Benefit Analysis and Regulatory Actions for Imported Palm Kernel Shell as an Environment-Friendly Energy Source in Taiwan

Abstract

:1. Introduction

2. Material and Methods

2.1. Thermochemical Characterization Analyses of PKS

2.2. Statistical Database and Its Environmental Benefit Analysis Using PKS as Biomass Fuel

2.2.1. Activity (Statistics and Status) of Imported PKS

2.2.2. Environmental Benefit Analysis of PKS-to-ENERGY

2.2.3. Regulatory Measures for Governing PKS-to-Energy

3. Results and Discussion

3.1. Thermochemical Characterization of Imported PKS

3.2. Statistics of Imported PKS in Taiwan

- -

- Indonesia and Malaysia were the two main countries of imported PKS in Taiwan. It is well known that they ranked the world palm oil production as No. 1 and No. 2, respectively. Based on the cost consideration, the imported PKS was shifted from Malaysia to Indonesia. For example, the percentages of PKS imported from Malaysia changed from 96.8% in 2011 to 3.5% in 2017.

- -

- The yearly imported amounts of PKS indicated an upward trend, up to the maximal amount at 92,591 metric tons in 2014. As explained later, it should be attributed to the regulatory measures for promoting PKS-to-energy in the industrial steam boilers and cogeneration turbines during this period. However, this trend began to decline since 2015, mainly due to the increasing PKS cost and the newly regulatory pressure for controlling air pollutant emissions from PKS-to-energy facilities in Taiwan. As seen in Table 2, the imported PKS amounts decreased from 92,591 metric tons in 2014 to 30,637 metric tons in 2017.

3.3. Environmental and Economic Benefit Analyses of PKS-to-Energy in Taiwan

- -

- Annual imported amount on an average (the data in 2014–2018, seen in Table 2): 60,000 metric tons.

- -

- Moisture content: 12 wt. %.

- -

- Calorific value: 20.8 MJ/kg (dry basis).

- -

- DEF values for PKS: 0 CO2 kg/TJ, 30 CH4 kg/TJ, and 4 N2O kg/TJ.

- -

- DEF values for fuel oil: 73,300 CO2 kg/TJ, 3 CH4 kg/TJ, and 0.6 N2O kg/TJ [17].

- -

- Global warming potential (GWP) values for 100-year time horizon: 25 for CH4 and 298 for N2O [19].

- -

- Annual imported amount on an average: 60,000 metric tons.

- -

- Annual fuel oil consumption: 20,000 KL (3.0 ton PKS/KL fuel oil, based on the calorific value and energy efficiency).

- -

- Purchase cost of fuel oil (low sulfur-0.5%): NT$18,000/KL.

- -

- Purchase cost of PKS (including marine transportation fee): NT$5000/ton20,000 KL × NT$18,000/KL − 60,000 ton × NT$5000/ton = NT$60,000,000

3.4. Regulatory Measures for Upgrading PKS-to-Energy in Taiwan

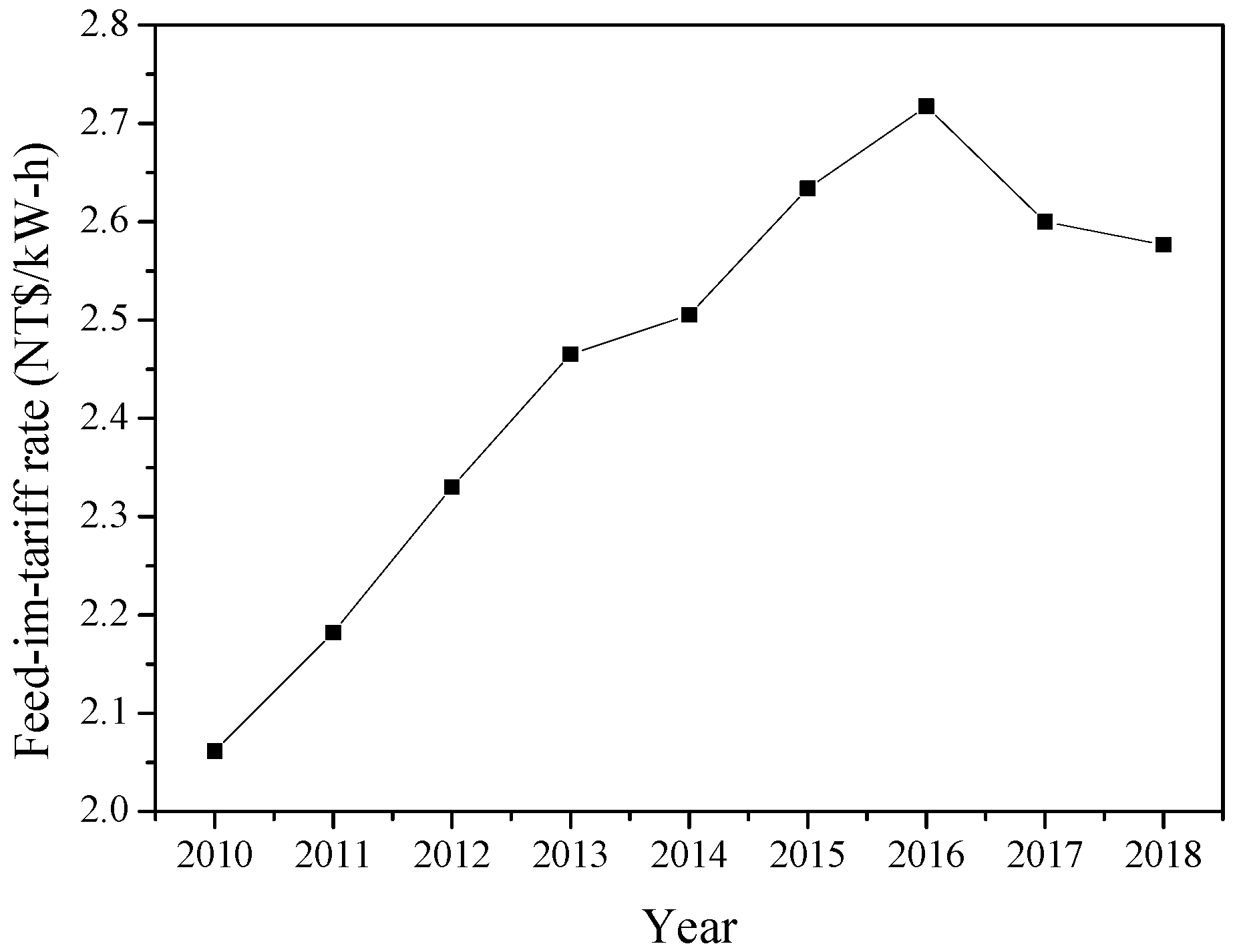

3.4.1. Renewable Energy Development Act

3.4.2. Customs Import Tariff

3.4.3. Waste Management Act

3.5. Regulatory Measures for Controlling Air Pollutant Emissions from PKS-to-Energy Facilities in Taiwan

3.5.1. Air Pollutant Emission Standards for Electricity Generation Facilities

- -

- In order to raise the heat efficiency, the concept of overall heat efficiency was adopted to relax the emission standards for cogeneration turbines. As listed in Table 3, the emission standards of air pollutants (i.e., SOx, NOx, and particulate matter) for existing facilities (came into force on 1 December 2016) are multiplied by 1.4 and 2.0 when the overall heat efficiency achieved over 52% and 72%, respectively. Herein, the overall heat efficiency (Hs) is an average value based on continuous 12-h operation and is defined below:Hs = (effective heat output + effective power output)/(lower heating value of fuel)

- -

- In order to cut the emissions of SOx, NOx and particulate matter, their standards for both newly installed and existing facilities were tightened after taking composite considerations of domestic emission circumstances, overseas emission standards, feasible control technologies, and cos-benefit analyses.

3.5.2. Air Pollutant Emission Standards for Boilers

4. Conclusions and Recommendations

- -

- Verifying the emissions from PKS-to-energy systems in compliance with the Air Pollutant Emission Standards for Boilers.

- -

- Increasing the FIT rates for biomass to-power systems regardless of its local or imported resources by reference to the Japan’s values.

- -

- Concerting PKS into biochar. This carbon-rich solid can be used as a biomass fuel due to its higher calorific value, low hygroscopicity and porous structure.

- -

- Concerting PKS into biochar. This carbon-rich solid can be used as a biomass fuel due to its higher calorific value, low hygroscopicity and porous structure.

- -

- Adopting gasification process for transforming PKS into syngas. This methane/carbon monoxide-rich product can be used as a gas fuel, or further converted it into C1 chemicals via catalytic synthesis.

- -

- Building PKS-to-power plants, or co-firing PKS in the coal-fired power plants, because this energy form can gain the FIT at higher rates.

- -

- Reusing bottom ash as a soil amendment, because the residue after the combustion of PKS possesses alkaline, mineral-rich and nontoxic characters.

Funding

Conflicts of Interest

References

- Ministry of Economic Affairs (MOEA). Energy Statistics Handbook—2017; MOEA: Taipei, Taiwan, 2018. (In Chinese) [Google Scholar]

- Tsai, W.T. Feed-in tariff promotion and innovative measures for renewable electricity: Taiwan case analysis. Renew. Sustain. Energy Rev. 2014, 1140, 1126–1132. [Google Scholar] [CrossRef]

- Klass, D.J. Biomass for Renewable Energy, Fuels, and Chemicals; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Ebeling, J.M.; Jenkins, B.M. Physical and chemical properties of biomass fuels. Trans. ASAE 1985, 28, 898–902. [Google Scholar] [CrossRef]

- Aziz, M.; Budianto, D.; Oda, T. Computational fluid dynamic analysis of co-firing of palm kernel shell and coal. Energies 2016, 9, 137. [Google Scholar] [CrossRef]

- Tsai, W.T.; Hsien, K.J. An analysis of cogeneration system utilized as sustainable energy in the industrial sector in Taiwan. Renew. Sustain. Energy Rev. 2007, 11, 2104–2120. [Google Scholar] [CrossRef]

- Shuit, S.H.; Tan, K.T.; Lee, K.T.; Kamaruddin, A.H. Oil palm biomass as a sustainable energy source: A Malaysian case study. Energy 2009, 34, 1225–1235. [Google Scholar] [CrossRef] [Green Version]

- Chiueh, P.T.; Lee, K.C.; Syu, F.S.; Lo, S.L. Implications of biomass pretreatment to cost and carbon emissions: Case study of rice straw and Pennisetum in Taiwan. Bioresour. Technol. 2012, 108, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Umar, M.S.; Jennings, P.; Urmee, T. Generating renewable energy from oil palm biomass in Malaysia: The feed-in tariff policy framework. Biomass Bioenergy 2014, 62, 37–46. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Shrestha, S.; Athar, S.; Ali, B.S.; Siddiqui, M.A. A critical analysis on palm kernel shell from oil palm industry as a feedstock for solid char production. Rev. Chem. Eng. 2016, 32, 489–505. [Google Scholar] [CrossRef]

- Asibev, M.O.; Yeboah, V.; Adabor, E.K. Palm biomass waste as supplementary source of electricity generation in Ghana: Case of the Juaben Oil Mills. Energy Environ. 2017, 29, 165–183. [Google Scholar] [CrossRef]

- Loh, S.K. The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. 2017, 141, 285–298. [Google Scholar] [CrossRef]

- Zainal, N.H.; Aziz, A.A.; Idris, J.; Mamat, R.; Hassan, M.A.; Bahrin, E.K.; Abd-Aziz, S. Microwave-assisted pre-carbonization of palm kernel shell produced charcoal with high heating value and low gaseous emission. J. Clean. Prod. 2017, 142, 2945–2949. [Google Scholar] [CrossRef]

- Wang, P.; Wang, G.W.; Zhang, J.L.; Lee, J.Y.; Li, Y.J.; Wang, C. Co-combustion characteristics and kinetic study of anthracite coal and palm kernel shell char. Appl. Therm. Eng. 2018, 143, 736–745. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction, 2nd ed.; Academic Press: London, UK, 2013. [Google Scholar]

- Customs Administration (Ministry of Finance, Taiwan). Trade Statistics Search. Available online: https://portal.sw.nat.gov.tw/APGA/GA03E (accessed on 1 November 2018).

- Intergovernmental Panel on Climate Change (IPCC). 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006. [Google Scholar]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2013: The Physical Science Basis; Cambridge Press: New York, NY, USA, 2013. [Google Scholar]

- Environmental Protection Administration (EPA). 2017 Taiwan Greenhous Gas Inventory; EPA: Taipei, Taiwan, 2017. (In Chinese)

- Hampf, B.; Rodseth, K.L. Carbon dioxide emission standards for US power plants: An efficiency analysis perspective. Energy Econ. 2015, 50, 140–153. [Google Scholar] [CrossRef]

- Zhang, X. Emission Standards and Control of PM2.5 from Coal-Fired Power Plant; International Energy Agency: London, UK, 2016. [Google Scholar]

| Property | Value | |

|---|---|---|

| Test 1 | Test 2 | |

| Proximate analysis a | ||

| Moisture (wt. %) | 11.89 | 12.20 |

| Ash (wt. %) | 3.87 | 2.98 |

| Combustibles b (wt. %) | 85.76 | 84.82 |

| Ultimate analysis c | ||

| Carbon (wt. %) | 50.83 | 50.81 |

| Hydrogen (wt. %) | 5.81 | 5.71 |

| Oxygen (wt. %) | 41.54 | 41.28 |

| Nitrogen (wt. %) | 0.65 | 0.53 |

| Sulfur (wt. %) | 0.00 | 0.00 |

| Calorific value (MJ/kg) c | 20.89 | 20.43 |

| Year | Total Imported Amount (MT) | Imported Country (%) | ||

|---|---|---|---|---|

| Indonesia | Malaysia | Other Countries b | ||

| 2010 | 2651.7 | 1579.9 (59.6%) | 0 (0.0%) | 1071.8 (40.4%) |

| 2011 | 21,870.4 | 55.6 (0.3%) | 21,167.3 (96.8) | 647.5 (3.0%) |

| 2012 | 18,070.1 | 8281.1 (45.8%) | 9611.0 (53.2%) | 178.0 (1.0%) |

| 2013 | 66,357.7 | 27,122.0 (40.9%) | 38,956.4 (58.7%) | 279.3 (0.4%) |

| 2014 | 92,591.4 | 75,697.3 (81.7%) | 16,081.0 (17.4%) | 813.1 (0.9%) |

| 2015 | 82,958.9 | 71,581.2 (86.3%) | 10,544.1 (12.7%) | 833.6 (1.0%) |

| 2016 | 49,049.5 | 35,920.9 (73.2%) | 13,037.1 (26.6%) | 91.5 (0.2%) |

| 2017 | 30,637.0 | 29,490.0 (96.3%) | 1082.5 (3.5%) | 64.5 (0.2%) |

| Air Pollutant | Overall Heat Efficiency (Hs) | Emission Standard b | |

|---|---|---|---|

| New Facility | Existing Facility | ||

| Particulate | Hs ˂ 50% | 10 mg/Nm3 | 20 mg/Nm3 |

| 50% ≤ Hs ˂ 52% | 28 mg/Nm3 | ||

| 52% ≤ Hs ˂ 72% | 14 mg/Nm3 | 28 mg/Nm3 | |

| 72% ≤ Hs ˂ 90% | 40 mg/Nm3 | ||

| Hs ≥ 90% | 50 mg/Nm3 | ||

| Sulfur oxides (SOx) | Hs ˂ 50% | 30 ppm | 60 ppm |

| 50% ≤ Hs ˂ 52% | 83 ppm | ||

| 52% ≤ Hs ˂ 72% | 43 ppm | 86 ppm | |

| 72% ≤ Hs ˂ 90% | 120 ppm | ||

| Hs ≥ 90% | 150 ppm | ||

| Nitrogen oxides (NOx) | Hs ˂ 50% | 30 ppm | 70 ppm |

| 50% ≤ Hs ˂ 52% | 97 ppm | ||

| 52% ≤ Hs ˂ 72% | 43 ppm | 101 ppm | |

| 72% ≤ Hs ˂ 90% | 140 ppm | ||

| Hs ≥ 90% | 175 ppm | ||

| Air Pollutant | Emission Standards a | Came into Force |

|---|---|---|

| Particulate | 30 mg/Nm3 | New units: 19 September 2018 Existing units: 19 September 2020 |

| Sulfur oxides (SOx) | 50 ppm | |

| Nitrogen oxides (NOx) | 100 ppm |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, W.-T. Benefit Analysis and Regulatory Actions for Imported Palm Kernel Shell as an Environment-Friendly Energy Source in Taiwan. Resources 2019, 8, 8. https://doi.org/10.3390/resources8010008

Tsai W-T. Benefit Analysis and Regulatory Actions for Imported Palm Kernel Shell as an Environment-Friendly Energy Source in Taiwan. Resources. 2019; 8(1):8. https://doi.org/10.3390/resources8010008

Chicago/Turabian StyleTsai, Wen-Tien. 2019. "Benefit Analysis and Regulatory Actions for Imported Palm Kernel Shell as an Environment-Friendly Energy Source in Taiwan" Resources 8, no. 1: 8. https://doi.org/10.3390/resources8010008

APA StyleTsai, W.-T. (2019). Benefit Analysis and Regulatory Actions for Imported Palm Kernel Shell as an Environment-Friendly Energy Source in Taiwan. Resources, 8(1), 8. https://doi.org/10.3390/resources8010008