Abstract

Collagen and its derivative proteins have been widely used as a major component for cosmetic formulations as a natural ingredient and moisturizer. Most commercially available collagens are animal-derived collagen type I and other forms of collagen, such as type III collagen, are far less prevalent in animals, making extraction and purification extremely difficult and expensive. Here, we report the production of a 50 kDa protein produced in yeast that is 100% identical to the N-terminus of the human type III collagen. This recombinant protein has a larger molecular weight than most incumbent recombinant collagen proteins available for personal care applications. We report the industrialization of both the fermentation and purification processes to produce a final recombinant protein product. This final protein product was shown to be safe for general applications to human skin and compatible with common formulation protocols, including ethanol-based formulations. This recombinant collagen type III protein was also shown to uniquely stimulate both collagen type I and type III production and secretion by primary human dermal fibroblasts. The unique combination of biostimulation, compatibility with beauty product formulations and demonstrated commercial production, make this novel recombinant type III collagen a good candidate for broad application in the cosmetics industry.

1. Introduction

Collagen is the most abundant protein in the human body, present in connective tissue such as cartilage, bones, tendons, ligaments and skin [1]. The collagen superfamily comprises twenty-eight members in which type I collagen is the most abundant form (~80–85% of total collagen) and the major protein in the extra-cellular matrix of human cells. It assembles into fibers that form the structural and mechanical scaffold (matrix) of bone, skin, tendons, cornea, blood vessel walls and other connective tissues.

Collagen type III is the second most abundant collagen (~10–15% of total collagen). It is primarily produced by young fibroblasts before tougher type I collagen is synthesized [2]. Collagen type III is found in granulation tissue, artery walls, skin, intestines and the uterus [3,4,5]. Both collagen type I and III are fibrillar collagens that form higher order structures (particularly fibrils, fibers and bundles), but they have slightly different structural properties. Type I collagen tends to form densely packed fibrils and rigid triple helices for structure building. On the other hand, type III collagen forms a more flexible triple helical structure that assembles into small fibrils that are associated with the more rigid type I collagen fibrils. As a result, collagen type III functions as a “modulator” of overall tissue elasticity and function. Indeed, the ratio of collagen type I/III correlates with skin aging and elasticity [6,7,8,9].

Type I collagen is frequently used as a supplement in cosmetics products. While most commercial forms of collagen come from mammals, such as bovine or porcine, other animal sources such as chicken, fish skin and jelly fish have also been reported [10,11,12,13,14,15,16]. Although animal-derived collagen is generally abundant and cheap, it does suffer drawbacks such as risk of infectious disease transmission, potential viral vector transmission from animals to humans, causing allergic reaction within the human body and can have an unpleasant smell and color [17]. Non-type I collagens, such as type III collagen, tend to be very rare and expensive due to challenges with sourcing sufficient protein quantities and purifying from natural sources [18].

In the last two decades, more and more effort has been put into recombinant collagen production as part of the rapid development of genetic engineering technology. Recombinant collagen molecules of different sizes have been expressed in all major expression platforms including mammalian cells, insect cells, yeast, bacteria and plant cells [19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37]. In general, high quality full-length collagen proteins have been produced in eukaryotic hosts but with very low productivity. Prokaryotic hosts, such as E. coli were also explored for production of unmodified collagen; however, these recombinant proteins were generally either very small (a few kDa up to 20 kDa) or differ extensively from wild-type human collagen sequences. For example, it is well known that prokaryotic hosts lack post-translational modification functions that are needed to generate the hydroxyproline amino acid residues that are found in mature, animal-derived collagen [38,39,40]. As such, previously produced recombinant collagen proteins generally only exhibit an unmodified collagen sequence.

To produce a novel collagen-based ingredient that is natural, safe, sustainable and inexpensive for cosmetics application we developed a scalable platform that produced a 50 kDa protein in a eukaryotic host (Pichia pastoris) that is 100% identical to an N-terminal portion of human type III collagen. We successfully increased production to an industrial scale and the final protein preparation has been shown to be safe to human skin, being neither allergenic nor mutagenic. It is also compatible with all formulation protocols we tested. Unexpectedly, this protein stimulated collagen synthesis in primary human dermal fibroblast assays making it an exciting new bioactive product for the cosmetics industry.

2. Materials and Methods

2.1. Formulation Compatibility Evaluation

The testing materials were each dissolved at 1% by weight concentration in deionized water, with 1% glycols for preservation. The resulting solutions were added at 3% by weight into seven base formulations to test compatibility and performance: gel (carbomer system); serum (ammonium acryloyldimethyltaurate/VP copolymer and acrylates/C10-30; alkyl acrylate crosspolymer system); cream emulsion (oil/water); hair conditioner (containing cetrimonium chloride and behentrimonium methosulfate); shampoo/cleanser (sulfate-free); toner (water-based system); toner (alcohol-based system). The result is repeatable in three individual experiments. Skin fell evaluation was a blind analysis of each material in a 1% solution with a request for feedback regarding stickiness, tack, roll-up, irritation, or any other feel-specific observation that the testers might comment on. The testers include chemists and licensed aesthetician.

2.2. EpiOcular

An EpiOcular irritation test was performed using a previously disclosed protocol [41].

2.3. Bacterial Reverse Mutation Assay

A bacterial reverse mutation assay (Ames Test) was done according to a previously used protocol [42]. The bacterial reverse mutation assay was used to evaluate the mutagenic potential of the test sample at a single concentration of the test sample: 1%. Testing was done with the appropriate solvent control and positive controls were plated with overnight cultures of the test systems (Salmonella Typhimurium TA97a, Salmonella Typhimurium TA98, Salmonella Typhimurium TA100, Salmonella Typhimurium TA102, Salmonella Typhimurium TA1535) on the selective minimal agar in the presence and absence of the Acroclor-induced rat liver S9. All dose levels of the test samples, solvent controls and positives were plated in triplicates.

2.4. MTT Assay

Primary human dermal fibroblast cells (ThermoFisher Scientific, Waltham, MA USA) were seeded in a petri dish. After a 2-day incubation, the cell culture medium was removed and the fibroblasts were washed twice with PBS to remove any remaining test material. After the final wash, 500 μL of DMEM supplemented with 0.5 mg/mL MTT was added to each well and the cells were incubated for 1 h at 37 °C and 5% CO2. After the incubation, the DMEM/MTT solution was removed and the cells were washed again once with PBS. Isopropyl alcohol (0.5 mL) was added to the well to extract the purple formazin crystals. Two hundred microliters of the isopropyl extracts were transferred to a 96-well plate and the plate was read at 540 nm using isopropyl alcohol as a blank. The mean MTT absorbance value for the negative control cells was calculated and used to represent 100% cell viability. The individual MTT values from the cells undergoing the various treatments were then divided by the mean value for the negative control cells and expressed as a percent to determine the change in cell viability caused by each treatment.

2.5. Type I Collagen Assay

Human primary dermal fibroblasts were seeded into the individual wells of a 24-well plate in 0.5 mL of Fibroblast Growth Media (FGM) and incubated overnight at 37 ± 2 °C and 5 ± 1% CO2. On the following day the media was removed via aspiration to eliminate any non-adherent cells and replaced with 0.5 mL of fresh FGM. The cells were grown until confluent, with a media change every 48 to 72 h. Upon reaching confluency the cells were treated for 24 h with DMEM supplemented with 1.5% FBS to wash out any effects from the growth factors included in the normal culture media. After this 24 h wash out period the cells were treated with the test materials at the specified concentrations dissolved in FGM with 1.5% FBS. TGF-β (50 ng/mL) was used as a positive control for collagen. Untreated cells (negative controls) just received DMEM with 1.5% FBS. The cells were incubated for 48 h and at the end of the incubation period cell culture medium was collected and either stored frozen (−75 °C) or assayed immediately. Materials were tested in triplicate.

A series of type I C-peptide standards were prepared ranging from 0 ng/mL to 640 ng/mL. Next, an ELISA microplate was prepared by removing any unneeded strips from the plate frame followed by the addition of 100 μL of peroxidase-labeled anti-procollagen type I-C peptide antibody to each well used in the assay. Twenty microliters of either the collected tissue culture media or the standard was then added to appropriate wells and the microplate was covered and allowed to incubate for 3 ± 0.25 h at 37 °C. After incubation, the wells were aspirated and washed three times with 400 μL of wash buffer. The final wash was removed; 100 μL of a peroxidase substrate solution (hydrogen peroxide + tetramethylbenzidine as a chromagen) was added to each well and the plate was incubated for 15 ± 5 min at room temperature. After the incubation, 100 μL of stop solution (1 N sulfuric acid) was added to each well and the plate was read using a microplate reader at 450 nm.

2.6. Type III Collagen Assays

A series of standards were prepared and 100 μL of these standards or samples were added to the wells of the type III collagen ELISA plates. The plates were then incubated at 37 °C for 1.5 h. After this incubation, the ELISA plates were washed twice with wash buffer, followed by the application of 100 μL of detection antibody solution. The ELISA plates were then incubated for 1 h at 37 °C. After incubation, all the ELISA plates were washed with wash buffer, followed by the addition of 100 μL of HRP conjugate solution and incubated at 37 °C for 30 min. After this incubation the ELISA plates were again washed and 100 μL of substrate solution was added to each well and the plates were incubated for 10–30 min at room temperature to allow the color generation reaction to occur. At the end of the color generation reaction, 100 μL of stop solution was added to each well and the plates were read at 460 nm using a plate reader.

3. Results

3.1. Characterization of 50 kDa Protein

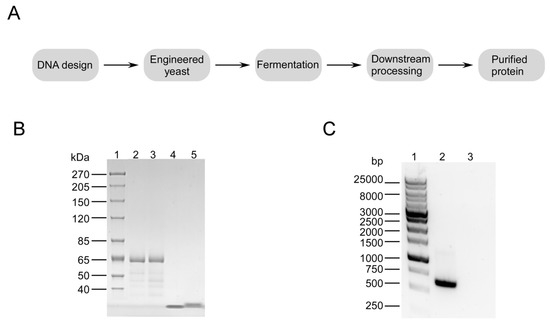

The production of recombinant 50 kDa protein is summarized in Figure 1A. We first generated a plasmid containing a promoter, a secretion signal and N-terminus of the human COL3A1 gene codon optimized for expression in Pichia pastoris. The circular plasmid was linearized and transformed into Pichia pastoris cells and transformants were selected on YPD plates with antibiotics (Zeocin, 100 μg/mL).

Figure 1.

(A) Workflow to produce 50 kDa protein. (B) SDS PAGE analysis of 50 kDa protein and other commercially available collagen proteins. Lane 1, protein ladder; Lane 2 &3, Modern Meadow 50 kDa protein; Lane 4, commercially available collagen protein sample # 1 (marine collagen); Lane 5, commercially available collagen protein sample # 2 (recombinant collagen produced in bacteria). (C) The final purified 50 kDa protein prep doesn’t contain detectable genetically modified DNA. Lane 1, DNA ladder; Lane 2, positive control PCR (10 ng plasmid DNA was used); Lane 3, PCR result of 50 kDa protein solution at 2% (1 μL was used as template).

After several rounds of screening, the best clone (PP1186) was promoted into fermentation development. A three-step fermentation process was started by inoculating the best clone in shake flasks, followed by a seed fermentation lasting approximately 23–27 h, which was then used to inoculate a production fermenter with BMGY media. The production fermenter was run for about 72 h with a 24 h batch phase followed by a 48 h fed-batch phase. At the end of fermentation, yeast cells were removed by centrifugation and the supernatant containing target protein was processed to further purify the recombinant protein.

The purified protein was diluted to 1% by weight and resolved on SDS PAGE (Bis-Tris 4–20%). Due to the protein’s extended conformation, it migrated at ~65 kDa, which is larger than the actual molecular weight of ~ 50 kDa (Figure 1B). Lanes 4 and 5 are two commercial collagen samples at 1%. We also checked for any residual genetically modified DNA in the final protein prep by PCR assay. As seen in Figure 1C, a PCR product between 500–750 bp (lane 2) was detected when the PCR template was the plasmid used to transform yeast cells. No band was detected under the same condition when 1 μL final protein prep was used as template at 2% (lane 3).

3.2. Formulation Testing and Potential Applications

First, we assessed the appearance and rheology of this protein. It dissolved quickly when mixing at 50 RPM, did not perceive any solubility issues. When dissolved in water, it shows as a clear to slightly hazy liquid and very flowable with low viscosity. This 1% protein solution readily incorporated into deionized water and ethanol. We tested various formulations including Gel, Serum, Cream, Hair conditioner, Shampoo, Toner (both water-based and alcohol-based), Carbomer Gel System, Acrylates Polymer Gel System, Emulsion System Hair Conditioner and Sulfate-free Cleanser and found this recombinant 50 kDa protein is compatible with all formulations within 10 min of mixing. Notably, the bioactive protein exhibited good color and odor and could easily be incorporated into certain formulas.

There was no negative skin feel observed for any of the 1% solutions at any of the evaluated levels. Enhanced elasticity, wrinkle reduction, smoothing, moisture-loss prevention, firming and film forming are all potential benefits seen or expected when incorporating the recombinant protein into typical formulations. As such, we believe this material could be safely formulated into the products listed in Table 1, as well as many other products, with a reasonable expectation that these formulations will be safe, stable and well suited for topical formulations in the personal care market.

Table 1.

Potential cosmetic applications of 50 kDa protein.

3.3. Safety Testing

We conducted ocular irritation test to verify the expected safety performance of this 50 kDa protein. Ocular irritation is defined as reversible damage to the eye following application of a test substance, whereas ocular corrosion is defined as irreversible damage. The data from EpiOcular test predicted that this protein to be classified as a GHS NC, with an average viability score of 85.3% and passed quality control checks.

We also assessed the risk of the protein to induce bacterial reverse mutation using the classical Ames test. This test was used to evaluate the mutagenic potential of the test sample at a 1% concentration. In the Ames mutagenic potential evaluation, this protein was found to be not cytotoxic to the test system and there was no detectable genotoxic activity associated with this protein at the 1% concentration.

3.4. Collagen Synthesis Induction in Human Primary Dermal Fibroblast by 50 kDa Protein

We used a fibroblast cell culture model to assess the ability of the recombinant 50 kDa protein to affect collagen synthesis. Fibroblasts are the main source of extracellular matrix peptides, including the structural proteins collagen and elastin. Procollagen is a large protein synthesized by fibroblasts in the dermal layer of the skin and is the precursor for collagen. As the protein chain is processed to form a mature collagen protein, the pro-peptide portion is cleaved off (forming a type I C-peptide). Both the mature collagen protein and the type I C- peptide fragments are then released into the extracellular environment. As collagen is synthesized, the type I C-peptide fragment accumulates into the tissue culture medium. Since there is a 1:1 stoichiometric ratio between the two parts of the procollagen peptide, assaying for type I C-peptide will reflect the amount of collagen protein synthesized. Type 1 C-peptide can be assayed via an ELISA-based method.

In addition, the viability of cells after exposure to the protein prep was assessed by the MTT assay. The MTT assay is a colorimetric analysis of the metabolic activity of the cell, which reflects the number of viable cells.

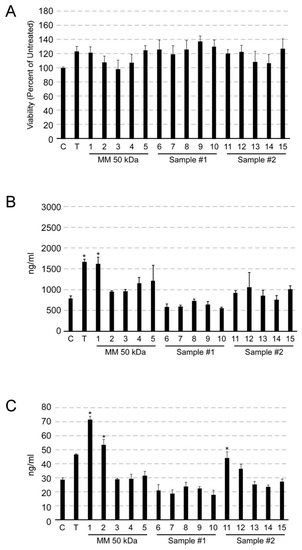

As seen in Figure 2A, untreated cells were used as a negative control and set as 100% and addition of 50 ng/mL TGFβ1 slightly increases cell viability by ~20%. The recombinant 50 kDa protein and other commercial samples did not decrease cell viability significantly at different concentrations.

Figure 2.

MTT assay and collagen synthesis induction data. C, negative control with no treatment; T, TGFβ at 50 ng/mL final concentration; bar #1, 0.1%; bar #2, 0.05%; bar #3, 0.01%; bar #4, 0.005%; bar #5, 0.001%; bar #6, 0.1%; bar #7, 0.05%; bar #8, 0.01%; bar #9, 0.005%; bar #10; bar #11, 1%; bar #12, 0.5%; bar #13, 0.1%; bar #14, 0.05%; bar #15, 0.01%; Sample #1 commercial collagen sample #1 in Figure 1B; Sample #2 commercial collagen sample #2 in Figure 1B. All samples were first dissolved in water at 2% and added into fibroblast growth media at different concentrations (A) MTT assay. (B) collagen type I assay (C) collagen type III assay. * p < 0.0001.

Both collagen type I and type III synthesis assays were performed under the same conditions. While commercial marine collagen samples did not stimulate any collagen I production, 50 kDa protein (0.1%) significantly increased collagen I production in fibroblast to ~200% of baseline (Figure 2B). This collagen induction effect is comparable to TGFβ1, which is well known as a potent collagen synthesis stimulator. This collagen induction activity was not detected at lower concentrations of the 50 kDa protein (0.05% or lower).

Similarly, the recombinant 50 kDa protein stimulated collagen III production in fibroblast with an even higher potency. The collagen protein prepared at both 0.1% and 0.05% significantly increased soluble collagen III synthesis more effectively than the TGFβ1 control (Figure 2C). The commercial marine collagen samples had no or some negative effect on collagen III synthesis at the same concentrations.

4. Discussion

Many previous studies have tried to produce recombinant collagen molecules in different systems including bacteria, yeast and plant [25,28,29,30,31,37,43,44,45,46]. These recombinant proteins include full-length or fragments of collagen I, II, III and XXI at different hydroxylation levels (unhydroxylated or hydroxylated). All hydroxylated collagen proteins were produced intracellularly with co-expression of P4H enzymes resulting in low productivity and recovery rate due to cell lysing. Some unhydroxylated collagen proteins were produced by secretory pathway but they only represent a very small portion of the full-length collagen polypeptide (<30 kDa). In other cases, collagen-like protein (CLP) was used or the wild-type collagen sequence was modified to enhance productivity and stability. This study illustrated the production and characterization of a 50 kDa recombinant protein from a eukaryotic host (yeast). Unlike many other recombinant collagen-like proteins, this protein is 100% identical to human collagen type III alpha chain without any sequence manipulation and mimics natural collagen III function. Given the close correlation between aging and the collagen I/III ratio, this protein could well balance the collagen composition.

Because this protein is produced in a single-cell organism (yeast), it may be amenable to scaling the fermentation process to industrial scale to reduce cost. We used simple fermentation media and mostly physical separation to purify the final sample and the resulting protein preparation is highly pure and free of harmful chemicals (strong acid or base), which are often seen in animal-derived collagen preparations. Since Pichia pastoris is a eukaryotic host, we also have the flexibility to add post-translational modifications on the final protein, such as proline-4 hydroxylation.

Many collagen samples suffer from poor color, possess an odor, have poor solubility and are difficult or impossible to formulate for use in personal care products. This 50 kDa final protein prep is odorless and has only light color at high concentrations. When we tested it in various formulation types, it was compatible with all formulations assessed, including ethanol-based protocols. Furthermore, from a safety perspective the Occular Irritation and Ames tests results verified the safety of the protein for personal care applications.

Collagen peptides have been shown to stimulate collagen I synthesis in human dermal fibroblast cultures, but only when they were mixed with antioxidant constituents such as Carnosine, CoEnzyme Q10, Resveratrol (red wine powder extract), Borage seed oil/Primrose oil Hyaluronic acid Piperine (Piper Nigrum seed extract), Lycopene (tomato pulp extract), Acai berry extract or Pomegranate juice (concentrated) [47]. Unexpectedly, this 50 kDa human collagen protein alone was able to enhance both collagen I and III production in fibroblasts comparable to or even better than the TGFβ1 positive control [48]. A specific motif in collagen type I alpha 2 chain has been found to induce collagen I synthesis in human dermal fibroblasts, but no such motif has been reported for collagen type III induction [49].

All these properties make this 50 kDa protein a good candidate for personal care product development. A panel of basic formulations have been tested for this protein and collagen stimulation data were acquired by in vitro cell culture assay. Further studies to better evaluate this novel recombinant protein include testing broader formulation testing and collagen induction study in skin model and clinical studies.

There are many known uses for collagen in the cosmetics and skincare industry. For example, skincare compositions that include collagen can be used to combat the effects of ageing and environmental stress on the appearance, elasticity and thickness of skin [50]. Ageing and environmental factors can lead to dermatological conditions including, but not limited to fine lines, wrinkles, dry skin, excessive pore size, skin dyschromia, reduced elasticity, unwanted hair, skin thinning, purpura, actinic keratosis, pruritus, eczema, acne, rosacea, erythema, telangiectasia, actinic telangiectasia, skin cancer and rhinophyma. Oral collagen supplements/drinks have been shown to improve skin hydration and elasticity for older people [51,52,53,54]. Although there are numerous skincare products on the market to improve skin appearance, many consumers are hesitant to use chemically synthesized products they perceive as being environmentally unfriendly or otherwise unsafe.

Therefore, this 50 kDa protein potentially can be used to treat a wide range of dermal conditions and applied in a variety of different compositions. Since this protein was produced in a natural yeast host and purified mostly by physical separation, it is a safer and more environmentally friendly substitute for animal-derived collagen. To achieve these goals, this recombinant protein can be formulated into various formulations described herein (Table 2).

Table 2.

Potential formulations of 50 kDa protein.

5. Conclusions

We reported the production of a recombinant 50 kDa protein in yeast at large scale. This protein is safe to human skin, compatible with many different formulations, stimulates collagen synthesis in human dermal fibroblast and we proposed its potential for broad cosmetic applications.

Author Contributions

Conceptualization, L.D.; methodology, J.-L.C., K.C., M.D., M.K., R.L., S.L., M.L., K.R., Z.S., M.C.S. and Z.Y.; investigation, N.A., E.B., M.d.L., B.F., E.G., A.H., C.K., J.M.K., J.M., S.R., K.R.-J., S.V., A.V., K.E.V. and J.W.; data curation, V.F.; writing—original draft preparation, L.D., C.R.-L. and I.H.-C.; writing—review and editing, C.R.-L., I.H.-C., S.C. and D.W.; supervision, D.D., B.R., K.A.R. and S.W.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank Paolo Giacomoni and Peter Foltis for critical review of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ricard-Blum, S. The collagen family. Cold Spring Harb. Perspect. Biol 2011, 3, a004978. [Google Scholar] [CrossRef] [Green Version]

- Fleischmajer, R.; MacDonald, E.D.; Perlish, J.S.; Burgeson, R.E.; Fisher, L.W. Dermal collagen fibrils are hybrids of type I and type III collagen molecules. J. Struct. Biol. 1990, 105, 162–169. [Google Scholar] [CrossRef]

- Kuivaniemi, H.; Tromp, G. Type III collagen (COL3A1): Gene and protein structure, tissue distribution, and associated diseases. Gene 2019, 707, 151–171. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, M.J.; Karsdal, M.A. Type III Collagen. In Biochemistry of Collagens, Laminins and Elastin, 1st ed.; Karsdal, M.A., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 21–30. [Google Scholar]

- Manturova, G.O.; Smirnova, V.A.; Stupin, E.V.; Silina, N.E. The ratio of collagen types I/III as a marker of skin aging and prognosis of aesthetic facial surgery results. J. Pharm. Sci. Res. 2018, 10, 2543–2546. [Google Scholar]

- Wang, C.; Rong, Y.; Ning, F.; Zhang, G. The content and ratio of type I and III collagen in skin differ with age and injury. Afr. J. Biotechnol. 2011, 10, 2524–2529. [Google Scholar]

- Parkin, J.D.; San Antonio, J.D.; Persikov, A.V.; Dagher, H.; Dalgleish, R.; Jensen, S.T.; Jeunemaitre, X.; Savige, J. The collagen III fibril has a “flexi-rod” structure of flexible sequences interspersed with rigid bioactive domains including two with hemostatic roles. PLoS ONE 2017, 12, e0175582. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Wu, H.; Byrne, M.; Krane, S.; Jaenisch, R. Type III collagen is crucial for collagen I fibrillogenesis and for normal cardiovascular development. Proc. Natl. Acad. Sci. USA 1997, 94, 1852–1856. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Brisson, B.K.; Terajima, M.; Li, Q.; Hoxha, K.; Han, B.; Goldberg, A.M.; Sherry Liu, X.; Marcolongo, M.S.; Enomoto-Iwamoto, M.; et al. Type III collagen is a key regulator of the collagen fibrillar structure and biomechanics of articular cartilage and meniscus. Matrix Biol. 2020, 85–86, 47–67. [Google Scholar] [CrossRef]

- Cliche, S.; Amiot, J.; Avezard, C.; Gariépy, C. Extraction and characterization of collagen with or without telopeptides from chicken skin. Poult. Sci. 2003, 82, 503–509. [Google Scholar] [CrossRef] [PubMed]

- Munasinghe, K.A.; Schwarz, J.G.; Nyame, A.K. Chicken Collagen from Law Market Value By-Products as an Alternate Source. J. Food Process. 2014, 2014, 298295. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.; Li, Y.; Yu, X.; Yang, H.; Ma, H.; Yagoub, A.E.A.; Cheng, Y.; Hu, J.; Out, P.N.Y. Extraction and characterization of chicken feet soluble collagen. LWT Food Sci. Technol. 2016, 74, 145–153. [Google Scholar] [CrossRef]

- Jafari, H.; Lista, A.; Siekapen, M.M.; Ghaffari-Bohlouli, P.; Nie, L.; Alimoradi, H.; Shavandi, A. Fish Collagen: Extraction, Characterization, and Applications for Biomaterials Engineering. Polymers 2020, 12, 2230. [Google Scholar] [CrossRef] [PubMed]

- O’Sullivan, A.; Shaw, N.B.; Murphy, S.C.; van de Vis, J.W.; van Pelt-Heerschap, H.; Kerry, J.P. Extraction of Collagen from Fish Skins and Its Use in the Manufacture of Biopolymer Films. J. Aquat. Food Prod. Technol. 2006, 15, 21–32. [Google Scholar] [CrossRef]

- Khong, N.M.H.; Yusoff, F.M.; Jamilah, B.; Basri, M.; Maznah, I.; Chan, K.W.; Armania, N.; Nishikawa, J. Improved collagen extraction from jellyfish (Acromitus hardenbergi) with increased physical-induced solubilization processes. Food Chem. 2018, 251, 41–50. [Google Scholar] [CrossRef]

- Coppola, D.; Oliviero, M.; Vitale, G.A.; Lauritano, C.; D’Ambra, I.; Iannace, S.; de Pascale, D. Marine Collagen from Alternative and Sustainable Sources: Extraction, Processing and Applications. Mar. Drugs 2020, 18, 214. [Google Scholar] [CrossRef] [Green Version]

- Browne, S.; Zeugolis, D.I.; Pandit, A. Collagen: Finding a solution for the source. Tissue Eng. Part A 2013, 19, 1491–1494. [Google Scholar] [CrossRef] [Green Version]

- Asgari, M.; Latifi, N.; Heris, H.K.; Vali, H.; Mongeau, L. In vitro fibrillogenesis of tropocollagen type III in collagen type I affects its relative fibrillar topology and mechanics. Sci. Rep. 2017, 7, 1392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fertala, A. Three Decades of Research on Recombinant Collagens: Reinventing the Wheel or Developing New Biomedical Products? Bioengineering 2020, 7, 155. [Google Scholar] [CrossRef]

- Schnieke, A.; Dziadek, M.; Bateman, J.; Mascara, T.; Harbers, K.; Gelinas, R.; Jaenisch, R. Introduction of the human pro alpha 1(I) collagen gene into pro alpha 1(I)-deficient Mov-13 mouse cells leads to formation of functional mouse-human hybrid type I collagen. Proc. Natl. Acad. Sci. USA 1987, 84, 764–768. [Google Scholar] [CrossRef] [Green Version]

- Olsen, A.S.; Geddis, A.E.; Prockop, D.J. High levels of expression of a minigene version of the human pro alpha 1 (I) collagen gene in stably transfected mouse fibroblasts. Effects of deleting putative regulatory sequences in the first intron. J. Biol. Chem. 1991, 266, 1117–1121. [Google Scholar] [CrossRef]

- Specks, U.; Mayer, U.; Nischt, R.; Spissinger, T.; Mann, K.; Timpl, R.; Engel, J.; Chu, M.L. Structure of recombinant N-terminal globule of type VI collagen alpha 3 chain and its binding to heparin and hyaluronan. EMBO J. 1992, 11, 4281–4290. [Google Scholar] [CrossRef] [PubMed]

- Mazzorana, M.; Gruffat, H.; Sergeant, A.; van der Rest, M. Mechanisms of collagen trimer formation. Construction and expression of a recombinant minigene in HeLa cells reveals a direct effect of prolyl hydroxylation on chain assembly of type XII collagen. J. Biol. Chem. 1993, 268, 3029–3032. [Google Scholar] [CrossRef]

- Fertala, A.; Sieron, A.L.; Ganguly, A.; Li, S.W.; Ala-Kokko, L.; Anumula, K.R.; Prockop, D.J. Synthesis of recombinant human procollagen II in a stably transfected tumour cell line (HT1080). Biochem. J. 1994, 298, 31–37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olsen, D.; Yang, C.; Bodo, M.; Chang, R.; Leigh, S.; Baez, J.; Carmichael, D.; Perälä, M.; Hämäläinen, E.R.; Jarvinen, M.; et al. Recombinant collagen and gelatin for drug delivery. Adv. Drug Deliv. Rev. 2003, 55, 1547–1567. [Google Scholar] [CrossRef] [PubMed]

- Fertala, A.; Shah, M.; Hoffman, R.; Arnold, W.V. Designing recombinant collagens for biomedical applications. Curr. Tissue Eng. 2016, 5, 73–84. [Google Scholar] [CrossRef]

- Bulleid, N.J.; John, D.C.; Kadler, K.E. Recombinant expression systems for the production of collagen. Biochem. Soc. Trans. 2000, 28, 350–353. [Google Scholar] [CrossRef]

- Ruggiero, F.; Exposito, J.Y.; Bournat, P.; Gruber, V.; Perret, S.; Comte, J.; Olagnier, B.; Garrone, R.; Theisen, M. Triple helix assembly and processing of human collagen produced in transgenic tobacco plants. FEBS Lett. 2000, 469, 132–136. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Gan, Q.; Clough, R.C.; Pappu, K.M.; Howard, J.A.; Baez, J.A.; Wang, K. Hydroxylation of recombinant human collagen type I alpha 1 in transgenic maize co-expressed with a recombinant human prolyl 4-hydroxylase. BMC Biotechnol. 2011, 11, 69. [Google Scholar] [CrossRef] [Green Version]

- Gellermann, P.; Schneider-Barthold, C.; Bolten, S.N.; Overfelt, E.; Scheper, T.; Pepelanova, I. Production of a Recombinant Non-Hydroxylated Gelatin Mimetic in Pichia pastoris for Biomedical Applications. J. Funct. Biomater. 2019, 10, 39. [Google Scholar] [CrossRef] [Green Version]

- Rutschmann, C.; Baumann, S.; Cabalzar, J.; Luther, K.B.; Hennet, T. Recombinant expression of hydroxylated human collagen in Escherichia coli. Appl. Microbiol. Biotechnol. 2014, 98, 4445–4455. [Google Scholar] [CrossRef] [Green Version]

- John, D.C.; Watson, R.; Kind, A.J.; Scott, A.R.; Kadler, K.E.; Bulleid, N.J. Expression of an engineered form of recombinant procollagen in mouse milk. Nat. Biotechnol. 1999, 17, 385–389. [Google Scholar] [CrossRef] [PubMed]

- Weber, S.C.; Herz, A.H. Method for Recombinant Yeast Expression and Isolation of Water-Soluble Collagen-Type Polypeptides. Application No. 383,748. U.S. Patent 5,710,252, 20 January 1998. [Google Scholar]

- Mashiko, T.; Takada, H.; Wu, S.H.; Kanayama, K.; Feng, J.; Tashiro, K.; Asahi, R.; Sunaga, A.; Hoshi, K.; Kurisaki, A.; et al. Therapeutic effects of a recombinant human collagen peptide bioscaffold with human adipose-derived stem cells on impaired wound healing after radiotherapy. J. Tissue Eng. Regen. Med. 2018, 12, 1186–1194. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Ma, X.; Gao, Y.; Fan, D.; Zhu, C.; Mi, Y.; Xue, W. Hydroxylation of Human Type III Collagen Alpha Chain by Recombinant Coexpression with a Viral Prolyl 4-Hydroxylase in Escherichia coli. Protein J. 2017, 36, 322–331. [Google Scholar] [CrossRef] [PubMed]

- Vuorela, A.; Myllyharju, J.; Nissi, R.; Pihlajaniemi, T.; Kivirikko, K.I. Assembly of human prolyl 4-hydroxylase and type III collagen in the yeast pichia pastoris: Formation of a stable enzyme tetramer requires coexpression with collagen and assembly of a stable collagen requires coexpression with prolyl 4-hydroxylase. EMBO J. 1997, 16, 6702–6712. [Google Scholar] [CrossRef] [Green Version]

- Báez, J.; Olsen, D.; Polarek, J.W. Recombinant microbial systems for the production of human collagen and gelatin. Appl. Microbiol. Biotechnol. 2005, 69, 245–252. [Google Scholar] [CrossRef]

- Sipilä, K.H.; Drushinin, K.; Rappu, P.; Jokinen, J.; Salminen, T.A.; Salo, A.M.; Käpylä, J.; Myllyharju, J.; Heino, J. Proline hydroxylation in collagen supports integrin binding by two distinct mechanisms. J. Biol. Chem. 2018, 293, 7645–7658. [Google Scholar] [CrossRef] [Green Version]

- Rappu, P.; Salo, A.M.; Myllyharju, J.; Heino, J. Role of prolyl hydroxylation in the molecular interactions of collagens. Essays Biochem. 2019, 63, 325–335. [Google Scholar]

- Pihlajaniemi, T.; Myllylä, R.; Kivirikko, K.I. Prolyl 4-hydroxylase and its role in collagen synthesis. J. Hepatol. 1991, 13 (Suppl. S3), S2–S7. [Google Scholar] [CrossRef]

- Kolle, S.N.; Rey Moreno, M.C.; Mayer, W.; van Cott, A.; van Ravenzwaay, B.; Landsiedel, R. The EpiOcular™ Eye Irritation Test is the Method of Choice for the In Vitro Eye Irritation Testing of Agrochemical Formulations: Correlation Analysis of EpiOcular Eye Irritation Test and BCOP Test Data According to the UN GHS, US EPA and Brazil ANVISA Classification Schemes. Altern. Lab. Anim. 2015, 43, 181–198. [Google Scholar]

- Ames, B.N.; Mccann, J.; Yamasaki, E. Methods for detecting carcinogens and mutagens with the Salmonella/mammalian-microsome mutagenicity test. Mutat. Res. 1975, 31, 347–364. [Google Scholar] [CrossRef]

- Myllyharju, J.; Nokelainen, M.; Vuorela, A.; Kivirikko, K.I. Expression of recombinant human type I–III collagens in the yeast Pichia pastoris. Biochem. Soc. Trans. 2000, 28, 353–357. [Google Scholar] [CrossRef]

- He, J.; Ma, X.; Zhang, F.; Li, L.; Deng, J.; Xue, W.; Zhu, C.; Fan, D. New strategy for expression of recombinant hydroxylated human collagen α1(III) chains in Pichia pastoris GS115. Biotechnol. Appl. Biochem. 2015, 62, 293–299. [Google Scholar] [CrossRef]

- Nokelainen, M.; Tu, H.; Vuorela, A.; Notbohm, H.; Kivirikko, K.I.; Myllyharju, J. High-level production of human type I collagen in the yeast Pichia Pastoris. Yeast 2001, 18, 797–806. [Google Scholar] [CrossRef] [Green Version]

- Ouzounov, N.; Lorestani, A.; Bhatia, M. Recombinant collagen and elastin molecules and uses thereof. U.S. Patent WO2019068018, 23 May 2019. [Google Scholar]

- Edgar, S.; Hopley, B.; Genovese, L.; Sibilla, S.; Laight, D.; Shute, J. Effects of collagen-derived bioactive peptides and natural antioxidant compounds on proliferation and matrix protein synthesis by cultured normal human dermal fibroblasts. Sci. Rep. 2018, 8, 10474. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.P.; Lan, W.H.; Chang, M.C.; Chen, Y.J.; Lan, W.C.; Chang, H.H.; Jeng, J.H. Effects of TGF-beta s on the growth, collagen synthesis and collagen lattice contraction of human dental pulp fibroblasts in vitro. Arch. Oral Biol. 2005, 50, 469–479. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.J.; Ha, G.H.; Seo, W.Y.; Kim, C.K.; Kim, K.; Lee, S.B. Human collagen alpha-2 type I stimulates collagen synthesis, wound healing, and elastin production in normal human dermal fibroblasts (HDFs). BMB Rep. 2020, 53, 539–544. [Google Scholar] [CrossRef] [PubMed]

- Bolke, L.; Schlippe, G.; Gerß, J.; Voss, W. A Collagen Supplement Improves Skin Hydration, Elasticity, Roughness, and Density: Results of a Randomized, Placebo-Controlled, Blind Study. Nutrients 2019, 11, 2494. [Google Scholar] [CrossRef] [Green Version]

- Lin, P.; Hua, N.; Hsu, Y.C.; Kan, K.W.; Chen, J.H.; Lin, Y.H.; Kuan, C.M. Oral Collagen Drink for Antiaging: Antioxidation, Facilitation of the Increase of Collagen Synthesis, and Improvement of Protein Folding and DNA Repair in Human Skin Fibroblasts. Oxid. Med. Cell. Longev. 2020, 2020, 8031795. [Google Scholar] [CrossRef] [PubMed]

- Yamanaka, H.; Okada, S.; Sanada, H. A multicenter, randomized, controlled study of the use of nutritional supplements containing collagen peptides to facilitate the healing of pressure ulcers. J. Nutr. Intermed. Metab. 2017, 8, 51–59. [Google Scholar] [CrossRef]

- Asserin, J.; Lati, E.; Shioya, T.; Prawitt, J. The effect of oral collagen peptide supplementation on skin moisture and the dermal collagen network: Evidence from an ex vivo model and randomized, placebo-controlled clinical trials. J. Cosmet. Dermatol. 2015, 14, 291–301. [Google Scholar] [CrossRef] [Green Version]

- Lee, G.; West, V.; Parker, T.; Vollmer, D. A Multi-Type Collagen-Based Drink Supplement Significantly Improved Markers of Aging, both in vitro and in a Human Clinical Study. J. Clin. Exp. Dermatol. Res. 2020, 11, 1000531. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).