A Procedure for Tracing Supply Chains for Perishable Food Based on Blockchain, Machine Learning and Fuzzy Logic

Abstract

1. Introduction

- The main objective of this study is to integrate machine learning and blockchain in order to improve the traceability system.

- Supporting the product’s shelf life for quality evaluation and preventing the time-consuming processes in the supply chain.

- Managing the traceability system by deploying the fuzzy logic platform.

- Light-weight characteristic that is deployed to address the need of the traceability system in the blockchain.

- The proposed food traceability system supplement the modern supply chain environment and generate dependable tracking monitoring and food quality results.

- The decision support in this system follows the fuzzy logic in order to specify the shelf life, rate, and the quality of the product based on the various environments in the perishable food traceability system.

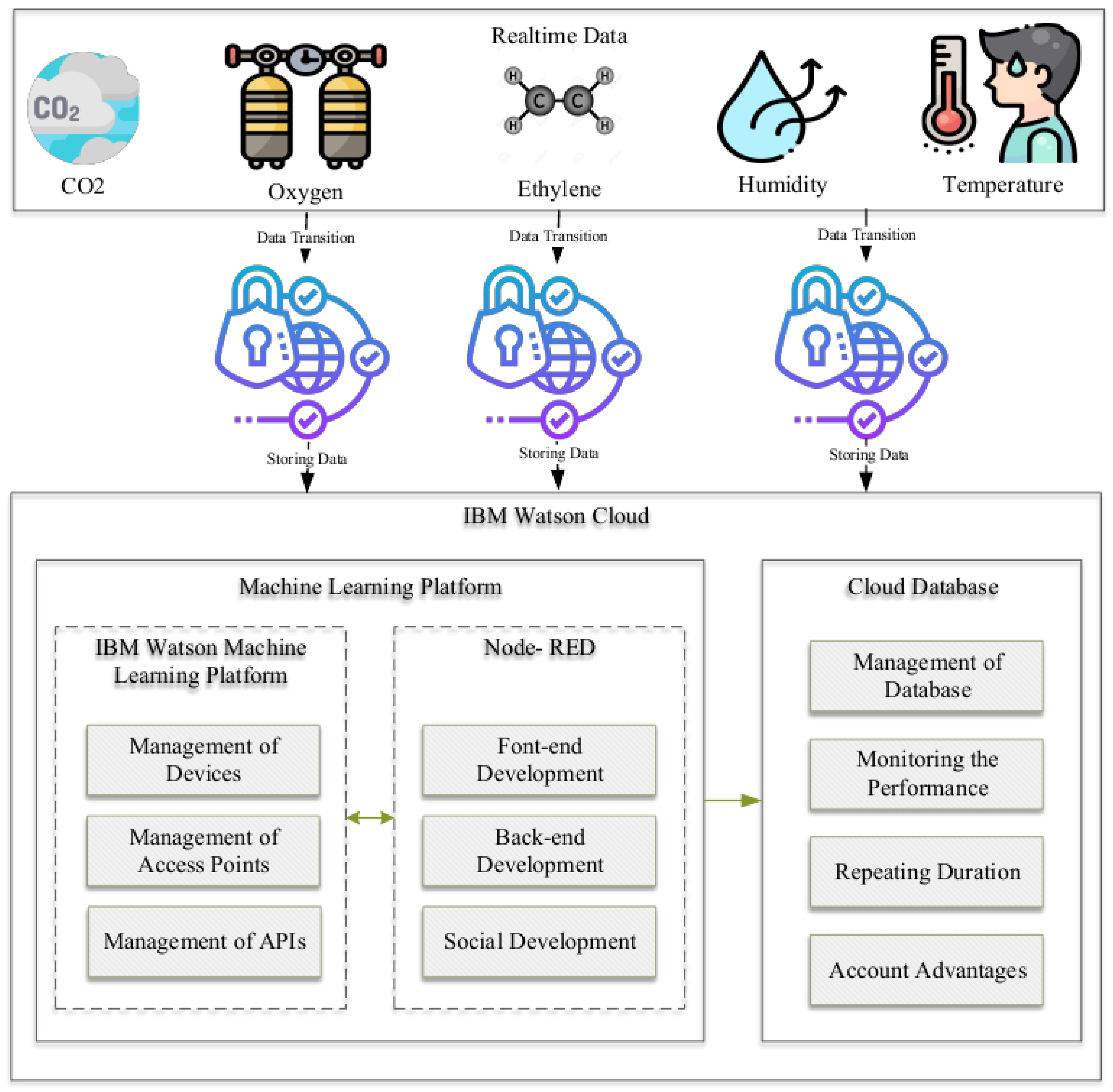

- In order to support the machine learning and monitoring of the environmental IoT sensors, the blockchain is defined to prove the further computational load and light-weight with cloud computing in order to support the machine learning and monitoring of the environmental IoT sensors.

2. Literature Review

2.1. Industry 4.0 Key Technology

2.2. Information Sharing in Supply Chains

2.3. State of Art Analysis

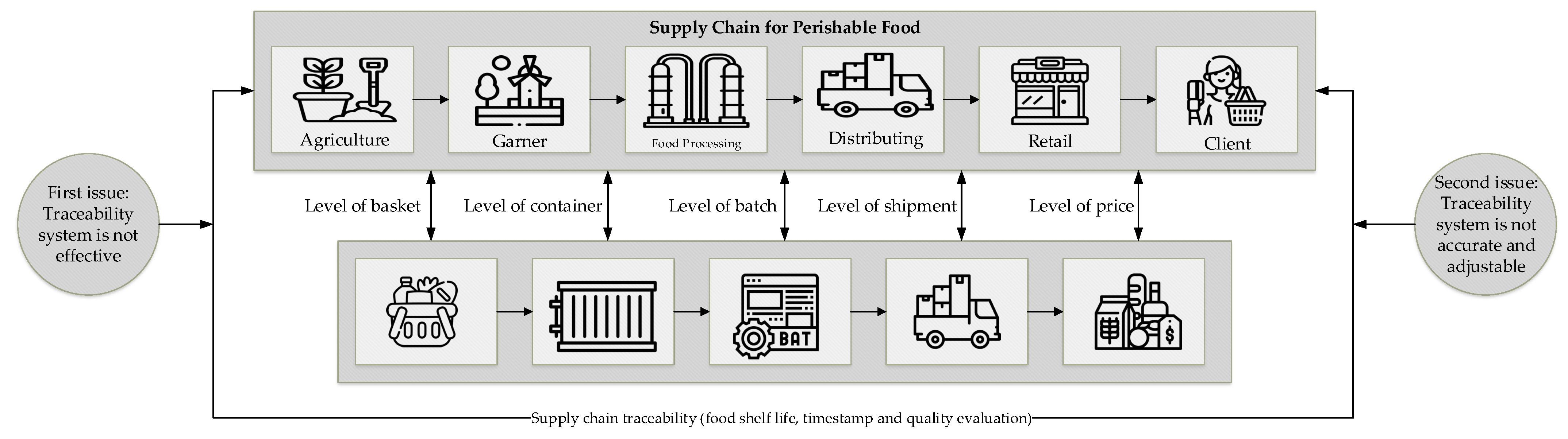

3. System Model of the Proposed Blockchain-Based Food Traceability Prediction in Warehouse Environment

3.1. Blockchain, IoT and Machine Learning Conceptual Scenario

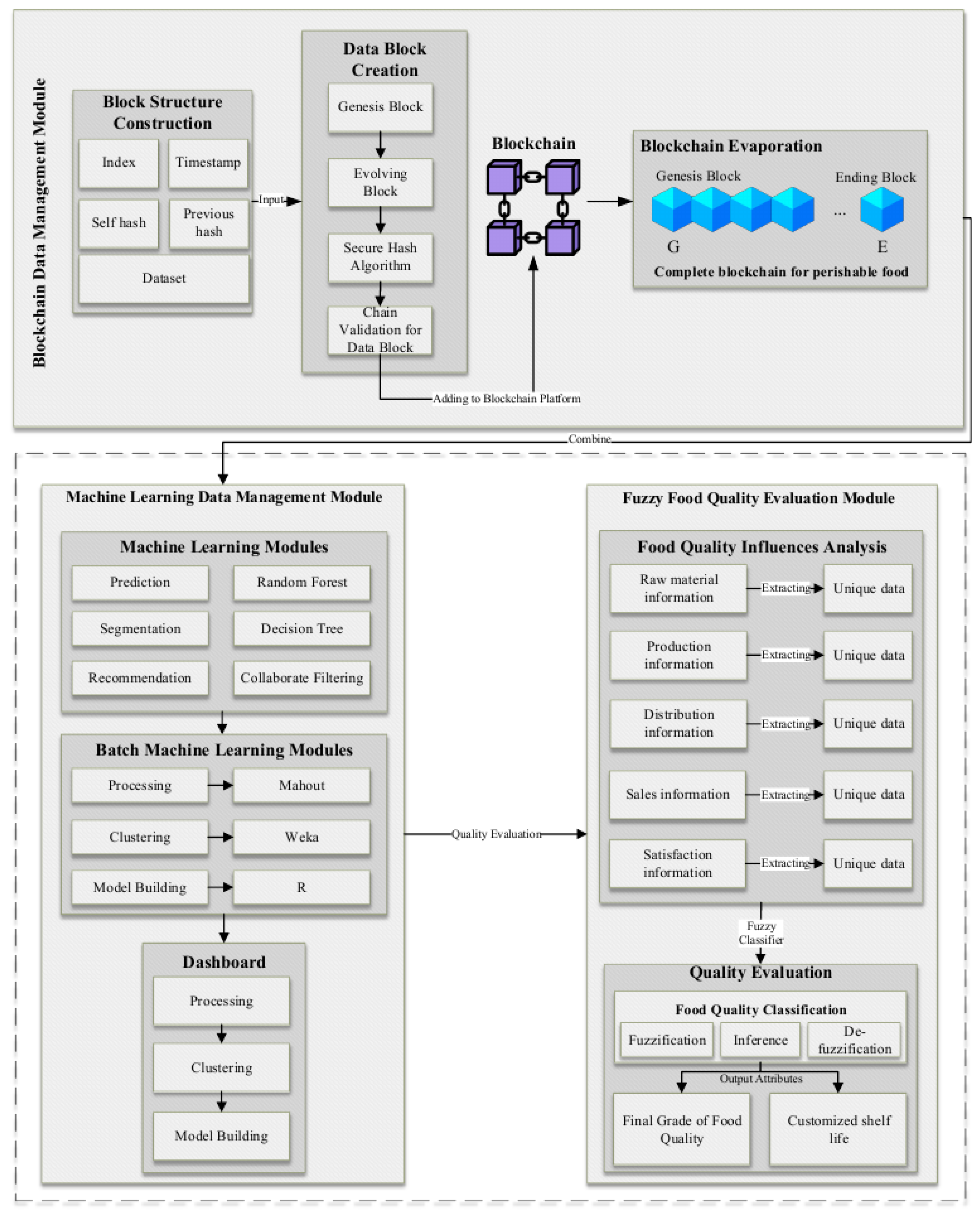

3.2. Proposed Food Traceability Blockchain Platform Architecture

3.3. Fuzzy Food Quality Evaluation Module

3.4. Fuzzy Inference System Structure

3.5. Quantitative Quality Measurement

- Maintainability: this attribute executes the software changes, e.g., improving the software, correcting the problems, and achieving the acceptable environment.

- Portability: this attribute can transfer the software to various environments.

- Reliability: this attribute improves performance based on stable conditions in a special period.

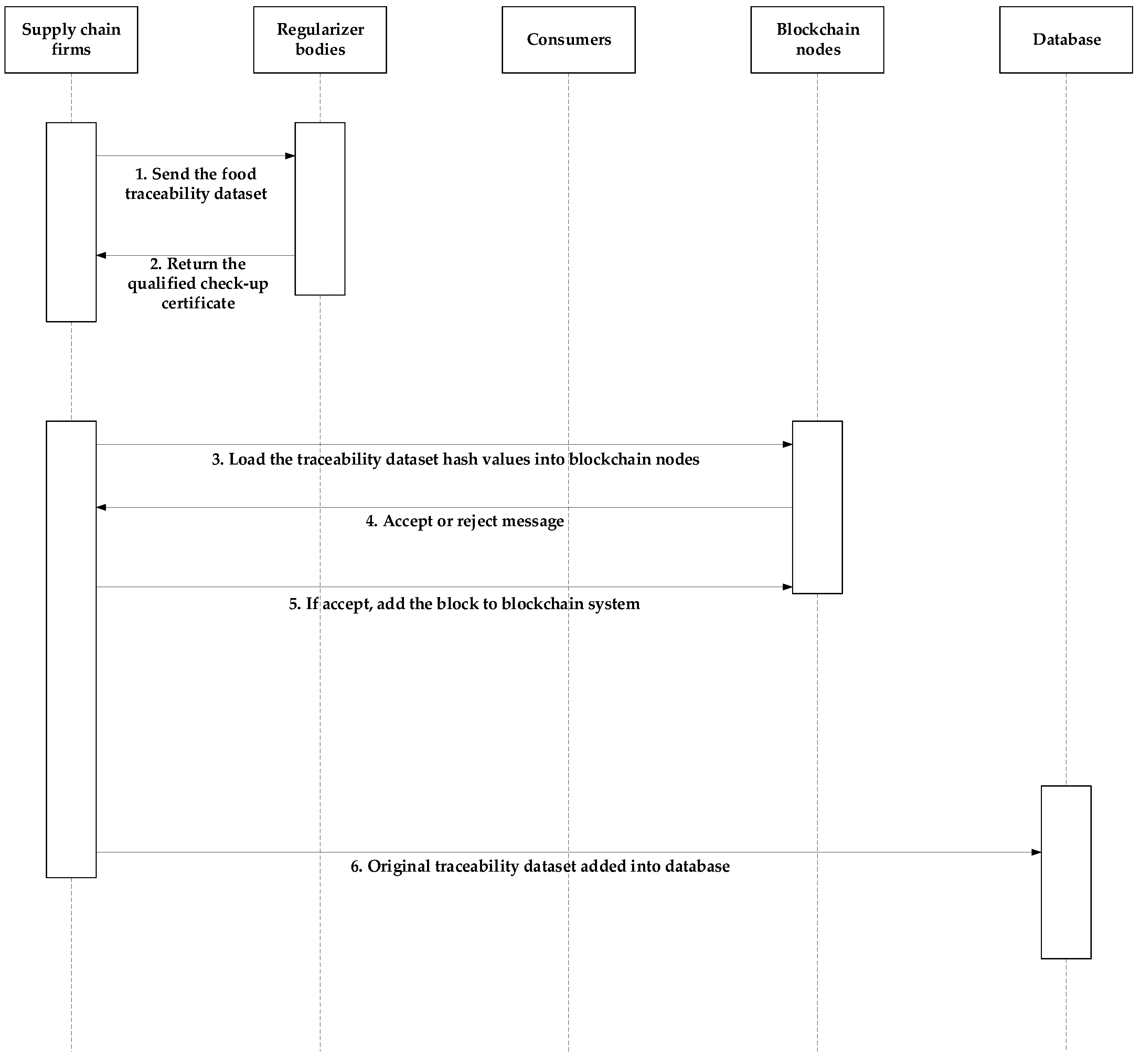

3.6. Smart Contract in the Proposed Food Traceability Blockchain Platform

4. Implementation Environment of the Proposed Food Traceability Blockchain Platform

4.1. Smart Contract Modeling of the Case Study

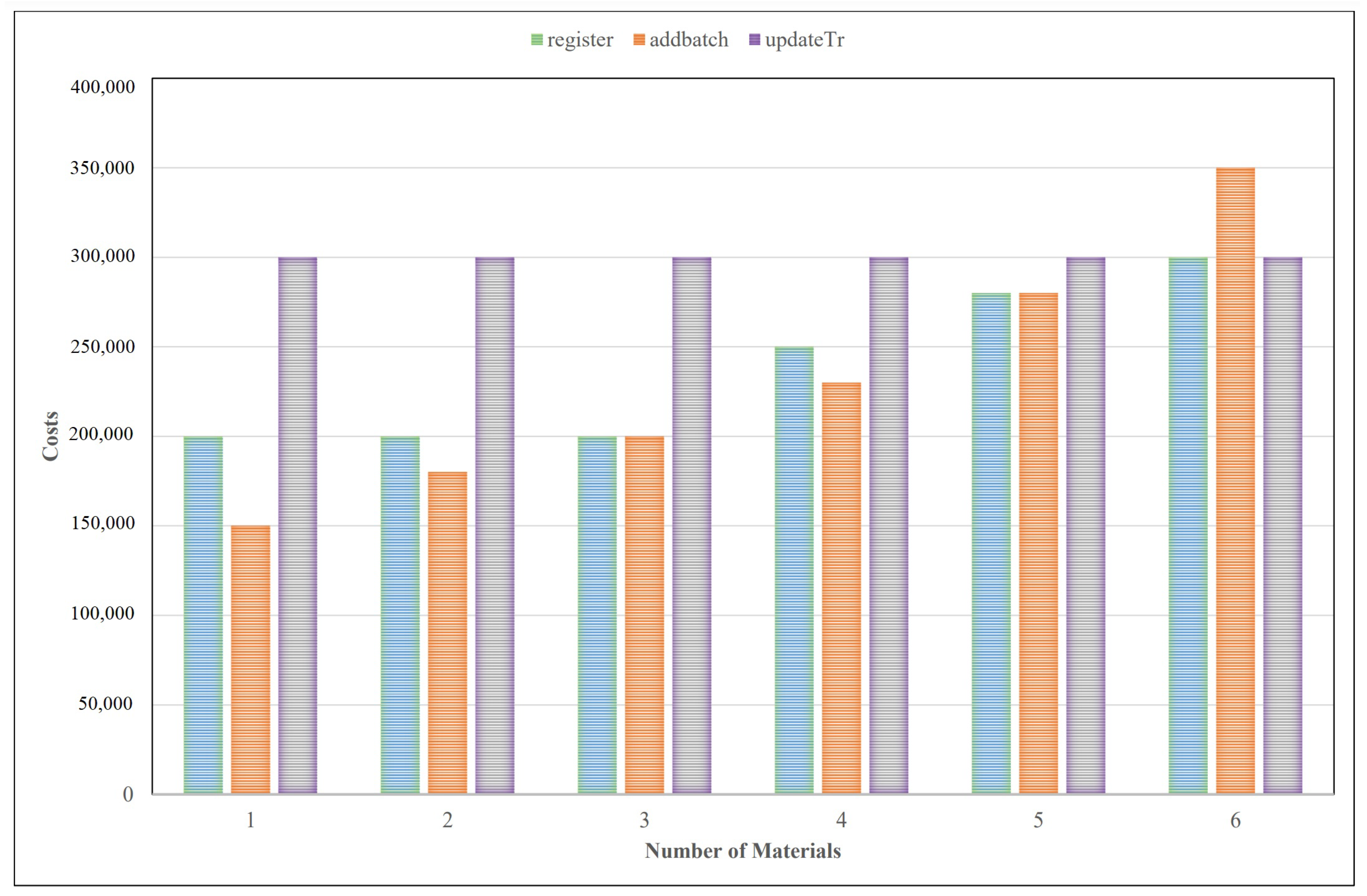

- Product Registration Contract (PRC): the PRC contract was established by the system manager to come up with product registration function “register ()” in order to save the complete product information. The registered information contains the product name, specific code for each product, and the customer’s name, which orders the product. Table 4 is an example of the mentioned information that is stored in the PRC contract. After the product registration, it will post into the BAC contract to save the product customer account information. The BAC contracts design a production batch based on the customer information and they are sure not to save the batches’ repeated information.

- Batch Addition Contract (BAC): the BAC contract was established by the product customer to register the product with the “addBatch ()” function in order to save the batch information. The batch information is designed to contract a batch for each product, including the batch number and the products’ raw information mentioned above. Table 5 presents an example of the BAC contract for a product. The product transaction updating in the TUC contract shows the product nodes in the supply chain in which the product entities go through the moving process.

- Transaction Update Contract (TUC): the TUC contract was designed to update the product transaction information, which defines the function of "updateTr" for the product batch. This process is updating the information based on the time that the sender is sending the product and how the customer receives the product. First, the transaction from the sender is built in order to make the receipt for the product and add the product transaction information. In this case, the product code and batch number are attached. Suppose that this information is not available in the previous transaction that is attached to the system. The second is when the transaction launch from the sender and the transaction information add to the transaction records. This process contains the hash of the current transaction. Table 6 is an example of the TUC contract to show the transaction list with the updates of the well-packed products in the blockchain and the previous valid transactions hash records. This process makes sure that the added transactions in the blockchain are reliable and legal, and similarly prevent any interruption in the product traceability process.

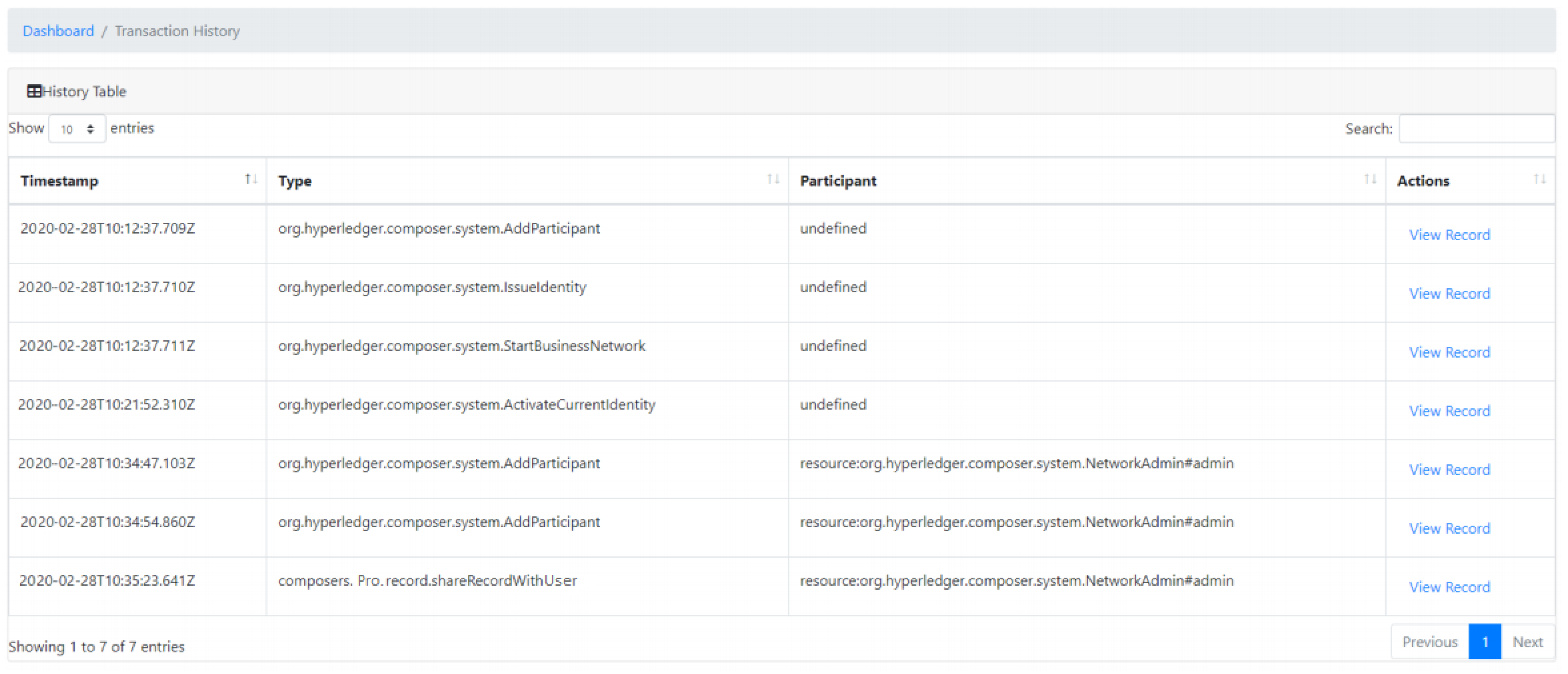

4.2. Execution Procedure of the Case Study

- Background of the company and problems: the MATRO Store in South Korea is the mentioned company, which is one of the famous 24 h marts, providing the perishable food product. It enthusiastically entered into the perishable food products business, which contains the e-commerce platform, food supplier appropriate sources, process the implementation, and multi-temperature delivery for last miles. The main provided aspects can be mentioned as business-to-customer (B2C) and customer-to-customer (C2C), which is a domestic food supply. In the generic platform of e-commerce, it is possible for the shipment detail information to provide to them. Customers are curious to know the shipment’s details regarding the supply chain covering information on the food quality and management environment, regardless of managing the e-commerce business of perishable food. Furthermore, some solutions provided while tracking the food quality to save time and reduce the costs. This is especially true in regards to covering the intentions that are related to shelf life. To sum up the contents, customers are interested in knowing the quality of the delivered product in the perishable food supply chain, which is the main aspect of the company for improving the company’s performance and image for the future. On the opposite side, if the customer receives the perishable food product with low quality and delivery, then it will damage the perishable food e-commerce business. Therefore, the company needs to provide a trustable food traceability system with an effective process and real-time monitoring.

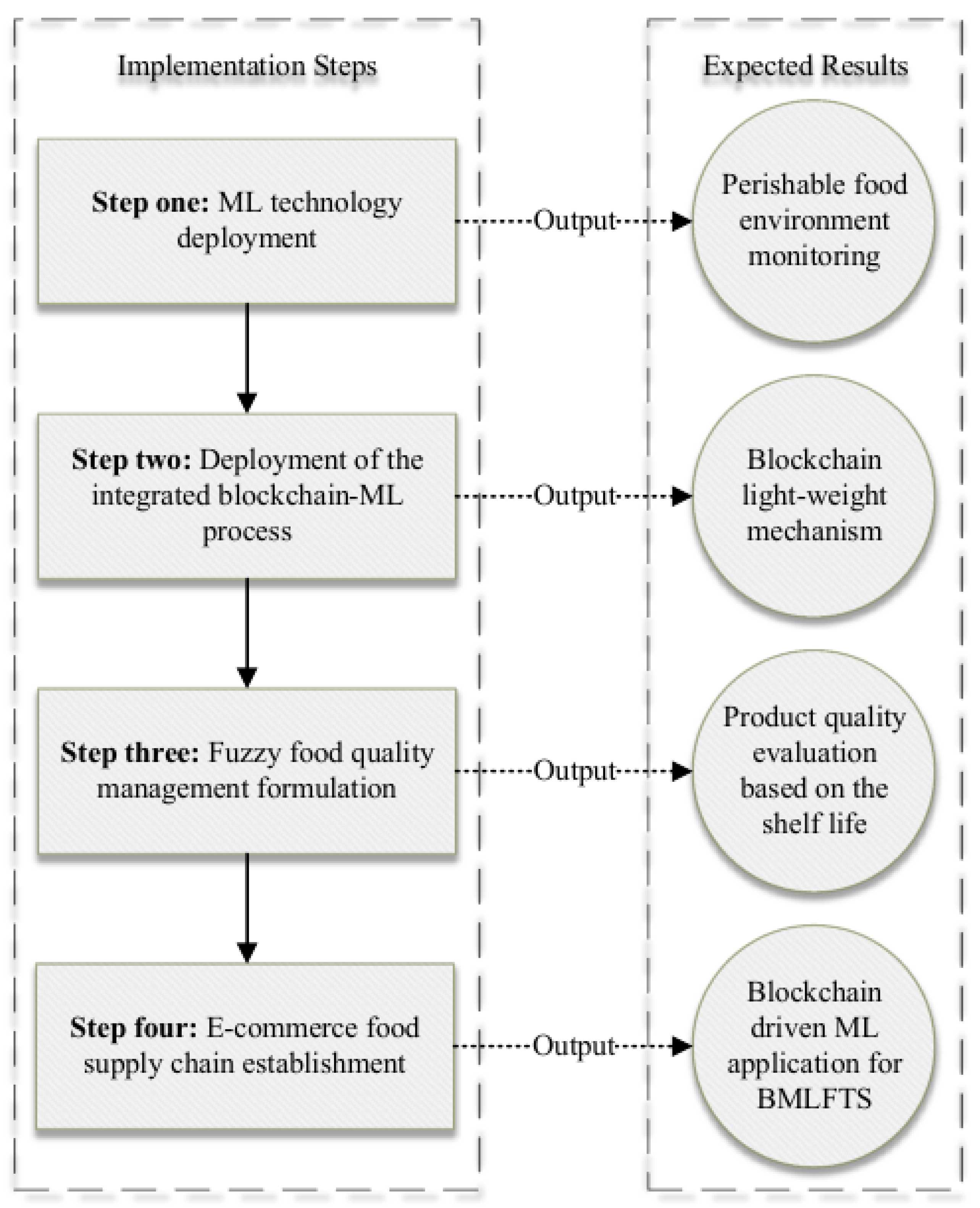

- BMLFTS Road-map Implementation: the proposed (BMLFTS) is for implementing the complete food traceability system based on the quality of food and the management system into recent technology.

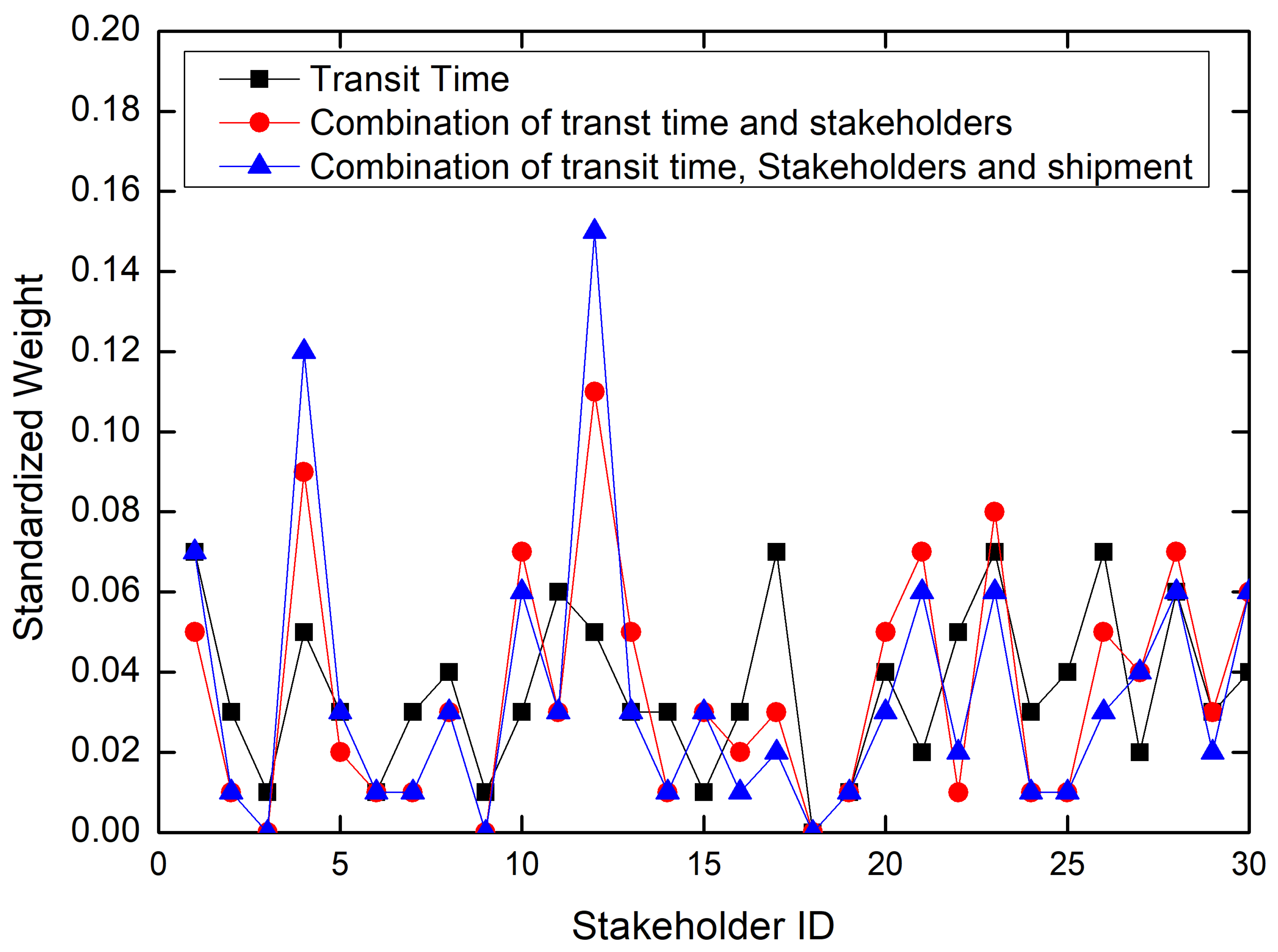

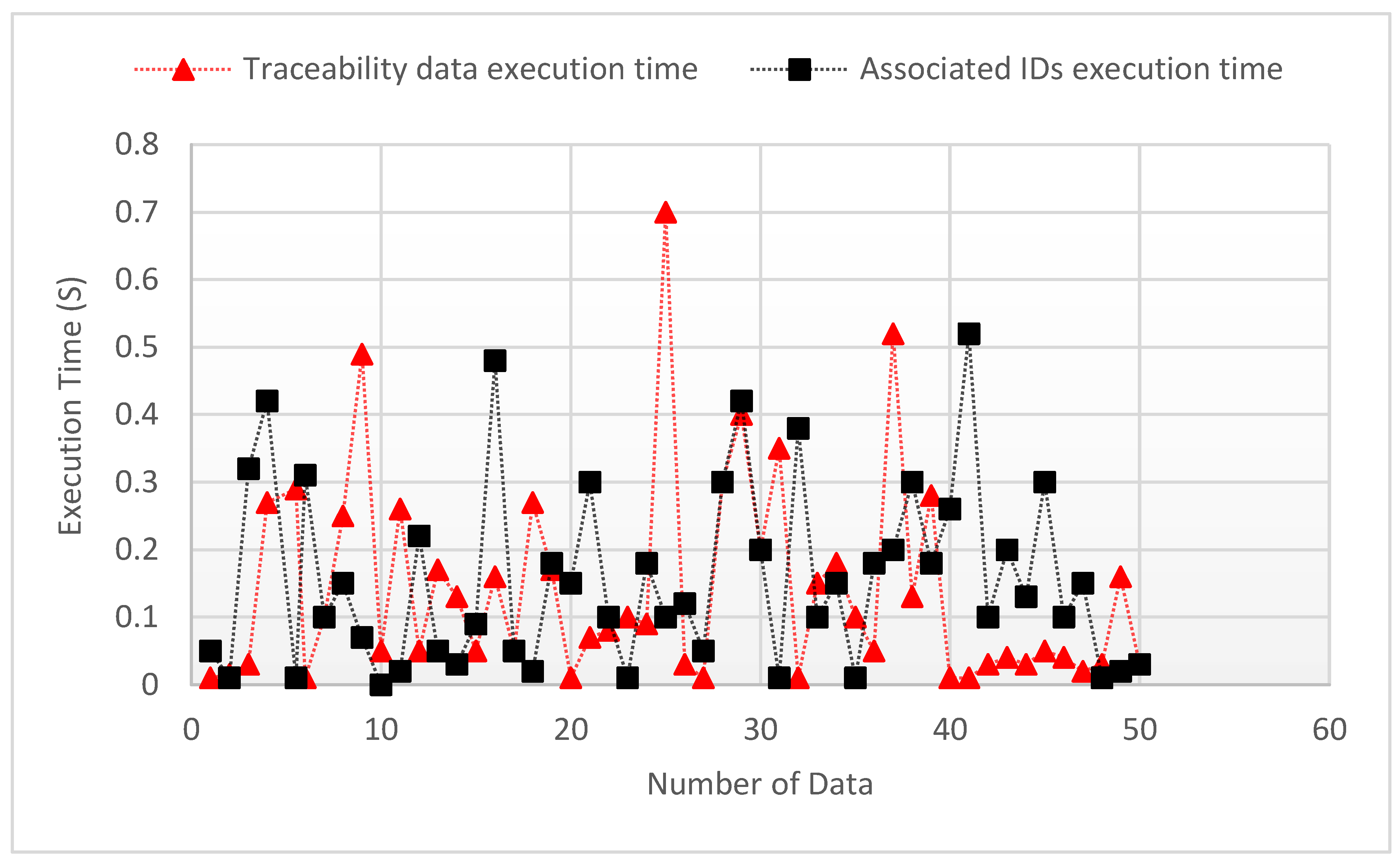

4.3. Proposed Machine Learning Based Predictive Analysis

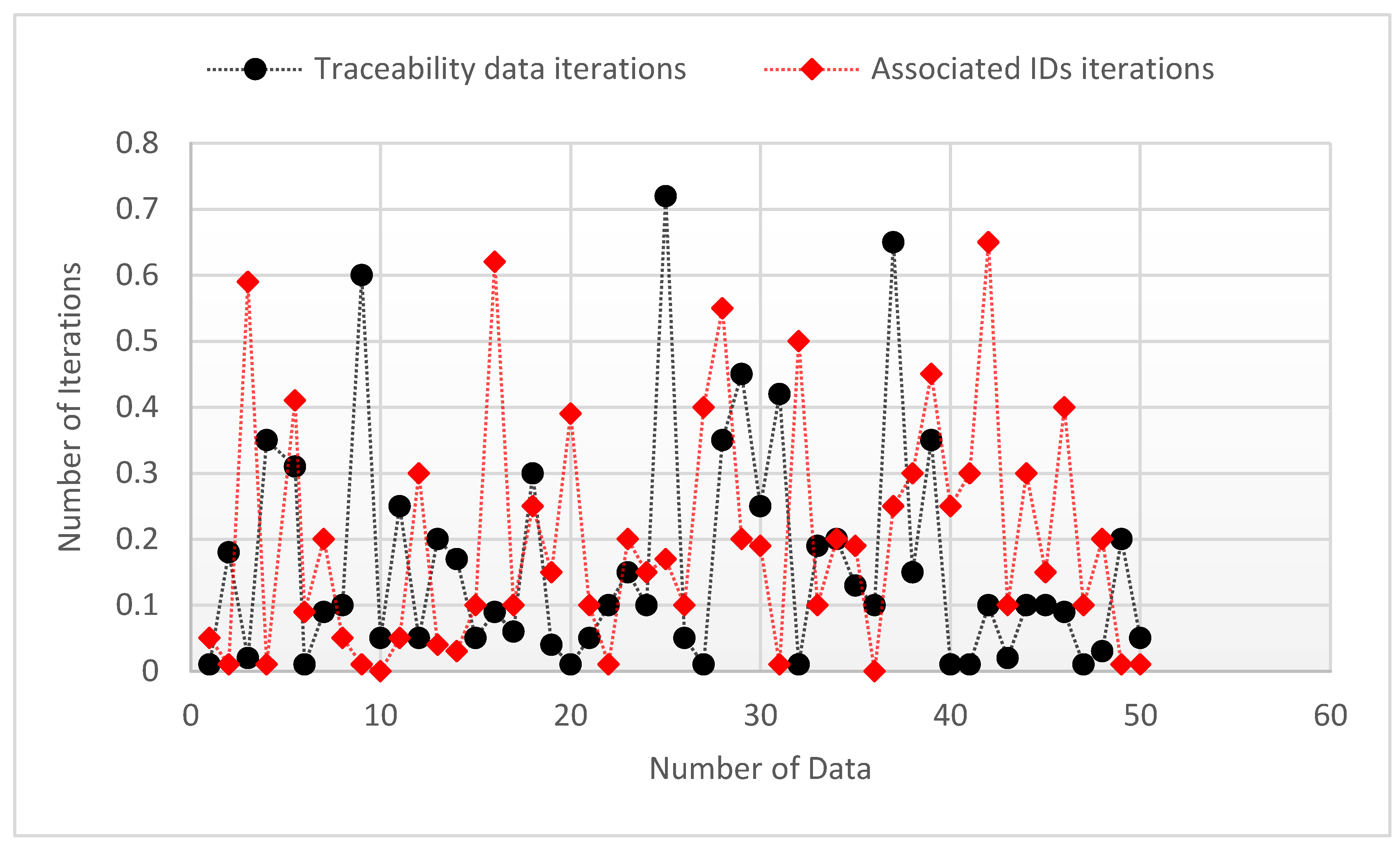

5. Experimental Result of the Food Traceability Blockchain Platform

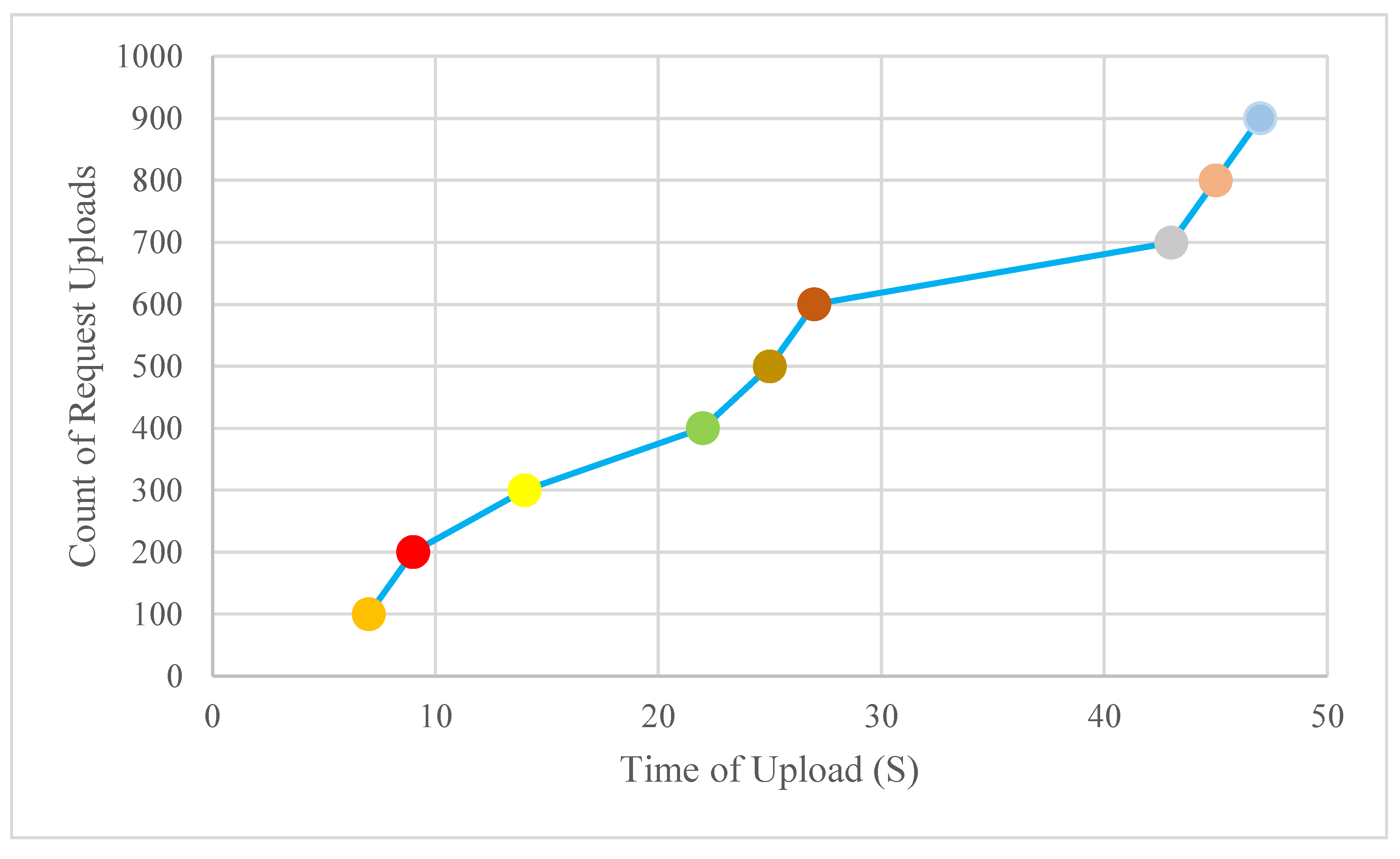

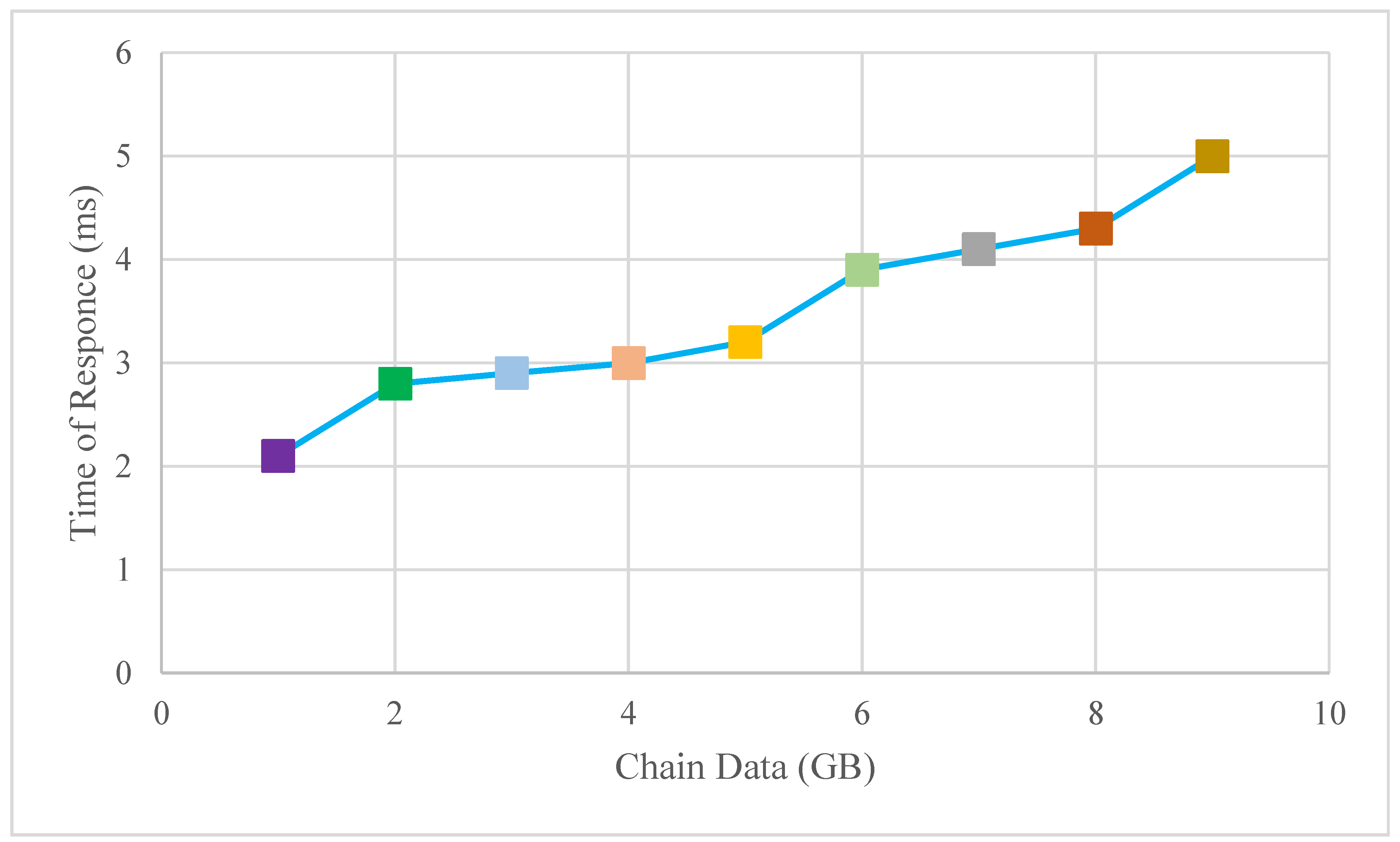

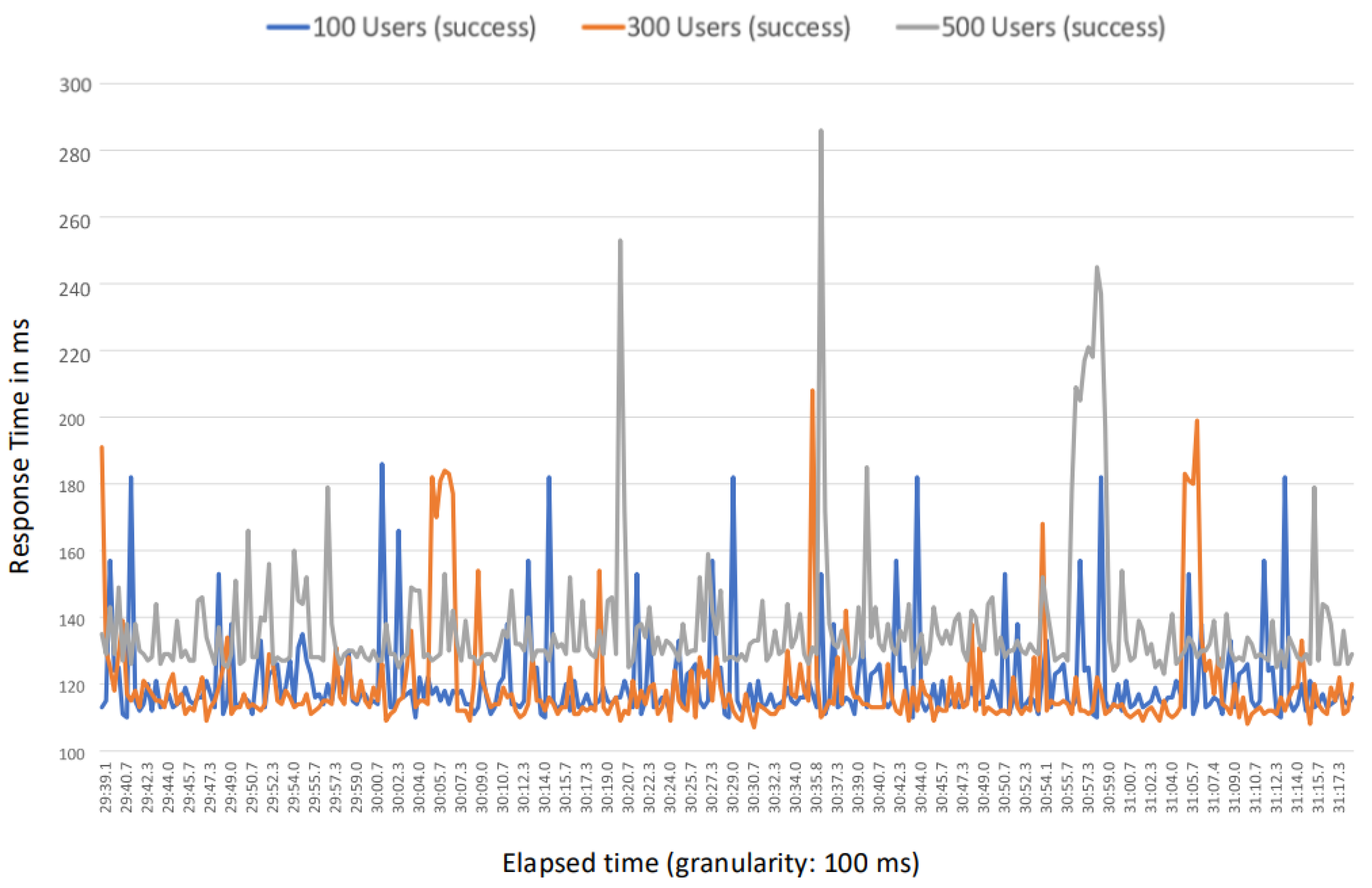

5.1. Performance Evaluation of the Food Traceability System

5.2. Comparison and Significance

- Traceability: the schemes also are part of the traceability system because of the traceability system comparison.

- Decentralization Degree: the proposed method uses blockchain technology in the food traceability system of the supply chain in order to clear the private changes of data due to investment. Similarly, consumers are able to join the system for supporting the blockchain public and clear data. In comparison with the previous approaches schemes, [50] has been specified in the partial decentralized scheme because the consumer is an off-line chain contributor and cannot access the copy of the supply chain ledger. Because of these reasons, the decentralization degree is relatively low.

- Scalability of the system: for the proposed framework in the development environment, the extension points are designed to add different functions easily, e.g., the reviews’ functionality.

| # | 1 [51] | 2 [50] | 3 [52] | 4 [53] | Proposed System |

|---|---|---|---|---|---|

| Traceability | Yes | Yes | No | Yes | Yes |

| Decentralization Degree | High | Low | High | High | High |

| Scalability | No | No | Yes | No | Yes |

5.3. Challenges of Applying BMLFTS in Food Traceability System

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aung, M.M.; Chang, Y.S. Temperature management for the quality assurance of a perishable food supply chain. Food Control 2014, 40, 198–207. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mishra, P.; Ruiz-García, L. Food traceability: New trends and recent advances. A review. Food Control 2015, 57, 393–401. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Fernández-Caramés, T.M. A review on blockchain technologies for an advanced and cyber-resilient automotive industry. IEEE Access 2019, 7, 17578–17598. [Google Scholar] [CrossRef]

- Fu, Y.; Zhu, J. Big production enterprise supply chain endogenous risk management based on blockchain. IEEE Access 2019, 7, 15310–15319. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M.; Fraga-Lamas, P. A Review on the Use of Blockchain for the Internet of Things. IEEE Access 2018, 6, 32979–33001. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M.; Fraga-Lamas, P. A review on the application of blockchain to the next generation of cybersecure industry 4.0 smart factories. IEEE Access 2019, 7, 45201–45218. [Google Scholar] [CrossRef]

- Yu, B.; Wright, J.; Nepal, S.; Zhu, L.; Liu, J.; Ranjan, R. Iotchain: Establishing trust in the internet of things ecosystem using blockchain. IEEE Cloud Comput. 2018, 5, 12–23. [Google Scholar] [CrossRef]

- Olsen, P.; Borit, M. The components of a food traceability system. Trends Food Sci. Technol. 2018, 77, 143–149. [Google Scholar] [CrossRef]

- Göransson, M.; Jevinger, Å.; Nilsson, J. Shelf-life variations in pallet unit loads during perishable food supply chain distribution. Food Control 2018, 84, 552–560. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Degryse, C. Digitalisation of the Economy and its Impact on Labour Markets. ETUI Research Paper-Working Paper. 2016. Available online: https://ssrn.com/abstract=2730550 (accessed on 9 November 2020).

- Jamil, F.; Hang, L.; Kim, K.; Kim, D. A novel medical blockchain model for drug supply chain integrity management in a smart hospital. Electronics 2019, 8, 505. [Google Scholar] [CrossRef]

- Jamil, F.; Iqbal, M.A.; Amin, R.; Kim, D. Adaptive thermal-aware routing protocol for wireless body area network. Electronics 2019, 8, 47. [Google Scholar] [CrossRef]

- Jamil, F.; Ahmad, S.; Iqbal, N.; Kim, D.H. Towards a Remote Monitoring of Patient Vital Signs Based on IoT-Based Blockchain Integrity Management Platforms in Smart Hospitals. Sensors 2020, 20, 2195. [Google Scholar] [CrossRef]

- Jamil, F.; Kim, D.H. Improving Accuracy of the Alpha–Beta Filter Algorithm Using an ANN-Based Learning Mechanism in Indoor Navigation System. Sensors 2019, 19, 3946. [Google Scholar] [CrossRef]

- Jamil, F.; Iqbal, N.; Ahmad, S.; Kim, D.H. Toward Accurate Position Estimation Using Learning to Prediction Algorithm in Indoor Navigation. Sensors 2020, 20, 4410. [Google Scholar] [CrossRef]

- Ahmad, S.; Jamil, F.; Khudoyberdiev, A.; Kim, D. Accident risk prediction and avoidance in intelligent semi-autonomous vehicles based on road safety data and driver biological behaviours. J. Intell. Fuzzy Syst. 2020, 38, 4591–4601. [Google Scholar] [CrossRef]

- Jamil, F.; Kim, D. Payment Mechanism for Electronic Charging using Blockchain in Smart Vehicle. Korea 2019, 30, 31. [Google Scholar]

- Khan, P.W.; Byun, Y.C.; Park, N. IoT-Blockchain Enabled Optimized Provenance System for Food Industry 4.0 Using Advanced Deep Learning. Sensors 2020, 20, 2990. [Google Scholar]

- Shahbazi, Z.; Byun, Y.C. Towards a Secure Thermal-Energy Aware Routing Protocol in Wireless Body Area Network Based on Blockchain Technology. Sensors 2020, 20, 3604. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the IEEE 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Baihaqi, I.; Sohal, A.S. The impact of information sharing in supply chains on organisational performance: An empirical study. Prod. Plan. Control 2013, 24, 743–758. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Treiblmaier, H. Leveraging the internet of things and blockchain technology in supply chain management. Future Internet 2019, 11, 161. [Google Scholar] [CrossRef]

- Khezr, S.; Moniruzzaman, M.; Yassine, A.; Benlamri, R. Blockchain technology in healthcare: A comprehensive review and directions for future research. Appl. Sci. 2019, 9, 1736. [Google Scholar] [CrossRef]

- Duan, J.; Zhang, C.; Gong, Y.; Brown, S.; Li, Z. A Content-Analysis Based Literature Review in Blockchain Adoption within Food Supply Chain. Int. J. Environ. Res. Public Health 2020, 17, 1784. [Google Scholar] [CrossRef] [PubMed]

- Choy, K.L.; Gunasekaran, A.; Lam, H.Y.; Chow, K.H.; Tsim, Y.C.; Ng, T.W.; Tse, Y.K.; Lu, X.A. Impact of information technology on the performance of logistics industry: The case of Hong Kong and Pearl Delta region. J. Oper. Res. Soc. 2014, 65, 904–916. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Jamil, F.; Byun, Y. Topic modeling in short-text using non-negative matrix factorization based on deep reinforcement learning. J. Intell. Fuzzy Syst. 2020, 39, 753–770. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. Product Recommendation Based on Content-based Filtering Using XGBoost Classifier. Int. J. Adv. Sci. Technol. 2019, 29, 6979–6988. [Google Scholar]

- Shahbazi, Z.; Hazra, D.P.; Park, S.; Byun, Y.C. Toward Improving the Prediction Accuracy of Product Recommendation System Using Extreme Gradient Boosting and Encoding Approaches. Symmetry 2020, 29, 1566. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. Toward Social Media Content Recommendation Integrated with Data Science and Machine Learning Approach for E-Learners. Symmetry 2020, 29, 1798. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. Analysis of Domain-Independent Unsupervised Text Segmentation Using LDA Topic Modeling over Social Media Contents. Int. J. Adv. Sci. Technol 2020, 29, 5993–6014. [Google Scholar]

- Turkanović, M.; Hölbl, M.; Košič, K.; Heričko, M.; Kamišalić, A. EduCTX: A blockchain-based higher education credit platform. IEEE Access 2018, 6, 5112–5127. [Google Scholar] [CrossRef]

- Singh, S.; Singh, N. Blockchain: Future of financial and cyber security. In Proceedings of the IEEE 2016 2nd international conference on contemporary computing and informatics (IC3I), Noida, India, 14–17 December 2016; pp. 463–467. [Google Scholar]

- Xia, Q.; Sifah, E.B.; Asamoah, K.O.; Gao, J.; Du, X.; Guizani, M. MeDShare: Trust-less medical data sharing among cloud service providers via blockchain. IEEE Access 2017, 5, 14757–14767. [Google Scholar] [CrossRef]

- Wu, H.T.; Tsai, C.W. Toward blockchains for health-care systems: Applying the bilinear pairing technology to ensure privacy protection and accuracy in data sharing. IEEE Consum. Electron. Mag. 2018, 7, 65–71. [Google Scholar] [CrossRef]

- Akarca, D.; Xiu, P.; Ebbitt, D.; Mustafa, B.; Al-Ramadhani, H.; Albeyatti, A. Blockchain Secured Electronic Health Records: Patient Rights, Privacy and Cybersecurity. In Proceedings of the IEEE 2019 10th International Conference on Dependable Systems, Services and Technologies (DESSERT), Leeds, UK, 5–7 June 2019; pp. 108–111. [Google Scholar]

- Guan, Z.; Si, G.; Zhang, X.; Wu, L.; Guizani, N.; Du, X.; Ma, Y. Privacy-preserving and efficient aggregation based on blockchain for power grid communications in smart communities. IEEE Commun. Mag. 2018, 56, 82–88. [Google Scholar] [CrossRef]

- Aitzhan, N.Z.; Svetinovic, D. Security and privacy in decentralized energy trading through multi-signatures, blockchain and anonymous messaging streams. IEEE Trans. Dependable Secur. Comput. 2016, 15, 840–852. [Google Scholar] [CrossRef]

- Yazdinejad, A.; Parizi, R.M.; Dehghantanha, A.; Choo, K.K.R. Blockchain-enabled authentication handover with efficient privacy protection in SDN-based 5G networks. IEEE Trans. Netw. Sci. Eng. 2019. [Google Scholar] [CrossRef]

- Alladi, T.; Chamola, V.; Parizi, R.M.; Choo, K.K.R. Blockchain applications for industry 4.0 and industrial IoT: A review. IEEE Access 2019, 7, 176935–176951. [Google Scholar] [CrossRef]

- Kuzmin, A.; Znak, E. Blockchain-base structures for a secure and operate network of semi-autonomous Unmanned Aerial Vehicles. In Proceedings of the IEEE 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Singapore, Singapore, 31 July–2 August 2018; pp. 32–37. [Google Scholar]

- Ren, L.; Ward, P.A. Distributed Consensus and Fault Tolerance Mechanisms. In Essentials of Blockchain Technology; CRC Press: Boca Raton, FL, USA, 2019; p. 1. [Google Scholar]

- Wang, N.; Zhou, X.; Lu, X.; Guan, Z.; Wu, L.; Du, X.; Guizani, M. When energy trading meets blockchain in electrical power system: The state of the art. Appl. Sci. 2019, 9, 1561. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Yang, T. Blockchain-enabled security in electric vehicles cloud and edge computing. IEEE Netw. 2018, 32, 78–83. [Google Scholar] [CrossRef]

- Angrish, A.; Craver, B.; Hasan, M.; Starly, B. A case study for Blockchain in manufacturing: “FabRec”: A prototype for peer-to-peer network of manufacturing nodes. Procedia Manuf. 2018, 26, 1180–1192. [Google Scholar] [CrossRef]

- Scrivens, G. Mean kinetic relative humidity: A new concept for assessing the impact of variable relative humidity on pharmaceuticals. Pharm. Technol. 2012, 36, 52–57. [Google Scholar]

- Vesely, S.; Klöckner, C.A.; Dohnal, M. Predicting recycling behaviour: Comparison of a linear regression model and a fuzzy logic model. Waste Manag. 2016, 49, 530–536. [Google Scholar] [CrossRef] [PubMed]

- Szabo, N. Formalizing and securing relationships on public networks. First Monday 1997. [Google Scholar] [CrossRef]

- Pãnescu, A.-T.; Manta, V. Smart Contracts for Research Data Rights Management over the Ethereum Blockchain Network. Sci. Technol. Lib. 2018, 37, 235–245. [Google Scholar] [CrossRef]

- Malik, S.; Kanhere, S.S.; Jurdak, R. Productchain: Scalable blockchain framework to support provenance in supply chains. In Proceedings of the 2018 IEEE 17th International Symposium on Network Computing and Applications (NCA), Cambridge, MA, USA, 1–3 November 2018; pp. 1–10. [Google Scholar]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the IEEE 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Salah, K.; Nizamuddin, N.; Jayaraman, R.; Omar, M. Blockchain-based soybean traceability in agricultural supply chain. IEEE Access 2019, 7, 73295–73305. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, H.; Pei, X.; Wang, J. Food safety traceability system based on blockchain and EPCIS. IEEE Access 2019, 7, 20698–20707. [Google Scholar] [CrossRef]

| # | Problem Statement | Proposed Solution | Applied Algorithm | Use of Smart Contract | Platform | Transaction Data |

|---|---|---|---|---|---|---|

| 1 | Management system decentralized records [32] | Distributed ledger protocol | PoA | Yes | Ethereum | Medical records |

| 2 | Health records securing system [33] | Dual blockchain structure | PoC | Yes | Ethereum hyperledger fabric | Medical records, Patient records, Practitioners public profile |

| 3 | Data privacy risk reduction [34] | side blocks with smart contract | DNA | Yes | Private blockchain | Medical records |

| 4 | Smart medicine with healthcare [35] | bilinear pairing and public key cryptography technology | PoA | Yes | Private blockchain | Medical records |

| 5 | Pharma supply chain data integrity [36] | IoT and smart contact | PoC PoE | Yes | Ethereum | humidity, temperature data, serial number |

| 6 | Credit based payment optimal loan price [37] | Theory of games | PoA | No | Private blockchain | Energy coin related transactions |

| 7 | localized electricity transaction privacy and security [38] | P2P training model on consortium blockchain | PoA | No | Consortium blockchain | Energy trading data |

| 8 | Information sharing in trust-less network [39] | P2P decentralized blockchain platform | PoA | Yes | Ethereum | Machine type, Event record |

| 9 | Agri-food supply chain trust and reliability [40] | blockchain and IoT | DNA | Yes | Ethereum, Hyperledger | Sensor data |

| 10 | Global education credit platform [41] | European credit transfer and accumulation system | Distributed PoS | No | Hyperledger fabric | Certified grain quality data |

| 11 | UAV compromised detection [42] | UAV pre-registered private key | PoA | Yes | Hyperledger Indy | UAV surveillance detail |

| 12 | Data aggregation privacy preserving [43] | Blockchain and bloom filter, pseudonyms | PoA | No | Private blockchain | Electricity consumption data |

| 13 | Heterogenous vehicular seamless connection [44] | Combination of EV cloud computing and EV edge computing | PoA and PoS | No | Distributed blockchain | coin data |

| 14 | Manufacturing privacy and security enhancement [45] | IoT System bitcoin inspire | PoA | No | Private blockchain | Content request, Address request |

| Notations | Meaning |

|---|---|

| Temperature measurement | |

| Humidity measurement | |

| Activation energy | |

| G | Gas constant |

| S | Moisture sensitivity |

| Relative humidity | |

| Time | Transit time |

| Input | Formula | Class of Fuzzy | Membership Function | Type |

|---|---|---|---|---|

| Temperature | (Celsius) | High Medium Low | (20,30,55) (5,15,30,40) (0,5,15) | trimf trapmf trimf |

| Humidity | High Medium Low | (65,75,105) (35,45,65,75) (0,35,45) | trimf tapmf trimf | |

| Transit Time | High Medium | (55,105,155) (35,55,105) | trimf trimf | |

| Output | ||||

| Shelf life | Increase No effect Decrease | (0,55,105) (–55,0,55) (–100,–55,0) | trimf trimf trimf | |

| Quality Decay Rate | Medium Low | (0.03, 0.05, 0.07, 0.09) (0,0.03, 0.05) | trapmf trimf | |

| Quality Decay Order | First order Second order Zero order | (0,1,2) (1,2,2) (0,0,1) | trimf trimf trimf |

| # | Product Code | Product Name | Product Owner | Raw Material | Timestamp | BAC Address |

|---|---|---|---|---|---|---|

| 1 | 210846924 | eggplant | 0x08...g0w5 | / | 1451054044 | 0xcdf0...e5d88 |

| 2 | 276547524 | carrot | 0x45d...e345 | / | 1451054105 | 0x5706...8301d |

| 3 | 7039501445899 | cucumber | 0x91b...2342 | 210845924 | 1451054165 | 0xb022...0bd6b |

| 4 | 294224218 | apple | 0x45q...0f3s | / | 151054300 | 0xb256...0f7e5 |

| ... | ... | ... | ... | ... | ... | ... |

| # | Batch Code | Raw Material with Batch Code | Batch Manager | Timestamp | TUC Address |

|---|---|---|---|---|---|

| 1 | 202018232716 | 101846924(202017392137) | 0x70b...11124 | 1673733835 | 0xc357...2ffcg |

| 2 | 202018242317 | 101846924(202017312647) | 0x49d...0e3b | 1673833867 | 0xd2c3...e8160 |

| 3 | 202018242927 | 101846924(202017412649) | 0x00g...d1d2 | 1673933890 | 0x9887...24ee5 |

| 4 | 202018252839 | 101846924(202017112649) | 0xbb5...ef74 | 1673033927 | 0x5005...de880 |

| ... | ... | ... | ... | ... | ... |

| # | TrHash | Sending | Receiving | PreviousTr | Timestamp |

|---|---|---|---|---|---|

| 1 | 0xb7147...9g6829d | 0x2b0...d90c | 0xeef...09b0 | 7039501445899(202018232716) | 1674734858 |

| 2 | 0x0bef5...3203gf | 0xeef...19b1 | 0x3cc...1366 | 0xb7147...9g6829d | 1674934948 |

| 3 | 0x9d697...f510b6 | 0x3cc...0166 | 0xdb8...d755 | 0x0bef5...3204gh | 1674734164 |

| 4 | 0xegb0c...eg3578 | 0xdb8...d755 | 0xbb5...ef74 | 0x7d697... | 1674735178 |

| ... | ... | ... | ... | ... | ... |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahbazi, Z.; Byun, Y.-C. A Procedure for Tracing Supply Chains for Perishable Food Based on Blockchain, Machine Learning and Fuzzy Logic. Electronics 2021, 10, 41. https://doi.org/10.3390/electronics10010041

Shahbazi Z, Byun Y-C. A Procedure for Tracing Supply Chains for Perishable Food Based on Blockchain, Machine Learning and Fuzzy Logic. Electronics. 2021; 10(1):41. https://doi.org/10.3390/electronics10010041

Chicago/Turabian StyleShahbazi, Zeinab, and Yung-Cheol Byun. 2021. "A Procedure for Tracing Supply Chains for Perishable Food Based on Blockchain, Machine Learning and Fuzzy Logic" Electronics 10, no. 1: 41. https://doi.org/10.3390/electronics10010041

APA StyleShahbazi, Z., & Byun, Y.-C. (2021). A Procedure for Tracing Supply Chains for Perishable Food Based on Blockchain, Machine Learning and Fuzzy Logic. Electronics, 10(1), 41. https://doi.org/10.3390/electronics10010041