The better the immersion, the more expensive it is. The virtual environment is servers providing VR/AR tools, which are accessed from everywhere using the client-server approach. The integration of VR/AR tools in I4.0 demands assessing the cost factors and the benefits of the specific VR/AR technologies and servers.

- A matter of investigation and consideration is finding how to use simulation and VR/AR models to produce reliable approaches for adapting physical engines in I4.0. Physical movements not close to reality may negatively impact or give wrong results when simulations refer to user interaction with the environment.

- The nature of VR/AR realization in the industrial environment is essential. Users need time to adapt to the VR/AR environment if they use glasses; otherwise, they will feel lost and sick if they use them. The VR/AR methodology (3D glasses and VR booth) should be user-friendly.

- VR/AR is used for real-time visualization of specific virtual models and simulation results, but it has to be considered the adaptation factor of known and implemented virtual models to new events and circumstances. This requires a viable use case scenario and serious programming effort. In order to maintain the VR/AR scenarios existing code needs updating, which is time-consuming and challenging for users with little to no coding experience. Consequently, design adaptable virtual models need a lot of time and effort.

- Furthermore, we have to consider connectivity issues of the visualization software with the connecting parts (physical systems, embedded systems, sensors, actuators, electronic hardware, software, etc.) Sometimes, VR/AR online software may lag if the user has a poor connection, resulting in poor performance and poor experience. The software needs to be optimized to reduce the stress in both the internet connection and the computer’s graphical S&W to provide a smoother experience.

- Ensuring that VR/AR models will produce real-time concrete results. The VR modes must deal with complex real-time events and reproduce the VR representation based on simulation feedback.

4.10. Digital Twin

- a physical product,

- a virtual representation of the product,

- the bi-directional data connections, from the physical to the virtual representation, and vice versa.

- Real-time remote monitoring and control.

- Greater efficiency and safety.

- Predictive maintenance and scheduling.

- Scenario and risk assessment.

- Better intra- and inter-team synergy and collaborations.

- More efficient and informed decision support system.

- Personalization of products and services.

- Better documentation and communication.

4.11. Blockchain

4.12. Horizontal and Vertical System Integration

- horizontal integration that is the collaboration between enterprises along a value chain;

- vertical integration that is the extensive automation inside an enterprise,

- end-to-end integration envisions connections across the value chains between every couple of digitally enabled participants (machine-to-machine, human-to-machine, human-to-human) [67].

4.13. Cybersecurity

- complex cybersecurity deployment landscapes,

- cyber-attacks on physical systems,

- physical attacks on and physics-based cyber-system mitigation.

5. Security Challenges in Industry 4.0

5.1. The Main Threats in Industry 4.0

- Confidentiality: All the produced physical or logical data from all the I4.0 components must not be accessed by unauthorized entities. If the confidentiality property is not preserved, the produced products or data may be stolen.

- Integrity: All the provided services from all components of I4.0 must preserve their integrity. When someone compromises the integrity property, this compromise may stay hidden while being exploited constantly.

- Availability: All the provided services from all the components of I4.0 must be available by authorized users and services. If the availability property is not preserved to all I4.0 components, the produced products may be lost, and services, data, and products may be unrecoverable.

5.2. The Security Threats for Main Issues of Industry 4.0

- Threats in Operation of I4.0:

- ○

- Failure to run a requested task: Attacks can prevent an active function from being finished in the production line, and the participating companies/parties are always vulnerable.

- ○

- Failure or holding back to run planned tasks: If one of the participating members/companies of I4.0 is exposed to continuous attacks, it is infeasible to recover.

- ○

- Financial and reputation loss and lack of consistency: In I4.0, the participating entities are committed to terms and legal conditions that may not be satisfied.

- ○

- Loss of trustworthiness: Market relations of the participating entities are fundamental for utilizing the production line of I4.0, and these relations are based on trust between entities/companies. This established trustworthiness may not be preserved if an entity could not accomplish a task without uncontrolled or unmanaged threats.

- Threats in Components of I4.0:

- ○

- Malfunction of the infrastructure of I4.0: Malicious users could take advantage of I4.0 vulnerabilities to damage the physical facilities of I4.0.

- ○

- Malfunction in information systems or networks: Cyber-attacks, such as ransomware, could relentlessly disable the underlying IT infrastructure that supports the I4.0 environment

- ○

- Malfunction in parts: Managing threats to a hugely dynamic, interconnected environment of I4.0 becomes trying to manage the threats against physical/digital assets due to the supply chain transforming into a chaotic supply web.

- ○

- Stealing or modifying the produced data: The data produced and transmitted on the dynamic environment of I4.0 can be tampered with by malicious adversaries; this attack could lead to loss of companies’ intellectual property and makes it difficult to capitalize companies’ know-how.

- ○

- Loss of trustworthiness: This highly dynamic environment helps any participant company to steal the intellectual property of any other participated entity.

- Threats in participating entities:

- ○

- Threatening user’s safety: If customers could succeed in modifying the production methodology of I4.0, these may cause accidents and threaten the user’s safety.

- ○

- Decreasing people’s trust: Customers are the final point of I.0.4, and they have to trust the products of I4.0. Thus, the trustworthiness will be decreased if the customers know that someone could interfere with the production line and not trust the quality/safety standards of the produced goods.

- Threats to economic/social relations:

6. Discussion—Conclusions

- Ensure the integrity of shared data: No unauthorized changes should be made on stored or shared sources. Data integrity in I4.0 is achieved through symmetric and PKI cryptographic signing schemes. Moreover, hash functions can be applied for archiving accountability of the produced data.

- Secure the communication: Guarantee the confidentiality of the physical/digital information managed and/or produced in the I4.0 environment.

- Ensure continuous certification of actors: Traditional authentication mechanisms, such as symmetric or PKI cryptographic, can guarantee the confidentiality and integrity requirement, but they cannot preserve the user’s privacy for increasing the trustworthiness between the participated actors. Privacy attribute-based credentials (P-ABCs) [91] allow users to disclose certified information, minimally authenticating with online service providers. There are several attempts ([92,93,94,95]) to use PETs technology to provide an identity-based management scheme via internet providers, smartphones, and the cloud, but it does not apply to all the I4.0 systems’ actors such as PLCs and IoT devices. Confidentiality requirements for the communication between IoT devices, PLCs, and servers can be achieved by applying symmetric encryption schemes or PKI cryptographic tools. Privacy ABCs can provide an identity management scheme for authenticating the actions of all actors of I4.0 for securing I4.0 infrastructure by providing an access control system and data sharing policies. PET technology could be used for utilizing centralized identity management schemes for providing trust mechanisms. Blockchain technology [96] and differential privacy techniques [97] could also preserve user’s privacy by providing a distributed trust management scheme.

- Security robustness to faults/malicious events: Sensors and industrial equipment are typically prone to faults (as a result of the low-cost equipment), the various conditions of deployment, and may be forced to faults by an attacker. In all cases, P-ABC identity management could revoke the device’s credentials, but a monitoring/detection mechanism is needed to verify the availability of the I4.0 assets. Unfortunately, we have to deal with the fact that a component of I4.0 may be compromised, and the industrial company will not dispose of the incident thinking of its reputation. In this case, we must preserve the integrity of any component’s services and constantly exploit the compromised component. In order to meet robustness requirements, any asset of the I4.0 should be monitored by a detection mechanism that must be combined with IoT/CPS components for creating a continuously monitoring, secure industrial environment. Recent research on blockchain technology introduced efficient distributed detection mechanisms and risk management schemes [98,99,100].

- Increase user awareness of security tools/features: All the actors should be aware of the I4.0 security vulnerabilities and risks. A lack of industrial employees’ cybersecurity awareness concerning information on attacks and vulnerabilities and a lack of cybersecurity training industrial personnel and industrial stakeholders will increase potential risks for the industry. Methodologies for training users on security tools and features of I4.0 infrastructure are crucial for building a secure and trustworthy I4.0 ecosystem [62,101].

Author Contributions

Funding

Conflicts of Interest

References

- Azizi, A.; Yazdi, P.G.; Al-Humairi, A. Design and Fabrication of Intelligent Material Handling System in Modern Manufacturing with Industry 4.0 Approaches. Int. Robot. Autom. J. 2018, 4, 186–195. [Google Scholar] [CrossRef]

- Azizi, A.; Yazdi, P.G.; Al-Humairi, A. Applications of Control Engineering in Industry 4.0: Utilizing Internet of Things to Design an Agent Based Control Architecture for Smart Material Handling System. Int. Robot. Autom. J. 2018, 4, 253–257. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef] [Green Version]

- Peralta, G.; Iglesias-Urkia, M.; Barcelo, M.; Gomez, R.; Moran, A.; Bilbao, J. Fog Computing Based Efficient IoT Scheme for the Industry 4.0. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics (ECMSM), Donostia, Spain, 24–26 May 2017; pp. 1–6. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. SME Manuf. Lett. 2014, 3, 18–23. [Google Scholar] [CrossRef]

- Patel, P.; Ali, M.I.; Sheth, A. On Using the Intelligent Edge for IoT Analytics. IEEE Intell. Syst. 2017, 32, 64–69. [Google Scholar] [CrossRef]

- IEEE Fueling the 4th Industrial Revolution. Innovate. Available online: https://innovate.ieee.org/innovation-spotlight-ieee-fueling-fourth-industrial-revolution/ (accessed on 23 March 2021).

- Kim, T. Cyber Physical Systems Framework of Edge-, Fog-, and Cloud-Computing. In Proceedings of the 2019: International Conference on Embedded Systems, Cyber-physical Systems, and Applications (ESCS), Las Vegas, NV, USA, 29 July–1 August 2019; pp. 10–14. [Google Scholar]

- Riminucci, M. Industry 4.0 and Human Resources Development: A View from Japan. E-J. Int. Comp. Labour Stud. 2018, 7. Available online: http://ejcls.adapt.it/index.php/ejcls_adapt/article/view/496 (accessed on 23 March 2021).

- Görmüş, A. Future of Work with the Industry 4.0. In Proceedings of the 2019: International Congress on Social Sciences (INCSOS), Wuhan, China, 15–17 March 2019; pp. 317–323. [Google Scholar]

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Chikonkolo Mwape, M.; Sheron Mpofu, N.; Tigalana, D. Industry 4.0 Disruption and Its Neologisms in Major Industrial Sectors: A State of the Art. Available online: https://www.hindawi.com/journals/je/2020/8090521/ (accessed on 16 February 2021).

- Madsen, D.Ø. The Emergence and Rise of Industry 4.0 Viewed through the Lens of Management Fashion Theory. Adm. Sci. 2019, 9, 71. [Google Scholar] [CrossRef] [Green Version]

- Kovacs, O. Big IFs in Productivity-Enhancing Industry 4.0. Soc. Sci. 2019, 8, 37. [Google Scholar] [CrossRef] [Green Version]

- Haseeb, M.; Iqbal-Hussain, H.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A Solution towards Technology Challenges of Sustainable Business Performance. Soc. Sci. 2019, 8, 154. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, A.M.; Volpi, L.; Settembre-Blundo, D.; García-Muiña, F.E. Dynamic Life Cycle Assessment (LCA) Integrating Life Cycle Inventory (LCI) and Enterprise Resource Planning (ERP) in an Industry 4.0 Environment. J. Clean. Prod. 2021, 286, 125314. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, A.; Wasan, P. Industry 4.0, Cleaner Production and Circular Economy: An Integrative Framework for Evaluating Ethical and Sustainable Business Performance of Manufacturing Organizations. J. Clean. Prod. 2021, 295, 126253. [Google Scholar] [CrossRef]

- Sony, M. Pros and Cons of Implementing Industry 4.0 for the Organizations: A Review and Synthesis of Evidence. Prod. Manuf. Res. 2020, 8, 244–272. [Google Scholar] [CrossRef]

- Adolphs, P.; Bedenbender, H.; Dirzus, D.; Ehlich, M.; Epple, U.; Hankel, M.; Heidel, R.; Hoffmeister, M.; Huhle, H.; Kärcher, B.; et al. Reference Architecture Model Industrie 4.0 (Rami4.0). In ZVEI and VDI, Status Report; ZVEI: Frankfurt am Main, Germany, 2015; Available online: https://ec.europa.eu/futurium/en/system/files/ged/a2-schweichhart-reference_architectural_model_industrie_4.0_rami_4.0.pdf (accessed on 23 March 2021).

- Wübbeke, J.; Meissner, M.; Zenglein, M.J.; Ives, J.; Conrad, B. Made in China 2025. Mercator Inst. China Stud. Pap. China 2016, 2, 74. [Google Scholar]

- Sargent, J.F.J. The Obama Administration’s Proposal to Establish a National Network for Manufacturing Innovation; Congressional Research Service (CRS): Washington, DC, USA, 27 February 2014. [Google Scholar]

- Moghaddam, M.; Cadavid, M.N.; Kenley, C.R.; Deshmukh, A.V. Reference Architectures for Smart Manufacturing: A Critical Review. J. Manuf. Syst. 2018, 49, 215–225. [Google Scholar] [CrossRef]

- Lu, Y.; Morris, K.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems. Nat. Inst. Stand. Technol. 2016, 8107, 1–39. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-Physical Systems in Manufacturing. Cirp Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Xu, X. From Cloud Computing to Cloud Manufacturing. Robot. Comput. Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in Smart Manufacturing: Research Challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef] [Green Version]

- Morrar, R.; Arman, H.; Mousa, S. The Fourth Industrial Revolution (Industry 4.0): A Social Innovation Perspective. Technol. Innov. Manag. Rev. 2017, 7, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart Manufacturing Systems for Industry 4.0: Conceptual Framework, Scenarios, and Future Perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0-Standardization as the Crucial Challenge for Highly Modular, Multi-Vendor Production Systems. IFAC-Pap. 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Aceto, G.; Persico, V.; Pescapé, A. A Survey on Information and Communication Technologies for Industry 4.0: State-of-the-Art, Taxonomies, Perspectives, and Challenges. IEEE Commun. Surv. Tutor. 2019, 21, 3467–3501. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How Smart, Connected Products Are Transforming Competition. Harv. Bus. Rev. 2014, 92, 64–88. [Google Scholar]

- Wang, K.; Yu, J.; Yu, Y.; Qian, Y.; Zeng, D.; Guo, S.; Xiang, Y.; Wu, J. A Survey on Energy Internet: Architecture, Approach, and Emerging Technologies. IEEE Syst. J. 2017, 12, 2403–2416. [Google Scholar] [CrossRef]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart Manufacturing, Manufacturing Intelligence and Demand-Dynamic Performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Parrot, A.; Warshaw, L. Industry 4.0 and the Digital Twin; Deloitte University Press: Westlake, TX, USA, 2017. [Google Scholar]

- Hegde, G.S. Mechatronics; Jones and Bartlett Publishers: Burlington, VT, USA, 2010. [Google Scholar]

- Kuru, K.; Yetgin, H. Transformation to Advanced Mechatronics Systems Within New Industrial Revolution: A Novel Framework in Automation of Everything (AoE). IEEE Access 2019, 7, 41395–41415. [Google Scholar] [CrossRef]

- Alciatore, D.G. Introduction to Mechatronics and Measurement Systems; McGraw-Hill Education: New York, Ny, USA, 2019. [Google Scholar]

- Delsing, J. Local Cloud Internet of Things Automation: Technology and Business Model Features of Distributed Internet of Things Automation Solutions. IEEE Ind. Electron. Mag. 2017, 11, 8–21. [Google Scholar] [CrossRef]

- Ferrari, R. Writing Narrative Style Literature Reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

- Greer, C.; Burns, M.; Wollman, D.; Griffor, E. Cyber-Physical Systems and Internet of Things; NIST: Gaithersburg, MD, USA, 2019. [Google Scholar] [CrossRef]

- Braeken, A.; Liyanage, M.; Kanhere, S.; Dixit, S. Blockchain and Cyberphysical Systems. IEEE Ann. Hist. Comput. 2020, 53, 31–35. [Google Scholar] [CrossRef]

- Molano, J.I.R.; Lovelle, J.M.C.; Montenegro, C.E.; Granados, J.J.R.; Crespo, R.G. Metamodel for Integration of Internet of Things, Social Networks, the Cloud and Industry 4.0. J. Ambient Intell. Humaniz. Comput. 2018, 9, 709–723. [Google Scholar] [CrossRef]

- Chhetri, S.R.; Rashid, N.; Faezi, S.; Faruque, M.A.A. Security Trends and Advances in Manufacturing Systems in the Era of Industry 4.0. In Proceedings of the 2017 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), Irvine, CA, USA, 13–16 November 2017; pp. 1039–1046. [Google Scholar] [CrossRef]

- Ibarra-Esquer, J.; González-Navarro, F.; Flores-Rios, B.; Burtseva, L.; Astorga-Vargas, M. Tracking the Evolution of the Internet of Things Concept Across Different Application Domains. Sensors 2017, 17, 1379. [Google Scholar] [CrossRef] [PubMed]

- Bradley, D.A.; Russell, D.; Ferguson, R.I.; Isaacs, J.P.; MacLeod, A.M.; White, R. The Internet of Things: The Future or the End of Mechatronics. Mechatronics 2015, 27, 57–74. [Google Scholar] [CrossRef]

- Canavan, L. What Is IIoT? The Industrial Internet of Things Primer. Industrial IoT Consortium. 25 September 2019. Available online: https://blog.iiconsortium.org/2019/09/what-is-iiot-the-industrial-internet-of-things-primer.html (accessed on 23 March 2021).

- Update on Software Issue Impacting Certain Customers. 2018. Available online: https://www.ericsson.com/en/press-releases/2018/12/update-on-software-issue-impacting-certain-customers (accessed on 23 March 2021).

- Chatzigiannakis, I.; Liagkou, V.; Spirakis, P.G. Brief Announcement: Providing End-to-End Secure Communication in Low-Power Wide Area Networks. In Proceedings of the Cyber Security Cryptography and Machine Learning (CSCML 2018), Beer Sheva, Israel, 21–22 June 2018; pp. 101–104. [Google Scholar]

- Forsstrom, S.; Butun, I.; Eldefrawy, M.; Jennehag, U.; Gidlund, M. Challenges of Securing the Industrial Internet of Things Value Chain. In Proceedings of the 2018 Workshop on Metrology for Industry 4.0 and IoT, Brescia, Italy, 16–18 April 2018. [Google Scholar] [CrossRef] [Green Version]

- Kouicem, D.E.; Bouabdallah, A.; Lakhlef, H. Internet of Things Security: A Top-down Survey. Comput. Netw. 2018, 141, 199–221. [Google Scholar] [CrossRef] [Green Version]

- Gantz, J.; Reinsel, D. Extracting Value from Chaos. IDC Iview 2011, 1142, 1–12. [Google Scholar]

- Li, J.; Tao, F.; Cheng, Y.; Zhao, L. Big Data in Product Lifecycle Management. Int. J. Adv. Manuf. Technol. 2015, 81, 667–684. [Google Scholar] [CrossRef]

- Cohen, P.R.; Feigenbaum, E.A. The Handbook of Artificial Intelligence: Volume 3; Butterworth-Heinemann: Oxford, UK, 2014; Volume 3. [Google Scholar]

- Siciliano, B.; Khatib, O. Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Nolfi, S.; Floreano, D. Evolutionary Robotics, The Biology, Intelligence and Technology of Self-Organizing Machines. In A Bradford Book; MIT Press: Cambridge, MA, USA, 2000. [Google Scholar]

- Thames, L.; Schaefer, D. Software-Defined Cloud Manufacturing for Industry 4.0. Procedia Cirp 2016, 52, 12–17. [Google Scholar] [CrossRef] [Green Version]

- Hao, Y.; Helo, P. The Role of Wearable Devices in Meeting the Needs of Cloud Manufacturing: A Case Study. Robot. Comput. Integr. Manuf. 2017, 45, 168–179. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X. Industry 4.0 and Cloud Manufacturing: A Comparative Analysis. J. Manuf. Sci. Eng. 2017, 139, 034701. [Google Scholar] [CrossRef]

- Iorga, M.; Feldman, L.; Barton, R.; Martin, M.J.; Goren, N.; Mahmoudi, C. Fog Computing Conceptual Model; NIST: Gaithersburg, MD, USA, 2018. [Google Scholar] [CrossRef]

- Svorobej, S.; Endo, P.; Bendechache, M.; Filelis-Papadopoulos, C.; Giannoutakis, K.; Gravvanis, G.; Tzovaras, D.; Byrne, J.; Lynn, T. Simulating Fog and Edge Computing Scenarios: An Overview and Research Challenges. Future Internet 2019, 11, 55. [Google Scholar] [CrossRef] [Green Version]

- Kovar, J.; Mouralova, K.; Ksica, F.; Kroupa, J.; Andrs, O.; Hadas, Z. Virtual Reality in Context of Industry 4.0 Proposed Projects at Brno University of Technology. In Proceedings of the 2016 17th International Conference on Mechatronics—Mechatronika (ME), Prague, Czech Republic, 7–9 December 2016; pp. 1–7. [Google Scholar]

- Liagkou, V.; Salmas, D.; Stylios, C. Realizing Virtual Reality Learning Environment for Industry 4.0. Procedia CIRP 2019, 79, 712–717. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers From a Modeling Perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards Future Industrial Opportunities and Challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Boeckl, K.; Fagan, M.; Fisher, W.; Lefkovitz, N.; Megas, K.N.; Nadeau, E.; O’Rourke, D.G.; Piccarreta, B.; Scarfone, K. Considerations for Managing Internet of Things (IoT) Cybersecurity and Privacy Risks; NIST: Gaithersburg, MD, USA, 2019. [Google Scholar] [CrossRef]

- AL-Salman, H.I.; Salih, M.H. A Review Cyber of Industry 4.0 (Cyber-Physical Systems (CPS), the Internet of Things (IoT) and the Internet of Services (IoS)): Components, and Security Challenges. J. Phys. Conf. Ser. 2019, 1424, 012029. [Google Scholar] [CrossRef]

- ENISA. Good Practices for Security of Internet of Things in the Context of Smart; ENISA: Attiki, Greece, 2018; Available online: https://www.enisa.europa.eu/publications/good-practices-for-security-of-iot (accessed on 23 March 2021).

- Suvorov, A. Securing Industrial Revolution 4.0. 2016. Available online: https://www.kaspersky.com/blog/securing-industrial-revolution-4-0/15136/ (accessed on 23 March 2021).

- Levite, A. ICT Supply Chain Integrity: Principles for Governmental and Corporate Policies. Available online: https://carnegieendowment.org/2019/10/04/ict-supply-chain-integrity-principles-for-governmental-and-corporate-policies-pub-79974 (accessed on 23 March 2021).

- How China Used a Tiny Chip in a Hack That Infiltrated U.S Companies. Bloomberg. 4 October 2018. Available online: https://www.bloomberg.com/news/features/2018-10-04/the-big-hack-how-china-used-a-tiny-chip-to-infiltrate-america-s-top-companies (accessed on 23 March 2021).

- Brandom, R. Russian Hackers Used Kaspersky Software to Find Vulnerable NSA Docs, Says Report. Available online: https://www.theverge.com/2017/10/5/16431564/kaspersky-russian-hackers-nsa-document-breach (accessed on 23 March 2021).

- Russian Hackers Target Industrial Control Systems: US Intel Chief|SecurityWeek.Com. Available online: https://www.securityweek.com/russian-hackers-target-industrial-control-systems-us-intel-chief (accessed on 23 March 2021).

- Stubbs, J.; Matthias, W. Ukraine Scrambles to Contain New Cyber Threat after “NotPetya” Attack. Reuters. 5 July 2017. Available online: https://www.reuters.com/article/us-cyber-attack-ukraine-backdoor-idUSKBN19Q14P (accessed on 23 March 2021).

- Dragonfly: Western Energy Sector Targeted by Sophisticated Attack Group. Available online: https://symantec-enterprise-blogs.security.com/blogs/threat-intelligence/dragonfly-energy-sector-cyber-attacks (accessed on 23 March 2021).

- Stubbs, J.; Menn, J.; Bing, C. Stealing Clouds. Available online: https://www.reuters.com/investigates/special-report/china-cyber-cloudhopper/ (accessed on 23 March 2021).

- ShadowPad: How Attackers Hide Backdoor in Software Used by Hundreds of Large Companies around the World. Available online: https://www.kaspersky.com/about/press-releases/2017_shadowpad-how-attackers-hide-backdoor-in-software-used-by-hundreds-of-large-companies-around-the-world (accessed on 23 March 2021).

- Check Point Software Technologies LTD. Cyber Attack Trends: 2019 Mid-Year Report; Check Point Software Technologies LTD: San Carlos, CA, USA, 2019; p. 24. Available online: https://research.checkpoint.com/2019/cyber-attack-trends-2019-mid-year-report/ (accessed on 23 March 2021).

- Hackers Hijacked ASUS Software Updates to Install Backdoors on Thousands of Computers. Available online: https://www.vice.com/en/article/pan9wn/hackers-hijacked-asus-software-updates-to-install-backdoors-on-thousands-of-computers (accessed on 23 March 2021).

- Mirrorthief Hits Campus Online Stores Using Magecart. Available online: https://www.trendmicro.com/en_us/research/19/e/mirrorthief-group-uses-magecart-skimming-attack-to-hit-hundreds-of-campus-online-stores-in-us-and-canada.html (accessed on 23 March 2021).

- Magecart Delivered Via Advertising Supply Chain. Available online: https://www.trendmicro.com/en_us/research/19/a/new-magecart-attack-delivered-through-compromised-advertising-supply-chain.html (accessed on 23 March 2021).

- Operation Sheep: Pilfer-Analytics SDK in Action. Available online: https://research.checkpoint.com/2019/operation-sheep-pilfer-analytics-sdk-in-action/ (accessed on 23 March 2021).

- 2018 Cyber Threatscape report, Accenture, US. 2018. Available online: https://www.accenture.com/_acnmedia/PDF-83/Accenture-Cyber-Threatscape-Report-2018.pdf (accessed on 23 March 2021).

- Insecure SCADA Systems Blamed in Rash of Pipeline Data Network Attacks. Available online: https://threatpost.com/insecure-scada-systems-blamed-in-rash-of-pipeline-data-network-attacks/130952/ (accessed on 23 March 2021).

- Jan 29, S.P.|T.|U.; 2016; Ist, 19:54. 3 Wipro Employees Arrested for Hacking UK Firm TalkTalk—Times of India. Available online: https://timesofindia.indiatimes.com/tech-news/3-wipro-employees-arrested-for-hacking-uk-firm-talktalk/articleshow/50764649.cms (accessed on 23 March 2021).

- Bateman, T. Police Warning after Drug Traffickers’ Cyber-Attack. BBC News. 16 October 2013. Available online: https://www.bbc.com/news/world-europe-24539417 (accessed on 23 March 2021).

- Lu, G.; Koufteros, X.; Talluri, S.; Hult, G.T.M. Deployment of Supply Chain Security Practices: Antecedents and Consequences. Decis. Sci. 2019, 50, 459–497. [Google Scholar] [CrossRef]

- Cargo Plane Bomb Plot: Ink Cartridge Bomb “Timed to Blow up over US”. Available online: https://www.telegraph.co.uk/news/uknews/terrorism-in-the-uk/8124226/Cargo-plane-bomb-plot-ink-cartridge-bomb-timed-to-blow-up-over-US.html (accessed on 23 March 2021).

- Camenisch, J.; Lysyanskaya, A. Signature Schemes and Anonymous Credentials from Bilinear Maps; Springer: Berlin/Heidelberg, Germany, 2004; pp. 56–72. [Google Scholar] [CrossRef] [Green Version]

- Papadamou, K.; Gevers, S.; Xenakis, C.; Sirivianos, M.; Zannettou, S.; Chifor, B.; Teican, S.; Gugulea, G.; Caponi, A.; Recupero, A.; et al. Killing the Password and Preserving Privacy With Device-Centric and Attribute-Based Authentication. IEEE Trans. Inf. Forensics Secur. 2020, 15, 2183–2193. [Google Scholar] [CrossRef]

- Liagkou, V.; Stylios, C. A Trustworthy and Privacy Preserving Model for Online Competence Evaluation System; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 338–347. [Google Scholar] [CrossRef]

- Liagkou, V.; Metakides, G.; Pyrgelis, A.; Raptopoulos, C.; Spirakis, P.; Stamatiou, Y.C. Privacy Preserving Course Evaluations in Greek Higher Education Institutes: An e-Participation Case Study with the Empowerment of Attribute Based Credentials; Springer: Berlin/Heidelberg, Germany, 2014; pp. 140–156. [Google Scholar] [CrossRef]

- Liagkou, V.; Stylios, C.; Petunin, A. Handling Privacy and Concurrency in an Online Educational Evaluation System. Balt. J. Mod. Comput. 2019, 7, 86–98. [Google Scholar] [CrossRef]

- Bernabe, J.B.; Canovas, J.L.; Hernandez-Ramos, J.L.; Moreno, R.T.; Skarmeta, A. Privacy-Preserving Solutions for Blockchain: Review and Challenges. IEEE Access 2019, 7, 164908–164940. [Google Scholar] [CrossRef]

- Bouchelaghem, S.; Omar, M. Secure and Efficient Pseudonymization for Privacy-Preserving Vehicular Communications in Smart Cities. Comput. Electr. Eng. 2020, 82, 106557. [Google Scholar] [CrossRef]

- Min, H. Blockchain Technology for Enhancing Supply Chain Resilience. Bus. Horiz. 2019, 62, 35–45. [Google Scholar] [CrossRef]

- Gawanmeh, A.; Parvin, S.; Venkatraman, S.; Souza-Daw, T.; Kang, J.; Kaspi, S.; Jackson, J. A Framework for Integrating Big Data Security Into Agricultural Supply Chain. In Proceedings of the 2019 IEEE Fifth International Conference on Big Data Computing Service and Applications (BigDataService), Newark, CA, USA, 4–9 April 2019; pp. 191–194. [Google Scholar] [CrossRef]

- Cha, J.; Singh, S.K.; Pan, Y.; Park, J.H. Blockchain-Based Cyber Threat Intelligence System Architecture for Sustainable Computing. Sustainability 2020, 12, 6401. [Google Scholar] [CrossRef]

- Skare, P.M. Method and System for Cyber Security Management of Industrial Control Systems. U.S. Patent No. 8,595,831, 26 November 2013. [Google Scholar]

| Advantages | Disadvantages |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| Security Property | Component of I.0.4 | Threat Category | Threat Event | Reference | ||

|---|---|---|---|---|---|---|

| Confidentiality | Integrity | Availability | - | - | - | - |

| - | x | - | CPS, IoT, Cloud | Threats in operation of I.4.0 | Countries use cyber threats for controlling production lines | [72,73,74,75] |

| - | x | x | CPS, IoT, Cloud | Threats in operation of I.4.0 | NotPetya attack | [72,76] |

| - | x | x | CPS, IoT, Cloud, VR/AR | Threats in operation of I.4.0 | Energy sector Attack | [77] |

| x | - | - | CPS, IoT, Cloud | Threats in components of I.4.0 | Hacking service providers | [78] |

| x | x | - | CPS, IoT, Cloud | Threats in participating entities | SW hijacked for installing backdoors | [79,80,81] |

| x | x | - | CPS, IoT, Cloud | Threats in participating entities | Online credit card skimming attack | [80,82,83] |

| x | - | - | IoT | Threats in participating entities | Harvesting data via SDK | [84] |

| x | - | - | CPS | Threats in components of I.4.0 | Compromise S/W for harvesting Data | [85] |

| x | - | - | CPS | Threats in components of I.4.0 | Compromise S/W in industrial control systems | [85] |

| - | x | x | CPS | Threats in operation of I.4.0 | Exploiting insecure SCADA systems | [86] |

| x | - | - | - | Threats in participating entities | Compromised employees | [87] |

| - | x | CPS, IoT, Cloud | Threats in components of I.4.0 | Antwerp port smuggling | [72] | |

| - | x | CPS | Threats in components of I.4.0 | Eli Lilly warehouse theft | [73] | |

| - | x | - | CPS, IoT | Threats in participating entities | Contamination of meat products | [74] |

| - | x | x | - | Threats in participating entities | Explosive printer cartridges | [75] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liagkou, V.; Stylios, C.; Pappa, L.; Petunin, A. Challenges and Opportunities in Industry 4.0 for Mechatronics, Artificial Intelligence and Cybernetics. Electronics 2021, 10, 2001. https://doi.org/10.3390/electronics10162001

Liagkou V, Stylios C, Pappa L, Petunin A. Challenges and Opportunities in Industry 4.0 for Mechatronics, Artificial Intelligence and Cybernetics. Electronics. 2021; 10(16):2001. https://doi.org/10.3390/electronics10162001

Chicago/Turabian StyleLiagkou, Vasiliki, Chrysostomos Stylios, Lamprini Pappa, and Alexander Petunin. 2021. "Challenges and Opportunities in Industry 4.0 for Mechatronics, Artificial Intelligence and Cybernetics" Electronics 10, no. 16: 2001. https://doi.org/10.3390/electronics10162001

APA StyleLiagkou, V., Stylios, C., Pappa, L., & Petunin, A. (2021). Challenges and Opportunities in Industry 4.0 for Mechatronics, Artificial Intelligence and Cybernetics. Electronics, 10(16), 2001. https://doi.org/10.3390/electronics10162001