Design of Refueling Control System with Multi-ControlTerminal Based on Network

Abstract

1. Introduction

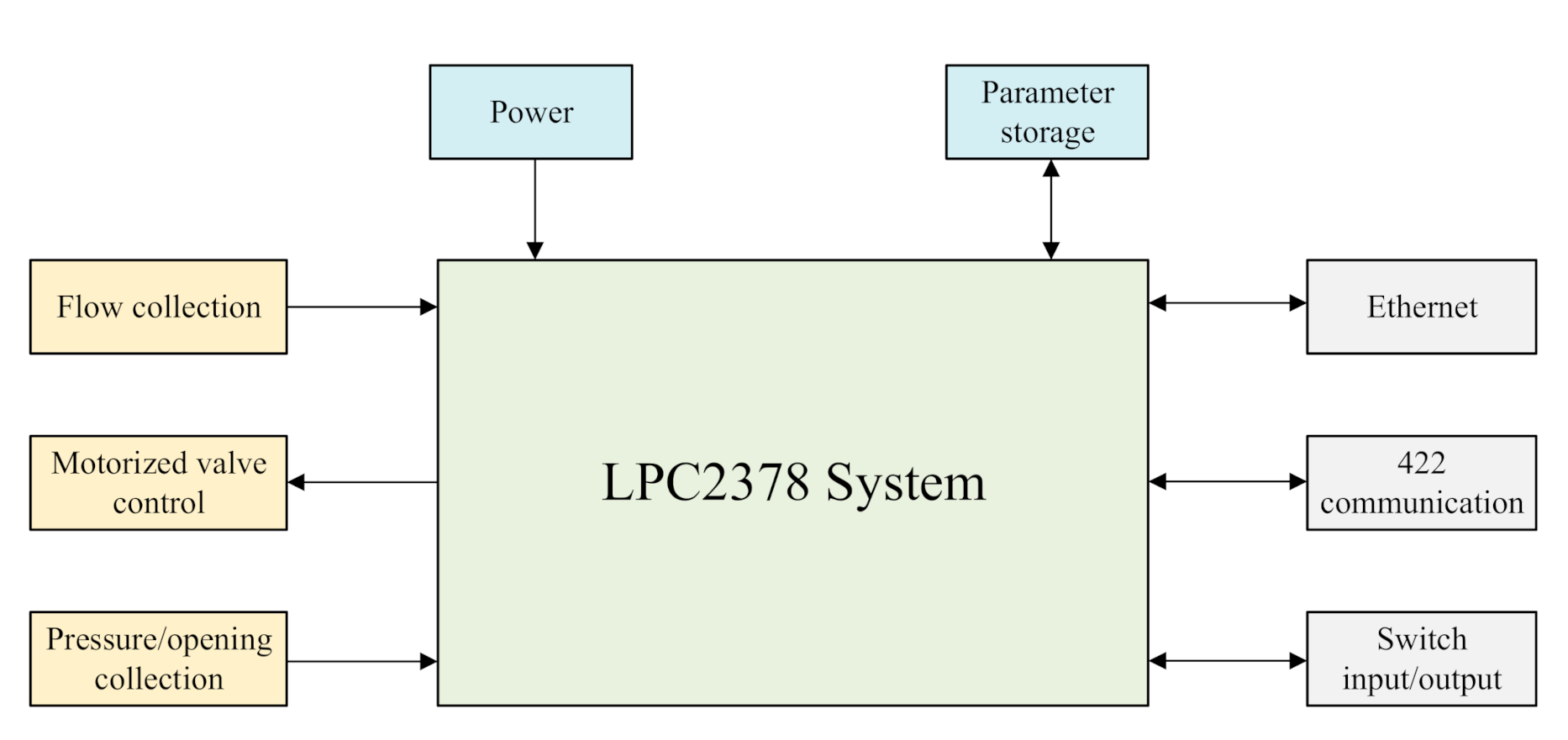

2. System Function and Overall Plan

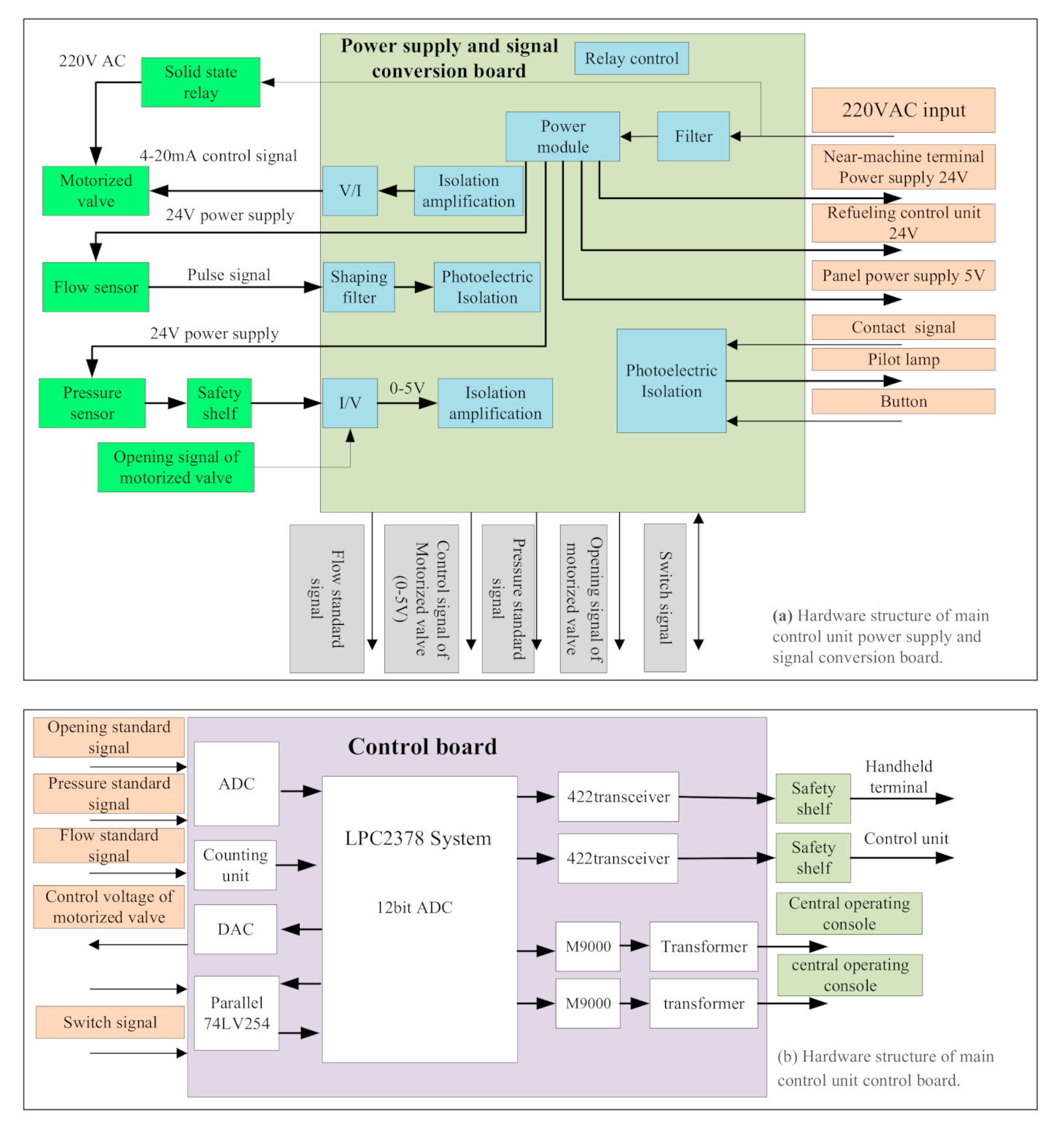

3. Hardware Design of MCU

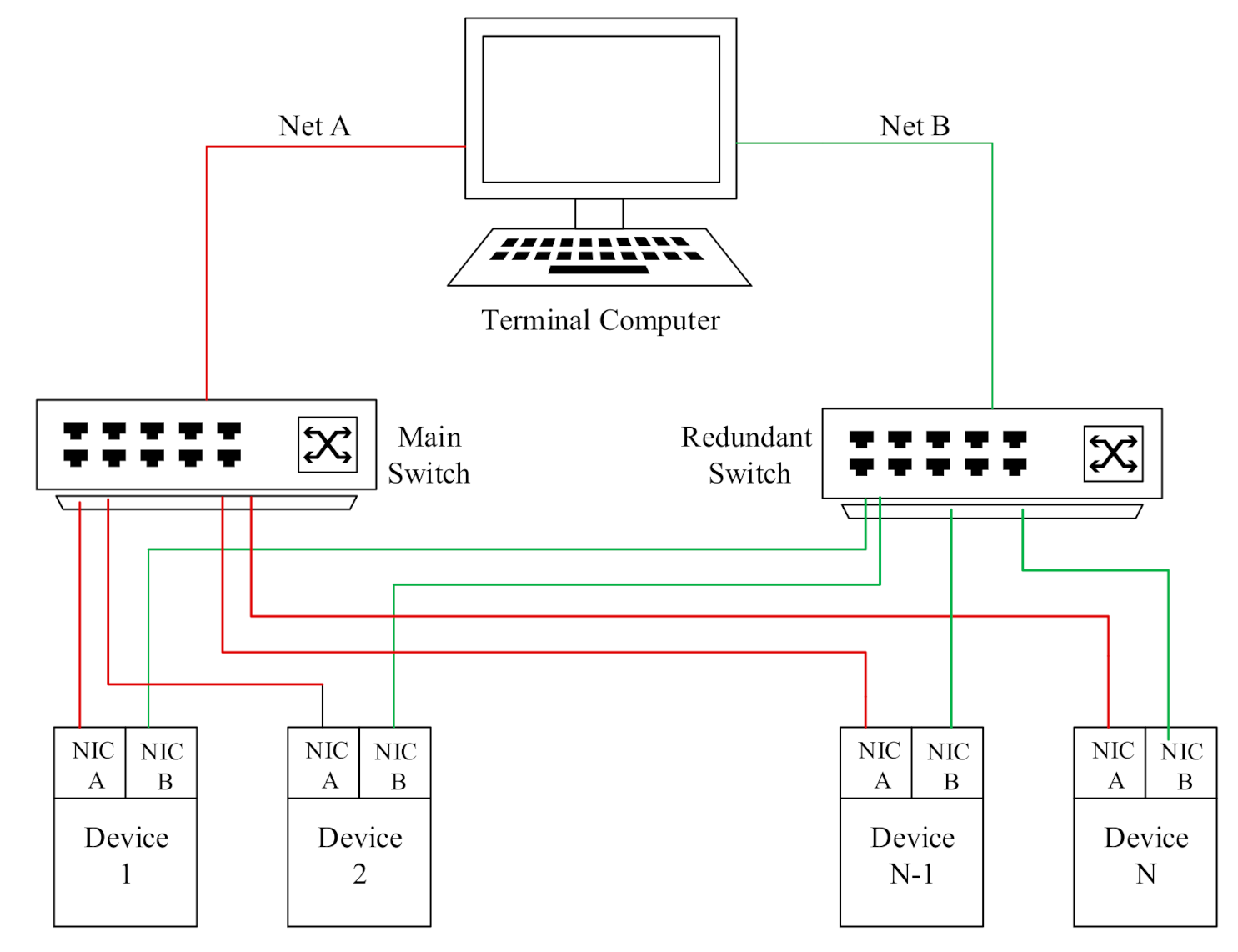

3.1. Overall Introduction of Hardware

3.2. Main Hardware Design

4. System Software Design

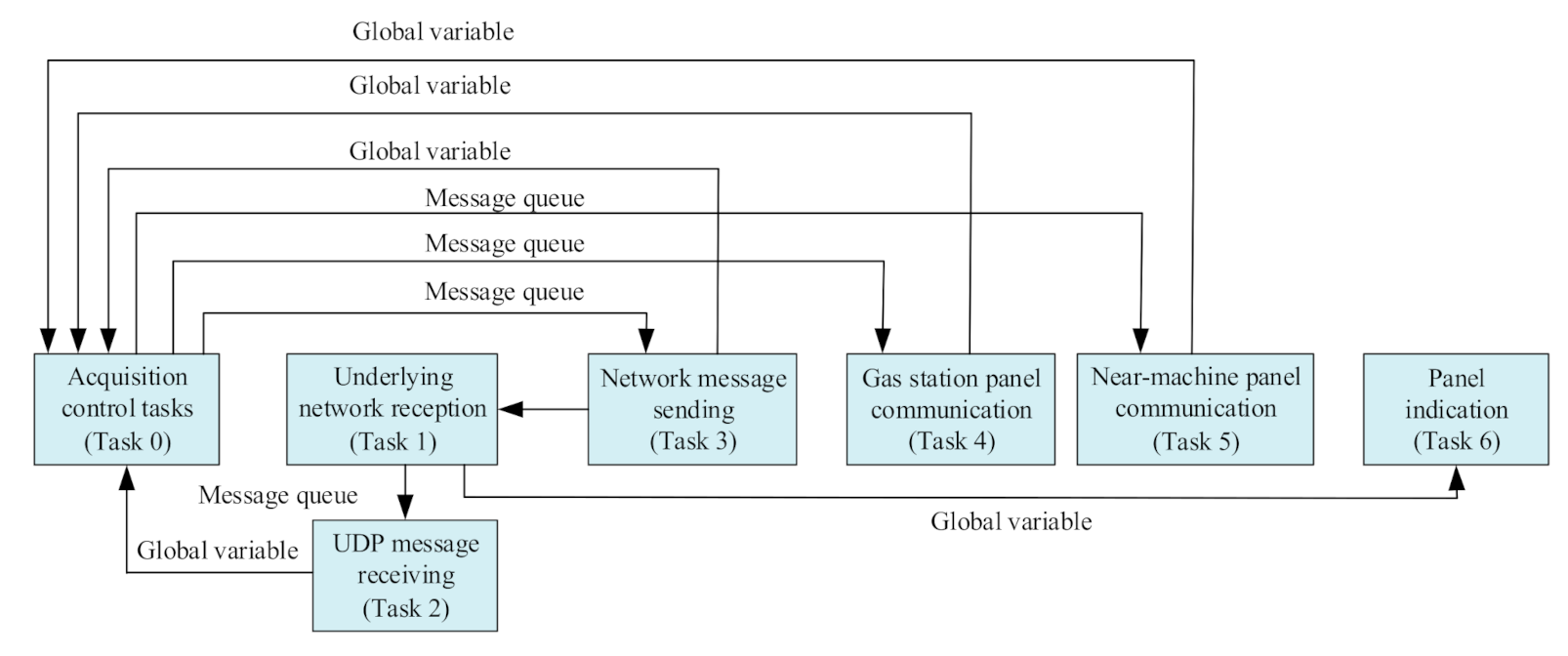

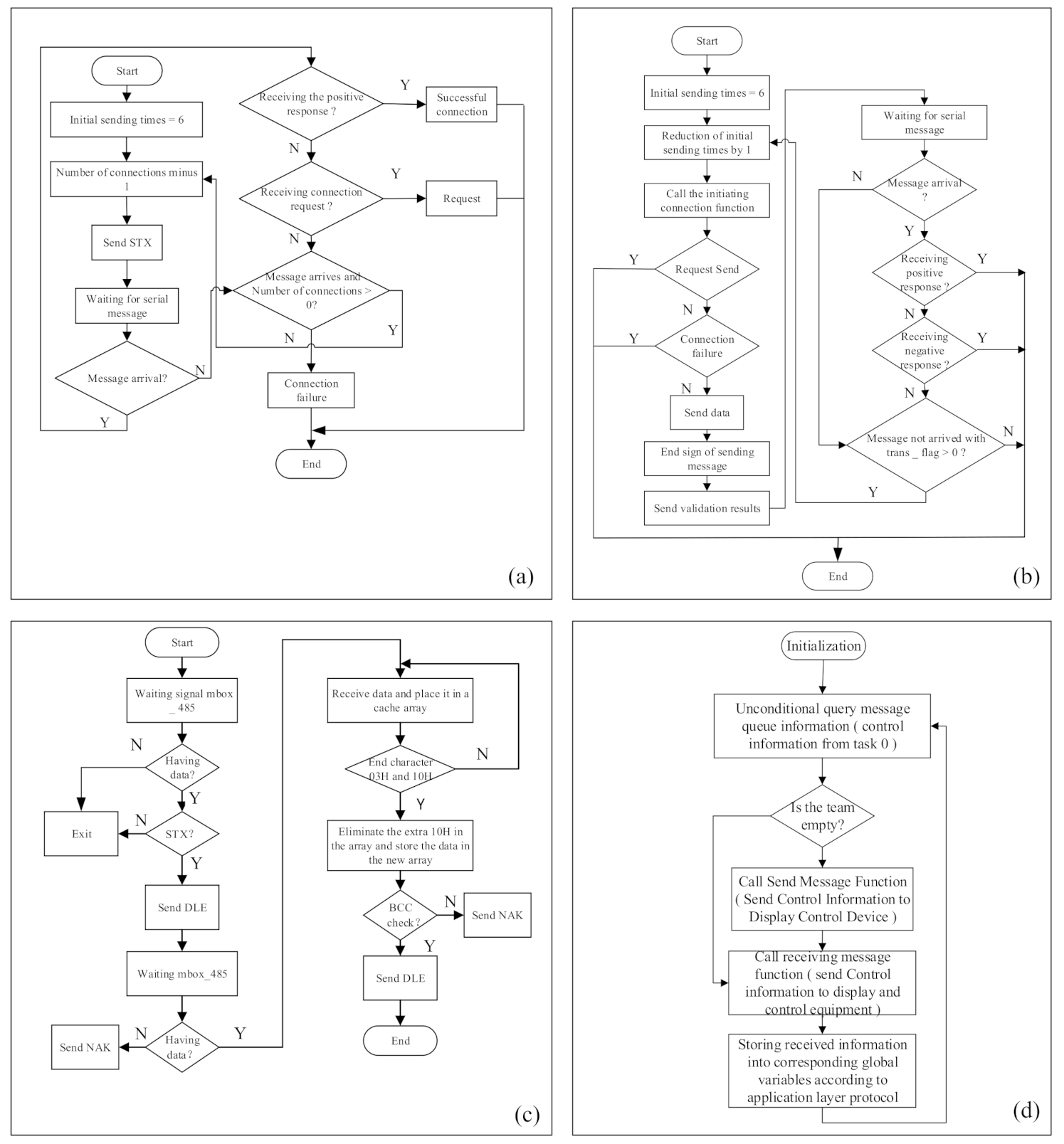

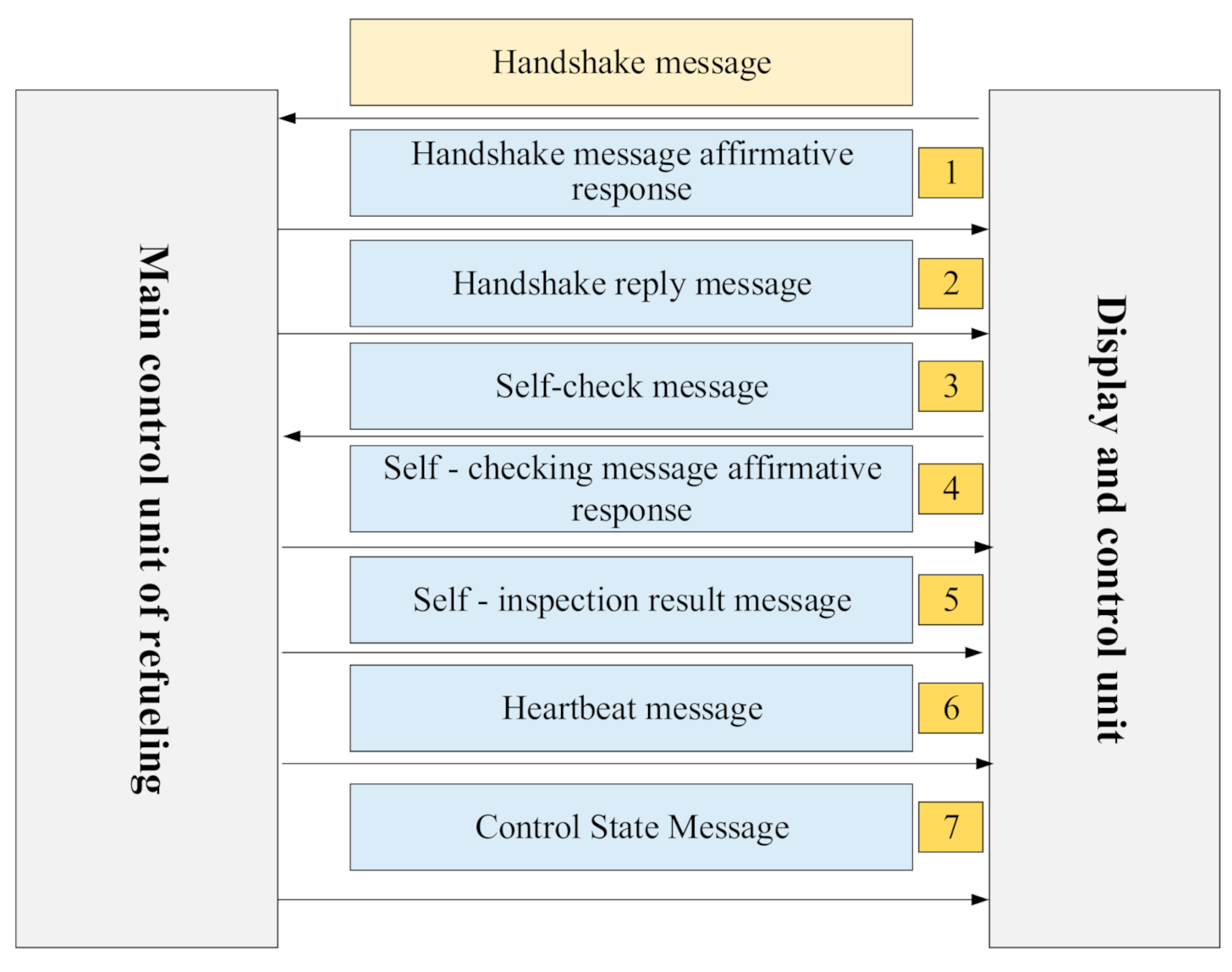

4.1. Embedded Software Design

- (1)

- Task 0 is the highest priority and mainly completes the flow, pressure collection, and velocity closed-loop control. The sampling period is 200 ms in the system. The process information of the control task is transmitted to Tasks 3, 4, and 5 through three message queues to realize the information output of the three terminals.

- (2)

- Task 1 is the second priority and mainly achieves the network packet query reception and redundant switching of Ethernet main equipment network.

- (3)

- Task 2 receives the UDP message of the application layer, and the working message queue of Task 1 is passed to Task 2. Task 2 passes control commands to Task 0 through global variables.

- (4)

- Task 3 sends site control information UDP message to the central console. Task 3 receives information from Task 0 through the queue buffer.

- (5)

- Task 4, an information exchange with the DCU of refueling station mutual, including sending information and receiving setting instructions. The queue buffer receives control information from Task 0 and sets control instructions for Task 0 through global variables.

- (6)

- Task 5 interacts with the near-machine DCU. The queue buffer receives control information from Task 0 and sends simple control instructions to Task 0 through global variables.

- (7)

- Task 6 is a low real-time task, such as indicator light control.

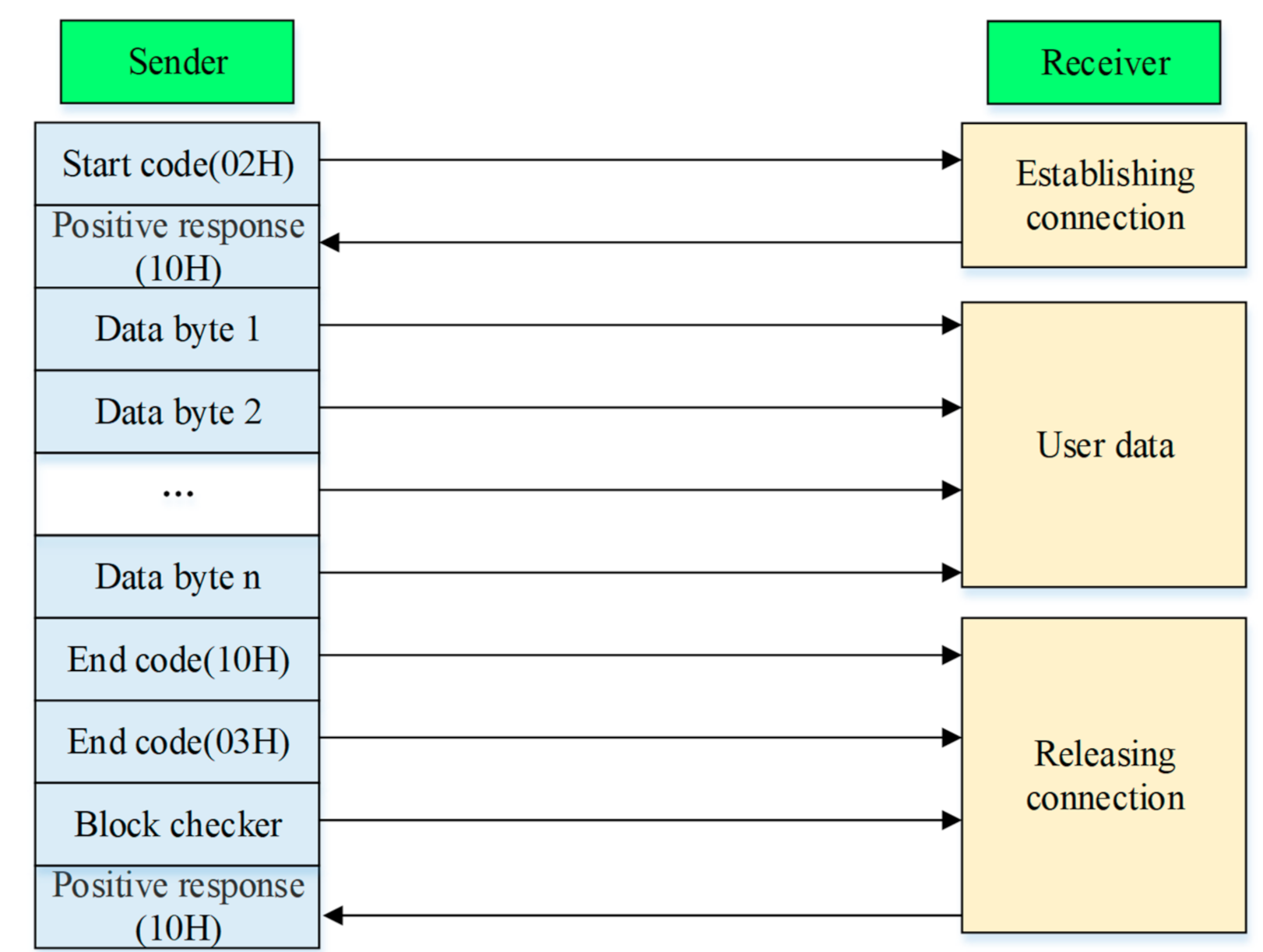

4.2. Communication Part

4.2.1. The 485 Communication

4.2.2. Dual-Redundant NIC

- (1)

- Normal switching

- (2)

- Passive switching

- (3)

- Increased switching of abnormal messages

4.3. Sampling Control Part

4.3.1. Flow Control

- (4)

- Flow collection: the external pulse counter is used to calculate the number of external pulses; the sampling period is set to 200 ms; the counter is 16 bits. Two situations need to be considered when accumulative fueling statistics:

- (a)

- When the current 16-bit calculated value is greater than the previous 16-bit value, the cumulative pulse number NT in 200 ms can be expressed as follows:where is the value of the current sampling period counter, and is the value of the last sampling period counter.

- (b)

- When the current 16-bit value is less than the previous 16-bit value within 200 ms, the accumulated pulses within 200 ms is as follows:

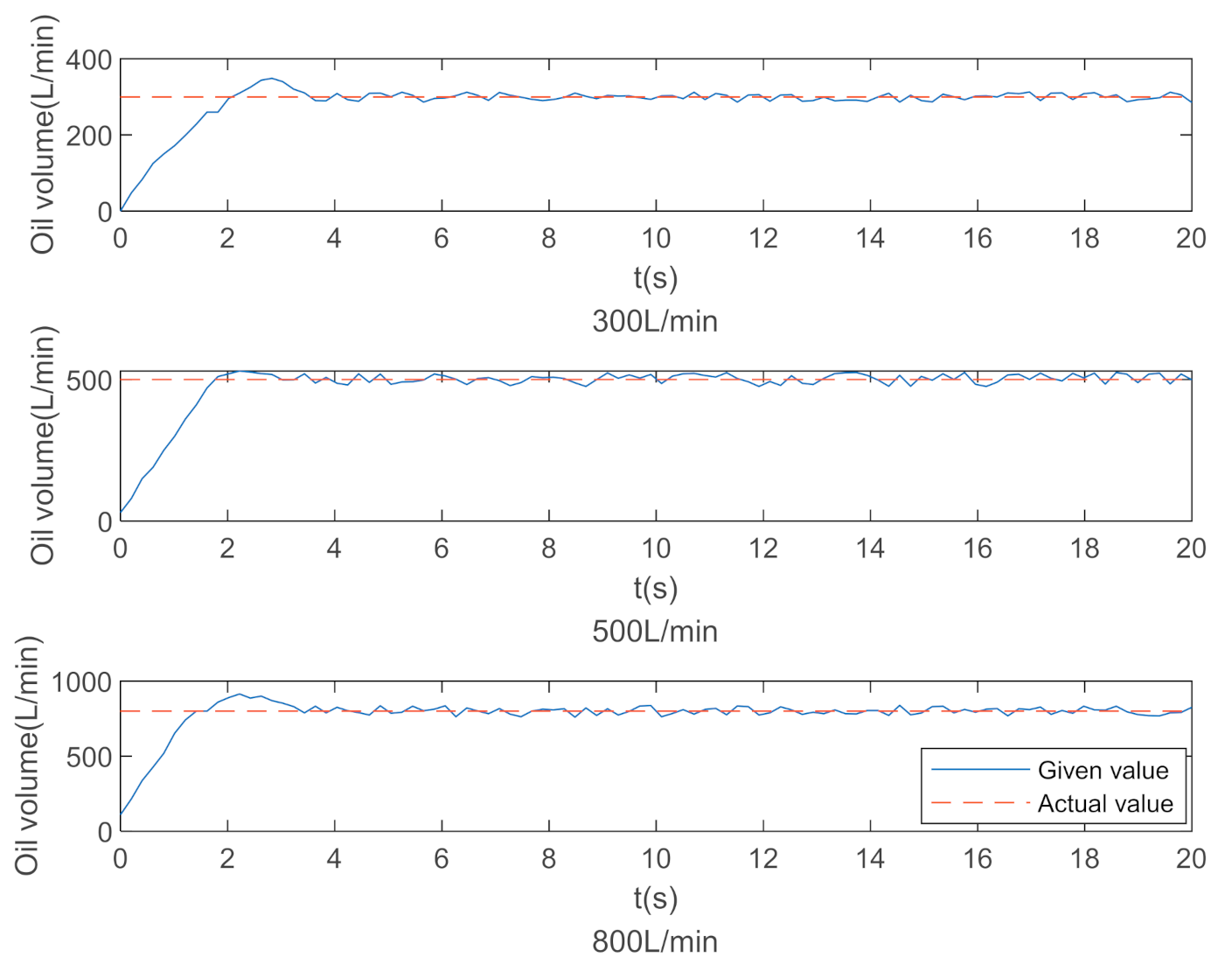

4.3.2. Flow Velocity Control

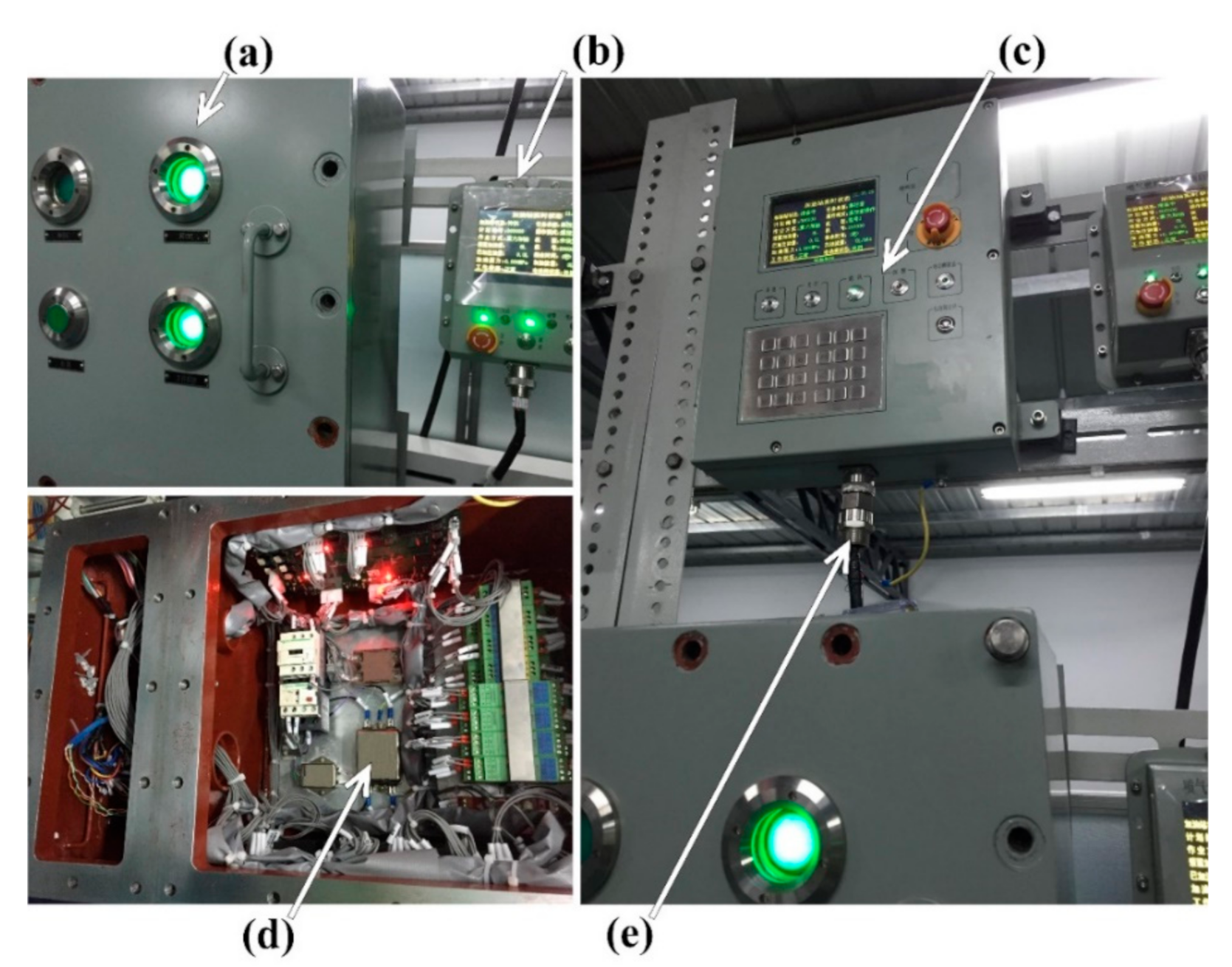

5. Experiments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, K.; Quan, Q.; Wonham, W.M. Failsafe Mechanism Design for Autonomous Aerial Refueling using State Tree Structures. Unmanned Syst. 2019, 7, 261–279. [Google Scholar] [CrossRef]

- Sun, S.; Yin, Y.; Wang, X.; Xu, D. Robust Landmark Detection and Position Measurement Based on Monocular Vision for Autonomous Aerial Refueling of UAVs. IEEE Trans. Cybern. 2019, 49, 4167–4179. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Li, H.; Luo, Q.; Zhang, C.; Li, C.; Li, P.; Deng, Y. A binocular vision-based UAVs autonomous aerial refueling platform. Sci. China Inf. Sci. 2016, 59, 1–7. [Google Scholar] [CrossRef][Green Version]

- Xu, Y.; Duan, H.; Li, C.; Deng, Y. On-board visual navigation system for unmanned aerial vehicles autonomous aerial refueling. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2017, 233, 1193–1203. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, Q. Visual Measurement in Simulation Environment for Vision-Based UAV Autonomous Aerial Refueling. IEEE Trans. Instrum. Meas. 2015, 64, 2468–2480. [Google Scholar] [CrossRef]

- Brisse, A.; Zeller, M.; Ludwig, B.; Brabandt, J. Solid Oxide Electrolyzer System Operational at the H2 Refueling Station of Karlsruhe. Fuel Cells 2019, 19. [Google Scholar] [CrossRef]

- Riedl, S.M. Development of a Hydrogen Refueling Station Design Tool. Int. J. Hydrogen Energy 2020, 45, 1–9. [Google Scholar] [CrossRef]

- Xu, X.; Hu, W.; Cao, D.; Huang, Q.; Liu, W.; Jacobson, M.Z.; Chen, Z. Optimal operational strategy for an offgrid hybrid hydrogen/electricity refueling station powered by solar photovoltaics. J. Power Sources 2020, 451, 227810. [Google Scholar] [CrossRef]

- Williamson, W.R.; Glenn, G.J.; Dang, V.T.; Speyer, J.L.; Stecko, S.M.; Takacs, J.M. Sensor Fusion Applied to Autonomous Aerial Refueling. J. Guid. Contr. Dynam. 2015, 32, 262–275. [Google Scholar] [CrossRef]

- Chen, C.-I.; Koseluk, R.; Buchanan, C.; Duerner, A.; Jeppesen, B.; Laux, H. Autonomous Aerial Refueling Ground Test Demonstration—A Sensor-in-the-Loop, Non-Tracking Method. Sensors 2015, 15, 10948–10972. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Yuan, D.; Yan, J.; Qu, Y. Hardware-in-loop Simulation System for the Disturbed Movement of Hose-drogue During Aerial Refueling. In Proceedings of the 2018 IEEE CSAA Guidance, Navigation and Control Conference (GNCC), Xiamen, China, 10–12 August 2018. [Google Scholar]

- Plaza, E.; Santos, M. Knowledge based approach to ground refuelling optimization of commercial airplanes. Expert Syst. 2021, 38. [Google Scholar] [CrossRef]

| No. | Control Character | Value | Explanation |

|---|---|---|---|

| 1 | STX | 02 H | The starting point of the text being transmitted |

| 2 | DLE | 10 H | Positive response |

| 3 | ETX | 03 H | The endpoint of a transmitted message |

| 4 | BCC | Longitudinal parity test results of data(DLE and ETX) | |

| 5 | NAK | 15 H | Negative response |

| Group | Switch Direction | Measured Time (ms) | Variance |

|---|---|---|---|

| 1 | A to B | 32.1 | 1.89 |

| 2 | B to A | 46.3 | 1.85 |

| 3 | A to B | 35.2 | 1.87 |

| 4 | B to A | 48.2 | 1.88 |

| 5 | A to B | 32.3 | 1.90 |

| 6 | B to A | 48.2 | 1.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, B.; Zhang, Z.; Zhang, X.; Xiang, J. Design of Refueling Control System with Multi-ControlTerminal Based on Network. Electronics 2021, 10, 1559. https://doi.org/10.3390/electronics10131559

Zeng B, Zhang Z, Zhang X, Xiang J. Design of Refueling Control System with Multi-ControlTerminal Based on Network. Electronics. 2021; 10(13):1559. https://doi.org/10.3390/electronics10131559

Chicago/Turabian StyleZeng, Bowen, Zhongmin Zhang, Xiao Zhang, and Jing Xiang. 2021. "Design of Refueling Control System with Multi-ControlTerminal Based on Network" Electronics 10, no. 13: 1559. https://doi.org/10.3390/electronics10131559

APA StyleZeng, B., Zhang, Z., Zhang, X., & Xiang, J. (2021). Design of Refueling Control System with Multi-ControlTerminal Based on Network. Electronics, 10(13), 1559. https://doi.org/10.3390/electronics10131559