Towards Sustainable Color Cosmetics Packaging

Abstract

1. Introduction

2. Background

2.1. Color Cosmetics

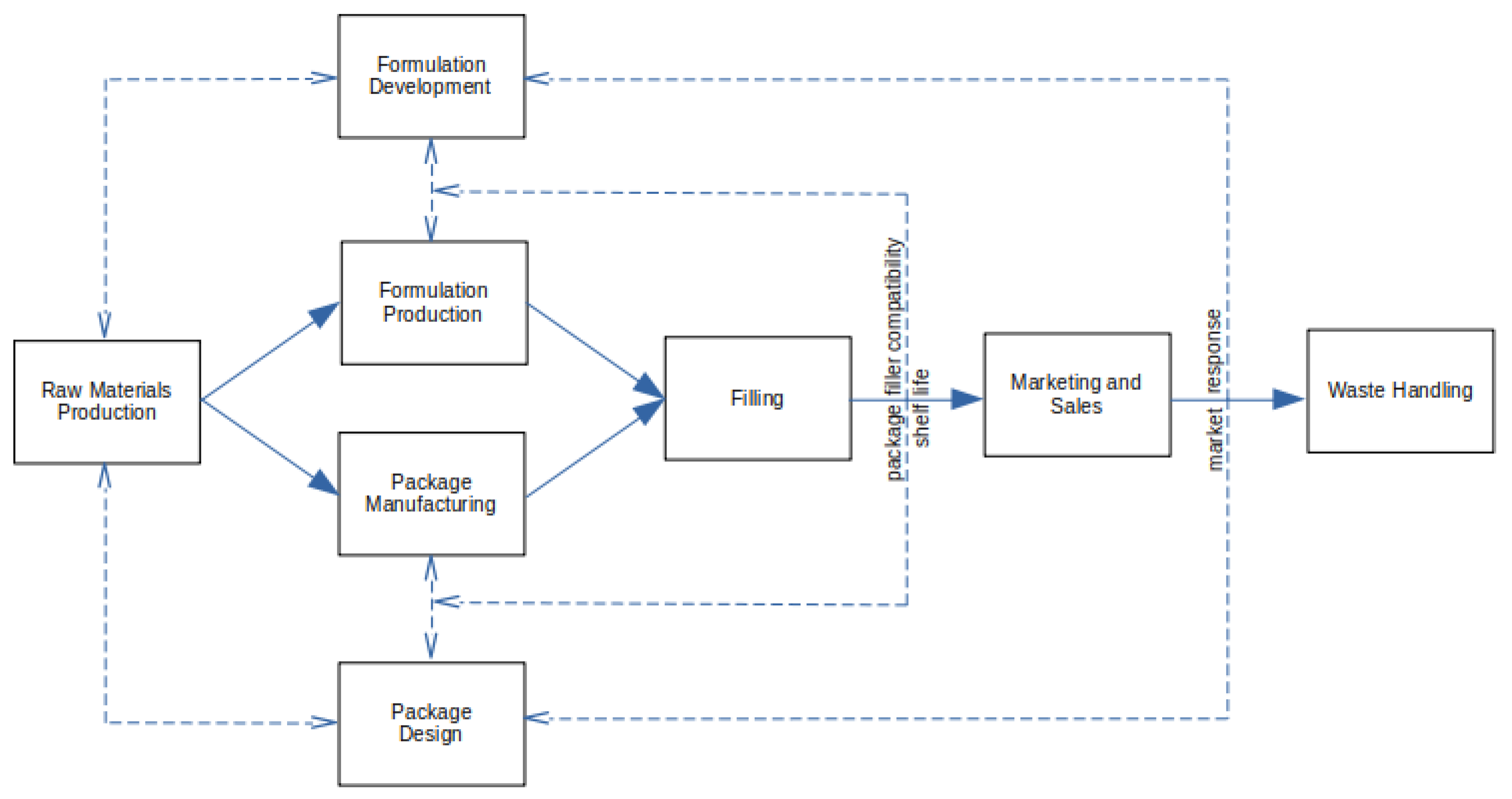

2.2. Putting Packaging in Perspective

Relevance of the Estimate

2.3. The Problem for Public-Facing Sectors

2.4. Sustainable Packaging Defined?

The term “sustainable” has become ubiquitous in the marketplace since 2012 and is used in many different contexts. Therefore, the marketplace would greatly benefit from specific guidance within the Green Guides. Companies should not be allowed to market their products as “sustainable” without completing full lifecycle assessments (LCAs) for each product and acquiring third party certification that the product meets each hotspot identified in the LCAs. Further, companies should not be allowed to market themselves as a “sustainable” company without fulfilling the above requirements for every product/service line offered and without performing an LCA on the company as a whole, including all suppliers and contractors.

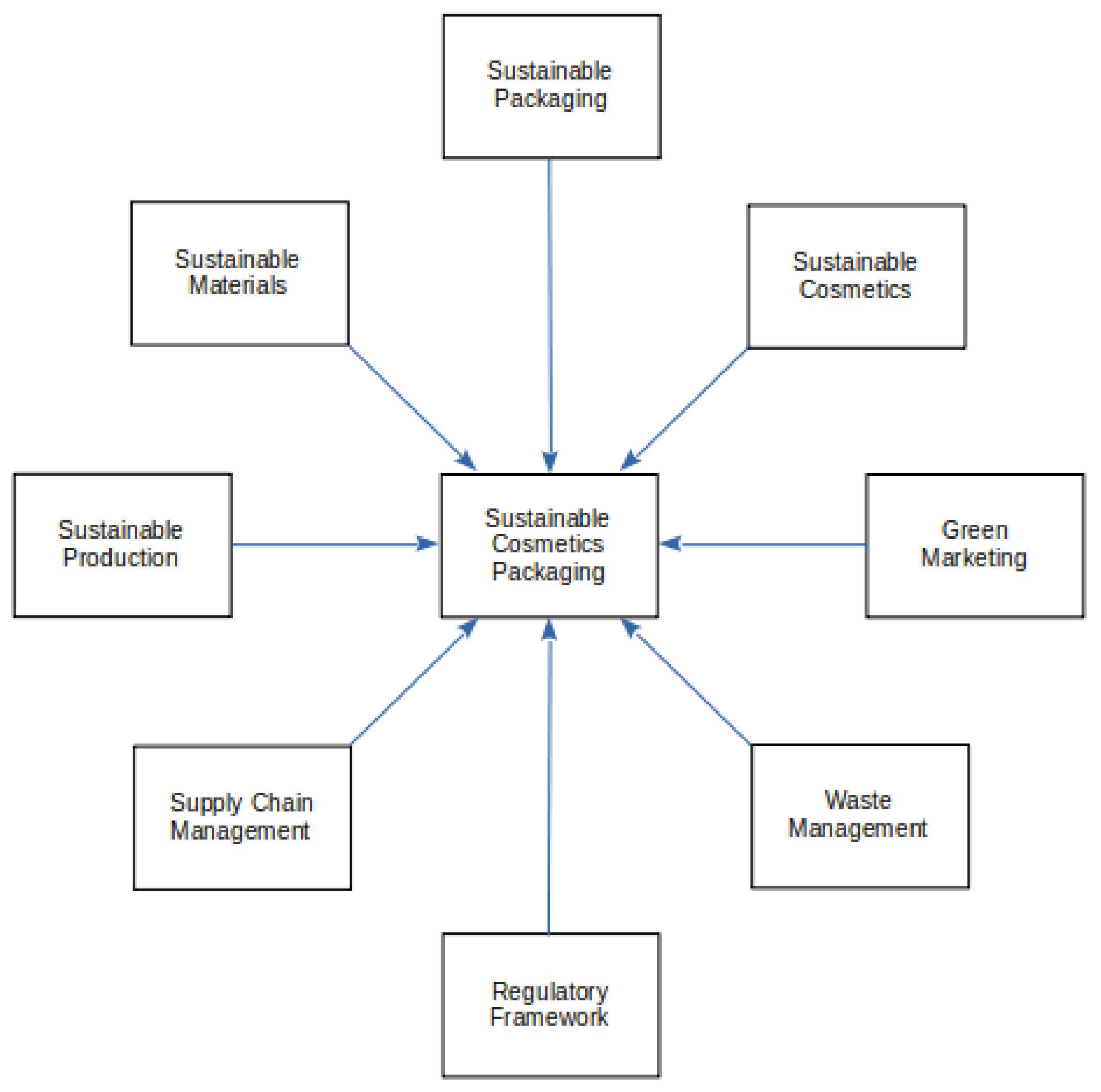

2.5. Supply Chain Actors for Sustainability

3. Product Development Pitfalls

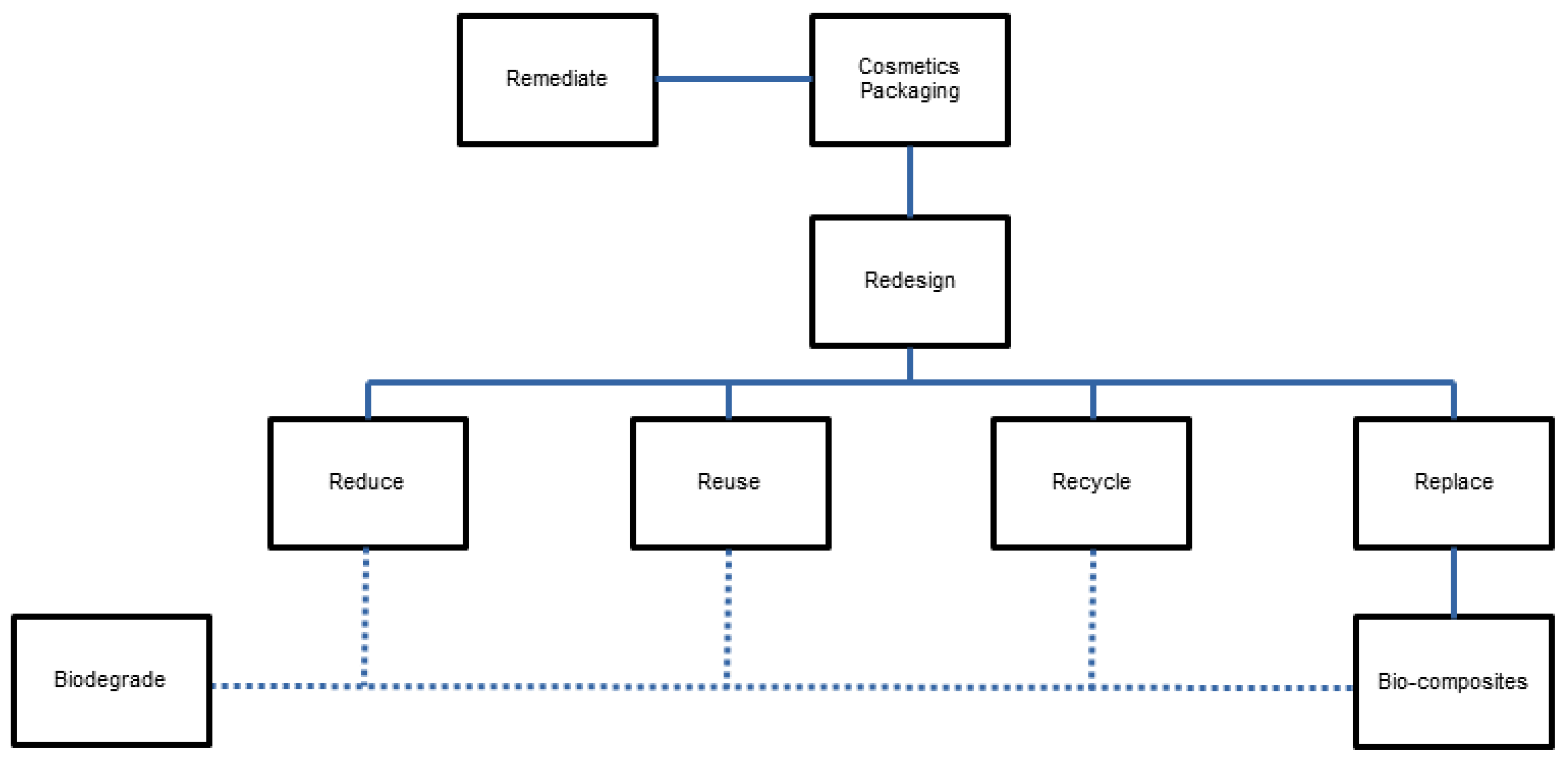

3.1. Circular Strategies

3.2. Predicting Sustainability

3.2.1. Consumer Behavior

3.2.2. Material Behavior

3.2.3. Impact of Technology

3.2.4. Social Sustainability

3.2.5. Economic Sustainability

3.3. Assessing Sustainability

3.4. Regulatory Environment

4. Sustainable Packaging Strategies

4.1. Reduce

4.2. Reuse

4.3. Recycle

4.4. Replace

4.4.1. Biopolymers

4.4.2. Biocomposites

5. Discussion and Conclusions

5.1. Existence of Need

5.2. Desirable Characteristics

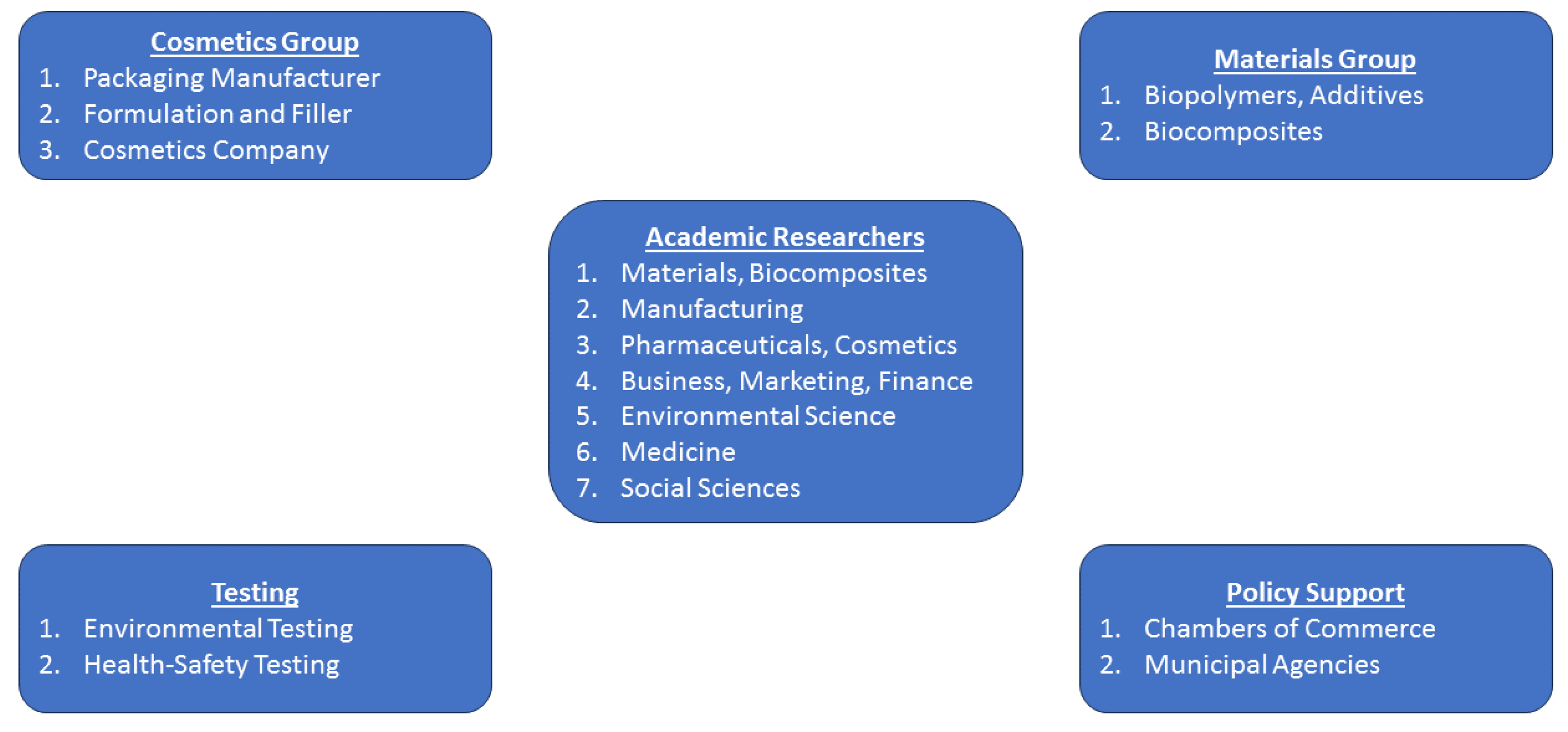

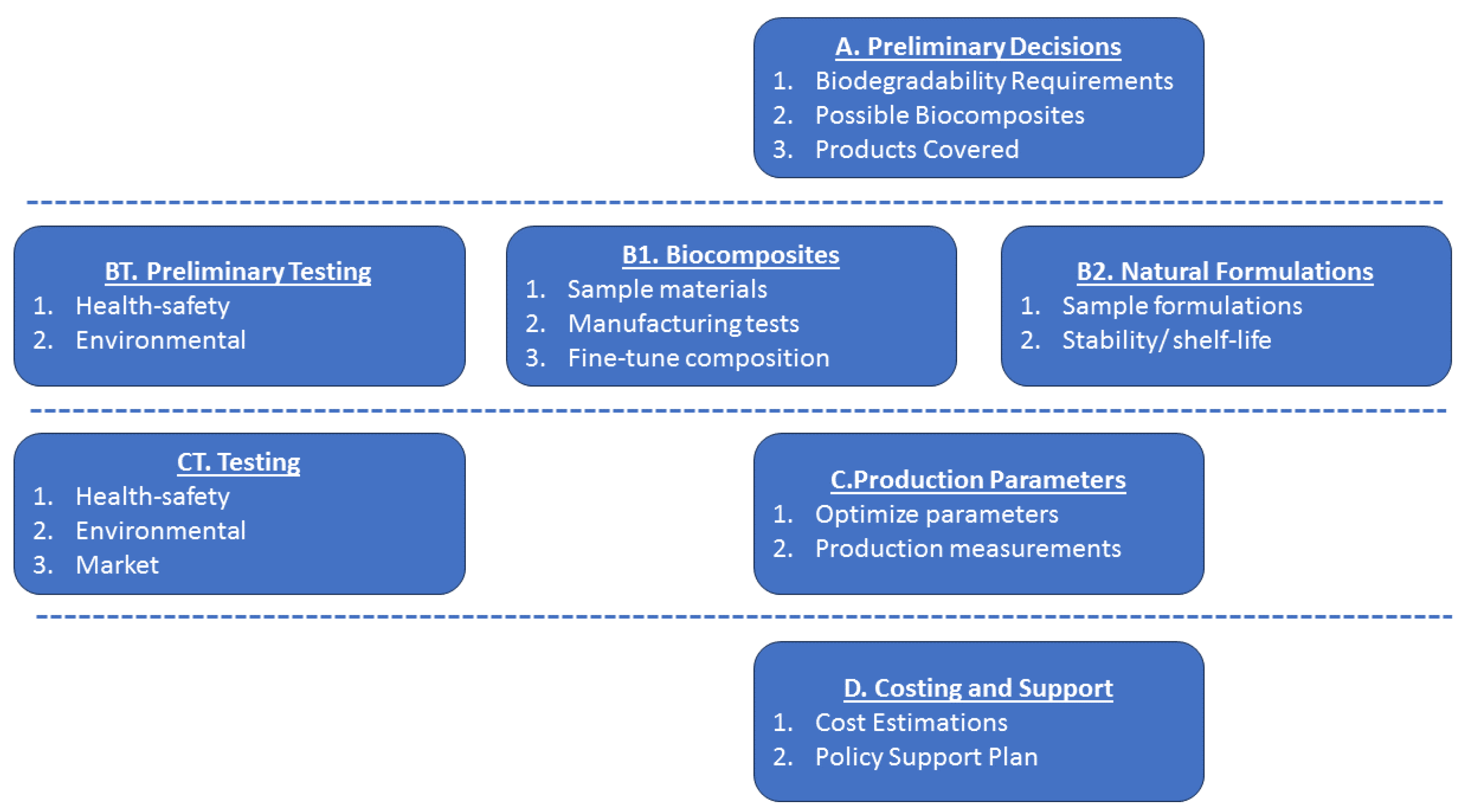

5.3. Proposed Research Program

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, S. Exploratory analysis of global cosmetics industry: Major players, technology and market trends. Technovation 2005, 25, 1263–1272. [Google Scholar] [CrossRef]

- Prothero, A.; McDonagh, P. Producing Environmentally Acceptable Cosmetics? The Impact of Environmentalism on the United Kingdom Cosmetics and Toiletries Industry. J. Mark. Manag. 1992, 8, 147–166. [Google Scholar] [CrossRef]

- Morganti, P.; Lohani, A.; Gagliardini, A.; Morganti, G.; Coltelli, M.-B. Active Ingredients and Carriers in Nutritional Eco-Cosmetics. Compounds 2023, 3, 122–141. [Google Scholar] [CrossRef]

- Cubas, A.L.V.; Bianchet, R.T.; dos Reis, I.M.A.S.; Gouveia, I.C. Plastics and Microplastic in the Cosmetic Industry: Aggregating Sustainable Actions Aimed at Alignment and Interaction with UN Sustainable Development Goals. Polymers 2022, 14, 4576. [Google Scholar] [CrossRef] [PubMed]

- Taylor, K.; Rego-Alvarez, L. Regulatory drivers in the last 20 years towards the use of in silico techniques as replacements to animal testing for cosmetic-related substances. Comput. Toxicol. 2020, 142, 100112. [Google Scholar] [CrossRef]

- Gao, P.; Lei, T.; Jia, L.; Yury, B.; Zhang, Z.; Du, Y.; Fang, Y.; Xing, B. Bioaccessible trace metals in lip cosmetics and their health risks to female consumers. Environ. Pollut. 2018, 238, 554–561. [Google Scholar] [CrossRef]

- Bilal, M.; Mehmood, S.; Iqbal, H.M.N. The Beast of Beauty: Environmental and Health Concerns of Toxic Compounds in Cosmetics. Cosmetics 2020, 7, 13. [Google Scholar] [CrossRef]

- Teo, T.L.L.; Coleman, H.M.; Khan, S.J. Chemical contaminants in swimming pools: Occurrence, implications and control. Environ. Int. 2015, 76, 16–31. [Google Scholar] [CrossRef]

- Jurado, A.; Gago-Ferrero, P.; Vazquez-Sune, E.; Carrera, J.; Pujades, E.; Diaz-Cruz, M.S.; Barcelo, D. Urban groundwater contamination by residues of UV filters. J. Hazard. Mater. 2014, 271, 141–149. [Google Scholar] [CrossRef]

- Tang, Z.; Han, X.; Li, G.; Tian, S.; Yang, Y.; Zhong, F.; Han, Y.; Yang, J. Occurrence, distribution and ecological risk of ultraviolet absorbents in water and sediment from Lake Chaohu and its inflowing rivers, China. Ecotoxicol. Environ. Saf. 2018, 164, 540–547. [Google Scholar] [CrossRef]

- Juliano, C.; Magrini, G.A. Cosmetic Ingredients as Emerging Pollutants of Environmental and Health Concern. A Mini-Review. Cosmetics 2017, 4, 11. [Google Scholar] [CrossRef]

- Giokas, D.L.; Salvador, A.; Chisvert, A. UV filters: From sunscreens to human body and the environment. Trends Anal. Chem. 2007, 26, 360–374. [Google Scholar] [CrossRef]

- Sanchez-Quilez, D.; Tovar-Sanchez, A. Are sunscreens a new environmental risk associated with coastal tourism. Environ. Int. 2017, 83, 158–170. [Google Scholar] [CrossRef]

- Jaini, A.; Quoquab, F.; Mohammad, J.; Hussin, N. I buy green products, do you...? The moderating effect of eWOM on green purchase behavior in Malaysian cosmetics industry. Int. J. Pharm. Healthc. Mark. 2020, 14, 89–112. [Google Scholar] [CrossRef]

- Zhou, Y.; Ashokkumar, V.; Amobonye, A.; Bhattacharjee, G.; Sirohi, R.; Singh, V.; Flora, G.; Kumar, V.; Pillai, S.; Zhang, Z.; et al. Current research trends on cosmetic microplastic pollution and its impacts on the ecosystem: A review. Environ. Pollut. 2023, 320, 121106. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, W.; Ye, S.; Batista, L. Packaging design for the circular economy: A systematic review. Sustain. Prod. Consum. 2022, 32, 817–832. [Google Scholar] [CrossRef]

- Ogor, G. How to Address France’s AGEC Law. Glob. Cosmet. Ind. 2023, 191, DM2. [Google Scholar]

- Grappe, C.G.; Lombart, C.; Louis, D.; Durif, F. Clean labeling: Is it about the presence of benefits or the absence of detriments? Consumer response to personal care claims. J. Retail. Consum. Serv. 2022, 65, 102893. [Google Scholar] [CrossRef]

- The Courage to Change. Available online: https://britishbeautycouncil.com/wp-content/uploads/2021/03/the-courage-to-change.pdf (accessed on 20 August 2023).

- Packaging Innovation Tracker: Refillables, Waste Reduction & More. Global Cosmetic Industry 2023. Available online: https://gcimagazine.texterity.com/gcimagazine/january_2023/MobilePagedArticle.action?articleId=1847474#articleId1847474 (accessed on 3 March 2023).

- Gatt, I.J.; Refalo, P. Reusability and recyclability of plastic cosmetic packaging: A life cycle assessment. Resour. Conserv. Recycl. Adv. 2022, 15, 200098. [Google Scholar] [CrossRef]

- Girotto, G. Sustainability and Green Strategies in the Cosmetic Industry: Analysis of Natural and Organic Cosmetic Products from the Value Chain to Final Certification. Master’s Thesis, Universita Cá Foscari Di Venezia, Venezia, Italy, 2012. [Google Scholar]

- De Abreu Sofiatti Dalmarco, D.; Hamza, K.M.; Aoqui, C. The implementation of product development strategies focused on sustainability: From Brazil—The case of Natura Sou Cosmetics brand. Environ. Qual. Manag. 2015, 24, 1–5. [Google Scholar] [CrossRef]

- Bennett, T.M.; Portal, J.; Jeanne-Rose, V.; Taupin, S.; Ilchev, A.; Irvine, D.J.; Howdle, S.M. Synthesis of model terpene-derived copolymers in supercritical carbon dioxide for cosmetic applications. Eur. Polym. J. 2021, 157, 110621. [Google Scholar] [CrossRef]

- Aguirre, A. Sustainability Improvement in Luxury Packaging: A Case Study in Giorgio Armani and Helena Rubinstein Brands. Master’s Thesis, Aalto University, Bordeaux, France, 20 June 2020. [Google Scholar]

- De, S.K.; Kawda, P.; Gupta, D.; Pragya, N. Packaging plastic waste management in the cosmetic industry. Manag. Environ. Qual. 2023, 34, 820–942. [Google Scholar] [CrossRef]

- Drobac, J.; Alivojvodic, F.; Maksic, P.; Stamenovic, M. Green Face of Packaging–Sustainability Issues of the Cosmetic Industry Packaging. In MATEC Web of Conferences 318; EDP Sciences: Les Ulis, France, 2020; p. 01022. [Google Scholar]

- Martins, A.M.; Marto, J.M. A sustainable life cycle for cosmetics: From design and development to post-use phase. Sustain. Chem. Pharm. 2023, 35, 101178. [Google Scholar] [CrossRef]

- Global Lipstick Market. Available online: https://www.techsciresearch.com/report/global-lipstick-market/1268.html (accessed on 20 August 2023).

- Product Roundup: Unique Packaging, Formulations & More. Global Cosmetic Industry 2023. Available online: https://gcimagazine.texterity.com/gcimagazine/january_2023/MobilePagedArticle.action?articleId=1847465#articleId1847465 (accessed on 3 March 2023).

- Color Cosmetics Packaging & Ingredient Launches. Global Cosmetic Industry 2023. Available online: https://www.gcimagazine.com/packaging/color-cosmetics/article/22631232/color-cosmetics-packaging-ingredient-launches (accessed on 3 March 2023).

- Packaging Innovation Trend Tracker. Global Cosmetic Industry 2023. Available online: https://www.gcimagazine.com/packaging/article/22860488/packaging-innovation-trend-tracker (accessed on 3 March 2023).

- Packaging Trends + Launches. Global Cosmetic Industry 2023. Available online: https://gcimagazine.texterity.com/gcimagazine/april_2023/MobilePagedArticle.action?articleId=1868685#articleId1868685 (accessed on 3 March 2023).

- Packaging Innovation Trend Tracker. Global Cosmetic Industry 2023. Available online: https://www.gcimagazine.com/packaging/article/22863487/packaging-innovation-trend-tracker (accessed on 3 March 2023).

- Caruana, P. Ethical Consumerism in the Cosmetics Industry: Measuring How Important Sustainability Is to the Female Consumer. Bachelor’s Thesis, University of Twente, Enschede, The Netherlands, 26 June 2020. [Google Scholar]

- Linda, K.; Christoph, S.; Nikolas, N.; Christian, W. Sustainable Circular Packaging Design: A Systematic Literature Review on Strategies and Applications in the Cosmetics Industry. In Proceedings of the International Conference on Engineering Design ICED23, Bordeaux, France, 24–28 July 2023. [Google Scholar]

- Bom, S.; Jorge, J.; Ribeiro, H.M.; Marto, J. A step forward on sustainability in the cosmetics industry: A review. J. Clean. Prod. 2019, 225, 270–290. [Google Scholar] [CrossRef]

- Rocca, R.; Acerbi, F.; Fumagalli, L.; Taisch, M. Sustainability paradigm in the cosmetics industry: State of the art. Clean. Waste Syst. 2022, 21, 100057. [Google Scholar] [CrossRef]

- Liobikiene, G.; Bernatoniene, J. Why determinants of green purchase cannot be treated equally? The case of green cosmetics: Literature review. J. Clean. Prod. 2017, 162, 109–120. [Google Scholar] [CrossRef]

- Lewis, H.; Fitzpatrick, L.; Verghese, K.; Sonneveld, K.; Jordon, R.; Alliance, S.P. Sustainable Packaging Redefined; Sustainable Packaging Alliance: Melbourne, Australia, 2007. [Google Scholar]

- U.S. Environmental Protection Agency Comments on the Federal Trade Commission’s Proposed Rule entitled “Guides for the Use of Environmental Marketing Claims”. Available online: https://s3.documentcloud.org/documents/23789593/epa-comments-to-ftc.pdf (accessed on 20 August 2023).

- Impact of French Anti-Waste Law on the Cosmetics Sector. Available online: https://www.toxpartner.com/articles/impact-of-anti-waste-law-on-the-cosmetics-sector/ (accessed on 5 September 2023).

- Handling Recycling in Life Cycle Assessment. Available online: https://earthshiftglobal.com/client_media/files/pdf/Handling_Recycling_in_Life_Cycle_Assessment_2019-11-15.pdf (accessed on 20 August 2023).

- Ren, Z.; Zhang, D.; Gao, Z. Sustainable design strategy of cosmetic packaging in China based on life cycle assessment. Sustainability 2022, 14, 8155. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Voigt, S.; Walter, D.; Fullana-i-Palmer, P. Improving the production chain with LCA and eco-design: Application to cosmetic packaging. Resour. Conserv. Recycl. 2019, 151, 104475. [Google Scholar] [CrossRef]

- Kash, D.E. Impact Assessment Premises–Right and Wrong. Impact Assess. 1982, 1, 5–14. [Google Scholar] [CrossRef][Green Version]

- Lawless, E.W. Anticipating Technologically-Derived Risk. Impact Assess. 1982, 1, 54–66. [Google Scholar] [CrossRef][Green Version]

- Meijer, L.J.J.; van Emmerik, T.; van der Ent, R.; Schmidt, C.; Lebreton, L. More than 1000 rivers account for 80% of global riverine plastic emissions into the ocean. Sci. Adv. 2021, 7, eaaz5803. [Google Scholar] [CrossRef] [PubMed]

- Dube, S.; Dube, M. SomPack: If You Can’t Beat Them, Join Them? Ivey Publishing/Harvard Business Case Collection: London, ON, Canada, 2010. [Google Scholar]

- Todd, A.M. The aesthetic turn in green marketing: Environmental consumer ethics of natural personal care products. Ethics Environ. 2004, 86–102. [Google Scholar] [CrossRef]

- The Body Shop Case Analysis. The Challenges of Managing Business as Holistic Configuration. Available online: https://www.researchgate.net/profile/Vladimir-Korovkin-2/publication/341255107_The_Body_Shop_Case_Analysis_The_Challenges_of_Managing_Business_As_Holistic_Configuration/links/5eb9469e92851cd50da8d7b8/The-Body-Shop-Case-Analysis-The-Challenges-of-Managing-Business-As-Holistic-Configuration.pdf (accessed on 31 May 2023).

- Peattie, K.; Crane, A. Green marketing: Legend, myth, farce or prophesy? Qual. Mark. Res. Int. J. 2005, 8, 357–370. [Google Scholar] [CrossRef]

- Fortunati, S.; Martiniello, L.; Morea, D. The Strategic Role of the Corporate Social Responsibility and Circular Economy in the Cosmetic Industry. Sustainability 2020, 12, 5120. [Google Scholar] [CrossRef]

- Morea, D.; Fortunati, S.; Martiniello, L. Circular economy and corporate social responsibility: Towards an integrated strategic approach in the multinational cosmetics industry. J. Clean. Prod. 2021, 315, 128232. [Google Scholar] [CrossRef]

- Tiscini, R.; Martiniello, L.; Lombardi, R. Circular economy and environmental disclosure in sustainability reports: Empirical evidence in cosmetic companies. Bus. Strategy Environ. 2022, 31, 892–907. [Google Scholar] [CrossRef]

- Amberg, N.; Magda, R. Environmental Pollution and Sustainability or the Impact of the Environmentally Conscious Measures of International Cosmetic Companies on Purchashing Organic Cosmetics. Visegr. J. Bioecon. Sustain. Dev. 2018, 7, 23–30. [Google Scholar] [CrossRef]

- Kolling, C.; Ribeiro, J.L.D.; de Medeiros, J.F. Performance of the cosmetics industry from the perspective of Corporate Social Responsibility and Design for Sustainability. Sustain. Prod. Consum. 2022, 30, 171–185. [Google Scholar] [CrossRef]

- De Carvalho, A.P.; Barbieri, J.C. Innovation and Sustainability in the Supply Chain of a Cosmetics Company: A Case Study. J. Technol. Manag. Innov. 2012, 7, 144–156. [Google Scholar] [CrossRef]

- Berard, C.; Szostak, B.; Abdesselam, R. Corporate Social Responsibility: A Driving Force for Exploration and Exploitation in SMEs? J. Innov. Econ. Manag. 2022, 38, 119–146. [Google Scholar] [CrossRef]

- Bocquet, R.; Mothe, C.D. Exploring the relationship between CSR and innovation: A comparison between small and largesized French companies. Rev. Sci. Gest. 2011, 80, 101–119. [Google Scholar]

- Dijkstra, H.; van Beukering, P.; Broiwer, R. Business models and sustainable plastic management: A systematic review of the literature. J. Clean. Prod. 2020, 258, 120967. [Google Scholar] [CrossRef]

- Etcoff, N.L.; Stock, S.; Haley, L.E.; Vickery, S.A.; House, D.M. Cosmetics as a feature of the extended human phenotype: Modulation of the perception of biologically important facial signals. PLoS ONE 2011, 6, e25656. [Google Scholar] [CrossRef]

- 4 Trends Driving Color Cosmetics’ Pandemic Comeback. Global Cosmetic Industry, 2023. Available online: https://www.gcimagazine.com/brands-products/color-cosmetics/article/22631225/4-trends-driving-color-cosmetics-pandemic-comeback (accessed on 3 March 2023).

- Lochhead, R.Y.; Anderson, L. Intellectual Property Trends in Color Cosmetics; Intellectual Property: Beijing, China, 2009; Volume 8, p. 9. [Google Scholar]

- Lipstick Market by Product Type and Distribution Channel. Available online: https://www.alliedmarketresearch.com/lipstick-market (accessed on 5 September 2023).

- Lipstick Market Analysis. Available online: https://www.coherentmarketinsights.com/market-insight/lipstick-market-3060 (accessed on 20 August 2023).

- Lipstick Market Size and Forecast. Available online: https://www.verifiedmarketresearch.com/product/global-lipstick-market-size-and-forecast/ (accessed on 20 August 2023).

- How Department Stores Lost Their Clout in the Beauty Industry to Ulta, E-Commerce and Influencers. Available online: https://www.cnbc.com/2019/12/27/how-department-stores-lost-their-clout-in-the-beauty-industry.html (accessed on 5 September 2023).

- Plunkett, J.W. Plunkett’s Consumer Products, Cosmetics, Hair & Personal Services Industry Almanac 2023; Plunkett Research: Houston, TX, USA, 2023. [Google Scholar]

- Jain, J.; Bhatti, N.; Baker, H.; Chao, H.; Dekhil, M.; Harville, M.; Lyons, N.; Schettino, J.; Susstrunk, S. Color match: An imaging based mobile cosmetics advisory service. In Proceedings of the 10th International Conference on Human Computer Interaction with Mobile Devices and Services, Amsterdam, The Netherlands, 2–5 September 2008; pp. 331–334. [Google Scholar]

- Makeup Market Size. Available online: https://www.fortunebusinessinsights.com/makeup-market-102587 (accessed on 20 August 2023).

- The Malaysian Government Tells Women to Wear Makeup and Tight Clothes for Their Husbands During Quarantine. Available online: https://www.eviemagazine.com/post/the-malaysian-government-tells-women-to-wear-makeup-and-tight-clothes-for (accessed on 5 September 2023).

- Gleason-Allured, J. 3 Things to Watch in 2023. Glob. Cosmet. Ind. 2023, 191, 5. [Google Scholar]

- Bellomo, M.; Pleyers, G. Sustainable Cosmetics: The Impact of Packaging Materials, Environmental Concern and Subjective Norm on Green Consumer Behaviour. Master’s Thesis, Louvain School of Management, Université Catholique de Louvain, Louvain-la-Neuve, Belgium, 2021. [Google Scholar]

- Cosmetics & Personal Care. Available online: https://www.statista.com/markets/415/topic/467/cosmetics-personal-care/#statistic2 (accessed on 8 September 2023).

- Lipstick and Lipstains Market. Available online: https://www.stellarmr.com/report/Lipstick-and-Lipstains-Market/1036 (accessed on 20 August 2023).

- Lipstick Market. Available online: https://www.imarcgroup.com/lipstick-market (accessed on 20 August 2023).

- Press Release: Mascara Market 2023 Research Report. Available online: https://www.wicz.com/story/48325872/Mascara-Market-2023-Research-Report-which-Shows-Huge-Growth-Rate-Revenue-Progress-Insight-and-Forecast-to-2028 (accessed on 20 August 2023).

- Cosmetic Packaging Market Size & Industry Forecast. Available online: https://www.fortunebusinessinsights.com/cosmetic-packaging-market-102130 (accessed on 20 August 2023).

- Makeup Packaging Market. Available online: https://www.coherentmarketinsights.com/market-insight/makeup-packaging-market-3051 (accessed on 20 August 2023).

- Marinova, V. Trends in packaging sector. Izv. J. Union Sci.—Varna 2021, 10, 3–13. [Google Scholar]

- Plastic Packaging Market Size Worth USD 317463.4 Million by 2030, Displaying Growth at a Rate of 4.70%. Available online: https://www.globenewswire.com/en/news-release/2023/06/15/2688626/0/en/Plastic-Packaging-Market-Size-worth-USD-317463-4-million-by-2030-displaying-growth-at-a-rate-of-4-70-Report-by-Market-Research-Future-MRFR.html (accessed on 20 August 2023).

- Plastic Packaging Market. Available online: https://www.grandviewresearch.com/industry-analysis/plastic-packaging-market (accessed on 20 August 2023).

- Walker, T.R.; Fequet, L. Current trends of unsustainable plastic production and micro(nano) plastic pollution. Trends Anal. Chem. 2023, 160, 116984. [Google Scholar] [CrossRef]

- Navarre, N.; Mogollón, J.M.; Tukker, A.; Barbarossa, V. Recycled plastic packaging from the Dutch food sector pollutes Asian oceans. Resour. Conserv. Recycl. 2022, 185, 106508. [Google Scholar] [CrossRef]

- L’Oreal2021 Report. Available online: https://ellenmacarthurfoundation.org/global-commitment-2021/signatory-reports/ppu/loreal#key-metrics (accessed on 20 August 2023).

- Top 20 Companies. Available online: https://www.beautypackaging.com/heaps/view/10647/1/441978/ (accessed on 20 August 2023).

- L’Oreal2021 Report. Available online: https://ellenmacarthurfoundation.org/global-commitment-2021/signatory-reports/ppu/unilever (accessed on 20 August 2023).

- Environmental-Waste. Available online: https://www.pginvestor.com/esg/environmental/plastic-packaging/default.aspx (accessed on 20 August 2023).

- Plastic Packaging Market Size & Share Analysis. Available online: https://www.mordorintelligence.com/industry-reports/plastic-packaging-market (accessed on 20 August 2023).

- Law, K.L.; Narayan, R. Reducing environmental plastic pollution by designing polymer materials for managed end-of-life. Nat. Rev. Mater. 2022, 7, 104–116. [Google Scholar] [CrossRef]

- Lebreton, L.; Royer, S.J.; Peytavin, A.; Strietman, W.J.; Smeding-Zuurendonk, I.; Egger, M. Industrialised fishing nations largely contribute to floating plastic pollution in the North Pacific subtropical gyre. Sci. Rep. 2022, 12, 12666. [Google Scholar] [CrossRef]

- The Most Dangerous Single Source of Ocean Plastic No One Wants to Talk About. Available online: https://www.seashepherdglobal.org/latest-news/marine-debris-plastic-fishing-gear/ (accessed on 20 August 2023).

- Ghost Gear: The Abandoned Fishing Nets Haunting Our Oceans. Available online: https://www.greenpeace.org/static/planet4-international-stateless/2019/11/8f290a4f-ghostgearfishingreport2019_greenpeace.pdf (accessed on 20 August 2023).

- White, D.; Winchester, N. The Plastic Intensity of Industries in the USA: The Devil Wears Plastic. Environ. Model. Assess. 2023, 28, 15–28. [Google Scholar] [CrossRef]

- Anagnosti, L.; Varvaresou, A.; Pavlou, P.; Protopapa, E.; Carayanni, V. Worldwide actions against plastic pollution from microbeads and microplastics in cosmetics focusing on European policies. Has the issue been handled effectively? Mar. Pollut. Bull. 2021, 162, 111883. [Google Scholar] [CrossRef] [PubMed]

- ‘Clean’ Beauty Has Taken over the Cosmetics Industry, but That’s about All Anyone Agrees On. Available online: https://static1.squarespace.com/static/5e7b7a51a6ae892949d34c86/t/5e8a6ba5e37ead7fc587afcf/1586129829184/What+does+clean+beauty+mean%3F+-+The+Washington+Post+pdf.pdf (accessed on 20 August 2023).

- Is Lush Guilty of Greenwashing? We Take a Closer Look. Available online: https://bettergoods.org/lush/ (accessed on 1 July 2023).

- Boz, Z.; Kothonen, V.; Sand, C.K. Consumer Considerations for the Implementation of Sustainable Packaging: A Review. Sustainability 2020, 12, 2192. [Google Scholar] [CrossRef]

- Schiano, A.N.; Drake, M.A. Sustainability: Different perspectives, inherent conflict. J. Dairy Sci. 2021, 103, 11386–11400. [Google Scholar] [CrossRef]

- Wandosell, G.; Parra-Merono, M.C.; Alcayde, A.; Banos, R. Green Packaging from Consumer and Business Perspectives. Sustainability 2021, 13, 1356. [Google Scholar] [CrossRef]

- Murtas, G.; Pedeliento, G.; Andreini, D. To Pack Sustainably or Not to Pack Sustainably? A Review of the Relationship between Consumer Behaviour and Sustainable Packaging. Manag. Sustain. 2022, 15, 147–168. [Google Scholar]

- Lal, B.S. Green Marketing: Opportunities and Issues. Int. J. Multidiscip. Res. Mod. Educ. 2015, 1, 2454–6119. [Google Scholar]

- Escursell, S.; Llorach-Massana, P.; Roncero, M.B. Sustainability in e-commerce packaging: A review. J. Clean. Prod. 2021, 280, 124314. [Google Scholar] [CrossRef]

- Laroche, M.; Bergeron, J.; Barbaro-Forleo, G. Targeting consumers who are willing to pay more for environmentally friendly products. J. Consum. Mark. 2001, 18, 503–520. [Google Scholar] [CrossRef]

- Herrmann, C.; Rhein, S.; Srater, K.F. Consumers’ sustainability-related perception of and willingness-to-pay for food packaging alternatives. Resour. Conserv. Recycl. 2022, 181, 106216. [Google Scholar] [CrossRef]

- Kardgar, A.K.; Ghosh, D.; Sturve, J.; Agarwal, S.; Almroth, B.C. Chronic poly(L-lactide) (PLA)-microplastic ingestion affects social behavior of juvenile European perch (Perca fluviatilis). Sci. Total Environ. 2023, 88, 163425. [Google Scholar] [CrossRef]

- Boisacq, P.; De Keuster, M.; Prinsen, E.; Jeong, Y.; Bervoets, L.; Eens, M.; Covaci, A.; Willems, T.; Groffen, T. Assessment of poly- and perfluoroalkyl substances (PFAS) in commercially available drinking straws using targeted and suspect screening approaches. Food Addit. Contam. Part A 2023, 40, 1230–1241. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EU) No 1151/2023 of the European Parliament and of the Council of 21 November 2012 on quality schemes for agricultural products and foodstuffs. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2012:343:0001:0029:en:PDF (accessed on 5 September 2023).

- Bellasen, V.; Drut, M.; Hilal, M.; Bodini, A.; Donati, M.; de Labarre, M.D.; Filipović, J.; Gauvrit, L.; Gil, J.M.; Hoang, V.; et al. The economic, environmental and social performance of European certified food. Ecol. Econ. 2022, 191, 107244. [Google Scholar] [CrossRef]

- The Ugly Side of Beauty: The Cosmetics Industry’s Plastic Packaging Problem. Available online: https://www.plasticpollutioncoalition.org/blog/2022/1/25/the-ugly-side-of-beauty-the-cosmetics-industrys-plastic-packaging-problem (accessed on 20 August 2023).

- The Minimalist Beauty Company Tackling The Industry’s Waste Problem. Available online: https://www.forbes.com/sites/lucysherriff/2019/09/17/the-minimalist-beauty-company-tackling-the-industrys-waste-problem/?sh=3d7a2b744326 (accessed on 20 August 2023).

- Environmental Impact of Cosmetics & Beauty Products. Available online: https://www.trvst.world/sustainable-living/environmental-impact-of-cosmetics/ (accessed on 20 August 2023).

- How to Recycle Beauty Products (What Happens with the Packages?). Available online: https://cosmeticworld.ca/blogs/articles/recycle-beauty-products (accessed on 20 August 2023).

- The Sad Truth About Mini and Sample-Sized Beauty Products. Available online: https://www.popsugar.com/beauty/beauty-samples-recycling-problem-48805333 (accessed on 20 August 2023).

- How to Correctly Recycle Your Empty Beauty Products. Available online: https://www.realsimple.com/beauty-fashion/how-to-recycle-beauty-products (accessed on 20 August 2023).

- California Rules: No More No. 1 Resin Code for PETG. Available online: https://www.plasticsnews.com/news/california-rules-no-more-no-1-resin-code-petg (accessed on 5 September 2023).

- Our Packaging. Available online: https://www.thebodyshop.com/en-gb/about-us/brand-values/sustainability/sustainable-packaging/a/a00012 (accessed on 20 August 2023).

- Sustainability. Available online: https://www.un.org/en/academic-impact/sustainability (accessed on 20 August 2023).

- Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 20 August 2023).

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Johnston, P.; Everard, M.; Santillo, D.; Robert, H.-K. Reclaiming the Definition of Sustainability. Environ. Sci. Pollut. Res. Int. 2007, 13, 60–66. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Vargas-Gonzalez, M.; Witte, F.; Martz, P.; Gilbert, L.; Humbert, S.; Jolliet, O.; van Zelm, R.; L’Haridon, J. Operational Life Cycle Impact Assessment weighting factors based on Planetary Boundaries: Applied to cosmetic products. Ecol. Indic. 2019, 107, 105498. [Google Scholar] [CrossRef]

- Hoogmartens, R.; Van Passel, S.; Van Acker, K.; Dubois, M. Bridging the gap between LCA, LCC and CBA as sustainability assessment tools. Environ. Impact Assess. Rev. 2014, 48, 27–33. [Google Scholar] [CrossRef]

- Bridges, J.W.; Greim, H.; van Leeuwen, K.; Stegmann, R.; Vermeire, T.; den Haan, K. Is the EU chemicals strategy for sustainability a green deal? Regul. Toxicol. Pharmacol. 2023, 139, 105356. [Google Scholar] [CrossRef]

- Roy, S. Development, Environment and Poverty: Some Issues for Discussion. Econ. Political Wkly. 1996, 31, PE29–PE41. [Google Scholar]

- COP26: Did India Betray Vulnerable Nations? Available online: https://www.bbc.com/news/world-asia-india-59286790 (accessed on 31 May 2023).

- What It Will Cost to Get to Net-Zero. Available online: https://www.mckinsey.com/mgi/overview/in-the-news/what-it-will-cost-to-get-to-net-zero (accessed on 31 May 2023).

- Don’t Pay UK: Campaign to Boycott Payment of Energy Bills Gathers Pace. Available online: https://www.euronews.com/2022/08/04/dont-pay-uk-campaign-to-boycott-payment-of-energy-bills-gathers-pace (accessed on 31 May 2023).

- Emotion and Pain’ as Dutch Farmers Fight Back against Huge Cuts to Livestock. Available online: https://www.theguardian.com/environment/2022/jul/21/emotion-and-pain-as-dutch-farmers-fight-back-against-huge-cuts-to-livestock (accessed on 31 May 2023).

- Dabla-Norris, E.; Helbling, T.; Khalid, S.; Khan, H.; Magistretti, G.; Sollaci, A.; Srinivasan, S. Public Perceptions of Climate Mitigation Policies: Evidence from Cross-Country Surveys. In IMF Staff Discussion Note SDN2023/002; International Monetary Fund: Washington, DC, USA, 2023. [Google Scholar]

- Exxon Mobil Corporation Proxy Statement Pursuant to Section 14(a) of the Securities Exchange Act of 1934. Available online: https://ir.exxonmobil.com/static-files/da018d10-fb85-4eb9-9251-d2e04f1923d5 (accessed on 31 May 2023).

- An Update on Vanguard’s Engagement with the Net Zero Asset Managers Initiative. Available online: https://corporate.vanguard.com/content/corporatesite/us/en/corp/articles/update-on-nzam-engagement.html (accessed on 31 May 2023).

- Lloyd’s Becomes the 10th Major Player to Mark Its Exit from NZIA. Available online: https://www.reinsurancene.ws/lloyds-becomes-the-10th-major-player-to-mark-its-exit-from-nzia/ (accessed on 31 May 2023).

- Sustainable Packaging Coalition Definition of Sustainable Packaging Version 2.0. Available online: https://web.archive.org/web/20200721011252/https://sustainablepackaging.org/wp-content/uploads/2017/09/Definition-of-Sustainable-Packaging.pdf (accessed on 20 August 2023).

- The Responsible Packaging Code. Available online: https://incpen.org/wp-content/uploads/2018/02/The-Responsible-Packaging-Code.pdf (accessed on 20 August 2023).

- Handbook on Indian Standards on Sustainable Packaging. Available online: https://www.bis.gov.in/wp-content/uploads/2023/01/Final-handbook-coloured_F_compressed.pdf (accessed on 20 August 2023).

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Pollman, F. Corporate Social Responsibility, ESG, and Compliance. In The Cambridge Handbook of Compliance; van Rooij, B., Sokol, D.D., Eds.; Cambridge University Press: Cambridge, UK, 2021; pp. 662–672. [Google Scholar]

- Damanpour, F.; Wischnevsky, J.D. Research on innovation in organizations: Distinguishing innovation-generating from innovation-adopting organizations. J. Eng. Technol. Manag. 2006, 23, 269–291. [Google Scholar] [CrossRef]

- Moldaschl, M. Why Innovation Theories Make no Sense. In Papers and Preprints of the Department of Innovation Research and Sustainable Resource Management; Chemnitz University of Technology: Chemnitz, Germany, 2010. [Google Scholar]

- Suchek, N.; Fernandes, C.I.; Kraus, S.; Filser, M.; Sjorgren, H. Innovation and the circular economy: A systematic literature review. Bus. Strategy Environ. 2021, 30, 3686–3702. [Google Scholar] [CrossRef]

- Intezari, A.; Taskin, N.; Pauleen, D.J. Looking beyond knowledge sharing: An integrative approach to knowledge management culture. J. Knowl. Manag. 2017, 21, 492–515. [Google Scholar] [CrossRef]

- Lopez-Torres, G.C.; Garza-Reyes, J.A.; Maldonado-Guzman, G.; Kumar, V.; Rocha-Lona, L.; Cherrafi, A. Knowledge management for sustainability in operations. Prod. Plan. Control 2019, 30, 813–826. [Google Scholar] [CrossRef]

- Martins, V.W.B.; Rampasso, I.S.; Anholon, R.; Quelhas, O.L.G.; Leal Filho, W. Knowledge management in the context of sustainability: Literature review and opportunities for future research. J. Clean. Prod. 2019, 229, 489–500. [Google Scholar] [CrossRef]

- Sanguankaew, P.; Ractham, V.V. Bibliometric Review of Research on Knowledge Management and Sustainability, 1994–2018. Sustainability 2019, 11, 4388. [Google Scholar] [CrossRef]

- Aubin, S.; Beaugrand, J.; Berteloot, M.; Boutrou, R.; Buche, P.; Gontard, N.; Guillard, V. Plastics in a circular economy: Mitigating the ambiguity of widely-used terms from stakeholders consultation. Environ. Sci. Policy 2022, 134, 119–126. [Google Scholar] [CrossRef]

- Springer, A.; Ziegler, H.; Bach, K. The Influence of Antioxidant Plant Extracts on the Oxidation of O/W Emulsions. Cosmetics 2023, 10, 40. [Google Scholar] [CrossRef]

- Beauty Has a Waste Problem, and It’s Not Packaging. Available online: https://www.voguebusiness.com/sustainability/beauty-has-a-waste-problem-and-its-not-packaging (accessed on 20 August 2023).

- How Travel-Size Beauty Products Are Being Used to Reach New Customers. Available online: https://www.glossy.co/beauty/how-travel-size-beauty-products-are-being-used-to-reach-new-customers/ (accessed on 20 August 2023).

- Ding, B. Pharma Industry 4.0: Literature review and research opportunities in sustainable pharmaceutical supply chains. Process. Saf. Environ. Prot. 2018, 119, 115–130. [Google Scholar] [CrossRef]

- Alejandrino, C.; Mercante, I.T.; Bovea, M.D. Combining O-LCA and O-LCC to support circular economy strategies in organizations: Methodology and case study. J. Clean. Prod. 2022, 336, 130365. [Google Scholar] [CrossRef]

- Puglieri, F.N.; Salvador, R.; Romero-Hernandez, O.; Filho, E.E.; Piekarksi, C.M.; de Francisco, A.C.; Ometto, A.R. Strategic planning oriented to circular business models: A decision framework to promote sustainable development. Bus. Strategy Environ. 2022, 31, 3254–3273. [Google Scholar] [CrossRef]

- Acerbi, F.; Rocca, R.; Fumagalli, L.; Taisch, M. Enhancing the cosmetics industry sustainability through a renewed sustainable supplier selection model. Prod. Manuf. Res. 2023, 11, 2161021. [Google Scholar] [CrossRef]

- Cinelli, P.; Coltelli, M.B.; Signori, F.; Morganti, P.; Lazzeri, A. Cosmetic Packaging to Save the Environment: Future Perspectives. Cosmetics 2019, 6, 26. [Google Scholar] [CrossRef]

- Rosenow, P.; Destler, E.; Springer, A. The Search for Suitable Packaging for Cosmetics—A Case Study. SOFW J. 2022, 148, 56–59. [Google Scholar]

- Klitkou, A.; Bolwig, S.; Hansen, T.; Wessberg, N. The role of lock-in mechanisms in transition processes: The case of energy for road transport. Environ. Innov. Soc. Transit. 2015, 16, 22–37. [Google Scholar] [CrossRef]

- Poma, L.; Al Shawwa, H.; Nicolli, F.; Quaglietti, V. Towards sustainability: The Impact of Environmental Sustainability of Consumer Goods in the Italian Packaging Sector. Transnatl. Mark. J. 2022, 10, 443–457. [Google Scholar]

- Jager-Roschko, M.; Petersen, M. Advancing the circular economy through information sharing: A systematic literature review. J. Clean. Prod. 2022, 369, 133210. [Google Scholar] [CrossRef]

- Ali, S.S.; Abdelkarim, E.A.; Elsamahy, T.; Al-Tohamy, R.; Li, F.; Kornaros, M.; Zuorro, A.; Zhu, D.; Sun, J. Bioplastic production in terms of life cycle assessment: A state-of-the-art review. Environ. Sci. Ecotechnol. 2023, 15, 100254. [Google Scholar] [CrossRef]

- Dube, M.; Dube, S. SomPack: Succession planning gone wrong. Emerald Emerg. Mark. Case Stud. 2021, 11, 1–33. [Google Scholar] [CrossRef]

- Kayicki, Y.; Kazanoglu, Y.; Gozacan-Chase, N.; Lafci, C.; Batista, L. Assessing smart circular supply chain readiness and maturity level of small and medium-sized enterprises. J. Bus. Res. 2022, 149, 375–392. [Google Scholar]

- Dangelico, R.M.; Volcalelli, D. Green Marketing: An analysis of definitions, strategy steps, and tools through a systematic review of the literature. J. Clean. Prod. 2017, 165, 1263–1279. [Google Scholar] [CrossRef]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- A European Strategy for Plastics in a Circular Economy—Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 31 May 2023).

- Stumpf, L.; Schoggl, J.-P.; Baumgartner, R.J. Circular plastics packaging—Prioritizing resources and capabilities along the supply chain. Technol. Forecast. Soc. Chang. 2023, 188, 122261. [Google Scholar] [CrossRef]

- Heredia-Colaco, V. Pro-environmental messages have more effect when they come from less familiar brands. J. Prod. Brand Manag. 2023, 32, 436–453. [Google Scholar] [CrossRef]

- Morin, C. Neuromarketing: The new science of consumer behavior. Society 2011, 48, 131–135. [Google Scholar] [CrossRef]

- Stokes, P. Brain Power. Acuity 2015, 2, 44–47. [Google Scholar]

- Adhami, M. Using Neuromarketing to Discover How We Really Feel About Apps. Int. J. Mob. Mark. 2013, 8, 95–103. [Google Scholar]

- Chun, R. What Holds Ethical Consumers to a Cosmetics Brand: The Body Shop Case. Bus. Soc. 2016, 55, 528–549. [Google Scholar] [CrossRef]

- Yenipazarli, A.; Vakharia, A. Pricing, market coverage and capacity: Can green and brown products co-exist? Eur. J. Oper. Res. 2015, 242, 304–315. [Google Scholar] [CrossRef]

- Cosentino, C.; Freschi, P.; Paolino, R.; Valentini, V. Market sustainability analysis of jenny milk cosmetics. Emir. J. Food Agric. 2013, 25, 635–340. [Google Scholar] [CrossRef]

- Sundar, A.; Cao, E.S.; Machleit, K.A. How product aesthetics cues efficacy beliefs of product performance. Psychol. Mark. 2020, 37, 1246–1262. [Google Scholar] [CrossRef]

- Sundar, A.; Noseworthy, T.; Machleit, K. Beauty in a bottle: Package aesthetics cues efficacy beliefs of product performance. In Proceedings of the ACR North American Advances, vol 41, eds. Simona Botti and Aparna Labroo, Chicago, IL, USA, 2013, 3–6 October; pp. 400–404.

- Srivastava, P.; Ramakanth, D.; Akhila, K.; Gaikwad, K.K. Package design as a branding tool in the cosmetic industry: Consumers’ perception vs. reality. SN Bus. Econ. 2022, 2, 58. [Google Scholar] [CrossRef] [PubMed]

- Sung, I. Interdisciplinary Literaure Analysis between Cosmetic Container Design and Customer Purchasing Intention. J. Ind. Distrib. Bus. 2021, 12, 21–29. [Google Scholar]

- Koetting, S.L. The Power of Packaging’s Visual Influence. Glob. Cosmet. Ind. 2023, 191, 36–39. [Google Scholar]

- Mohammed, N.B.; Medina, I.G.; Romo, Z.G. The effect of cosmetics packaging design on consumers’ purchase decisions. Indian J. Mark. 2018, 48, 50–61. [Google Scholar] [CrossRef]

- Herich, D. Beauty Shoppers Reveal their Packaging Attitudes. Glob. Cosmet. Ind. 2023, 191, 38–42. [Google Scholar]

- Packaging Trend Tracker: Resolving Brands’ Challenges Global Cosmetic Industry 2023. Available online: https://www.gcimagazine.com/packaging/dispensing/article/22866386/packaging-trend-tracker-resolving-brands-challenges (accessed on 3 March 2023).

- Salem, M.Z. Effects of perfume packaging on Basque female consumers purchase decision in Spain. Manag. Decis. 2018, 56, 1748–1768. [Google Scholar] [CrossRef]

- Holzer, D.; Rauter, R.; Fleib, E.; Stern, T. Mind the gap: Towards a systematic circular economy encouragement of small and medium-sized companies. J. Clean. Prod. 2021, 98, 126696. [Google Scholar] [CrossRef]

- Colijn, I.; Fraiture, F.; Gommeh, E.; Schroën, K.; Metze, T. Science and media framing of the future of plastics in relation to transitioning to a circular economy. J. Clean. Prod. 2022, 370, 133472. [Google Scholar] [CrossRef]

- Dugo, G.; Mancuso, T.; Massa, C.; Zerbo, A.; Gatto, S. Recycling of plastic materials obtaining second raw materials in a circular economy perspective. Procedia Environ. Sci. Eng. Manag. 2020, 7, 167–174. [Google Scholar]

- Sastre, R.M.; de Paula, I.C.; Echeveste, M.E.S.; Greaves, A.J. A Systematic Literature Review on Packaging Sustainability: Contents, Opportunities, and Guidelines. Sustainability 2022, 14, 6727. [Google Scholar] [CrossRef]

- Bom, S.; Gouveia, L.P.; Pinto, P.; Martins, A.M.; Ribeiro, H.M.; Marto, J. A mathematical modeling strategy to predict the spreading behavior on skin of sustainable alternatives to personal care emollients. Colloids Surf. B Biointerfaces 2021, 205, 111865. [Google Scholar] [CrossRef] [PubMed]

- Luengo, G.S.; Fameau, A.-L.; Leonforte, F.; Greaves, A.J. Surface science of cosmetic substrates, cleansing actives and formulations. Adv. Colloids Interface Sci. 2021, 290, 102383. [Google Scholar] [CrossRef] [PubMed]

- Calvo, F.; Gomez, J.M.; Ricardez-Sandoval, L.; Alvarez, O. Integrated design of emulsified cosmetic products: A review. Impact Assess. 1982, 1, 30–43. [Google Scholar] [CrossRef]

- Groening, C.; Sarkis, J.; Zhu, Q. Green marketing consumer-level theory review: A compendium of applied theories and further research directions. J. Clean. Prod. 2018, 172, 1848–1866. [Google Scholar] [CrossRef]

- Testa, F.; Cosic, A.; Iraldo, F. Determining factors of curtailment and purchasing energy related behaviours. J. Clean. Prod. 2018, 112, 3810–3819. [Google Scholar] [CrossRef]

- Yuriev, A.; Dahmen, M.; Paille, P.; Boiral, O.; Guillaumie, L. Pro-environmental behaviors through the lens of the theory of planned behavior: A scoping review. Resour. Conserv. Recycl. 2020, 155, 104660. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, F. Why Do Consumers Make Green Purchase Decisions? Insights from a Systematic Review. Int. J. Environ. Res. Public Health 2020, 17, 6607. [Google Scholar] [CrossRef]

- Askadilla, W.L.; Krisjanti, M.N. Understanding indonesian green consumer behavior on cosmetic products: Theory of planned behavior model. Pol. J. Manag. Stud. 2017, 15, 7–15. [Google Scholar] [CrossRef]

- Chin, J.; Jiang, B.C.; Mufidah, I.; Persada, S.F.; Noer, B.A. The investigation of consumers’ behavior intention in using green skincare products: A pro-environmental behavior model approach. Sustainability 2018, 10, 3922. [Google Scholar] [CrossRef]

- Lestari, D.D. Green Cosmetic Purchase Intention: Impact of Green Brand Positioning, Attitude, and Knowledge. Bachelor’s Thesis, Universitas Islam Indonesia, Yogyakarta, Indonesia, 2020. [Google Scholar]

- Suphasomboon, T.; Vassanadumrongdee, S. Toward sustainable consumption of green cosmetics and personal care products: The role of perceived value and ethical concern. Sustain. Prod. Consum. 2022, 33, 230–243. [Google Scholar] [CrossRef]

- Grădinaru, C.; Obadă, D.R.; Grădinaru, I.A.; Dabija, D.C. Enhancing Sustainable Cosmetics Brand Purchase: A Comprehensive Approach Based on the SOR Model and the Triple Bottom Line. Sustainability 2022, 14, 14118. [Google Scholar] [CrossRef]

- Muralidhar, S.; Naresh, N.R.; Sharmila, A.; Shwetha, B.V.; Ramesh, S. Consumer Consideration for Herbal Cosmetic Products with respect to Present Scenario. J. Pharm. Negat. Results 2023, 14, 2594–2601. [Google Scholar]

- Patnaik, A.; Tripathy, S.; Dash, A. Identifying the features influencing sustainable products: A study on green cosmetics. In Advances in Mechanical Processing and Design: Select Proceedings of ICAMPD 2019; Springer: Singapore, 2021; pp. 631–640. [Google Scholar]

- Acharya, S.; Bali, S.; Bhatia, B.S. Exploring consumer behavior towards sustainability of green cosmetics. In Proceedings of the IEEE 2021 International Conference on Advances in Electrical, Computing, Communication and Sustainable Technologies (ICAECT), Bhilai, India, 19–20 February 2021; pp. 1–6. [Google Scholar]

- Amberg, N.; Fogarassy, C. Green Consumer Behavior in the Cosmetics Market. Resources 2019, 8, 137. [Google Scholar] [CrossRef]

- Grappe, C.G.; Lombart, C.; Louis, D.; Durif, F. “Not tested on animals”: How consumers react to cruelty-free cosmetics proposed by manufacturers and retailers? Int. J. Retail. Distrib. Manag. 2021, 49, 1532–1553. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, S.; Hanifah, H.; Iqbal, Q. An Exploratory Study of Consumer Attitudes toward Green Cosmetics in the UK Market. Adm. Sci. 2018, 8, 71. [Google Scholar] [CrossRef]

- Mugobo, V.V.; Ntuli, H.; Iwu, C.G. Consumer Perceptions of the Use of Nondegradable Plastic Packaging and Environmental Pollution: A Review of Theories and Empirical Literature. J. Risk Financ. Manag. 2022, 15, 244. [Google Scholar] [CrossRef]

- Wojciechowska, P.; Wiszumirska, K. Sustainable Communication in the B2C Market—The Impact of Packaging. Sustainability 2022, 14, 2824. [Google Scholar] [CrossRef]

- Long, Y.; Ceschin, F.; Harrison, D.; Terzioğlu, N. Exploring and Addressing the User Acceptance Issues Embedded in the Adoption of Reusable Packaging Systems. Sustainability 2022, 14, 6146. [Google Scholar] [CrossRef]

- Shimul, A.S.; Cheah, I. Consumers’ preference for eco-friendly packaged products: Pride vs guilt appeal. Mark. Intell. Plan. 2023, 41, 186–198. [Google Scholar] [CrossRef]

- Vincent, F.Y.; Aloina, G.; Eccarius, T. Adoption intentions of home-refill delivery service for fast-moving consumer goods. Transp. Res. Part E Logist. Transp. Rev. 2023, 171, 103041. [Google Scholar]

- Wu, S.; Gong, X.; Wang, Y.; Cao, J. Consumer cognition and management perspective on express packaging pollution. Int. J. Environ. Res. Public Health 2022, 19, 4895. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Cai, L.; Yuen, K.F.; Wang, X. Exploring consumers’ usage intention of reusable express packaging: An extended norm activation model. J. Retail. Consum. Serv. 2023, 72, 103265. [Google Scholar] [CrossRef]

- Xu, Y.; Ward, P.S. Environmental Attitutdes and Consumer Preference for Environmentally-Friendly Beverage Packaging: The Role of Information Provision and Identity Labeling in Influencing Consumer Behavior. Front. Agric. Sci. Eng. 2023, 10, 95–108. [Google Scholar]

- Najm, A.A.; Salih, S.A.; Fazry, S.; Law, D.; Azfaralariff, A. Moderated mediation approach to determine the effect of natural packaging factors on intention to purchase natural skincare products among the population of Klang Valley, Malaysia. J. Sens. Stud. 2023, 38, e12811. [Google Scholar] [CrossRef]

- Muhammad, N.H.; Yusoff, A.M.; Nawi, N.M.; Razak, N.F.; Simpong, D.B. Pro-environmental Behaviour Impacts on the Willingness to Pay for Bio-based Sustainable Food Packaging. In The Implementation of Smart Technologies for Business Success and Sustainability: During COVID-19 Crises in Developing Countries; Springer International Publishing: Cham, Switzerland, 2022; pp. 325–334. [Google Scholar]

- Jain, P.; Hudnurkar, M. Sustainable packaging in the FMCG industry. Clean. Responsible Consum. 2022, 7, 100075. [Google Scholar] [CrossRef]

- Kapse, U.; Mahajan, Y.; Hudnurkar, M.; Ambekar, S.; Hiremath, R. The Effect of Sustainable Packaging Aesthetic on Consumer Behavior: A Case Study from India. Australas. Account. Bus. Financ. J. 2023, 17, 236–246. [Google Scholar] [CrossRef]

- Mahmoud, M.A.; Tsetse, E.K.; Tulasi, E.E.; Muddey, D.K. Green Packaging, Environmental Awareness, Willingness to Pay and Consumers’ Purchase Decisions. Sustainability 2022, 14, 16091. [Google Scholar] [CrossRef]

- Gutierrez Tano, D.; Hernandez Mendez, J.; Díaz-Armas, R. An extended theory of planned behaviour model to predict intention to use bioplastic. J. Soc. Mark. 2022, 12, 5–28. [Google Scholar] [CrossRef]

- Montes, R.M.A.; Delapaz, G.V.; Oliquiano, J.I.D.R.; Pascasio, H.K.A.; Lugay, C.I.J.R.P. A Study on the Impact of Green Cosmetic, Personal Care Products, and their Packaging on Consumers’ Purchasing Behavior in Luzon, Philippines. In Proceedings of the 7th North American International Conference on Industrial Engineering and Operations Management, Orlando, FL, USA, 12–14 June 2022; pp. 119–128. [Google Scholar]

- Koch, J.; Frommeyer, B.; Schewe, G. Managing the transition to eco-friendly packaging—An investigation of consumers’ motives in online retail. J. Clean. Prod. 2022, 351, 131504. [Google Scholar] [CrossRef]

- Baptista, J.R.D. Thoughtful Packaging: How Inner Motivations Can Influence the Purchase Intention for Green Packaged Cosmetics. Master’s Thesis, Universidade Nova de Lisboa, Lisboa, Portugal, November. 2021. [Google Scholar]

- Haba, H.F.; Bredillet, C.; Dastane, O. Pharma Green consumer research: Trends and way forward based on bibliometric analysis. Clean. Responsible Consum. 2023, 8, 100089. [Google Scholar] [CrossRef]

- Gomes, G.M.; Moreira, N.; Ometto, A.R. Role of consumer mindsets, behaviour, and influencing factors in circular consumption systems: A systematic review. Sustain. Prod. Consum. 2022, 32, 1–4. [Google Scholar] [CrossRef]

- The Elusive Green Consumer. Available online: https://hbr.org/2019/07/the-elusive-green-consumer (accessed on 31 May 2023).

- Jung, B.; Joo, J. Blind Obedience to Environmental Friendliness: The Goal Will Set Us Free. Sustainability 2021, 13, 12322. [Google Scholar] [CrossRef]

- Bratt, C. Consumers’ Environmental Behavior Generalized, Sector-Based, or Compensatory? Environ. Behav. 1999, 31, 28–44. [Google Scholar] [CrossRef]

- Filiciotto, L.; Rothenberg, G. Biodegradable Plastics: Standards, Policies, and Impacts. ChemSusChem 2021, 14, 56–72. [Google Scholar] [CrossRef] [PubMed]

- Nettleton, D.F.; Fernandez-Avila, C.; Sanchez-Esteva, S.; Verstichel, S.; Coltelli, M.B.; Marti-Soler, H.; Aliotta, L.; Gigante, V. Biodegradation Prediction and Modelling for Decision Support. In Proceedings of the 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications, Lisbon, Portugal, 14–16 July 2022; pp. 26–35. [Google Scholar]

- Bioplastics Innovation ‘Particularly Poorly Covered’ in Cosmetics: Report. Available online: https://www.cosmeticsdesign-europe.com/Article/2020/04/27/Bioplastics-packaging-innovation-poor-in-cosmetics-finds-Clarivate-Analytics (accessed on 31 May 2023).

- Beltrami, M.; Orzes, G.; Sarkis, J.; Sartor, M. Industry 4.0 and sustainability: Towards conceptualization and theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- da Rocha, A.B.T.; de Oliveira, K.B.; Espuny, M.; da Motta Reis, J.S.; Oliveira, O.J. Business transformation through sustainability based on Industry 4.0. Heliyon 2022, 8, e10015. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Choi, T.-M.; Latan, J. ‘Better together’: Evidence on the joint adoption of circular economy and industry 4.0 technologies. Int. J. Prod. Econ. 2022, 252, 108581. [Google Scholar] [CrossRef]

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 and sustainable development: A systematic mapping of triple bottom line, Circular Economy and Sustainable Business Models perspectives. J. Clean. Prod. 2021, 297, 126655. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. J. Clean. Prod. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular supply chains in the era of industry 4.0: A systematic literature review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Behl, A.; Singh, R.; Pereira, V.; Laker, B. Analysis of Industry 4.0 and circular economy enablers: A step towards resilient sustainable operations management. Technol. Forecast. Soc. Change 2023, 189, 122363. [Google Scholar] [CrossRef]

- Touriki, F.E.; Benkhati, I.; Kample, S.S.; Belhadi, A.; El fezazi, S. An integrated smart, green, resilient, and lean manufacturing framework: A literature review and future research directions. J. Clean. Prod. 2021, 319, 128691. [Google Scholar] [CrossRef]

- Aniza, R.; Chen, W.-H.; Petrissans, A.; Hoang, A.T.; Ashokkumar, V.; Petrissans, M. A review of biowaste remediation and valorization for environmental sustainability: Artificial intelligence approach. Environ. Pollut. 2023, 324, 121363. [Google Scholar] [CrossRef] [PubMed]

- Hughes, A.; Urban, M.A.; Wojcik, D. Alternative ESG Ratings: How Technological Innovation Is Reshaping Sustainable Investment. Sustainability 2021, 13, 3551. [Google Scholar] [CrossRef]

- Huntingford, C.; Jeffers, E.S.; Bonsall, M.B.; Christensen, H.M.; Lees, T.; Yang, H. Machine learning and artificial intelligence to aid climate change research and preparedness. Environ. Res. Lett. 2010, 14, 124007. [Google Scholar] [CrossRef]

- Al-Dahoud, A.; Fezari, M.; Aldahoud, A. Machine Learning in Renewable Energy Application: Intelligence System for Solar Panel Cleaning. WSEAS Trans. Environ. Dev. 2023, 19, 472–478. [Google Scholar] [CrossRef]

- Sadeghi, K.; Kim, J.; Seo, J. Packaging 4.0: The threshold of an intelligent approach. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2615–2638. [Google Scholar] [CrossRef]

- Design for Recycled Content Guide. Available online: https://recycledcontent.org/ (accessed on 20 August 2023).

- Padilla-Rivera, A.; Russo-Garido, S.; Merveille, N. Addressing the Social Aspects of a Circular Economy: A Systematic Literature Review. Sustainability 2020, 12, 7912. [Google Scholar] [CrossRef]

- Dube, S.; Dube, M.; Turan, A. Information technology in Turkey: Creating high-skill jobs along with more unemployed highly-educated workers? Telecommun. Policy 2015, 38, 811–829. [Google Scholar] [CrossRef]

- Tschang, F.T.; Almirall, E. Artificial intelligence as augmenting automation: Implications for employment. Acad. Manag. Perspect. 2021, 35, 642–659. [Google Scholar] [CrossRef]

- Yang, Y. Analysis of the Impact of Artificial Intelligence Development on Employment. In Proceedings of the IEEE 2020 International Conference on Computer Engineering and Application, Gunupur, India, 13–14 March 2020; pp. 324–327. [Google Scholar]

- Zeng, T. Impacts of consumers’ perceived risks in eco-design packaging on food wastage behaviors. Br. Food J. 2022, 124, 2512–2532. [Google Scholar] [CrossRef]

- Helmi, A.; Komaladewi, R.; Sarasi, V.; Yolanda, L. Characterizing Young Consumer Online Shopping Style: Indonesian Evidence. Sustainability 2023, 15, 3998. [Google Scholar] [CrossRef]

- Orzan, G.; Cruceru, A.F.; Balaceanu, C.T.; Chivu, R.-G. Consumers’ Behavior Concerning Sustainable Packaging: An Exploratory Study on Romanian Consumers. Sustainability 2018, 10, 1787. [Google Scholar] [CrossRef]

- Rathner, S. The Influence of Primary Study Characteristics on the Performance Differential between Socially Responsible and Conventional Investment Funds: A Meta Analysis. J. Bus. Ethics 2013, 118, 349–363. [Google Scholar] [CrossRef]

- Halbritter, G.; Dorfleitner, G. The wages of social responsibility—Where are they? A critical review of ESG investing. Rev. Financ. Econ. 2015, 26, 25–35. [Google Scholar] [CrossRef]

- Henke, H.-M. The effect of social screening on bond mutual fund performance. J. Bank. Financ. 2016, 67, 69–84. [Google Scholar] [CrossRef]

- Das, N.; Ruf, B.; Chatterjee, S.; Sunder, A. Fund Characteristics and Performances of Socially Responsible Mutual Funds: Do ESG Ratings Play a Role? J. Account. Financ. 2018, 18, 57–69. [Google Scholar]

- Keisel, F.; Lucke, F. ESG in credit ratings and the impact on financial markets. Financ. Mark. Inst. Instrum. 2019, 28, 263–290. [Google Scholar] [CrossRef]

- Hubel, B.; Scholz, H. Integrating sustainability risks in asset management: The role of ESG exposures and ESG ratings. J. Asset Manag. 2020, 21, 52–69. [Google Scholar] [CrossRef]

- Aslan, A.; Poppe, L.; Posch, P. Are Sustainable Companies More Likely to Default? Evidence from the Dynamics between Credit and ESG Ratings. Sustainability 2021, 13, 8568. [Google Scholar] [CrossRef]

- Zhang, J.; Se Speigeleer, J.; Schoutens, W. Implied Tail Risk and ESG Ratings. Mathematics 2021, 9, 1611. [Google Scholar] [CrossRef]

- Denuwara, N.; Kim, A.; Newenhisen, P.; Gibson, C.; Schork, D.; Hakovirta, M. Corporate economic performance and sustainability indices: A study based on the Dow Jones Sustainability Index. Springer Nat. Bus. Econ. 2022, 2, 77. [Google Scholar] [CrossRef] [PubMed]

- Naumer, H.-J.; Yurtoglu, B. It is not only what you say, but how you say it: ESG, corporate news, and the impact on CDS spreads. Glob. Financ. J. 2022, 52, 100571. [Google Scholar] [CrossRef]

- Stellner, C.; Klein, C.; Zwergel, B. Corporate social responsibility and Eurozone corporate bonds: The moderating role of country sustainability. J. Bank. Financ. 2015, 59, 538–549. [Google Scholar] [CrossRef]

- Crespi, F.; Migliavacca, M. The Determinants of ESG Rating in the Financial Industry: The Same Old Story or a Different Tale? Sustainability 2020, 12, 6398. [Google Scholar] [CrossRef]

- Feng, M.; Wang, X.; Kreuze, J.G. Corporate social responsibility and firm financial performance: Comparison analyses across industries and CSR categories. Am. J. Bus. 2017, 32, 106–133. [Google Scholar] [CrossRef]

- Drempatick, S.; Klein, C.; Zwergel, B. The Influence of Firm Size on the ESG Score: Corporate Sustainability Ratings Under Review. J. Bus. Ethics 2020, 167, 333–360. [Google Scholar] [CrossRef]

- Kim, E.-H.; Lyon, T.P. Greenwash vs. Brownwash: Exaggeration and Undue Modesty in Corporate Sustainability Disclosure. Organ. Sci. 2015, 26, 705–723. [Google Scholar] [CrossRef]

- Escrig-Olmedo, E.; Fernandez-Izquierdo, M.A.; Ferrero-Ferrero, I.; Rivera-Lirio, J.M.; Munoz-Torres, M.J. Rating the Raters: Evaluating how ESG Rating Agencies Integrate Sustainability Principles. Sustainability 2019, 11, 915. [Google Scholar] [CrossRef]

- MacMahon, S. The Challenge of Rating ESG Performance. Harv. Bus. Rev. 2020, 98, 52–54. [Google Scholar]

- Bergman, M.S.; Curran, D.; Deckelbaum, A.J.; Karp, B.S.; Martos, S.D. ESG Ratings and Data: How to Make Sense of Disagreement. Corp. Gov. Advis. 2021, 29, 14–18. [Google Scholar]

- Hartzmark, S.M.; Shue, K. Counterproductive sustainable investing: The impact elasticity of brown and green firms. In Working Paper; Boston College: Boston, MA, USA, 2023. [Google Scholar]

- Pena, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Caldeira-Pires, A.; Widema, B.; Mieras, E.; Wang, F.; Fava, J.; Milà i Canals, L.; et al. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- ISO 14040:2006: Environmental management—Life cycle assessment—Principles and framework. Available online: https://www.iso.org/standard/37456.html (accessed on 5 September 2023).

- ISO 14044:2006: Environmental management—Life cycle assessment—Requirements and guidelines. Available online: https://www.iso.org/standard/38498.html (accessed on 5 September 2023).

- Vital, X. Environmental Impacts of Cosmetic Products. In Sustainability: How the Cosmetics Industry Is Greening Up; Sahota, A., Ed.; John Wiley & Sons: New York, NY, USA, 2014; pp. 17–46. [Google Scholar]

- Rathore, S.; Schuler, B.; Park, J. Life cycle assessment of multiple dispensing systems used for cosmetic product packaging. Packag. Technol. Sci. 2023, 36, 533–547. [Google Scholar] [CrossRef]

- Castillo-Gonzalez, E.; Giraldi-Diaz, M.R.; De Medina-Salas, L.; Velasquez-De la Cruz, R. Environmental Impacts Associated to Different Stages Spanning from Harvesting to Industrialization of Pineapple though Life Cycle Assessment. Appl. Sci. 2020, 10, 7007. [Google Scholar] [CrossRef]

- Peiris, R.L.; Kulatunga, A.K.; Jinadasa, K.B.S.N. Conceptual model of Life Cycle Assessment based generic computer tool towards Eco-Design in manufacturing sector. Procedia Manuf. 2019, 33, 83–90. [Google Scholar] [CrossRef]

- Bom, S.; Ribeiro, H.M.; Marto, J. Sustainability calculator: A tool to assess sustainability in cosmetic products. Sustainability 2020, 12, 1437. [Google Scholar] [CrossRef]

- Cılız, N.K.; Değirmen, C.; Uzun, M.; Kalıpçıoğlu, C.; Ahmed, I.A.; Birpınar, M.E.; Ecer, M.; Moralı, E.K.; Atay, S.; Ulutaş, Ö.; et al. The Contribution of LCA Applications to the Development of National Ecolabel Criteria for the Personal Care and Cosmetic Sector. Int. J. Innov. Eng. Sci. Res. 2022, 6, 30–40. [Google Scholar]

- Santi, R.; Elegir, G.; Del Curto, B. Designing for Sustainable Behavior Practices in Consumers: A Case Study on Compostable Materials for Packaging. In Proceedings of the International Design Society: DESIGN Conference, Cavtat, Croatia, 26–29 October 2020; Volume 1, pp. 1647–1656. [Google Scholar]

- Morgan, R.K. Environmental impact assessment: The state of the art. Impact Assess. Proj. Apprais. 2012, 30, 5–14. [Google Scholar] [CrossRef]

- Keken, Z.; Hanusova, T.; Kulendik, J.; Wimmerova, L.; Zitkova, J.; Zdrazil, V. Environmental impact assessment—The range of activities covered and the potential of linking to post-project auditing. Environ. Impact Assess. Rev. 2022, 93, 106726. [Google Scholar] [CrossRef]

- Halla, P.; Merino-Saum, A.; Binder, C.R. How to link sustainability assessments with local governance?—Connecting indicators to institutions and controversies. Environ. Impact Assess. Rev. 2022, 93, 106741. [Google Scholar] [CrossRef]

- Estevas, A.M.; Franks, D.; Vanclay, F. Social impact assessment: The state of the art. Impact Assess. Proj. Apprais. 2012, 30, 34–42. [Google Scholar] [CrossRef]

- Vanclay, F. Reflections on Social Impact Assessment in the 21st century. Impact Assess. Proj. Apprais. 2020, 38, 126–131. [Google Scholar] [CrossRef]

- Neumann, V.A.; Hack, J. Revealing and assessing the costs and benefits of nature-based solutions within a real-world laboratory in Costa Rica. Environ. Impact Assess. Rev. 2022, 93, 106737. [Google Scholar] [CrossRef]

- What You Should Know When Packaging Cosmetics Compliant to FDA Regulations. Available online: https://www.desjardin.fr/en/blog/what-you-should-know-when-packaging-cosmetics-compliant-to-fda-regulations (accessed on 20 August 2023).

- Regulation (EC) No 1223/2009 of the European Parliament and of the Council of 30 November 2009 on cosmetic products. Available online: https://health.ec.europa.eu/system/files/2016-11/cosmetic_1223_2009_regulation_en_0.pdf (accessed on 5 September 2023).

- Understanding REACH. Available online: https://echa.europa.eu/regulations/reach/understanding-reach (accessed on 5 September 2023).

- European Parliament and Council Directive 64/92/EC of 20 December 1994 on packaging and packaging waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:01994L0062-20180704 (accessed on 5 September 2023).

- Information Exchange on Cosmetic Packaging Materials along the Value Chain in the Context of the EU Cosmetics Regulation EC 1223/2009. Available online: https://cosmeticseurope.eu/download/UG14b1RFS01qdlllbFBwdTZlRXRwdz09 (accessed on 20 August 2023).

- Ferreira, M.; Matos, A.; Couras, A.; Marto, J.; Ribeiro, H. Overview of Cosmetic Regulatory Frameworks around the World. Cosmetics 2022, 9, 72. [Google Scholar] [CrossRef]

- Eissenberger, K.; Ballesteros, A.; De Bisschop, R.; Bugnicourt, E.; Cinelli, P.; Defoin, M. Approaches in Sustainable, Biobased Multilayer Packaging Solutions. Polymers 2023, 15, 1184. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Brint, A.; Shi, E.; Upadhyay, A.; Ruan, X. Integrating sustainable supply chain practices with operational performance: An exploratory study of Chinese SMEs. Prod. Plan. Control Manag. Oper. 2019, 30, 464–478. [Google Scholar] [CrossRef]

- Gottardo, S.; Mech, A.; Drbohlavova, J.; Malyska, A.; Bowadt, S.; Sintes, J.R.; Rauscher, H. Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials. NanoImpact 2021, 21, 100297. [Google Scholar] [CrossRef]

- Waste No More: Introducing Europe’s New Waste Laws. Available online: https://eeb.org/waste-no-more-introducing-europes-new-waste-laws/ (accessed on 20 August 2023).

- EUInfringe2021 EU Infringement Decisions. Available online: https://ec.europa.eu/commission/presscorner/detail/en/inf_21_2743 (accessed on 20 August 2023).

- EU Packaging Waste Directive Implications for E-Commerce. Available online: https://www.ecosistant.eu/en/eu-packaging-waste-directive-implications-for-e-commerce/ (accessed on 20 August 2023).

- Revision of the Packaging and Packaging Waste Directive. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2023/745707/EPRS_BRI(2023)745707_EN.pdf (accessed on 20 August 2023).

- Europen Position on Extended Producer Responsibility for Post-Consumer Packaging in the EU. Available online: https://www.europen-packaging.eu/wp-content/uploads/2021/03/2013-09-16-EUROPEN-position-on-EPR-for-packaging-waste.pdf (accessed on 20 August 2023).

- McDonald’s Leads Lobbying Offensive Against Laws to Reduce Packaging Waste in Europe. Available online: https://www.desmog.com/2023/05/08/mcdonalds-leads-lobbying-offensive-against-laws-to-reduce-packaging-waste-in-europe/ (accessed on 20 August 2023).

- Fonseca-Santos, B.; Correa, M.A.; Chorilli, M. Sustainability, natural and organic cosmetics: Consumer, products, efficacy, toxicological and regulatory considerations. Braz. J. Pharm. Sci. 2015, 51, 17–26. [Google Scholar] [CrossRef]

- Bozza, A.; Campi, C.; Garelli, S.; Ugazio, E.; Battagila, L. Current regulatory and market frameworks in green cosmetics: The role of certification. Sustain. Chem. Pharm. 2022, 30, 100851. [Google Scholar] [CrossRef]

- Kattstrom, D.; Beronius, A.; Ruden, C.; Agerstrand, M. Stricter regulation applies to antimicrobial substances when used as biocides compared to cosmetics under current EU legislation. Emerg. Contam. 2022, 8, 229–242. [Google Scholar] [CrossRef]

- US Cosmetics Are Full of Chemicals Banned by Europe—Why? Available online: https://www.theguardian.com/us-news/2019/may/22/chemicals-in-cosmetics-us-restricted-eu (accessed on 20 August 2023).

- EU Commission to Backtrack on Harmful Chemicals Ban. Available online: https://www.euractiv.com/section/endocrine-disruptors/news/eu-commission-to-backtrack-on-harmful-chemicals-ban/ (accessed on 20 August 2023).

- Sreedhar, D.; Manjula, N.; Pise, A.; Pise, S.; Ligade, V.S. Ban of Cosmetic Testing on Animals: A Brief Overview. Int. J. Curr. Res. Rev. 2020, 12, 113–116. [Google Scholar]

- Huang, J. Sustainable development of green paper packaging. Environ. Pollut. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Dos Santos, J.W.; Garcia, V.A.; Venturini, A.C.; Carvalho, R.A.; da Silva, C.F.; Yoshida, C.M. Sustainable Coating Paperboard Packaging Material Based on Chitosan, Palmitic Acid, and Activated Carbon: Water Vapor and Fat Barrier Performance. Foods 2022, 11, 4037. [Google Scholar] [CrossRef]

- Kozik, N. Sustainable packaging as a tool for global sustainable development. In SHS Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 74, p. 04012. [Google Scholar]

- Stark, N.M.; Matuana, L.M. Trends in sustainable biobased packaging materials: A mini review. Mater. Today Sustain. 2021, 15, 100084. [Google Scholar] [CrossRef]

- Ibrahim, I.D.; Hamam, Y.; Sadiku, E.R.; Ndambuki, J.M.; Kupolati, W.K.; Jamiru, T.; Eze, A.A.; Snyman, J. Need for Sustainable Packaging: An Overview. Polymers 2022, 14, 4430. [Google Scholar] [CrossRef]

- Cappelletti, F.; Rossi, M.; Germani, M. How de-manufacturing supports circular economy linking design and EoL—A literature review. J. Manuf. Syst. 2022, 63, 118–133. [Google Scholar] [CrossRef]

- Vasiljević, D. Organic and natural cosmetic products-who benefits the most? Arh. Farm. 2021, 71 (Suppl. 5), S26–S27. [Google Scholar]

- Resimović, L.; Brozović, M.; Kovačević, D. Design of sustainable packaging for natural cosmetics. J. Appl. Packag. Res. 2022, 14, 2. [Google Scholar]

- Nadagouda, M.N.; Ginn, M.; Rastogi, V. A review of 3D printing techniques for environmental applications. Curr. Opin. Chem. Eng. 2020, 28, 173–178. [Google Scholar] [CrossRef]

- Facts and Figures about Materials, Waste and Recycling Containers and Packaging: Product-Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/containers-and-packaging-product-specific (accessed on 20 August 2023).

- Sánchez, C. Fungal potential for the degradation of petroleum-based polymers: An overview of macro-and microplastics biodegradation. Biotechnol. Adv. 2020, 40, 107501. [Google Scholar] [CrossRef]

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M. Plastic waste and its management strategies for environmental sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Damayanti, D.; Saputri, D.R.; Marpaung, D.S.; Yusupandi, F.; Sanjaya, A.; Simbolon, Y.M.; Asmarani, W.; Ulfa, M.; Wu, H.S. Current prospects for plastic waste treatment. Polymers 2022, 14, 3133. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, R.; Azad, N.; Dutta, D.; Yadav, B.R.; Kumar, S. A critical review and future perspective of plastic waste recycling. Sci. Total Environ. 2023, 13, 163433. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, S.; Sharma, B.; Shukla, P. Integrated approaches in microbial degradation of plastics. Environ. Technol. Innov. 2020, 17, 100567. [Google Scholar] [CrossRef]

- Coelho, P.M.; Corona, B.; ten Klooster, R.; Worrell, E. Sustainability of reusable packaging—Current situation and trends. Resour. Conserv. Recycl. X 2020, 6, 100037. [Google Scholar] [CrossRef]

- Liu, L.; Xu, M.; Ye, Y.; Zhang, B. On the degradation of (micro) plastics: Degradation methods, influencing factors, environmental impacts. Sci. Total Environ. 2022, 806, 151312. [Google Scholar] [CrossRef]

- Calero, C.; Godoy, V.; Queseda, L.; Martin-Lara, M.A. Green strategies for microplastics reduction. Curr. Opin. Green Sustain. Chem. 2021, 28, 100442. [Google Scholar] [CrossRef]

- Beitzen-Heineke, E.F.; Balta-Ozkan, N.; Reefke, H. The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J. Clean. Prod. 2017, 140, 1528–1541. [Google Scholar] [CrossRef]

- The Body Shop Brings Sustainable Packaging Effort to U.S. Available online: https://chainstoreage.com/body-shop-brings-sustainable-packaging-effort-us (accessed on 20 August 2023).

- Body Shop Loses Its Distinctive Bottle. Available online: https://www.theguardian.com/business/1999/oct/22/3 (accessed on 5 September 2023).

- Keller, A.A.; Vosti, W.; Wang, H.; Lazareva, A. Release of engineered nanomaterials from personal care products throughout their life cycle. J. Nanopart. Res. 2014, 16, 2489. [Google Scholar] [CrossRef]

- The Number of Makeup Products the Average Woman Owns Is Just Plain Shocking. Available online: https://www.goodhousekeeping.com/beauty/makeup/a34976/average-makeup-products-owned/ (accessed on 20 August 2023).

- Vanity Fare: How Much Makeup Does a Typical Woman Own? A Look at the Trends. Available online: https://www.latimes.com/archives/la-xpm-1988-01-31-tm-39292-story.html (accessed on 5 September 2023).

- All You Need Are 3 Perfect Lipsticks. Available online: https://bistrochic.net/beauty/3-perfect-lipsticks/ (accessed on 20 August 2023).

- Mystery Solved: How Many Swipes Are in a Tube of Lipstick. Available online: https://www.refinery29.com/en-us/2013/03/44794/lipstick-life-span-expiration-date (accessed on 20 August 2023).

- Loretz, L.J.; Api, A.M.; Barraj, L.M.; Burdick, J.; Dressler, W.E.; Gettings, S.D.; Hsu, H.H.; Pan, Y.H.; Re, T.A.; Renskers, K.J.; et al. Exposure data for cosmetic products: Lipstick, body lotion, and face cream. Food Chem. Toxicol. 2005, 43, 279–291. [Google Scholar] [CrossRef] [PubMed]

- How Often Should You Replace Your Makeup? Available online: https://www.allinahealth.org/allina-news/2018/05/how-often-should-you-replace-your-makeup (accessed on 20 August 2023).

- Risks of Using Expired Makeup. Available online: https://www.mayoclinichealthsystem.org/hometown-health/speaking-of-health/risks-of-using-expired-makeup (accessed on 20 August 2023).

- Nestle Sues Sara Lee over Coffee Pods. Available online: https://www.ausfoodnews.com.au/2010/06/17/nestle-sues-sara-lee-over-coffee-pods.html (accessed on 20 August 2023).

- Nestle Loses Coffee Capsule Battle in Germany. Available online: https://www.foxnews.com/world/nestle-loses-coffee-capsule-battle-in-germany (accessed on 20 August 2023).

- Nespresso Agrees to Break Down Barriers to Coffee Rivals. Available online: https://www.reuters.com/article/nespresso-competition-idUSL5N0R53DG20140904 (accessed on 20 August 2023).

- Swiss Mark Nespresso Capsules Deleted. Available online: https://legal-patent.com/trademark-law/swiss-mark-nespresso-capsules-deleted/ (accessed on 20 August 2023).

- Nestle Loses Battle to Extend Trademark on Original Capsule. Available online: https://bartalks.net/nestle-loses-battle-to-extend-trademark-on-original-capsule/ (accessed on 20 August 2023).

- Tarabashkina, L.; Devine, A.; Quester, P.G. Encouraging product reuse and upcycling via creativity priming, imagination and inspiration. Eur. J. Mark. 2022, 56, 1956–1984. [Google Scholar] [CrossRef]

- Arena, U.; Ardolino, F. Technical and environmental performances of alternative treatments for challenging plastics waste. Resour. Conserv. Recycl. 2022, 183, 106379. [Google Scholar] [CrossRef]

- Beauty Laid Bare: The ‘gritty’ truth about your cosmetics. Available online: https://www.bbc.co.uk/bbcthree/article/41d1b43e-d39b-450e-be74-e37b14a5e265 (accessed on 20 August 2023).

- Turkey: Plastic Recycling Harms Health, Environment. Available online: https://www.hrw.org/news/2022/09/21/turkey-plastic-recycling-harms-health-environment (accessed on 20 August 2023).

- Zhao, P.; Xie, J.; Gu, F.; Sharmin, N.; Hall, P.; Fu, J. Separation of mixed waste plastics via magnetic levitation. Waste Manag. 2018, 76, 46–54. [Google Scholar] [CrossRef] [PubMed]

- Meys, R.; Frick, F.; Westhues, S.; Sternberg, A.; Klankermayer, J.; Bardow, A. Towards a circular economy for plastic packaging waste—The environmental potential of chemical recycling. Resour. Conserv. Recycl. 2020, 163, 105101. [Google Scholar] [CrossRef]

- Lewandowski, K.; Skórczewska, K. A brief review of poly (vinyl chloride)(PVC) recycling. Polymers 2022, 14, 3035. [Google Scholar] [CrossRef] [PubMed]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D printing filament as a second life of waste plastics—A review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef]

- Wang, J.; Tang, M.; Wang, H. Research on the Design of Intelligent Recycling System for Cosmetics Based on Extenics. Procedia Comput. Sci. 2022, 199, 937–945. [Google Scholar] [CrossRef]

- Babaremu, K.; Oladijo, O.P.; Akinlabi, E. Biopolymers: A suitable replacement for plastics in product packaging. Adv. Ind. Eng. Polym. Res. 2023. In Press. [Google Scholar] [CrossRef]

- Wen, Z.; Xie, Y.; Chen, M.; Dinga, C.D. China’s plastic import ban increases prospects of environmental impact mitigation of plastic waste trade flow worldwide. Nat. Commun. 2021, 12, 425. [Google Scholar] [CrossRef]

- Turkey Repeals Plastic Import Ban. Available online: https://waste-management-world.com/artikel/turkey-repeals-plastic-import-ban/ (accessed on 31 May 2023).

- Plastic Waste Makers Index 2023. Available online: https://cdn.minderoo.org/content/uploads/2023/02/04205527/Plastic-Waste-Makers-Index-2023.pdf (accessed on 31 May 2023).

- America’s Broken Recycling System. Available online: https://cmr.berkeley.edu/2023/05/america-s-broken-recycling-system/ (accessed on 5 September 2023).

- Circular Claims Fall Flat. Available online: https://www.greenpeace.org/usa/research/report-circular-claims-fall-flat/ (accessed on 20 August 2023).

- Gupta, S.; Sharma, S.; Nadda, A.K.; Husain, M.S.; Gupta, A. Biopolymers from waste biomass and its applications in the cosmetic industry: A review. Mater. Today Proc. 2022, 68, 873–879. [Google Scholar] [CrossRef]

- ASTM D6866-22: Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. Available online: https://www.astm.org/d6866-22.html (accessed on 5 September 2023).

- ISO 16620-1:2015 Plastics — Biobased content — Part 1: General principles. Available online: https://www.iso.org/standard/63766.html (accessed on 5 September 2023).

- ISO 16620-2:2019 Plastics — Biobased content — Part 2: Determination of biobased carbon content. Available online: https://www.iso.org/standard/72474.html (accessed on 5 September 2023).

- ISO 16620-3:2015 Plastics — Biobased content — Part 3: Determination of biobased synthetic polymer content. Available online: https://www.iso.org/standard/63768.html (accessed on 5 September 2023).

- ISO 16620-4:2016 Plastics — Biobased content — Part 4: Determination of biobased mass content. Available online: https://www.iso.org/standard/63817.html (accessed on 5 September 2023).

- ISO 16620-5:2017 Plastics — Biobased content — Part 5: Declaration of biobased carbon content, biobased synthetic polymer content and biobased mass content. Available online: https://www.iso.org/standard/65218.html (accessed on 5 September 2023).

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Joseph, T.M.; Unni, A.B.; Joshy, K.S.; Kar Mahapatra, D.; Haponiuk, J.; Thomas, S. Emerging Bio-Based Polymers from Lab to Market: Current Strategies, Market Dynamics and Research Trends. C 2023, 9, 30. [Google Scholar] [CrossRef]

- Tyagi, P.; Agate, S.; Velev, O.D.; Lucia, L.; Pal, L. A critical review of the performance and soil biodegradability profiles of biobased natural and chemically synthesized polymers in industrial applications. Environ. Sci. Technol. 2022, 56, 2071–2095. [Google Scholar] [CrossRef]