Abstract

Over the past decade, new models of hybrid electric vehicles have been released worldwide, and the fuel efficiency of said vehicles has increased by more than 5%. To further improve fuel efficiency, vehicle manufacturers have made efforts to design modules (e.g., engines, motors, transmissions, and batteries) with the highest efficiency possible. To do so, the fuel economy test process, which is conducted primarily using a chassis dynamometer, must produce reliable and accurate results. To accurately analyze the fuel efficiency improvement rate of each module, it is necessary to reduce the test deviation. When the test conducted by human drivers, the test deviation is somewhat large. When the test is conducted by a physical robot driver, the test deviation is improved; however, these robots are expensive and time-consuming to install and take up considerable amount of space in the driver’s seat. To compensate for these shortcomings, we propose a simple, structured robot system that manipulates electrical signals without using mechanical link structures. The controller of this robot driver uses the widely used PI controller. Although PI controllers are simple and perform well, since the dynamics of each test vehicle is different (e.g., acceleration response), the PI controller has a disadvantage in that it cannot determine the optimal PI gain value for each vehicles. In this work, the fuzzy control theorem is applied to overcome this disadvantage. By using fuzzy control to deduce the optimal value of the PI gain, we confirmed that our proposed system is available to conduct tests on vehicles with different dynamics.

1. Introduction

Regulations regarding fuel efficiency and emissions in the automotive industry have become stricter since 1992, and developing eco-friendly vehicles has become an inevitable challenge for automakers. To satisfy these regulations, hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) have been widely developed by the major automobile companies.

There are two types of powertrain systems for (P)HEVs: (i) add-on type, where electric motors are added to the existing internal combustion engine transmission system and (ii) dedicated hybrid transmissions (DHTs), which are especially designed for use in (P)HEVs [1]. The application of these systems have contributed to the commercialization of (P)HEVs by achieving a 50% reduction in fuel efficiency compared to the conventional ICE (internal combustion engine) vehicles [2].

Even though HEVs and PHEVs are already commercialized, continuous development for fuel efficiency is needed to meet these regulations. Additionally, there has been a rapid paradigm shift regarding eco-friendly cars according to the automobile market, and to counteract this, many vehicle manufacturers are increasing the portion of eco-friendly vehicle in their vehicle models. In the European automobile market, (H)EVs are expected to replace vehicles with conventional internal combustion engines by 2030, and more than 50% of these vehicles will be electric [3]. Moreover, the prevalence of fuel cell vehicles is expected to grow more than 40% annually. For HEVs to compete with eco-friendly cars, the former must satisfy regulations, have reduced development costs, and demonstrate improved fuel efficiency [4]. Over the past decade, the fuel efficiency of HEVs has improved by more than 5% compared with that of previously released models. As fuel efficiency competition becomes fiercer, developing fuel-efficient vehicles becomes more challenging, and vehicle manufacturers are making every effort to develop control methods and hardware to raise fuel efficiency figures even by the factor of 0.1%.

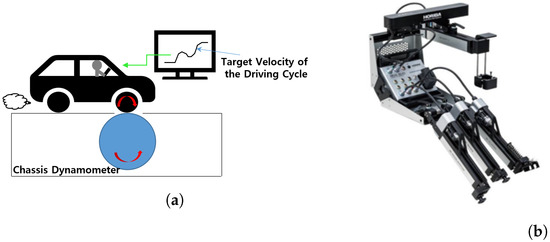

In addition to improving hardware and software to improve fuel efficiency, demonstrating effectiveness through real-world testing is also emerging as an important methodology. The real-world test is carried out by driving a predetermined drive cycle on a chassis dynamometer [5]. The chassis dynamometer is an instrument that mimics a real-world road consisting of fixed rollers (Figure 1a). It is essential in the vehicle development procedure because it has the advantage of being easy to run repeatedly under the same external conditions. However, other test conditions, such as changes in driving characteristics by different drivers, are uncontrollable factors. In fact, even though a skilled and qualified professional driver conducts a long-term repeated test cycle, the target velocity error will be inconsistent, thus making it difficult to verify the test results because of human errors. Therefore, there is a demand for robot drivers that autonomously drive to follow speed profiles on behalf of professional drivers.

Figure 1.

(a) Fuel Economy and Exhaust Test with Chassis Dynamometer. (b) HORIBA ADS EVO.

The current commercialized robot drivers have multiple physical actuators, and these directly control the pedals of the vehicle (Figure 1b). This physical robot driver is installed directly in the driver’s seat and has multiple mechanical parts that take up space here. Due to these characteristics, existing robot drivers have the disadvantage of being complicated in the installation process, difficult to use in real road driving, and expensive.

To solve these problems, we propose a simple robotic driver system (SimRoDS) based on CAN (controller area network) signal. It has a simple structure because it has no physical actuators, and instead of physical actuators the vehicle control is carried out by electric signals. Because of its simplicity, the proposed system does not take much space, enabling driving tests on real roads with a driver in the driver’s seat.

The PI controller, which is widely used in the control system of robot driver [5,6], is applied in our system. The speed-following performance of the proposed system is significantly related to the control parameters (P, I gains). In this research, we have implemented two different control methods for the PI controller; conventional PI control method using fixed gain and fuzzy-logic-based dynamic control method where the P, I gains are dynamically altered as the result of our fuzzy control logic.

Numerous successful attempts have already been made to eliminate human errors and improve the repeatability of tests. The H-infinite-based controller was proposed for speed tracking conducted by a robot driver [7], whereas proportional integral derivative(PID) control was applied to speed tracking by a robotic driver [5]. However, according to the test results, there were several issues, such as the inability to locate to optimal control parameters, a large overshoot, and speed fluctuation. A vehicle model was constructed to improve vehicle speed-tracking performance [6,8]. A robot driver system that combined cooperative and sliding mode control has been proposed [9]. Fuzzy neural control was implemented on an unmanned robot for an automotive test [10]. A driver model based on the iterative learning control algorithm has been proposed [11]. A robot driver that considers the shift manipulator mechanism has been designed [12]. A fuzzy-logic-based dynamic speed control method was applied to a robot driver [13]. However, these studies are based on robots that have a physical manipulator. In this research, we propose a novel robotic driver system that does not use a physical manipulator for operating acceleration and brake pedal. Instead, the proposed system uses the CAN and electric signals to accelerate or brake the test vehicle.

In many fields and not just in automotive engineering, various approaches have been used to improve the performance of the PID controller by dynamically modifying the control parameters. Dynamic PID control was first introduced and it was demonstrated better performance than that of fixed gain method [14]. A fuzzy-logic-based self tuning PID controller was developed for a heating, ventilating, and air conditioning system [15]. According to research, fuzzy dynamic control outperformed the conventional PID control method. The dynamic fuzzy PID controller has been applied to an autonomous underwater vehicle [16]. The fuzzy-logic-based BLDC motor controller was proposed and it was shown that the dynamic fuzzy controller performed better than a conventional PID controller [17]. The fuzzy dynamic PID controller was also applied to feed a servo system of CNC machine tools [18], and a fuzzy-logic-based PID control system was presented for the attitude stabilization of a quad-rotor unmanned aerial vehicle [19]. In the automotive field, gradient descent-based dynamic PID control was proposed for full car suspension control [20]. A dynamic fuzzy PID control-based strategy for vehicle yaw stability was developed; the control strategy they proposed resulted in significant improvements in the safety and stability of the vehicle under different road conditions compared with the conventional control policy [21]. Fuzzy dynamic PID control was applied for the purpose of speed tracking of a pure electric vehicle [22]. Moreover, power distribution for electric vehicle, steering control, and active suspension system control have recently experienced increased performance by utilizing fuzzy dynamic control [23,24,25]. However, the above studies verified their systems only through simulation. A fuzzy PID controller was implemented a to improve the comfort and stability of the vehicle [26]. The fuzzy-logic-based PID controller outperformed the conventional PID controller in most of the prior research. In this work, we apply an dynamic fuzzy PID controller to the proposed robot driver system for the purpose of speed tracking. The main contribution of this paper can be summarized in two parts:

- The CAN (controller area network) signal-operated robot driver system is proposed for accurate and reproducible fuel efficiency tests with easier installation and less cost replacing the physical robot driver system.

- Powered by a simple dynamic PI gain autotuning algorithm based on fuzzy logic, the proposed robot driver system demonstrates much improved target velocity following performance compared to fixed PI gain approach, enabling accurate fuel efficiency testing including industry standards such as the FTP cycle.

2. Problem Description

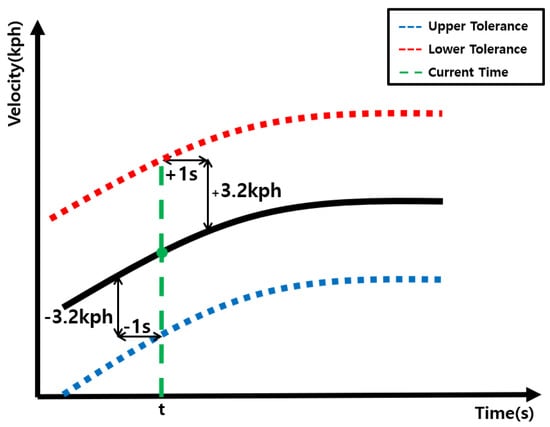

Most fuel efficiency testing methods define a target velocity profile which should be followed by the tester during the test. When the vehicle is driven by a human driver, it is almost impossible to accurately adhere to the planned target speed at every second. For this reason, speed tolerance is defined. Figure 2 shows the speed tolerance regulation for the vehicle emission test. The regulation is as follows: the upper speed tolerance is 3.2 km/h higher than the highest velocity on the speed profile within ±1 s of the prescribed time (t), and the lower speed tolerance is 3.2 km/h lower than the lowest velocity on the speed pr ofile within ±1 s of the prescribed time (t). If this tolerance is exceeded for a certain period of time, the relevant test results are nullified.

Figure 2.

Speed Tolerance.

The fuel economy and exhaust test requires the driver to adhere to the defined velocity profile. The fuel economy and exhaust test is conducted with the vehicle installed in the chassis dynamometer (Figure 1a). When the installation is complete, the test vehicle can be controlled by the driver, who manipulates the acceleration and brake pedal. When the driving is complete, the result is obtained by calculating the fuel consumption and amount of exhaust gas. When developing a vehicle’s fuel economy and exhaust performance, the deviation of the result must be small when multiple tests are conducted. A couple of problems arise when the test is conducted by human drivers.

- When several time-consuming tests, such as distance to empty (DTE), are conducted, it can result in large variations.

- Training professional drivers are costly.

To resolve these problems, robotic systems are employed. Currently, various models of robot drivers can be used to conduct the test with chassis dynamometer. HORIBA’s ADS EVO (Figure 1b) and Stahle’s SAP 2000 are representative commercialized robots. By using a robot driver for a vehicle fuel economy and exhaust test, the problems associated with human drivers are resolved. However, physical robots also introduce a few problems.

- Robot drivers require a relatively long installation time, and after installation, depending on the vehicle pedal position, an additional calibration process may be necessary.

- Robot drivers are expensive.

- Because robot drivers physically occupy the driver’s seat, vehicle with robot drivers cannot be tested on actual roads.

To overcome these drawbacks, we propose a fuzzy-logic-based robotic driver system when using the chassis dynamometer to test HEVs and PHEVs. The robot drivers presented in this paper are more easily mounted, and automatic testing is cost-efficient.

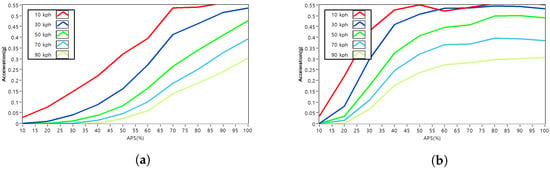

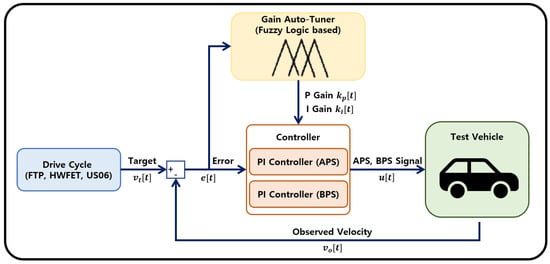

The acceleration of a vehicle depends on how the engine and motor are mapped to the acceleration position signal (APS). Therefore, different vehicles have different vehicle dynamics. The dynamics of a single vehicle can also vary depending on the drive mode. Vehicle manufacturers usually set a larger acceleration response when the vehicle is in sports mode compared with when the vehicle is in eco mode (Figure 3). In addition, it can be seen from Figure 3 that the acceleration response of the vehicle is highly nonlinear. Therefore, when the dynamics of the vehicle change, the control parameters must be adjusted. However, it takes a long time to modify the control parameters every time the dynamics changes. To overcome this problem, we applied fuzzy logic to autotune the control parameters (Figure 4). The error, , is calculated using target velocity, , and observed velocity, . With the given error, the fuzzy controller modifies the P gain, , and I gain, , of the PI controller. The APS, BPS signals, , are calculated by the PI controller using the calculated control parameters. In this way, dynamic control based on vehicle state is possible, rendering the manual tuning process unnecessary.

Figure 3.

(a) Acceleration Response (Eco Mode). (b) Acceleration Response (Sports Mode).

Figure 4.

System Overview.

3. Proposed Robot Driver System Configuration

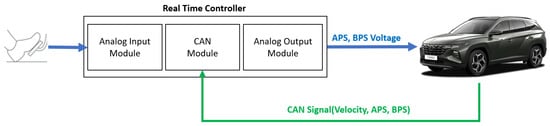

The proposed robot driver system is based on the idea that the electrical signal from the acceleration/brake pedal is A/D converted from the controller and used as an internal variable (Figure 5). The proposed system utilizes this electrical signal to control the vehicle. The electrical signal is converted into a digital signal by the system’s hardware and software, meaning that vehicle control can be achieved by inputting this converted signal into the controller (Figure 6). Particularly, HEVs and PHEVs use an electric braking system, which means that the braking can be controlled via voltage. A conventional braking system is activated through the adjustment of the brake hydraulic pressure when the driver presses the brake pedal, but an electric braking system switches the braking force of the brake pedal into an electrical signal.

Figure 5.

A/D Conversion Acceleration/Brake Pedal Value.

Figure 6.

Vehicle Control by the Proposed System.

3.1. Hardware Configuration

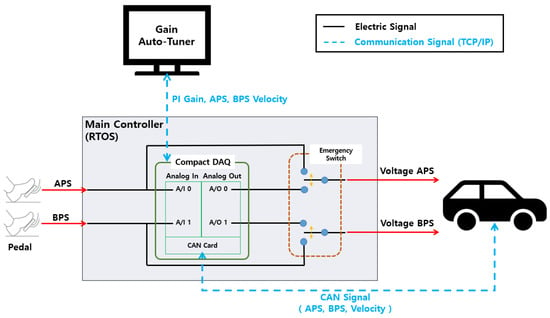

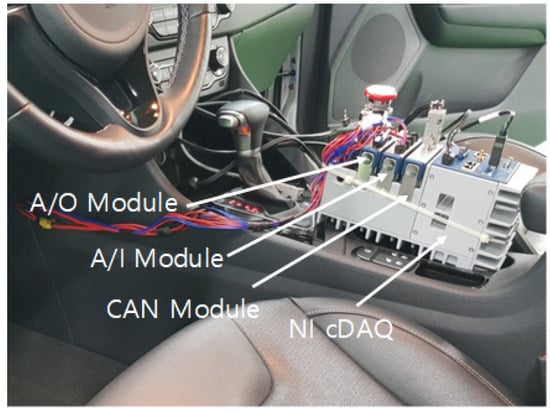

The design of an automotive control system must guarantee stability and reliability. Real-time control should be guaranteed for these systems deeply related to safety. Thus, the main controller must be implemented using a computing system with real-time operating system (RTOS) rather than a universal operating system such as Windows. Another computer is used for the user interface and gain autotuning (Figure 7). The gain autotuner executes the main controller configured with RTOS and monitors the status values of the vehicle from the RTOS. The hardware of the main controller is shown in Figure 8. The National Instrument’s cDAQ-9136 model is used in the robot driving system’s hardware. This model is a commercial product that has RTOS. Additionally, analog input, analog output, and CAN card modules are configured for control signals.

Figure 7.

Simple Robotic Driver System (SimRoDS).

Figure 8.

Hardware Vehicle Installation.

3.2. Software Configuration

The software of SimRoDS was written with LabView, and a PI controller is used to control the vehicle. Because of the noise of the vehicle system, derivative control, which is sensitive to noise, is not implemented in the vehicle controller. The control cycle of our system is set to 10 Hz, which is frequently used in applications related to vehicle safety [27,28]. Although more precise control is possible with the faster control cycle, a control cycle of 10 Hz is chosen to implement the human-like control form and sustainability of the system. The software of our system can be divided into two main components (Figure 7).

- Gain autotuner that runs on a Windows-based PC.

- The PI controller that controls the test vehicle.

The gain autotuner that runs on the Windows-based PC performs the following operations:

- Creates a gain value using fuzzy logic and send this value to the controller via TCP/IP communication.

- Shows the status (on, off, malfunction) of the robot driver.

- Visualizes the vehicle CAN signals (velocity, APS, BPS).

The controller that runs on the real-time OS performs the following operations:

- Receives the gain values from the PC and applies them to the PI controller.

- Sends the vehicle and control status to the PC.

4. Method

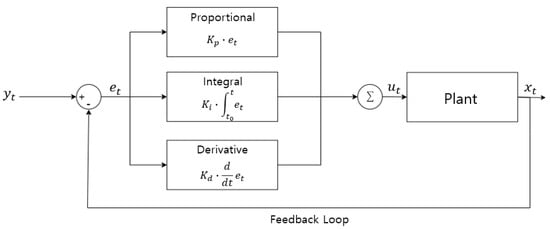

4.1. PI Controller

PID or PI control is the most common control algorithm used in the automotive industry and has been universally accepted in industrial control. In typical control systems, the process variable is the system parameter that must be controlled and it is controlled by PID controller using control loop mechanism to employ feedback. A PID controller continuously calculates an error value as the difference between a desired set point and a measured process variable and applies a correction on the basis of proportional, integral, and derivative terms.

Figure 9 shows a diagram of PID controller. As mentioned, above, a PID controller has three different control modes (proportional, integral and derivative), and each of these modes reacts differently to the error. In our case, we adopt PI controller with only proportional and integral part because of the high noise of the vehicle test environment.

Figure 9.

PID Controller.

The proposed system requires the control of multiple types of vehicles on a chassis dynamometer. For this reason, different control variables (PI gains) are required for each test vehicle, and the process of determining these variables must be completed before the main test. Because of the the nonlinearity of the vehicle, a conventional autotuning method, such as Ziegler–Nichols, cannot be applied. If a manual tuning method is applied, the tuning process becomes time-consuming and inefficient. Additionally, the tuned value may not be optimal. To solve this problem, we propose a PI gain autotuning algorithm based on fuzzy logic.

4.2. Fuzzy Logic

Fuzzy logic is an approach to variable processing that allows for multiple values to be processed through the same variable. Fuzzy logic attempts to solve problems with an open, imprecise spectrum of data that makes it possible to obtain an array of accurate conclusions. Fuzzy logic is designed to solve problems by considering all available information and making the best possible decision given the input. The fuzzy controller is a nonlinear controller, and its most relevant characteristics are as follows:

- The mathematical model of the vehicle to be controlled is not required.

- The control output is generated by membership functions when a defined variable is given.

- The inference is developed through a rules table of query and decision

When using a fuzzy controller, it is important to define the membership function according to knowledge of the system’s operation.

4.3. Fuzzy-Logic-Based Autotuning

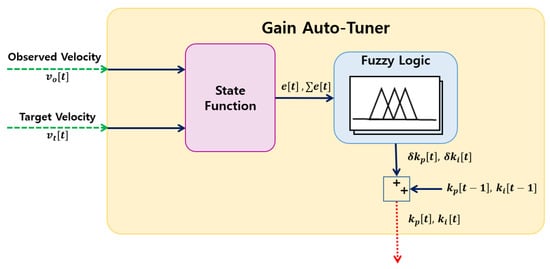

Figure 10 shows a block diagram of the gain autotuner that is applied in the proposed system. From this figure, it can be seen that the change rate of the gain values, and , are calculated by the fuzzy logic when the state is given. The state, , is a 2-dimensional vector consisting of the current error, , and sum of past errors, . The control parameters for the PI controller are calculated by adding past gain values with the output from the fuzzy logic. The APS, BPS is then calculated by the PI controller using the control parameters from the gain autotuner (Equation (1)). The controller’s operating process is as follows:

Figure 10.

Fuzzy-Logic-Based Gain Autotuner.

- Before the test, the default gain value is defined.

- When the test is initiated, the current error is given to the fuzzy logic.

- With the given error, the change rate of PI gain is calculated.

- The default gain is totaled using the change rate of the gain value (Equation (1)).

- The new gain value is sent to the PI controller via TCP/IP and replaces the default gain value.

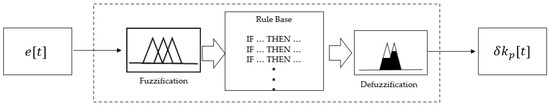

Figure 11 shows the structure of the fuzzy controller for proportional controller. When the current error is given to the fuzzy logic, the change rate of the P gain is obtained.

Figure 11.

Structure of the Proportional Controller Fuzzy Inference System.

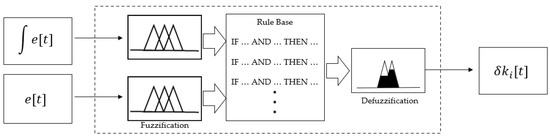

Figure 12 shows the structure of the fuzzy controller for the integral controller. When the current error and sum of the error are given to the fuzzy logic, the change rate of the I gain is obtained.

Figure 12.

Structure of the Integral Controller Fuzzy Inference System.

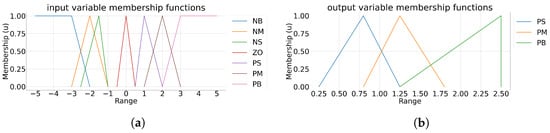

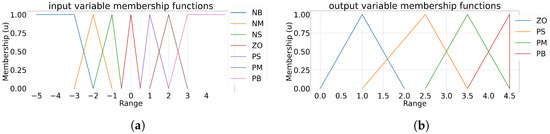

4.3.1. Fuzzy Membership Function

In our fuzzy controller, there are three membership functions: one for proportional control and two for integral control. The triangular membership function, which is most frequently used, is implemented in all of our membership functions, and fuzzy rules are represented by control rules in the form of IF–THEN. The actuator signal consists of APS and BPS. In this work, two different fuzzy membership functions are used because the sensitivities of APS and BPS differ. P and N stand for positive and negative, respectively, and ZO, B, M, and S stand for zero, big, medium, and small, respectively. Therefore, the name of the positive input membership functions PB, PM, and PS refer to positive big, positive medium, and positive small, respectively. The name of the negative input membership functions NB, NM, and NS refer to negative big, negative medium, and negative small, respectively.

4.3.2. Fuzzy Proportional Controller

Figure 13 illustrates the membership function for the APS. The output of the membership function uses ZO, PS, PM, and PB. The initial value of is set low, and the output value is set from 0 to 2.5. The small initial value is compensated for with the output value, which is the change rate of the P gain (APS). When the vehicle is accelerating, the velocity of the vehicle is below the target velocity. Therefore, this function activates when the value of error () is positive. Figure 14 demonstrates the membership function for the BPS. Similar to the output of the membership function for the APS, the membership function for BPS uses ZO, PS, PM, and PB. When the vehicle is decelerating, the velocity of the vehicle is above the target velocity. Therefore, this function activates when the value of error () is negative.

Figure 13.

(a) Input Membership Function of for the APS. (b) Output Membership Function of for the APS.

Figure 14.

(a) Input Membership Function of for BPS. (b) Output Membership Function of for BPS.

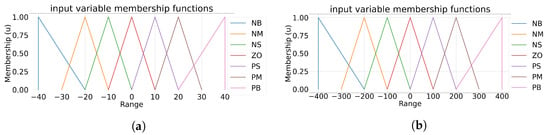

4.3.3. Fuzzy Integral Controller

In the case of deceleration, the difference in characteristics of each vehicle is not significant compared with acceleration. As such, the fuzzy integral controller for APS is applied in the controller. The fuzzy integral controller was designed with a multi-input multi-output (MIMO) system. The sum of error and error value are used as inputs. Considering the control period of 0.1 s and the speed tolerance of 3.2 km/h, the input range of error was determined to be −40 to 40 km/h. Figure 15 shows the input membership functions of and and Figure 16 shows the output membership functions of the I gain (APS).

Figure 15.

(a) Input Membership Function of for the APS. (b) Input Membership Function of for the APS.

Figure 16.

Output Membership Function for the I Gain (APS).

5. Experiment

The test was conducted by driving the second slope of FTP cycle. The Hyundai Tucson HEV is used in the experiment and the chassis dynamometer type is AVL ROADSIM. To evaluate the system’s response toward different vehicle dynamics, the test was conducted using two different modes: eco and sports as shown in Figure 3. The root mean squared error (RMSE) value is used as a metric to evaluate the performance of our robot driver system.

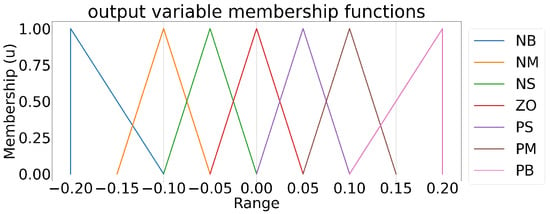

5.1. Experiment Result with Fixed Gain

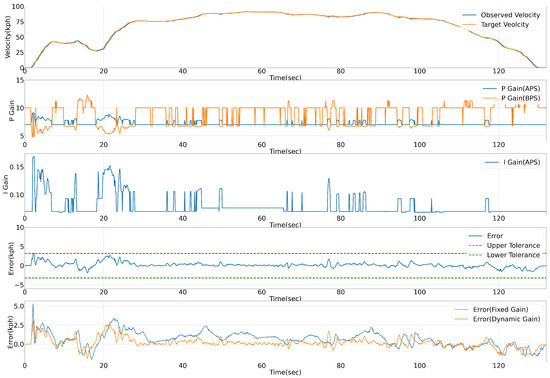

The test results of using fixed gain method in eco mode is shown in Figure 17. The following control parameters were manually tuned by the system operators: (i) P gain for APS—10.0; (ii) P gain for BPS—10.0; (iii) I gain for APS—0.03; (iv) I gain for BPS—0.03. The RMSE for this case was 0.985. In Figure 17, it can be seen that errors exceed the speed tolerance in many sections of the test cycle, especially at initial acceleration and when the vehicle accelerate in high-speed regions.

Figure 17.

Test Results of the Fixed Gain Method in Eco Mode.

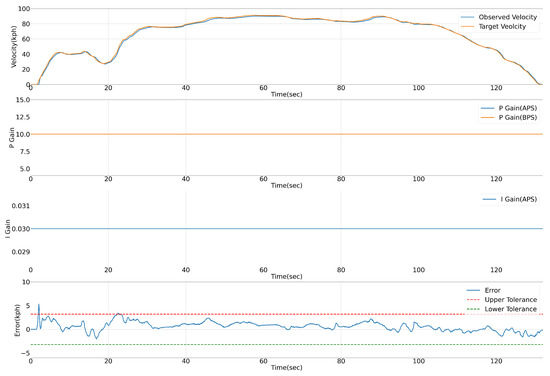

5.2. Experiment Result with Dynamic Gain

The experiment results of using dynamic gain by fuzzy controller is shown in Figure 18 and Figure 19 for eco mode and sports mode, respectively. The RMSE for the eco mode was 0.682. Compared to the RMSE for fixed gain method, the RMSE value of the dynamic gain method was about 30% lower. In particular, the error is smaller at the high-speed acceleration region where velocity is higher than 60 kph. This demonstrates that using dynamic gain showed better performance and control was more stable compared with the fixed gain method.

Figure 18.

Test Results of Dynamic Gain Method in Eco Mode.

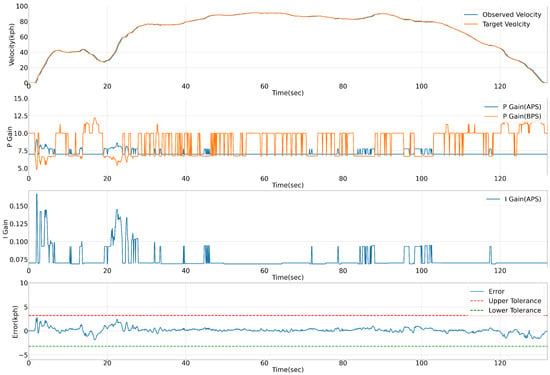

Figure 19.

Test Results of the Dynamic Gain Method in Sports Mode.

Additional tests have been conducted to test the performance of fuzzy controller on different vehicle dynamics, and the experimental results are shown in Figure 19. The experiment was conducted by setting the vehicle in sports mode. The RMSE for this case was 0.668, which is similar to the experiment conducted in eco mode. From this test, it can be demonstrated that the fuzzy controller shows similar performance even when the dynamics of the vehicle are different.

6. Conclusions and Future Work

In this paper, we proposed a fuzzy-logic-based robotic driver system to reduce the fuel efficiency test deviation of HEVs and PHEVs. The performance of the proposed system was verified through practical tests. The advantages of the proposed system are as follows: When installed, it takes up minimal space in the driver’s seat, meaning a driver can sit in the driver’s seat, and the vehicle can be tested on actual roads. Compared with the physical robot, our system is more cost-effective and requires less installation time. Additionally, an applied fuzzy-logic-based PI controller is capable of testing multiple types of vehicles. This was verified by experiments that were conducted in different drive modes. Based on the experimental results, the fuzzy-PI controller outperformed the conventional PI controller by a factor of about 30% in terms of the RMSE error. However, due to the nature of the PI controller, a downside of the proposed algorithm is that control output can only be generated when an error occurs. Therefore, the error can initially be relatively large. To solve this problem and enhance the performance of the proposed system, in future research, we are planning to implement data-driven predictive control in our proposed robotic driver system.

Author Contributions

Conceptualization, K.H. and S.L.; methodology, K.H. and J.P.; software, K.H., J.P. and H.K.; validation, T.-Y.K. and S.L.; formal analysis, K.H.; investigation, J.P., H.K. and S.L.; resources, K.H. and T.-Y.K.; data curation, K.H., J.P. and H.K.; writing—original draft preparation, K.H.; writing—review and editing, J.P. and S.L.; visualization, K.H. and H.K.; supervision, T.-Y.K. and S.L.; project administration, K.H. and S.L.; and funding acquisition, K.H. and S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Hyundai Motor Group, the AI-based Autonomous Driving Computing Module Development and Service Demonstration Program funded by the Ministry of Trade, Industry, and Energy of Korea (No. 20005673), and the BK21 Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (No. 5199990814084).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| EV | Electric Vehicle |

| HEV | Hybrid Electric Vehicle |

| PHEV | Plug-in Hybrid Electric Vehicle |

| DHTs | Dedicated Hybrid Transmissions |

| ICE | Internal Combustion Engine |

| APS | Acceleration Position Signal |

| BPS | Brake Position Signal |

| PC | Personal Computer |

| CAN | Controller Area Network |

| DTE | Distance To Empty |

| NEDC | New European Driving Cycle |

| WLTP | Worldwide Harmonized Light Vehicle Test Procedure |

| FTP | Federal Test Procedure |

| UDDS | Urban Dynamometer Driving Schedule |

| TCP/IP | Transmission Control Protocol/Internet Protocol |

| MIMO | Multiple Input and Multiple Output |

| PID | Proportional Integral Derivative |

| RMSE | Root Mean Squared Error |

References

- Sieg, C.; Küçükay, F. Benchmarking of Dedicated Hybrid Transmissions. Vehicles 2020, 2, 100–125. [Google Scholar] [CrossRef]

- Al-Samari, A. Study of emissions and fuel economy for parallel hybrid versus conventional vehicles on real world and standard driving cycles. Alex. Eng. J. 2017, 56, 721–726. [Google Scholar] [CrossRef]

- Kuhnert, F.; Stürmer, C.; Koster, A. Five Trends Transforming the Automotive Industry; PricewaterhouseCoopers GmbH Wirtschaftsprüfungsgesellschaft: Berlin, Germany, 2018; Volume 1, pp. 1–48. [Google Scholar]

- Preeti Wadhwani, P.S. Fuel Cell Electric Vehicle (FCEV) Market Size by Vehicle (Heavy Duty Vehicles, Agriculture, Buses, Port Vehicles/Container Handling or Transport, Automotive, Class 8/Long Haul), by Distance (Short, Long), Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Market Share & Forecast, 2020–2026; Global Market Insights Inc.: Selbyville, DE, USA, 2019; pp. 1–235. [Google Scholar]

- Namik, H.; Inamura, T.; Stol, K. Development of a robotic driver for vehicle dynamometer testing. In Proceedings of the 2006 Australasian Conference on Robotics and Automation, Auckland, New Zealand, 6–8 December 2006; pp. 1–9. [Google Scholar]

- Sailer, S.; Buchholz, M.; Dietmayer, K. Flatness based velocity tracking control of a vehicle on a roller dynamometer using a robotic driver. In Proceedings of the 2011 50th IEEE Conference on Decision and Control and European Control Conference, Orlando, FL, USA, 12–15 December 2011; pp. 7962–7967. [Google Scholar]

- Muller, K.; Leonhard, W. Computer control of a robotic driver for emission tests. In Proceedings of the 1992 International Conference on Industrial Electronics, Control, Instrumentation, and Automation, San Diego, CA, USA, 9–13 November 1992; Volume 3, pp. 1506–1511. [Google Scholar]

- Sailer, S.; Buchholz, M.; Dietmayer, K. Driveaway and braking control of vehicles with manual transmission using a robotic driver. In Proceedings of the 2013 IEEE International Conference on Control Applications (CCA), Hyderabad, India, 28–30 August 2013; pp. 235–240. [Google Scholar]

- Chen, G.; Zhang, W.G.; Zhang, X.N. Speed tracking control of a vehicle robot driver system using multiple sliding surface control schemes. Int. J. Adv. Robot. Syst. 2013, 10, 90. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, W.G.; Zhang, X.N. Fuzzy neural control for unmanned robot applied to automotive test. Int. J. Robot. Res. Appl. 2013, 40, 450–461. [Google Scholar] [CrossRef]

- Eriksson, L.; Norrlöf, M. Improved Drive Cycle Following with an ILC Supported Driver Model. IFAC-PapersOnLine 2015, 48, 347–353. [Google Scholar] [CrossRef]

- Mizutani, N.; Ishida, Y.; Matsui, H.; Yano, K.; Takahashi, T. Automatic driving control by robotic driver considering the lack of a driving force at changing gears. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 3075–3080. [Google Scholar]

- Chen, G.; Zhang, W.; Li, X.; Yu, B. Adaptive speed control method for electromagnetic direct drive vehicle robot driver based on fuzzy logic. Meas. Control. 2019, 52, 1344–1353. [Google Scholar] [CrossRef]

- Tjokro, S.; Shah, S.L. Adaptive PID Control. In Proceedings of the 1985 American Control Conference, Boston, MA, USA, 19–21 June 1985; pp. 1528–1534. [Google Scholar]

- Soyguder, S.; Karakose, M.; Alli, H. Design and simulation of self-tuning PID-type fuzzy adaptive control for an expert HVAC system. Expert Syst. Appl. 2009, 36, 4566–4573. [Google Scholar] [CrossRef]

- Khodayari, M.H. Modeling and control of autonomous underwater vehicle (AUV) in heading and depth attitude via self-adaptive fuzzy PID controller. J. Mar. Sci. Technol. 2015, 20, 559–578. [Google Scholar] [CrossRef]

- Kandiban, R.; Arulmozhiyal, R. Speed Control of BLDC Motor Using Adaptive Fuzzy PID Controller. Procedia Eng. 2012, 38, 306–313. [Google Scholar] [CrossRef]

- Xie, D.; Zhu, J.; Wang, F. Fuzzy PID Control To Feed Servo System of CNC Machine Tool. Procedia Eng. 2012, 29, 2853–2858. [Google Scholar]

- Ahmed, S.F.; Kushsairy, K.; Bakar, M.I.A.; Hazry, D.; Joyo, M.K. Attitude stabilization of Quad-rotor (UAV) system using Fuzzy PID controller (an experimental test). In Proceedings of the 2015 Second International Conference on Computing Technology and Information Management (ICCTIM), Johor, Malaysia, 21–23 April 2015; pp. 99–104. [Google Scholar]

- Khan, L.; Qamar, S.; Khan, U. Adaptive PID control scheme for full car suspension control. J. Chin. Inst. Eng. 2016, 39, 169–185. [Google Scholar] [CrossRef]

- Pan, S.; Zhou, H. An adaptive fuzzy PID control strategy for vehicle yaw stability. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 December 2017; pp. 642–646. [Google Scholar]

- Xu, S.-W.; Lu, J.; Zhao, X. The Driving Control Strategy of Pure Electric Vehicle Based on Fuzzy Self-adaptive PID. In Proceedings of the 2016 4th International Conference on Machinery, Materials and Computing Technology, Hangzhou, China, 23–24 January 2016; Atlantis Press: Dordrecht, The Netherlands, 2016; pp. 940–946. [Google Scholar]

- Eckert, J.J.; de Alkmin Silva, L.C.; Dedini, F.G.; Corrêa, F.C. Electric vehicle powertrain and fuzzy control multi-objective optimization, considering dual hybrid energy storage systems. IEEE Trans. Veh. Technol. 2020, 69, 3773–3782. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Rath, J.; Guerra, T.M.; Palhares, R.; Zhang, H. Robust set-invariance based fuzzy output tracking control for vehicle autonomous driving under uncertain lateral forces and steering constraints. In Proceedings of the 2020 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), Glasgow, UK, 19–24 July 2020; pp. 1–12. [Google Scholar]

- Min, X.; Li, Y.; Tong, S. Adaptive fuzzy output feedback inverse optimal control for vehicle active suspension systems. Neurocomputing 2020, 403, 257–267. [Google Scholar] [CrossRef]

- Nazemian, H.; Masih-Tehrani, M. Hybrid Fuzzy-PID Control Development for a Truck Air Suspension System. SAE Int. J. Commer. Veh. 2020, 13, 55–70. [Google Scholar] [CrossRef]

- Eze, E.C.; Zhang, S.; Liu, E. Vehicular ad hoc networks (VANETs): Current state, challenges, potentials and way forward. In Proceedings of the 2014 20th International Conference on Automation and Computing, Cranfield, UK, 12–13 September 2014; pp. 176–181. [Google Scholar]

- Lin, Y.; McPhee, J.; Azad, N.L. Comparison of deep reinforcement learning and model predictive control for adaptive cruise control. IEEE Trans. Intell. Veh. 2020, 6, 221–231. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).