Abstract

Electrical and electronic products have become an integral part of the current economy and, with the development of newer technologies, the life span of these products are getting shorter. As a consequence, the volume of electronic waste is increasing drastically around the globe. With the implementation of new rules, regulations, and policies by the government, the landfilling of electronic waste has been reduced. The presence of valuable metals in the e-waste stream provides a major economic benefit for recycling industries but, due to the presence of hazardous materials, a proper recycling technique is required prior to the disposal of the e-waste. The total e-waste generated in Canada was 725 kt in 2014. There are several organizations currently working in various provinces to deal with the collection and recycling of e-waste. These organizations collected nearly 20% of the total e-waste generated in 2014. The collection rate for e-waste can be boosted by increasing awareness and by creating more centers to collect all kinds of e-waste. The collected e-waste is processed at local processing facilities mostly dealing with dismantling and hazardous material removal processes and then shipping the remaining material to a central location for subsequent processing.

1. Introduction

Electrical and electronic equipment has become an integral part of the global economy. With technological advancements, industries have moved towards automation, which has increased the use of electrical and electronic equipment. At the same time, with the development of new technologies and equipment, the life span of electronics products is getting shorter and shorter, which in turn forces outdated technologies to be disposed of in the waste stream.

The total electronic waste (e-waste) generated worldwide was estimated at approximately 41.8 million tons in 2014 (5.9 kg/inhabitant), with the majority being generated by developed economies. The total amount of e-waste is expected to reach 50 million tons by 2018. The total e-waste generated by Canada was 725 kt in 2014. The e-waste generated per inhabitant was 20.4 kg [1].

It was suggested that there are up to 60 different metals present in the electronic waste including copper, silver, gold, and other precious metals, which provides an economic incentive to recycling organizations [2]. Additionally, e-waste also contains hazardous substances such as mercury, cadmium, chromium, lead, and polychlorinated biphenyl that pose environmental and public health issues if disposed of without proper treatment. The recycling organizations mostly use dismantling and physical separation followed by hydro or pyro-metallurgical routes to extract valuable materials from the electronic waste.

This paper presents an overview of the statistics of e-waste being generated and recycled from a Canadian perspective. The Canadian regulations, policies, and laws currently in place are summarized in the paper. The current recycling routes and challenges are also discussed. An alternative strategy to increase e-waste collection and recycling is also suggested in this paper.

2. Objectives and Methodology

The major objective of this paper is to analyze the e-waste management system in Canada, collect data regarding e-waste collection, and discuss recycling practices in Canada. The secondary objectives and adopted approaches are listed below.

- Defining e-waste, discussing the benefits of recycling and issues associated with the process in brief from various sources.

- Collecting data on sales of electrical and electronics equipment, mostly from Stat Canada.

- Discussing consumer behavior regarding e-waste disposal in different provinces.

- Exploring the e-waste management system in Canada; identifying related organizations, programs, and their overall performance by calculating the total collection rate.

- Discussing the e-waste recycling practice adopted by two organizations in Canada, one involved with reuse, refurbishing, and recycling and the other dealing with manual dismantling and recycling, in order to study the current e-waste processing route in Canada.

3. Definition and Categories

Solving the E-waste Problem (StEP) is an international initiative that works on developing solutions for the e-waste issue around the globe. According to StEP, “E-waste is a term used to cover items of all types of electrical and electronic equipment (EEE) and its part that have been discarded by the owner as waste without intention of re-use” [3].

Environment Canada has a similar approach and has defined e-waste as Electrical and Electronic Equipment (EEE), destined for disposal, recycling or reuse, is commonly referred to as “e-waste”, “e-scrap” or “waste electrical and electronic equipment (WEEE)” [4]. The e-waste stream is divided into six distinct categories [1]:

- Temperature exchange equipment: refrigerators, freezers, air conditioners, heat pumps

- Screens & monitors: televisions, monitors, laptops, notebooks, tablets

- Lamps: fluorescent lamps, LED lamps, high-intensity discharge lamps

- Large equipment: washing machines, clothes dryers, electric stoves, large printing machines, copying machines, photovoltaic panels

- Small equipment: vacuum cleaners, toasters, microwaves, ventilation equipment, scales, calculators, radio, electric shavers, kettles, camera, toys, electronic tools, medical devices, small monitoring and control equipment

- Small IT and telecommunication equipment: mobile phones, GPS, pocket calculators, routers, personal computers, printers, telephones.

4. Opportunities for E-Waste

E-waste contains different materials, including valuable and hazardous materials. Recovery of these metals provides an opportunity for urban mining and also safe disposal of hazardous materials for environmental and public safety. Balde et al. [1] estimated the total value of valuable materials present in e-waste is approximately USD 53.4 billion, as shown in Table 1. The e-waste stream is growing at a rate of 3%–5% every year [5].

Table 1.

Value of materials present in e-waste stream.

The highest amounts of critical materials and precious materials are embedded into notebooks, tablets, and smartphones. It is suggested that the printed circuit boards from these e-waste streams account for 3%–6% of the e-waste mass, which contains more than 20 different types of metals including gold, silver, platinum, copper, and aluminum with a potential revenue of USD 23,568/ton [5,6].

The growing amount of e-waste has created two major problems: a shortage of mineral resources for sustaining the electronic industry, and potential environmental pollution and human health risks [7]. The electronic sectors consumed 44% of mined copper, 50% of tin, 30% of silver, 9% of gold, and 14% of platinum group metals in 2014 [6].

Recycling of e-waste and recovery of different metals from e-waste can also reduce the burden on the mining industry by reducing the total global demand for new metal production, which in turns helps reduce greenhouse gas emissions [8]. Studies have shown that globally the ore grade is declining and mines are forced to excavate more complex and fine grained ore deposits to meet the global metal demand [9]. Additionally, recovery of materials also provides an energy savings when compared to the manufacturing of virgin materials. The energy savings from materials commonly present in e-waste is shown in Table 2. It is suggested that the recycling of desktops and laptops saves 80% and 87% of natural resources, respectively [10].

Table 2.

Recycled material energy savings over virgin materials [11].

On the other side, the toxic materials present in e-waste are a threat to the environment and have to be treated prior to its disposal. A list of the hazardous materials present in e-waste is listed below [12]:

- Metals: antimony, cadmium, chromium, lead, mercury

- Components: batteries

- Chemicals: poly-/brominated flame retardants in plastics, phosphors, polychlorinated biphenyl (old capacitors), polybrominated biphenyl ether, hexavalent chromium, ozone-depleting substances.

A typical recovery method in the informal recycling sector for recovering copper from cables is to burn polyvinyl chloride in open air; acid/caustic leaching is also performed on printed circuit boards to obtain precious metals [13]. These methods and the disposal of these chemicals/metals in landfills or by incineration produce harmful effects on the environment and humans and other living things can be exposed to these chemicals through water, air, soil, dust, or food [8]. The amount of cadmium present in a cell phone battery has the potential to contaminate 600 m3 of water [14]. At the same time, these hazardous materials can impair mental development, damage the kidneys and liver, and release carcinogens into the air, causing lung damage in humans.

5. Statistics

5.1. Total E-Waste Generation

The total e-waste produced around the world was 41.8 million tons in 2014. The total e-waste produced in the Americas (North, Central, and South) was estimated at 11.7 million tons (7.9 Mt in North America, 1.1 Mt in Central America, and 2.7 Mt in South America).

The total amount of e-waste produced in Canada was 725 kt in 2014, accounting for almost 6.2% of the total e-waste produced in Americas and 1.7% of the total e-waste produced in the world. The e-waste generated per inhabitant was 20.4 kg. Using the ratio of amount of waste in each category to the total e-waste generated in the Americas and assuming the same ratio for Canada, the total waste in each category was estimated as shown in Table 3. From Table 3, it is clear that small and large equipment, temperature exchange equipment, and screens/monitors are the major contributors to the electronic waste stream.

Table 3.

E-waste in different categories in Canada.

Table 4 shows the e-waste generation statistics of developed countries such as the United States, Germany, France, United Kingdom, Japan, Switzerland, Belgium, Finland, and Australia and developing countries such as China, India, Brazil, and Mexico. The table suggests that the total e-waste generated in Canada in 2014 was lower than that of the United States, Germany, or the United Kingdom. A reason might be the lower population. The e-waste generation for Canada is similar to developed countries with similar populations. On the other hand, the e-waste generated per capita is very similar to other developed countries, which might be due to higher purchasing power (GDP per capita).

Table 4.

E-waste generation in other countries [1].

5.2. Sales of Electrical and Electronic Products in Canada

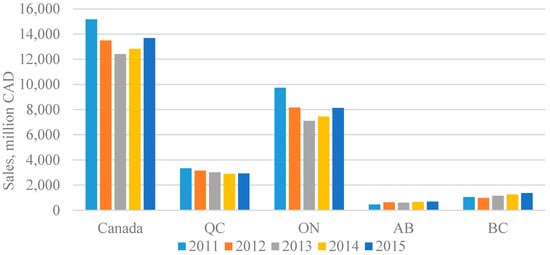

Statistics Canada [15] has tabulated the sales data for various manufacturing industries. The sales statistics of computer and electronic products and electrical equipment, appliances and components are shown in Figure 1 and Figure 2 for Quebec City (QB), Ontario (ON), British Columbia (BC), and Alberta (AB).

Figure 1.

Sales of computer and electronic products.

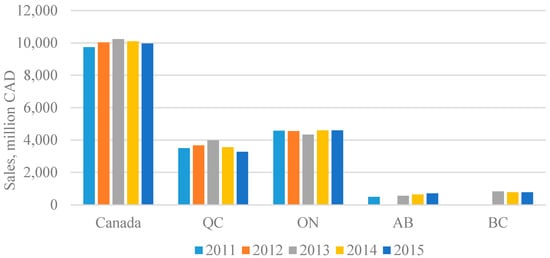

Figure 2.

Sales of electrical equipment, appliances, and components.

The sales data for some of the Canadian provinces (Nova Scotia (NS), Newfoundland & Labrador (NL), Prince Edward Island (PE), New Brunswick (NB), Manitoba (MB), Saskatchewan (SK), Yukon (YT), Northwest Territories (NT), and Nunavut (NU)) are not completely available, while data for British Columbia (BC) and Alberta (AB) are not available for some of the years. Figure 1 and Figure 2 show a slight decrease in total sales in 2015 compared to 2011, which might be due to the reduced prices of electrical and electronics equipment. With the decreasing unit prices of electrical and electronics products, the total sales value might decrease even with an increase in the total number of units sold.

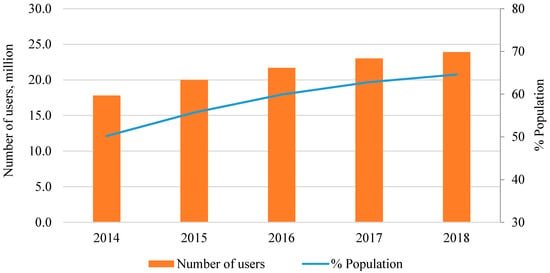

In terms of using smartphones, eMarketer [16] showed that more than half the population of Canada is currently using smartphones and that number is expected to grow to approximately 65% by 2018. Figure 3 shows the anticipated increase in the number of smartphone users by 2018 in Canada.

Figure 3.

Smartphone users in Canada.

Figure 1, Figure 2 and Figure 3 show the electrical and electronic products that are repeatedly purchased by residents, thus increasing the total amount of equipment being used every year. At the end of their lifetime, these products will contribute to the total amount of e-waste.

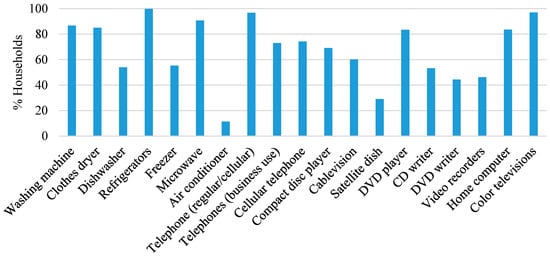

The average penetration of electrical and electronic products in the Canadian household is shown in Figure 4 [17]. The figure showed that almost all households in Canada rely heavily on electrical and electronic equipment. In the 13,320,610 households in Canada surveyed in 2011 [18], approximately 172 million items of household equipment were in use by 2012.

Figure 4.

Penetration of household electrical and electronic equipment in Canada in 2012.

Researchers have shown that the average estimated life of electrical and electronic products is approximately seven years, with a lower limit at 2–3 years for cellphones and computers and an upper limit at 10–12 years for dishwashers, freezers, and refrigerators [19]. Figure 1, Figure 2, Figure 3 and Figure 4 combined with the average estimated life suggest that by 2018–2019 most of the equipment currently being purchased or in use will enter the waste stream.

6. Disposal of E-Waste

General Practices

This section looks into the current practices adopted by Canadian households for disposal of e-waste in different provinces. The general trend for e-waste disposal is to put it in the garbage, return it to the supplier, drop it off at a depot, or donate it.

Figure 5 shows the percentage of households who had some e-waste to dispose of in 2011 [20]. It can be seen that nearly half of the households in Canada had some kind of electronic waste for disposal.

Figure 5.

Percentage of households with e-waste to dispose of.

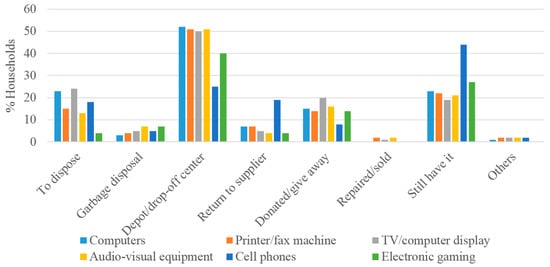

Figure 6 shows the general trends in disposal practices followed by Canadian households for various e-waste items [20]. It shows that the households are more likely to send the waste to a drop-off center or depot, which is then either sent to landfill or recycling. The figure also shows that there are approximately 20%–25% households that still have the e-waste. This might be due to lack of awareness regarding disposal methods or unavailability of a drop-off center.

Figure 6.

Disposal practices by household.

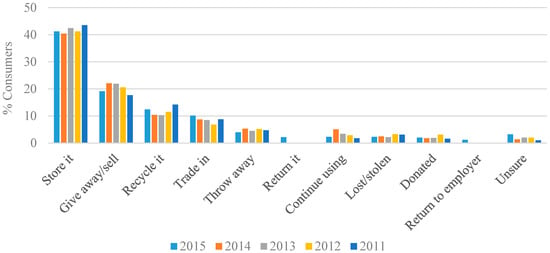

Figure 7 represents the consumer behavior regarding cellphones, based on survey data from the Canadian Wireless Telecommunication Association [21]. It shows that consumer behavior has not changed much in the last five years.

Figure 7.

Consumers’ cellphone disposal practices.

Figure 5, Figure 6 and Figure 7 suggest that nearly half of Canadian households currently have e-waste to dispose of and most of it is dropped off at a depot or to the supplier. However, a large percentage also remains with the household and these practices have not changed much in the last five years.

7. E-Waste Management in Canada

7.1. Rules and Regulations

Electronic waste management in Canada is regulated by the Ministry of the Environment. A set of principles for electronics product stewardship were sanctioned by the Canadian Council of Ministers of the Environment (CCME) to regulate e-waste management within Canada. A non-profit, industry-led organization, Electronics Product Stewardship Canada (EPSC), was established in 2003 to design, promote, and implement sustainable solutions for the recycling of electronic waste [22]. Environment Canada regulates policy regarding the handling and disposal of toxic waste, import and export of hazardous waste, and hazardous recyclable material. Environment Canada is also responsible for the development of technical documents about municipal solid waste management and waste incineration.

At the provincial level, extended producer responsibility (EPR) targets electronic products. These programs are developed by industry and funded by consumers through an eco-fee applied during the purchase. The extended producer responsibility is adopted from the European Union and uses an industry-managed and -financed approach to provide flexibility to brand owners. There is no federal entity to implement a federal approach for the EPR but the Canadian Environmental Protection Act provided regulations for organizations to address products containing toxic chemicals [23].

In order to obtain the recycling license, a business has to be audited and approved by the national Recycler Qualification Program (RQP). The RQP defines the minimum requirements for end-of-life electronics processors and recyclers to operate under a provincial electronics recycling stewardship program and to manage the e-waste in an environmentally safe manner.

The Electronics Reuse and Refurbishing Program (ERRP) is a certification designed for businesses related to the reuse and refurbishing of electronics products, thus extending their life in an environmentally friendly, safe, and secure manner.

7.2. E-Waste Collection Organizations

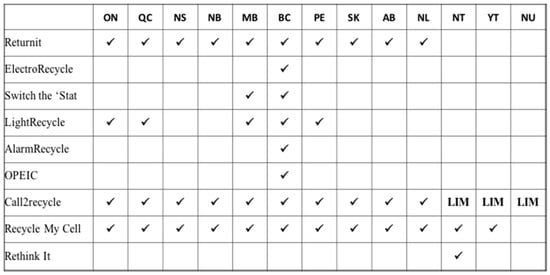

There are several national and provincial organizations dealing with the collection and recycling of electronic waste in Canada. A list of the major organizations, program names, and their province of operation is shown in Table 5 and Figure 8. All the organizations and programs are discussed in detail in Appendix A.

Table 5.

Major e-waste collecting organizations in Canada.

Figure 8.

Province of operation for the collecting programs. LIM: limited availability.

As can be seen from Table 5 and Figure 8, there are several e-waste collection programs available in various provinces concentrating on specific commodities that are then sent to different recyclers for further processing. All these organizations have drop-off locations around the country. This system provides the benefit of pre-sorting waste products into distinct categories prior to any processing and thus reducing cross-contamination.

7.3. E-Waste Collection Summary

The combined weight of all the e-waste collected by all the abovementioned programs in 2014 is shown in Table 6. The total amount of e-waste generated in Canada in 2014 was 725 kt. The total e-waste collected by these organizations and programs is approximately 148 kt, which represents nearly 20% of the total e-waste generated in 2014. There are some other small e-waste collection programs available in some provinces, but due to unavailability of any reliable data source those numbers were not used for the calculation.

Table 6.

Total e-waste collected by various program in 2014.

This data suggest that more than half the e-waste generated in Canada does not get collected and is either lost as municipal waste or stays in household storage. One of the reasons might be the complicated collection system. A one-point collection system where all types of e-waste can be dropped off at the same location would be preferred. This would also increase the total number of drop-off locations, thus increasing accessibility.

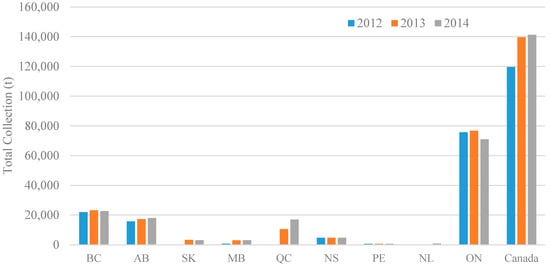

Figure 9 shows the e-waste collection rate from EPRA from 2012 to 2014. It shows that the overall collection rate in Canada is on the rise. The reason might be an increase in drop-off locations and increased awareness. The total collection by all the organizations cannot be calculated as most of these programs were started recently and hence data from early years are not available. The collection rate of other recycling programs has also increased in recent years, as seen in Appendix A.

Figure 9.

Total e-waste collection by EPRA.

8. E-Waste Landfilling

Landfilling is one of the most commonly used practices around the globe for e-waste disposal. The process involves excavating soil and burying the waste, usually covered with a liner of plastic or clay. The major drawback of this process is leaching of toxic materials into the soil, soil contamination, and seepage into groundwater. According to Shift Recycling [24], approximately 140,000 tons of e-waste are disposed in Canadian landfills each year.

The municipal cost savings from recycling is almost four times more than landfilling. The estimated cost savings from landfilling and recycling in different provinces is shown in Table 7.

Table 7.

Municipal cost savings from recycling [25].

In Canada, Nova Scotia, Prince Edward Island, and Newfoundland are the only three provinces that have banned electronic waste disposal in landfills, whereas as a municipality Vancouver has banned e-waste landfill disposal [25]. Approximately 85% of residents in British Columbia and 79% of residents in Ontario fall into the jurisdiction where e-waste is banned from landfill. The average landfill tipping fee across Canada is CAD 20–100 per ton. The increased tipping fee and landfill bans intensify diversion, recycling, and reuse of end-of-life electronics.

9. Current Recycling Practice

The e-waste collected is either sent to landfill or for recycling. In the last few years, the recycling business has attracted major investment and support from the government. There are various recyclers in Canada dealing with the recycling of end-of-life electronics. The major players are [26]:

- eCycle Solutions: Alberta, British Columbia, Ontario, Quebec

- Global Electric Electronic Processing: Alberta, British Columbia, Ontario, Quebec

- FCM Recycling: British Columbia, Nova Scotia, Ontario, Quebec

- KC Recycling Ltd.: British Columbia

- Exner E-waste processing Inc.: Manitoba

- Resnet: New Brunswick

- ADL Process Inc.: Ontario

- Shift Recycling: Ontario

- CFER: Quebec

Most of the recyclers obtain the e-waste collected by the organizations mentioned in Section 6 of this paper. At the same time, e-waste can be dropped off directly at these locations. These recyclers have a smaller dismantling unit in most of the provinces. The major operation performed by these local centers is to remove the hazardous materials. Other activities such as removing the outer case (steel, aluminum, or plastics), removing the printed circuit boards, wire removal, battery dismantling, removal of ink/toner from printers, etc. are also performed at these local centers before the e-waste is sent to specific processing centers for further processing. The remaining material is then bailed and shipped to a central facility for further processing, where it is shredded and separated into various streams using a combination of magnets, gravity, and electrical separators and sorters. Most of the central processing facilities in Canada are located in Quebec City.

The recycling practice adopted by a center specializing in refurbishing, reusing, and recycling located in British Columbia is discussed in Case I, whereas the recycling practice adopted by a manual dismantling company is laid out as Case II.

9.1. Case I: Reuse, Refurbish, and Recycling Practice in BC

Case I is a recycling center located in Vancouver, BC. This center specializes in the refurbishing, reusing, and recycling of desktops, laptops, LCD/LED monitors, printers, scanners, cellphones, fax machines, game consoles, CDs, DVDs, and computer accessories. The employees at this location are mostly volunteers who are engaged to gain experience and skills in computers and electronics. The e-waste dropped at this center is mostly from Encorp Pacific Canada, but individuals and businesses can drop off their end-of-life electronics directly at the center. A pick-up service for e-waste can be requested as well.

The waste received at this location is tested for its reusability. If the electronic product is still functional, it is sold at a lower cost for reuse. The components of the electronics are tested separately as well and the working components are either sold individually or sometimes used to refurbish a new model and then sold as a unit.

The electronics items that cannot be reused are sent for recycling. No machinery is used at this location. The electronics are manually dismantled and separated into various streams and then individual streams are shipped to various locations for subsequent processing. The dismantling process is used to remove metals (especially steel), plastics, printed circuit boards, and ink/toner before the e-waste is shipped to specific processers. A list of the subsequent processors is shown in Table 8. The rest of the bulk mixed waste is packed and shipped back to Encorp Pacific or Quebec City for further processing.

Table 8.

Customers for individual streams in Case I.

9.2. Case II: Manual Dismatling and Recycling Practice in BC

This center is located in Chilliwack, British Columbia and specializes in all kind of e-waste from computers and televisions to small home appliances. The main objective of this center is to remove hazardous materials from the waste stream and then ship the remaining material to the central location in Quebec for subsequent processing.

This processing center receives almost 50 tons of e-waste every day from Encorp Pacific, EPRA, and CESA. This location has 64 employees working one shift a day and five days a week. There are four separate processing lines at this location.

- Line 1

- deals with computers and laptops. Workers remove components such as wire, circuit boards, and outer casings, and put them in separate containers for shipping.

- Line 2

- works on removing hazardous materials from small home appliances. Major hazardous materials are batteries and mercury tubes.

- Line 3

- is the accessories line dealing with the processing of computer accessories such as keyboards, printers, scanners, mouse, hard drives, etc. The major hazardous material to be removed from this line is the ink and toner from the printer.

- Line 4

- is the display processing line dealing with dismantling of televisions and computer displays. The back panel of the CRT screen is leaded glass and is removed from the front panel, which is the high-quality glass. In the case of flat screens, the glycol assembly and mercury bulb are the major hazardous materials that are removed from the system.

After the dismantling and hazardous material removal, the remaining materials (mostly metal and plastic) are bailed and shipped to Quebec for final processing. On average, four truckloads of materials are shipped every day, costing CAD 800–2000 per shipment.

10. Major Challenges for Recycling E-Waste in Canada

As shown in Section 6, the total amount of e-waste collected is approximately 20% of the total e-waste generated in Canada. A significant portion of e-waste generated is lost to municipal waste, exported to developing countries, or ends up in landfill. The major challenges for e-waste recycling and possible remedies are listed in this section.

10.1. Regulations and Organizations

In Canada, the regulations for e-waste management are provided by the Ministry of Environment but, due to the lack of federal regulations and organizations working on the national level, e-waste management is not the same in all provinces. Some provinces like British Columbia have programs for every type of e-waste, whereas provinces like Alberta, Saskatchewan, and Yukon lack such programs. The kind of provincial programs operating in British Columbia, Manitoba, and Ontario should be adopted in other provinces as well.

Programs similar to Call2Recycle and Recycle My Cell that have the authority to work at the national level should be implemented by the Ministry of Environment and EPSC.

Currently, most of the mentioned programs are in the development stage in other provinces or are in the process of finalizing legal processes. EPRA is developing the e-waste collection program in New Brunswick and Yukon.

10.2. E-Waste Collection

The e-waste collection rate in Canada is significantly lower than the total amount of e-waste being produced every year. Even with the availability of various programs for e-waste collection, the total e-waste collected in 2014 was approximately 20%. One of the reasons might be the complexity of recycling programs. Not all the programs and drop-off depots/locations accept all kind of e-waste, which decreases the public awareness of and willingness to comply with proper e-waste disposal.

Merging different types of e-waste programs into a single entity will allow these programs to share drop-off locations and thus increase the overall availability of drop-off locations. Programs similar to ecoATM [27] that provide cash in exchange for electronics products will be able to increase public interest in proper disposal.

10.3. Processing Facilities

Most of the provinces in Canada have sorting and dismantling facilities, but a large volume of material is required to be transported for subsequent processing to other provinces, which is time-consuming and costly. Indeed, one of the significant barriers to recycling is the long-distance transportation of materials.

A province-based central recycling facility can reduce transportation costs and time. The local facilities can perform the dismantling and other smaller processes such as shredding and cost-effective separation, e.g. magnetic and gravity separation, to sort easy-to-separate streams. The final material can be shipped to a central provincial location that can handle the final stage of the sorting process. This will reduce the volume needed for transportation and also reduce the transportation distance, thus reducing the costs and greenhouse gas emissions associated with transportation. This “best of two worlds” approach for recycling (“to seek technical and logistic integration of best preprocessing in developing countries to manually dismantle e-waste and best end-processing to treat hazardous and complex fractions in international state-of-the-art end-processing facilities” [28,29]) can be an effective tool to improve recycling rates.

10.4. Recycling Methodology

One of the challenges with e-waste recycling is rapidly changing technology. Electronic technologies evolve quickly. The development of new, small, and complex technologies used in cellphones, tablets, and laptops will pose a challenge to the current recycling methodology that involves manual dismantling and manual sorting.

Designing and researching flexible and automated systems will be required to deal with next-generation e-waste that uses complex and nanoscale manufacturing processes and includes new polymers and materials. Systems like Liam, developed by Apple Inc. [30], is one complex disassembly system for recycling iPhones.

11. Conclusions

E-waste is a growing concern, not just in Canada but across the world. The e-waste recycling industry provides financial benefits and at the same time provides an environmentally friendly disposal route for e-waste.

The e-waste collection in Canada has increased in recent years; however, the overall e-waste collection rate is very low compared to the e-waste generation rate. One of the reasons for that low collection rate might be the lack of federal collection programs. Since the recycling programs operate at the provincial level, not all the provinces benefit from them. Merger of various recycling programs, the establishment of central recycling facilities in each province, and research and development on new recycling systems are options for improving the e-waste recycling rate in Canada.

Acknowledgments

The author would like to acknowledge the financial support provided by Maria Holuszko, University of British of Columbia.

Author Contributions

This paper has ben written and developed by Amit Kumar as his Ph.D. research. The supervision and revision work was performed by Maria Holuszko.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Electronic Product Recycling Association (EPRA)

The EPRA is an industry-led, non-profit organization that regulates the recycling programs across Canada to ensure safe, secure, and environmentally friendly handling of electronic waste. All the recyclers associated with EPRA are audited and approved under the national Recycler Qualification Program. Currently, EPRA operates in British Columbia, Manitoba, Saskatchewan, Ontario, Quebec, Nova Scotia, Prince Edward Island, and Newfoundland & Labrador. EPRA has also been working with recycle NB to develop an e-waste management program in New Brunswick since October 2015 [31]. EPRA collects the e-waste through Return-It depots where e-waste can be dropped off.

Encorp Pacific Canada

Encorp Pacific Canada is a federally incorporated, non-profit product stewardship corporation established in 1994 to deal with the recycling of beverage containers. In 2007, Encorp Pacific got the recovery and recycling contract for electronic waste in British Columbia [32]. It also collects the e-waste through Return-It depots.

Alberta Recycling

Alberta Recycling is a non-profit association that manages the collection and recycling of tires, electronic waste, and paint in Alberta. The electronic recycling program was initiated in 2004 in Alberta to keep old computers and televisions out of landfills.

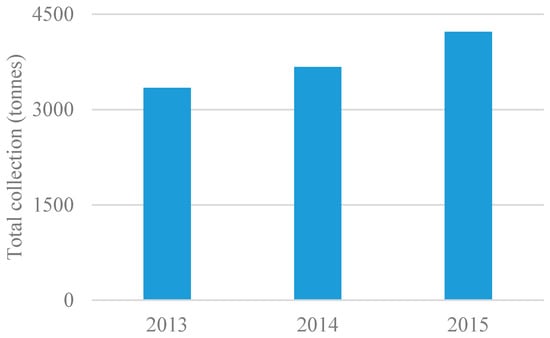

Canadian Electrical Stewardship Association (CESA)

CESA is a non-profit organization established in 2010 to develop a recycling program to manage end-of-life products like various small household appliances and power tools. CESA is currently managing the recycling program ElectroRecycle in British Columbia [33]. Figure A1 shows the total end-of-life electrical products collected by ElectroRecycle in British Columbia. The rise in collection is due to easier access to a drop-off location and increased awareness. The number of collection sites increased from 162 in 2013 to 197 in 2015.

Figure A1.

Total electrical products collected by ElectroRecycle.

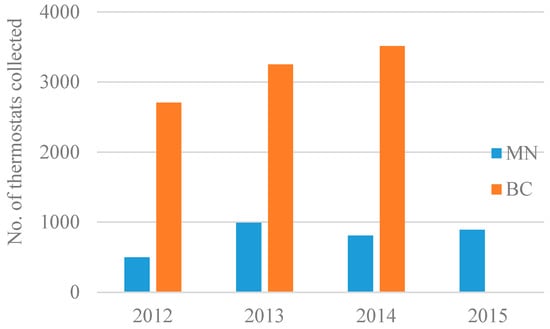

Scout Environmental

Scout Environmental is a non-profit organization that develops and implements product stewardship and waste management, especially in the automobile sector. It works in the field of recycling end-of-life vehicles, removing and managing mercury-containing light switches and anti-lock brake systems [34]. In the field of electronic waste, the Switch the ‘Stat program initiated by Scout Environmental in 2006 is focused on recovering and managing old thermostats and removing mercury from e-waste in British Columbia and Manitoba. On 1 July 2016, the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) launched a Thermostat Recovery program to replace the Switch the ‘Stat program in most of the provinces. Figure A2 shows the equivalent number of thermostats collected in British Columbia and Manitoba under the Switch the ‘Stat program. The data for 2015 in British Columbia are yet not available.

Figure A2.

Total number of thermostats collected by Scout Environmental.

The amount of materials recovered by the processing of collected thermostats is shown in Table A1. The Switch the ‘Stat program has been able to recover approximately 529 kg mercury so far [35].

Table A1.

Materials recovered from thermostats.

| Material | British Columbia, 2014 (in kg) | Manitoba, 2015 (in kg) |

|---|---|---|

| Mercury | 14.46 | 2.87 |

| Glass | 5.78 | NA |

| Metals | 80.67 | 17.99 |

| Plastics | 109.18 | 58.04 |

ReGeneration

ReGeneration is the recycling initiative from Product Care Association dealing with paints, lighting products, pesticides, fertilizers, smoke and CO alarms, and small appliances. LightRecycle (RecycFluo in Quebec) is a program to collect and recover lights in British Columbia, Manitoba, Ontario, Quebec, Prince Edward Island, and Washington state (USA). AlarmRecycle is the program to collect used/expired smoke and carbon monoxide (CO) alarms across British Columbia. The recycling of small appliances is handled by the ElectroRecycle program offered by CESA.

Table A2 shows the categories of lamps and other lighting products collected in British Columbia and Manitoba in 2013 and 2014 by LightRecycle. It shows a significant increase in the numbers of lamps collected in 2014 compared to 2013, which suggests an increased awareness among residents.

Table A2.

Amount of lamps collected by LightRecycle.

| Province | British Columbia | Manitoba | ||

|---|---|---|---|---|

| Type | 2013 | 2014 | 2013 | 2014 |

| Lamps, units | 3,603,533 | 4,548,481 | 52,525 | 74,822 |

| Residential fixtures, tons | 140 | 262 | NA | NA |

| PCB ballasts, tons | 15.2 | 22.5 | NA | NA |

| Crushed lamps, tons | 18.7 | 18.5 | NA | NA |

Similarly, according to AlarmRecycle data, the number of alarms collected in 2014 was 44,253 compared to 32,460 in 2013 [36].

The Outdoor Power Equipment Institute of Canada (OPEIC)

The OPEIC is a non-profit organization established in 2012 in British Columbia dealing with the recycling of outdoor power equipment such as chain saws, leaf blowers, lawn mowers, wood chippers/splitters, lawn tractors, etc.

The number of OPEIC collection sites increased from 102 in 2012 to 121 in 2014. The absolute number of items of outdoor power equipment collected every year is not available but a sample of the data from 10 collection sites provided by OPEIC suggests that 0.17% of the total sampled material was electrical outdoor power equipment [37].

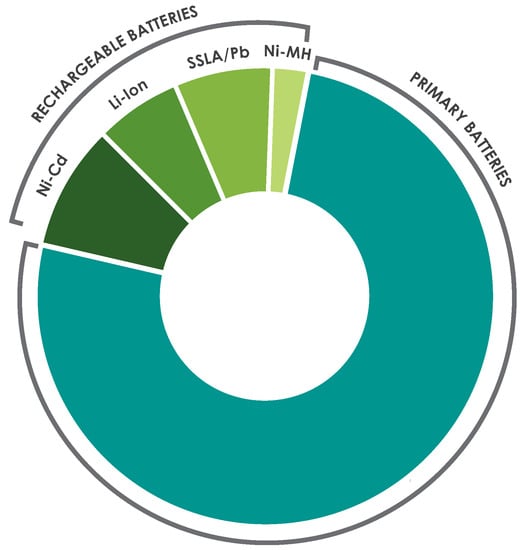

Call2Recycle

Call2Recycle is an industry-led recycling program established in 1994 in Canada and the United States to collect and recycle batteries. In Canada, the program was previously known as Rechargeable Battery Recycling Corporation Canada (RBRCC). It is a nationwide program handling batteries in all Canadian provinces. It has also signed an MoU with the Canada Battery Association to share and increase access to the collection sites.

The amount of batteries collected in Canada reached 2500 tons in 2015 compared to 2286 tons in 2014, which includes rechargeable and non-rechargeable batteries [38]. Figure A3 shows the different types of batteries collected by the Call2Recycle. It suggests that primary (non-rechargeable) batteries are the major portion of total batteries collected and recycled.

Figure A3.

Types and relative amounts of different types of batteries collected [39].

Recycle My Cell

Recycle My Cell is a national industry-led recycling program for cell phones and mobile devices. The program is operated by the Canadian Wireless Telecommunications Association (CWTA), cell phone carriers, and cell phone manufacturers. It is also a nationwide program, being operated in all the provinces. According to a survey by CWTA [21], 48% of Canadians reported that they have at least one cellphone in storage and up to 3% have more than four phones in storage.

A total of 670,701 cellphones were recovered in Canada in 2015 [40]. There are 3520 drop-off locations across Canada for cellphones.

Rethink It

Rethink It is a waste reduction and recovery initiative from the government of Northwest Territories and includes a beverage container program, a single-use retail bag program, and an electronics recycling program. The electronics recycling program was launched in February 2016 to recycle laptops, desktop computers, printers, etc. More than 25 tons of electronics have been collected since 2013 through the recycling pilot project in NWT.

References

- Balde, K.; Wang, F.; Huisman, J.; Kuehr, R. The Global E-Waste Monitor; United Nations University: Bonn, Germany, 2015. [Google Scholar]

- Namias, J. The Future of Electronic Waste Recycling in the United States: Obstacles and Domestic Solutions; Columbia University: New York, NY, USA, 2013. [Google Scholar]

- StEP Initiative. One Global Definition of E-Waste; StEP Initiative: Bonn, Germany, 2014. [Google Scholar]

- Schroeder, H. E-Waste Management in Canada; Environment Canada: Fredericton, NB, Canada, 2013.

- Cucchiella, F.; D’Adamo, I.; Koh, S.C.L.; Rosa, P. Recycling of WEEEs: An economic assessment of present and future e-waste streams. Renew. Sustain. Energy Rev. 2015, 51, 263–272. [Google Scholar] [CrossRef]

- Golev, A.; Schmeda-Lopez, D.R.; Smart, S.K.; Corder, G.D.; McFarland, E.W. Where next on e-waste in Australia? Waste Manag. 2016. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Yang, C.; Chiang, J.F.; Li, J. Innovating e-waste management: From macroscopic to microscopic scales. Sci. Total Environ. 2016, 575, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Heacock, M.; Kelly, C.B.; Asante, K.A.; Birnbaum, L.S.; Bergman, Å.L.; Bruné, M.-N.; Buka, I.; Carpenter, D.O.; Chen, A.; Huo, X.; et al. E-Waste and Harm to Vulnerable Populations: A Growing Global Problem. Environ. Health Perspect. 2015, 124, 550–555. [Google Scholar] [CrossRef] [PubMed]

- Lèbre, É.; Corder, G. Integrating Industrial Ecology Thinking into the Management of Mining Waste. Resources 2015, 4, 765–786. [Google Scholar] [CrossRef]

- Van Eygen, E.; de Meester, S.; Tran, H.P.; Dewulf, J. Resource savings by urban mining: The case of desktop and laptop computers in Belgium. Resour. Conserv. Recycl. 2016, 107, 53–64. [Google Scholar] [CrossRef]

- Cui, J.; Forssberg, E. Mechanical recycling of waste electric and electronic equipment: A review. J. Hazard. Mater. 2003, 99, 243–263. [Google Scholar] [CrossRef]

- Brigden, K.; Labunska, I.; Santillo, D.; Allsopp, M. Recycling of Electronic Wastes in China & India: Workplace & Environmental Contamination; Greenpeace International: Exeter, UK, 2005. [Google Scholar]

- Velis, C.; Mavropoulos, A. Unsound waste management and public health: The neglected link? Waste Manag. Res. 2016, 34, 277–279. [Google Scholar] [CrossRef] [PubMed]

- Garlapati, V.K. E-waste in India and developed countries: Management, recycling, business and biotechnological initiatives. Renew. Sustain. Energy Rev. 2016, 54, 874–881. [Google Scholar] [CrossRef]

- Statistics Canada. Manufacturing Sales, by Subsector, by Province and Territory; Statistics Canada: Ottawa, ON, Canada, 2016. Available online: http://www.statcan.gc.ca/tables-tableaux/sum-som/l01/cst01/manuf33a-eng.htm (accessed on 16 June 2016).

- EMarketer. Over Half of Canada’s Population to Use Smartphones in 2015; EMarketer: New York, NY, USA, 2015; Available online: http://www.emarketer.com/Article/Over-Half-of-Canadas-Population-Use-Smartphones-2015/1011759 (accessed on 16 June 2016).

- Statistics Canada. Survey of Household Spending (SHS), Dwelling Characteristics and Household Equipment as of December 31, Three Territories and Selected Metropolitan Areas; Statistics Canada: Ottawa, ON, Canada, 2014. Available online: http://www5.statcan.gc.ca/cansim/a26?lang=eng&id=2030031 (accessed on 16 June 2016).

- Statistics Canada. Household Size, by Province and Territory (2011 Census); Statistics Canada: Ottawa, ON, Canada, 2013. Available online: http://www.statcan.gc.ca/tables-tableaux/sum-som/l01/cst01/famil53c-eng.htm (accessed on 16 June 2016).

- Gaidajis, G.; Angelakoglou, K.; Aktsoglou, D. E-waste: Environmental problems and current management. J. Eng. Sci. Technol. Rev. 2010, 3, 193–199. [Google Scholar]

- Statistics Canada. Disposal of Electronic Waste (E-Waste), by Province; Statistics Canada: Ottawa, ON, Canada, 2015.

- Canadian Wireless Telecomms. Understanding Cell Phone Recycling Behaviours; Canadian Wireless Telecomms: Ottawa, ON, Canada, 2016. [Google Scholar]

- Electronics Product Stewardship Canada. About EPSC; EPSC: Windsor, ON, Canada, 2011; Available online: http://epsc.ca/aboutepsc/ (accessed on 28 June 2016).

- Hickle, G.T. Comparative Analysis of Extended Producer Responsibility Policy in the United States and Canada. J. Ind. Ecol. 2013, 17, 249–261. [Google Scholar] [CrossRef]

- SHIFT Recycling. E-Waste Problem; SHIFT Recycling: Brampton, ON, Canada, 2010; Available online: http://shiftrecycling.com/e-waste.php (accessed on 20 June 2016).

- Kerr, S. E-Waste: A Success Story; Electronics Product Stewardship Canada: Windsor, ON, Canada, 2013. [Google Scholar]

- Recycler Qualification Office. RQO Aapproved Recyclers; Recycler Qualification Office: Barrie, ON, Canada, 2014; Available online: http://rqp.ca/verified-recyclers/ (accessed on 4 July 2016).

- ecoATM. How It Works; ecoATM: Tulsa, OK, USA, 2016; Available online: https://www.ecoatm.com/ (accessed on 11 July 2016).

- Wang, F.; Huisman, J.; Meskers, C.E.M.; Schluep, M.; Stevels, A.; Hagelüken, C. The Best-of-2-Worlds philosophy: Developing local dismantling and global infrastructure network for sustainable e-waste treatment in emerging economies. Waste Manag. 2012, 32, 2134–2146. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zeng, X.; Chen, M.; Ogunseitan, O.A.; Stevels, A. ‘Control-Alt-Delete’: Rebooting Solutions for the E-Waste Problem. Environ. Sci. Technol. 2015, 49, 7095–7108. [Google Scholar] [CrossRef] [PubMed]

- Mashable. Inside Liam, Apple’s Super-Secret, 29-Armed Robot That Tears down Your iPhone; Mashable: New York, NY, USA, 2016; Available online: http://mashable.com/2016/03/21/apple-liam-recycling-robot/#2YwqNx45HqqA (accessed on 11 July 2016).

- Electronic Products Recycling Association (EPRA). What Is a Steward? EPRA: Mississauga, ON, Canada, 2014; Available online: http://epra.ca/ (accessed on 11 July 2016).

- Encorp Pacific. What Is Encorp? Encorp Pacific: Burnaby, BC, Canada, 2014; Available online: https://www.return-it.ca/about/ (accessed on 1 July 2016).

- ElectroRecycle. Annual Report; ElectroRecycle: Vancouver, BC, Canada, 2015. [Google Scholar]

- Scout Environmental. Our Programs. Available online: http://scoutenvironmental.com/site/programs (accessed on 1 July 2016).

- Switch the ‘Stat. Switch the ‘Stat Counter; Switch the ‘Stat: Toronto, ON, Canada, 2016; Available online: http://www.switchthestat.ca/eng/index.php (accessed on 3 July 2016).

- AlarmRecycle. Annual Report; AlarmRecycle: Vancouver, BC, Canada, 2015. [Google Scholar]

- Outdoor Power Equipment Institute of Canada (OPEIC). Annual Report; OPEIC: Toronto, ON, Canada, 2015. [Google Scholar]

- Call2Recycle. Annual Report; Call2Recycle: Toronto, ON, Canada, 2014. [Google Scholar]

- Call2Recycle. Annual Report; Call2Recycle: Toronto, ON, Canada, 2015. [Google Scholar]

- RecycleMyCell. Facts and Figures; RecycleMyCell: Ottawa, ON, Canada, 2015. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).