Abstract

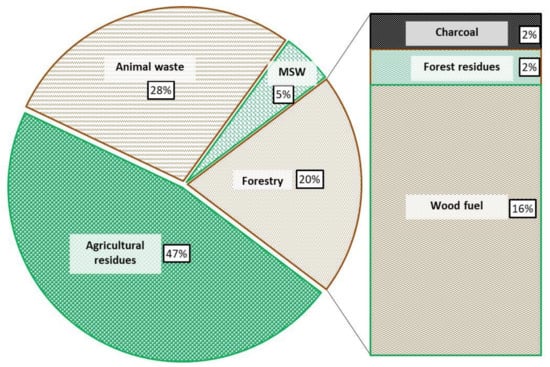

Nigeria is a developing country with an insufficient supply of energy to meet the continuously growing demand. However, there are several biomass resources available within the country. This paper presents a desk review, which investigates the potential resources for biomass energy generation within the country. Energy policies to aid biomass use as an energy source within the country were also reviewed. Biomass resources identified within Nigeria include forest residues, agricultural residues, human and animal wastes, aquatic biomass, and energy crops. However, several of the resources, particularly agricultural residues, have competing uses, such as livestock feed and soil rejuvenation. An estimation of the technical energy potential of the biomass resources revealed that about 2.33 EJ could be generated from the available resources in Nigeria. Agricultural residues have an energy potential of about 1.09 EJ, with cassava, maize, oil palm, plantain, rice, and sorghum being the major contributors. Animal wastes, municipal solid waste, and forest residues have energy potentials of 0.65, 0.11, and 0.05 EJ, respectively. The potentials of wood fuel and charcoal are 0.38 and 0.05 EJ, respectively. The study found that despite the available potential and existing policies, not much has been done in the implementation of large-scale bioenergy within the country. However, there has been laboratory and research-scale investigations. The review suggests that more policies and stronger enforcement will aid bioenergy development within the country. From the review, it has been suggested that the agricultural sector needs to be developed to generate more biomass resources. More research, development, and implementation have to be carried out on biomass resources and bioenergy generation processes. The production of non-edible energy crops in marginal lands should also be considered prime to the development of bioenergy within the country.

1. Introduction

The importance of energy in the development and growth of a nation cannot be overemphasized. Development growth and human prosperity are heavily dependent on adequate supply, security, and efficient use of energy [1]. Lior [2] suggested that energy resources and consumption are intimately related to environmental quality and other vital resources, such as water and food. Lior [3] proposed that Africa’s energy deserves a close look and development to synergistically advance the quality of life of its populace and sell global-capacity energy to the rest of the world.

The global energy crisis, coupled with the global warming menace, has called for the diversion from the sustained utilization of fossil fuels. It has been realized that without alternative means of energy, there would continue to be an energy shortage and the environment will continue to be at risk. Alternative forms of energy would include energy sources that are clean, sustainable, and renewable. An alternative energy supply is being sourced from the exploration of wind, solar, biomass, hydroelectric, ocean, and geothermal energy sources. Each of these sources has their benefits and limitations. According to Abolhosseini et al. [4], the three primary motivators that stimulate the growth of renewable energy technologies include energy security, economic impacts, and carbon dioxide emission reduction.

Developing countries, in particular, appear to be the worst hit by the energy crisis. Economies of developing countries are volatile to energy markets due to their heavy reliance on non-renewable energy sources and their low capability to maintain a stable energy stock and expensive energy mix [5]. However, developing countries, including Nigeria, very often, have an abundant stock of untapped renewable energy resources, which have several potential uses [6,7,8,9]. Piebalgs [10] opined that developing countries are in strong positions to promote the use of renewable energies due to abundant renewable resources, which include wind, solar, geothermal, biomass, and hydro. This may, however, be with some financial and political support. It has been shown that renewable energy is an important factor that positively influences growth and economic development, through employment creation [11]. In addition, using renewable energy increases the chances for energy self-sufficiency whilst preventing environmental degradation [12,13].

Evans et al. [14] assessed the social impacts of renewable energy technologies and ranked them against indicators for sustainable development. Of the technologies ranked, it was observed that wind power was the most sustainable, followed by hydropower, photovoltaic, and geothermal in order. Mas’ud et al. [15] also assessed the renewable energy readiness in Nigeria and Cameroon and found that there is a high solar irradiation and excellent wind speed in the two countries. It was also stated that Africa has abundant energy resources, which can promote economic growth and provide sufficient capacity to meet up future electricity demand. Ajayi [16] suggested that the attending challenges bedeviling the development of renewable energy technologies vary from the lack of awareness to technical ineptitude.

Several developing countries, particularly those in the sub-Saharan region, have a large base of arable land and agriculture contributes to a large extent to the economy. Such regions have abundant biomass resources, which can be utilized for power generation. However, the biomass resources are often utilized in ways that are not beneficial and create harm to the environment. Despite this, biomass provides about 70% of the total energy consumption in some developing countries [17]. Keles et al. [17] anticipates that about 823 million people in Africa would rely on biomass for cooking and heating in the developing country by 2030. Gujba et al. [18] suggested that the introduction of advanced stoves should be prioritized to reduce health impact from indoor pollution and also to reduce pressure on biomass resources.

There have been several climate change conferences and summits organized by the United Nations to discuss issues relating to the mitigation of the effects of climate change. The series of conferences have led to the negotiation of treaties and agreements bothering on the responsibilities of member states to reduce the emission of greenhouse gases. One such treaty is the Kyoto protocol adopted in 1997 (COP3), which noted that there is an occurrence of global warming based on a scientific consensus and this is likely caused by emissions of man-made CO2. The main objective of the Kyoto protocol was to control major anthropogenic greenhouse gases in ways that reflect underlying national differences in emissions, wealth, and capacity [19]. The Paris agreement resulted from the conference in 2015 (COP21), which was to guide the climate change reduction measures from 2020. It had been realized that net zero emissions need to be realized by 2050 to limit the global warming to 1.5 °C, which is considered to be socially, economically, and politically safe [20]. The recent conference held in 2019 (COP25) at Madrid, Spain aimed to address issues required to bring the Paris agreement into full operation. The conference also intended that countries would present new and updated climate action plans. Although there were disagreements on certain issues on the robustness of the rules, it was agreed that improved emission reduction plans would be brought to COP26 [21].

Abolhosseini et al. [4] identified that the two main solutions for reducing CO2 emissions and to overcoming the climate change problem are to replace fossil fuels with renewable energy as much as possible and through enhancing energy efficiency. Keles et al. [17] also noted that systematic data are still inadequate or unavailable for biomass energy planning and for developing specific energy policies for supply and demand. It is required that the biomass resources are appropriately managed and deployed for effective energy and power generation. This study identifies potential biomass resources, which can be deployed for the purpose of energy generation in Nigeria, and reviews the appropriate technologies, which can be used for bioenergy generation. The theoretical and technical potentials of available biomass resources are estimated, and the policies developed in Nigeria for promoting the use of biomass are also reviewed.

2. Geographical Location and Demography of Nigeria

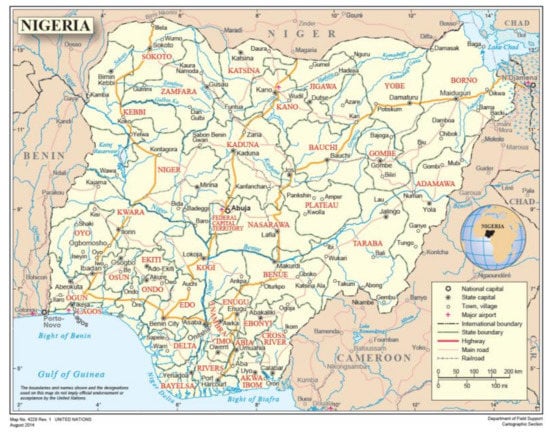

Nigeria is located in West Africa between latitudes 3°15′ and 13°30′ N and longitudes 2°59′ and 15°00′ E. It is located in the tropics, where the climate is seasonally damp and very humid. Nigeria shares land borders with the Republic of Benin in the west, Cameroon and Chad in the east, and Niger in the north. It is bounded in the south by the Gulf of Guinea. The location and boundaries are shown in Figure 1. Nigeria has an estimated population of about 200 million people with a land mass area of 920,000 km2. It is considered to be the largest population in Africa and the seventh-largest population in the world. The population in Nigeria has been projected by Sambo [22] to be 352.67 million by 2030, with a growth rate reaching up to 4%. Table 1 shows the projected population growth rate, the share of the urban population, and the number of persons per household.

Figure 1.

Map of Nigeria showing boundaries and location based on the UN map [23].

Table 1.

Projected demographic parameters for Nigeria [22].

Nigeria is rich in natural resources. However, the lack of access to electrical power has hindered the development of the country despite these resources. There is a strong correlation between socioeconomic development and the availability of electricity [10]. Rural community and stand-alone electrification can be achieved by including renewable energy into the national energy mix. This will reduce the internal consumption and conserve petroleum resources for continued export for foreign exchange earnings.

3. Energy Situation in Nigeria

Nigeria is rich in both conventional and renewable energy sources. Crude oil reserves reach up to 36.2 billion barrels and natural gas is about 166 trillion scf. [24,25]. Coal and lignite reserves are up to 2.7 billion tons and tar sands are about 31 billion barrels of oil equivalent [26,27]. Despite the abundance of the fossil fuels, the availability and acquisition in Nigeria is uncertain and highly erratic [28]. Ezema et al. [29] describes the situation where energy services are either insufficient or inaccessible to those who need it as suppressed demand. Inadvertently, the use of renewable energy would be important to solve the problem of suppressed energy demand due to unavailability and inadequacies of fossil fuels.

Renewable energy sources within the country include solar radiation with insolation between 3.5 and 7 kWh/m2/day; wind with speeds up to 4 m/s at 10 meters height; and biomass from varying sources [28]. Ezema et al. [29] and Ojolo et al. [30] are of the opinion that the renewable energy sources can meet the energy demand of Nigeria all year round. Okeke [31] noted that Nigeria is capable of generating 600,000 MW of solar power from only 1% of her land mass, is able to provide 14,750 MW of electrical power from hydroelectricity, and has 77.8% of her total land mass available for biomass energy.

As observed from Table 1, the population is projected to increase progressively. This also places more demand for energy availability. A projection for the energy demand in Nigeria is presented in Table 2. Ojolo et al. [30] predicted that the energy demand could rise to 250.84 MTOE by 2030, with the industrial sector having the highest demand. Sambo [22] also predicted that the demand could range from 224.54 to 747.27 MTOE by 2030 depending on the growth rate of the identified sectors. JICA [32] estimated that energy demand would reach 138.84 MTOE by 2030.

Table 2.

Projected total energy demand in Nigeria (MTOE) [30].

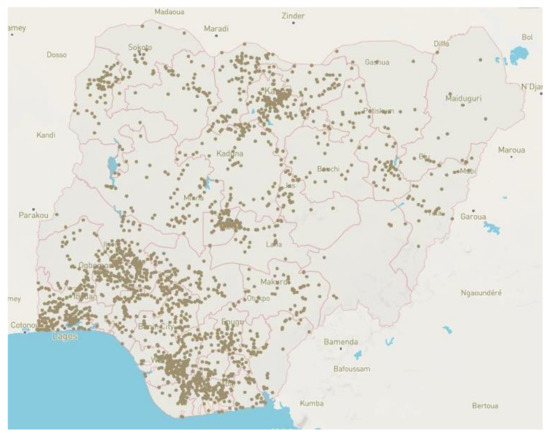

The energy demand outweighs the energy supplied within the country. IEA [33] noted that the electricity consumption in Nigeria was about 27.91 TWh (2.4 MTOE) as at 2018. This is just about 2.2% of the energy demand, which is grossly inadequate. Figure 2 shows the electrified communities in Nigeria. It is observed that a large portion of the country is without electrical power. Oyedepo [34] noted that 60% to 70% of the Nigerian population does not have access to electricity. The rural communities are often the worst victims as they are not connected to the electricity grid. Power delivered to regions that have access to electricity is insufficient and unreliable, which creates a huge supply gap [35]. Oyedepo [34] noted that the electricity supplied to the industrial sector is not adequate and other private arrangements for generating power were explored by the industries. To address the shortage of electricity, the off-grid electricity supply using renewable energy has been advocated by some researchers [29,36,37]. This will ensure the adequate access to electricity in the remote and rural areas of the country.

Figure 2.

Electrified communities in Nigeria [38].

The estimated projection of the electricity supply from 2015 to 2019 based on the National Energy Master Plan 2014 [32] is presented in Table 3. Currently, most of the electricity supply is gas and hydro powered. It is seen from the table that the highest contributor is natural gas while the contribution of biomass seems insignificant. Maren et al. [37] criticized the overreliance on oil and gas as the source of energy to every sector of the economy despite enormous renewable energy potentials in the nation.

Table 3.

Electricity supply projection by fuel type (MW) [32].

Although, biomass is not significantly used in the generation of electricity, it is considered to be predominant in the primary energy mix due to the interplay of factors, such as poverty, lack of easy access to commercial energy sources, and cultural factors [39,40]. As at 2018, IEA [33] presented the primary energy demand in Nigeria. The component within the energy mix providing the highest energy are biofuels and waste (114.02 MTOE) followed by oil (26.31 MTOE), gas (14.92 MTOE), hydro (0.55 MTOE), and coal (0.02 MTOE). The contributions of solar PV and other low-carbon sources were quite small. Sa’ad and Bugaje [39] showed that poverty levels are highly correlated (positively) with biomass consumption in Nigeria, but a negative correlation existed between biomass consumption and real incomes.

4. Biomass Resources in Nigeria

Biomass is a naturally occurring carbonaceous resource. It refers to material that is of biological origin and is a complex renewable material with enormous chemical variability [41,42]. Tursi [43] noted that biomass can be classified based on the types existing in nature, which is in accordance to ecological or type of vegetation. The classification groups biomass into five, which include wood and woody biomass, herbaceous biomass, aquatic biomass, animal and human waste biomass, and biomass mixtures. Biomass mixtures include substrate that combines other classes, such that it exists in a mixed form.

4.1. Wood and Woody Biomass

Woody biomass includes components whose major constituents are carbohydrates and lignin. This includes live trees, forest and manufacturing residues, or consumer waste materials. Woody biomass has been defined by United States Department of Agriculture as trees and woody plants, including limbs, tops, needles, leaves, and other woody parts, grown in a forest, woodland, or rangeland environment, that are the by-products of forest management [44]. Tursi [43] stated that the production of energy and fuel comes from four primary sources, which include production residues, non-merchant timber residues, post-consumption wood wastes, and urban wastes.

Assessments for Nigeria and sub-regions has been carried out by several authors to investigate the management of forest reserves [45], environmental sustainability [46], security threats of forest reserves [47], depletion and changes to the forest reserves [48], biodiversity and carbon potentials [49], and the energy potential of forest reserves and residues [30]. Details of forest reserves and forest plantations by the state in Nigeria are presented in Table 4. It has been noted that about 10% of the total land mass of Nigeria is allocated to forest reserves [46].

Table 4.

Forest reserves and plantations by state [46].

Forest residues include logging residues, such as tops and branches; process residues, such as off-cuts and sawdust from wood industries; and demolition wood. Forest products that are produced in Nigeria include wood pulp, wood fuel, wood charcoal, paper board, particle board, plywood, sawn wood, printing, and writing paper amongst others [50]. The products and annual production rates are presented in Table 5.

Table 5.

Forestry products and production quantity in Nigeria for 2018 [55].

Zalfar [51] noted that the generated residues during the processing of wood into furniture is about 45% of the wood and is about 52% of the wood when processed in a sawmill. Ogunrinde and Owoyemi [52] noted that less than 80% of the harvested tree is taken away from the forest during logging with the rest left as residue. FAO [53] also stated that less than two-thirds of a typical tree is taken from the forest for further processing. Furthermore, FAO [53] noted that after processing, only 28% of the original tree becomes lumber. The residues obtained during the processing of wood are stated in Table 6. Ojolo et al. [30] estimated the total energy derivable, considering full capacity, from forest residues in Nigeria to be 8.3 PJ.

Table 6.

Division of a typical tree harvested for sawn timber [53].

Currently, most forestry residues are left, burnt, or collected as fuel wood by local inhabitants. Some of the wastes, particularly sawdust from sawmills, are integrated into the manufacture of particle boards with up to a maximum capacity 40,000 cubic meters produced annually, which is quite low [54]. Ogunrinde and Owoyemi [52] admitted that harvesting residue poses a lot of problems to waste management authorities in Nigeria, which is why they are largely unutilized. This is because of the large quantity of wastes generated compared to the timber available for processing. In addition to this is the lack of appropriate harvesting technology and unavailable equipment. The utilization of these residues for energy generation will aid in a reduction of exploitation of forest resources for fuel and consequently curb the rate of deforestation.

4.2. Herbaceous Biomass

Herbaceous biomass is obtained from plants with a non-woody stem and they die at the end of the growing season. It includes grain and seed crops from the food processing industry and their by-products. Herbaceous crops can be sub-divided into agricultural residues and energy crops [43].

4.2.1. Agricultural Residues

Agricultural residues are by-products of food, fibers, or food industries. Due to the huge agricultural activity in Nigeria and its large land mass, there is an abundant source of residues from agricultural activity. The crops produced in Nigeria are shown in Table 7. The table shows the area harvested, which is the area from which a crop is obtained but excludes areas where there was no harvest due to damage, failure, or other occurrences. The yield is the harvested production per unit of harvested area for the crop products in tons per hectare (t/ha). The production quantity refers to the actual harvested production from the field excluding harvest and threshing losses.

Table 7.

Agricultural production data in Nigeria for 2017; residue-to-product ratio (RPR) and typical chemical composition of agricultural residues in Nigeria.

Compilations of the residue-to-product ratio of agricultural residues and fuel characteristics have been presented by Koopmans and Koppejan [56], Lal [57], Jekayinfa and Scholz [58], Ojolo et al. [30] and Cáceres et al. [59], Jekayinfa and Scholz [60], and Seglah et al. [61]. The residue to product ratio is presented in Table 7 along with the agricultural production data. Details about the production of the products and utilization of the residues are discussed in subsequent sections.

Cassava

Cassava (Manihot esculenta) is a staple food crop and a chief source of dietary food energy in Nigeria [62,63]. Nigeria has also been adjudged to be the largest producer of cassava in the world [64]. Cassava is known to be able to survive in the soil, when unharvested, for up to two years but begins to deteriorate immediately harvested. Cassava can be harvested at any time of the year when the roots reach maturity. The harvest period is normally between 6 and 36 months after planting depending on its genotype, environment, soil type, and intended use [65]. According to Asante-Pok [66], the highest cassava-producing states are in the south-western part of the country followed by the south-eastern and interior sections. Only negligible quantities are produced in the northern part. It is estimated that cassava was harvested from about 6792,349 hectares of land mass of Nigeria in 2017, which yielded about 87,578 hg/ha [55].

Cassava can be processed into a wide range of traditional cassava forms (which include gari, fufu, lafun, abacha, amongst others), which are useful for human consumption [62,63]. Cassava also finds industrial applications in areas, such as animal feed, flour used in biscuits and confectionery, starch, hydrolysates for pharmaceuticals and seasonings, and in brewing industries [62].

The processing of cassava, which is mostly done traditionally, include peeling, washing, grating, fermentation, pressing, sieving, frying, cooking, bagging, and drainage. Taiwo [63] reviewed the constraints of these processes and proposed a solution to them. Asante-Pok [66] also noted that constraints in cassava production include a wide range of technical, institutional, and socioeconomic factors. These factors include pests and diseases, agronomic problems, land degradation, shortage of planting materials, access to markets, limited processing options, and inefficient or ineffective extension delivery systems.

Olukanni and Olatunji [67] identified three main types of residues, which include peels, solid fibrous material, and starchy wastewater. Recently, there is interest in the utilization of cassava stems as a bioenergy resource as less than 20% of the stems are used for propagation and the rest are allowed to waste. It was noted that the residues, which are available throughout the year, are rich in carbohydrate and are generated in large amounts during processing. Currently, residues, particularly the peels, are mainly left for animal feed. However, the quantities generated, together with the remoteness of the generating communities, result in a lot of unused residue, which is burned or left to rot. It has been noted that peels constitute 10% to 20% by mass of each tuber [68].

It has also been noted that ethanol used within the country by the distillers, pharmaceutical, and chemical industries are largely imported. Graffham et al. [69] noted that potential markets for alcohol in Nigeria are partial substitute for petrol in motor car fuel and replacement for kerosene for cooking. Although, ethanol from cassava has been regarded as a first-generation biofuel, the wastes produced could be beneficial in the production of ethanol. Ozoegwu et al. [68] noted that cassava is a suitable feedstock for biofuel production from the first generation, second generation, and integrated processes. A study by Pothraj et al. [70] showed that cassava waste could be converted directly into ethanol through microbial saccharification and fermentation of cassava waste. Ubalua [71] also proposed that cassava residues can be converted to energy carriers, such as biogas or methane and ethanol. Anyanwu et al. [72] stated that potential ethanol production from peels is more than enough for blending 10% of ethanol with gasoline (E-10). Veiga et al. [73] characterized cassava waste, including seed stem, thick stalks, and thin stalks, and found that the properties of cassava waste were analogous to those of woody biomass regarding elemental composition, higher heating value, and thermogravimetric analysis. Jekayinfa and Scholz [74] investigated the production of biogas from cassava peels and tubers.

Cocoa

Nigeria is the fourth-largest producer of cocoa (Theobroma cacao) following Côte d’Ivoire, Ghana, and Indonesia in order [55]. The area of the land mass cultivated for cocoa is 1,191,812 hectares, which gives a yield of 328,200 ton of cocoa beans. Amao et al. [75] noted that cocoa is produced in 16 states in Nigeria. However, Hamzat et al. [76] and Cadoni [77] noted that asides from Cross River and Edo States in the south-south, the major producing states are in the south-western zone of Nigeria. These include Ekiti, Ogun, Ondo, Osun, and Oyo states. The other cocoa-producing states include Kogi, Akwa Ibom, Delta, Abia, Kwara, Ebonyi, Rivers, Taraba, and Adamawa states.

Amao et al. [75] and Cadoni [77] noted that the majority of cocoa is exported as beans; however, the first processing of other cocoa-derived products takes place in Nigeria. Cocoa is normally processed into cocoa butter and cocoa powder, which are intermediary products useful for chocolates and confectionary products. It was noted that the harvesting of cocoa is intensive between December and June, but the process of harvesting is crude as the process has not been mechanized.

Adewuyi et al. [78] stated that the ripe pods are removed from the tree using hand-held tools. The ripe pods are then split with a hammer or similar instrument and the cream-colored beans are removed from the pods. Consequently, the beans are allowed to ferment before they are dried. The residue generated during pod splitting is the husk and the inner membrane, which are discarded. Balentić et al. [79] identified that in addition to the husks, mucilage and shells are also considered as wastes during processing of cocoa. The method of discarding these residues, leaving them to rot, cause environmental problems, such as unpleasant odors, and may propagate diseases [80]. Cocoa shells and husks have found applications in animal feedstuff, adsorbent, dye production, food products, and suppressing weed growth in agriculture. Cocoa shells have also been investigated for use as biofuels, such as ethanol [81], biogas [82,83,84], and pyrolysis [85]. Cocoa pod husks have been characterized by Adjin-Tetteh et al. [85] and Titiloye et al. [86]. Although the moisture content was high, which could reduce the effectiveness of thermochemical conversion processes, the resource was considered suitable for bioenergy through such processes.

Coconut

Coconut palm, Cocus nucifera, was planted on 39,124 hectares across Nigeria in 2017 [55]. It has been successfully grown in the tropic and sub-tropic areas and has different varieties, such as West African tall, dwarf green, Malayan dwarf yellow, Malayan dwarf red, and hybrid coconut [87]. It has been noted that coconut is not indigenous to Nigeria. Its cultivation, however, is by the coastal and nearby region throughout the whole world. It is known that Nigeria is bounded in the south by the Coast of Guinea, which is probably why Lagos state is the highest producer of coconut in Nigeria. Uwubanmwen et al. [88] noted that more than 90% of Nigeria’s coconut belt is a continuation of the plantations of groves along the West African coast running from Cote d’Ivoire and south-east towards Ghana, Togo, and Benin to Lagos state. Other coconut-producing states in Nigeria include Adamawa, Bauchi, Borno, Jigawa, Kaduna, Kano, Katsina, Kebbi, Nassarawa, Niger, Ogun, Plateau, Sokoto, Taraba, Yobe, and Zamfara states.

Coconut products include the nut or meat, the liquid endosperm, the dehydrated meal, coconut oil, coconut milk, and coconut cake. Osemwegie et al. [87] noted that coconut products are useful in many areas, including human nutrition, animal feed, cosmetics, and pharmaceutical industries. Uwubanmwen et al. [88] reviewed other applications of coconut. Before these coconut products can be produced, harvested coconuts have to be dehusked and shelled.

Dehusking is mostly done manually due to the lack of mechanized equipment. The process of dehusking requires a few impaling strokes using a sharp metal stake mounted on a platform [89]. Dehusking is also carried out using a cutlass [90]. According to Suharto [91], one has to be physically strong and has to be expert to prevent accidents or injury. Dehusking exposes the shell, which is the hardest part of the coconut. Uwubanmwen et al. [88] explained that to detach the shell from the kernel, open cups are dried in the sun with the open side turned towards the sun. The kernel gets detached from the shell, after which it can easily be removed by means of a thin wooden lever.

Coconut residues include the shell, husk, coir dust, and usable products. The husks constitute 35% to 40% of the residue whilst the shell is about 12%. Coconut shells have been applied in the production of activated charcoal, as a filler and extender in the synthesis of plastics. Coconut husk fiber has been used industrially and domestically [87,88]. The fibers can be woven into items like ropes, yarns for nets, mats, rugs, chair and cushion stuffing, padding for mattresses, and bags. It has been shown that coconut residues are good potential materials for biofuels [92,93]. Amoako and Mensah-Amoah [94] found that coconut shells and coconut husks had calorific values of 17.4 and 10.0 MJ/kg, respectively, which imply that they have a huge potential for energy generation in regions where they are largely generated. Cabral et al. [95] investigated the bioethanol production from coconut husk fiber and obtained a sugar to ethanol conversion efficiency of 59.6%. Tooy et al. [96] also discussed the effectiveness of gasification coconut husks.

Coffee

Coffee belongs to the genus Coffenin and is considered to be a minor crop in Nigeria. Although there are about 90 to 100 species belonging to the genus, most of the coffee produced in Nigeria is the C. canephora. Other species cultivated include C. arabica, C. excelsa, C. stenophyilla, and C. liberica, which are indigenous to Nigeria [97,98]. A land mass of 1198 hectares is used in harvesting coffee to produce about 1600 ton of coffee product [55]. The major current coffee production states in Nigeria spans across the six geopolitical zones and include Taraba, Plateau, Adamawa, Oyo, Osun, Ondo, Ogun, Lagos, Edo, Kwara, Kogi, Niger, Kaduna, Benue, Abia, Cross River, and Akwa Ibom [99].

Coffee passes through various stages of primary processing, which is mainly to separate the beans from the pulp, before it is exported as unroasted green coffee. Coffee may be processed by one of two methods, which are the wet and dry methods. The wet method involves soaking the cherries in water for a period between 12 to 48 h before it is passed through a pulping machine to separate the skin from the bean. After the process, the product is dried to the maximum moisture content of about 12% [100]. The dry method, which is mostly used in areas where there is a limited supply of water, involves sun-drying of the coffee berries on huge surfaces to ensure effective drying. Dried berries are then sent to the mill for hulling, sorting, grading, and bagging.

Figueroa et al. [101] noted that coffee cherry husks represent about 12% of the berry on a dry weight basis whilst the coffee pulp juice is about 29%. The wet process of processing coffee generates a lot of wastewater, which has a high level of pollutants. Coffee wastewater consists of organic matter, which resulted from pulping, where the mesocarp is removed and the mucilage texture around the parchment is partly degraded. It was noted by von Enden [102] that the wastewater consists of pulp and mucilage, which are made up of quickly fermenting sugars, proteins, and polysaccharide carbohydrates. Spent coffee also forms part of the by-product resulting from the processing of soluble instant coffee preparation.

Figueroa et al. [101] noted that valorization of solid coffee products has been used in the reinforcement of polymer composites, in activation/decolorization, as an electrode material, and in application to wastewater treatment and cosmetic products amongst other applications. There have also been applications of coffee wastes for bioenergy generation. Chala et al. [103] demonstrated that coffee processing waste, including husk, pulp, parchment, mucilage, and wastewater, could be used to generate biogas. Vítěz et al. [104] also generated biogas from spent coffee grounds. Luz et al. [105] also investigated bio-oil production from spent coffee grounds.

Cowpea

Cowpea (Vigna unguiculata L.) is a common food in Nigeria and serves as an important source of protein. Ajetomobi and Abiodun [106] stated that the major cowpea-producing states are Benue, Kaduna, Kwara, Anambra, Yobe, and Oyo states. The other states producing cowpea, but at a lower yield, are Kano, Jigawa, Zamfara, Niger, Borno, Katsina, Plateau, and Sokoto. As at 2017, the total land mass used in cultivating cowpea is 3,782,760 ha with the produced quantity of dried cowpea being about 3.41 million tons [55].

Cowpea is processed by threshing, which is carried out manually by beating the plants or bagged pods with sticks once they are dry enough [107]. Threshing and winnowing machines have also been developed. Cowpea shells are the residues that result during postharvest processing. The residues have been investigated for use in agricultural productivity when incorporated into fertilizers [108].

In terms of bioenergy applications, Kemausuor et al. [109] noted that there is some potential for generating biogas and cellulosic ethanol from cowpea shells. Madhukara et al. [110] investigated the production of methane from green pea shells in floating dome digesters. Martín et al. [42] considered peanut shells, being ligno-cellulosic residues, for ethanol production.

Fruits and Vegetables

Fruits and vegetables play important roles in nutrition and health. The major fruits produced in Nigeria include mango, pineapple, banana, citrus, guava, and pawpaw. Vegetables include onion, tomato, okra, pepper, amaranthus, carrot, melon, Corchorus olitorus, Hibiscus sabdariffa, and Adansonia digtata amongst others. Fruits and vegetables are produced enormously in Nigeria [111]. It was estimated from FAOSTAT [55] that about 8.5 million hectares were cultivated for fruits and vegetables in 2017 with over 30 million tons of produce.

The loss of agricultural produce is a major problem in the post-harvest chain in Nigeria. It was also noted by Singh et al. [112] that more than a 30% loss occurs globally at the retail and consumer levels. Ibeawuchi et al. [111] noted that wastes may be considerable depending on the prevailing situations, which relate to a variety of factors, such as growing conditions to handling at the retail level. Due to the large losses from the post-harvest chain, only fruit and vegetable wastes should be considered for energy production. This is important considering the value of fruits and vegetables to the nutrition of the poor populace, who may rely on them for nutritional value.

Fruits and vegetable wastes often have a high moisture content, which ranges between 80% and 93% wet basis. Singh et al. [112] reviewed the means of converting fruit and vegetable wastes to bioenergy. These include biomethane from anaerobic digestion, biodiesel for wastes with high-fat content, bioethanol, and biohydrogen. Several studies have been carried out on the conversion of fruit and vegetable wastes to bioenergy, particularly biogas. Recent studies include Jekayinfa et al. [113], Zhao et al. [114], Edwiges et al. [115], Ravi et al. [116], Xu et al. [117], and Martí-Herrero et al. [118]. Ola and Jekayinfa [119] investigated the thermal decomposition of mango stone.

Groundnut

Nigeria is the largest producer of groundnut (Arachis hypogea) in West Africa and it accounts for 51% of the production in the region. Nigeria also accounts for 10% of the global groundnut production and 39% of the production in Africa [120]. The area harvested for groundnut has been estimated to be about 2.8 million ha, which produces about 2.4 million tons of the product. Nigeria is ranked the fifth-largest producer of groundnut globally [55].

Duc et al. [121] noted that groundnut shells are rich in many functional compounds and composed of cellulose, hemicellulose, and lignin. This enables the shells to be used in different ways. Muhammad et al. [122] assessed the management of groundnut wastes and found that some of the wastes were used as animal feed whilst others were disposed in landfills or simply burnt. The conversion of groundnut waste to biofuel would be more lucrative than utilization in ways that affect the environment. Some of the biofuels identified by Duc et al. [121] that can be obtained from groundnut shells include biodiesel and bioethanol. Oyelaran et al. [123] investigated the production of briquettes from groundnut shells with waste paper. Nyachaka et al. [124] and Olafimihan et al. [125] investigated the production of bioethanol from groundnut shells whilst Radhakrishnan and Gnanamoorthi [126] produced bio-oil from the shells through pyrolysis.

Maize

Maize (Zea mays) is one of the major staple foods in developing countries accounting for up to 90% of the calorie intake of the rural population. It is the most important cereal crop in sub-Saharan Africa [127]. Maize has several uses, which include food, medicines, and raw materials for industries [128]. In 2017, Nigeria produced about 11.2 million tons of maize over a cultivated area of 6.5 million hectares [55]. Nigeria is ranked among the top 15 producers of maize globally. All states in Nigeria produce maize, with the top five producing states being Kaduna, Borno, Taraba, Plateau, and Niger states [129].

Maize residues include cobs, stalk, and husk. Maize residues have been largely applied to livestock bedding, feed, and, in some cases, manure [130,131]. Although maize residues have been used as cooking fuels, it has not been utilized efficiently [61]. Maize residues have been converted to more efficient solid fuels through briquetting [132,133,134]. Ethanol has been produced from corn residues by [125,135,136]. Corn stover has also been used to produce saturated and monounsaturated aliphatic methyl ketones in the C11 to C15 (diesel) range [137,138]. Biogas has also been generated through anaerobic digestion by using the residues with or without a co-substrate [139,140,141,142]. Thermochemical processing was carried out on the residues in studies by Biswas et al. [143], Ceranic et al. [144], and Tippayawong et al. [145].

Millet

Millet, Pennisetum glaucum, is one of the major cereal crops in Nigeria, which is extensively used in northern Nigeria [146]. It is cultivated in arid to semi-arid regions and is considered to be a staple in those regions [147]. In 2017, Nigeria produced 1.5 million tons of millet over a cultivated area of over 2.2 million ha and was ranked as the eighth-largest producer of millet globally [55]. The highest millet-producing state in Nigeria is Sokoto state [50]. Other states that produce millet are Kaduna, Yobe, Kano, and Borno states.

Processing millet involves decortication or dehulling, washing, drying, milling, fermenting, molding, steaming, and drying. The residues from millet processing are basically the straws or stovers, which are left in the field after grain harvest. Millet residues are mostly used for forage due to its drought tolerance, leafiness, and succulent stems [148,149]. Oyedepo et al. [150] identified that although bioethanol can be derived from millet, the stalks can be converted to solid fuel through briquetting.

Oil Palm

Oil palm (Elaeis guineesis) had a cultivated area of over 3 million ha and production quantity of about 7.8 million tons in 2017 [55]. Nigeria has also been rated as the fourth-largest producer of oil palm in Nigeria. Oil palm is one of the major agro-businesses in Nigeria and contributes significantly to the nation’s economic growth and development [151].

Solid wastes generated during the processing of oil palm include empty fruit bunch, palm press fibre, chaff, and palm kernel shell. The solid wastes result from threshing, pressing, and kernel cracking. Although, the solid wastes are mostly used as fuel for the palm oil mill, a large quantity is still unused and eventually burnt, which results in air pollution. In addition to this, there is undesirable discharge of untreated palm oil mill effluents into the environment [151].

Ahmad et al. [152] reviewed the renewable energy options to tackle the problems resulting from palm oil mill effluent. Bioenergy routes identified and suggested include biomethane, biohydrogen, biodiesel, and bioethanol. Ahmad et al. [153] investigated the anaerobic degradation of lipids in palm oil effluent. For the solid residues, the main constituents are cellulose, hemicellulose, and lignin. Hamzah et al. [154] noted that the high cellulose and hemicellulose contents can be converted to simple sugars and processed into biofuels or biochemicals. The solid residues can also be compressed to pellets and briquettes as fuel [155,156]. Safana et al. [157] investigated the thermochemical treatment of oil-palm waste using pyrolysis.

Plantain

Plantain (Musa spp.) is a parthenocarpic (seedless fruit) plant propagated via its suckers and plantlet. Nigeria is one of the largest producers of plantain in the world. From data obtained from FAOSTAT [55], it is ranked the sixth-largest producer of plantain globally. Akinyemi et al. [158] also noted that plantain remains an important staple food and has a high demand within the country. Nigeria cultivates over 493,000 hectares for the production of plantain and has a yield of about 64,000 hg/ha. In Nigeria, large quantities of plantain are produced in Edo, Delta, Ogun, and Ondo states. Other producing states include Rivers, Cross River, Imo, Anambra, Lagos, Kwara, Benue, Plateau, Kogi, Abia, and Enugu states [159].

Plantain peels are used as feed for livestock and the dried peels for soap production. Additionally, the dried leaves, sheath, and petioles are used as tying materials, sponges, and roofing material. Plantain leaves are also used for wrapping, packaging, marketing, and serving of food [158,160]. Plantain peels have also been found to be useful in the generation of biofuels. Agwa et al. [161], Olafimihan et al. [125], and Itelima et al. [162] investigated the production of bioethanol from plantain wastes. Parra-Ramírez et al. [163] and Ilori et al. [164] produced biogas from plantain wastes whilst Adeniyi et al. [165] and Ogunjobi and Lajide [166] carried out pyrolysis on plantain peels to obtain bio-oil and bio-char.

Potato

Nigeria cultivates both sweet and Irish potatoes, producing about 5.3 million tons of produce over an area of 2 million hectares. Ugonna et al. [167] noted that Nigeria is the fourth-largest producer of potato in sub-Saharan Africa. Sweet potatoes are consumed as food in the tropics and also have diverse industrial uses, such as being a raw material for snacks [168]. Major cultivation of potato in Nigeria is done in Plateau state.

Potato (Solanum tuberosum) wastes have been largely used as feed for ruminant animals. Sepelev and Galoburda [169] noted that there is a big potential for potato peel extract as an antioxidant in food systems due to its high phenol content. It was also discovered that potato peel powder could serve as a partial flour replacement in dough without causing significant changes in the sensory properties. For biofuel generation, Ugonna et al. [167], Ghosal et al. [168], and Sepelev and Galoburda [169] noted potato wastes, such as the peels and other wastes with no value, are rich in starch and can be liquefied and fermented to produce fuel-grade ethanol. Jekayinfa et al. [113] investigated biogas production from potato peels.

Rice

Rice (Oryza sativa) production and processing are profitable ventures in Nigeria as it has good nutritional value and a high inclination towards its consumption [170,171]. Rice is one of the most valuable staple foods in Nigeria. It is cultivated over an area of 4.9 million hectares with the quantity produced reaching 9.8 million tons. Udemezue [172], however, noted that only about half of the domestic demand has been met, but rice production keeps growing. According to Udemezue [172], only 8 of the 30 six states can produce rice in a large scale and they include Anambra, Nassarawa, Ebonyi, Kaduna, Niger, Kano, Adamawa, and Benue.

Postharvest operations for rice cultivation include threshing and milling. Paddy rice undergoes processes, such as hulling, polishing, grading, and destoning [173]. The by-products of rice are the husks, bran, and stalks. Mohammed [174] noted that these by-products can be used as animal feeds and Osabuohien et al. [171] noted that they can be buried in the soil in a production system with no-tillage or conservation tillage.

Teh and Jamari [175], Wajima and Sakakibara [176], and Alhinai et al. [177] carried out studies on the torrefaction and pyrolysis of rice husk and rice straw. Abudi et al. [178] investigated biogas production from co-digestion of municipal solid waste with thickened waste-activated sludge and rice straw. Ajimotokan et al. [179] investigated the production of briquettes from rice husk. Abbas and Ansumali [180] noted that there is a huge potential to satisfy the global ethanol biofuel demand for a 10% gasohol fuel blend.

Sorghum

Sorghum (Sorhum bicolor), also known as guinea corn, is grown predominantly in the semi-arid savannah and grassland areas of northern Nigeria. Being nutritionally rich, it serves as staple food in most parts of northern Nigeria. Jacob et al. [181] noted that sorghum is potentially useful as raw material for the brewing, food, textile, and beauty industries. Sorghum was cultivated in Nigeria over an area of 5.8 million hectares and with a yield of 11,923 hg/ha in 2017 [55]. According to data from FAOSTAT [55], Nigeria was the second-largest producer of sorghum after the United States. Mundia et al. [182] stated that the production of sorghum surpasses all other crops in Nigeria.

Ahmad et al. [183] noted that ruminant animals feed on sorghum crop fodders although they are low in protein and mineral contents. Saeed et al. [184] determined the cellulose and lignin contents of sorghum stalks and determined the strength of hand sheet made from the residue. Turhollow et al. [185], however, noted that sorghum has a great potential as an annual energy crop, describing energy sorghum as forage sorghum bred for high biomass production. Rodias et al. [186] and Shahandeh et al. [187] noted that sweet sorghum is an important energy crop for bioethanol production. Sundstrom et al. [188] pre-treated sorghum biomass using ionic liquid and carried out saccharification and fermentation to produce sesquiterpene bisabolene, which is a precursor to renewable diesel. Olaoye and Kudabo [189] also investigated briquette production from sorghum stovers.

Soybean

Soybean (Glycine max), is cheap, rich in protein, and contains edible oil and a good balance of amino acids. Soybean, though not one of the popular staple foods, is gaining prominence in Nigeria [190,191]. Major soybean-producing states in Nigeria are Benue, Kaduna, Plateau, and Niger states. Other states involved with the production of soybeans include Nassarawa, Kebbi, Kwara, Oyo, Jigawa, Borno, Bauchi, Sokoto, and Taraba states. Soybean is considered as one of the major industrial and food crops grown in every continent. The market for soybean in Nigeria is growing very fast and includes livestock feed, oil mills, and cereal industries [192]. In Nigeria, 730,000 tons of soybean is produced over an area of 750,000 hectares [55].

The residues generated during soybean harvesting and post-harvesting operations include the stalk and the husk. Kiš et al. [193] proposed that soybean straw is a good basis for the production of second-generation biofuels from renewable sources by a biomass-to-liquid procedure. Soybean oil has been used for the production of biodiesel and soybean husk has good potential for the production of briquettes and pellets [194,195].

Sugarcane

Sugarcane (Saccharum officinarum) is one of the most important crops globally as it provides 60% of the total global sugar requirement. In Nigeria, two types of sugarcane are grown, which are the industrial and soft, or chewing, cane [196]. Sugarcane is, however, largely consumed domestically as the sugar industry is yet to be developed [197,198]. From observations by Gourichon [199], sugarcane is not a major commodity in the country in terms of the value and quantity of production compared to other crops. About 1.5 million tons of sugarcane is produced over an area of 89,000 hectares [55]. Nmadu et al. [196] noted that local farmers grow soft cane all over Nigeria.

The residues from sugarcane are bagasse and leaves. Bagasse is obtained after sugarcane is crushed to obtain juice used for sugar and ethanol production. Bagasse is used in the production of industrial enzymes, organic acids, xylitol, and ethanol. The leaves are also called sugarcane trash and are generally burnt in fields. This produces fly ash and severely damages soil microbial diversity and raises environmental concerns [200,201]. By-products of sugarcane have found application in medicine, pharmaceuticals, confectionary and beverages, electricity, and motor fuels [202].

Machado et al. [200] noted that both the bagasse and leaves of sugarcane have potential to be used as substrates to obtain high value-added products from their cellulosic fractions, such as organic acids, biofuels, and biopolymers. Bispo et al. [203] produced bio-oil through pyrolysis of sugarcane straw. Simo et al. [204] investigated anaerobic digestion of sugarcane bagasse to produce biogas while Patil and Deshannavar [205] investigated the potential of using sugarcane leaves for producing briquettes.

Wheat

Wheat (Triticum aestivum) is considered to be an important crop with household and industrial importance, both in Nigeria and globally [206]. There is an increasing consumption and demand for wheat in Nigeria due to the increase and expansion in wheat-based foods and the confectionary industry, such as the bread and pasta industries [207]. As at 2017, the production of wheat in Nigeria was about 66,576 tons over an area of 70,496 hectares [55].

Gupta et al. [208] noted that residues of wheat, particularly wheat straw, are left in the open field after harvesting for open burning. This has been found to result in nutrient and resource loss, which affects the soil properties adversely. An alternative is to incorporate the wheat residues into the soil to improve the nitrogen content in the soil. The conversion methods of wheat residues to other useful bioenergy resources have been investigated. Biswas et al. [143] investigated the pyrolysis of wheat straw to obtain bio-oil. Mancini et al. [84] investigated the production of biogas from wheat straw.

Yam

Apart from cereals, yam (Dioscorea sp.) is the most important food crop in West Africa and the second most important tuber globally [209]. It is an annual crop, which is grown in tropical regions and mostly in the savannah region of West Africa. Yam is a staple food crop and serves as an integral vehicle for food security in Nigeria [210]. Nigeria is the world’s largest producer of yams, with over 47 million tons produced in 2017 over an area of over 5.9 million hectares [55].

Yam peels are the basic wastes or by-products generated during processing and are mostly used in animal feed [211,212]. For the generation of bioenergy, Olayemi et al. [213] and Ebabhi et al. [214] investigated the production of bioethanol from yam peels. Fasina [19] investigated the pyrolysis of yam peels, noting that the peels were potential biomass feedstock due to a high heating value and medium ash content.

4.2.2. Energy Crops

Energy crops are dedicated crops, which are grown for bioenergy purposes. Demirbaş [215] described commercial energy crops as typically densely planted high-yielding crop species, which will be burnt to generate power. Parrish and Fike [216] noted that ideal energy crops should have attributes like ready establishment and management, ease of genomic manipulation, more efficient conversion into liquid fuels, and provision of key ecosystem services. Energy crops can take many forms and can be converted to a number of products, with several species being useful for the production of more than one type of energy product [217]. Parrish and Fike [216] proposed that perennial species are preferred to annual species and first-generation biofuels or food crops as second-generation biofuels. This is because they can be grown with modest inputs and have lower environmental impacts.

The common energy crops have been classified by Sims et al. [217] into oil crops, cereals, starch and sugar crops, cellulose crops, and solid energy crops. Oil crops include vegetable oils that can be used directly in heating fuels or refined to transport fuels. They include oilseed rape, linseed, field mustard, hemp, sunflower, safflower, castor oil, palm, coconut, and groundnut. Cereals (such as barley, wheat, oats, maize, and rye), starch and sugar crops (such as potato, sugar beet, and sugarcane) or cellulose crops (such as straw, wood, and short rotation crops) can be used to produce ethanol. Solid energy crops can be utilized whole to produce heat and electricity and they include sorghum, whole crop maize, reed canary grass, miscanthus, poplar, and eucalyptus.

In Nigeria, most of the crops grown are potential energy crops. However, it will be erroneous to state that they would constitute a part of the supply for bioenergy resources. This is due to the competition it would create with food. This view is shared by Matemilola et al. [218]. Consequently, Nigeria has not focused on the cultivation of crops for bioenergy utilization despite its high potential in that regard [219]. One such crop is Jatropha curcas and other oil-producing non-edible seeds, which have been found to be potentially suitable for the production of biodiesel [220,221].

Outlining key issues concerning the production of biomass for energy use, Okoro et al. [222] and Schubert et al. [223] stated that there is a strict opposition to the direct or indirect conversion of woodland, forests, and wetlands into agricultural land for energy crops. It was further stated that such conversion is usually accompanied by non-compensable greenhouse emissions with negative impacts on biological diversity and soil carbon storage. Schubert et al. [223] and Wicke [224] recommend the use of marginal and degraded land for the production of energy crops. Wicke [224] noted that the production of energy crops on marginal or degraded land avoids the negative effects related to land use change since the land is largely unsuitable and economically unattractive for agricultural crop production. According to Olanrewaju and Ezekiel [225], marginal lands in Nigeria are extensive, forming more than 40% of the total land mass and spans throughout the country. The causes and areas of marginal lands in Nigeria are presented in Table 8. These regions serve as potential areas for the cultivation of energy crops.

Table 8.

Causes and areas of marginal lands in Nigeria [225,226].

4.3. Aquatic Biomass

Nigeria has several kinds of aquatic environment suitable for the cultivation of aquatic biomass [227]. The country is bounded in the coastal regions by the Atlantic Ocean, which spans eight states. Lohdip and Gongden [228] also noted that the full extent of the number of water bodies cannot be accurately stated as they vary with the season. The water bodies include small and big rivers, dams, and lakes. Considering the large body of water in Nigeria, there is a huge potential for the production of aquatic biomass. Aquatic biomass includes algae and emerging plants [43,229]. These include marine or freshwater algae, macroalgae or micro algae, seaweed, kelp, lake weed, and water hyacinth. Kaur et al. [230] stated that aquatic weeds have exceptionally high reproduction rates and are rich in cellulose and hemicellulose with a very low lignin content, which makes them efficient as biofuel crops. Simonyan and Fasina [50] noted that the three common fast-growing aquatic weeds in Nigeria are water hyacinth, water lettuce, and brackenfern.

Tursi [43] noted that aquatic biomass is currently being considered as an ideal raw material for the production of third-generation biodiesel since it is not in competition with food crops. Aquatic biomass also has the advantage of producing larger amounts of biomass per hectare compared to land crops. Kundu et al. [231] also noted that aquatic biomass can be utilized in the generation of biogas. Calicioglu et al. [232] investigated a cascaded biorefinery for the production of ethanol, fatty acids, and methane for aquatic biomass (duckweed). Studies have been carried out by Ahmad et al. [233] and Alves et al. [234] on the pyrolysis of aquatic biomass. Cheng et al. [235] and Fedler and Duan [236] investigated the cultivation of aquatic crops in waste water.

4.4. Animal and Human Waste

Energy from livestock waste has been regarded as a unique and important source, which is able to supplement current energy needs and solve waste management problems [237]. The animal population obtained from data as at 2017 obtained from FAOSTAT [55] is presented in Table 9 along with the biogas yield [30,238,239]. The table shows that there is a huge population of animals in Nigeria that produce wastes that can be harnessed for energy production. Orakwe et al. [240] noted that there are encouraging potentials for biogas production in Nigeria and the problems associated with the technology are surmountable. A number of studies have investigated different aspects regarding the production of biogas from animal wastes [241,242,243].

Table 9.

Animal population in Nigeria and biogas yield from animal wastes.

There is an aversion to the use of human waste for energy generation in developing countries. However, Oseji et al. [244] found that treating human waste by anaerobic digestion is a credibly ethical sanitation technology and a potent way of reducing the biochemical oxygen demand and chemical oxygen demand. Most importantly, anaerobic digestion reduces pathogens and averts serious public health risk posed by the waste. Kumar et al. [245] also investigated the utilization of pre-treated animal and human waste as media for the cultivation of microalgae for biodiesel production.

4.5. Municipal Solid Waste

Municipal solid waste refers to classes of wastes considered as trash. They are highly non-homogeneous, being a mixture of residential, commercial, and industrial wastes [246,247]. Globally, and particularly in developing countries, the management of municipal solid waste constitutes an important environmental concern [248,249]. The average rate of solid waste generation in Nigeria is approximately 0.5 kg/capita/day [250], which is typical to low-income countries [247,250]. There is, however, a wide variation of the waste generation rates in different cities. For instance, two cities in southwestern Nigeria, Ado-Ekiti and Ogbomoso, have the highest (0.71 kg/capita/day) and lowest (0.13 kg/capita/day) solid waste generation rates per capita, respectively [247,250]. The solid waste generation rate depends on the peculiar characteristics of the city.

The composition of the waste also varies with location, and the composition of municipal solid waste in some Nigerian cities has been compiled in different studies [247,250,251]. Generally, from all characterizations, it is observed that the organic constituent of the wastes has the highest contribution. The organic content in municipal solid waste could reach up to 78%. Due to the high organic content, municipal solid waste can be incinerated or degraded anaerobically to generate methane. However, the energy potential of municipal solid waste cannot be harnessed unless proper waste management is practiced. This will require replacing the current hazardous dumpsites with appropriately designed landfills. There will be a need to revamp the waste collection chain for proper collection, handling, and processing of the waste.

5. Overview of Biomass Conversion Technologies in Nigeria

There are quite a number of technologies available for the conversion of biomass to energy. The technologies could produce solid, liquid, or gaseous fuels. They have been classified into physical or mechanical conversion, thermochemical conversion, and biochemical conversion. An assessment, by desk review, of the research and development of the biomass conversion technologies in Nigeria is carried out in this section.

5.1. Physical or Mechanical Conversion

Physical or mechanical biomass conversion processes involve means of physically altering the structure of cellulose. They include chipping, grinding, milling, and densification. Densification produces solid fuels like briquettes and pellets when raw biomass is subjected to pressure. When a binder is not used, an elevated temperature is required to form the briquettes or pellets. Several works have been done to research into biomass briquetting in Nigeria. Recent works, which investigated various aspects of biomass densification and technologies involved, include Jekayinfa et al. [132], Ojolo et al. [252], Orisaleye et al. [133,134,253,254,255], Orisaleye and Ojolo [256,257], Ojomo et al. [258], Dairo et al. [259], and Adeleke et al. [260]. Abdulkareem et al. [261] investigated the combustion characteristics of biomass briquettes while Umar et al. [262] investigated the application of briquettes to fish processing.

Although there has been a lot of research work carried out locally with available biomass materials, there is yet to be an industrial or domestic application of the briquettes. This may, perhaps, be due to the unavailable technologies for the utilization of the solid fuels. A potential market exists for densified solid fuel in Nigeria since there is a huge dependence on fuelwood. Lamido [263] noted that briquetting could be beneficial to address deforestation problems as well as economic problems linked to unemployment. Obi et al. [264] reviewed factors that limit the commercialization of biomass briquetting in Nigeria and suggested that appropriate briquetting machines for the commercialization of biomass briquetting in Nigeria need to be developed.

5.2. Thermochemical Conversion

Thermochemical conversion involves the generation of energy from biomass by the application of heat and chemical processes. Existing thermochemical conversion processes include combustion, pyrolysis, gasification, and liquefaction [43]. Most of the energy generation from biomass is obtained by combustion processes. However, the efficiency of combustion processes used in Nigeria is very low and results in the eventual waste of energy. Biomass combustion in Nigeria is mostly carried out in the rural poor communities to supply energy for cooking. This process is characterized by inefficient three-stone stoves, which perform poorly and have a high specific fuel consumption. Other processes include charcoal stoves and sawdust stoves. Bello et al. [265] obtained efficiencies of 52.64%, 64.38%, and 34.56% for the sawdust stove, charcoal stove, and three-stone stove, respectively. Gujba et al. [18] also pointed out that the efficiencies of fuelwood, charcoal, and agricultural residue used in cooking were 18%, 22%, and 10%, respectively, which are lower than the efficiencies of kerosene, liquefied petroleum gas, and electric stoves, with efficiencies ranging from 55% to 95%. Advanced combustion technologies, therefore, need to be adopted within the country. Ofori et al. [266] identified that there are health effects linked with household biomass fuel use and these include increased systolic blood pressure, carotid intima media thickness, and pre-hypertension. In another study, Adefuye et al. [267] found that there is a risk of respiratory diseases for users of biomass fuel in Nigeria.

Pyrolysis is the thermal decomposition of lignocellulosic biomass in the absence of air under an inert atmosphere. The end products of pyrolysis are biochar, bio-oil, and gases. The products obtained from pyrolysis will depend on the operating temperature, solid residence time, reactor type, and heating rates of the process [268]. Torrefaction and carbonization are also thermochemical processes linked with pyrolysis. At low pyrolysis temperatures between 300 and 400 °C, char is the basic product obtained during the reaction time. Rapid pyrolysis occurs at temperatures ranging from 500 to 650 °C, with bio-oil as the main product, and at temperatures higher than 700 °C, the product obtained is methane [269,270]. Commonly used reactors include fixed bed reactors, fluidized bed reactors, and rotary kiln or mobile rectors [271]. Pyrolysis, torrefaction, and carbonization are still at the laboratory scale in Nigeria. Ola and Jekayinfa [272,273] carried out investigations using sandbox (Hura crepitans) shells and found that varying the temperature, heating time, and particle size of the feedstock significantly affected the biochar yield from the shells. Fuwape and Faruwa [274] carried out torrefaction on wood samples of Pinus carrebea and Leucaena leucocephala to investigate the effect of temperature on the physical and combustion properties of the product. Garba et al. [275] and Akanni et al. [276] also carried out torrefaction studies on rice straw and woody biomass (Melina and Teak wood), respectively, varying both temperatures and residence times. Farrow et al. [277] investigated the characteristics of char produced from cassava peelings whilst Onifade et al. [278] characterized bio-oil produced from palm fruit fiber and physic nut shell. Okekunle et al. [279] assessed the pyrolysis products from different wood sources (Gmelina arborea, Anogeissus leiocarpa, Parkia biglobosa, and Adansonia kilima).

Gasification involves the conversion of biomass to natural gas synthesis gas (or syngas), which is a mixture of CO2, CO, and H2. Some hydrocarbons may also be produced during the gasification process [280]. The gas can be applied in heat energy applications or power generation. Gasification occurs in reactors, which come in different designs. These include moving or fixed-bed gasifiers (updraft and downdraft gasifiers), fluidized-bed gasifiers (bubbling bed and circulating bed), and entrained flow gasifiers [281]. Gasification has been proposed as a means of combatting the shortage of the power supply compared to the high demand. Several authors have proposed rural electrification using gasification as part of the solution to the energy problem in Nigeria [282,283]. Laboratory investigations on gasification have been carried out by Kuhe and Aliyu [284], Olufemi [285], Ojolo et al. [286], Abdulrahman et al. [287], and Ojolo and Orisaleye [288]. Van den Braak [289] reported that there are pilot plants existing at the University of Sokoto, Obafemi Awolowo University, University of Agriculture, Maiduguri, and the University of Nigeria, Nsukka due to Nigeria’s University Research Program. The report also informs that large gasification plants would be established in Niger and Ogun states following government approvals.

5.3. Biochemical Conversion

Biochemical conversion processes for biomass include anaerobic digestion, fermentation, and transesterification. Anaerobic digestion produces biogas from wet organic substrate in the absence of oxygen. Biogas is a mixture of methane and carbon dioxide, with traces of hydrogen, hydrogen sulphide, and nitrogen [290]. Studies on biogas production in biodigesters include Adebayo et al. [241,291,292,293], Aigbodion et al. [290], Dahunsi, et al. [294], Ayodele et al. [295], and Ngulde et al. [296]. The utilization of biogas in Nigeria was investigated by Orhorhoro et al. [297], Ngumah et al. [298], and Akinbami et al. [299]. It was noted that biogas technology is not popular in Nigeria, but some scientific, engineering, and economic-based research works have been carried out at the institutional level.

Fermentation is the process where carbohydrates, such as starch and sugar, are converted to ethanol by a variety of microorganisms. Investigations on the production of ethanol from various biomass materials have been carried out by Ndukwe et al. [300], Ogali et al. [301], Otaraku et al. [302], Omotosho and Amori [303], and Etsuyankpa et al. [304]. The performance of ethanol blends with gasoline in spark ignition engines has been investigated by Igbokwe et al. [305], Nwufo et al. [306], and Okoronkwo et al. [307]. Yahuza and Dandakouta [308] reviewed the performance of ethanol blends with diesel in compression ignition engines.

Transesterification is the displacement of alcohol from an ester by another one in the presence of an acid or a base catalyst. It is the process that is used in the production of biodiesel from fatty acid methyl esters. Several researchers have carried out laboratory investigations on the production of biodiesel from different oils [309,310,311,312,313,314,315,316].

6. Energy Potential of Biomass in Nigeria

The theoretical energy potential of agricultural residues available in Nigeria is presented in Table 10. The estimation of the energy potential of each residue is based on the production rate of the related crop, the average of the range of the RPR specified in Table 7, and the average energy content. The theoretical potential derived from residue-based biomass is the sum of the energy potential of agricultural residues and is estimated as 3.64 EJ. The energy potential derived from animal waste converted to biogas is presented in Table 11. Ojolo et al. [30] found that biogas has an energy content ranging between 15.7 and 29.5 MJ/m3. An average of the range of values, estimated to be 22.6 MJ/m3, was used in the estimation for the energy potential. The theoretical energy potential of animal waste in Nigeria is determined to be 2.17 EJ. The estimated theoretical potential for agricultural residues and animal wastes is 5.81 EJ.

Table 10.

Energy potential of agricultural residues in Nigeria.

Table 11.

Energy potential of animal wastes in Nigeria.

The technical potential is a fraction of the theoretical potential, which can be harnessed for energy use. This depends on the availability factor of each biomass resource, which ranges from 0 to 1. The availability factor is used considering that only a portion of the annual available theoretical biomass potential could be collected [317]. Deng et al. [318] presented availability factors for different countries and regions. Due to the large uncertainty of the availability factor, a range of values were used. For West Africa, the range of values of the availability factor were between 0.10 and 0.30 for cereals, reaching up to 0.40 for rice, and between 0.08 and 0.50 for sugarcane. For grass, the range was from 0.10 to 0.25 whilst it was between 0.50 and 0.75 for wood residues. Since the range of values have not been specified for all categories of agricultural products, a generalized availability factor was assumed in this work. For agricultural products and animal wastes, a generalized availability factor of 0.30 was used, in line with Deng et al. [318]. With this, the technical potential of biomass energy from agricultural residues and animal wastes would be about 1.74 EJ.

For forest resources, the residues generated are in the form of sawdust, wood chips, and barks. It had been noted that only a fraction of the harvested trees get converted to the product for which they were harvested [51,52,53]. From Table 6, it is observed that about 72% of the harvested tree becomes residues. The estimation of the energy potential is based on saw logs and veneer logs, pulpwood, and other industrial wood listed in Table 5. Wood fuel and charcoal are also considered in the estimation due to the currently high dependence on it for domestic heating in rural poor areas. However, the continued dependence on wood fuel could pose a danger to the environment by degrading the fragile forest ecosystem. To provide sustainable wood fuel, a viable forest management system needs to be developed [319,320]. This is to ensure that the pressure on valuable trees of economic and ecological importance is minimized.

Table 12 shows the estimation of the energy potential from forestry residues, wood fuel, and charcoal. The densities used in the estimation were obtained from [321,322]. The heating values of wood residues vary between 17 and 23 MJ/kg [53]. A value of 19.5 MJ/kg was used in the estimation of the energy potential of forest residues and wood fuel and 28.0 MJ/kg for wood charcoal [323]. The theoretical energy potential of forestry residues is estimated to be 0.17 EJ without consideration of wood fuel. The theoretical potential, however, rises to 0.80 EJ with the inclusion of wood fuel. Following Deng et al. [318], an availability factor of 0.6 is assumed to give a technical energy potential value of 0.10 EJ for forest residues with charcoal alone. With the consideration of wood fuel, the technical energy potential is 0.48 EJ.

Table 12.

Energy potential of forest in Nigeria.

The daily generation of municipal solid waste has been taken to be 0.50 kg/capita/day. The current population of Nigeria is about 200 million people. Consequently, the annual generation of municipal solid waste is estimated to be 36.5 million tons per year. The energy content of samples of municipal solid waste was obtained by Amber et al. [324] to be 17.23 MJ/kg. IEA [325] stated that the heating value of mixed MSW, ranging between 8 and 12 MJ/kg, is about a third of the calorific value of coal. Using a value of 12 MJ/kg, the theoretical energy potential of municipal solid waste is 0.44 EJ. Amber et al. [324] noted that 65% to 80% of the energy content of organic matter can be recovered as heat energy. However, a factor of 0.25 is utilized to cater for the availability factor and conversion efficiency. The technical energy potential of municipal solid waste is therefore 0.11 EJ.

Based on the estimate of the technical potential, the energy derivable from agricultural residues, animal wastes, forestry residues, and charcoal is 1.95 EJ. This value rises to 2.33 EJ when wood fuel is considered. Figure 3 shows the contributions of the biomass sources identified. It is shown that agricultural residues have the highest contribution followed by animal wastes and wood fuel, respectively. It has been projected that the energy demand could grow up to 10.5 EJ in 2030, with the projection of 2020 being 4.55 EJ [30]. The projection is subject to growth in the industry, transport, household, and services sectors at rates of 16.2%, 4.7%, 2.6%, 8.7%, and 8.3%, respectively. It may be observed that biomass alone cannot effectively meet the energy demand. However, sustaining increased biomass within the renewable energy mix within the country will, no doubt, be immensely beneficial. The current projection of 54 MW (less than 2 GJ) by 2030 [32] is much lower than the potential derivable from biomass resources.

Figure 3.

Contributions of biomass sources to the overall technical potential.

Increasing agricultural activities within the country would enhance the available biomass resource potential. More importantly, the deliberate introduction of energy crops and aquatic crops by utilizing the marginal lands and uncharted waterways within the country would be immensely valuable to increasing the biomass energy potential. This can be realized by the development and implementation of aggressive agriculture and renewable energy policies.

7. Renewable Energy Policy

The sustainability of biomass energy will depend on the efficient management of biomass resources and government policy. Upon examining the implications of consumption of biomass energy in Nigeria, Sa’ad and Bugaje [39] noted that there is a need for deliberate policies to enhance the efficiency and sustainability of biomass energy in Nigeria. The need for the policies would be to make clean commercial energy more accessible and relatively cheaper.

ICREEE [326] noted that more than 30 draft policy documents have been formulated by various actors in the energy sector, with only a few of them being approved and enforced. The approved policies include the National Electric Power Policy (NEPP) in 2002; National Energy Policy (NEP) in 2003, 2006, and 2013; Rural Electrification Policy Paper in 2009; Roadmap for Power Sector Reforms in 2010; National Renewable Energy and Energy Efficiency Policy (NREEEP) in 2015; and National Determined Contribution (NDC) in 2015.

Emodi and Ebele [327] and ICREEE [326] reviewed the policies, particularly those enhancing renewable energy development in Nigeria. It was noted that the main goal of the National Energy Policy (NEP) is to create energy security through a robust energy supply mix by diversifying the energy supply and the energy carriers. The National Renewable Energy and Energy Efficiency Policy (NREEEP) intends to increase the share of on-grid renewable energy in the total electricity supply from 1.3% in 2015 to 16% in 2030. In line with this, the National Determined Contribution (NDC) established Nigeria’s commitment to greenhouse gas emission. ICREEE [326] noted that there are approved regulations to strengthen the plans. They include a bankable renewable energy feed-in tariff regulation and a competitive renewable energy procurement program under the approved bulk power procurement regulation. It has been identified that the private sector plays a very limited role, with much of the influence being from international organizations.