Shedding Light on the Anthropogenic Europium Cycle in the EU–28. Marking Product Turnover and Energy Progress in the Lighting Sector

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

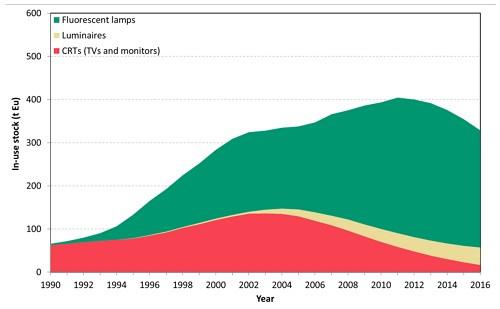

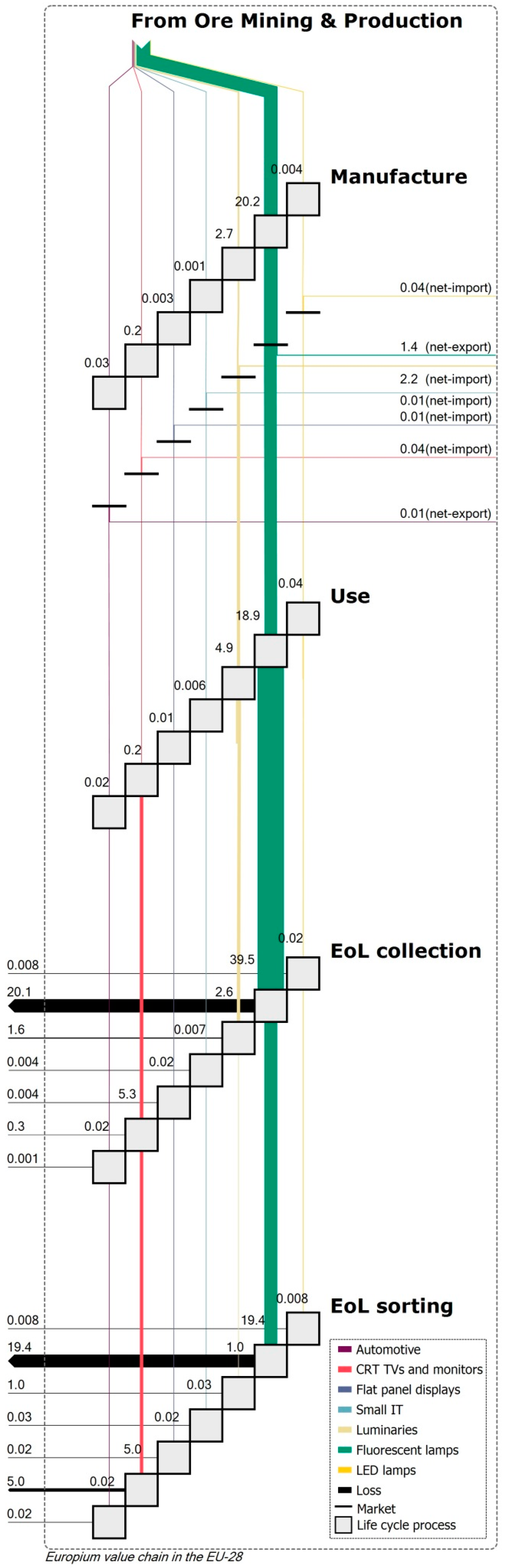

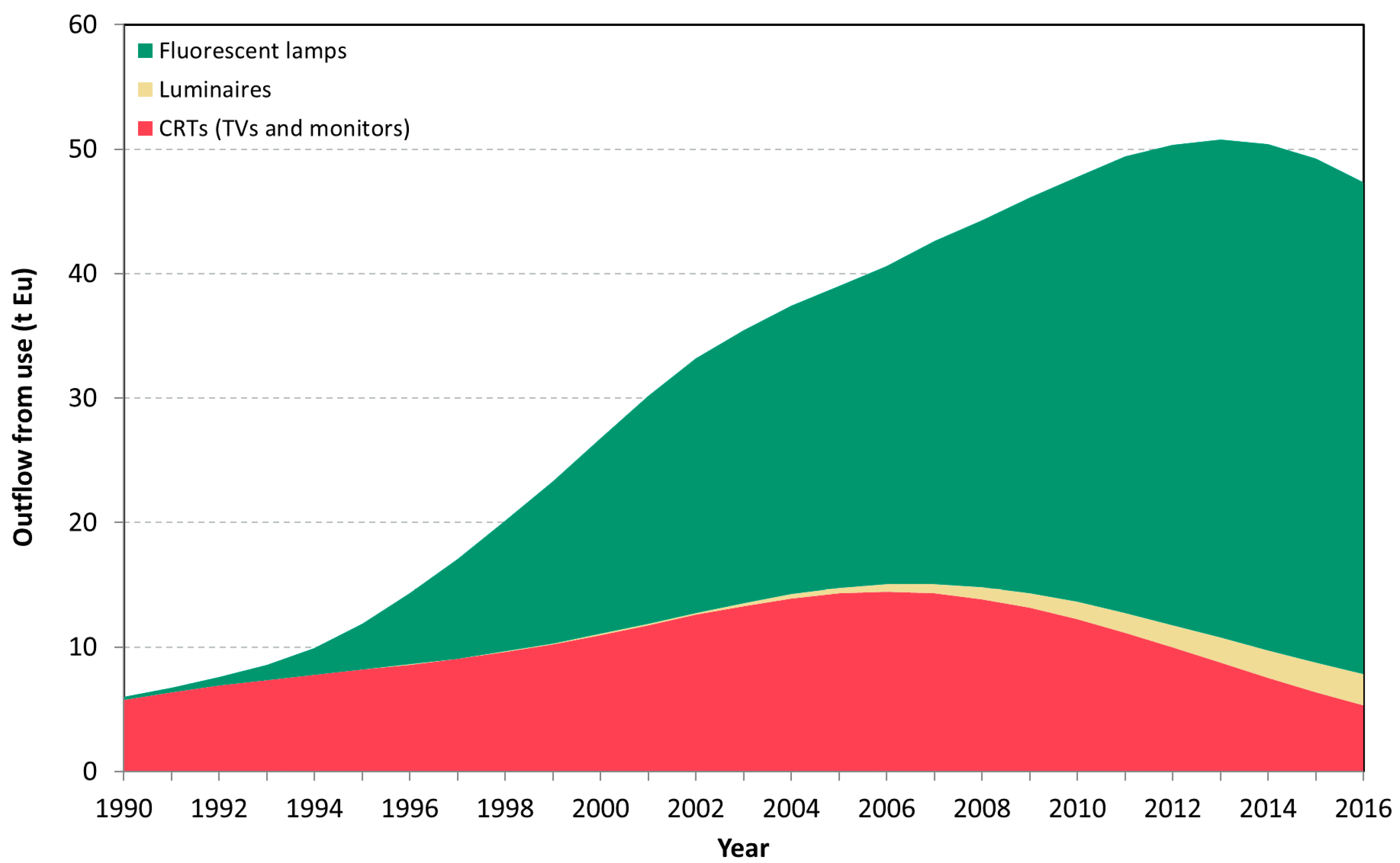

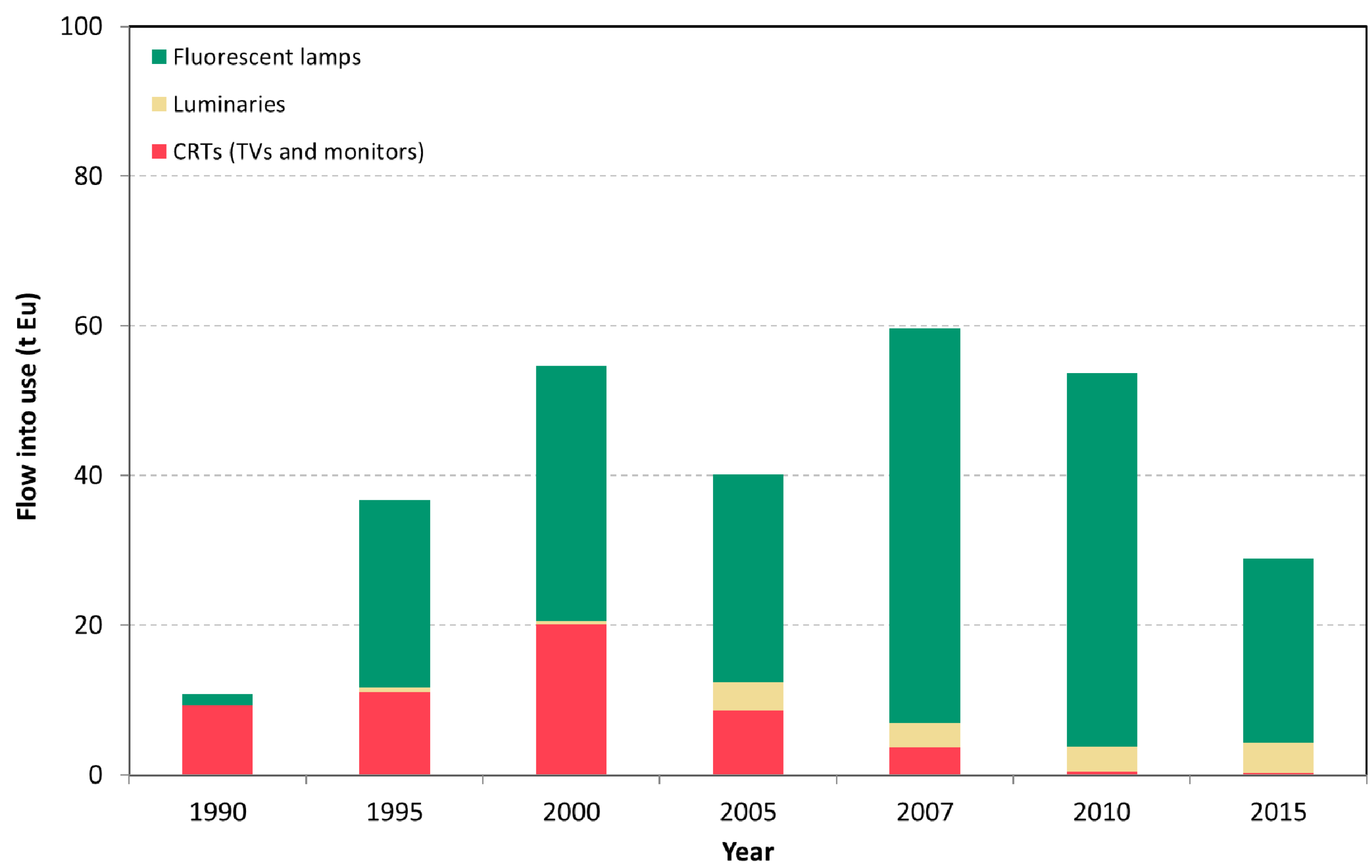

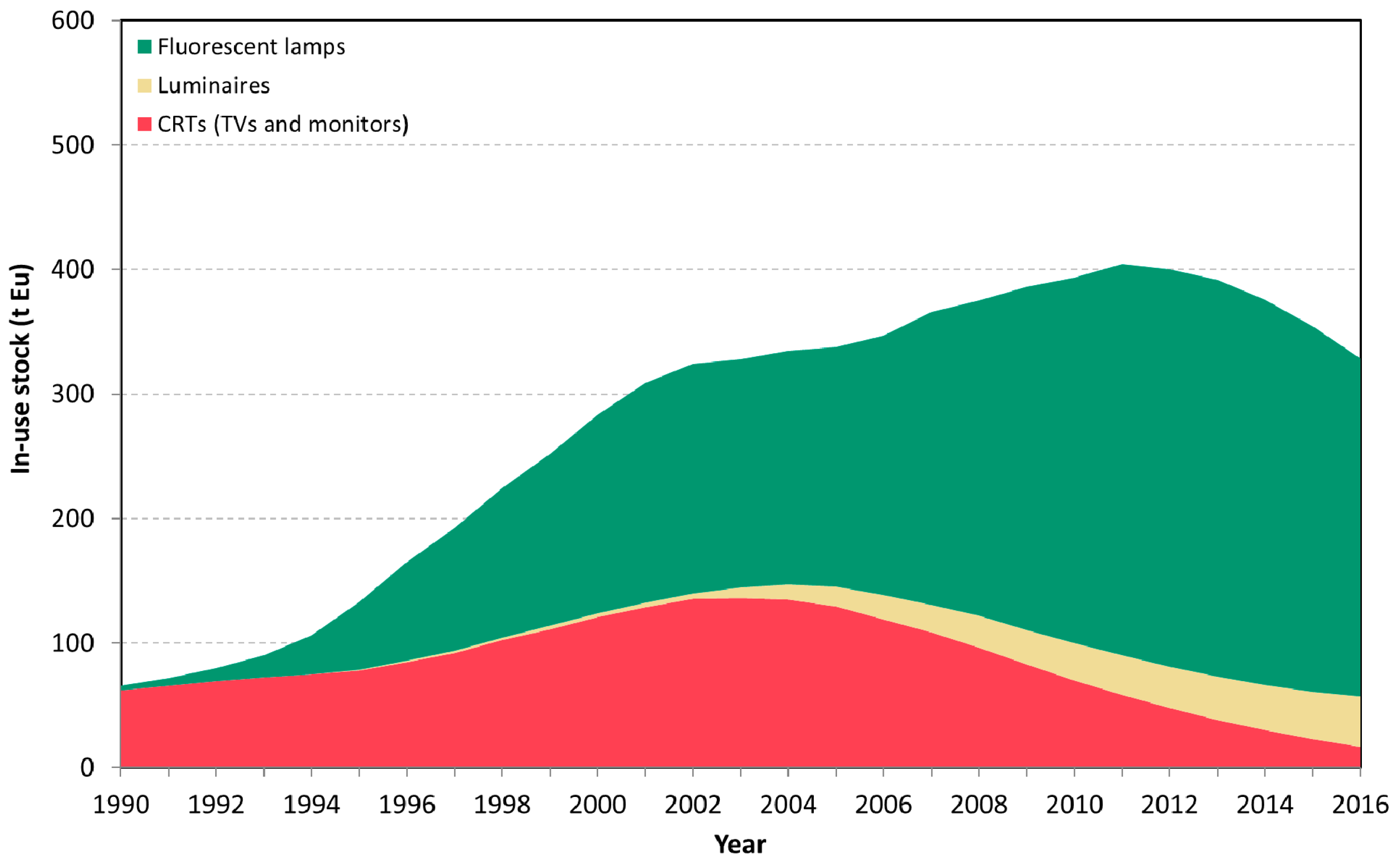

3.1. The Contemporary Europium Cycle in the EU–28

3.2. Potentials for End-of-Life Recovery and for Closing the Europium Cycle in the EU–28

3.3. Europium as a Marker of Product Turnover and Progress in Lighting Efficiency

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. Lighting the Future—Accelerating the Deployment of Innovative Lighting Technologies; Green Paper com(2011) 889 Final; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Sangwan, K.S.; Bhakar, V.; Naik, S.; Andrat, S.N. Life cycle assessment of incandescent, fluorescent, compact fluorescent and light emitting diode lamps in an indian scenario. Procedia CIRP 2014, 15, 467–472. [Google Scholar] [CrossRef]

- Lighting Europe. 2017 Annual Report. Available online: www.lightingeurope.org (accessed on 17 September 2018).

- European Commission. Background for the European Led Quality Charter. Available online: https://e3p.jrc.ec.europa.eu/sites/default/files/files/documents/Lighting/eu_led_qc_background_report_10_feb_2011_final.pdf (accessed on 17 September 2018).

- Bertoldi, P. Proceedings of the 9th International Conference on Energy Efficiency in Domestic Appliances and Lighting (EEDAL ‘17): Part I, EUR 28961 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-77172-9. [Google Scholar] [CrossRef]

- Jackson, M. Research Report: Led Lighting; WCP—Woodside Capital Partners International: East Palo Alto, CA, USA; London, UK, 2012; Available online: http://www.woodsidecap.com/wp-content/uploads/2012/02/WCP-LED-Lighting-Report-20123 (accessed on 17 September 2018).

- European Union. Indoor Lighting—Technical Background Report. Green Public Procurement, Report for the European Commission—DG Environment by BRE; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- International Energy Agency. Energy Efficiency 2017; OECD; IEA: Paris, France, 2017. [Google Scholar]

- Wu, Y.; Yin, X.; Zhang, Q.; Wang, W.; Mu, X. The recycling of rare earths from waste tricolor phosphors in fluorescent lamps: A review of processes and technologies. Resour. Conserv. Recycl. 2014, 88, 21–31. [Google Scholar] [CrossRef]

- Machacek, E.; Richter, J.L.; Habib, K.; Klossek, P. Recycling of rare earths from fluorescent lamps: Value analysis of closing-the-loop under demand and supply uncertainties. Resour. Conserv. Recycl. 2015, 104, 76–93. [Google Scholar] [CrossRef]

- Buchert, M.; Manhart, A.; Bleher, D.; Pingel, D. Recycling Critical Raw Materials from Waste Electronic Equipment; Commissioned by the North Rhine-Westphalia State Agency for Nature, Environment and Consumer Protection; Oeko-Institut e.V.: Darmstadt, Germany, 2012. [Google Scholar]

- Bergesen, J.D.; Tähkämö, L.; Gibon, T.; Suh, S. Potential long-term global environmental implications of efficient ligh-source technologies. J. Ind. Ecol. 2015, 20, 263–275. [Google Scholar] [CrossRef]

- European Commission. Study on the Review of the List of Critical Raw Materials. Criticality Assessments—Final Report. Available online: http://www.Europa.Eu (accessed on 17 September 2018).

- Resende, L.V.; Morais, C.A. Process development for the recovery of europium and yttrium from computer monitor screens. Miner. Eng. 2015, 70, 217–221. [Google Scholar] [CrossRef]

- Weeks, M.E. The discovery of the elements. XVI. The rare earth elements. J. Chem. Educ. 1932, 9, 1751–1773. [Google Scholar] [CrossRef]

- Deloitte, B. Study on Data for a Raw Material System Analysis: Roadmap and Test of the Fully Operational MSA for Raw Materials; Prepared for the European Commission; DG Grow: Bruxelles, Belgium, 2015. [Google Scholar]

- Nassar, N.T.; Du, X.; Graedel, T.E. Criticality of the rare earth elements. J. Ind. Ecol. 2015, 19, 1044–1054. [Google Scholar] [CrossRef]

- Gunn, G. British Geological Survey. Critical Metals Handbook; Wiley & Sons: Keyworth, Nottingham, UK, 2014. [Google Scholar]

- Binnemans, K.; Jones, P.T.; Van Acker, K.; Blanpain, B.; Mishra, B.; Apelian, D. Rare-earth economics: The balance problem. JOM 2013, 65, 846–848. [Google Scholar] [CrossRef]

- Machacek, E.; Kalvig, P. Assessing advanced rare earth element-bearing deposits for industrial demand in the eu. Resour. Policy 2016, 49, 186–203. [Google Scholar] [CrossRef]

- Goodenough, K.M.; Schilling, J.; Jonsson, E.; Kalvig, P.; Charles, N.; Tuduri, J.; Deady, E.A.; Sadeghi, M.; Schiellerup, H.; Müller, A.; et al. Europe’s rare earth element resource potential: An overview of REE metallogenetic provinces and their geodynamic setting. Ore Geol. Rev. 2016, 72, 838–856. [Google Scholar] [CrossRef]

- Müller, F.; Kosmol, J.; Keßler, H.; Angrick, M.; Rechenberg, B. Dematerialization—A disputable strategy for resource conservation put under scrutiny. Resources 2017, 6, 68. [Google Scholar] [CrossRef]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Nuss, P.; Reck, B.K. Criticality of metals and metalloids. Proc. Natl. Acad. Sci. USA 2015, 112, 4257–4262. [Google Scholar] [CrossRef] [PubMed]

- Clift, R.; Druckman, A. Taking Stock of Industrial Ecology; Springer International Publishing: Cham, Switzerland; Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2016; Available online: https://link.springer.com/content/pdf/10.1007/978-3-319-20571-7.pdf (accessed on 17 September 2018).

- Kim, J.; Guillaume, B.; Chung, J.; Hwang, Y. Critical and precious materials consumption and requirement in wind energy system in the EU 27. Appl. Energy 2015, 139, 327–334. [Google Scholar] [CrossRef]

- Pauliuk, S.; Müller, D.B. The role of in-use stocks in the social metabolism and in climate change mitigation. Glob. Environ. Chang. 2014, 24, 132–142. [Google Scholar] [CrossRef]

- Chen, W.-Q.; Graedel, T. Anthropogenic cycles of the elements: A critical review. Environ. Sci. Technol. 2012, 46, 8574–8586. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Graedel, T.E. Uncovering the global life cycles of the rare earth elements. Sci. Rep. 2011, 1, 145. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Graedel, T.E. Global in-use stocks of the rare earth elements: A first estimate. Environ. Sci. Technol. 2011, 45, 4096–4101. [Google Scholar] [CrossRef] [PubMed]

- Guyonnet, D.; Planchon, M.; Rollat, A.; Escalon, V.; Tuduri, J.; Charles, N.; Vaxelaire, S.; Dubois, D.; Fargier, H. Material flow analysis applied to rare earth elements in Europe. J. Clean. Prod. 2015, 107, 215–228. [Google Scholar] [CrossRef]

- Rollat, A.; Guyonnet, D.; Planchon, M.; Tuduri, J. Prospective analysis of the flows of certain rare earths in europe at the 2020 horizon. Waste Manag. 2016, 49, 427–436. [Google Scholar] [CrossRef] [PubMed]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Ciacci, L.; Vassura, I.; Passarini, F. Urban mines of copper: Size and potential for recycling in the EU. Resources 2017, 6, 6. [Google Scholar] [CrossRef]

- Ciacci, L.; Werner, T.T.; Vassura, I.; Passarini, F. Backlighting the European indium recycling potentials. J. Ind. Ecol. 2018. [Google Scholar] [CrossRef]

- Roskill Information Service. Rare Earths: Global Industry, Markets and Outlook, 16th ed.; Roskill Information Service: London, UK, 2016. [Google Scholar]

- Eurostat. Easy Comext. Available online: http://epp.eurostat.ec.europa.eu/newxtweb/ (accessed on 17 September 2018).

- Eurostat. Prodcom—Statistics by Product. Available online: http://ec.Europa.Eu/eurostat/web/prodcom (accessed on 17 September 2018).

- Klochkov, E.P.; Risovanyi, V.D.; Vaneev, Y.E.; Dorofeev, A.N. Radiation characteristics of europium-containing control rods in a SM-2 reactor after long-term operation. At. Energy 2002, 93, 656–660. [Google Scholar] [CrossRef]

- Poelman, D.; Smet, P.F. Europium-Doped Phosphors for Lighting: The Past, the Present and the Future; Department of Solid State Sciences, Ghent University: Belgium, Belgium, 2011. [Google Scholar]

- Deubzer, O.; Jordan, R. Cycled—Cycling Resources Embedded in Systems Containing Light Emitting Diodes; Deliverable 2.1: Categorization of Led Products; Fraunhofer IZM: Weßling, Germany, 2012. [Google Scholar]

- Chen, W.-Q.; Graedel, T.E. In-use product stocks link manufactured capital to natural capital. Proc. Nat. Acad. Sci. USA 2015, 112, 6265–6270. [Google Scholar] [CrossRef] [PubMed]

- Ciacci, L.; Reck, B.K.; Nassar, N.T.; Graedel, T.E. Lost by design. Environ. Sci. Technol. 2015, 49, 9443–9451. [Google Scholar] [CrossRef] [PubMed]

- Classen, M.; Althaus, H.J.; Blaser, S.; Tuchschmid, M.; Jungbluth, N.; Doka, G.; Faist Emmenegger, M.; Scharnhorst, W. Life Cycle Inventories of Metals; Final Report Ecoinvent Data 2.1, No 10; EMPA Dübendorf, Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2009. [Google Scholar]

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework, 1st ed.; Reference Number ISO 14040:2006 (e); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Ardente, F.; Cellura, M. Economic allocation in life cycle assessment. J. Ind. Ecol. 2012, 16, 387–398. [Google Scholar] [CrossRef]

- Tunsu, C.; Ekberg, C.; Retegan, T. Characterization and leaching of real fluorescent lamp waste for the recovery of rare earth metals and mercury. Hydrometallurgy 2014, 144–145, 91–98. [Google Scholar] [CrossRef]

- Hu, A.H.; Kuo, C.-H.; Huang, L.H.; Su, C.-C. Carbon footprint assessment of recycling technologies for rare earth elements: A case study of recycling yttrium and europium from phosphor. Waste Manag. 2017, 60, 765–774. [Google Scholar] [CrossRef] [PubMed]

- Solvay S.A. Layman’s Report EC Life + Programme—Solvay “Loop” Project LIFE11/ENV/FR/00744. An Innovative Process of Rare Earth Recycling from Used Fluorescent Lamps; Solvay S.A.: Bruxelles, Belgium, 2014. [Google Scholar]

- Rollat, A.; (Solvay-rhodia). Personal communication, 2018.

- Smith, S.J.; Wei, M.; Sohn, M.D. A retrospective analysis of compact fluorescent lamp experience curves and their correlations to deployment programs. Energy Policy 2016, 98, 505–512. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on Closing the Loop—An EU Action Plan for the Circular Economy; 2.12.2015, com (2015) 614 Final; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Wang, F.; Huisman, J.; Stevels, A.; Baldé, C.P. Enhancing e-waste estimates: Improving data quality by multivariate input–output analysis. Waste Manag. 2013, 33, 2397–2407. [Google Scholar] [CrossRef] [PubMed]

- Principi, P.; Fioretti, R. A comparative life cycle assessment of luminaires for general lighting for the office—Compact fluorescent (CFL) vs light emitting diode (LED)—A case study. J. Clean. Prod. 2014, 83, 96–107. [Google Scholar] [CrossRef]

- Müller, D.B.; Wang, T.; Duval, B.; Graedel, T.E. Exploring the engine of anthropogenic iron cycles. Proc. Natl. Acad. Sci. USA 2006, 103, 16111–16116. [Google Scholar] [CrossRef] [PubMed]

- Daigo, I.; Iwata, K.; Ohkata, I.; Goto, Y. Macroscopic Evidence for the Hibernating Behavior of Materials Stock. Environ. Sci. Technol. 2015, 49, 8691–8696. [Google Scholar] [CrossRef] [PubMed]

- Sekine, N.; Daigo, I.; Goto, Y. Dynamic Substance Flow Analysis of Neodymium and Dysprosium Associated with Neodymium Magnets in Japan. J. Ind. Ecol. 2016, 21, 356–367. [Google Scholar] [CrossRef]

- Ecolamp. Available online: http://www.ecolamp.It (accessed on 17 September 2018).

- Schaeffer, N.; Feng, X.; Grimes, S.; Cheeseman, C. Recovery of an yttrium europium oxide phosphor from waste fluorescent tubes using a brønsted acidic ionic liquid, 1-methylimidazolium hydrogen sulfate. J. Chem. Technol. Biotechnol. 2017, 92, 2731–2738. [Google Scholar] [CrossRef]

- Belardi, G.; Ippolito, N.; Piga, L.; Serracino, M. Investigation on the status of rare earth elements contained in the powder of spent fluorescent lamps. Thermochim. Acta 2014, 591, 22–30. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T. Perspectives for the recovery of rare earths from end-of-life fluorescent lamps. J. Rare Earths 2014, 32, 195–200. [Google Scholar] [CrossRef]

- European Union. Eurostat. Available online: http://ec.Europa.Eu/eurostat (accessed on 17 September 2018).

- Ciacci, L.; Nuss, P.; Reck, B.; Werner, T.; Graedel, T. Metal criticality determination for australia, the us, and the planet—Comparing 2008 and 2012 results. Resources 2016, 5, 29. [Google Scholar] [CrossRef]

- Ciacci, L.; Harper, E.M.; Nassar, N.T.; Reck, B.K.; Graedel, T.E. Metal dissipation and inefficient recycling intensify climate forcing. Environ. Sci. Technol. 2016, 50, 11394–11402. [Google Scholar] [CrossRef] [PubMed]

- United Nations Environment Programme. Metal Recycling: Opportunities, Limits, Infrastructure. A Report of the Working Group on the Global Metal Flows to the International Resource Panel; Reuter, M.A., Hudson, C., van Schaik, A., Heiskanen, K., Meskers, C., Hagelüken, C., Eds.; United Nations Environment Programme: Paris, France, 2013. [Google Scholar]

- Ueberschaar, M.; Geiping, J.; Zamzow, M.; Flamme, S.; Rotter, V.S. Assessment of element-specific recycling efficiency in weee pre-processing. Resour. Conserv. Recycl. 2017, 124, 25–41. [Google Scholar] [CrossRef]

- Ku, A.Y.; Setlur, A.A.; Loudis, J. Impact of ligh emitting diode adoption on rare earth element use in lighting—Implications for yttrium, europium, and terbium demand. Electrochem. Soc. Interf. 2015, 24, 45–49. [Google Scholar] [CrossRef]

- McKinsey & Company. Lighting the Way: Perspectives on the Global Lighting Market, 2nd ed. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/automotive%20and%20assembly/lighting_the_way_perspectives_on_global_lighting_market_2012.ashx (accessed on 17 September 2018).

- Liu, G.; Bangs, C.E.; Muller, D.B. Stock dynamics and emission pathways of the global aluminium cycle. Nat. Clim. Chang. 2013, 3, 338–342. [Google Scholar] [CrossRef]

- Odyssee-MURE. Odyssee Database. Available online: http://www.Indicators.Odyssee-mure.Eu/energy-efficiency-database.Html (accessed on 17 September 2018).

- Petrides, D.; Papacharalampopoulos, A.; Stavropoulos, P.; Chryssolouris, G. Dematerialisation of products and manufacturing-generated knowledge content: Relationship through paradigms. Int. J. Prod. Res. 2018, 56, 86–96. [Google Scholar] [CrossRef]

- Tähkämö, L.; Bazzana, M.; Ravel, P.; Grannec, F.; Martinsons, C.; Zissis, G. Life cycle assessment of light-emitting diode downlight luminaire—A case study. Int. J. Life Cycl. Assess. 2013, 18, 1009–1018. [Google Scholar] [CrossRef]

- Chitnis, M.; Sorrell, S.; Druckman, A.; Firth, S.K.; Jackson, T. Turning lights into flights: Estimating direct and indirect rebound effects for UK households. Energy Policy 2013, 55, 234–250. [Google Scholar] [CrossRef]

- Zhong, M.; Hedges, M.P.; Ahlefeldt, R.L.; Bartholomew, J.G.; Beavan, S.E.; Wittig, S.M.; Longdell, J.J.; Sellars, M.J. Optically addressable nuclear spins in a solid with a six-hour coherence time. Nature 2015, 517, 177–180. [Google Scholar] [CrossRef] [PubMed]

- Bünzli, J.G. Rising stars in science and technology: Luminescent lanthanide materials. Eur. J. Inorg. Chem. 2017, 5058–5063. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciacci, L.; Vassura, I.; Passarini, F. Shedding Light on the Anthropogenic Europium Cycle in the EU–28. Marking Product Turnover and Energy Progress in the Lighting Sector. Resources 2018, 7, 59. https://doi.org/10.3390/resources7030059

Ciacci L, Vassura I, Passarini F. Shedding Light on the Anthropogenic Europium Cycle in the EU–28. Marking Product Turnover and Energy Progress in the Lighting Sector. Resources. 2018; 7(3):59. https://doi.org/10.3390/resources7030059

Chicago/Turabian StyleCiacci, Luca, Ivano Vassura, and Fabrizio Passarini. 2018. "Shedding Light on the Anthropogenic Europium Cycle in the EU–28. Marking Product Turnover and Energy Progress in the Lighting Sector" Resources 7, no. 3: 59. https://doi.org/10.3390/resources7030059

APA StyleCiacci, L., Vassura, I., & Passarini, F. (2018). Shedding Light on the Anthropogenic Europium Cycle in the EU–28. Marking Product Turnover and Energy Progress in the Lighting Sector. Resources, 7(3), 59. https://doi.org/10.3390/resources7030059