Sustainability in Maritime Sector: Waste Management Alternatives Evaluated in a Circular Carbon Economy Perspective

Abstract

1. Introduction

2. Materials and Methods

2.1. Identification of the Measures

- GHG emissions reduction potential: assessment of a significant contribution of the measure to the reduction in GHG emissions;

- cost: analysis of potential costs for installation and management of the measure;

- feasibility/replicability: analysis of potential replicability in the maritime sector and evaluation of the possible difficulties in the implementation;

- environmental sustainability: assessment of the environmental sustainability of the measure in terms of impacts different from the GHG emissions;

- existence of an approved specific methodology: analysis of internationally recognized CO2e calculation methodologies (e.g., UNFCCC, IMO).

- Measure No.3.—Thermochemical treatment of waste oils and sludge for the obtaining of fuel oils;

- Measure No.10.—Installation of a waste-to-energy plant and next energy recovery on board.

2.2. GHG Emission Reduction Calculation

2.2.1. Thermochemical Treatment

- A: Information about average sludge production on board from a private communication of the Carnival Maritime (Hamburg, Germany);

- B: Chemical analysis of a sludge sample kindly provided by Grandi Navi Veloci (GNV), an Italian Ro-Ro ferry company, made by the Research Centre for Alternative and Renewable Energy (Florence, Italy);

- C: Data from the literature [23];

- D: Calculated data from the current study.

- ERy: Emission reduction in the year y (tCO2e/year);

- BEy: Baseline emissions at year y (tCO2e/year);

- PEy: Project activity emissions in the year y (tCO2e/year);

- LEy: Leakage emissions in the year y (tCO2e/year).

- PECOM,PIR: Emissions from pyrolysis of non-biogenic carbon in the year y (tCO2e/year);

- PEFC,PIR: Emissions from the consumption of auxiliary fuel by the pyrolysis facility in the year y (tCO2e/year);

- PETRAS,PIR: Emissions from fossil fuel consumption due to incremental transportation in the year y (tCO2e/year);

- PEEC,PIR: Emissions from electricity or diesel consumption in the year y (tCO2e/year).

2.2.2. Installation of a Waste-to-Energy Plant

- BEelec,y: baseline annual emissions due to electrical energy transfer (t CO2);

- fcap: ratio between the energy generated by the waste and the total energy used in the project activity to produce useful energy (in year y);

- fwcm: ratio between the electricity generated by the project activity and the energy generated by the waste used to produce it;

- EGi: amount of electricity supplied, which in the absence of project activity would have been purchased during the year y;

- EFElec: CO2 emission factor for the energy source replaced by the project activity, during the year y, being:

- EFCO2,i,j: the CO2 emission factor per unit of energy of the fossil fuel used in the baseline generation source i;

- ηPlant, j= the overall efficiency of the identified existing plant that would be used by jth recipient in the absence of the project activity.

- fcap = 1, because the amount of energy generated by waste for the project activity is the same as the energy that would have been necessary for the operation of the plant before the introduction of the project activity itself;

- fwcm = 1, since the energy necessary for the operation of the refrigeration system is provided in total by the waste-to-energy plant.

- System working only during navigation outside 12 nautical miles;

- Use factors set equal to 25%, 50% and 75%;

- Daily operation of 11 h;

- COP (coefficient of performance) = 2.12, related to the equipment that would be replaced with the use of the ammonia-water absorption cycle;

- Use of ammonia steam generator with an assumed power of 900 kW supplied by exhaust gases;

- Consumption of fuel (diesel) in the primary engine = 200 g/kWh (data obtained from a previous study carried out on a cruise ship);

- Installed electric power of 195.5 kW relative to the plant dedicated to refrigeration of the cold room.

- PEAF,y: combustion of auxiliary fuel to supplement waste gas/heat

- PEEL,y: emissions due to consumption of electricity for gas cleaning before being used for generation of electricity or other supplementary electricity consumption by the project activity

3. Results

3.1. GHG Emission Reduction for Termochemical Treatment

- As the sludge consists mainly of hydrocarbons, all the sludge fed to the reactor downstream of the sedimentation are considered as non-biogenic carbon;

- Since there are few data available concerning pyrolysis processes, it is not easy to determine the value of QCO2, pyro in Equation (4). In first approximation it was considered that all the gas produced by the process was CO2: about 17% of the sludge fed (see Table 4);

- Emissions from the consumption of auxiliary fuel by the pyrolysis facility—PEFC,PIR in Equation (3)—were not considered since the heat recovery is done totally through sources already present on board the ship (incinerator);

- Emissions from fossil fuel consumption due to incremental transportation—PETRAS,PIR in Equation (3)—were not considered as this type of transport is not foreseen;

- As regard emissions from electricity—PEEC,PIR in Equation (3)—, those related to agitators and pumps have been included.

3.2. GHG Emission Reduction for Waste-to-Energy Plant

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EU. Directive 2009/29/EC of the European Parliament and of the Council of 23 April 2009 (Amending Directive 2003/87/EC so as to Improve and Extend the Greenhouse Gas Emission Allowance Trading Scheme of the Community). 2009. Available online: https://ec.europa.eu/clima/policies/strategies/2020 (accessed on 3 April 2020).

- EU. COM (2014) 15—Communication: A Policy Framework for Climate and Energy in the Period from 2020 to 2030. 2014. Available online: https://ec.europa.eu/clima/policies/strategies/2030 (accessed on 3 April 2020).

- IMO. Second IMO GHG Study 2009. International Maritime Organization, 2009. Available online: http://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Documents/SecondIMOGHGStudy2009.pdf (accessed on 3 April 2020).

- EU. Regulation (EU) 2015/757 of the European Parliament and of the Council of 29 April 2015 on the Monitoring, Reporting and Verification of Carbon Dioxide Emissions from Maritime Transport, and Amending Directive 2009/16/EC. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32015R0757&from=EN (accessed on 3 April 2020).

- IMO. IMO Action to Reduce Greenhouse Gas Emissions from International Shipping. 2019. Available online: http://www.imo.org/en/MediaCentre/HotTopics/Documents/IMO%20ACTION%20TO%20REDUCE%20GHG%20EMISSIONS%20FROM%20INTERNATIONAL%20SHIPPING.pdf (accessed on 3 April 2020).

- EU. 72nd Session of the Marine Environment Protection Committee (MEPC 70) at the International Maritime Organization (IMO). 2018. Available online: https://ec.europa.eu/clima/sites/clima/files/news/20180413_memo_en.pdf (accessed on 3 April 2020).

- EU. Directive 2003/87/EC of the European Parliament and of the Council of 13 October 2003 Establishing a Scheme for Greenhouse Gas Emission Allowance Trading within the Community and Amending COUNCIL Directive 96/61/EC. 2003. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32003L0087&from=EN (accessed on 3 April 2020).

- Gallo, M.; Marotta, V.; Magrassi, F.; Taramasso, A.C.; Del Borghi, A. University campus waste prevention and reduction: A circular-economy approach. Econ. POLICY ENERGY Environ. 2017, 235–252. [Google Scholar] [CrossRef]

- Butt, N. The impact of cruise ship generated waste on home ports and ports of call: A study of Southampton. Mar. Policy 2007, 31, 591–598. [Google Scholar] [CrossRef]

- Gallo, M.; Del Borghi, A.; Strazza, C.; Parodi, L.; Arcioni, L.; Proietti, S. Opportunities and criticisms of voluntary emission reduction projects developed by Public Administrations: Analysis of 143 case studies implemented in Italy. Appl. Energy 2016, 179, 1269–1282. [Google Scholar] [CrossRef]

- Magrassi, F.; Del Borghi, A.; Gallo, M.; Strazza, C.; Robba, M. Optimal Planning of Sustainable Buildings: Integration of Life Cycle Assessment and Optimization in a Decision Support System (DSS). Energies 2016, 9, 490. [Google Scholar] [CrossRef]

- UNFCCC Methodologies. Available online: https://cdm.unfccc.int/methodologies/methodologiesAccrv6/index.html (accessed on 3 April 2020).

- Gallo, M.; Del Borghi, A.; Strazza, C. Analysis of potential GHG emissions reductions from methane recovery in livestock farming. Int. J. Glob. Warm. 2015, 8, 516. [Google Scholar] [CrossRef]

- Bhargavi, G.; Nageswara Rao, P.; Renganathan, S. Review on the Extraction Methods of Crude oil from all Generation Biofuels in last few Decades. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012024. [Google Scholar] [CrossRef]

- Kuo, J.; Dow, J. Biogas production from anaerobic digestion of food waste and relevant air quality implications. J. Air Waste Manag. Assoc. 2017, 67, 1000–1011. [Google Scholar] [CrossRef] [PubMed]

- Giwa, A.S.; Xu, H.; Wu, J.; Li, Y.; Chang, F.; Zhang, X.; Jin, Z.; Huang, B.; Wang, K. Sustainable recycling of residues from the food waste (FW) composting plant via pyrolysis: Thermal characterization and kinetic studies. J. Clean. Prod. 2018, 180, 43–49. [Google Scholar] [CrossRef]

- Strazza, C.; Del Borghi, A.; Gallo, M. Development of Specific Rules for the Application of Life Cycle Assessment to Carbon Capture and Storage. Energies 2013, 6, 1250–1265. [Google Scholar] [CrossRef]

- Boubenia, A.; Hafaifa, A.; Kouzou, A.; Mohammedi, K.; Becherif, M. Carbone dioxide capture and utilization in gas turbine plants via the integration of power to gas. Petroleum 2017, 3, 127–137. [Google Scholar] [CrossRef]

- Del Borghi, A.; Gaggero, P.L.; Gallo, M.; Strazza, C. Development of PCR for WWTP based on a case study. Int. J. Life Cycle Assess. 2008, 13, 512–521. [Google Scholar] [CrossRef]

- Block, C.; Van Caneghem, J.; Van Brecht, A.; Wauters, G.; Vandecasteele, C. Incineration of Hazardous Waste: A Sustainable Process? Waste Biomass Valorization 2015, 6, 137–145. [Google Scholar] [CrossRef]

- Strazza, C.; Del Borghi, A.; Gallo, M.; Manariti, R.; Missanelli, E. Investigation of green practices for paper use reduction onboard a cruise ship—a life cycle approach. Int. J. Life Cycle Assess. 2015, 20, 982–993. [Google Scholar] [CrossRef]

- SWOT Analysis: Discover New Opportunities, Manage and Eliminate Threats. Available online: https://www.mindtools.com/pages/article/newTMC_05.htm (accessed on 3 April 2020).

- Wang, Z.; Guo, Q.; Liu, X.; Cao, C. Low Temperature Pyrolysis Characteristics of Oil Sludge under Various Heating Conditions. Energy Fuels 2007, 21, 957–962. [Google Scholar] [CrossRef]

- UNFCCC. ACM0022: Alternative Waste Treatment Processes—Version 2.0. 2014. Available online: https://cdm.unfccc.int/methodologies/DB/YINQ0W7SUYOO2S6GU8E5DYVP2ZC2N3 (accessed on 3 April 2020).

- UNFCCC. Methodological Tool: Emissions from Solid Waste Disposal Site—Version 07.0. 2015. Available online: https://cdm.unfccc.int/methodologies/PAmethodologies/tools/am-tool-04-v7.pdf (accessed on 3 April 2020).

- UNFCCC/CCNUCC. Indicative Simplified Baseline and Monitoring Methodologies for Selected Small-Scale CDM Project Activity Categories. Available online: https://cdm.unfccc.int/EB/031/eb31_repan17.pdf (accessed on 3 April 2020).

- UNFCCC/CCNUCC. Methodological Tool: Baseline, project and/or leakage emissions from electricity consumption and monitoring of electricity generation (Version 03.0). 2017. Available online: https://cdm.unfccc.int/methodologies/PAmethodologies/tools/am-tool-05-v3.0.pdf (accessed on 3 April 2020).

- UNFCCC. Large-scale Consolidated Methodology Production of biofuel (version 03.1). 2017, p. 35. Available online: https://cdm.unfccc.int/methodologies/DB/ZNCG27VU8E0ABXO6GHGKTR75U0MIWL (accessed on 3 April 2020).

- Makarichi, L.; Jutidamrongphan, W.; Techato, K. The evolution of waste-to-energy incineration: A review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- UNFCCC. AMS-III.Q.: Waste Energy Recovery—Version 6.1. 2015. Available online: https://cdm.unfccc.int/methodologies/DB/RGPW18XV4FJH1FTTGS2LSD3BWNKNAA (accessed on 3 April 2020).

- IPCC. Climate Change 2013—The Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change, Ed.; Cambridge University Press: Cambridge, UK, 2014; ISBN 978-1-107-41532-4. [Google Scholar]

- Perry, R.; Green, D. Perry’s Chemical Engineers’ Handbook, 7th ed.; McGraw-Hill Professional: New York, NY, USA, 2007. [Google Scholar]

- MATTM. Tabella Parametri Standard Nazionali; MATTM: Rome, Italy, 2015; Available online: https://www.minambiente.it/sites/default/files/archivio/allegati/emission_trading/tabella_coefficienti_standard_nazionali_2012_2014_v1.pdf (accessed on 3 April 2020).

- UNFCCC. Methodological Tool: Upstream Leakage Emissions Associated with Fossil Fuel Use—Version 02.0. 2014. Available online: https://cdm.unfccc.int/methodologies/PAmethodologies/tools/am-tool-15-v2.0.pdf (accessed on 3 April 2020).

- EU. COM(2014) 398 final “Towards a circular economy: A zero waste programme for Europe”. Brussels, 2.7.2014. Available online: https://ec.europa.eu/environment/circular-economy/pdf/circular-economy-communication.pdf (accessed on 3 April 2020).

| ID | Waste | Description | Measure |

|---|---|---|---|

| 1 | Organic | Characterisation of substrates deriving from food scrap and organic waste | Pre-treatment |

| 2 | Organic | Thermo-chemical treatment of materials with high organic content for syngas production. | Treatment |

| 3 | Waste oils and sludge | Thermo-chemical treatment of waste oils and sludge for the obtaining of fuel oils [14]. | Treatment |

| 4 | Oily water | Separation system for oily water through a cyclone separator, recycling of waste oils and use in engines and subsequent treatment of separated water, with possible reuse onboard or unloading into sea. | Treatment |

| 5 | Organic | Systems of anaerobic conversion with thermophilic bacteria for organic matrices of various types [15]. | Treatment |

| 6 | Waste vegetable oils | Cleaning and characterisation of the combustion properties of syngas/biogas derived from waste. Optimised energy conversion of syngas/biogas derived from waste in internal combustion engines (gas turbine/alternative engine) also with supply of waste vegetable oils [16]. | Treatment |

| 7 | Waste Heat | Waste Heat Recovery. The measure consists in the adoption of Organic Rankine Cycles (ORC), which have a good operating flexibility, high safety due to low operating pressures and would allow the heat recovery of waste heat from other systems. | Treatment |

| 8 | CO2 | Carbon capture and storage (CCS) onboard through adsorption due to solid substances—such as calcium hydroxide and potassium hydroxide—as sorbent directly to the unloading and the next CO2 recycling through calcination. Possibility of combination with methanation and/or union to another syngas [17,18]. | Treatment |

| 9 | Grey/black water | System of biologic treatment grey/black water through separation of solids, disinfection, drying [19]. | Treatment |

| 10 | All waste | Installation of a waste-to-energy plant and next energy recovery [20]. | Treatment |

| 11 | Garbage | Onboard separation of garbage with a dedicated space. | Pre-treatment |

| 12 | Plastic | Plastic grinding and treatment for possible use of 3D printer for gadgets and items production. | Best Practice |

| 13 | Paper | Decrease of paper use, through an increase of the digitalization [21]. | Best Practice |

| 14 | Glass | Decrease of glass use through installation of dispenser and re-usable containers. | Best Practice |

| 15 | Packaging | Decrease of packaging on board. | Best Practice |

| 16 | All waste | Installation of a grinding and compaction system for multi-material treatments. | Treatment |

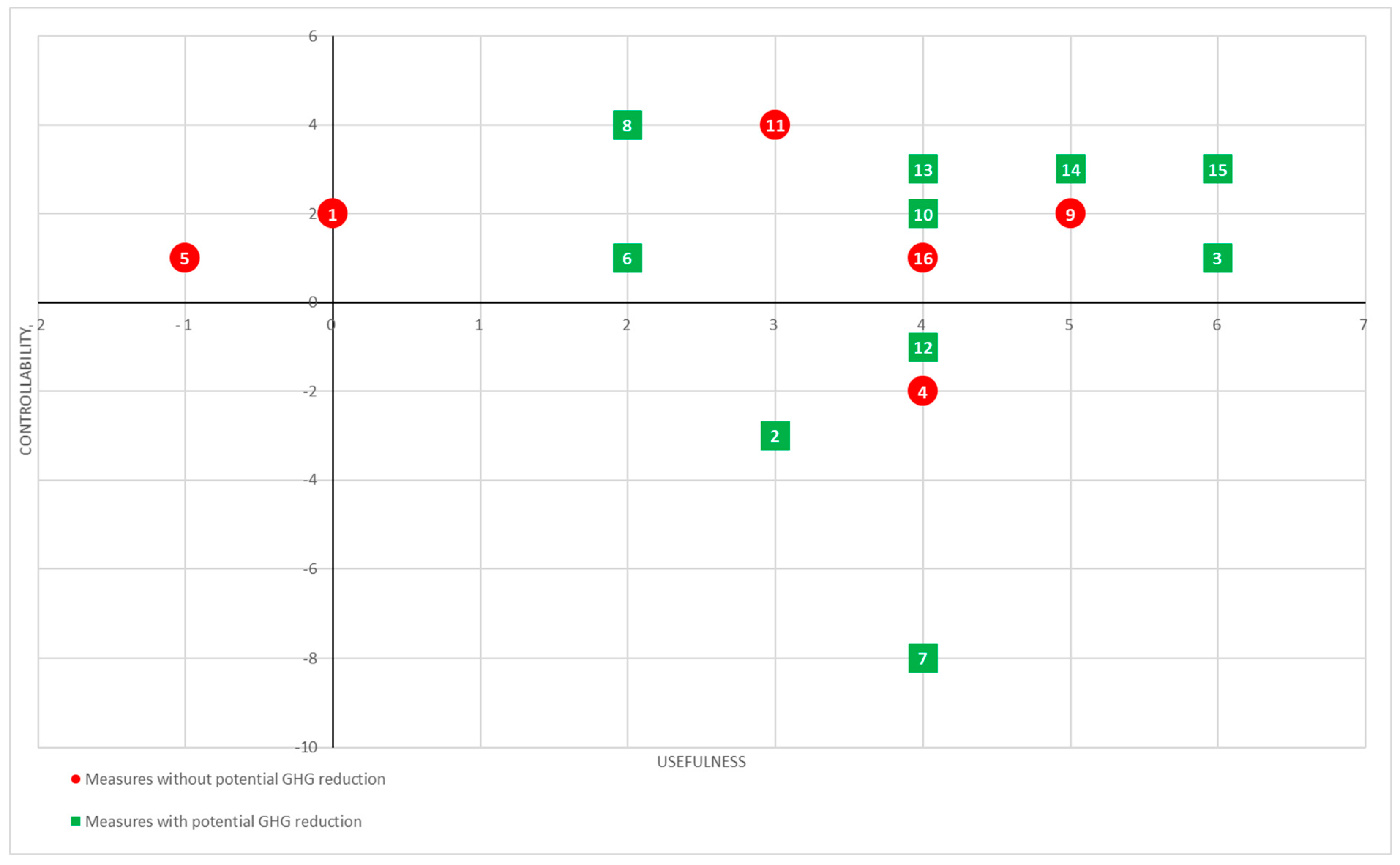

| Category | Usefulness | Controllability |

|---|---|---|

| Strength | Possible achievement of the goals of reduction in GHG emissions | Achievement of the goals depending on internal factors |

| Weakness | Difficulty in achieving the goals of reduction in GHG emissions | Achievement of the goals depending on internal factors |

| Opportunity | Possible achievement of the goals of reduction in GHG emissions | Achievement of the goals depending on external factors |

| Threat | Difficulty in achieving the goals of reduction in GHG emissions | Achievement of the goals depending on external factors |

| Score | ||||

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | |

| Strength | Not present | Low | Medium | High |

| Weakness | Not present | Low | Medium | High |

| Opportunity | Not present | Low | Medium | High |

| Threat | Not present | Low | Medium | High |

| Parameter | Value | Source |

|---|---|---|

| Average quantity of oily sludge | 1057 t/year | [A] |

| Water contained in oily sludge | 63.4% | [B] |

| Process yield on secondary fuel oil | 30% | [C] |

| Gas production | 17% | [C] |

| Solid production | 32% | [C] |

| Water production | 21% | [C] |

| Quantity of settled oily sludge | 390 t/year | [D] |

| Secondary fuel oil obtained by pyrolysis | 118 t/year | [D] |

| Gaseous product obtained by pyrolysis | 67 t/year | [D] |

| Solid product obtained by pyrolysis | 125 t/year | [D] |

| Parameter | Value | Annotation | |

|---|---|---|---|

| φy | Model correction factor to account for model uncertainties for year y | 0.85 | Default value for wet conditions |

| fy | Fraction of methane captured at the SWDS and flared, combusted or used in another manner that prevents the emissions of methane to the atmosphere in year y | 0.7 | Typical average value |

| GWP,CH4 | Global Warming Potential of methane | 30 | [31] |

| OX | Oxidation factor (reflecting the amount of methane from SWDS that is oxidised in the soil or other material covering the waste) | 0.1 | Default value |

| F | Fraction of methane in the SWDS gas (volume fraction) | 0.5 | Default value |

| DOCf,y | Fraction of degradable organic carbon (DOC) that decomposes under specific conditions occurring in the SWSD for year y (weight fraction) | 0.5 | Default value |

| MCFy | Methane correction factor for year y | 0.5 | Default value for semi-aerobic managed SWDS |

| j | Type of residual waste or types of waste in the municipal solid waste | Only oily sludge | |

| Wj,x | Amount of solid waste type j disposed or prevented from disposal in the SWDS in the year x [t/year] | 1057 | See Table 4 |

| DOC,j | Fraction of degradable organic carbon in the waste type j (weight fraction) | 0.09 | Default value for industrial sludge |

| kj | Decay rate for the waste type j [1/year] | 0.06 | Default value for industrial sludge |

| x | Years in the time period in which waste is disposed at the SWDS, extending from the first year in the time period (x = 1) to year y (x = y) | 1 | To be precautionary and make a comparison relative to a year, only one year of production of sludge to be disposed is considered |

| y | Year of the crediting period for which methane emissions are calculated | 1 | |

| Parameter | Value | Annotation | |

|---|---|---|---|

| Agitator power (kW) | 0.7 | 0.3–1 kW/m3: for agitated vessel [32] | |

| Pump power (kW) | 2 | From data sheet of a pump similar to that needed in this case (www.dabpumps.com) | |

| Working hours (h/year) | 1400 | 4 h/day for 50 week/year | |

| Fuel consumption (g/kWh) | 171 | From data sheet of Wartsila engine: type of engine usually installed on cruise ships (www.wartsila.com) | |

| EC—Quantity of electricity consumed (MWh/year) | 3.8 | Calculated from the current study | |

| FC—Quantity of fossil fuel fired in the plant to produce electricity (tcomb/year) | 0.65 | Calculated from the current study | |

| NCV—Average net calorific value of fossil fuel used (GJ/tfuel) | 41.08 | For fuel oil [33] | |

| EFCO2—CO2 emission factor of fossil fuel used [tCO2/GJ] | 0.0765 | For fuel oil [33] | |

| EG—Quantity of electricity generated in plant | 3.8 | Calculated from the current study | |

| TDL—Average technical transmission and distribution losses for providing electricity to source | 0 | Assumed 0 as a simplification according to [27] |

| Project Emissions | Disposal (tCO2e/year) | Reuse (tCO2e/year) |

|---|---|---|

| From pyrolysis process | 67 | 67 |

| From electricity consumption | 2 | 2 |

| From solid residue disposal | 0.7 | - |

| Total | 70 | 69 |

| Parameter | Value | Annotation | |

|---|---|---|---|

| fcap | Ratio between the energy generated by the waste and the total energy used in the project activity to produce useful energy (in year y) | 1 | The amount of energy generated by waste for the project activity is the same as the energy that would have been necessary for the operation of the plant before the introduction of the project activity itself |

| fwcm | Ratio between the electricity generated by the project activity and the energy generated by the waste used to produce it | 1 | The energy necessary for the operation of the refrigeration system is provided in total by the waste-to-energy plant |

| EGi | Amount of electricity supplied | 0.0191 TJ | In the absence of project activity would have been purchased during the year y |

| EFelec | CO2 emission factor for the energy source replaced | 73.3 t CO2/TJ | Energy source replaced by the project activity, during the year y |

| ηPlant,j | Overall efficiency of the identified existing plant | 0.365 | η diesel engine = 0.40 η mechanical transmission = 0.99 η electric generator = 0.97 η electric transmission = 0.99 η converter = 0.96 |

| Strategy | Reduction in GHG Emissions | Annotation |

|---|---|---|

| Thermo-chemical treatment of waste oils and sludge to obtain fuel oil and innovative oil waste management system (without waste transport) | −18 t CO2e/year | There is no reduction in emissions on an annual basis, but there is a slight increase in CO2 emissions |

| Installing a waste-to-energy plant and recovery energy | 1262 t CO2e/year | The reduction in GHG emissions is not particularly significant |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallo, M.; Moreschi, L.; Mazzoccoli, M.; Marotta, V.; Del Borghi, A. Sustainability in Maritime Sector: Waste Management Alternatives Evaluated in a Circular Carbon Economy Perspective. Resources 2020, 9, 41. https://doi.org/10.3390/resources9040041

Gallo M, Moreschi L, Mazzoccoli M, Marotta V, Del Borghi A. Sustainability in Maritime Sector: Waste Management Alternatives Evaluated in a Circular Carbon Economy Perspective. Resources. 2020; 9(4):41. https://doi.org/10.3390/resources9040041

Chicago/Turabian StyleGallo, Michela, Luca Moreschi, Michela Mazzoccoli, Veronica Marotta, and Adriana Del Borghi. 2020. "Sustainability in Maritime Sector: Waste Management Alternatives Evaluated in a Circular Carbon Economy Perspective" Resources 9, no. 4: 41. https://doi.org/10.3390/resources9040041

APA StyleGallo, M., Moreschi, L., Mazzoccoli, M., Marotta, V., & Del Borghi, A. (2020). Sustainability in Maritime Sector: Waste Management Alternatives Evaluated in a Circular Carbon Economy Perspective. Resources, 9(4), 41. https://doi.org/10.3390/resources9040041