Risk Assessment in a Materials Recycling Facility: Perspectives for Reducing Operational Issues

Abstract

1. Introduction

- the application of a curbside collection of various recyclable waste (mostly plastic, paper, glass, metals and food waste);

- the implementation of collection centers for specific streams (waste from electric and electronic equipment, batteries, other plastics, green waste, among others); and

- the use of a pay-as-you-throw system, that incentives SC as demonstrated in the recent literature [14].

- to separate the rejects and impurities detectable within the waste (wood, glass, unrecyclable plastic); and

- to improve the quality of the separation of valuable materials (aluminum, PET, PE).

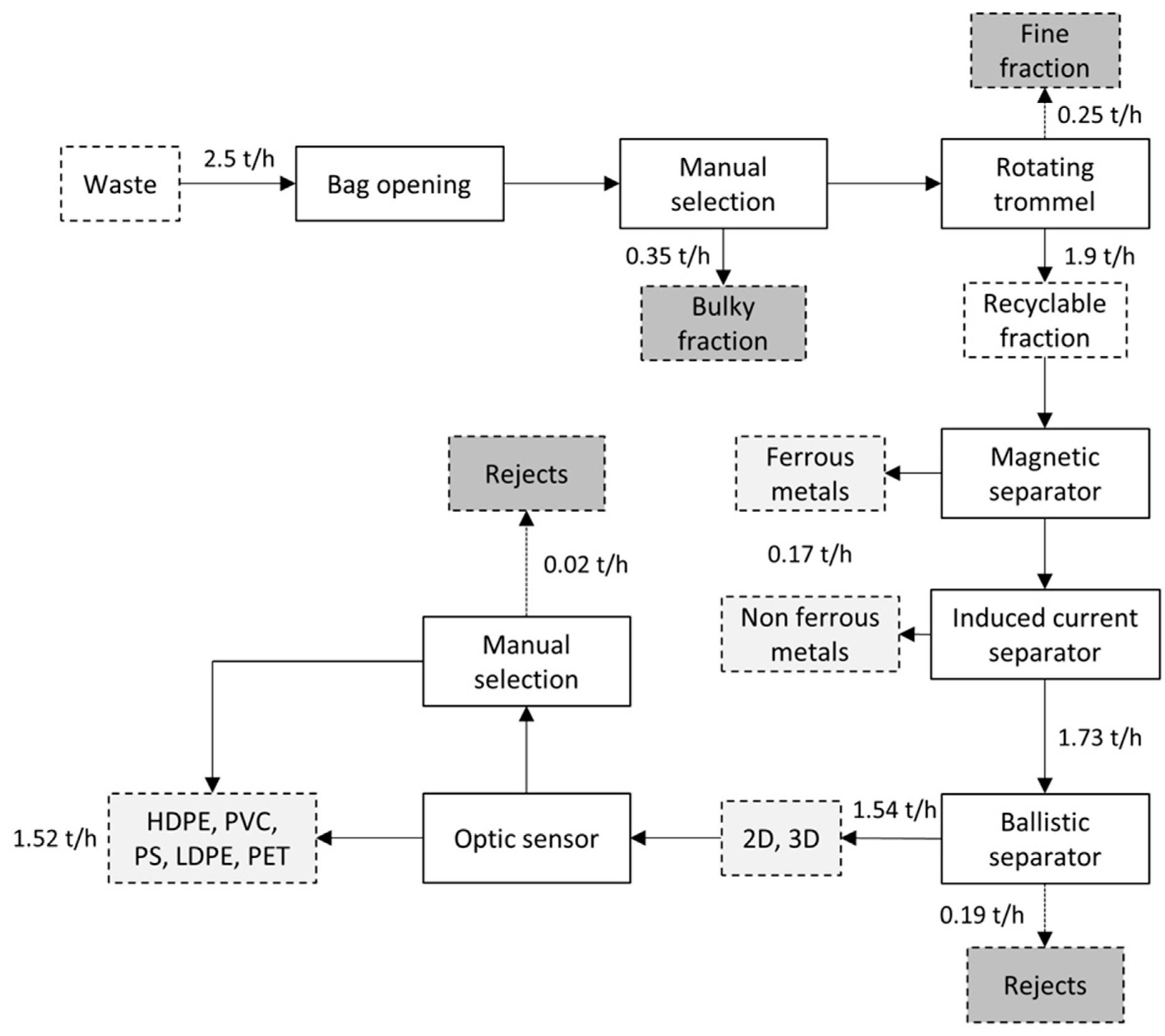

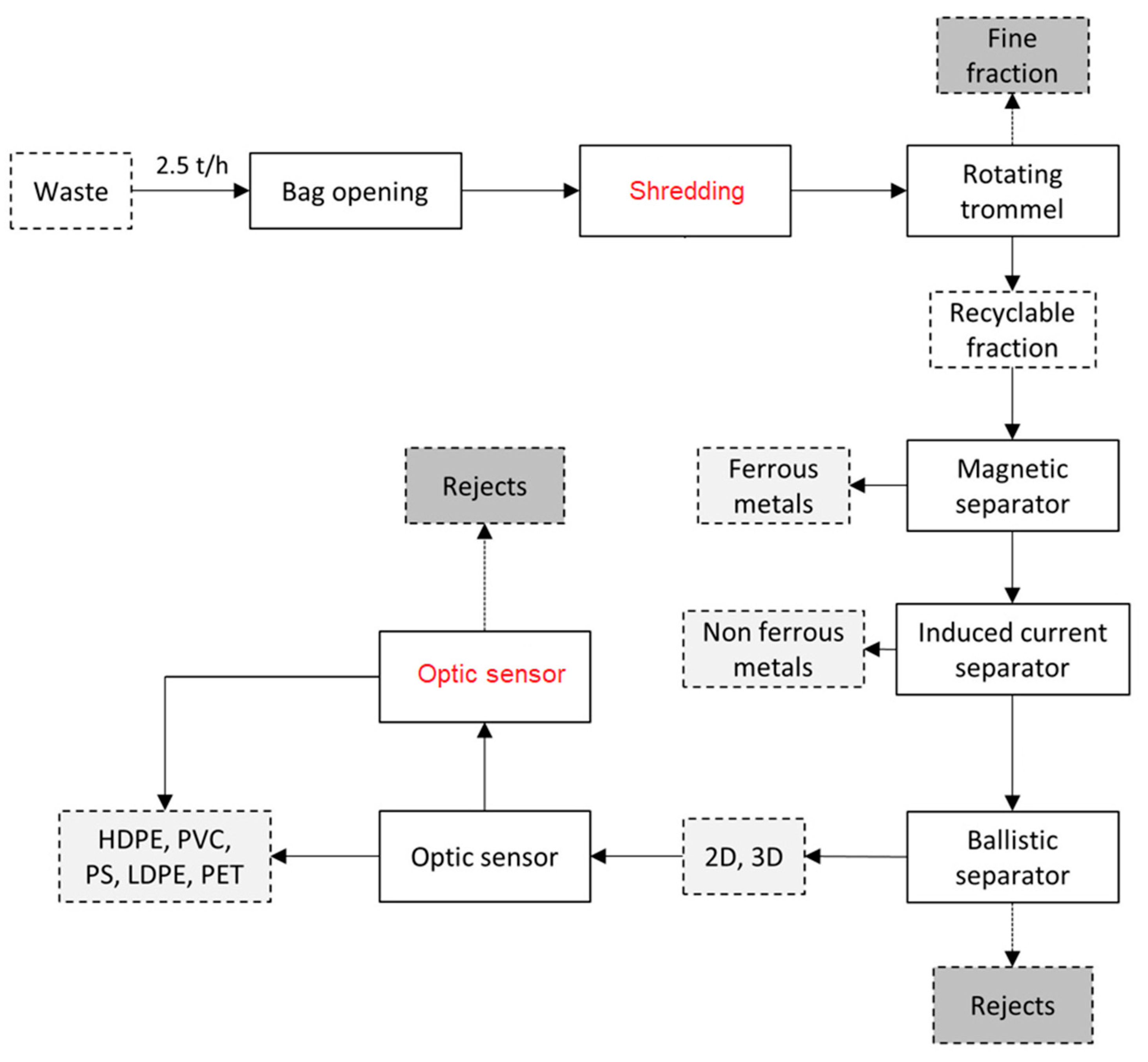

Structure of the MRF

- a bag opening system as light packaging is assumed to come in plastic bags;

- a preliminary manual separation to separate bulky waste;

- a rotating trommel aimed to separate the stream in two outputs; the over sieve is considered recyclable;

- a magnetic separator for ferrous packaging;

- an induced current separator aimed mainly to separate aluminum cans;

- a ballistic separator (heavy materials are assumed as rejects);

- an optic separator (separating according to polymer and color); and

- a second manual separation to support the optic separator.

2. Methods

3. Results

- proposals for enhancement of specific steps of treatment [26]; and

3.1. Risks Assessment of the Manual Separation

3.2. Risks Assessment of the Mechanical Separation

3.3. Economic Comparison

3.4. Change of Context

- The behavior of the citizens can affect the biological risk (and not only) at the MRF; that depends on the skills of the population in avoiding putrescible materials in the light packaging waste stream. In well-organized contexts putrescible materials are source separated in a dedicated stream, according to the principles of waste management in the EU.

- The composition of Municipal Solid Waste can affect the risk at the MRF. e.g., in case of bad source separation of cans (cutting elements) the risk could be lower than the case of good behavior in separating. These aspects should be taken into account carefully when designing a MRF.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References and Notes

- EC—European Commission. Implementation of the Circular Economy Action Plan. Circular Economy Package. 2018. Available online: http://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 3 September 2018).

- Rada, E.C.; Ragazzi, M.; Torretta, V.; Castagna, G.; Adami, L.; Cioca, L.I. Circular economy and waste to energy. AIP Conf. Proc. 2018, 1968, 030050. [Google Scholar] [CrossRef]

- Park, S.; Lah, T.J. Same material different recycling standards: Comparing the municipal solid waste standards of the European Union, South Korea and the USA. Int. J. Environ. Waste Manag. 2018, 21, 80–93. [Google Scholar] [CrossRef]

- Dijkgraaf, E.; Gradus, R. An EU Recycling Target: What Does the Dutch Evidence Tell Us? Environ. Resour. Econ. 2017, 68, 501–526. [Google Scholar] [CrossRef]

- Gregson, N.; Crang, M.; Botticello, J.; Calestani, M.; Krzywoszynska, A. Doing the ‘dirty work’ of the green economy: Resource recovery and migrant labour in the EU. Eur. Urban Reg. Stud. 2016, 23, 541–555. [Google Scholar] [CrossRef]

- Ciudin, R.; Isarie, C.; Cioca, L.; Petrescu, V.; Nederita, V.; Ranieri, E. Vacuum waste collection system for an historical city centre. UPB Sci. Bull. 2014, 76, 215–222. [Google Scholar]

- Lakatos, E.S.; Cioca, L.I.; Dan, V.; Ciomos, A.O.; Crisan, O.A.; Barsan, G. Studies and investigation about the attitude towards sustainable production, consumption and waste generation in line with circular economy in Romania. Sustainability 2018, 10, 865. [Google Scholar] [CrossRef]

- ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale. Rapporto Rifiuti Urbani 2016; ISPRA: Rome, Italy, 2016. Available online: http://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2016 (accessed on 3 September 2018). (In Italian)

- Ragazzi, M.; Fedrizzi, S.; Rada, E.C.; Ionescu, G.; Ciudin, R.; Cioca, L.I. Experiencing Urban Mining in an Italian Municipality towards a Circular Economy vision. Energy Procedia 2017, 119, 192–200. [Google Scholar] [CrossRef]

- Rada, E.C.; Zatelli, C.; Mattolin, P. Municipal solid waste selective collection and tourism. WIT Trans. Ecol. Environ. 2014, 180, 187–197. [Google Scholar] [CrossRef]

- Ranieri, E.; Rada, E.C.; Ragazzi, M.; Masi, S.; Montanaro, C. Critical analysis of the integration of residual municipal solid waste incineration and selective collection in two Italian tourist areas. Waste Manag. Res. 2014, 32, 551–555. [Google Scholar] [CrossRef]

- Rada, E.C.; Zatelli, C.; Cioca, L.I.; Torretta, V. Selective Collection Quality Index for Municipal Solid Waste Management. Sustainability 2018, 10, 257. [Google Scholar] [CrossRef]

- Tantau, A.D.; Maassen, M.A.; Fratila, L. Models for analyzing the dependencies between indicators for a circular economy in the European Union. Sustainability 2018, 10, 2141. [Google Scholar] [CrossRef]

- Morlok, J.; Schoenberger, H.; Styles, D.; Galvez-Martos, J.L.; Zeschmar-Lahl, B. The Impact of Pay-As-You-Throw Schemes on Municipal Solid Waste Management: The Exemplar Case of the County of Aschaffenburg, Germany. Resources 2017, 6, 8. [Google Scholar] [CrossRef]

- MRF facilities in Italy. Available online: http://www.corepla.it/documenti/a6a80177-58a5-4353-a876-dc279e8ce855/Anagrafica+CSS+giu17.pdf (accessed on 3 September 2018).

- Moussiopoulos, N. Investigation of the occupational health and safety conditions in Hellenic solid waste management facilities and assessment of the in-situ hazard level. Saf. Sci. 2017, 96, 192–197. [Google Scholar] [CrossRef]

- Battaglia, M.; Passetti, E.; Frey, M. Occupational health and safety management in municipal waste companies: A note on the Italian sector. Saf. Sci. 2015, 72, 55–65. [Google Scholar] [CrossRef]

- Bastani, M.; Moore, D.E.; Celik, N. Case studies on quantification of occupational health risks for solid waste workers in Floridian counties. In Proceedings of the IIE Annual Conference and Expo, Montreal, QC, Canada, 31 May–3 June 2014; pp. 633–642. [Google Scholar]

- Rubio-Romero, J.C.; del Carmen Pardo-Ferreira, M.; De la Varga-Salto, J.; Galindo-Reyes, F. Composite leading indicator to assess the resilience engineering in occupational health & safety in municipal solid waste management companies. Saf. Sci. 2018, 108, 161–172. [Google Scholar] [CrossRef]

- La sicurezza per gli operatori degli impianti di trattamento e di stoccaggio dei rifiuti solidi urbani. Available online: https://www.inail.it/cs/internet/comunicazione/pubblicazioni/catalogo-generale/la-sicurezza-per-gli-operatori-degli-impianti.html (accessed on 20 November 2018). (In Italian).

- Sorting and Processing of Light Weight Packaging Waste. Available online: https://www.retech-germany.net/ (accessed on 3 September 2018).

- De Vecchi, F. Definizione Delle Linee Guida per la Gestione di un Impianto di Selezione di Imballaggi Leggeri in Italia. Master’s Thesis, University of Trento, Trento, Italy, 2014–2015. (In Italian). [Google Scholar]

- Italian single text on health and safety at work. D.lgs. 9 April 2008, n. 81, coordinated with the D.Lgs. 3 August 2009, n. 106: Italian Gazzetta Ufficiale n. 101 of 30 April 2008—Annex n. 108 and Integrative Decree on Gazzetta Ufficiale n. 180 of 05 August 2009, Annex n. 142/L. Available online: http://www.gazzettaufficiale.itg. (accessed on 3 September 2018). (In Italian).

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Gu, F.; Guob, J.; Zhang, W.; Summers, P.A.; Hall, P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci. Total. Environ. 2017, 601–602, 1192–1207. [Google Scholar] [CrossRef]

- Lupo, E.; Moroni, M.; La Marca, F.; Fulco, S.; Pinzi, V. Investigation on an innovative technology for wet separation of plastic wastes. Waste Manag. 2016, 51, 3–12. [Google Scholar] [CrossRef]

- Martínez Urreaga, J.; Gonzalez-Sanchez, C.; Martínez-Aguirre, A.; Fonseca-Valero, C.; Acosta, J.; de la Orden, M.U. Sustainable eco-composites obtained from agricultural and urban waste plastic blends and residual cellulose fibers. J. Clean. Prod. 2015, 108, 377–384. [Google Scholar] [CrossRef]

- Cossu, R.; Garbo, F.; Girotto, F.; Simion, F.; Pivato, A. PLASMIX management: LCA of six possible scenarios. Waste Manag. 2017, 69, 567–576. [Google Scholar] [CrossRef]

- Schaefer, C.E.; Kupwade-Patil, K.; Ortega, M.; Soriano, C.; Büyüköztürk, O.; White, A.E.; Short, M.P. Irradiated recycled plastic as a concrete additive for improved chemo-mechanical properties and lower carbon footprint. Waste Manag. 2018, 71, 426–439. [Google Scholar] [CrossRef] [PubMed]

| Matrix of Risk | Magnitude | ||||

|---|---|---|---|---|---|

| Probability | 1 | 1 | 2 | 3 | 4 |

| 2 | 2 | 4 | 6 | 8 | |

| 3 | 3 | 6 | 9 | 12 | |

| 4 | 4 | 8 | 12 | 16 | |

| Risks | Characteristics |

|---|---|

| Biological | Presence of bacteria, parasites, fungus, allergies, intoxications, infections and pathogens even if the material is dry. |

| Chemical | Emission of chemical compounds during the storage of waste or functioning of the machines (conveyed and diffused emissions). |

| Noise | Caused by the functioning of the mechanics or machines that could affect the hearing system. |

| Vibrations | Caused by the functioning of the machines and operation near mechanical systems. |

| Machines moving | Due to the operation of the machines that move waste and provide it to the facility. |

| Falling of workers | Mainly caused by any kind of work at high altitude, e.g., along footbridges or in suspended areas. |

| Falling of objects | Waste or other materials could fall down the machines. |

| Cuts | Caused by the contact with sharps materials detectable in the mixed waste or by the contact with parts of the machines. |

| Effort | The work and the activities required during the process could be cause of loss of attention. |

| Indoor environment | Within the facility, different climatic conditions could occur due to extreme temperatures or the low quality of the air. |

| Fire | Caused by the overheating of the machineries and the presence of combustible materials (specifically in the case of light packaging). |

| Assessed Risk | Risks | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Biological | Chemical | Noise | Vibrations | Machines | Cuts | Fallings | Effort | Indoor Environment | ||

| Operations | Manual separation | 12 | 9 | 4 | 2 | 2 | 16 | 2 | 3 | 6 |

| Waste storage | 9 | 9 | 2 | 2 | 2 | 8 | 2 | 3 | 2 | |

| Manual movement of the waste | 9 | 9 | 8 | 2 | 6 | 8 | 6 | 3 | 2 | |

| Mechanical movement of the waste | 6 | 6 | 4 | 4 | 4 | 4 | 2 | 6 | 2 | |

| Cleaning of the area | 12 | 12 | 6 | 2 | 6 | 8 | 2 | 3 | 4 | |

| Assessed Risk | Risks | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Biological | Chemical | Noise | Vibration | Machine | Falling | Falling of Objects | Cuts | Effort | Fire | ||

| Operations | Waste charging | 2 | 4 | 9 | 4 | 9 | 2 | 3 | 2 | 4 | 2 |

| Shredding | 1 | 2 | 9 | 4 | 3 | 4 | 9 | 4 | 2 | 2 | |

| Waste storage | 2 | 2 | 6 | 4 | 6 | 2 | 3 | 4 | 4 | 1 | |

| Waste movement | 2 | 4 | 6 | 4 | 6 | 2 | 3 | 4 | 4 | 1 | |

| Clean of the areas | 2 | 4 | 9 | 2 | 9 | 4 | 9 | 6 | 2 | 1 | |

| Assessed Risk | Risks | |||||||

|---|---|---|---|---|---|---|---|---|

| Biological | Chemical | Noise | Vibrations | Machines | Cuts | Efforts | ||

| Operations | Optic separation | 2 | 1 | 1 | 1 | 2 | 2 | 1 |

| Waste charging | 2 | 1 | 1 | 1 | 2 | 4 | 1 | |

| Waste movements | 2 | 1 | 1 | 2 | 4 | 2 | 2 | |

| Clean of the areas | 2 | 1 | 1 | 2 | 4 | 4 | 1 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cioca, L.I.; Ferronato, N.; Viotti, P.; Magaril, E.; Ragazzi, M.; Torretta, V.; Rada, E.C. Risk Assessment in a Materials Recycling Facility: Perspectives for Reducing Operational Issues. Resources 2018, 7, 85. https://doi.org/10.3390/resources7040085

Cioca LI, Ferronato N, Viotti P, Magaril E, Ragazzi M, Torretta V, Rada EC. Risk Assessment in a Materials Recycling Facility: Perspectives for Reducing Operational Issues. Resources. 2018; 7(4):85. https://doi.org/10.3390/resources7040085

Chicago/Turabian StyleCioca, Lucian Ionel, Navarro Ferronato, Paolo Viotti, Elena Magaril, Marco Ragazzi, Vincenzo Torretta, and Elena Cristina Rada. 2018. "Risk Assessment in a Materials Recycling Facility: Perspectives for Reducing Operational Issues" Resources 7, no. 4: 85. https://doi.org/10.3390/resources7040085

APA StyleCioca, L. I., Ferronato, N., Viotti, P., Magaril, E., Ragazzi, M., Torretta, V., & Rada, E. C. (2018). Risk Assessment in a Materials Recycling Facility: Perspectives for Reducing Operational Issues. Resources, 7(4), 85. https://doi.org/10.3390/resources7040085