1. Introduction

The rheology modifier category, which comprises all the raw materials that significantly participate in the rheology of monophasic or biphasic systems, also includes ingredients called gelatinizers. These increase the viscosity of oils, aqueous solutions, suspensions, emulsions, and surfactants, often giving rise to systems with the thickness of a gel [

1].

These substances might be classified according to their key application field, i.e. their use in hydrophilic, lipophilic, or surfactant systems. Alternatively, if the origin criteria are taken into account, they can be classified as natural, like guar, xanthan, and gellan gums or alginates [

2], “natural-modified”, for example cellulose derivatives (hydroxyethylcellulose, methylcellulose, hydroxypropylcellulose), synthetic, like products from the oil industry (acrylates, polyesters, waxes), or finally mineral, like clays and pyrogenic silica. As current market trends require greener, sustainable, and safe ingredients, the importance of natural ingredients is on the rise in the rheology modifiers field. Indeed, they have some limitations, such as, for instance, their high sensitivity to extreme pH or high ionic concentrations and their relative susceptibility to microbial and environmental contamination. The non-perfect reproducibility of the gelatinized system could be an additional drawback. Natural polymers usually show more or less branched polysaccharide backbones which are quite hydrophilic, and the gel formation is strictly related to their chemical structure and concentration, typically similar to carbohydrates [

3,

4].

Caesalpinia spinosa Gum

Caesalpinia spinosa gum, also known as Peruvian carob, is a natural gum obtained by grinding the endosperm of

Caesalpinia spinosa seeds.

Caesalpinia spinosa is a plant belonging to the Leguminosae family, native to the Peruvian and Bolivian Andes [

5].

Caesalpinia spinosa flour (

Figure 1), an odorless white to ivory-colored powder, has been to date been largely used in the food industry as a thickening agent. For this reason, it is internationally recognized as completely safe for other human applications.

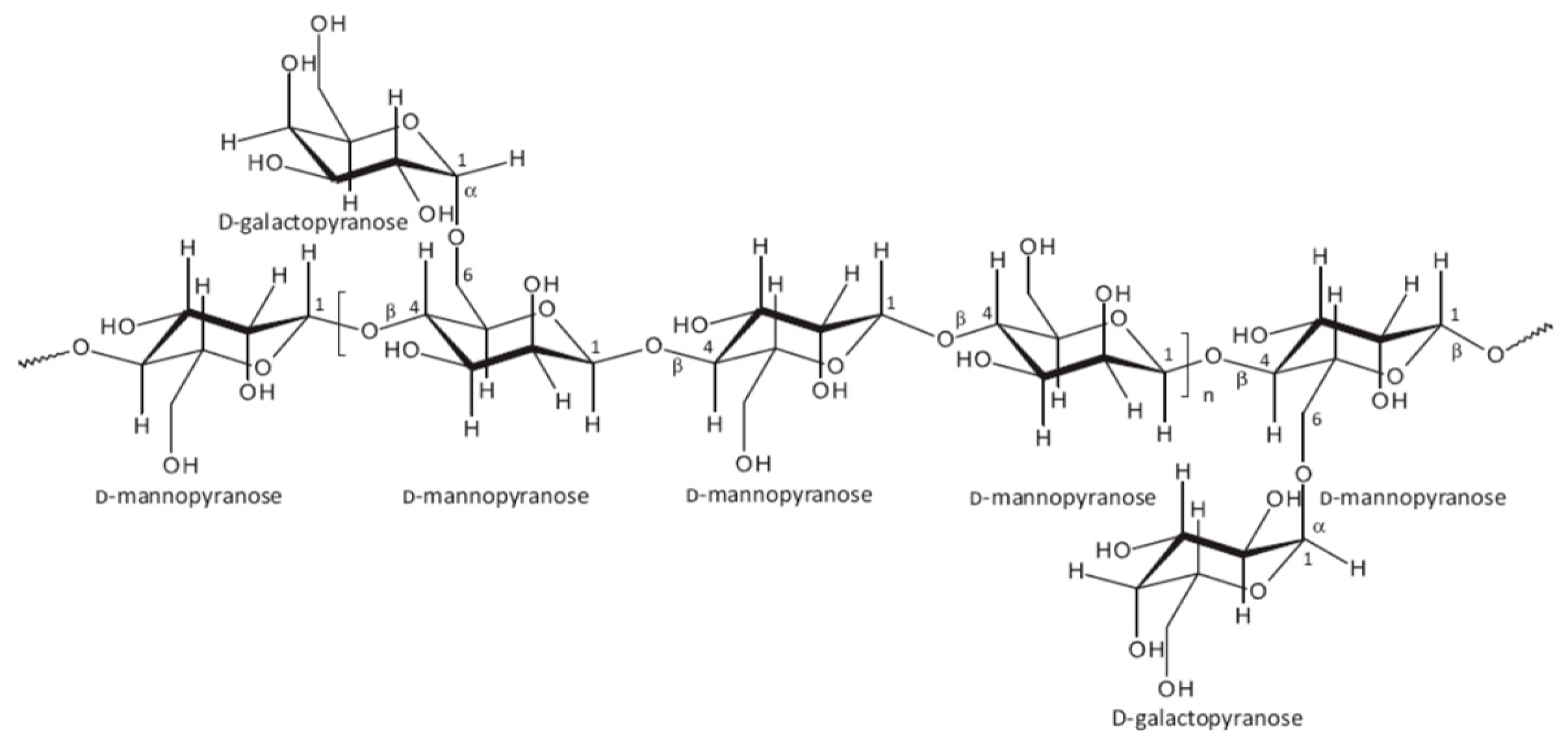

Chemically speaking,

Caesalpinia spinosa gum is a polysaccharide composed of (1-4)-β-D-manno-pyranose linear chains, branched through (1–6) bonds with α-D-galactopyranose units in a 3:1 ratio (

Figure 2), a characteristic structure resembling that of other natural gums such as guar and carob, which, on the other hand, show a different mannose to galactose ratio [

6,

7].

The dispersibility in water of these polymers is proportional to the percentage of galactopyranose units in the polysaccharide chains [

8].

Caesalpinia spinosa gum, with 25% galactose (meaning a medium branching level), results partially soluble in cold water, while it easily dissolves in hot water, fully hydrating while forming a medium force gel of exceptional softness. The pH value of an aqueous solution of

Caesalpinia spinosa gum at 2% is 6.4 at 25 °C.

2. Materials and Methods

2.1. Rheological and Viscosity Measurements

Aqueous solutions of one grade of Caesalpinia spinosa gum (Biosericum, Silvateam) at 0.1%, 0.2%, 0.5%, 1%, and 2% were prepared by homogenizing the powder in deionized water with a high shear mixer (Silverson L4R, Silverson Machines Ltd, Waterside, Chesham HP5 1PQ, UK) at 65 °C.

Rheological measurements were performed by using a rotational rheometer (Discovery HR-1Rheostress RS150, TA Instruments, New Castle, USA) at 25 °C.

Viscosity measurements were carried out with a rotational viscometer (Brookfield DV-I+,

Brookfield Engineering Laboratories, Inc.

11 Commerce Boulevard, Middleboro, MA 02346 U.S.A.) at different concentrations (0.1%, 0.2%, 0.5%, 1%, 2%) at 25 °C and at different temperatures (25 °C, 35 °C, 45 °C, 55 °C) at 1%.

2.2. Compatibility Trials

Compatibility trials were carried out by adding several common cosmetic ingredients to the aqueous solution of the gum at 1%. The samples were checked visually and their viscosity was measured immediately after the preparation, then after 24 and 48 hours.

- -

Salts: NaCl and MgSO4 up to 2% concentration.

- -

Chelating agents such as disodium and tetrasodium salts of ethylenediaminotetraacetic acid (0.1%), sodium salts of ethylenediamine disuccinic and glutamic-diacetic acids (0.4%).

- -

Hydrotropes: betaine, glycerin, isopentyldiol, propylene glycol, and 1,3-propandiol up to 5%.

- -

Ethanol up to 40%

- -

Lactic acid up to pH 3 and NaOH up to pH 12.

- -

Five common natural or synthetic thickeners were added to the aqueous solution of Caesalpinia spinosa gum at 0.5% by homogenizing: xanthan gum at 0.5%, carrageenan at 1%, carbomer at 0.5%, hydroxyethylcellulose at 1%, and the copolymer ammonium acryloyldimethyltaurate/VP at 0.5%. Sensory evaluations of the gels were carried out by a panel of trained experts.

The compatibility of the gum and its influence on the foam height and quality were tested with the following common surfactants: sodium laureth sulfate (SLES), disodium cocoamphodiacetate, disodium laureth sulfosuccinate, cocamidopropyl betaine, and coco-glucoside. Foam height was measured by preparing an aqueous solution of each surfactant at 0.5% (100 mL in a 400-mL beaker); the solution was homogenized with a high shear mixer (Silverson L4R,) equipped with a crown for emulsions with circular holes during 1 min. Then the foam was poured slowly in a 250-mL cylinder with an internal diameter of 35 mm. The foam height was measured with a ruler in millimeters (mm), 1 min and 5 min after preparation. The quality was checked visually and with in-use trials. The compatibility of Caesalpinia spinosa gum aqueous solution at 0.25%, 0.5%, and 1% was tested with each mentioned surfactant at Washing Active Substance - WAS 15. Then, blends made of sodium lauryl ether sulfate as main surfactant at 10% + secondary surfactant (disodium cocoamphodiacetate or disodium laureth sulfosuccinate or cocamidopropyl betaine or coco-glucoside) at 2% and 4% were tested in association with the aqueous solution of the gum at 0.5%. A visual analysis and viscosity measurements were performed immediately after the preparation, and after 24 and 48 hours.

Then, 1% cetrimonium chloride was added to the aqueous solution of the gum at 0.5% to test their compatibility. The sample was checked visually and its viscosity was measured immediately after the preparation, and after 24 and 48 hours.

Additional trials were carried out in order to investigate the compatibility with make-up pigments and the ability to keep them in suspension. The following inorganic solids were added to an aqueous solution of Caesalpinia spinosa gum at 1%: titanium dioxide 10%, zinc oxide 5%, brown iron oxide 5% (CI 77499, CI 77491, CI 77492), and D&C Red n.7 Calcium Lake (CI 15850) 2% by homogenizing with a high shear mixer (Silverson L4R). The dispersions were evaluated visually and by an optical microscope (Optika M-699, magnitude 600×,

OPTIKA Srl, Via Rigla, 30 – 24010 Ponteranica, Italy) just after the preparation and after 24/48 h.

Moreover, nano UV filters, i.e. uncoated zinc oxide at 25% and silica-coated titanium dioxide at 20% were added to an aqueous solution of the gum at 1% by homogenizing. The ease of dispersion during production and the appearance of the samples after 24/48 h were checked.

2.3. Suspending and Emulsification Power

In order to verify the suspending power of some inorganic solids, even in comparison with xanthan gum, dispersions of the two gums at 1% with 25% micronized ZnOor 10% TiO2 and at 0.2% with 10% TiO2 were prepared and centrifuged at different speeds (1000, 3000, 5000 rpm) for 5 min at 25 °C (Heraeus centrifuge, Multifuge 1-SR, Thermo Fisher Scientific, 3rd Avenue, Waltham, MA, USA).

Finally, an additional investigation was carried out to define the potential emulsification power of the gum. The assessment was performed by adding increasing amounts (0.3%, 0.6%, 0.9%, 1.2%, 3%) of an oil blend of medium polarity (composed of caprylic/capric triglyceride, dicaprylyl ether, hydrogenated polydecene 1:1:1) to Caesalpinia spinosa gum solution at 1% by homogenizing at maximum speed for 5 min (Silverson L4R,). The samples were evaluated visually and by optical microscopic observation (Optika M-699, magnitude 600×) measuring the average diameter of the oil drops (five measurements for each dispersion) immediately after the preparation, after 48 hours and one week.

3. Results and Discussion

3.1. Rheological and Viscosity Measurements

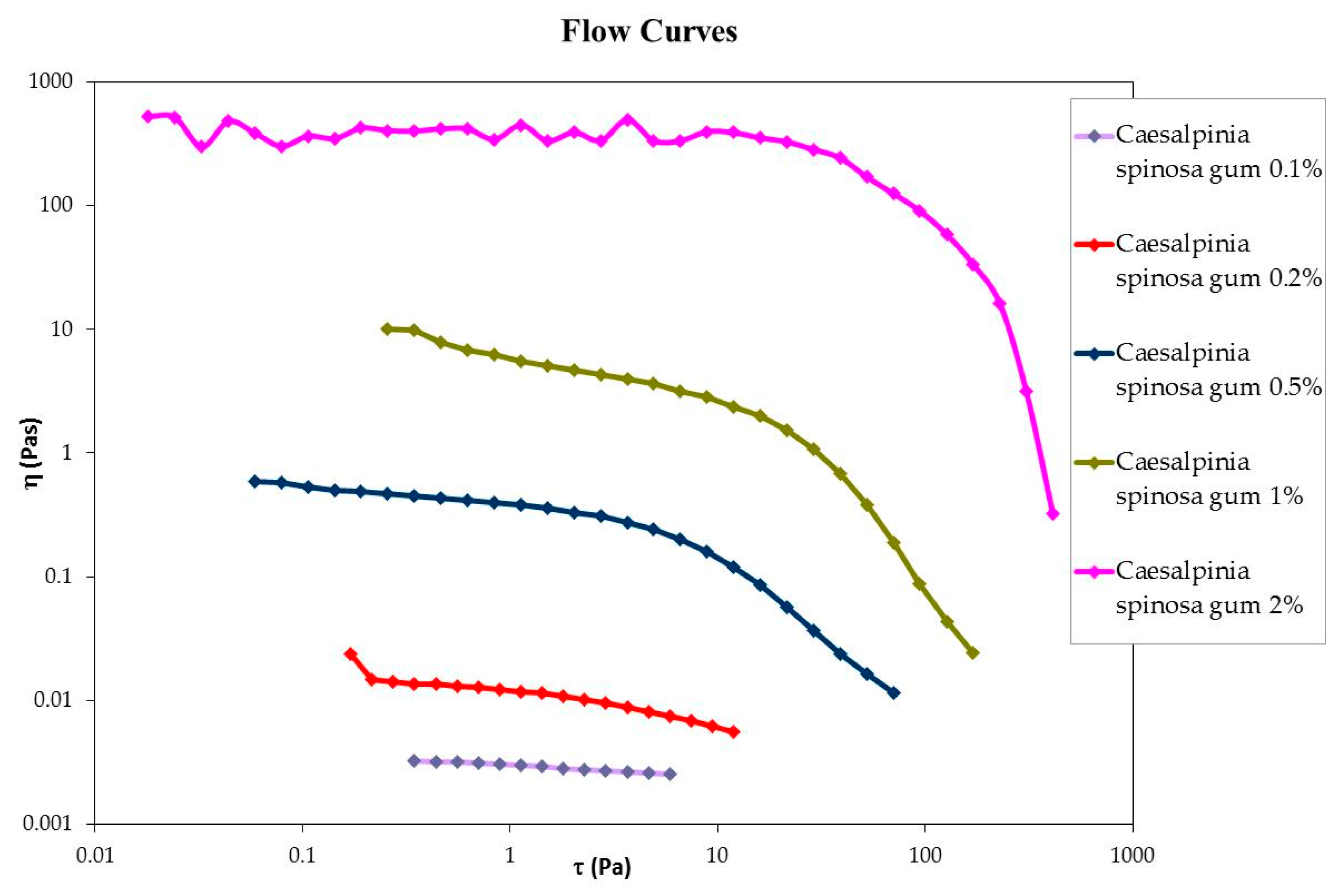

From a rheology point of view, very dilute

Caesalpinia spinosa gum aqueous solutions (0.1–0.2%) show an almost pure Newtonian behavior (

Figure 3). In other words, viscosity does not change when increasing the shear force. As concentrations progressively increase, the polymer solution acquires pseudoplastic characteristics and its viscosity decreases when increasing the shear force.

At high concentrations, such as 2%, its behavior becomes viscoelastic. Indeed, the polymer keeps a constant viscosity at increasing shear forces, up to a threshold value, where it takes on a properly pseudoplastic behavior.

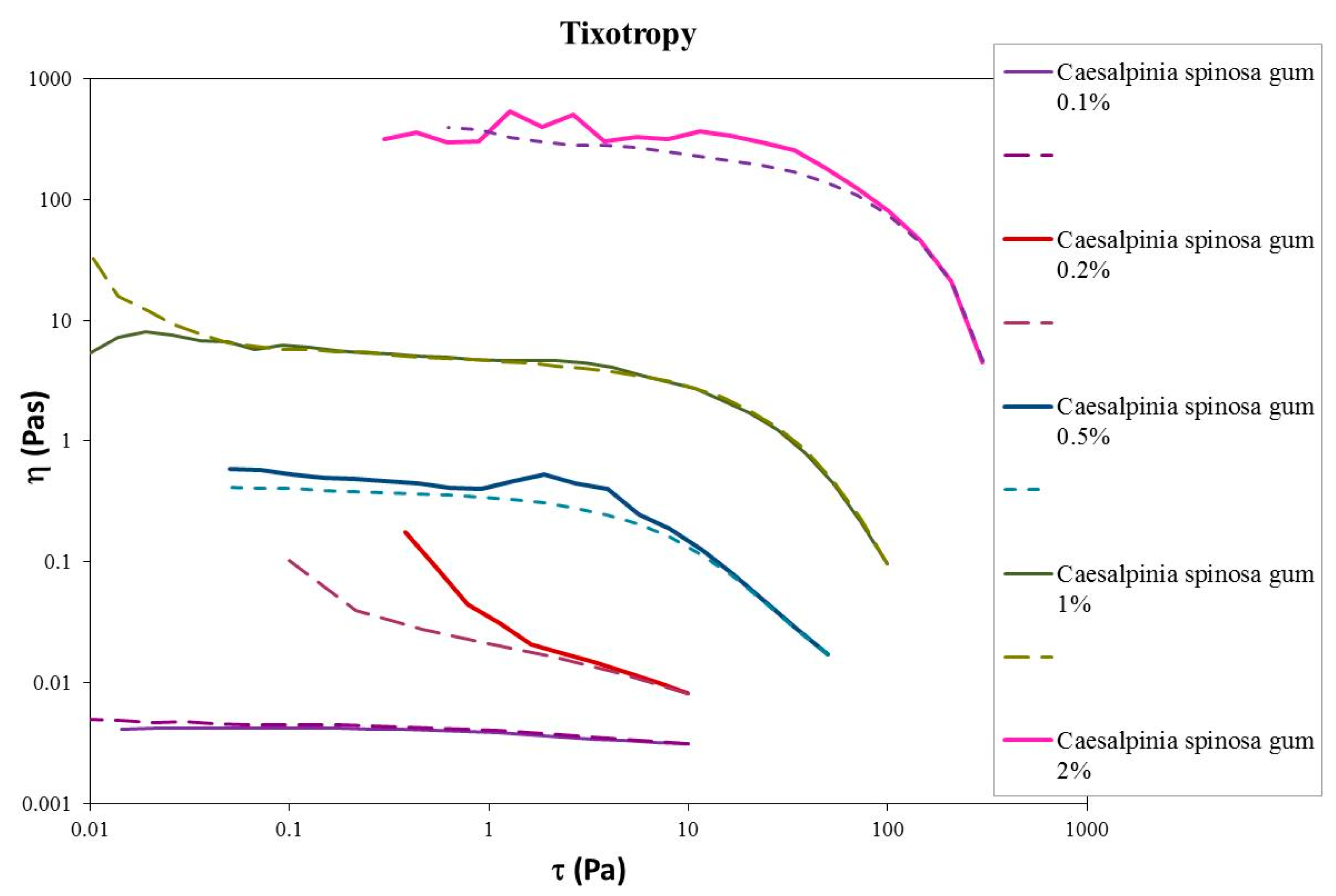

In general, aqueous solutions of

Caesalpinia spinosa gum do not exhibit thixotropic characteristics, and therefore their structure-rebuilding time is comparable to the initial part of the rheological path (

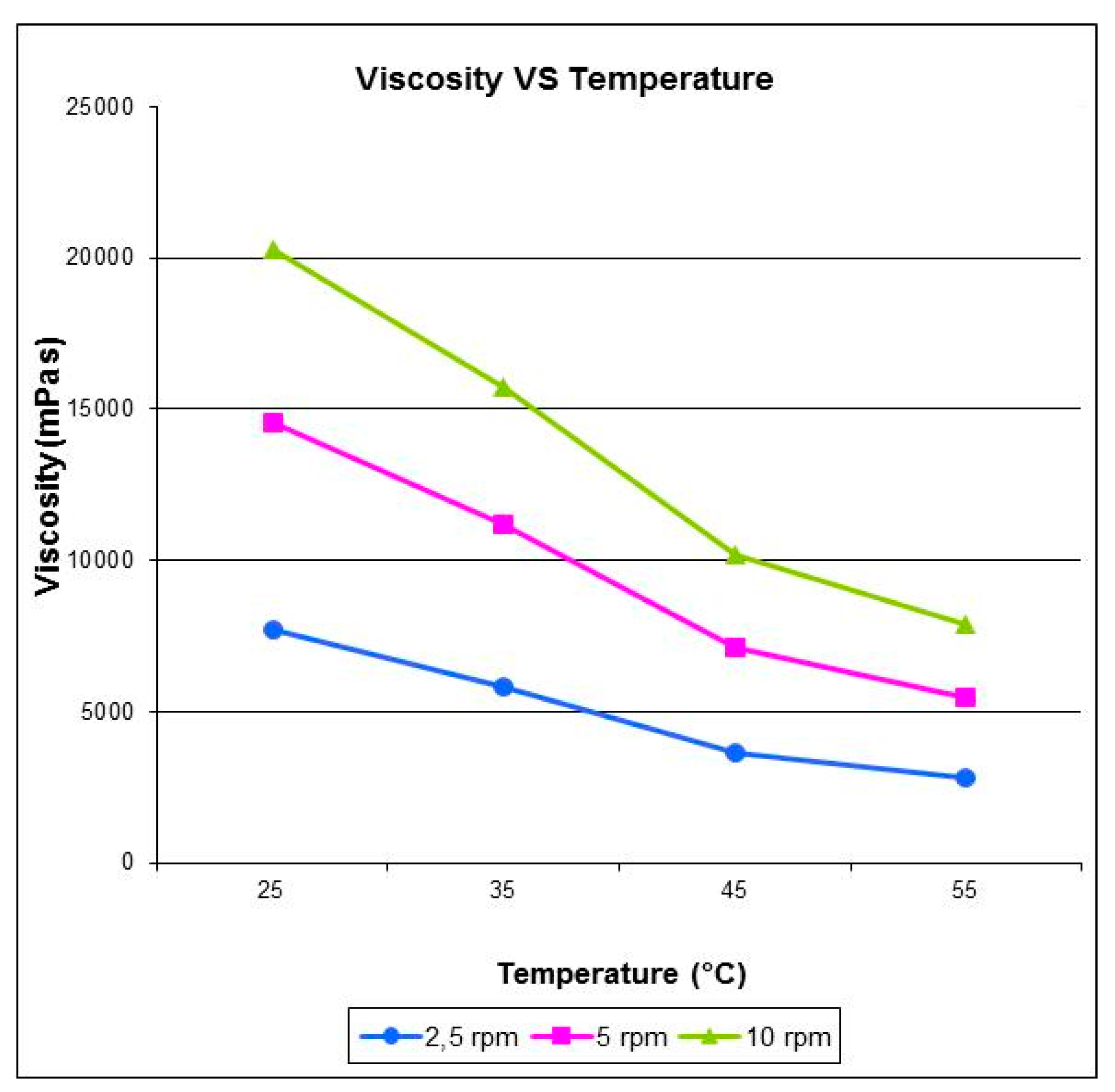

Figure 4). It is important to underline that viscosity is inversely proportional to temperature (

Figure 5), as occurs frequently.

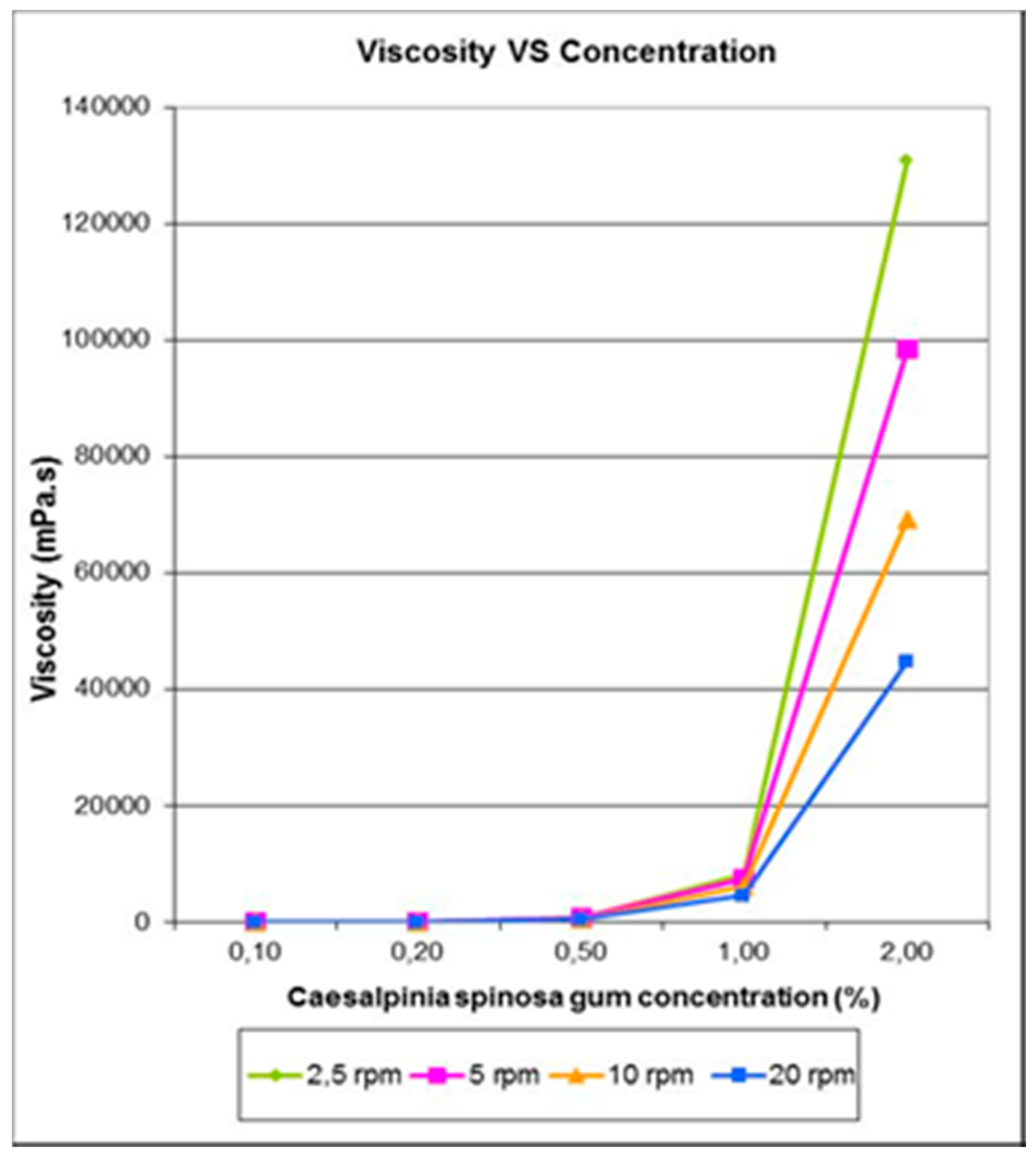

Table 1 and

Figure 6 show the relationship between viscosity and concentration. An important increase in viscosity is observed from the 1% concentration.

3.2. Compatibility Trials

This grade of Caesalpinia spinosa gum showed an excellent compatibility with most ingredients at concentrations usually adopted in cosmetics (such as sodium chloride and magnesium sulfate), salts commonly used to thicken cleansing formulae or to stabilize water in oil (W/O) emulsions, and chelating agents like sodium salts of ethylenediaminotetraacetic, ethylenediamine disuccinic, and glutamic-diacetic acids. In fact, the appearance of the samples did not change after 48 h and the viscosity slightly increased.

Hydrotropes, such as betaine, glycerin, isopentyldiol, propylene glycol, and 1,3-propandiol showed perfect compatibility and gave a slightly higher viscosity to aqueous dispersions. In addition, by preliminary wetting the gum with the fluid hydrotopes, the dispersion in water is easier, therefore facilitating the swelling procedure.

Caesalpinia spinosa gum proved to be stable in a pH range from 3 to 12, without changes in appearance nor viscosity. Moreover, it tolerated the addition of ethanol up to 10%, even if the viscosity underwent a significant increase.

Caesalpinia spinosa gum showed in general good compatibility with the natural and synthetic rheology modifiers tested, i.e., carrageenan, carbomer, hydroxyethylcellulose, and ammonium acryloyldimethyltaurate/VP copolymer, with a strong viscosity increase. Additionally, there was an interesting synergic effect with xanthan gum [

9,

10].

Indeed, the combination of the two polymers forms instantly a compact gel, sharing this characteristic with other galactomannans, unlike what happens when they are used alone [

11].

Moreover, Caesalpinia spinosa gum enhanced the sensorial properties of the binary gels in terms of softness, spreading, thickness, velvety after-feel, and lower stickiness.

The foam height of surfactants solutions tends to decrease when adding Caesalpinia spinosa gum, even if good foam stabilization is evident. The gum proved to be compatible at 0.25% with disodium cocamphodiacetate (WAS 15) and with sodium laureth sulfate (WAS 15) up to 1%, showing in this case an increase in viscosity. As far as the blends are concerned, the gum at 0.5% resulted compatible with SLES 10% + coco-glucoside up to 4% and SLES 10% + disodium laureth sulfosuccinate up to 4%, showing an increase in viscosity in both cases, and with SLES 10% + cocamidopropyl betaine at 2%, showing a decrease in viscosity. The benefits imparted to surfactants by Caesalpinia spinosa gum, such as improvement of foam quality, a thicker soft feeling during massaging, and the high safety level, make it ideal for delicate cleansing, for example in personal and baby hygiene and cleansing recipes for intolerant and hypersensitive skins. In addition, the gum proved to be compatible with the conditioner cetyltrimethylammonium chloride, making it suitable for thickening hair products, from cleansers to conditioning masks.

In the case of solid dispersions, Caesalpinia spinosa gum demonstrated good compatibility with the pigments used in make-up formulations, such as iron oxides, titanium dioxide, and zinc oxide, except the Calcium Lake, for which dispersion was difficult and not homogeneous. Even inorganic micronized UV filters like uncoated ZnO and silica-coated TiO2 proved to be compatible with this gum.

3.3. Suspending and Emulsification Power

Caesalpinia spinosa gum showed good suspending power of some inorganic powders at 1%, slightly more than xanthan gum. In fact, centrifuged samples of dispersions of both gums at 1% with nano ZnO 25% or TiO2 10% did not show any precipitate at 1000 rpm. In contrast, at 3000 and 5000 rpm they presented some precipitate, higher in case of xanthan gum, in particular with ZnO. Decreasing the percentage of the gums to 0.2% by dispersing 10% TiO2 the samples did not show any precipitate at 1000 rpm, similar amounts of precipitate at 3000 rpm, and a higher amount only in the case of Caesalpinia spinosa gum at 5000 rpm. However, it is important to underline that the difference in viscosity of the two gums at 0.2% influences the suspending properties (viscosity, Brookfield DV-I+, 25 °C, Spindle 2, 2.5 rpm: xanthan gum 1,200 mPa·s, C. spinosa gum 12 mPa·s).

Trials carried out by dispersing an oil blend into Caesalpinia spinosa gum aqueous solutions at 1% showed some oil emulsifying properties up to an oil concentration of about 1%. In fact, the average diameter of the oil droplets just after the preparation was 3.8 μm at 0.3% oil, 10.3 μm at 0.9% oil, and 20.0 μm at 3% oil. After one week, the values kept quite constant: 4.2 μm at 0.3% oil, 10.2 μm at 0.9% oil, and 21.8 μm at 3% oil. This characteristic, alongside its verified suspending power, makes Caesalpinia spinosa gum a good alternative to xanthan gum as a thickening and stabilizing agent.

3.4. Optimal Concentration of Usage

The right concentration of Caesalpinia spinosa gum to maximize its suspending properties, while avoiding any “gommage” effect after spreading the product over the skin, ranges between 0.1% and 1%. Indeed, the film forming properties become predominant above this concentration, even though they might be needed in the preparation of make-up products with long-lasting characteristics, such as eyeliners and mascaras or face masks and muds.

Formulation Examples

| After shave fresh gel (transparent microemulsion). |

| Phase | Ingredients (INCI* name) | % w/w |

| A | Aqua | to 100 |

| Allantoin | 0.10–0.30 |

| Xylitol | 2.00–5.00 |

| Zinc PCA | 0.05–0.15 |

| Panthenol | 0.20–0.60 |

| Trisodium Ethylenediamine Disuccinate, Aqua | 0.30 |

| A1 | Carbomer | 0.30–0.50 |

| A2 | Isopentyldiol | 3.00–6. 00 |

| Caesalpinia Spinosa Gum | 0.30–0.50 |

| B | Phenoxyethanol | 0.80 |

| o-Cymen-5-ol | 0.10 |

| Parfum | 0.10–0.30 |

| Menthol, Menthyl Lactate | 0.08–0.12 |

| PEG-40 Hydrogenated Castor Oil | 0.80–1.20 |

| E | Triethanolamine | qs to pH 6 |

| | 100.00 |

* INCI = International Nomenclature of Cosmetic Ingredients

Production technology:

Prepare phase A by mixing until complete solution.

Disperse A1 into phase A by homogenizing at room temperature.

Prepare phase A2 and add it to phase A while homogenizing.

Prepare phase B and add it into the main mixer while homogenizing.

Adjust pH to 6 by adding phase E and homogenize for 5 min.

Specifications:

pH: 6.0

Viscosity: (Brookfield DV-I+; S05; 25 °C, t = 24 h, mPa·s)

- -

2.5 rpm: 92,480

- -

5. 0 rpm: 56,000

- -

10.0 rpm: 33,880

Appearance: Transparent Gel

This formula shows the compatibility of Caesalpinia spinosa gum with common water-soluble additives of a different chemical nature. This good compatibility is also reported when blending Caesalpinia spinosa gum with other hydrophilic polymers. The result is an improvement of the sensorial properties of the end product, imparting softness and freshness.

| Discipline hair mask. |

| Phase | Ingredients (INCI name) | % W/W |

| A | Aqua | to 100 |

| A1 | Polyquaternium-10 | 0.05–0.15 |

| A2 | Caesalpinia Spinosa Gum | 0.80–1.20 |

| B | Behentrimonium Methosulfate, cetearyl alcohol | 3.00–6.00 |

| C12-13 Lactate | 2.00–4.00 |

| Isostearyl Alcohol | 0.50–1.50 |

| Cetrimonium Chloride | 0.50–1.50 |

| Stearamidopropyl Dimethylamine | 0.20–0.60 |

| Butyrospermum Parkii Butter | 1.00–3.00 |

| C | Aqua | 20.00–30.00 |

| D | Glycerin | 2.00–6.00 |

| E | Phenoxyethanol | 0.60 |

| F | Amodimethicone, Cetrimonium Chloride, Trideceth-10 | 2.00–6.00 |

| G | Aminopropyl Dimethicone | 0.50–1.50 |

| H | Parfum | 0.20–0.50 |

| I | Sodium Hydroxide, Aqua | 0.20–0.40 |

| L | Lactic Acid, Aqua | 0.20–0.40 |

| M | Sodium Benzoate, Potassium Sorbate, Aqua | 0.35 |

| | 100.00 |

Production technology:

Add phase A in the main mixer, then firstly add phase A1 and secondly add phase A2, while homogenizing at room temperature.

Heat up at 70 °C while homogenizing.

Prepare phase B in a side mixer and heat up to 70 °C.

Slowly add phase B into phase A, while homogenizing.

Add phase C gradually, while homogenizing.

Add phases D–H, homogenizing after each addition.

Add phases I–M, mixing after each addition.

Cool down to room temperature while mixing.

Specifications:

pH: 4.5

Viscosity: (Brookfield DV-I +; S06; 25 °C, t = 24 h, mPa·s)

- -

2.5 rpm: 118,000

- -

5.0 rpm: 72,600

- -

10.0 rpm: 43,800

Appearance: White Thick Emulsion

This formulation scheme shows the compatibility of Caesalpinia spinosa gum with different types of monomeric and polymeric cationic conditioners, silicones and a vegetal butter. At high concentrations, Caesalpinia spinosa gum provides a thick and firm gel structure, suitable for hair masks.

| Oil/Water (O/W) foundation |

| Phase | Ingredients (INCI name) | % W/W |

| A | Aqua | to 100 |

| Disodium EDTA | 0.05 |

| Betaine | 0.50–1.50 |

| A1 | Propylene Glycol | 1.00–3.00 |

| Glycerin | 4.00–8.00 |

| Caesalpinia Spinosa Gum | 0.20–0.60 |

| A2 | Glycerin, Inulin Lauryl Carbamate | 1.00–3.00 |

| B | Hydrogenated Polydecene | 2.00–5.00 |

| Butylene Glycol Dicaprylate/Dicaprate | 5.00–10.00 |

| Caprylic/Capric Triglyceride | 5.00–8.00 |

| Isoamyl Laurate | 2.00–6.00 |

| Limnanthes Alba Seed Oil, Butyrospermum Pparkii Butter Extract | 2.00–6.00 |

| Sorbitan Stearate | 0.50–2.00 |

| Glyceryl Stearate | 1.00–2.50 |

| BHT | 0.05 |

| B1 | CI 77891 | 8.00–12.00 |

| CI 77492 | 1.00–2.00 |

| CI 77491, CI 77492, CI 77499 | 1.00–2.00 |

| C | Phenoxyethanol, Ethylhexylglycerin | 1.00 |

| D | Parfum | 0.10–0.30 |

| | 100.00 |

Production technology:

After preparing phase A and phase A1 separately, slowly add phase A1 into phase A and homogenize.

Add phase A2 in the main mixer, heat up to 60 °C and homogenize again.

Prepare phase B in a side melting-vessel and heat up to 70 °C.

Add phase B1 pigments, previously mixed and milled, to the fluid B phase, while homogenizing.

Add slowly phase B to phase A while homogenizing.

Cool to room temperature.

Add phase C and phase D, then homogenize.

Specifications:

pH: 5.7

Viscosity: (Brookfield DV-I+; S04; 25 °C, t = 24 h, mPa·s)

- -

2.5 rpm: 28,480

- -

5.0 rpm: 19,600

- -

10.0 rpm: 13,160

Appearance: Skin-Colored Fluid Emulsion

This example demonstrates the compatibility of Caesalpinia spinosa gum with mineral pigments, favoring a long-lasting hiding and mat effect on the skin surface. It also shows the compatibility of Caesalpinia spinosa gum with other emulsifying polysaccharides and its stabilization power, even at low emulsifier concentration.

| Personal hygiene cleanser. |

| Phase | Ingredients (INCI name) | % W/W |

| A | Aqua | to 100 |

| Panthenol | 0.20–0.60 |

| Sodium Benzoate | 0.25 |

| Caesalpinia Spinosa Gum | 0.50–1.00 |

| Trisodium Ethylenediamine Disuccinate, Aqua | 0.30 |

| B | Phenoxyethanol | 0.80 |

| Phenethyl Alcohol | 0.10 |

| C | Coco Glucoside, Aqua | 2.00–5.00 |

| Sodium Laureth Sulfate, Aqua | 3.00–6.00 |

| Disodium Laureth Sulfosuccinate, Aqua | 2.00–5.00 |

| D | Lactic Acid, Aqua | to pH 4.70 |

| | 100.00 |

Production technology:

Prepare phase A while homogenizing, then heat up to 60 °C.

Cool down below 40 °C, then add phase B while homogenizing.

Add phase C, while mixing.

Use phase D to adjust pH to a value between 4.5 and 4.8.

Specifications:

pH: 4.7

Viscosity: (Brookfield DV-I +; S02; 25 °C, t = 0, mPa·s)

- -

2.5 rpm: 3760

- -

5.0 rpm: 3360

- -

10.0 rpm: 2836

Appearance: Slightly Opaque Fluid

This example shows the compatibility of Caesalpinia spinosa gum with surfactants, a very useful property to create delicate cleansing formulas. Using Caesalpinia spinosa gum, the foam is softer, the bubbles are finer, and after the application the skin is smooth.

| Toothpaste, sensitive gums |

| Phase | Ingredients (INCI Name) | % W/W |

| A | Aqua | to 100 |

| Sodium Saccharin | 0.15–0. 30 |

| Sodium Monofluorophosphate | 0.60–0.80 |

| Sorbitol | 25.00–35.00 |

| PEG-400 | 2.00–6.00 |

| Hydroxyacetophenone | 0.20 |

| A1 | Caesalpinia Spinosa Gum | 0.30–0.80 |

| B | Aqua | 2.00–6.00 |

| Titanium Dioxide | 0.50–1.50 |

| C | Hydrated Silica | 6.00–12.00 |

| Hydrated Silica | 8.00–14.00 |

| Silica | 1.00–3.00 |

| D | Aroma | 1.00–1.50 |

| CI 19140, CI 42090 | 0.03–0.06 |

| E | Aqua | 2.00–8.00 |

| Sodium Lauryl Sulfate | 1.00–1.50 |

| F | Sodium hydroxide, Aqua | 0.50–1.00 |

| | 100.00 |

Production technology:

Prepare phase A, adding each ingredient separately, then heat up to 60 °C, while stirring

Disperse Caesalpinia spinosa gum (A1), while homogenizing.

Pour phase B into phase A while homogenizing, then add phase C and homogenize again.

Cool down below 40 °C, then add phase D, while homogenizing.

Add phase E, while mixing.

Cool down to room temperature, then adjust pH using phase F.

Specifications:

pH: 6.8

Viscosity: (Brookfield RVT, Helipath-D; 25 °C, t = 24 h, mPa·s):

- -

2.5 rpm: 328,000

- -

5.0 rpm: 188,000

- -

10.0 rpm: 100,000

Appearance: Light-Green Paste

Caesalpinia spinosa gum can be easily added in any toothpaste formulation, being extremely compatible with abrasive agents such as hydrated silica. Caesalpinia spinosa gum gives the product a soft perception while tooth brushing, a useful property especially in the case of sensitive gums.

4. Conclusions

The application data presented above highlight the strengths of a grade of Caesalpinia spinosa gum as a novel rheology modifier for the cosmetic industry.

First of all, the good compatibility with a large amount of other common cosmetic ingredients enables a wide range of possible formulations.

Secondly, the synergy of Caesalpinia spinosa gum with xanthan gum is useful to create peculiar products such as jellies without the need to use large concentrations of the two thickeners.

Moreover, among the various properties, those of most impact are those linked to the enhancement of sensorial properties of finished products in terms of softer and richer skin-feel and velvety after-feel, completely free of any sticky perception.

Finally, other important key features of Caesalpinia spinosa gum include its low cost, its easiness of dispersion especially when pre-wet in glycols, and the fact that it is an extremely safe ingredient. These are all good reasons for its widespread use within the food industry. These characteristics make Caesalpinia spinosa gum an added-value ingredient within modern cosmetic formulation strategies, requiring, now more than ever, natural, safe, sustainable, economic, and versatile solutions.