Exergy, Economic, and Life-Cycle Assessment of ORC System for Waste Heat Recovery in a Natural Gas Internal Combustion Engine

Abstract

1. Introduction

2. Methodology

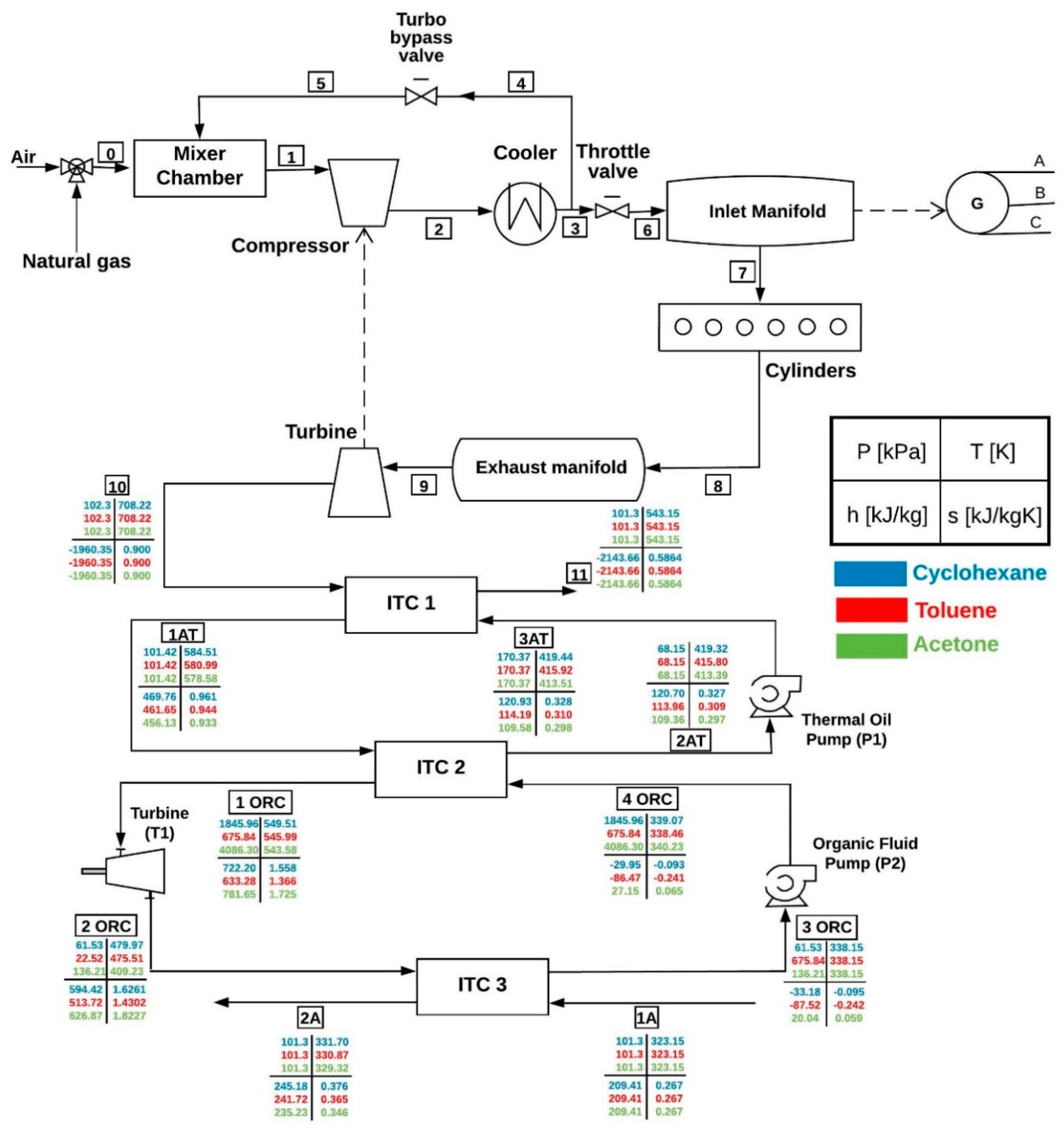

2.1. System Description

2.2. Thermodynamic Analysis

2.3. Thermo-Economic Analysis

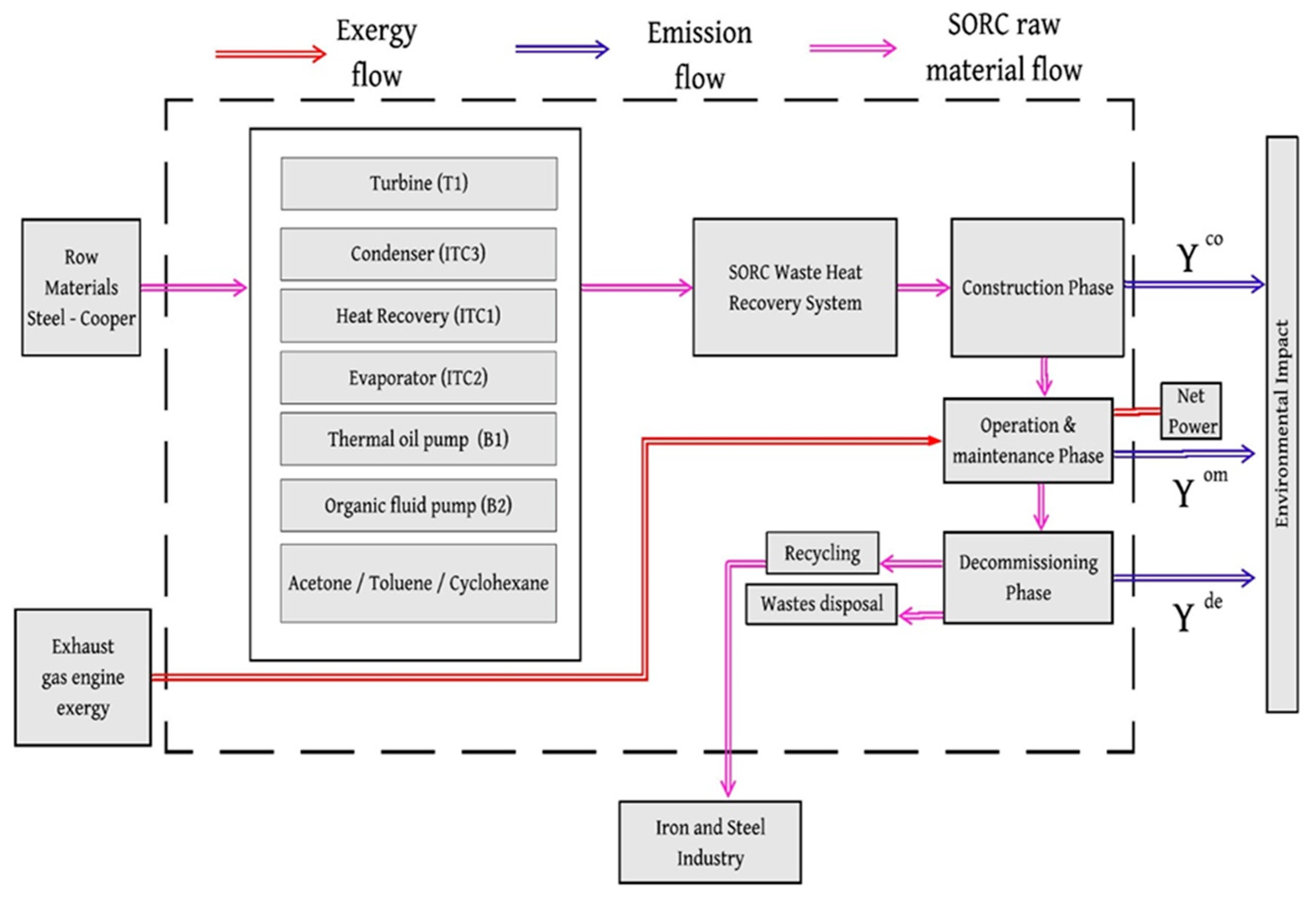

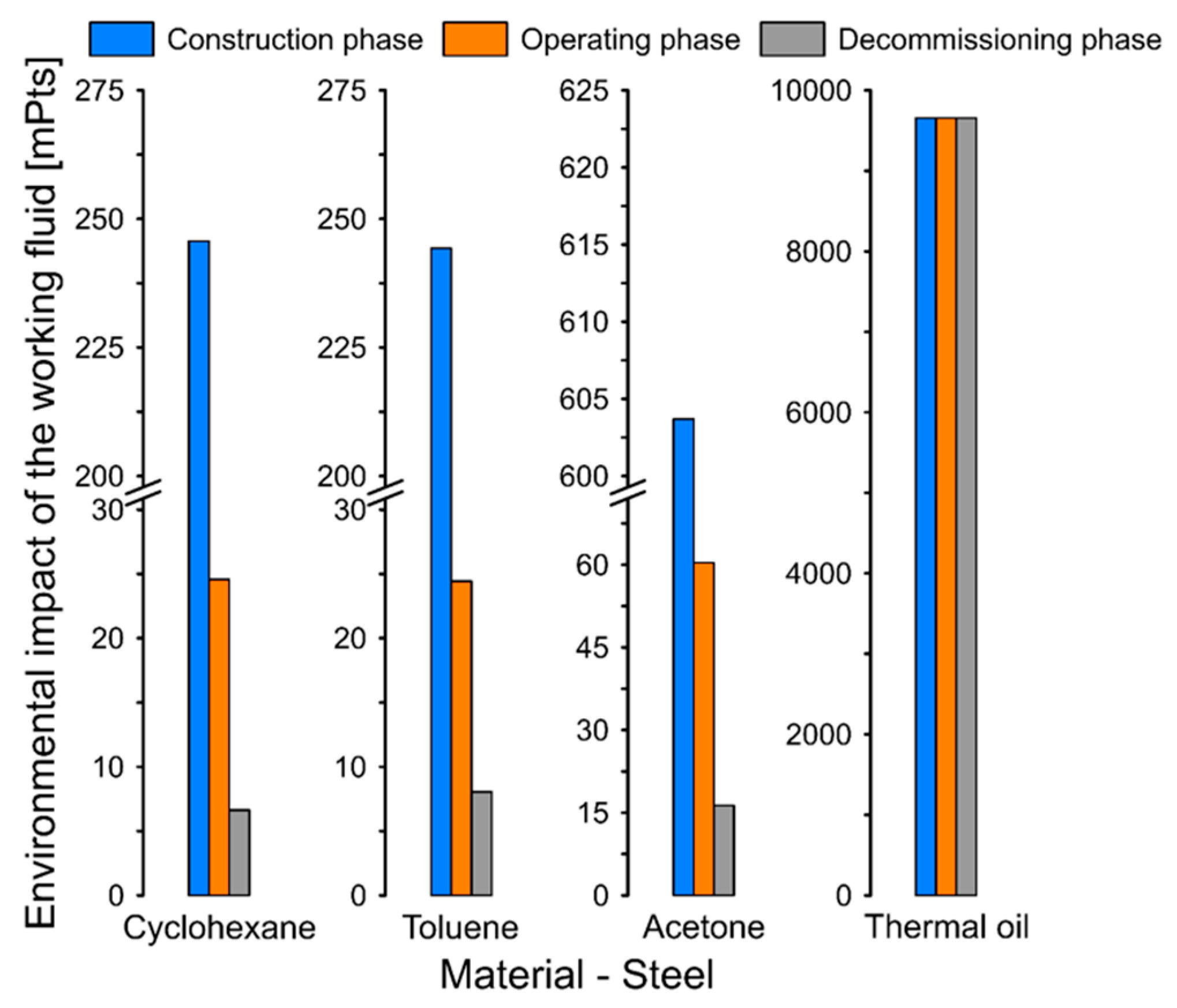

2.4. Waste Heat Recovery Systems Life Cycle Assessment

- The impact coefficients were available in the Eco-indicator 99 database [45] was used to calculate the LCA.

- The environmental impact of the components, the working fluids (Cyclohexane, Toluene, and Acetone) and the thermal oil are considered to have three phases: construction, operation, maintenance, and decommissioning.

- In an ORC system, the annual loss of working fluid is between 0% and 2%. An annual working fluid loss of 0.5% is assumed with a 20-year operation. Therefore, the working fluid loss rate in the operation phase is 10% [22].

- The fluid loss in the decommissioning phase is 3% of the losses in the operation phase.

- For the evaluation of the environmental impacts of the thermal oil, it was considered that the composition of the Therminol is 73.5% of Diphenyl Oxide.

3. Results and Discussion

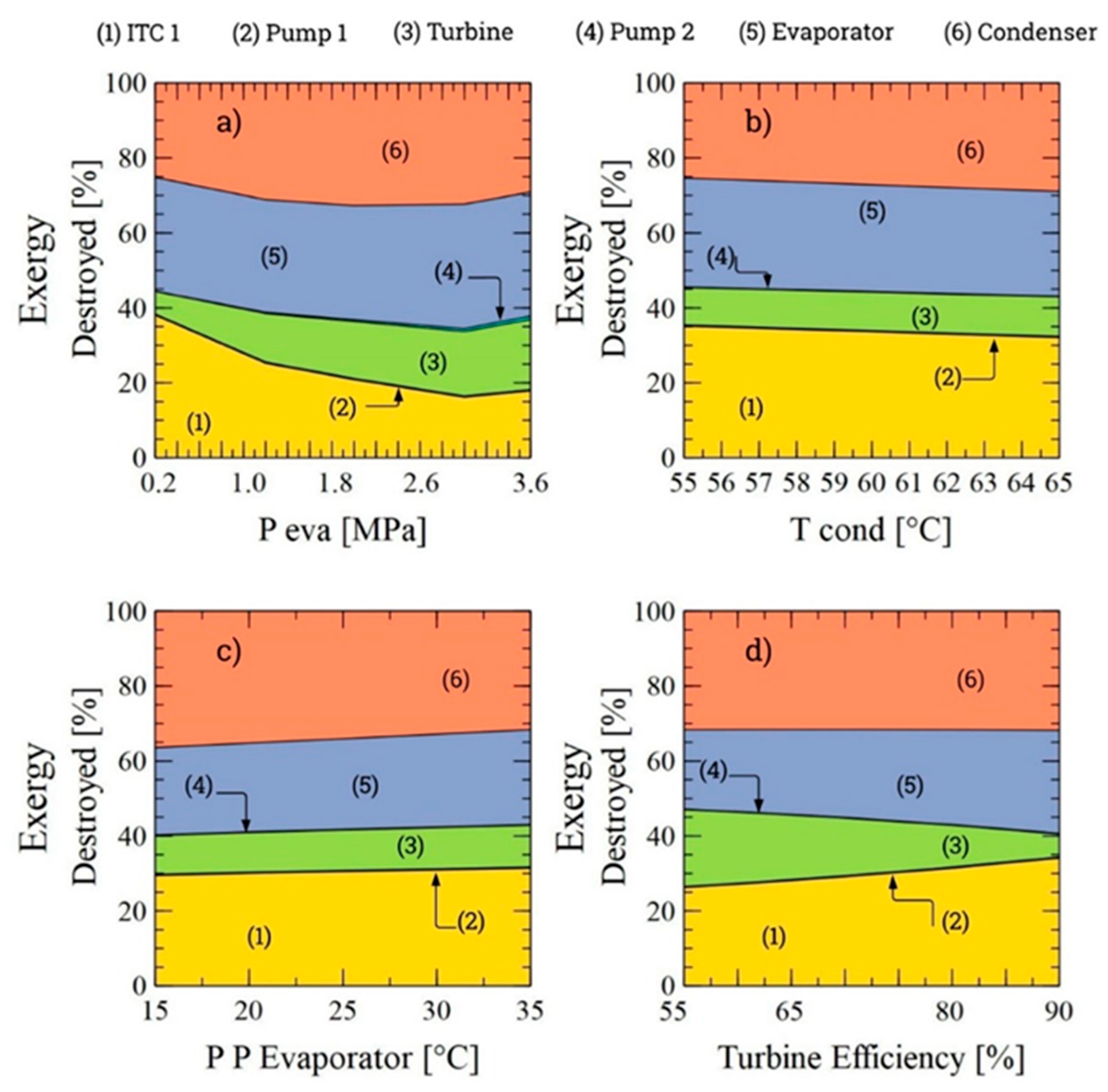

3.1. Analysis of the Influence on Destroyed Exergy

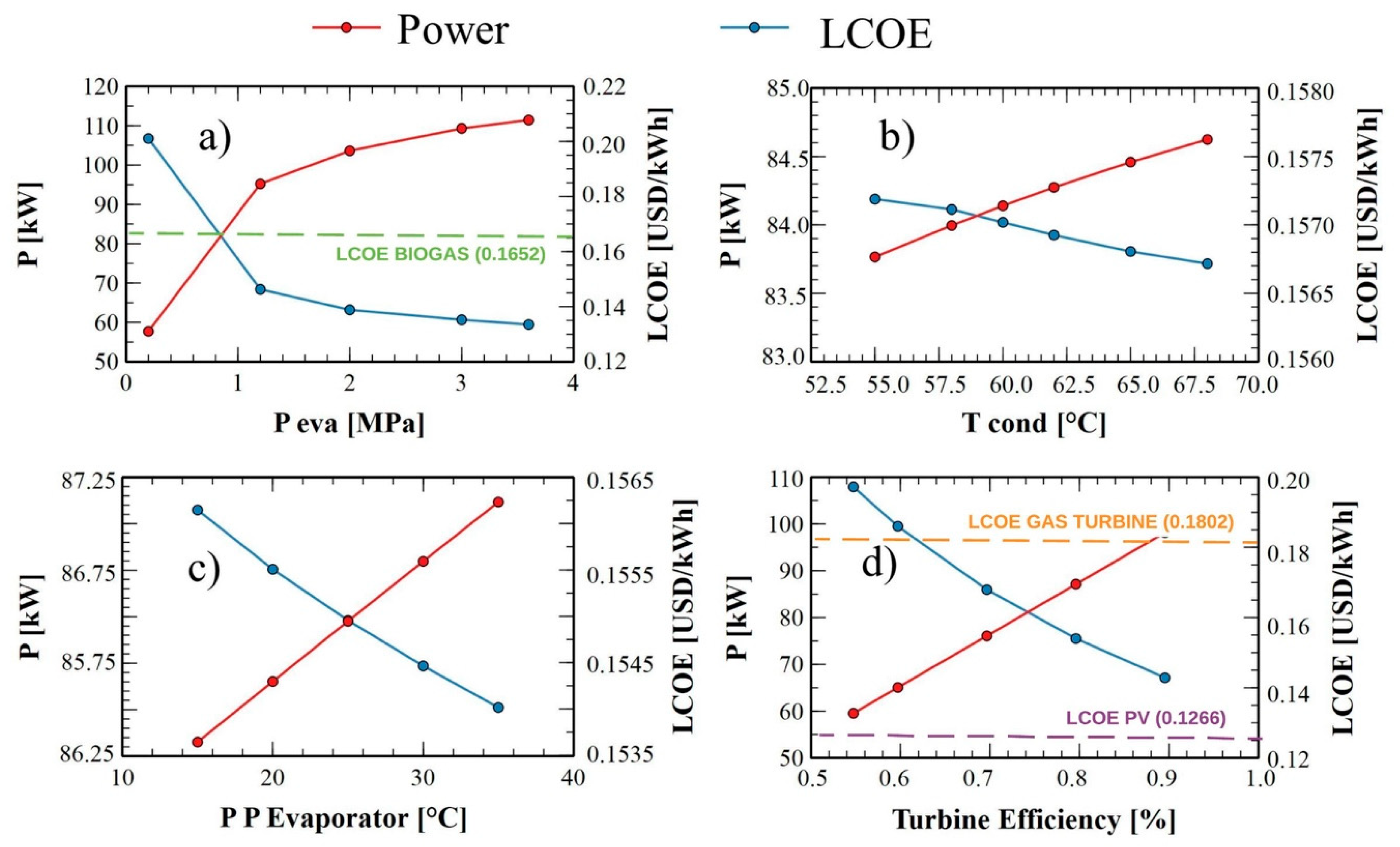

3.2. Analysis of the Influence on Net Power and LCOE

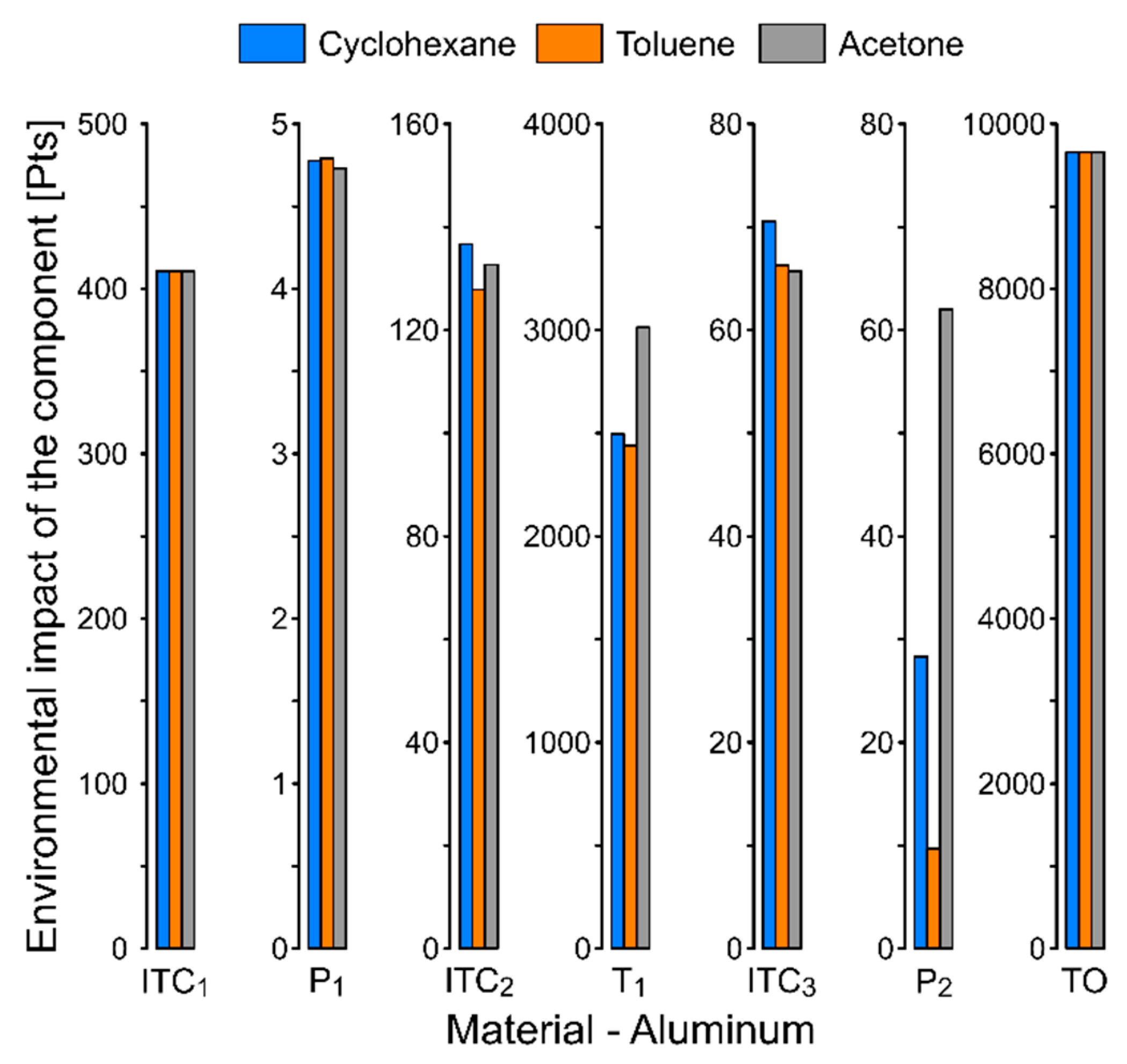

3.3. Life Cycle Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Heat rate (kW) | |

| Power (kW) | |

| Mass flow rate (kW) | |

| Enthalpy (kJ/kg·K) | |

| Specific entropy (kJ/kg·K) | |

| Exergy rate | |

| Exergy destruction rate | |

| Efficiency | |

| Mass (kg) | |

| Area (m) | |

| Thickness (m) | |

| Correction factor | |

| Environmental Impact (mPts) | |

| co | Construction |

| Om | Operation |

| De | decommissioning |

| Wf | Working fluid |

| CELF | Constant escalation leveling factor |

| CRF | Cost return factor |

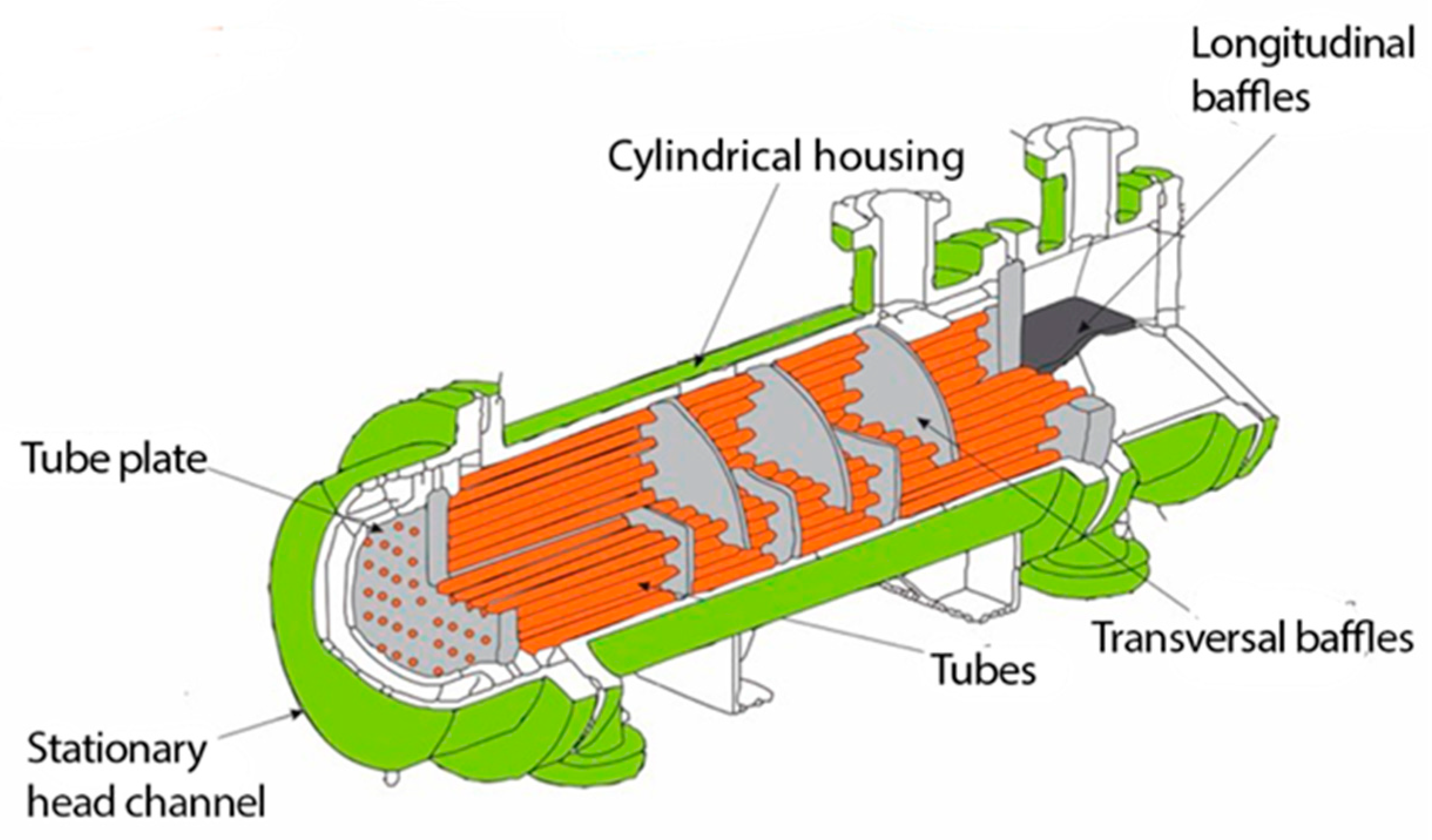

| ITC1 | Shell and tube heat exchanger |

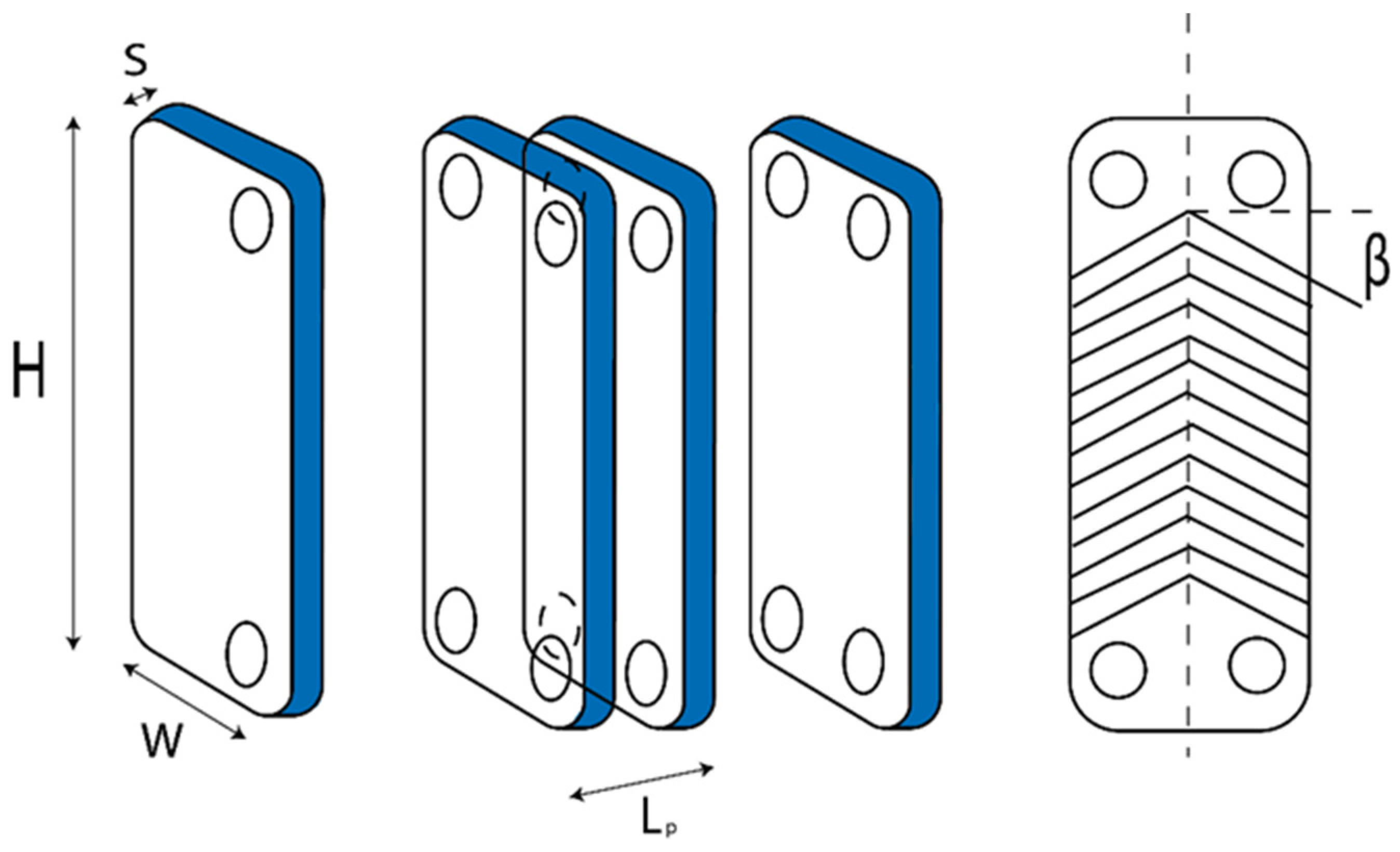

| ITC2 | Evaporator heat exchanger |

| ITC3 | Condenser heat exchanger |

| T1 | Turbine 1 |

| P1 | Thermal oil pump |

| P2 | Organic fluid pump |

| LCOE | Levelized cost of energy |

| LCA | Life cycle assessment |

| ORC | Organic Rankine cycle |

References

- Barrozo, F.; Valencia, G.; Cárdenas, Y. An economic evaluation of renewable and conventional electricity generation systems in shopping center using HOMER Pro. Contemp. Eng. Sci. 2017, 10, 1287–1295. [Google Scholar]

- Zhang, H.; Guan, X.; Ding, Y.; Liu, C. Emergy analysis of Organic Rankine Cycle (ORC) for waste heat power generation. J. Clean. Prod. 2018, 183, 1207–1215. [Google Scholar] [CrossRef]

- Valencia, G.; Acevedo, C.; Duarte, J. Thermoeconomic optimization with PSO Algorithm of waste heat recovery systems based on Organic Rankine Cycle system for a natural gas engine. Energies 2019, 21, 4165. [Google Scholar] [CrossRef]

- Valencia, G.; Fontalvo, A.; Cárdenas, Y.; Duarte, J.; Isaza, C. Energy and exergy analysis of different exhaust waste heat recovery systems for natural gas engine based on ORC. Energies 2019, 12, 2378. [Google Scholar] [CrossRef]

- Zhai, H.; An, Q.; Shi, L.; Lemort, V.; Quoilin, S. Categorization and analysis of heat sources for Organic Rankine Cycle systems. Renew. Sustain. Energy Rev. 2016, 64, 790–805. [Google Scholar] [CrossRef]

- Liu, X.; Liang, J.; Xiang, D.; Yang, S.; Qian, Y. A proposed coal-to-methanol process with CO2 capture combined Organic Rankine Cycle (ORC) for waste heat recovery. J. Clean. Prod. 2016, 129, 53–64. [Google Scholar] [CrossRef]

- Gholamian, E.; Habibollahzade, A.; Zare, V. Development and multi-objective optimization of geothermal-based Organic Rankine Cycle integrated with thermoelectric generator and proton exchange membrane electrolyzer for power and hydrogen production. Energy Convers. Manag. 2018, 174, 112–125. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, Y.; Yu, X. Thermo-economic analysis of a novel power generation system integrating a natural gas expansion plant with a geothermal ORC in Tianjin, China. Energy 2018, 164, 602–614. [Google Scholar] [CrossRef]

- Dimitrova, Z.; Lourdais, P.; Maréchal, F. Performance and economic optimization of an organic rankine cycle for a gasoline hybrid pneumatic powertrain. Energy 2015, 86, 574–588. [Google Scholar] [CrossRef]

- Vivian, J.; Manente, G.; Lazzaretto, A. A general framework to select working fluid and configuration of ORCs for low-to-medium temperature heat sources. Appl. Energy 2015, 156, 727–746. [Google Scholar] [CrossRef]

- Yu, H.; Feng, X.; Wang, Y. A new pinch based method for simultaneous selection of working fluid and operating conditions in an Organic Rankine Cycle (ORC) recovering waste heat. Energy 2015, 90, 36–46. [Google Scholar] [CrossRef]

- Invernizzi, C.M.; Iora, P.; Preißinger, M.; Manzolini, G. HFOs as substitute for R-134a as working fluids in ORC power plants: A thermodynamic assessment and thermal stability analysis. Appl. Therm. Eng. 2016, 103, 790–797. [Google Scholar] [CrossRef]

- Mavrou, P.; Papadopoulos, A.I.; Stijepovic, M.Z.; Seferlis, P.; Linke, P.; Voutetakis, S. Novel and conventional working fluid mixtures for solar Rankine cycles: Performance assessment and multi-criteria selection. Appl. Therm. Eng. 2015, 75, 384–396. [Google Scholar] [CrossRef]

- Rahbar, K.; Mahmoud, S.; Al-Dadah, R.K.; Moazami, N.; Mirhadizadeh, S.A. Review of organic Rankine cycle for small-scale applications. Energy Convers. Manag. 2017, 134, 135–155. [Google Scholar] [CrossRef]

- Karellas, S.; Braimakis, K. Energy–exergy analysis and economic investigation of a cogeneration and trigeneration ORC–VCC hybrid system utilizing biomass fuel and solar power. Energy Convers. Manag. 2016, 107, 103–113. [Google Scholar] [CrossRef]

- Pang, K.-C.; Chen, S.-C.; Hung, T.-C.; Feng, Y.-Q.; Yang, S.-C.; Wong, K.-W.; Lin, J.-R. Experimental study on organic Rankine cycle utilizing R245fa, R123 and their mixtures to investigate the maximum power generation from low-grade heat. Energy 2017, 133, 636–651. [Google Scholar] [CrossRef]

- Wang, J.; Diao, M.; Yue, K. Optimization on pinch point temperature difference of ORC system based on AHP-Entropy method. Energy 2017, 141, 97–107. [Google Scholar] [CrossRef]

- Mahmoudi, S.M.S.; Ghavimi, A.R. Thermoeconomic analysis and multi objective optimization of a molten carbonate fuel cell—Supercritical carbon dioxide—Organic Rankin Cycle integrated power system using liquefied natural gas as heat sink. Appl. Therm. Eng. 2016, 107, 1219–1232. [Google Scholar] [CrossRef]

- Zhang, Q.; Ogren, R.M.; Kong, S.-C. Thermo-economic analysis and multi-objective optimization of a novel waste heat recovery system with a transcritical CO2 cycle for offshore gas turbine application. Energy Convers. Manag. 2018, 172, 212–227. [Google Scholar] [CrossRef]

- Liu, C.; He, C.; Gao, H.; Xie, H.; Li, Y.; Wu, S.; Xu, J. The environmental impact of organic Rankine cycle for waste heat recovery through life-cycle assessment. Energy 2013, 56, 144–154. [Google Scholar] [CrossRef]

- Cioccolanti, L.; Rajabi Hamedani, S.; Villarini, M. Environmental and energy assessment of a small-scale solar Organic Rankine Cycle trigeneration system based on compound parabolic collectors. Energy Convers. Manag. 2019, 198, 111829. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, C.; Zhang, C.; Xu, X.; Li, Q.; Mao, L. Exergoenvironmental model of Organic Rankine Cycle system including the manufacture and leakage of working fluid. Energy 2018, 145, 52–64. [Google Scholar] [CrossRef]

- Heberle, F.; Schifflechner, C.; Brüggemann, D. Life cycle assessment of Organic Rankine Cycles for geothermal power generation considering low-GWP working fluids. Geothermics 2016, 64, 392–400. [Google Scholar] [CrossRef]

- Sun, W.; Yue, X.; Wang, Y. Exergy efficiency analysis of ORC (Organic Rankine Cycle) and ORC-based combined cycles driven by low-temperature waste heat. Energy Convers. Manag. 2017, 135, 63–73. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Amat-Albuixech, M. Multi-objective optimization of a novel reversible High-Temperature Heat Pump-Organic Rankine Cycle (HTHP-ORC) for industrial low-grade waste heat recovery. Energy Convers. Manag. 2019, 197, 111908. [Google Scholar] [CrossRef]

- Van Kleef, L.M.T.; Oyewunmi, O.A.; Markides, C.N. Multi-objective thermo-economic optimization of Organic Rankine Cycle (ORC) power systems in waste-heat recovery applications using computer-aided molecular design techniques. Appl. Energy 2019, 251, 112513. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Deng, S. A review of modified Organic Rankine Cycles (ORCs) for internal combustion engine waste heat recovery (ICE-WHR). Renew. Sustain. Energy Rev. 2018, 92, 95–110. [Google Scholar] [CrossRef]

- Valencia, G.; Duarte, J.; Isaza-Roldan, C. Thermoeconomic analysis of different exhaust waste-heat recovery systems for natural gas engine based on ORC. Appl. Sci. 2019, 9, 4071. [Google Scholar] [CrossRef]

- Da Silva, J.A.M.; Seifert, V.; de Morais, V.O.B.; Tsolakis, A.; Herreros, J.; Torres, E. Exergy evaluation and ORC use as an alternative for efficiency improvement in a CI-engine power plant. Sustain. Energy Technol. Assess. 2018, 30, 216–223. [Google Scholar] [CrossRef]

- Abam, F.I.; Ekwe, E.B.; Effiom, S.O.; Ndukwu, M.C. A comparative performance analysis and thermo-sustainability indicators of modified low-heat Organic Rankine Cycles (ORCs): An exergy-based procedure. Energy Rep. 2018, 4, 110–118. [Google Scholar] [CrossRef]

- Karvountzis-Kontakiotis, A.; Pesiridis, A.; Zhao, H.; Alshammari, F.; Franchetti, B.; Pesmazoglou, I.; Tocci, L. Effect of an ORC Waste Heat Recovery System on Diesel Engine Fuel Economy for Off-Highway Vehicles; SAE Technical Paper; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Ochoa, G.V.; Peñaloza, C.A.; Rojas, J.P. Thermoeconomic modelling and parametric study of a simple orc for the recovery ofwaste heat in a 2 MW gas engine under differentworking fluids. Appl. Sci. 2019, 9, 4526. [Google Scholar] [CrossRef]

- Khoo, H.H. LCA of plastic waste recovery into recycled materials, energy and fuels in Singapore. Resour. Conserv. Recycl. 2019, 145, 67–77. [Google Scholar] [CrossRef]

- Shyam Mishra, R.; Khan, Y. Exergy and energy analysis of modified organic rankine cycle for reduction of global warming and ozone depletion. Int. J. Res. Eng. Innov. 2017, 1, 1–12. [Google Scholar]

- Ochoa, G.V.; Isaza-Roldan, C.; Forero, J.D. A phenomenological base semi-physical thermodynamic model for the cylinder and exhaust manifold of a natural gas 2-megawatt four-stroke internal combustion engine. Heliyon 2019, 5, e02700. [Google Scholar] [CrossRef] [PubMed]

- Water, G.P. Jenbacher 612 GS-N. L 2MW. Tech. Specif. 2011, 1–4. Available online: http://kts-eng.com/assets/files/J-612.pdf (accessed on 28 December 2019).

- Barrozo, F.; Ochoa, G.V.; Cárdenas, Y.D. Hybrid PV & Wind grid-connected renewable energy system to reduce the gas emission and operation cost. Contemp. Eng. Sci. 2017, 26, 1269–1278. [Google Scholar]

- Zare, V. A comparative exergoeconomic analysis of different ORC configurations for binary geothermal power plants. Energy Convers. Manag. 2015, 105, 127–138. [Google Scholar] [CrossRef]

- El-Emam, R.S.; Dincer, I. Exergy and exergoeconomic analyses and optimization of geothermal organic Rankine cycle. Appl. Therm. Eng. 2013, 59, 435–444. [Google Scholar] [CrossRef]

- Calise, F.; Capuozzo, C.; Carotenuto, A.; Vanoli, L. Thermoeconomic analysis and off-design performance of an organic Rankine cycle powered by medium-temperature heat sources. Sol. Energy 2014, 103, 595–609. [Google Scholar] [CrossRef]

- Voros, N.G.; Kiranoudis, C.T.; Maroulis, Z.B. Solar energy exploitation for reverse osmosis desalination plants. Desalination 1998, 115, 83–101. [Google Scholar] [CrossRef]

- Valencia, G.; Benavides, A.; Cárdenas, Y. Economic and Environmental Multiobjective Optimization of a Wind–Solar–Fuel Cell Hybrid Energy System in the Colombian Caribbean Region. Energies 2019, 12, 2119. [Google Scholar] [CrossRef]

- Shengjun, Z.; Huaixin, W.; Tao, G. Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generation. Appl. Energy 2011, 88, 2740–2754. [Google Scholar] [CrossRef]

- Bhatt, A.; Bradford, A.; Abbassi, B.E. Cradle-to-grave life cycle assessment (LCA) of low-impact-development (LID) technologies in southern Ontario. J. Environ. Manag. 2019, 231, 98–109. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization (ISO). Environmental Management The ISO 14000 Family of International Standards ISO in Brief ISO and the Environment; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Arvanitoyannis, I.S. Life cycle assessment (LCA)—Principles and guidelines. Waste Manag. Food Ind. 2008, 14040, 97–132. [Google Scholar]

- Kost, C.; Schlegl, T.; Thomsen, J.; Nold, S.; Mayer, J.; Hartmann, N.; Senkpiel, C.; Philipps, S.; Lude, S.; Saad, N. Fraunhofer ISE: Levelized cost of electricity—Renewable energy technologies, March 2018. arXiv 2018, arXiv:cs/9605103. Available online: https://www.ise.fraunhofer.de/content/dam/ise/en/documents/publications/studies/EN2018_Fraunhofer-ISE_LCOE_Renewable_Energy_Technologies.pdf (accessed on 28 December 2019).

- Valencia, G.; Núñez, J.; Duarte, J. Multiobjective optimization of a plate heat exchanger in a waste heat recovery organic rankine cycle system for natural gas engines. Entropy 2019, 21, 655. [Google Scholar] [CrossRef]

- Diaz, G.A.; Forero, J.D.; Garcia, J.; Rincon, A.; Fontalvo, A.; Bula, A.; Padilla, R.V. Maximum Power From Fluid Flow by Applying the First and Second Laws of Thermodynamics. J. Energy Resour. Technol. 2017, 139, 032903. [Google Scholar] [CrossRef]

- Valencia, G.; Vanegas, M.; Villicana, E. Disponibilidad Geográfica y Temporal de la Energía Solar en la Costa Caribe Colombiana; Sello editorial de la Universidad del Atlántico: Barranquilla, Colombia, 2016. [Google Scholar]

| Items | Parameters | Units |

|---|---|---|

| Cylinder capacity | 74.852 | L |

| Compression ratio | 10.5 | - |

| Number of cylinders (In V–60°) | 12 | - |

| Air intake type | Turbocharged | - |

| Diameter in the chamber | 190 | mm |

| Maximum torque | 60.66 | kN·m |

| Power at nominal speed | 1820 | kW |

| Nominal speed | 1500 | rpm |

| Ignition type | Spark ignition | - |

| Operation range | 1000–1982 | kW |

| Output temperature | 580–650 | °C |

| Shell and Tube Heat Exchanger (ITC1) | Evaporator Heat Exchanger (ITC2) | Condenser Heat Exchanger (ITC3) | |||||||

| Cyclohexane | Toluene | Acetone | Cyclohexane | Toluene | Acetone | Cyclohexane | Toluene | Acetone | |

| Qi (kW) | 514.85 | 514.85 | 514.85 | 515.23 | 515.23 | 515.23 | 429.91 | 430.39 | 414.38 |

| Ai (m2) | 88.70 | 88.70 | 88.70 | 29.51 | 27.61 | 28.66 | 15.23 | 14.31 | 14.19 |

| εi (%) | 83.55 | 82.85 | 82.38 | 84.18 | 82.00 | 85.04 | 44.02 | 46.53 | 59.27 |

| ED,k (kW) | 40.24 | 41.95 | 43.10 | 32.35 | 36.51 | 30.16 | 40.49 | 36.05 | 20.13 |

| yD,k (%) | 31.45 | 32.54 | 37.49 | 25.29 | 28.32 | 26.24 | 31.64 | 27.97 | 17.51 |

| Thermal Oil Pump (P1) | Organic Fluid Pump (P2) | Turbine (T1) | |||||||

| Cyclohexane | Toluene | Acetone | Cyclohexane | Toluene | Acetone | Cyclohexane | Toluene | Acetone | |

| W (kW) | 0.37 | 0.37 | 0.37 | 2.21 | 0.75 | 4.85 | 87.53 | 85.58 | 105.70 |

| εi (%) | 15.85 | 15.60 | 15.43 | 77.63 | 77.60 | 77.69 | 86.17 | 86.03 | 83.98 |

| ED,k (kW) | 0.31 | 0.31 | 0.31 | 0.49 | 0.16 | 1.08 | 14.03 | 13.89 | 20.15 |

| yD,k (%) | 0.24 | 0.24 | 0.27 | 0.38 | 0.13 | 0.90 | 10.97 | 10.77 | 17.50 |

| Cyclohexane | Toluene | Acetone | |||||||

| WNET (kW) | 84.94 | 84.45 | 100.46 | ||||||

| nth ORC | 16.49 | 16.40 | 19.51 | ||||||

| nexer-overall | 34.70 | 34.50 | 41.04 | ||||||

| LCA Phase | Description | Organic Fluid | Thermal Oil | ||

|---|---|---|---|---|---|

| Cyclohexane | Toluene | Acetone | |||

| Construction Phase | Organic fluid filling amount (kg) | 487.55 | 476.73 | 588.74 | 184 |

| Operation Phase | Organic fluid leakage amount (kg) | 48.75 | 47.67 | 58.87 | 18 |

| Decommissioning Phase | Organic fluid emission loose amount (kg) | 13.16 | 12.87 | 15.89 | 5 |

| Working Fluid | Component | Material | w (mPts/kg) | Quality (kg) | Yco (mPts) | Yom (mPts) | Yde (mPts) | Y (mPts) |

|---|---|---|---|---|---|---|---|---|

| Cyclohexane | ITC1 | Steel | 86 | 1407 | 127,037 | 0 | 6049 | 133,086 |

| P1 | Steel | 86 | 5 | 472 | 0 | 22 | 495 | |

| ITC2 | Steel | 86 | 468 | 42,276 | 0 | 2013 | 44,289 | |

| T1 | Steel | 86 | 2733 | 246,768 | 0 | 11,751 | 258,519 | |

| ITC3 | Steel | 86 | 242 | 21,825 | 0 | 1039 | 22,865 | |

| P2 | Steel | 86 | 31 | 2799 | 0 | 133 | 2933 | |

| Thermal Oil | Diphenyl-oxide | 46,467 | 184 | 8,568,515 | 856,851 | 231,350 | 9,656,716 | |

| Fluid | Cyclohexane | 2639 | 93 | 245,687.62 | 24,568.76 | 6634 | 276,890 | |

| Toluene | ITC1 | Steel | 86 | 1407 | 127,036.71 | 0 | 6049 | 133,086 |

| P1 | Steel | 86 | 5 | 472.27 | 0 | 22 | 495 | |

| ITC2 | Steel | 86 | 438 | 39,545.83 | 0 | 1883 | 41,429 | |

| T1 | Steel | 86 | 2733 | 246,768.04 | 0 | 11,751 | 258,519 | |

| ITC3 | Steel | 86 | 227 | 20,505.05 | 0 | 976 | 21,481 | |

| P2 | Steel | 86 | 11 | 955.97 | 0 | 46 | 1002 | |

| Thermal Oil | Diphenyl-oxide | 46,467 | 184 | 8,568,515 | 856,851 | 231,350 | 9,656,716 | |

| Fluid | Toluene | 2680 | 91 | 244,290.51 | 24,429.05 | 8051 | 276,770 | |

| Acetone | ITC1 | Steel | 86 | 1407 | 127,036,71 | 0 | 6049 | 133,086 |

| P1 | Steel | 86 | 5 | 472.27 | 0 | 22 | 495 | |

| ITC2 | Steel | 86 | 455 | 41,045.80 | 0 | 1955 | 43,000 | |

| T1 | Steel | 86 | 2733 | 246,768.04 | 0 | 11,751 | 258,519 | |

| ITC3 | Steel | 86 | 225 | 20,325.20 | 0 | 968 | 21,293 | |

| P2 | Steel | 86 | 68 | 6131.37 | 0 | 292 | 6423 | |

| Thermal Oil | Diphenyl-oxide | 46,467 | 184 | 8,568,515 | 856,851 | 231,350 | 9,656,716 | |

| Fluid | Acetone | 5426 | 111 | 603,695.38 | 60,369.53 | 16,300 | 680,365 |

| Working Fluid | Component | Material | w (mPts/kg) | Quality (kg) | Yco (mPts) | Yom (mPts) | Yde (mPts) | Y (mPts) |

|---|---|---|---|---|---|---|---|---|

| Cyclohexane | ITC1 | Aluminum | 780 | 479 | 392,065 | 0 | 18,670 | 410,735 |

| P1 | Aluminum | 780 | 6 | 4559 | 0 | 217 | 4776 | |

| ITC2 | Aluminum | 780 | 159 | 130,475 | 0 | 6213 | 136,688 | |

| T1 | Aluminum | 780 | 2909 | 2,382,224 | 0 | 113,439 | 2,495,663 | |

| ITC3 | Aluminum | 780 | 82 | 67,358 | 0 | 3208 | 70,566 | |

| P2 | Aluminum | 780 | 33 | 27,022 | 0 | 1287 | 28,308 | |

| Thermal Oil | Diphenyl Oxide | 46,467 | 184 | 8,568,515 | 856,851 | 231,350 | 9,656,716 | |

| Fluid | Cyclohexane | 2639 | 488 | 1,287,783.2 | 128,660.84 | 34,738 | 1,451,182 | |

| Toluene | ITC1 | Aluminum | 780 | 479 | 392,065.41 | 0 | 18,670 | 410,735 |

| P1 | Aluminum | 780 | 6 | 4572.83 | 0 | 218 | 4791 | |

| ITC2 | Aluminum | 780 | 149 | 122,047.82 | 0 | 5812 | 127,860 | |

| T1 | Aluminum | 780 | 2844 | 2,329,362.99 | 0 | 110,922 | 2,440,285 | |

| ITC3 | Aluminum | 780 | 77 | 63,283.47 | 0 | 3013 | 66,297 | |

| P2 | Aluminum | 780 | 11 | 9227.90 | 0 | 439 | 9667 | |

| Thermal Oil | Diphenyl Oxide | 46,467 | 184 | 8,568,515 | 856,851 | 231,350 | 9,656,716 | |

| Fluid | Toluene | 2680 | 477 | 1,278,264.60 | 127,755.76 | 42,599 | 1,448,619 | |

| Acetone | ITC1 | Aluminum | 780 | 479 | 392,065.41 | 0 | 18,670 | 410,735 |

| P1 | Aluminum | 780 | 6 | 4515.14 | 0 | 215 | 4730 | |

| ITC2 | Aluminum | 780 | 155 | 126,677.09 | 0 | 6032 | 132,709 | |

| T1 | Aluminum | 780 | 3512 | 2,876,664.60 | 0 | 136,984 | 3,013,649 | |

| ITC3 | Aluminum | 780 | 77 | 62,728.40 | 0 | 2987 | 65,715 | |

| P2 | Aluminum | 780 | 72 | 59,185.03 | 0 | 2818 | 62,003 | |

| Thermal Oil | Diphenyl Oxide | 46,467 | 184 | 8,568,515 | 856,851 | 231,350 | 9,656,716 | |

| Fluid | Acetone | 5426 | 589 | 3,195,619.50 | 319,425.77 | 86,245 | 3,601,290 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valencia Ochoa, G.; Cárdenas Gutierrez, J.; Duarte Forero, J. Exergy, Economic, and Life-Cycle Assessment of ORC System for Waste Heat Recovery in a Natural Gas Internal Combustion Engine. Resources 2020, 9, 2. https://doi.org/10.3390/resources9010002

Valencia Ochoa G, Cárdenas Gutierrez J, Duarte Forero J. Exergy, Economic, and Life-Cycle Assessment of ORC System for Waste Heat Recovery in a Natural Gas Internal Combustion Engine. Resources. 2020; 9(1):2. https://doi.org/10.3390/resources9010002

Chicago/Turabian StyleValencia Ochoa, Guillermo, Javier Cárdenas Gutierrez, and Jorge Duarte Forero. 2020. "Exergy, Economic, and Life-Cycle Assessment of ORC System for Waste Heat Recovery in a Natural Gas Internal Combustion Engine" Resources 9, no. 1: 2. https://doi.org/10.3390/resources9010002

APA StyleValencia Ochoa, G., Cárdenas Gutierrez, J., & Duarte Forero, J. (2020). Exergy, Economic, and Life-Cycle Assessment of ORC System for Waste Heat Recovery in a Natural Gas Internal Combustion Engine. Resources, 9(1), 2. https://doi.org/10.3390/resources9010002