A Hybrid Optimization Approach for the Enhancement of Efficiency of a Piezoelectric Energy Harvesting System

Abstract

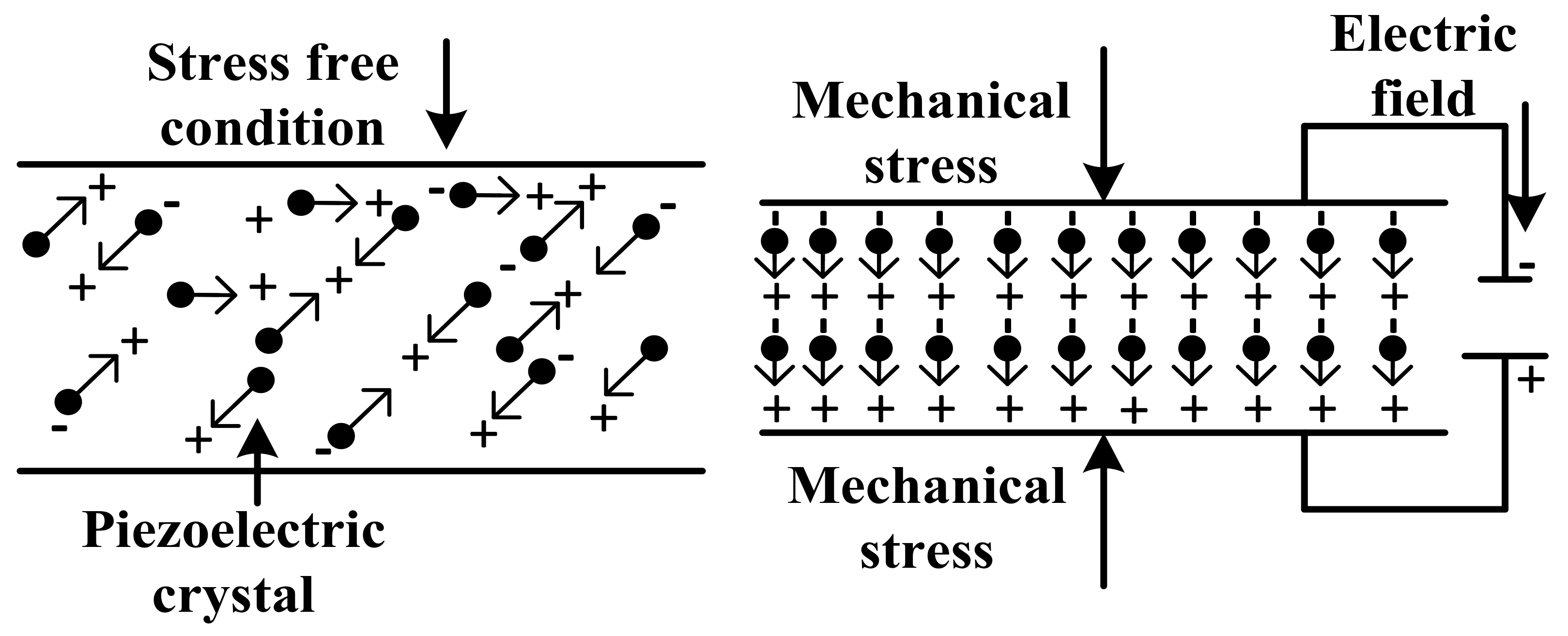

1. Introduction

2. PEHS Open Loop for Converter Controller Design

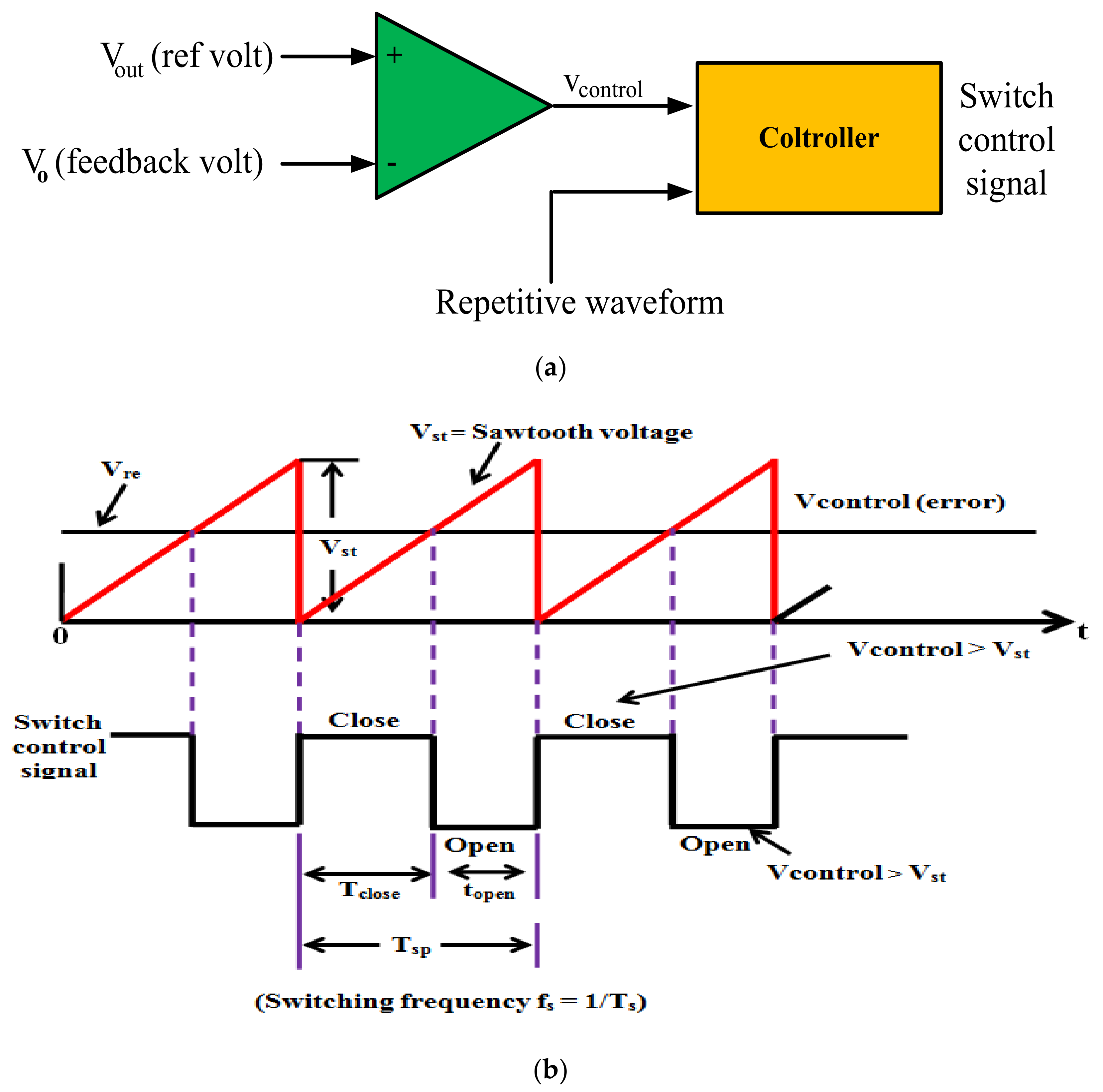

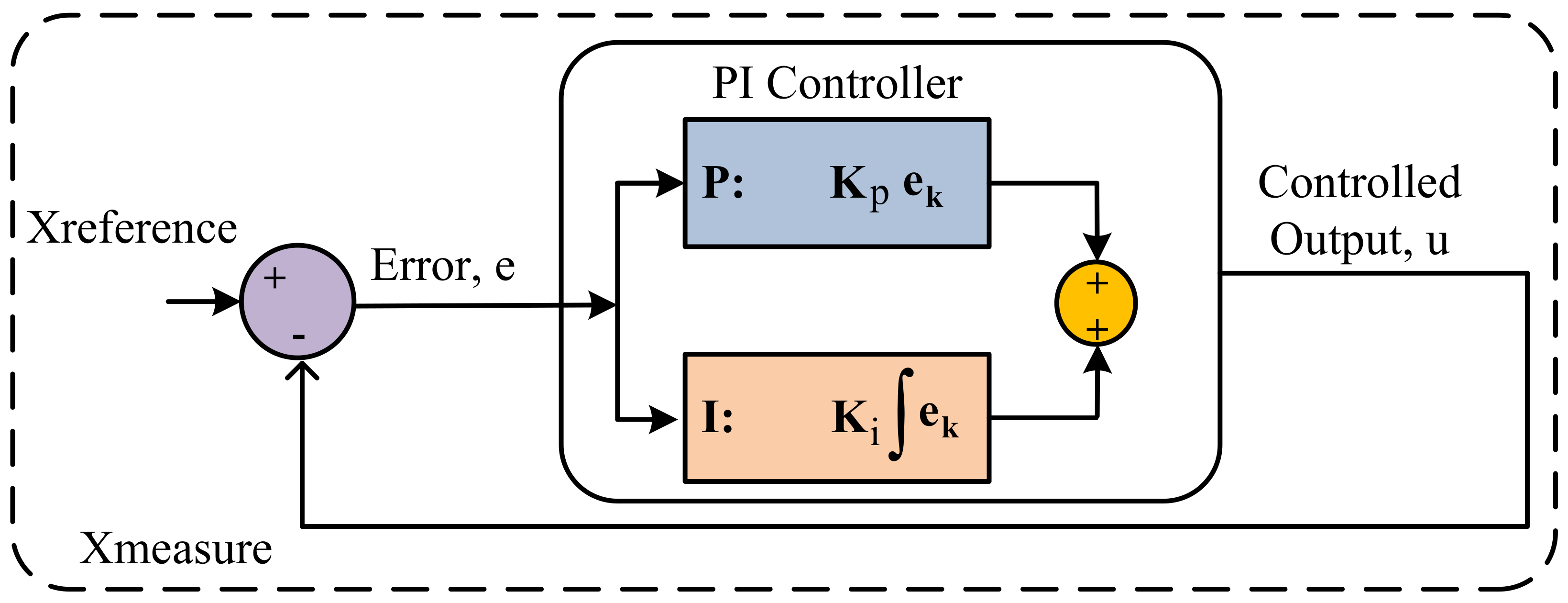

2.1. Controller

2.2. Step-Up Converter Control Technique for PEHS

2.2.1. Step-Up Converter Control

2.2.2. PWM Switching Technique

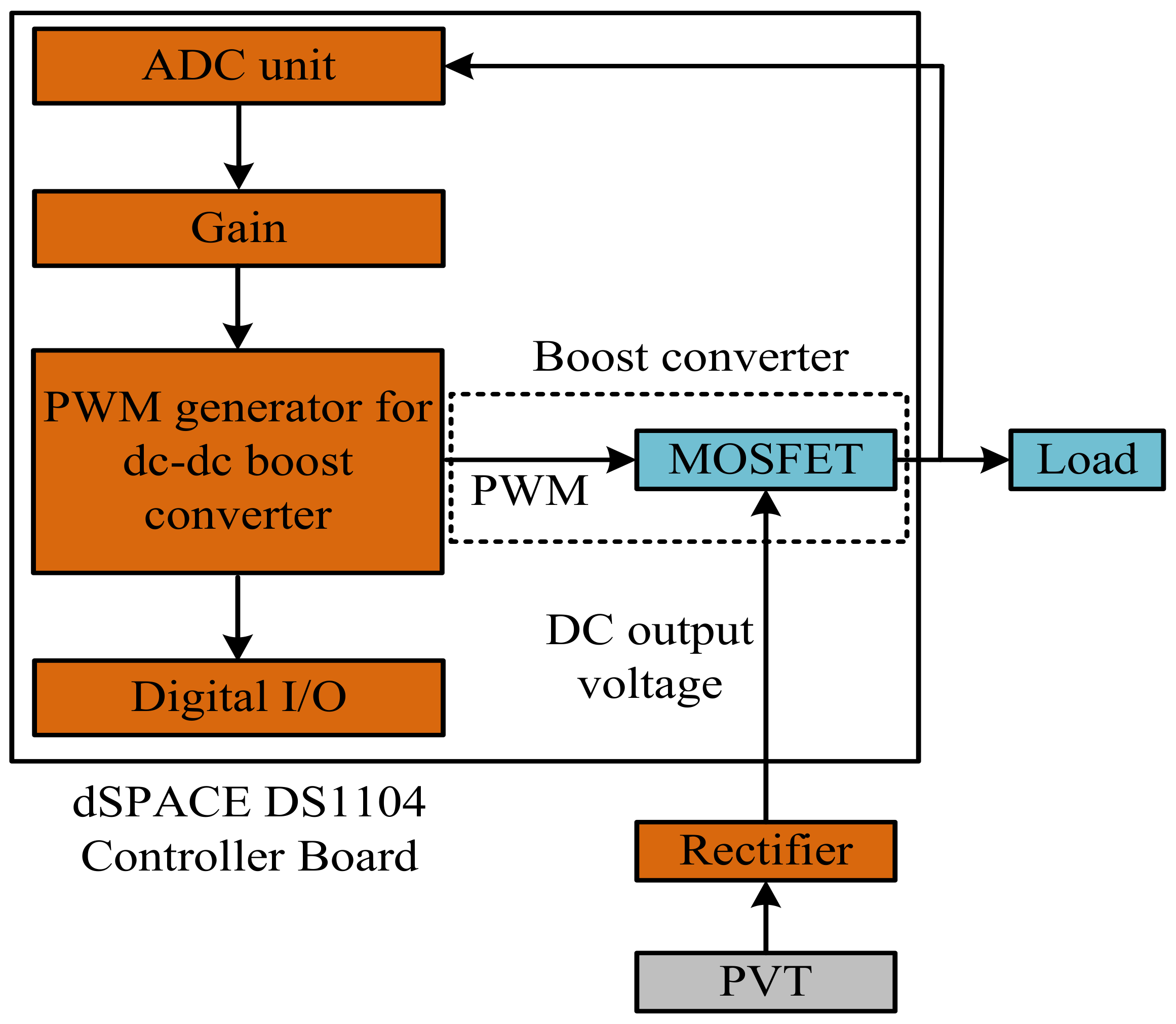

2.3. Step-Up Converter Control Technique for PEHS

2.4. Control Strategy

3. Proposed Hybrid Optimization Approach PIVC for PEHS Converter

3.1. Optimum PIVC Design Based on LSA

3.1.1. Input Information

3.1.2. Fitness Function

3.1.3. Optimization Constraints

3.2. LSA Theory

3.3. LSA to Achieve the Ideal PEHS Converter

4. Simulation Model of a PEHS Converter using the Proposed Hybrid Optimization Technique

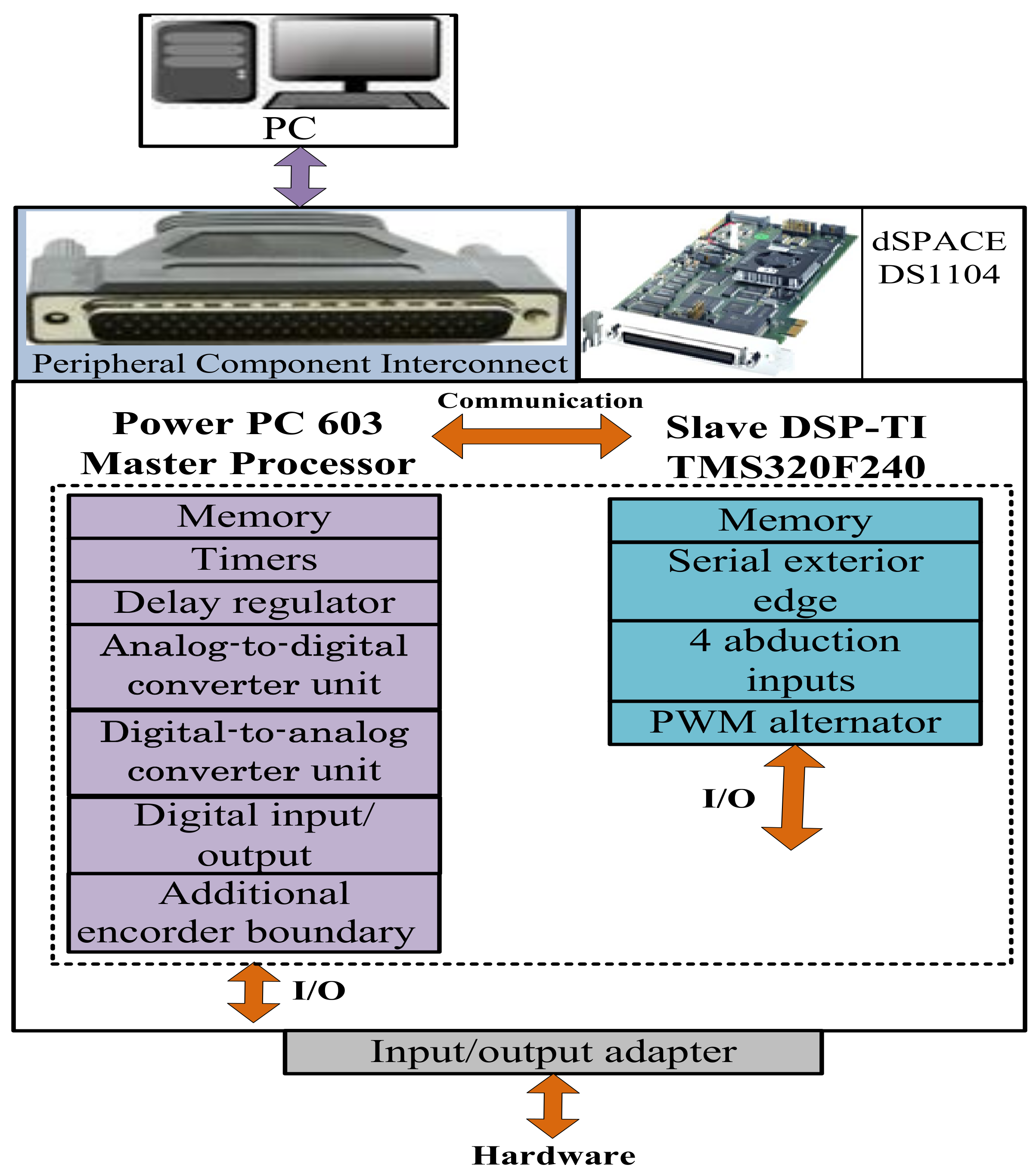

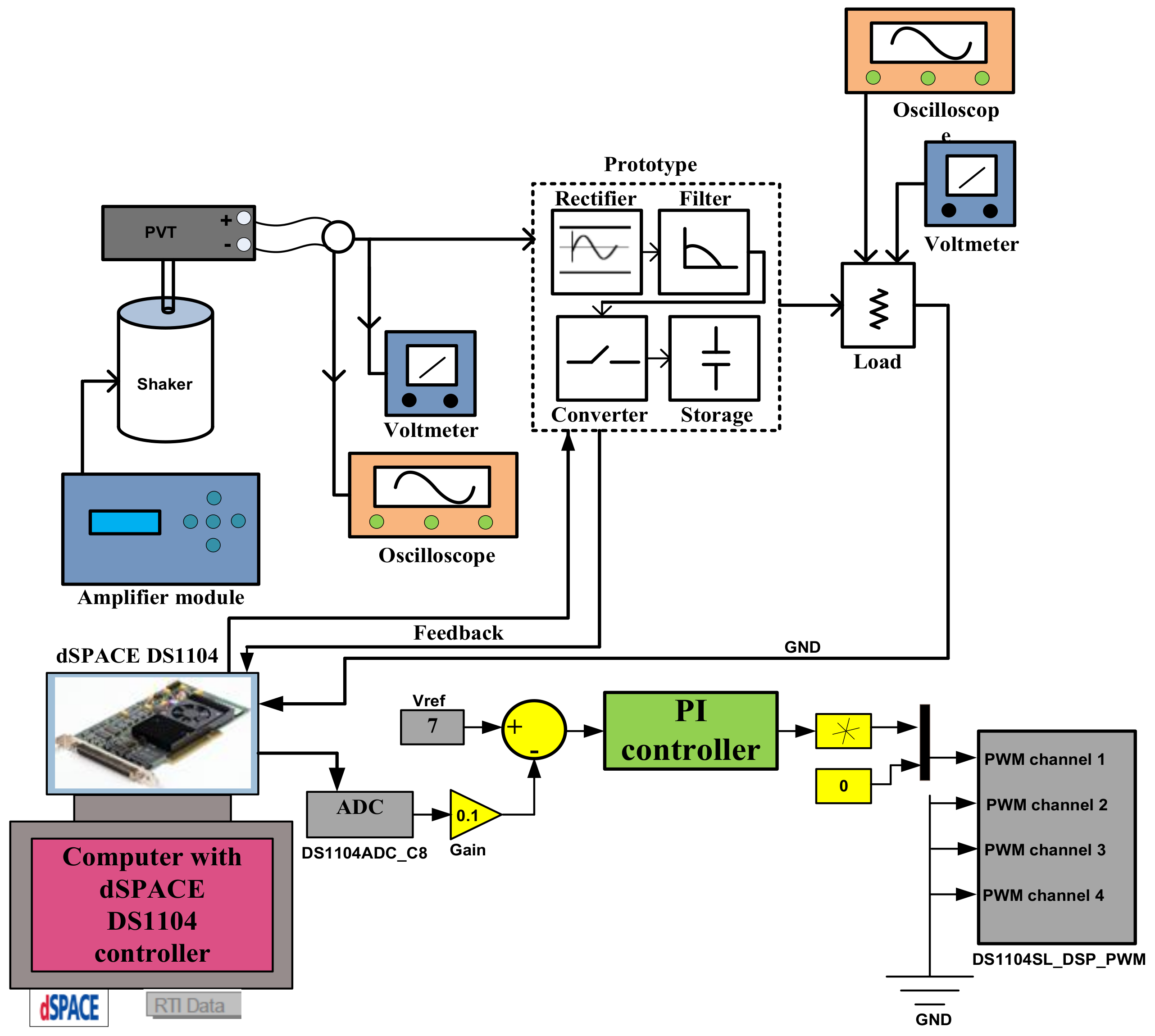

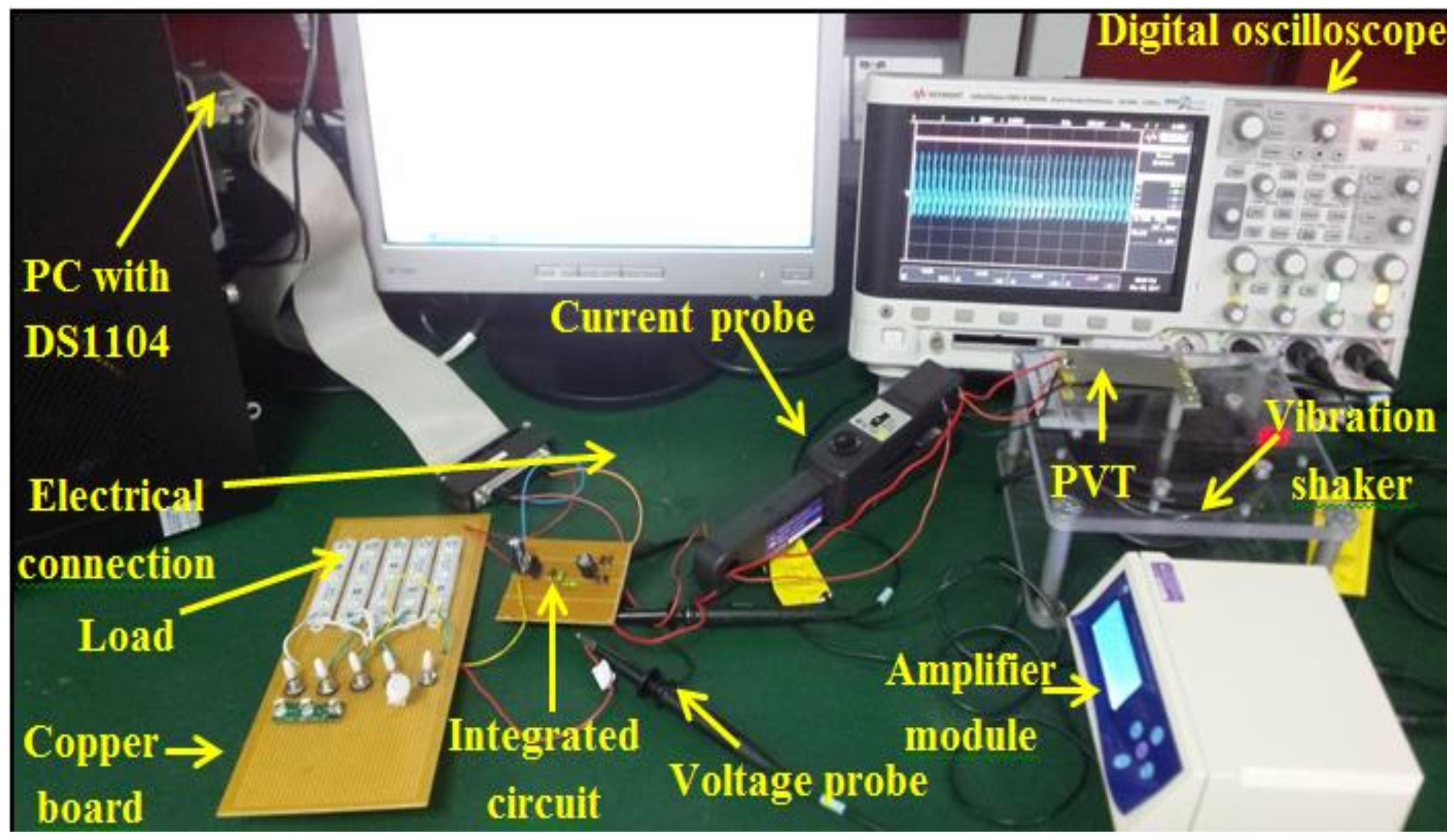

5. Hardware Implementation Setup

Experimental Setup

6. Results

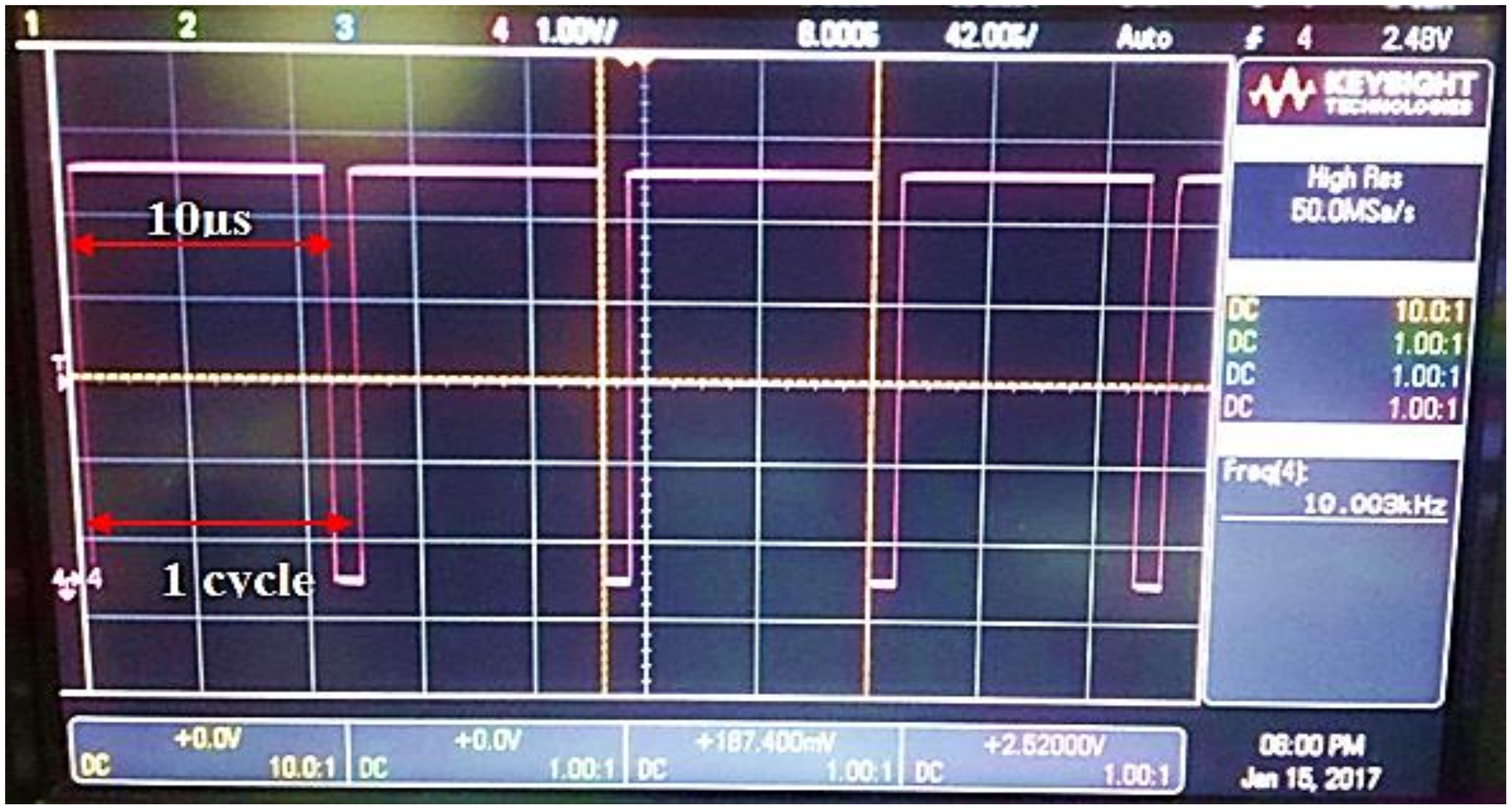

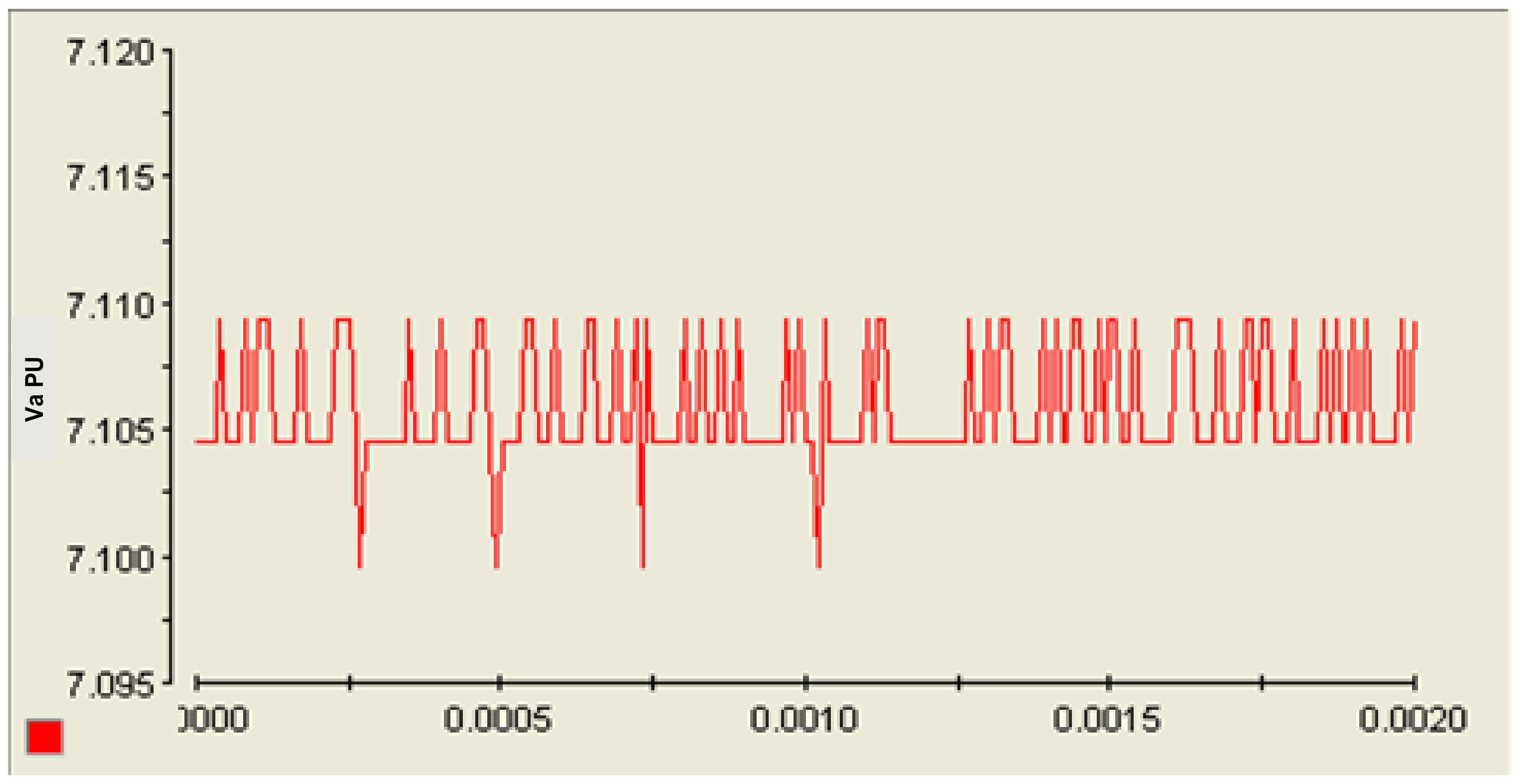

6.1. MOSFET PWM Switching Signals

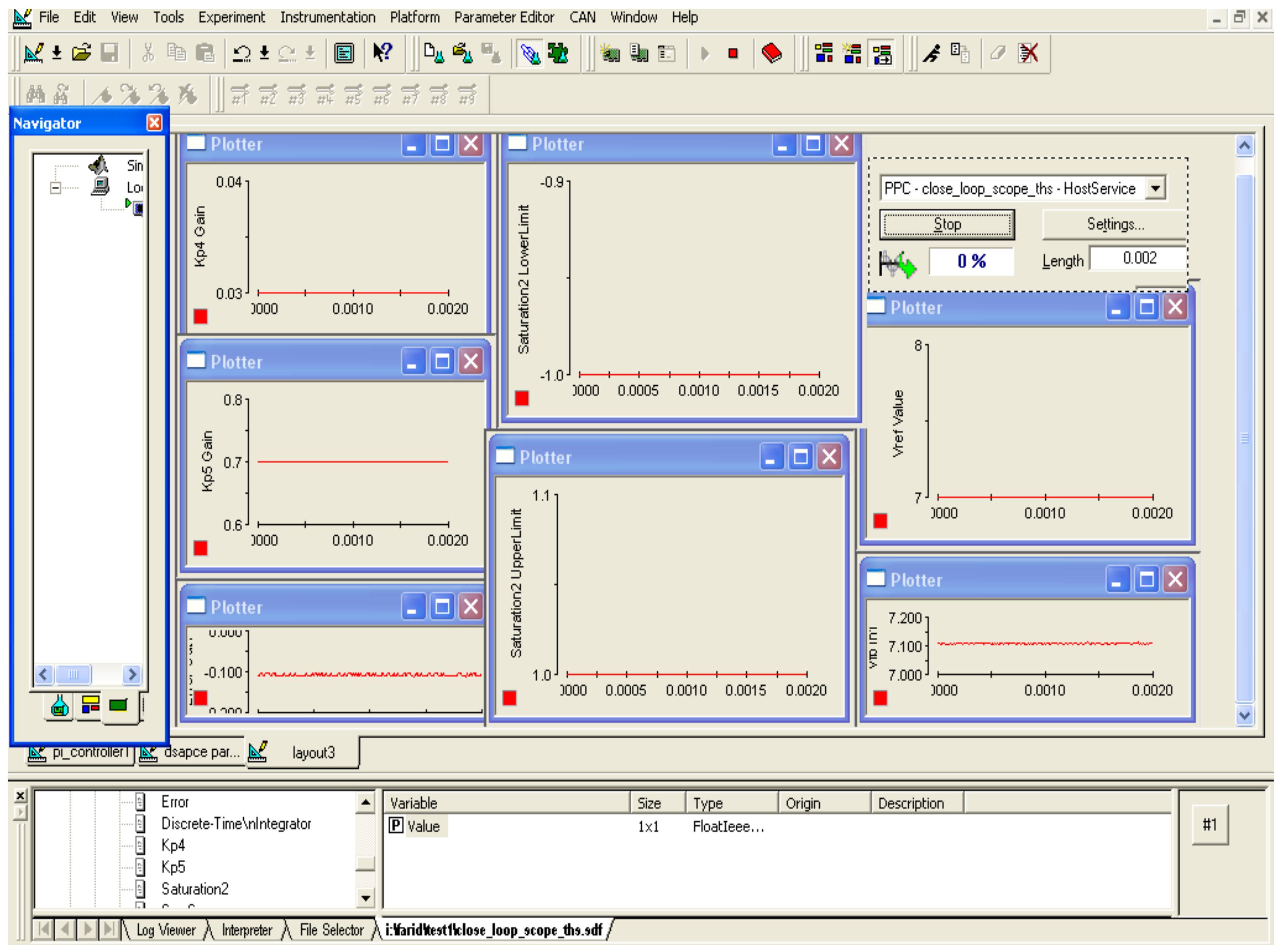

6.2. Controller Parameter Waveforms in dSPACE

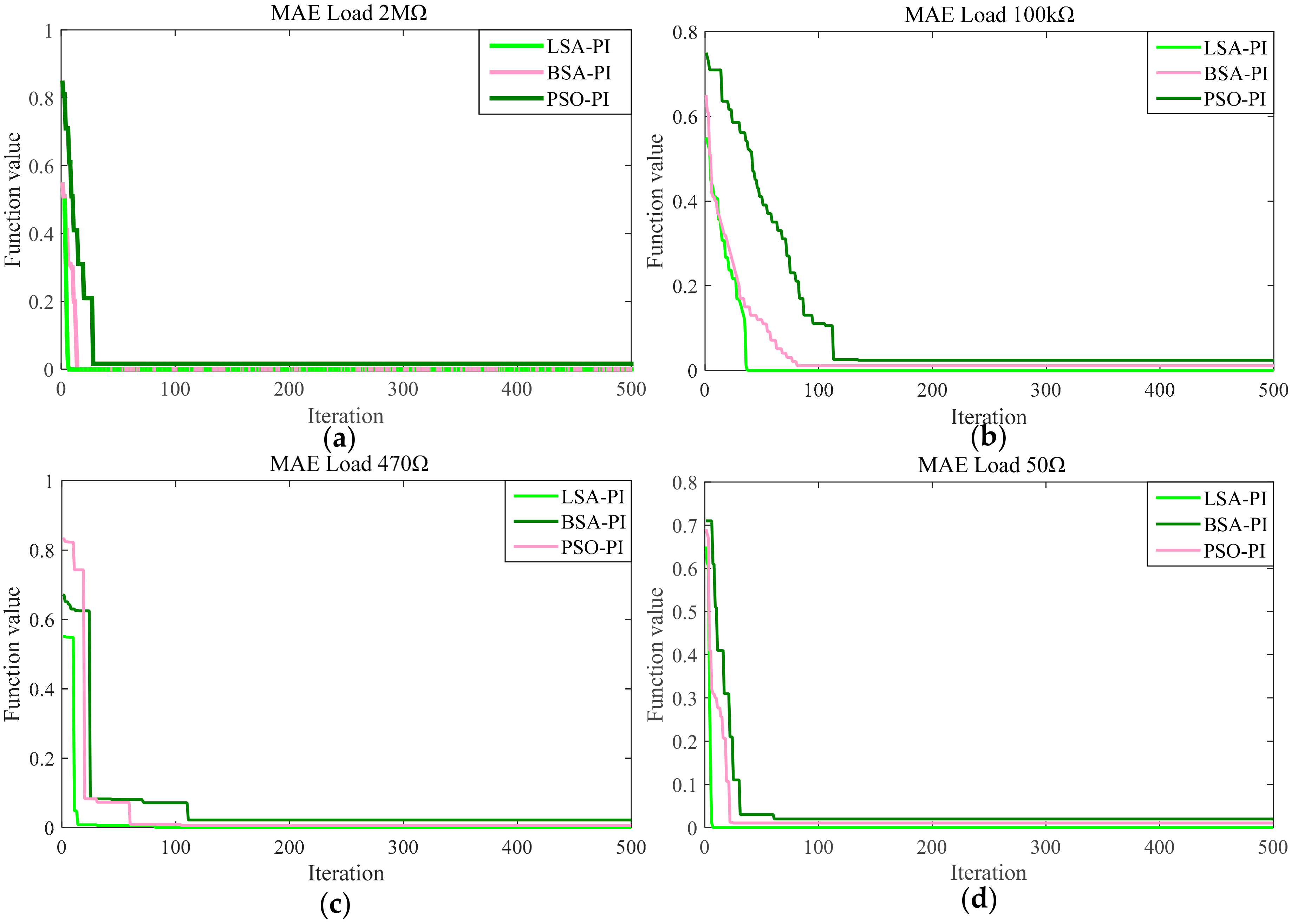

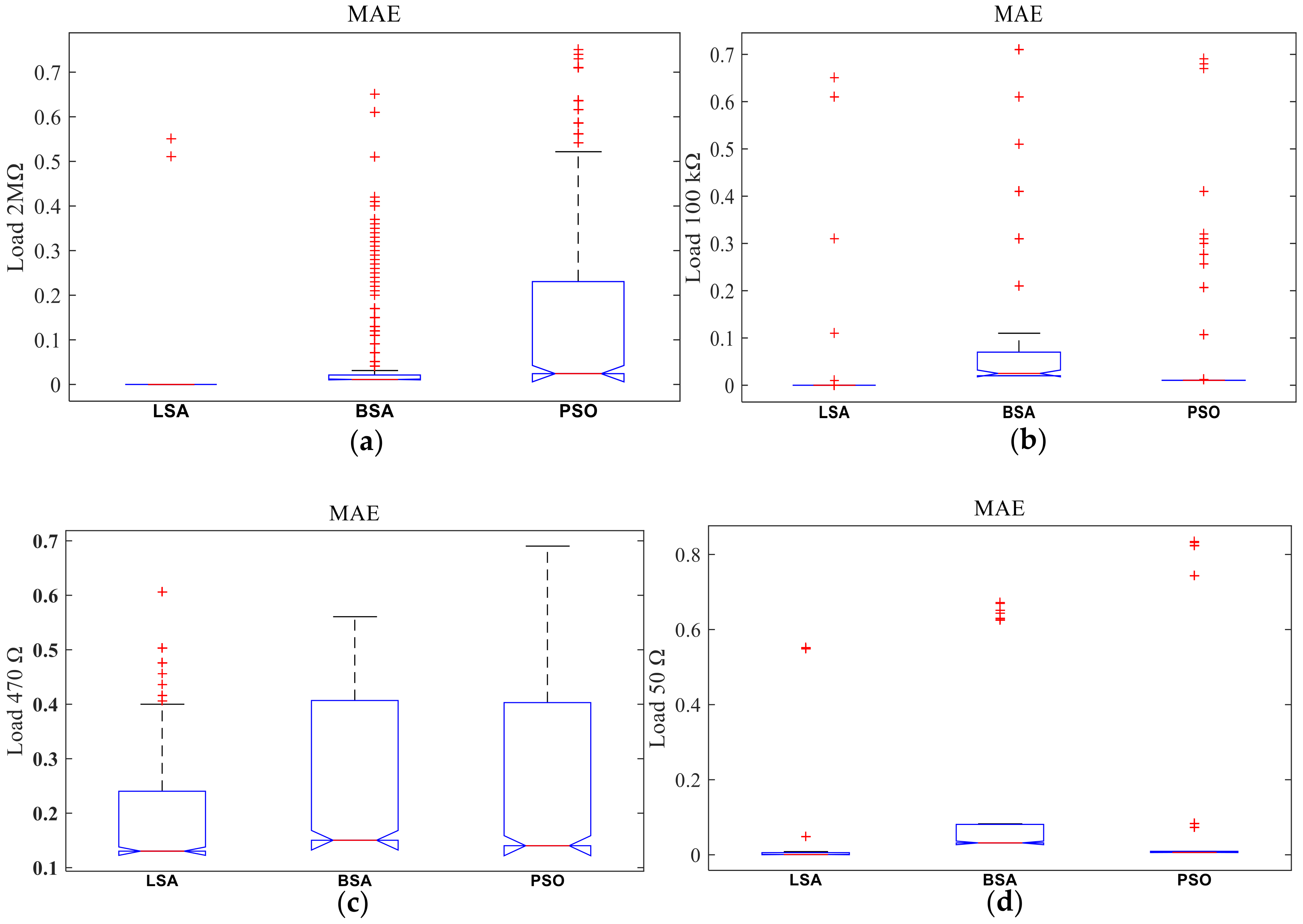

6.3. Simulation and Analysis for Fitness Function MAE with Various Loads

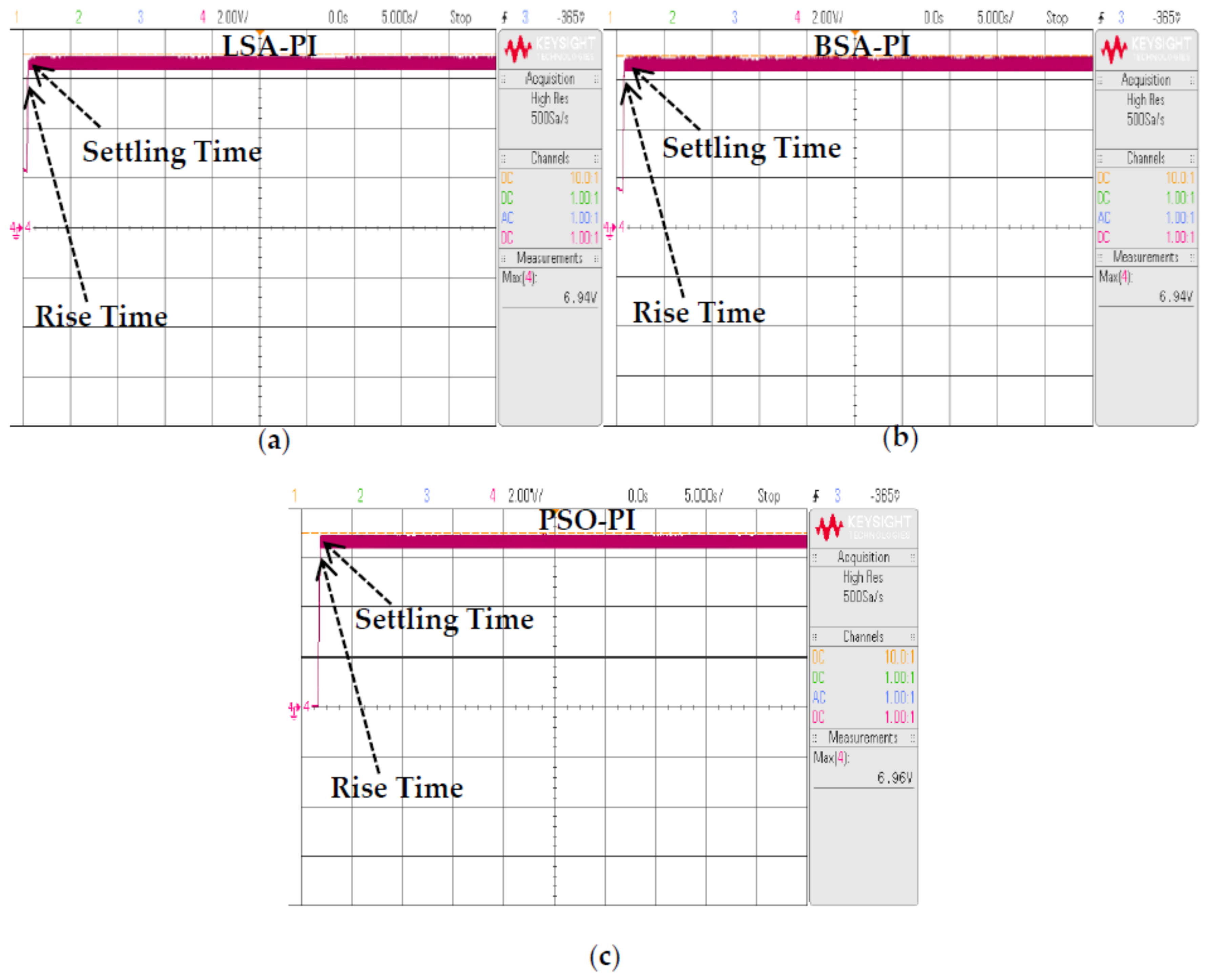

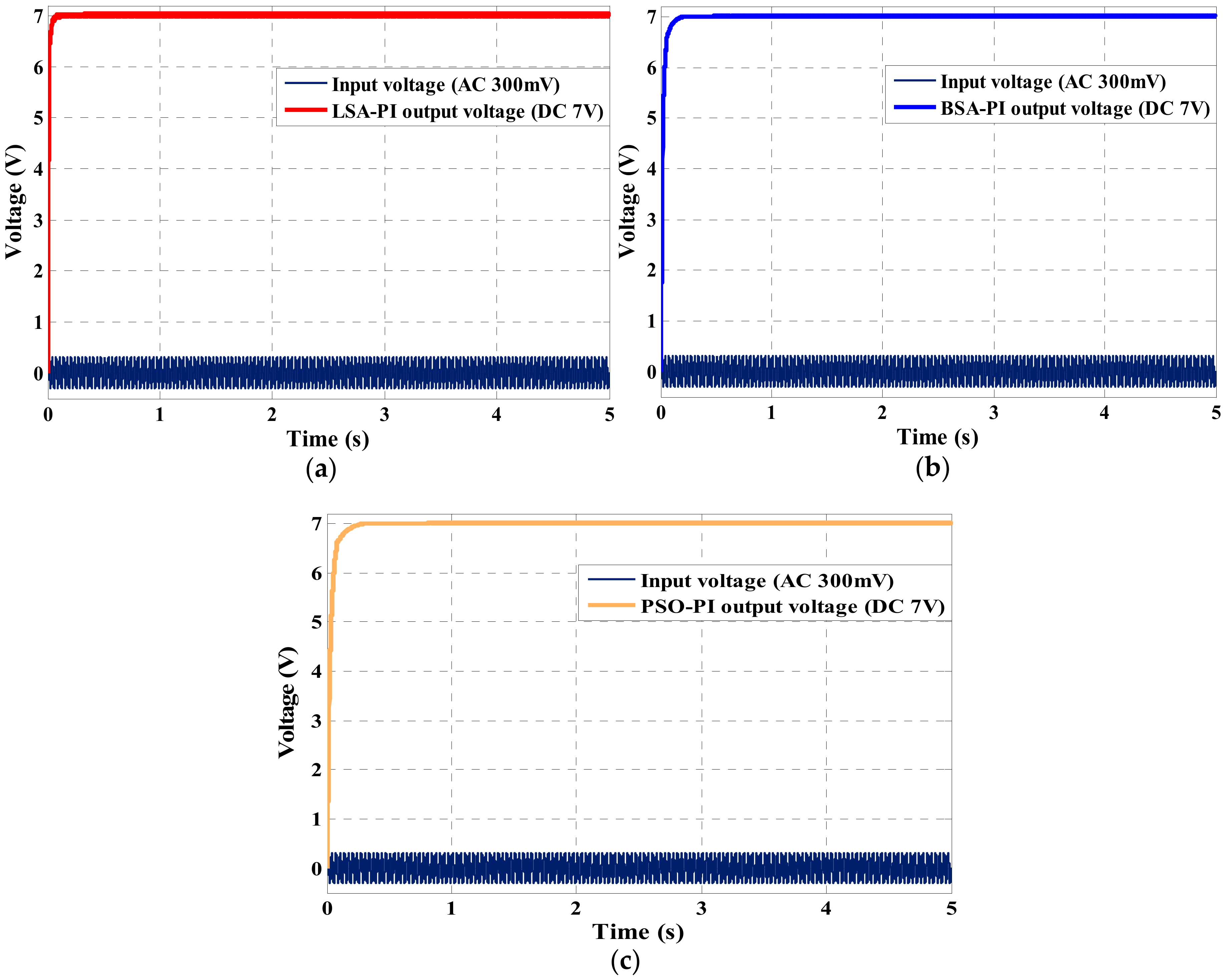

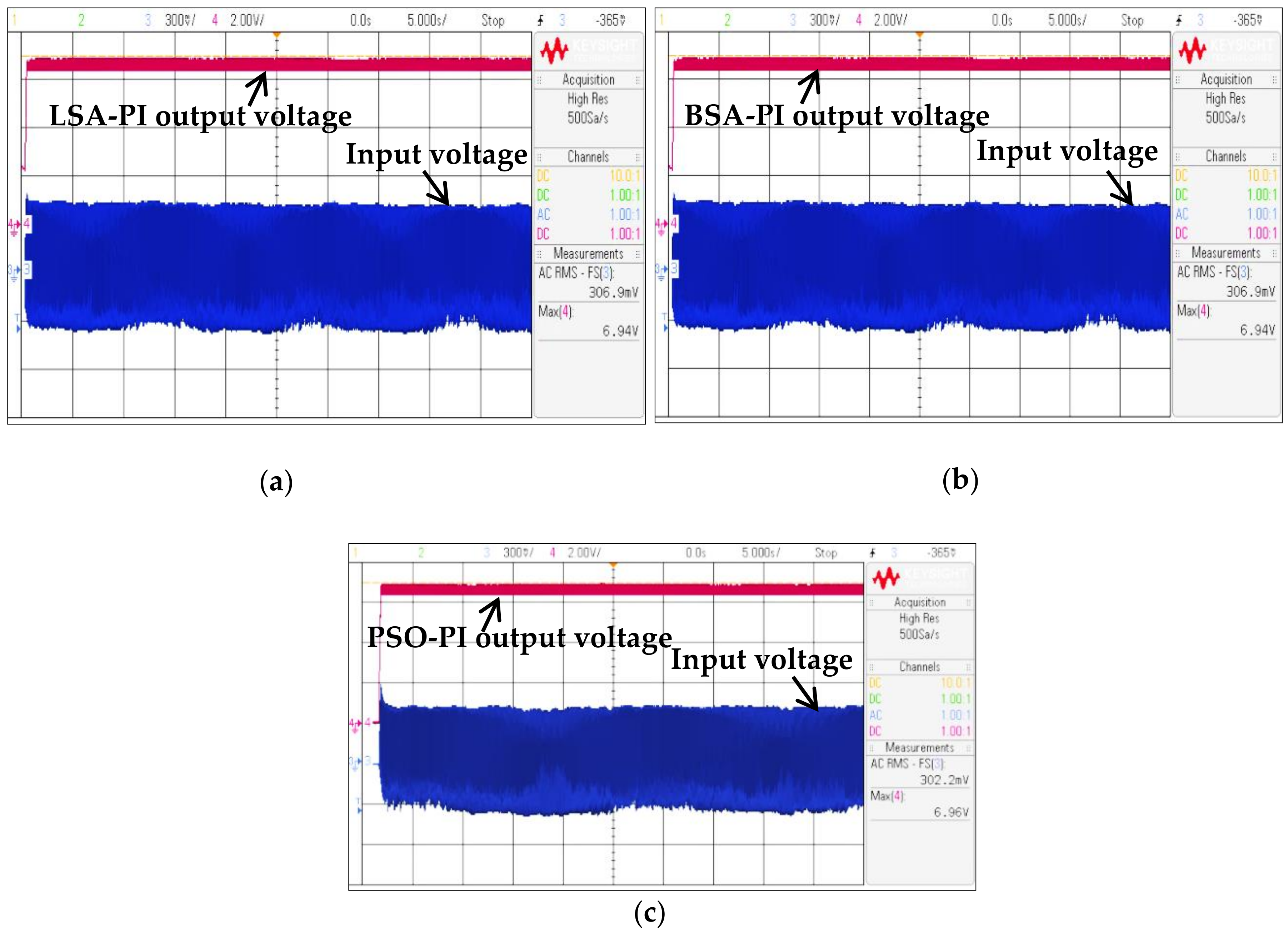

6.4. Simulation and Hardware Outcomes in Terms of the Settling Time and Rising Time

6.5. Loss Analysis and Simulation, Hardware Results of PEHS

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Algorithm A1. | Pseudo Code for LSA Optimization |

| 1 | Setting the parameters Input: I, P, M, i=1 process time Output: Error minimizer |

| 2 | for d = 1:P |

| 3 | Dpoint(d,1)=rand*(upper_kp-lower_kp)+lower_kp; |

| 4 | Dpoint(d,2)=and*(upper_ki-lower_ki)+lower_ki; |

| 5 | kp=Dpoint(d,1); |

| 6 | ki=Dpoint(d,2); |

| 7 | No. of sample a=size(error) |

| 8 | ObjFun(MAE) =sum(abs(error))/a(1); |

| 9: | Evaluation(d)= ObjFun(MAE); |

| 10 | End |

| 10 | ch_time = 0; |

| 11 | max_ch_time = 5; |

| 12 | fit_old = 10^10*(ones(1,P)); |

| 13 | direct = sign(unifrnd(-1,1,1,M)); |

| 14 | for i = 1:I |

| 15 | Evaluation; |

| 16 | ch_time = ch_time+1; |

| 17 | if ch_time>=max |

| 18 | [Ms ds]=sort(Evaluation, ‘ascend’); |

| 19 | Dpoint(ds(d),:) = Dpoint(ds(1),:); |

| 20 | Evaluation(ds(d)) = Evaluation(ds(1)); |

| 21 | ch_time = 0; |

| 22 | end |

| 23 | [Ms ds]=sort(Evaluation, ‘ascend’); |

| 24 | best = Evaluation(ds(1)); |

| 25 | worst = Evaluation(ds(d)); |

| 26 | Energy = 2.05 - 2*exp(-5*(T-t)/T); |

| 27 | for i = 1:P |

| 28 | dist=Dpoint(i,:)- Dpoint(ds(1),:); |

| 29 | for d = 1:M |

| 30 | if Dpoint(i,:)==Dpoint(ds(1),:) |

| 31 | Dpoint_temp(d)=Dpoint(i,d)+direct(d)*abs (normrnd(0,Energy)); |

| 32 | else |

| 33 | if dist(d)<0 |

| 34 | Dpoint_temp(d) = Dpoint(i,d)+exprnd(abs(dist(d))); |

| 35 | Else |

| 36 | Dpoint_temp(d) = Dpoint(i,d)-exprnd(dist(d)); |

| 37 | End |

| 38 | End |

| 39 | End |

| 40 | if (Dpoint_temp(1)>upper_kp)||(Dpoint_temp(1)<lower_kp) |

| 41 | Dpoint_temp(1)=rand*(upper_kp-lower_kp)+lower_kp; |

| 42 | end |

| 43 | if (Dpoint_temp(2)>upper_ki) || (Dpoint_temp(2)<lower_ki) |

| 44 | Dpoint_temp(2)=rand*(upper_ki-lower_ki)+lower_ki; |

| 45 | end |

| 46 | kp=Dpoint_temp(1); |

| 47 | ki=Dpoint_temp(2); |

| 48 | fv= ObjFun(MAE); |

| 49 | if fv < Evaluation(i) |

| 50 | Dpoint(i,:) = Dpoint_temp; |

| 51 | Evaluation(i) = fv; |

| 52 | end |

| 53 | end |

| 54 | if rand < 0.01 |

| 55 | for d = 1:M |

| 56 | Dpoint_fock(d,1) = upper_kp+lower_kp-Dpoint_temp(1); |

| 57 | Dpoint_fock(d,2) = upper_ki+lower_ki-Dpoint_temp(2); |

| 58 | End |

| 59 | kp=Dpoint_fock(d,1); |

| 60 | ki=Dpoint_fock(d,2); |

| 61 | a=size(error); |

| 62 | ObjFun(MAE)=sum(abs(error))/a(1); |

| 63 | fock_fit= ObjFun(MAE); |

| 64 | if fock_fit < Evaluation(i) |

| 65 | Dpoint(i,:) = Dpoint_fock; |

| 66 | Evaluation(i) = fock_fit; |

| 67 | end |

| 68 | end |

| 69 | Dpoint; |

| 70 | Evaluation; |

| 71 | Fitness(t) = min(Evaluation); |

| 72 | end |

References

- Li, S.; Crovetto, A.; Peng, Z.; Zhang, A.; Hansen, O.; Wang, M.; Li, X.; Wang, F. Bi-resonant structure with piezoelectric PVDF films for energy harvesting from random vibration sources at low frequency. Sens. Actuators A Phys. 2016, 247, 547–554. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, Y.; Huang, Z.; Lee, C.; Wang, F. Electret-material enhanced triboelectric energy harvesting from air flow for self-powered wireless temperature sensor network. Sens. Actuators A Phys. 2018, 271, 364–372. [Google Scholar] [CrossRef]

- Raouadi, M.H.; Touayar, O. Harvesting wind energy with pyroelectric nanogenerator PNG using the vortex generator mechanism. Sens. Actuators A Phys. 2018, 273, 42–48. [Google Scholar] [CrossRef]

- Mohamed, R.; Sarker, M.R.; Mohamed, A. An optimization of rectangular shape piezoelectric energy harvesting cantilever beam for micro devices. Int. J. Appl. Electromagn. Mech. 2016, 50, 537–548. [Google Scholar] [CrossRef]

- Cho, J.Y.; Kim, K.-B.; Jabbar, H.; Sin Woo, J.; Ahn, J.H.; Hwang, W.S.; Jeong, S.Y.; Cheong, H.; Yoo, H.H.; Sung, T.H. Design of optimized cantilever form of a piezoelectric energy harvesting system for a wireless remote switch. Sens. Actuators A Phys. 2018, 280, 340–349. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef]

- Yi, Z.; Yang, B.; Zhang, W.; Wu, Y.; Liu, J.-Q. Batteryless Tire Pressure Real-Time Monitoring System Driven by an Ultralow-frequency Piezoelectric Rotational Energy Harvester. IEEE Trans. Ind. Electron. 2020. [Google Scholar] [CrossRef]

- Lu, L.; Yang, B.; Zhai, Y.; Liu, J. Electrospinning core-sheath piezoelectric microfibers for self-powered stitchable sensor. Nano Energy 2020, 76, 104966. [Google Scholar] [CrossRef]

- Shin, Y.C.; Yoon, H.; Jo, S.H.; Choi, W.; Park, C.S.; Kim, M.; Youn, B.D. Phononic band gap of a quarter-wave stack for enhanced piezoelectric energy harvesting. Int. J. Mech. Sci. 2021, 189, 106003. [Google Scholar] [CrossRef]

- Mohamed, R.; Sarker, M.R.; Mohamed, A. Designing an integrated voltage tripled circuit using piezoelectric vibration generator. J. Eng. Appl. Sci. 2017, 12, 6892–6897. [Google Scholar]

- Wang, C.; Wang, S.; Li, Q.J.; Wang, X.; Gao, Z.; Zhang, L. Fabrication and performance of a power generation device based on stacked piezoelectric energy-harvesting units for pavements. Energy Convers. Manag. 2018, 163, 196–207. [Google Scholar] [CrossRef]

- Liang, J. Synchronized bias-flip interface circuits for piezoelectric energy harvesting enhancement: A general model and prospects. J. Intell. Mater. Syst. Struct. 2017, 28, 339–356. [Google Scholar] [CrossRef]

- Alghisi, D.; Dalola, S.; Ferrari, M.; Ferrari, V. Triaxial ball-impact piezoelectric converter for autonomous sensors exploiting energy harvesting from vibrations and human motion. Sens. Actuators A Phys. 2015, 233, 569–581. [Google Scholar] [CrossRef]

- Suzuki, K.; Adachi, K.; Shibamata, Y.; Suzuki, T. Structure of 100 W high-efficiency piezoelectric transformer for applications in power electronics. Jpn. J. Appl. Phys. 2016, 55, 086702. [Google Scholar] [CrossRef]

- Shen, H.; Ji, H.; Qiu, J.; Bian, Y.; Liu, D. Adaptive synchronized switch harvesting: A new piezoelectric energy harvesting scheme for wideband vibrations. Sens. Actuators A Phys. 2015, 226, 21–36. [Google Scholar] [CrossRef]

- Martinez, T.; Pillonnet, G.; Costa, F. A 15-mV Inductor-Less Start-up Converter Using a Piezoelectric Transformer for Energy Harvesting Applications. IEEE Trans. Power Electron. 2018, 33, 2241–2253. [Google Scholar] [CrossRef]

- Hsieh, P.-H.; Chen, C.-H.; Chen, H.-C. Improving the Scavenged Power of Nonlinear Piezoelectric Energy Harvesting Interface at Off-Resonance by Introducing Switching Delay. IEEE Trans. Power Electron. 2015, 30, 3142–3155. [Google Scholar] [CrossRef]

- Wang, H.; Tang, Y.; Khaligh, A. A Bridgeless Boost Rectifier for Low-Voltage Energy Harvesting Applications. IEEE Trans. Power Electron. 2013, 28, 5206–5214. [Google Scholar] [CrossRef]

- Alghisi, D.; Ferrari, V.; Ferrari, M.; Crescini, D.; Touati, F.; Mnaouer, A.B. Single- and multi-source battery-less power management circuits for piezoelectric energy harvesting systems. Sens. Actuators A Phys. 2017, 264, 234–246. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Cho, J.Y.; Hong, S.D.; Hwang, W.; Jabbar, H.; Ahn, J.H.; Jhun, J.P.; Sung, T.H. Self-Powered Operational Amplifying System with a Bipolar Voltage Generator Using a Piezoelectric Energy Harvester. Electronics 2019, 9, 41. [Google Scholar] [CrossRef]

- Chen, N.; Jung, H.J.; Jabbar, H.; Sung, T.H.; Wei, T. A piezoelectric impact-induced vibration cantilever energy harvester from speed bump with a low-power power management circuit. Sens. Actuators A Phys. 2017, 254, 134–144. [Google Scholar] [CrossRef]

- Rezaeisaray, M.; Gowini, M.E.; Sameoto, D.; Raboud, D.; Moussa, W. Low frequency piezoelectric energy harvesting at multi vibration mode shapes. Sens. Actuators A Phys. 2015, 228, 104–111. [Google Scholar] [CrossRef]

- Basilio, J.C.; Matos, S.R. Design of PI and PID controllers with transient performance specification. IEEE Trans. Educ. 2002, 45, 364–370. [Google Scholar] [CrossRef]

- Priyanka, E.B.; Maheswari, C.; Thangavel, S. Online Monitoring and Control of Flow rate in Oil Pipelines Transportation System by using PLC based Fuzzy-PID Controller. Flow Meas. Instrum. 2018, 62, 144–151. [Google Scholar] [CrossRef]

- Le, T.N.; Sentieys, O.; Berder, O.; Pegatoquet, A.; Belleudy, C. Power Manager with PID Controller in Energy Harvesting Wireless Sensor Networks. In Proceedings of the 2012 IEEE International Conference on Green Computing and Communications, Besancon, France, 20–23 November 2012; pp. 668–670. [Google Scholar]

- Perry, A.G.; Feng, G.; Liu, Y.; Sen, P.C. A Design Method for PI-like Fuzzy Logic Controllers for DC–DC Converter. IEEE Trans. Ind. Electron. 2007, 54, 2688–2696. [Google Scholar] [CrossRef]

- Elmas, C.; Yigit, T. Genetic Algorithm Based On-line Tuning of a PI Controller for a Switched Reluctance Motor Drive. Electr. Power Compon. Syst. 2007, 35, 675–691. [Google Scholar] [CrossRef]

- Mo, H.; Yin, Y. Research on PID tuning of servo-system based on Bacterial Foraging Algorithm. In Proceedings of the 2011 Seventh International Conference on Natural Computation, Shanghai, China, 26–28 July 2011; pp. 1758–1762. [Google Scholar]

- Luan, X.; Chen, Q.; Liu, F. Centralized PI control for high dimensional multivariable systems based on equivalent transfer function. ISA Trans. 2014, 53, 1554–1561. [Google Scholar] [CrossRef]

- Shareef, H.; Ibrahim, A.A.; Mutlag, A.H. Lightning search algorithm. Appl. Soft Comput. 2015, 36, 315–333. [Google Scholar] [CrossRef]

- Sefa, I.; Altin, N.; Ozdemir, S.; Demirtas, M. dSPACE based control of voltage source utility interactive inverter. In Proceedings of the 2008 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008; pp. 662–666. [Google Scholar]

- Amir, A.; Che, H.S.; Amir, A.; Khateb, A.E.; Rahim, N.A. Transformerless high gain boost and buck-boost DC-DC converters based on extendable switched capacitor (SC) cell for stand-alone photovoltaic system. Sol. Energy 2018, 171, 212–222. [Google Scholar] [CrossRef]

- Mostafa, M.G.; Motakabber, S.M.A.; Ibrahimy, M.I. Design and Analysis of a Buck-Boost Converter Circuit for Piezoelectric Energy Harvesting System. In Proceedings of the 2016 International Conference on Computer and Communication Engineering (ICCCE), Kuala Lumpur, Malaysia, 26–27 July 2016; pp. 204–207. [Google Scholar]

- Yi, Z.; Xie, F.; Tian, Y.; Li, N.; Dong, X.; Ma, Y.; Huang, Y.; Hu, Y.; Xu, X.; Qu, D.; et al. A Battery- and Leadless Heart-Worn Pacemaker Strategy. Adv. Funct. Mater. 2020, 30, 2000477. [Google Scholar] [CrossRef]

- Fathabadi, H. Solar energy harvesting in buildings using a proposed novel electrochemical device as an alternative to PV modules. Renew. Energy 2019, 133, 118–125. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Karkoub, M.; Her, M.-G. Energy harvesting devices for subsea sensors. Renew. Energy 2017, 101, 1334–1347. [Google Scholar] [CrossRef]

- Din, A.U.; Kamran, M.; Mahmood, W.; Aurangzeb, K.; Altamrah, A.S.; Lee, J.-W. An Efficient CMOS Dual Switch Rectifier for Piezoelectric Energy-Harvesting Circuits. Electronics 2019, 8, 66. [Google Scholar] [CrossRef]

- Bottion, A.J.B.; Barbi, I. Input-Series and Output-Series Connected Modular Output Capacitor Full-Bridge PWM DC–DC Converter. IEEE Trans. Ind. Electron. 2015, 62, 6213–6221. [Google Scholar] [CrossRef]

- Ang, J.A.N.D.; Borja, R.R.D.; Diaz, R.S.C.; Samson, S.D.O.; Sanchez, J.L.A.; Roxas, E.A.; Rocamora, J.M.B. Development of a DC-DC converter with Current Mode Control for multi-source renewable energy harvesting system. In Proceedings of the 2016 IEEE Region 10 Conference (TENCON), Singapore, 22–25 November 2016; pp. 556–559. [Google Scholar]

- Ghani, Z.A.; Hannan, M.A.; Mohamed, A. Simulation model linked PV inverter implementation utilizing dSPACE DS1104 controller. Energy Build. 2013, 57, 65–73. [Google Scholar] [CrossRef]

- Chen, Z.; Law, M.K.; Mak, P.I.; Zeng, X.; Martins, R.P. Piezoelectric energy-harvesting interface using split-phase flipping-capacitor rectifier with capacitor reuse for input power adaptation. IEEE J. Solid State Circuits 2020, 55, 2106–2117. [Google Scholar] [CrossRef]

- Salam, Z.; Soon, T.L.; Ramli, M.Z. Hardware Implementation of the High Frequency Link Inveter Using the dSPACE DS1104 Digital Signal Processing Board. In Proceedings of the 2006 IEEE International Power and Energy Conference, Putra Jaya, Malaysia, 28–29 November 2006; pp. 348–352. [Google Scholar]

- Kazimierczuk, M.K. Pulse-Width Modulated DC-DC Power Converters; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; ISBN 9780470694640. [Google Scholar]

- Richelli, A.; Comensoli, S.; Kovacs-Vajna, Z.M. A DC/DC Boosting Technique and Power Management for Ultralow-Voltage Energy Harvesting Applications. IEEE Trans. Ind. Electron. 2012, 59, 2701–2708. [Google Scholar] [CrossRef]

- Sarker, M.; Mohamed, A.; Mohamed, R.; Sarker, M.R.; Mohamed, A.; Mohamed, R. A New Method for a Piezoelectric Energy Harvesting System Using a Backtracking Search Algorithm-Based PI Voltage Controller. Micromachines 2016, 7, 171. [Google Scholar] [CrossRef]

- Sarker, M.R.; Mohamed, R.; Saad, M.H.M.; Mohamed, A. dSPACE Controller-Based Enhanced Piezoelectric Energy Harvesting System Using PI-Lightning Search Algorithm. IEEE Access 2019, 7, 3610–3626. [Google Scholar] [CrossRef]

- Bertacchini, A.; Scorcioni, S.; Cori, M.; Larcher, L.; Pavan, P. 250mV input boost converter for low power applications. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 533–538. [Google Scholar]

- Yu, H.; Zhou, J.; Deng, L.; Wen, Z. A Vibration-Based MEMS Piezoelectric Energy Harvester and Power Conditioning Circuit. Sensors 2014, 14, 3323–3341. [Google Scholar] [CrossRef]

- Khemmanee, B.; Isarakorn, D. Low-cost energy management circuit base on primary feedback self-oscillating flyback converter for piezoelectric energy harvesting. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 1035–1038. [Google Scholar]

| Type | Rise Time | Overshoot | Settling Time | Steady State Error |

|---|---|---|---|---|

| Kp | Lessening | Rise | Little change | Lessening |

| Ki | Lessening | Rise | Rise | Reduce |

| Load | Measurements | LSA | BSA | PSO |

|---|---|---|---|---|

| 2 MΩ | Best | 0.000000000077343 | 0.0001633201 | 0.000657771 |

| Worst | 0.00051020 | 0.030612321 | 0.031732138 | |

| Average | 0.000008150 | 0.006876100 | 0.030834701 | |

| Median | 0.0000023007 | 0.003061005 | 0.020081260 | |

| Standard Deviation | 0.000071341 | 0.015217271 | 0.009188011 | |

| 100 kΩ | Best | 0.0000007399 | 0.001786800 | 0.001026139 |

| Worst | 0.007010000 | 0.041251135 | 0.021731300 | |

| Average | 0.000251000 | 0.007970010 | 0.00191980 | |

| Median | 0.0000105161 | 0.001926101 | 0.012100108 | |

| Standard Deviation | 0.000912100 | 0.026190084 | 0.019500431 | |

| 470 Ω | Best | 0.00014500 | 0.019419001 | 0.003190087 |

| Worst | 0.10107936 | 0.211004200 | 0.12273209 | |

| Average | 0.008223118 | 0.023110209 | 0.00910008 | |

| Median | 0.00062002 | 0.019612906 | 0.010021490 | |

| Standard Deviation | 0.0091101006 | 0.031000031 | 0.041000120 | |

| 50 Ω | Best | 0.0000009110 | 0.020005160 | 0.023009811 |

| Worst | 0.030023418 | 0.080200145 | 0.893018799 | |

| Average | 0.002811000 | 0.030175100 | 0.20019932 | |

| Median | 0.0000026513 | 0.00081002 | 0.003001010 | |

| Standard Deviation | 0.006109510 | 0.030015951 | 0.400110010 |

| MAE | LSA | BSA | PSO |

|---|---|---|---|

| 0.000000000077343 | 0.0001633201 | 0.000657771 |

| Parameter | LSA | BSA | PSO |

|---|---|---|---|

| Population Size | 50 | 50 | 50 |

| Max. Iteration | 500 | 500 | 500 |

| c1 and c2 | - | - | 1.5 |

| F | - | 3 | - |

| Channel time | 10 | - | - |

| Techniques | Rise Time (s) | Settling Time (s) | Peak over Shoot | Consistent State Error |

|---|---|---|---|---|

| LSA-PI | 0.03579 | 0.0457 | 0% | 0.1 |

| BSA-PI | 0.05176 | 0.1213 | 0% | 0.1 |

| PSO-PI | 0.08235 | 0.1675 | 0% | 0.1 |

| Frequency | Vrms (Input) | Simulation Result | Experimental Results | Optimization Algorithm |

|---|---|---|---|---|

| 60 Hz | 300 mV | 7 V | 6.94 V 6.94 V 6.96 V | LSA-PI BSA-PI PSO-PI |

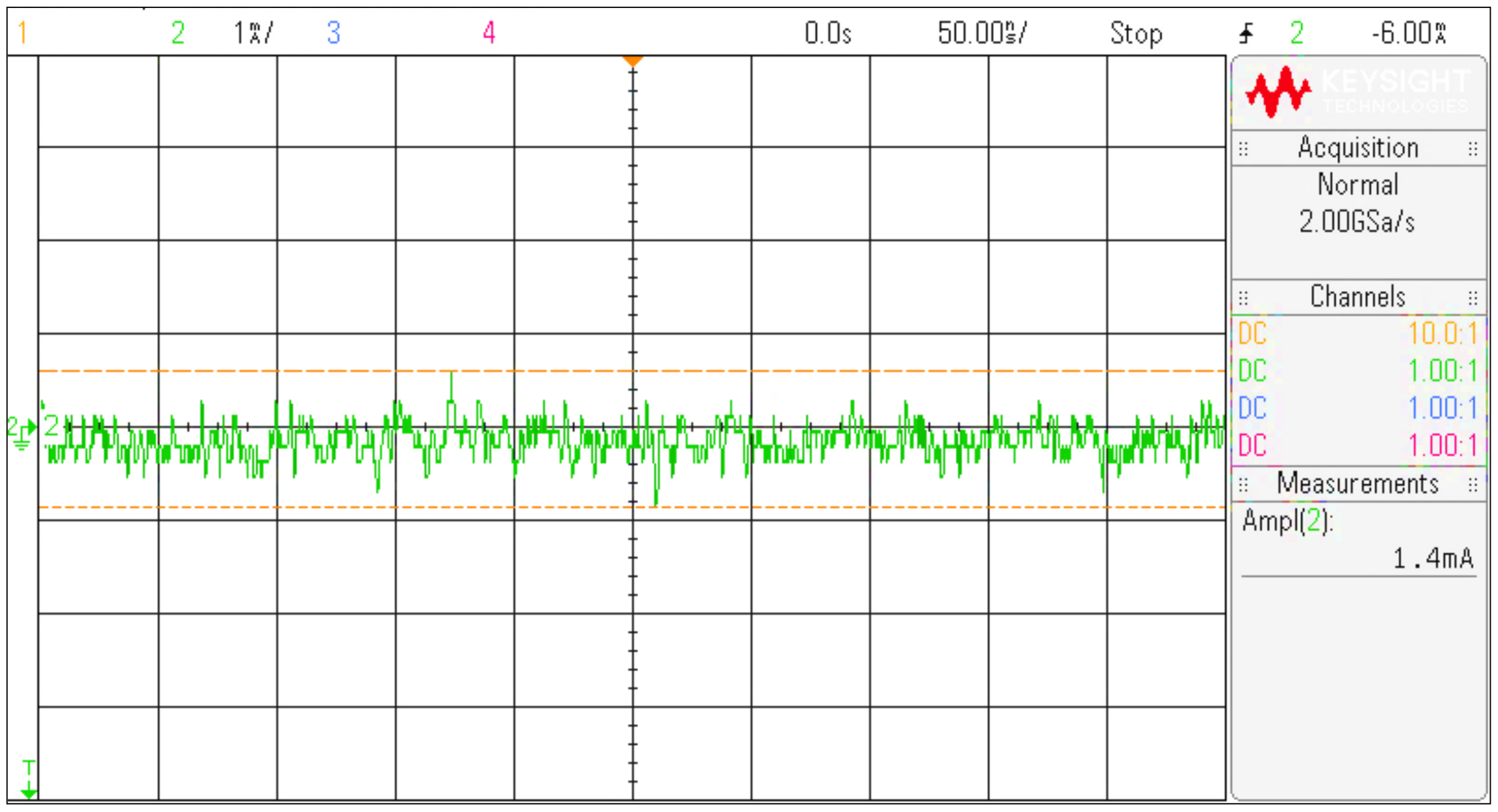

| Parameter | Measured Values |

|---|---|

| Input voltage (Vin) | 300 mV |

| Output voltage (Vout) | 7 V |

| Input current (Iin) | 1.4 mA |

| Input power (Pin) | 0.28 mW |

| Switching frequency (fs) | 10 kHz |

| Diode threshold voltage (VF) | 0.169 |

| Duty (U) | 0.95 |

| Resistance of the MOSFET (rDS) | 7.92 |

| Inductor resistance, (rL) | 6.87 |

| Diode forward resistance (RF) | 0.171 |

| References | [44] | [45] | [46] | [47] | [48] | [49] | This Study |

|---|---|---|---|---|---|---|---|

| Algorithm | N/A | BSA | LSA | N/A | N/A | NA | LSA-PI |

| Vin (Input voltage) | 0.12 V | 0.3 V | 0.25 V | 0.25 V–0.4 V | 40 mV | 2.5 V | 300 mV |

| Vo (Output voltage) | 1.2 V | 6.06 V | 7.05 V | 3.3 V | 4.1 V–5 V | 5 V | 6.94 V |

| Switching Frequency | 3 MHz | 10 kHz | 10 kHz | 170 kHz | 100 kHz | 50.39 kHz | 10 kHz |

| Load | 10 kΩ | Resistive load | Resistive load | 33 kΩ | Not Reported | Not Reported | 2 MΩ, 100 kΩ, 470 Ω, 50 Ω |

| Efficiency | 35% | Not Reported | Not Reported | 70% | Not Reported | Not Reported | 85% |

| Application | Energy harvesting | Energy Harvesting | Energy Harvesting | Energy harvesting | Low power | Energy Harvesting | Micro Devices for Energy Harvesting |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarker, M.R.; Mohamed, R.; Saad, M.H.M.; Tahir, M.; Hussain, A.; Mohamed, A. A Hybrid Optimization Approach for the Enhancement of Efficiency of a Piezoelectric Energy Harvesting System. Electronics 2021, 10, 75. https://doi.org/10.3390/electronics10010075

Sarker MR, Mohamed R, Saad MHM, Tahir M, Hussain A, Mohamed A. A Hybrid Optimization Approach for the Enhancement of Efficiency of a Piezoelectric Energy Harvesting System. Electronics. 2021; 10(1):75. https://doi.org/10.3390/electronics10010075

Chicago/Turabian StyleSarker, Mahidur R., Ramizi Mohamed, Mohamad Hanif Md Saad, Muhammad Tahir, Aini Hussain, and Azah Mohamed. 2021. "A Hybrid Optimization Approach for the Enhancement of Efficiency of a Piezoelectric Energy Harvesting System" Electronics 10, no. 1: 75. https://doi.org/10.3390/electronics10010075

APA StyleSarker, M. R., Mohamed, R., Saad, M. H. M., Tahir, M., Hussain, A., & Mohamed, A. (2021). A Hybrid Optimization Approach for the Enhancement of Efficiency of a Piezoelectric Energy Harvesting System. Electronics, 10(1), 75. https://doi.org/10.3390/electronics10010075