Abstract

This study explores the sustainable extraction and application of natural dyes from figs (Ficus carica) and Eucalyptus leaves using an aqueous alkaline medium. The dyeing process was optimized for cotton fabric using the exhaust-dyeing method. Fabrics dyed with Ficus carica extract and its blend with Eucalyptus exhibited enhanced color strength, excellent crocking fastness (rated 4–5), and good washing fastness (rated 3–4 on the gray scale). The use of Aloe barbadensis Miller as a bio-mordant significantly improved dye fixation, resulting in deeper, earthy shades, such as green, yellow–green, and yellowish brown. The highest K/S value (5.85) was recorded in samples treated with a mordant, sodium chloride (NaCl), and the combined dye extracts, indicating a synergistic effect among the components. Mosquito repellency tests revealed that treated fabrics exhibited up to 70% repellency, compared to just 20% in undyed samples. Antibacterial testing against E. coli showed that dyed fabrics achieved over 80% bacterial reduction after 24 h, indicating promising antimicrobial functionality. Air permeability slightly decreased post-dyeing due to the potential shrinkage in cotton fabrics. Furthermore, adsorption studies showed a removal efficiency of 57% for Ficus carica dye on graphene oxide (GO) under ultrasonication. These findings confirm the potential of GO as an effective adsorbent material for treating wastewater from natural textile dyes. Overall, the study highlights the environmental safety, functional performance, and multifunctional advantages of plant-based dyeing systems in sustainable textile applications.

1. Introduction

The global textile dyeing and finishing industry is widely recognized as a significant contributor to aquatic pollution and overall environmental degradation [1]. Wastewater generated from these processes is typically laden with toxic synthetic dyes, organic compounds, and various inorganic salts, posing significant risks to aquatic life [2]. The discharge of dye molecules into aquatic systems reduces water transparency, thereby impairing light penetration and decreasing the solubility of dissolved gases such as oxygen. This disruption poses a significant threat to aquatic ecosystems by hindering photosynthetic activity and compromising the survival of aquatic organisms [3]. In response to escalating environmental concerns and stringent regulatory pressures, the textile industry is increasingly shifting toward sustainable production practices. Instead of relying exclusively on conventional effluent treatment systems, which are often costly and inadequate for the complete removal of contaminants, there is a growing emphasis on preventive strategies aimed at minimizing pollutant generation at the source [4]. The adoption of cleaner production techniques in textile processing presents a more effective and sustainable approach to mitigating environmental impacts [5]. Growing environmental awareness has intensified the push to mitigate the ecological consequences associated with synthetic dyes, encouraging the exploration of renewable and natural alternatives. In this context, natural dyes have gained attention as promising substitutes, offering advantages such as biodegradability, low toxicity, and compatibility with ecological systems [6]. Their implementation in textile processing aligns with the principles of green chemistry and supports the pursuit of emission-free dyeing technologies [7]. In recent years, increasing research efforts have been directed toward utilizing various plant-based materials, such as seeds, peels, roots, husks, shells, and teak leaves, as sustainable sources for dye extraction, with applications in both textile coloration and functional finishing [8].

A major limitation of natural dyes is their restricted chromatic range and comparatively lower color intensity relative to synthetic dyes [9]. This limitation in the depth and range of hues achievable with natural dyes can restrict their applicability in industries where precise and vivid coloration is essential, particularly in modern textile dyeing and printing processes [10]. While several studies have investigated individual plant-based dyes for textile dyeing, the use of single-source natural colorants often results in a narrow hue spectrum. In a previous study, we reported the eco-friendly dyeing of cotton using Aloe barbadensis Miller-derived mordants; however, that work focused solely on a single natural dye extracted from black tea. According to Fan et al., natural dyes are predominantly suited for producing light, subtle shades that reflect their authentic hues, whereas synthetic dyes are engineered to provide vivid, intense coloration with deeper shades, making them more favorable for textile dyeing and printing applications [11]. This study aims to address the limited color range of natural dyes by combining extracts from Ficus carica and Eucalyptus leaves to broaden the color spectrum and enhance the aesthetic versatility of naturally dyed textiles [12]. Traditionally, Ficus carica leaf powder has been used for its disinfectant and anti-parasitic properties in disease treatment. Notably, the leaves of Ficus carica contain significantly higher concentrations of phenolic compounds than its bark extracts, which contribute to their superior bioactivity [13]. Textile substrates, particularly cotton fabrics, when dyed with natural extracts derived from Eucalyptus leaves, demonstrate notable biofunctional properties, including resistance to microbial growth. These treated fabrics have been reported to exhibit antimicrobial efficacy, along with antifungal and antiviral activities, making them promising candidates for applications in protective and medical textile finishes [14]. To overcome the chromatic limitations of natural dyes, the present study introduces a novel approach by blending extracts from two different natural sources Ficus carica and Eucalyptus. This combination strategy is hypothesized to expand the color range achieved on cotton fabrics, demonstrating improved versatility and potential for sustainable textile applications.

In conventional dyeing processes, textile dyes often necessitate the use of mordants to ensure adequate fixation onto textile substrates [15]. These mordants typically consist of inorganic salts derived from heavy metals, such as aluminum, iron, tin, copper, and chromium, or other chemically active agents, which promote bonding between dye molecules and fibers through chemical interactions. However, rising environmental and health concerns over the past few decades have driven a paradigm shift in the textile sector, favoring the use of natural dyes while eliminating toxic mordants from the dyeing process [16]. This problem is addressed in the present study by employing Aloe barbadensis Miller as a natural mordant, offering an eco-friendly alternative that facilitates effective dye fixation without the environmental and health hazards associated with conventional metallic mordants. Aloe barbadensis Miller is widely recognized for its medicinal and functional properties, including UV protection, antimicrobial, and antioxidant activity [17,18]. Among its bioactive constituents, acemannan is noted for its potent antibacterial effects [19].

The present study also investigates the use of graphene oxide as an efficient adsorbent for natural dye removal. Batch adsorption experiments, combined with ultrasonication-assisted techniques, were conducted to enhance the dye uptake efficiency [20]. The high surface area, functionalized surface groups, and exceptional adsorption capacity of graphene oxide make it a suitable candidate for capturing dye molecules from aqueous solutions [21]. Ultrasonication was utilized in this study due to its proven ability to enhance the adsorption capacity of carbon-based materials, thereby improving the removal efficiency of synthetic dyes from contaminated water [22]. By effectively removing dye residues from wastewater as an objective of the current study, this approach will not only mitigate color pollution but also prevent the obstruction of sunlight penetration in aquatic environments, thereby preserving photosynthetic activity and supporting the ecological balance of aquatic life.

In response to growing environmental and health concerns associated with synthetic dyes and mordants, this study investigates an eco-friendly dyeing approach of cotton using Ficus carica/eucalyptus-leaf extracts and bio-based mordants. The dyed fabrics were evaluated for color strength, washing and crocking fastness, air permeability, and anti-mosquito efficacy. Graphene oxide was incorporated as an adsorbent to enhance dye uptake through batch and ultrasonication-assisted adsorption methods. By integrating natural dyes from Ficus carica and Eucalyptus leaves [23] with environmentally benign mordants like Aloe barbadensis Miller, the research demonstrates a comprehensive, sustainable dyeing system with added biofunctional benefits such as mosquito-repellent properties [24]. This work not only improves color strength and fabric functionality through sustainable methods but also addresses critical ecological concerns, such as the reduction in sunlight penetration in aquatic environments, thereby contributing to the preservation of aquatic ecosystems.

2. Materials and Methods

2.1. Materials

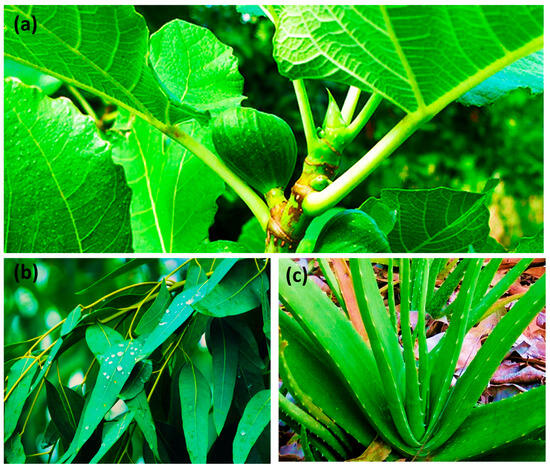

Ficus carica (Figure 1), Eucalyptus, and Aloe barbadensis Miller leaves were freshly collected from the from the home garden located at Valencia Town, Lahore. Bleached woven cotton fabric (100%) was provided by the School of Design and Textiles, UMT, Lahore, Pakistan. Laboratory-scale sodium chloride, sodium sulphate, and sodium hydroxide were obtained from Sigma-Aldrich, Darmstadt, Germany. Graphene oxide, a potential adsorbent, was purchased from Sigma Aldrich, Germany. All the chemical/reagents were used as-received without further purification.

Figure 1.

Plant sources used in this research are (a) Ficus carica, (b) Eucalyptus, and (c) Aloe barbadensis Miller (captured at a home garden located in Valencia Town, Lahore).

2.2. Methods

2.2.1. Extraction of Dyes

After collecting Ficus carica leaves, they were thoroughly washed with distilled water to remove surface dust, soil particles, and other potential contaminants. The cleaned leaves were then dried in a controlled environment at 60 °C for 24 h using a heating oven to ensure complete moisture removal. Once dried, the leaves were ground into a fine powder using a mechanical milling device to increase the surface area for efficient extraction.

For dye extraction, 20 g of the powdered Ficus carica leaves were mixed with 1000 mL of distilled water in a beaker. To facilitate the release of dye compounds, 10 g of sodium hydroxide was added, creating an alkaline medium that enhances the solubility of phenolic and flavonoid compounds responsible for coloration. The mixture was stirred continuously for two hours using a hot-plate magnetic stirrer at a moderate temperature to accelerate extraction while preventing thermal degradation.

Following extraction, the solution was filtered using a fine-mesh cloth to remove solid residues and obtain a clear dye solution suitable for textile application. The same extraction procedure was employed for Eucalyptus leaves to obtain a comparable natural dye solution under identical alkaline conditions.

2.2.2. Extraction of Mordant

Fresh, mature Aloe barbadensis Miller leaves were collected, thoroughly washed with distilled water to remove surface impurities, and allowed to dry at room temperature. The outer green rind was carefully removed using a stainless-steel knife to isolate the inner translucent gel. The extracted gel was then homogenized using a laboratory blender to obtain a uniform viscous liquid. The resulting pulp was filtered through muslin cloth to remove fibrous residues and particulates. The clear gel filtrate was subsequently used as a natural bio-mordant in the dyeing process without the addition of any synthetic chemicals. For enhanced stability and preservation, the gel was stored at 4 °C and used within 48 h to maintain its phytochemical integrity and reactivity.

2.2.3. Dyeing Method

Thirteen woven cotton fabric samples were prepared, each measuring 10 cm × 10 cm with an approximate weight of 5 g. The cotton fabric used was of plain weave construction, made from 100% bleached cotton, with a thread count of 60 ends × 60 picks per inch, and a grammage of approximately 120 g/m2. Among the samples, Sample S0 was left untreated and used as the control, while the other 12 samples (S1–S12) were subjected to various natural dyeing treatments.

The dyeing procedure was carried out using the conventional exhaust-dyeing method. Initially, the dye bath was preheated and maintained at 90 °C for one hour to ensure uniform thermal conditions. The dye solution was then prepared by adding the appropriate quantity of Ficus carica or eucalyptus-leaf extract, based on the weight of the cotton fabric sample, using a liquor-to-material ratio (LR) of 1:50. To enhance the dye–fiber interaction, 1 g of sodium chloride (NaCl) was added to selected dye baths as an electrolyte. Aloe barbadensis Miller gel, used as a natural bio-mordant, was incorporated into specific dye baths to improve dye fixation and functional performance.

Once the dye bath was fully prepared with the extract(s), salt, and Aloe barbadensis Miller (as per sample design), the cotton fabrics were immersed and dyed at 90 °C for 60 min. This process allowed for uniform distribution and interaction of dye and mordant molecules in solution prior to fabric contact, ensuring effective dye penetration and enhanced binding to the fiber surface.

The experimental setup involved a variety of treatment combinations across 13 different samples, as outlined below:

- Sample 0: this sample was left untreated and used as the control;

- Sample S1 and S2: dyed individually with Ficus carica extract and eucalyptus extract, respectively, without the addition of Aloe barbadensis Miller or salt;

- Sample S3: dyed using a mixture of Ficus carica and eucalyptus extracts;

- Samples S4 and S7: treated with Ficus carica and eucalyptus extracts, respectively, with salt added;

- Samples S5 and S8: dyed with Ficus carica and eucalyptus extracts, respectively, in the presence of Aloe barbadensis Miller gel;

- Samples S6 and S9: dyed with Ficus carica and eucalyptus extracts, respectively, using both Aloe barbadensis Miller gel and salt;

- Sample S10: dyed with a mixture of Ficus carica and eucalyptus extracts, along with salt;

- Sample S11: treated with a mixture of Ficus carica and eucalyptus extracts combined with Aloe barbadensis Miller;

- Sample S12: dyed using a mixture of Ficus carica and eucalyptus extracts in the presence of both Aloe barbadensis Miller gel and salt.

This structured design enabled a comparative evaluation of the effects of individual and combined plant extracts, Aloe barbadensis Miller mordanting, and salt addition on the dyeing performance and functional attributes of the cotton fabric. Table 1 presents the detailed parameters used for each dyeing condition.

Table 1.

Design of experiment for dyeing of cotton fabric (12 samples) using natural dye extract.

2.2.4. Adsorption of the Effluent Dyes on GO

Unlike synthetic dyes with a known molar extinction coefficient (ε), natural plant extracts comprise multiple chromophores and absorbing species, making it impractical to apply the Beer–Lambert law in a conventional manner. Thus, the removal of extract was estimated by comparing the reduction in absorbance before and after treatment. The maximum absorbance wavelength (λmax) of the extract was observed at 235 nm, which was used for all absorbance-based calculations. The initial concentration of the extract solution was prepared by boiling 20 g of dried plant material in 200 mL of distilled water, corresponding to a 1:10 (w/v) plant material-to-solvent ratio. This weight-to-volume ratio served as the reference for estimating initial extract concentration.

The extracted Ficus carica extract solution was individually combined with predetermined quantities of graphene oxide (GO) in separate batches. One dye mixture was stirred at 500 rpm using a magnetic hotplate stirrer, while the other was subjected to ultrasonic treatment in a bath sonicator (Cole-Parmer®, Vernon Hills, IL, USA) operating at a frequency of 42 kHz for varying durations of 5, 10, 15, 20, 25, and 30 min. Following this treatment with GO, the samples were collected at specific time intervals from each batch containing a known initial concentration of dye (Ci). The collected samples were filtered through a 0.45 μm nylon syringe filter to remove any suspended particles. The resulting filtrates were then analyzed using a UV-9000A, Shanghai Metash Instrument Ltd., Shanghai, China, spectrophotometer within the wavelength range of 200–700 nm. The absorbance readings were recorded, and the percentage removal (% adsorption, R) was determined and calculated based on Equation (1) [22].

where Ci (mg/L) is the initial concentration, and Ct (mg/L) is the concentration after time (t).

2.2.5. Testing and Characterization

The colorfastness to crocking of the developed samples was determined through both dry and wet crocking tests were performed on a laboratory crock meter (Model 255A, James H. Heal & Co. Ltd., Halifax, UK) in accordance with ISO 105-X12 [25]. Each sample underwent 20 crocking cycles, and the degree of staining transferred to a standard bleached test cloth was evaluated using the gray scale to determine the overall crocking fastness.

The color strength of the dyed samples was evaluated using a Datacolor Spectro 850 spectrophotometer (Suzhou, China). The K/S values, which represent the depth of shade, were calculated based on the Kubelka–Munk theory, as described in the literature (Equation (2)) [26].

In the Kubelka–Munk function (Equation (1)), K and S represent the absorption coefficient and scattering coefficient, respectively. “R” is the reflectance of the dyed fabric at the wavelength corresponding to the maximum absorption (λmax) of the sample in the visible range (400–700 nm). Measurements were performed under D65 illumination with a 10° standard observer. The λmax (400) value was used to ensure accurate representation of the depth of shade for each sample.

The colorfastness to washing of the dyed cotton fabrics was assessed according to ISO 105-C01 [27] using a Gyrowash machine (Model 315, James H. Heal & Co. Ltd., Halifax, UK). Each specimen was washed at 60 °C for 30 min in the presence of a multifiber adjacent fabric, followed by drying in a laboratory oven. Post-wash evaluations of color staining were conducted using the standard gray-scale method, with ratings ranging from 1 (poor) to 5 (excellent).

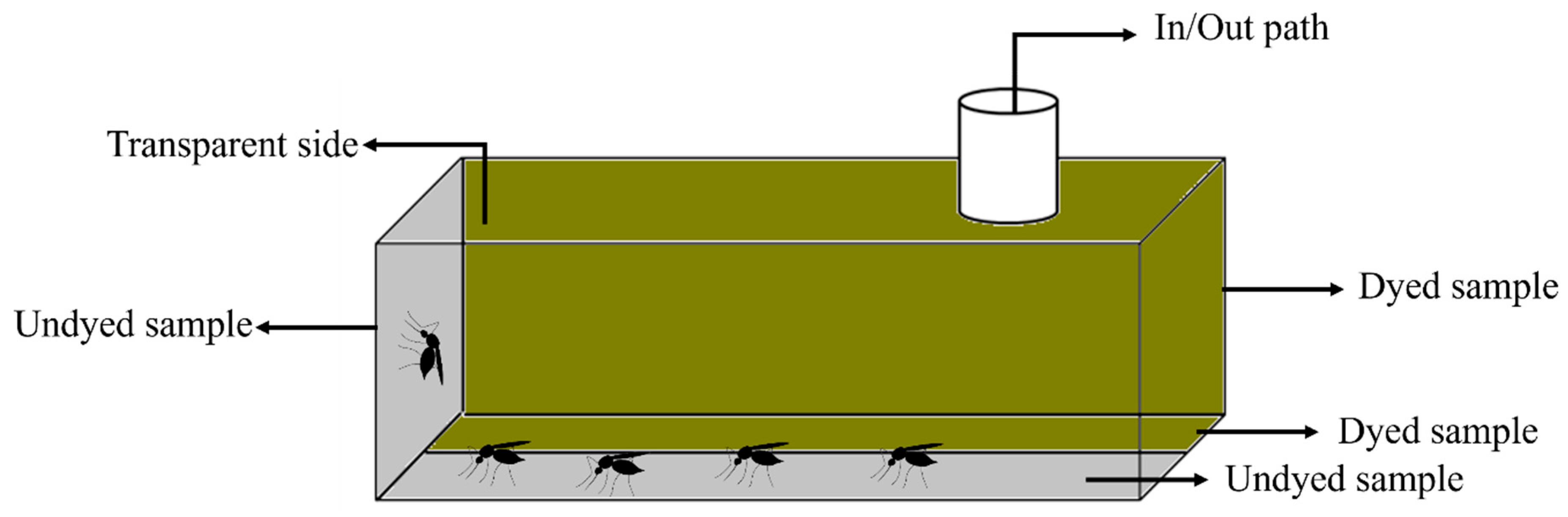

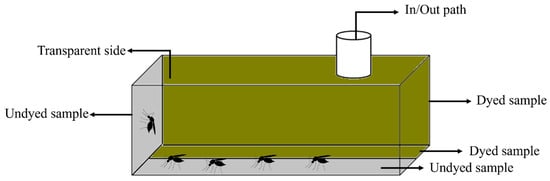

For the mosquito repellency test, a transparent glass chamber measuring 50 × 30 × 40 cm (as schematically illustrated in Figure 2) was used, adapted from the experimental setup reported in a previous study [28]. Unlike earlier approaches, this setup was specifically developed to evaluate the mosquito-repellent efficacy of dyed fabrics without direct human involvement. For the experimental layout, a control fabric (untreated) was affixed to one inner wall of the chamber, while the opposite wall featured the dyed fabric. The top of the chamber remained uncovered. The bottom was divided equally—half covered with untreated fabric and half with the dyed fabric. The remaining two side walls were each covered with one type of fabric (dyed and untreated). A total of 10 mosquitoes were released into the chamber and allowed to acclimate for 2–3 min. Observations were recorded at 5, 30, and 60 min intervals to assess repellency. The number of mosquitoes landing on each fabric type was averaged, and the repellency percentage was calculated by Equation (3) [29].

Figure 2.

Schematic diagram of cage mosquito repellency test.

The total exposed specimen is denoted as T, while D represents the number of mosquitoes settled on the fabric.

To assess the air permeability of cotton fabrics dyed with Ficus carica and eucalyptus-leaf extracts, tests were conducted using a standard air permeability tester. In this method, the fabric sample was securely clamped over the air inlet of the apparatus to prevent edge leakage. A controlled vacuum pump generated airflow through the fabric, and the volume of air passing through a defined area over a specific duration was measured. All tests were performed under standard atmospheric conditions, and the results are expressed in cm3/cm2/s. This evaluation offers valuable insights into the breathability and porosity of the dyed fabrics, which are essential attributes for determining their comfort and functional performance in apparel and technical textile applications.

2.2.6. Antibacterial Testing

The AATCC (American Association of Textile Chemists and Colorists) 100 test method is a quantitative standard testing protocol to assess the antibacterial efficacy of dyed cotton fabrics. In this method, the colony forming units (CFU) observed on the dyed cotton fabrics are counted and compared with the undyed cotton. The % reduction in bacteria is calculated using Equation (4).

% Reduction = [Control CFU − Treated CFU/Control CFU] ×100

3. Results

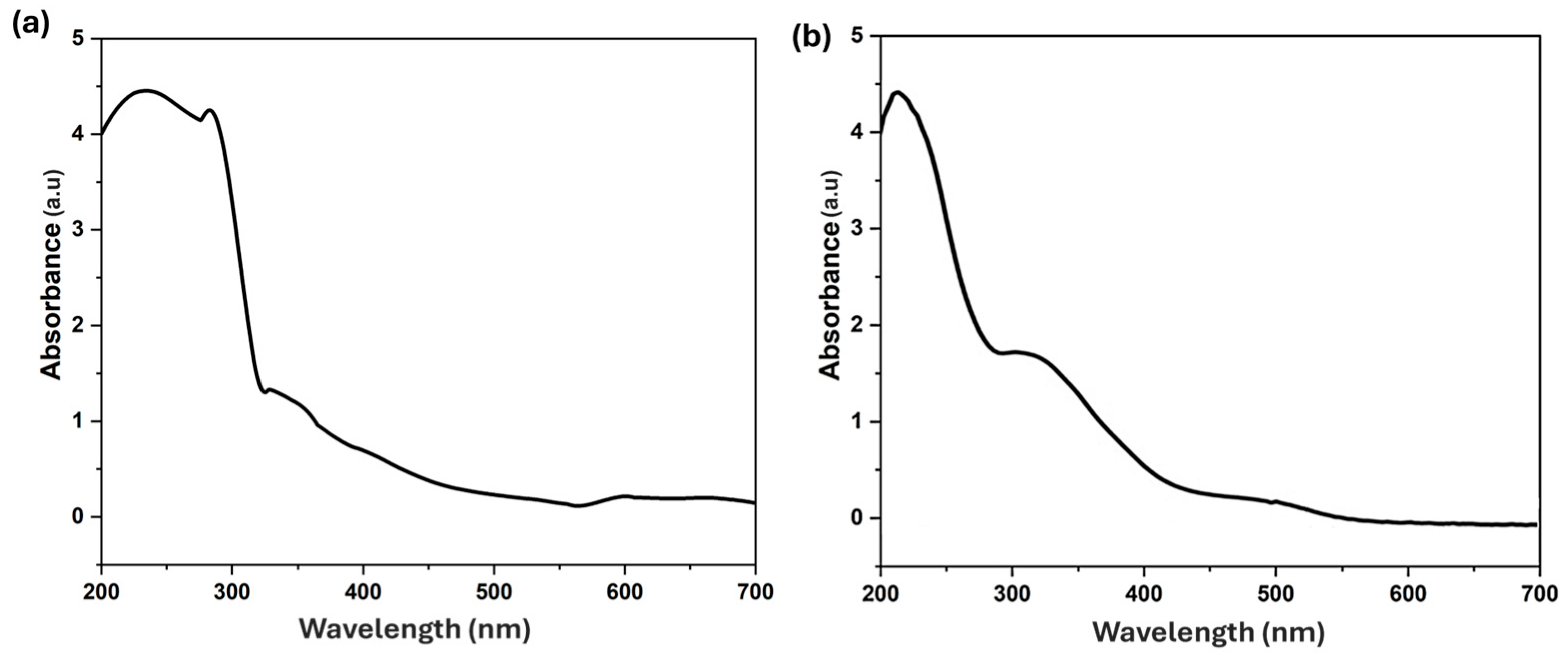

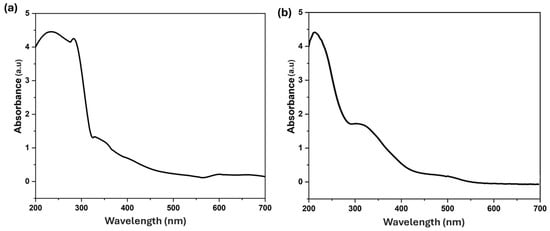

3.1. Ultraviolet–Visible Spectrum of Ficus carica and Eucalyptus Leaf Extracts

The UV–visible absorption spectra of the plant extracts were recorded in the range of 200–700 nm and are presented in Figure 3a (Ficus carica extract) and Figure 3b (eucalyptus extract). The Ficus carica leaves extract exhibited two prominent absorbance peaks in the ultraviolet region, with a strong peak of around 210–230 nm (absorbance of ~4.4 a.u.) and a secondary broad shoulder near 270–280 nm (absorbance of ~4.0 a.u.). Similarly, the eucalyptus extract showed a strong UV absorbance peak around 210–220 nm (absorbance of ~4.6 a.u), followed by a gradual decrease in absorbance across the 300–500 nm range. Absorbance approached baseline levels beyond 600 nm.

Figure 3.

Ultraviolet–visible spectra of (a) Ficus carica and (b) eucalyptus-leaves extract.

These UV–visible spectra indicate the presence of aromatic and conjugated compounds such as polyphenols and flavonoids, which are known for their strong UV absorbance and their ability to interact with textile fibers. Although the visible absorbance of both extracts was relatively low, their dyeing capability is attributed to molecular interactions and possible complex formation with mordants or fiber functional groups. This spectral behavior supports the observed coloration on fabrics and validates the extracts’ potential as natural dyes.

3.2. Color Strength and Fastness Properties of Dyed Samples

The results of color strength (K/S values), crocking fastness (dry and wet), and washing fastness ratings for dyed textile samples are reported in Table 2. As per the K/S values, the fabric dyed with Ficus carica extract alone (S1) exhibited a K/S value of 1.35, while the sample dyed with eucalyptus extract (S2) showed a higher value of 1.83, indicating a comparatively deeper shade. Upon incorporating Aloe barbadensis Miller as a natural mordant, the K/S values improved to 2.24 for Ficus carica (S5) and 2.63 for Eucalyptus (S8). This enhancement can be attributed to the presence of polysaccharides and polyphenolic compounds in Aloe barbadensis Miller, which form hydrogen bonds and coordinate with the dye molecules, thereby improving their fixation onto the fiber matrix [30]. Similarly, the addition of salt further increased the K/S values to 3.18 and 4.06 for Ficus carica (S4) and Eucalyptus (S7), respectively. Salt acts as an electrolyte in the dye bath, reducing the negative surface charge of the cotton fibers and facilitating the interaction between anionic dye molecules and the fiber. This charge neutralization minimizes repulsion and promotes stronger dye absorption, resulting in higher color yield [31]. The combination of Ficus carica, salt, and Aloe barbadensis Miller yielded a K/S value of 4.28 for S6, while the corresponding combination with Eucalyptus reached 4.85 for S9. When both dye extracts (Ficus carica and Eucalyptus) were used together, the K/S value for S3 was 4.36, which further increased to 4.87 for S11 with the addition of Aloe barbadensis Miller, and to 5.12 (S10) upon the addition of salt. Remarkably, the highest color strength was observed when the dye mixture of Ficus carica and Eucalyptus was applied in the presence of both Aloe barbadensis Miller and salt, producing a K/S value of 5.85 for S12. This result demonstrates a synergistic effect between the natural mordants and salt, significantly enhancing dye fixation and overall shade depth.

Table 2.

Summary of color strength (K/S values), crocking fastness (dry and wet), and washing fastness ratings for dyed textile samples.

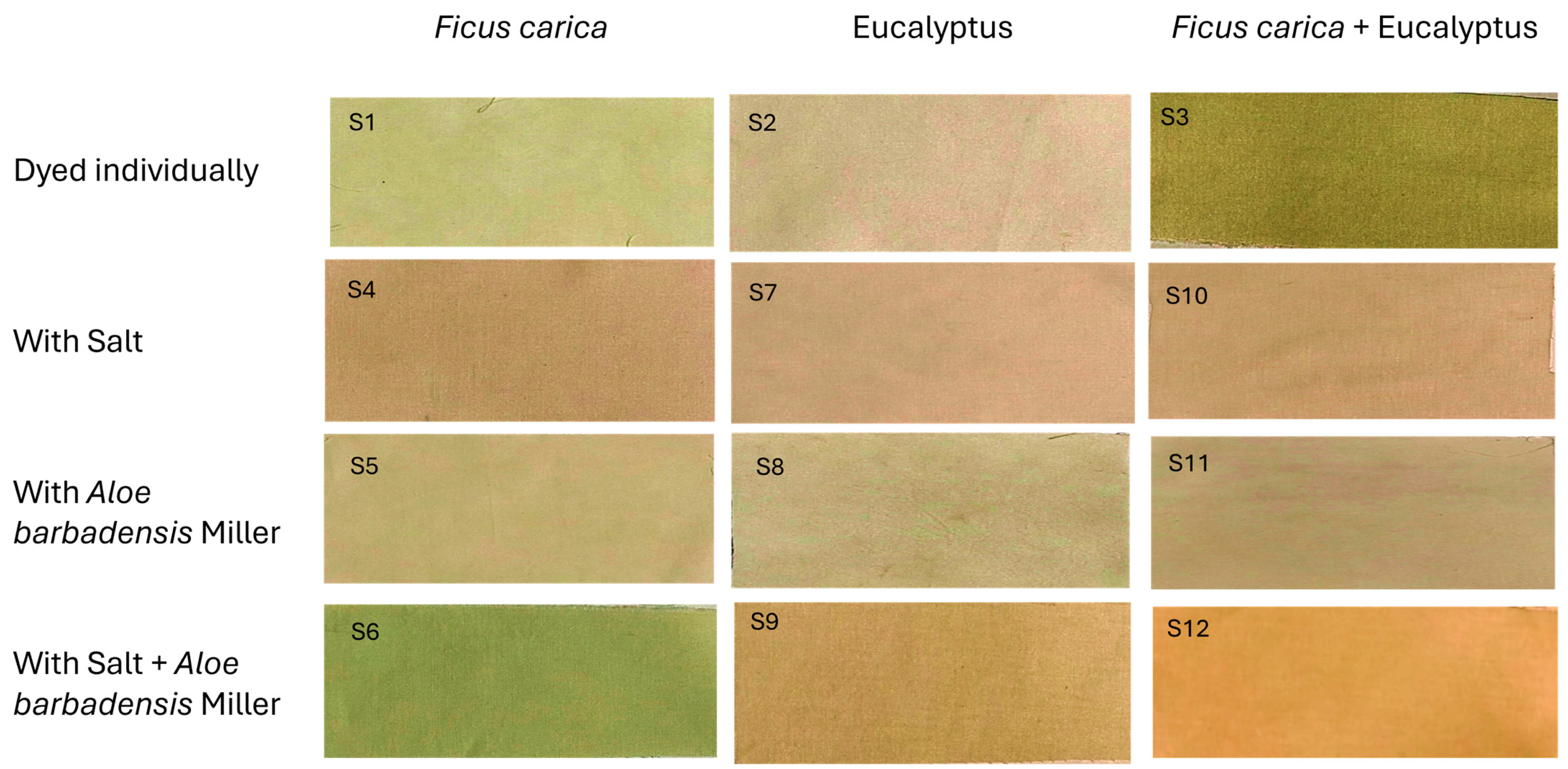

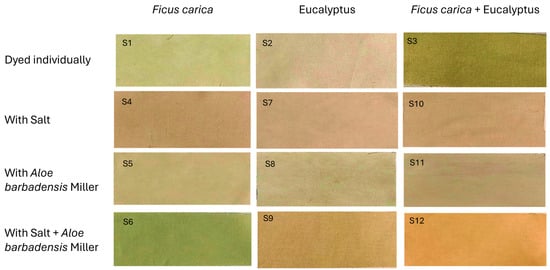

As illustrated in Figure 4, the addition of salt and Aloe barbadensis Miller notably influenced the color strength and shade of the dyed samples. Significant improvements in both depth and uniformity of color were observed, particularly when Ficus carica and eucalyptus extracts were used in combination with these additives. These results demonstrate the effectiveness of salt and Aloe barbadensis Miller in enhancing dye uptake and modifying the final color appearance.

Figure 4.

Developed shade samples produced during the study, illustrating the range of color variations achieved.

The crocking test was conducted to evaluate the colorfastness of the dyed textiles under dry and wet conditions, with results are summarized in Table 2. All dyed samples exhibited significant dry crocking fastness, with ratings ranging from 4 to 4–5, indicating good resistance to color transfer under dry conditions. However, the wet crocking test yielded slightly lower ratings compared to the dry test, with values ranging from 3 to 4. This indicates moderate resistance to color transfer in wet conditions, which is typical for natural dyes due to their lower affinity and fixation compared to synthetic dyes. It was observed that the samples dyed using Aloe barbadensis Miller as a natural mordant in combination with salt demonstrated superior crocking fastness, achieving ratings of 4–5 on the gray scale, which indicates very good to excellent resistance to crocking. In contrast, the sample dyed without the addition of salt and using only Aloe barbadensis Miller as the mordant showed a slightly lower crocking fastness, receiving a gray-scale rating of 4. This suggests that the presence of salt may enhance the binding of the dye to the fabric, thereby improving the overall crocking fastness performance.

The wash durability of the cotton samples dyed with and without mordant and salt was evaluated, and the results are presented in Table 2. Samples dyed solely with Ficus carica and eucalyptus-leaf extracts exhibited relatively low wash fastness, with gray-scale ratings of 3 and 3–4, respectively, indicating moderate-to-poor resistance to washing. However, the inclusion of salt as a mordant enhanced the wash fastness, with values improving to 3–4 for Ficus carica-dyed samples and to 4 for those dyed with eucalyptus extract. Notably, the combination of Ficus carica, Eucalyptus, salt, and Aloe barbadensis Miller resulted in the highest wash fastness performance, achieving gray-scale ratings of 4–5. This suggests a synergistic effect of salt and Aloe barbadensis Miller as mordants in strengthening dye fixation on cotton fibers, thereby improving wash durability.

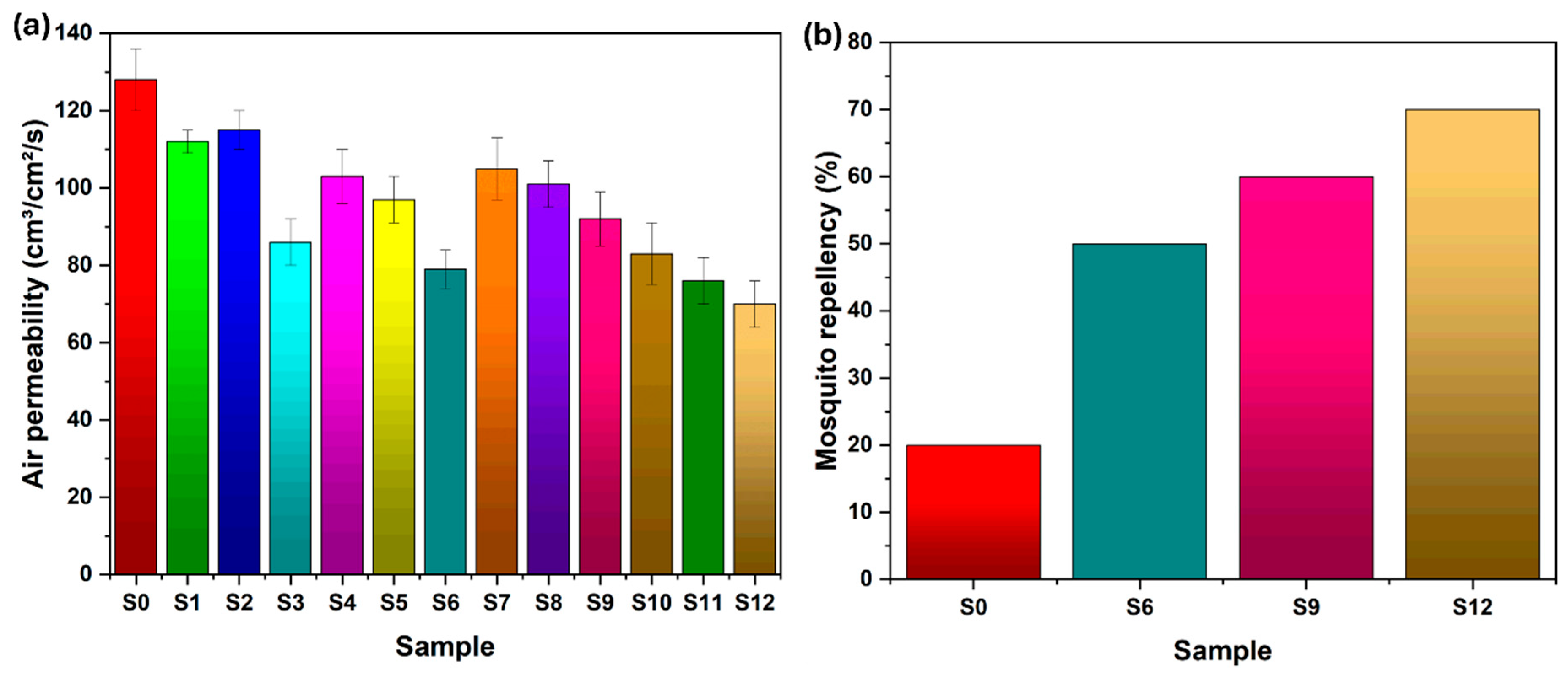

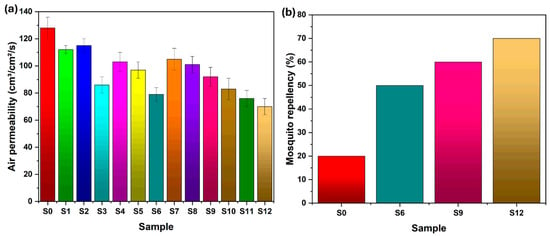

3.3. Air Permeability and Mosquito Repellency

The air permeability values of the dyed and undyed cotton samples are presented in Figure 5a. The undyed (control) sample exhibited the highest air permeability value of 128 cm3/cm2/s, indicating maximum fabric porosity and breathability. In comparison, the sample dyed with Ficus carica leaf extract (without any mordant) showed a reduced air permeability of 112 cm3/cm2/s, while the sample dyed with eucalyptus-leaf extract recorded a slightly higher value of 115 cm3/cm2/s. This reduction in air permeability compared to the untreated sample can be attributed to the fabric shrinkage and densification caused by exposure to elevated dyeing temperatures and moisture during the dyeing process. These conditions lead to tighter fiber packing, which restricts airflow through the fabric [32,33]. Further reductions were observed with the use of mordants. The sample dyed with Ficus carica in the presence of salt and Aloe barbadensis Miller exhibited an air permeability of 79 cm3/cm2/s. Similarly, the sample dyed with a combination of Ficus carica and Eucalyptus along with salt and Aloe barbadensis Miller showed a slightly higher value of 92 cm3/cm2/s. The most significant decrease in air permeability was recorded for the sample dyed with both Ficus carica and Eucalyptus, in the presence of both salt and Aloe barbadensis Miller, showing a value of just 70 cm3/cm2/s. The overall decrease in air permeability with the addition of mordants (salt and Aloe barbadensis Miller) is likely due to the formation of more compact dye–mordant–fiber complexes on the fabric surface. These complexes may partially fill the fabric pores and reduce inter-fiber spaces, leading to a denser structure and lower porosity. While this may affect breathability, it could potentially enhance other properties such as barrier performance.

Figure 5.

(a) Air permeability and (b) mosquito repellency investigations of dyed cotton fabric using standard testing protocols.

The mosquito repellency performance of the dyed fabric samples is summarized in Figure 5b. Based on the percentage of repellency observed. The fabric sample dyed with Ficus carica leaf extract in the presence of both salt and Aloe barbadensis Miller exhibited a mosquito repellency rate of 50%. Similarly, the sample dyed with eucalyptus-leaf extract under the same treatment conditions showed a repellency rate of 60%. Notably, the fabric sample dyed with a combination of Ficus carica and eucalyptus-leaf extracts, along with salt and Aloe barbadensis Miller, demonstrated the highest mosquito repellency of 70%, indicating a possible synergistic effect of the combined plant extracts. In contrast, the undyed control fabric sample displayed only 20% repellency, highlighting the significant enhancement in repellent activity imparted by the plant-based dye treatments, especially when used in conjunction with natural mordants such as salt and Aloe barbadensis Miller. These findings suggest that both Ficus carica and Eucalyptus possess inherent mosquito-repelling properties. These findings suggest that both Ficus carica and Eucalyptus possess inherent mosquito-repelling properties due to the presence of bioactive compounds such as flavonoids, terpenoids, and essential oils, which exhibit insecticidal or repellent activity against mosquitoes [34,35].

3.4. Antibacterial Assessment

Due to limited availability of sample testing in BioLab, we investigated a total of four samples including the undyed sample for better comparison. The observations presented in Table 3 clearly confirmed the antibacterial activity of the dyed cotton samples against the E. Coli in quantitative assessments. Interestingly, all three samples revealed a more than 80% reduction in bacteria after 24 h of incubation time.

Table 3.

Antibacterial assessment of dyed and undyed cotton fabrics against E. Coli (Gram-positive, spherically shaped bacterium) using AATCC test method 100.

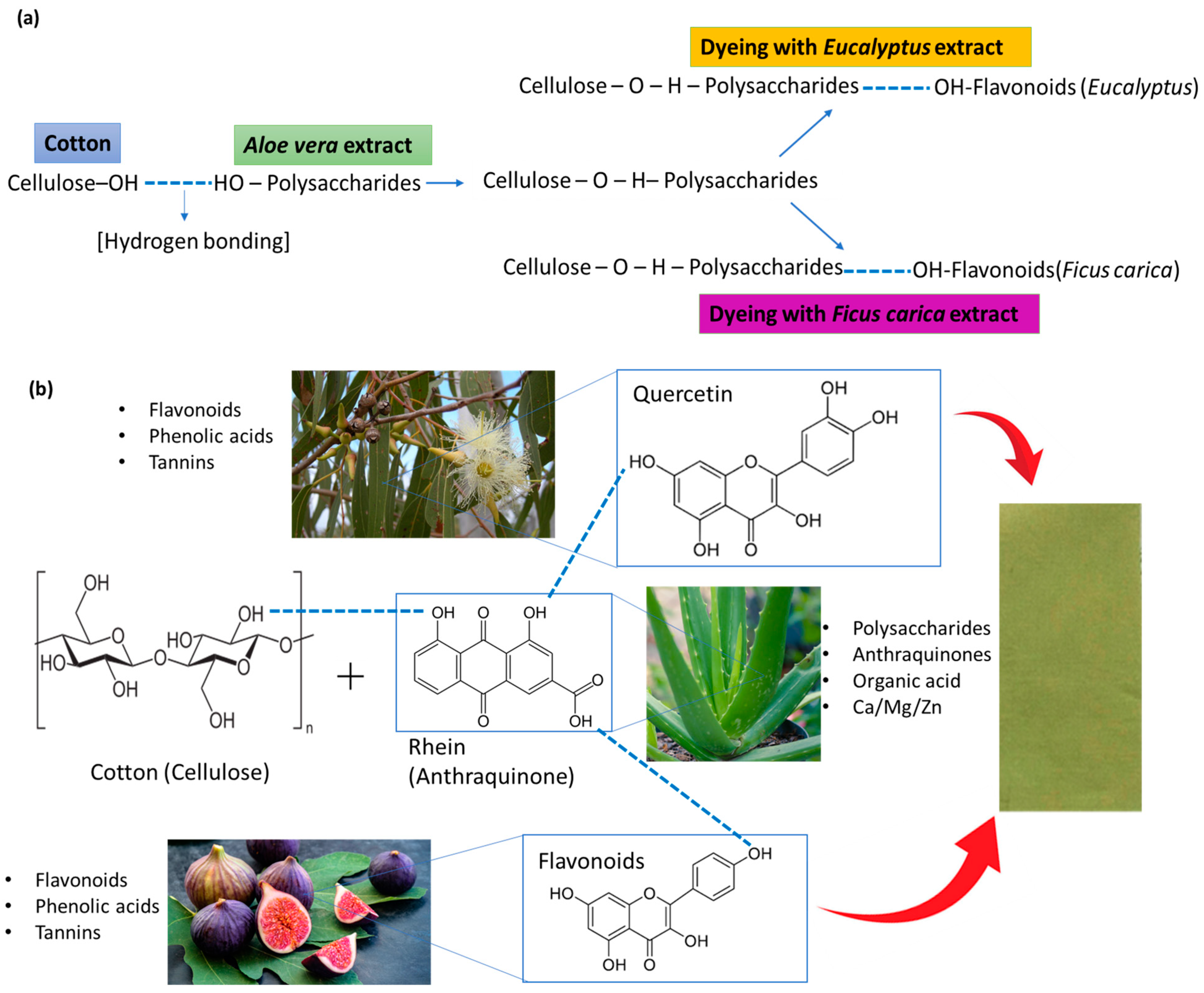

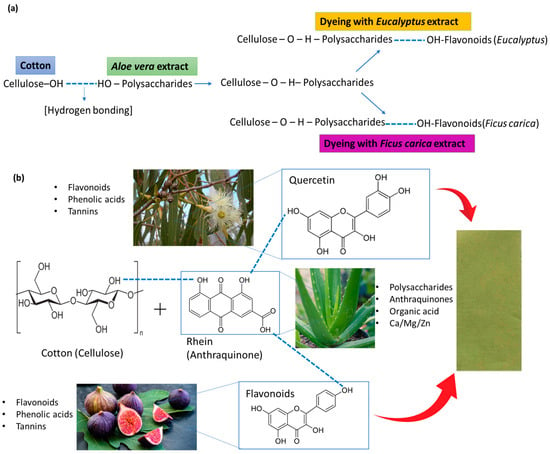

3.5. Proposed Mechanism

The chemical interaction between Ficus carica/eucalyptus extract and cotton fabric, facilitated by Aloe barbadensis Miller extract, as a natural bio-mordant, is governed by a combination of hydrogen bonding, chelation, metal–ligand coordination, and weak covalent (ester) bonding. Cotton, being a cellulose-based fiber, possesses a high density of surface hydroxyl (–OH) groups that serve as reactive sites for mordant. Aloe barbadensis Miller gel, rich in polysaccharides (such as acemannan and glucomannan), anthraquinones (including rhein, emodin, chrysophanol, and others), organic acids (e.g., citric and malic acids), and trace metal ions (like Zn2+ and Ca2+), plays a dual role: it enhances the binding of dye molecules and acts as a low-level crosslinker. The hydroxyl groups on the cotton surface readily engage in hydrogen bonding with the –OH groups of polysaccharides present in Aloe barbadensis Miller extract (as illustrated in Figure 6a). In addition, hydrogen bonding can also occur between the hydroxyl groups of cellulose and the carboxylic acid (–COOH) functional groups of anthraquinone derivatives (e.g., rhein, emodin, and chrysophanol) found in Aloe barbadensis Miller (shown in Figure 6b). These interactions not only enhance the surface reactivity of cotton but also establish a functional bridge that facilitates the subsequent attachment of natural dye molecules. Next, the Aloe barbadensis Miller’s hydroxyl and carboxyl groups form hydrogen bonds with polyphenolic compounds (such as flavonoids, carotenoids, and tannins) found in Ficus carica and eucalyptus extract, thereby enabling effective dye anchoring as shown in Figure 6. Simultaneously, upon application and mild heat treatment, carboxylic groups from Aloe barbadensis Miller can undergo esterification with the hydroxyl groups of cellulose, forming semi-permanent bonds that anchor the gel to the cotton surface. Additionally, metal ions present in the Aloe barbadensis Miller extract can form coordination complexes with these dye molecules, further strengthening the interaction. This synergistic interaction results in a dye–mordant–fiber network stabilized by hydrogen bonding, van der Waals forces, coordination bonds, and restrained ester linkages. The outcome is significantly enhanced dye uptake and improved fastness properties (to washing and light), all achieved through a sustainable, eco-friendly alternative to synthetic metallic mordants.

Figure 6.

Proposed mechanism of the interaction between (a) cotton–Aloe barbadensis Miller’s hydroxyl group–Ficus carica/eucalyptus extract and (b) cotton–Aloe barbadensis Miller’s carboxyl group–Ficus carica/eucalyptus extract.

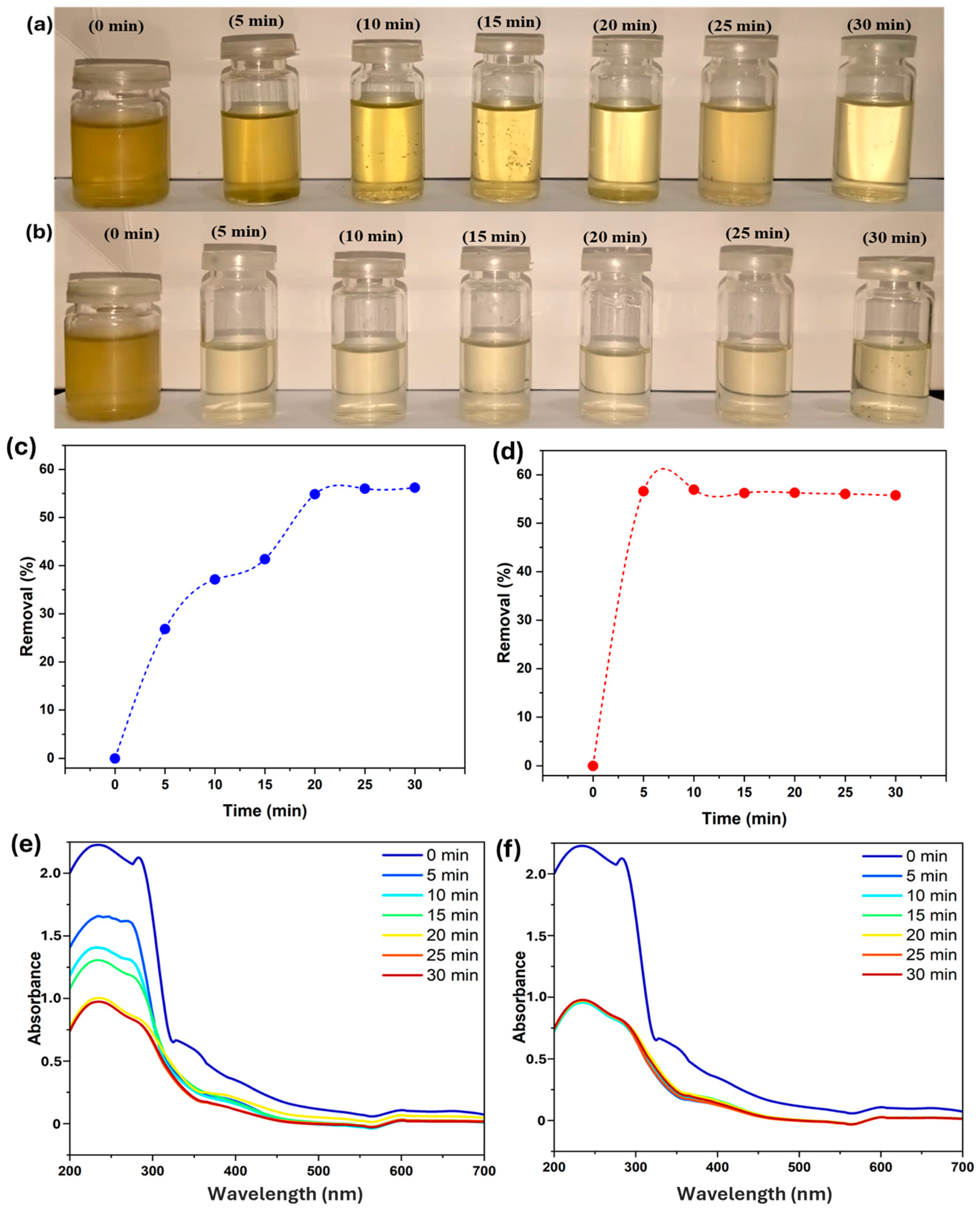

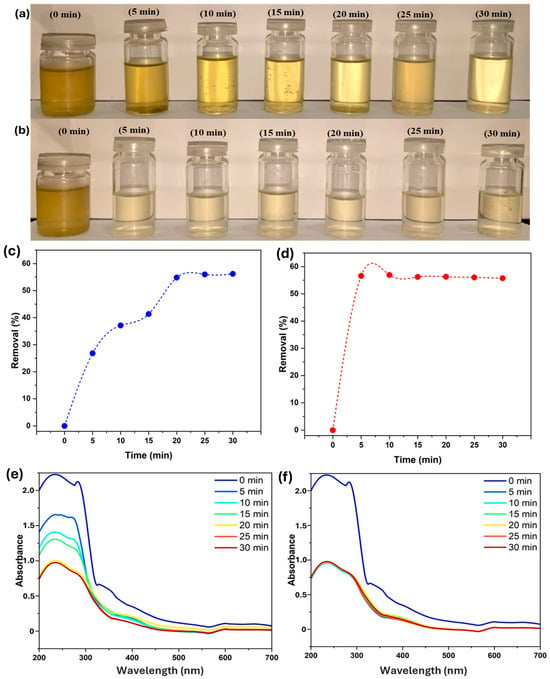

3.6. Adsorption of Extract on GO

The adsorption efficiency of Ficus carica and eucalyptus-leaf extract onto graphene oxide (GO) as a function of contact time is illustrated in Figure 7. Figure 7a,b show the samples collected at regular time intervals (5, 10, 15, 20, 25, and 30 min) during the adsorption experiments conducted using conventional (non-sonicated) and ultrasonic-assisted methods, respectively. The experimental for the batch adsorption results demonstrate a rapid increase in extract removal during the initial 20 min of exposure reaching 55% (Figure 7c). This swift uptake is primarily attributed to the abundant availability of active adsorption sites on the GO surface, which readily interact with extract molecules through mechanisms such as π–π stacking, hydrogen bonding, and electrostatic interactions. As the exposure time extends beyond 20 min, the adsorption process approaches equilibrium, with minimal changes observed over the next 10 min, ultimately reaching a maximum removal of 56%. This is due to the progressive occupation of active sites on the GO, resulting in reduced availability for further adsorption. On the other hand, the ultrasonic-assisted adsorption achieved 57% dye removal within the first 5 min (Figure 7d), significantly outperforming the conventional batch adsorption method. The removal efficiency remained constant over the next 25 min, indicating that equilibrium was attained rapidly. This accelerated adsorption can be attributed to the effect of sonication, which enhances mass transfer by disrupting the boundary layer around the adsorbent surface and promoting better diffusion of dye molecules into the active sites. The adsorption studies were confirmed by measuring UV–visible spectra after specific intervals, validating the removal efficiencies for the conventional method (Figure 7e) and ultrasonic-assisted method (Figure 7f). These findings also confirm that GO is an effective adsorbent for natural plant-based dyes, and the adsorption process is strongly time-dependent, with equilibrium typically reached within 20 min (for batch adsorption) and 5 min (for ultrasonication-assisted). As previously discussed, the release of dye molecules into aquatic systems can significantly reduce water transparency, impair light penetration, and decrease the solubility of dissolved gases such as oxygen. These changes negatively affect aquatic ecosystems by hindering photosynthetic activity and threatening the survival of aquatic organisms. Therefore, the adsorption of the remaining extract molecules onto GO was explored as a potential eco-friendly method for treating dye effluents and minimizing their environmental impact.

Figure 7.

Collection of samples at regular time intervals during the adsorption process using (a) conventional and (b) ultrasonic-assisted methods. Time-dependent removal percentage of the extract using (c) conventional and (d) ultrasonic-assisted methods. UV–visible spectra of the collected samples during treatment using (e) conventional and (f) ultrasonic-assisted methods.

4. Conclusions

This study successfully demonstrated the sustainable extraction and application of natural extracts derived from Ficus carica and Eucalyptus leaves using an aqueous method. The extracts were applied to cotton fabric through the exhaust-dyeing technique with natural mordants, Aloe barbadensis Miller and salt, which produced a variety of earthy tones including green, yellow–green, and yellowish brown. Color strength measurements (K/S values) indicated that the combination of salt and Aloe barbadensis Miller significantly enhanced dye fixation, producing deeper shades. The combination of Ficus carica and Eucalyptus with both salt and Aloe barbadensis Miller yielded the highest K/S value (5.85) for S12, confirming the synergistic effect of mordants in improving dye uptake. Washing and crocking fastness tests showed strong resistance to color loss, with grades of 4–5 on the gray scale, highlighting the durability of the dyed fabric. Moreover, mosquito repellency tests revealed that fabrics treated with both plant extracts and mordants exhibited significantly improved bioactivity. The mosquito repellency increased from 20% in untreated samples to 70% in samples dyed with Ficus carica and eucalyptus extracts in the presence of salt and Aloe barbadensis Miller. A similar trend was observed in the antibacterial activity test of dyed and undyed cotton samples. For instance, air permeability dropped from 128 cm3/cm2/s (untreated) to 112 cm3/cm2/s and 115 cm3/cm2/s for Ficus carica- and Eucalyptus-dyed fabrics, respectively. The lowest air permeability (70 cm3/cm2/s) was observed in samples dyed with a combination of both dyes and mordants, which may be due to increased surface loading and fabric compaction. In addition, the adsorption behavior of these natural dyes on graphene oxide (GO) was evaluated under ultrasonication. Equilibrium was reached at 60 min, with Eucalyptus and Ficus carica showing removal efficiencies of 77% and 71%, respectively. This confirms GO’s high adsorption potential and supports its use as an effective bio-based dye carrier or filtration material in textile wastewater treatment applications.

Overall, this research confirms that Ficus carica and Eucalyptus leaves are viable sources of natural dyes, capable of imparting durable color, enhanced mosquito repellency, and acceptable air permeability to cotton fabrics. Furthermore, their strong adsorption onto GO opens potential applications in dye purification, filtration, and reinforcing the environmental and multifunctional benefits of plant-based dyeing systems.

Author Contributions

Conceptualization, I.A.K. and K.J.; methodology, H.K., A.F. and I.A.K.; writing—original draft preparation, I.A.K.; writing—review and editing, A.K., A.F. and H.K.; supervision, K.J., visualization A.F., the project administration, resources and review of the research article K.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.-G.; Elsamahy, T.; Jiao, H.; Fu, Y.; Sun, J. A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160. [Google Scholar] [CrossRef]

- Khan, I.A.; Deen, K.M.; Asselin, E.; Yasir, M.; Sadiq, R.; Ahmad, N.M. Boosting water flux and dye removal: Advanced composite membranes incorporating functionalized AC-PAA for wastewater treatment. J. Ind. Eng. Chem. 2025, 145, 705–720. [Google Scholar] [CrossRef]

- Khan, I.A.; Ahmad, N.M. Smart membranes engineered by surface-initiated ATRP polymer-grafting of carbon nanotubes and analyzed with RSM modelling. Emergent Mater. 2024, 8, 1–15. [Google Scholar] [CrossRef]

- Khatri, A.; Peerzada, M.H.; Mohsin, M.; White, M. A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. J. Clean. Prod. 2015, 87, 50–57. [Google Scholar] [CrossRef]

- Xu, C.; Yu, H.; Zhang, S.; Shen, C.; Ma, C.; Wang, J.; Li, F. Cleaner production evaluation system for textile industry: An empirical study from LCA perspectives. Sci. Total Environ. 2024, 913, 169632. [Google Scholar] [CrossRef] [PubMed]

- Alegbe, E.O.; Uthman, T.O. A review of history, properties, classification, applications and challenges of natural and synthetic dyes. Heliyon 2024, 10, e33646. [Google Scholar] [CrossRef]

- Baaka, N.; Haddar, W.; Ticha, M.B.; Mhenni, M.F. Eco-friendly dyeing of modified cotton fabrics with grape pomace colorant: Optimization using full factorial design approach. J. Nat. Fibers 2019, 16, 652–661. [Google Scholar] [CrossRef]

- Hussain, T.; Arain, M.F.; Khan, I.A.; Javed, K.; Khan, H.; Ahmed, A.; Khan, A. Recycling orange waste for the sustainable dyeing of polyester fabric. J. Indian Chem. Soc. 2024, 101, 101293. [Google Scholar] [CrossRef]

- Santiago, D.; Cunha, J.; Cabral, I. Chromatic and medicinal properties of six natural textile dyes: A review of eucalyptus, weld, madder, annatto, indigo and woad. Heliyon 2023, 9, e22013. [Google Scholar] [CrossRef]

- Miranda, B.M.; Junior, O.V.; Fernandes, S.S.; Lemos, G.R.M.; Schwan, C.L.; Aliaño-González, M.J.; Barbero, G.F.; Otero, D.M. Potential of New Plant Sources as Raw Materials for Obtaining Natural Pigments/Dyes. Agronomy 2025, 15, 405. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, Y.Q.; Yan, K.; Long, J.J. Synthesis of a Novel Disperse Reactive Dye Involving a Versatile Bridge Group for the Sustainable Coloration of Natural Fibers in Supercritical Carbon Dioxide. Adv. Sci. 2019, 6, 1801368. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, H.; Rehman, T.; Shehzad, H.; Aslam, M.; Ahymed, I.; Fatima, M.; Ali, A. Hepatoprotective activity of fruit and leaf extracts of Ficus carica and Ficus benghalensis in experimental rats. J. Anim. Plant Sci. 2024, 34, 168–176. [Google Scholar] [CrossRef]

- Shiraishi, C.S.H.; Zbiss, Y.; Roriz, C.L.; Dias, M.I.; Prieto, M.A.; Calhelha, R.C.; Alves, M.J.; Heleno, S.A.; V., d.C.M.; Carocho, M.; et al. Fig Leaves (Ficus carica L.): Source of Bioactive Ingredients for Industrial Valorization. Processes 2023, 11, 1179. [Google Scholar] [CrossRef]

- Endris, J.; Govindan, N. Dyeing and finishing of cotton fabric with eucalyptus leaves extracts. Res. J. Text. Appar. 2021, 25, 193–208. [Google Scholar] [CrossRef]

- Pizzicato, B.; Pacifico, S.; Cayuela, D.; Mijas, G.; Riba-Moliner, M. Advancements in Sustainable Natural Dyes for Textile Applications: A Review. Molecules 2023, 28, 5954. [Google Scholar] [CrossRef]

- Benli, H. Bio-mordants: A review. Environ. Sci. Pollut. Res. 2024, 31, 20714–20771. [Google Scholar] [CrossRef]

- Canche-Escamilla, G.; Colli-Acevedo, P.; Borges-Argaez, R.; Quintana-Owen, P.; May-Crespo, J.F.; Cáceres-Farfan, M.; Puc, J.A.Y.; Sansores-Peraza, P.; Vera-Ku, B.M. Extraction of phenolic components from an Aloe barbadensis Miller (Aloe barbadensis Miller) crop and their potential as antimicrobials and textile dyes. Sustain. Chem. Pharm. 2019, 14, 100168. [Google Scholar] [CrossRef]

- El-Sayed, G.; Diaa, M.; Hassabo, A. Potential Uses of Aloe barbadensis Miller Extract in Textile Wet Process. J. Text. Color. Polym. Sci. 2021, 18, 159–169. [Google Scholar] [CrossRef]

- Rehman, A.; Rehman, M.U.; Naveed, M.; Javed, K.; Khan, A. Eco-friendly dyeing of cotton with natural colorants using natural mordants obtained from Aloe barbadensis Miller. J. Indian Chem. Soc. 2024, 101, 101182. [Google Scholar] [CrossRef]

- Alzahrani, M.Y.; Alshaikhi, A.I.; Hazzazi, J.S.; Kurdi, J.R.; Ramadan, M.F. Recent insight on nutritional value, active phytochemicals, and health-enhancing characteristics of fig (Ficus craica). Food Saf. Health 2024, 2, 179–195. [Google Scholar] [CrossRef]

- Salim, A.; Abbas, M.A.; Khan, I.A.; Khan, M.Z.; Javaid, F.; Mushtaq, S.; Batool, M.; Yasir, M.; Khan, A.L.; Khan, A.U.; et al. Graphene oxide incorporated polyether sulfone nanocomposite antifouling ultrafiltration membranes with enhanced hydrophilicity. Mater. Res. Express 2022, 9, 075503. [Google Scholar] [CrossRef]

- Khan, I.A.; Khan, A.U.; Deen, K.M.; Asselin, E.; Sadiq, R.; Yasir, M.; Ahmad, N.M. Ultrasonic assisted removal of methyl orange and bovine serum albumin from wastewater using modified activated carbons: RSM optimization and reusability. Mater. Res. Express 2024, 11, 095505. [Google Scholar] [CrossRef]

- Almas, I.; Innocent, E.; Machumi, F.; Kisinza, W. Chemical composition of essential oils from Eucalyptus globulus and Eucalyptus maculata grown in Tanzania. Sci. Afr. 2021, 12, e00758. [Google Scholar] [CrossRef]

- Mosaad, M.M. New approaches of utilization Aloe barbadensis Miller in wet processing of textiles. Egypt. J. Chem. 2021, 64, 5387–5396. [Google Scholar] [CrossRef]

- ISO 105-X12; Textiles—Tests for Colour Fastness—Part X12: Colour Fastness To Rubbing. International Organization for Standardization: Geneva, Switzerland, 2016.

- Jiang, H.; Hu, X.; Meena, B.I.; Khan, A.; Hussain, M.T.; Yao, J.; Wang, J. Extraction of natural dyes from the stem of Caulis spatholobi and their application on wool. Text. Res. J. 2019, 89, 5209–5217. [Google Scholar] [CrossRef]

- ISO 105-C01; Textiles—Tests for Colour Fastness—Part C01: Colour Fastness to Washing. International Organization for Standardization: Geneva, Switzerland, 2006.

- Al Parvez, A.; Hossain, J.; Hossain, Z.; Sohan, M.S.H.; Hoque, F.; Ahsan, H.; Hoque, S. Mosquito repellent fabric: Development and characterization of peppermint and garlic mixture finish on knitted fabric to examine mosquito repellency. Heliyon 2023, 9, e15944. [Google Scholar] [CrossRef]

- Rastogi, D.; Jain, A.; Negi, A. Development of Mosquito Repellent Finish for Textiles Using Neem Oil: An Eco-Friendly Approach. In Sustainable Approaches in Textiles and Fashion. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Singapore, 2022; pp. 183–195. [Google Scholar] [CrossRef]

- Mondal, M.I.H.; Saha, J.; Rahman, M.A. Functional Applications of Aloe barbadensis Miller on Textiles: A Review. J. Polym. Environ. 2021, 29, 993–1009. [Google Scholar] [CrossRef]

- Burkinshaw, S.M. The role of inorganic electrolyte (salt) in cellulosic fibre dyeing: Part 2 theories of how inorganic electrolyte promotes dye uptake. Color. Technol. 2021, 137, 547–586. [Google Scholar] [CrossRef]

- Kumpikaitė, E.; Laureckienė, G.; Milašienė, D.; Petraitienė, S. Investigation of the Shrinkage and Air Permeability of Woolen Blankets and Blankets Made with Regenerated Wool. Materials 2022, 15, 3596. [Google Scholar] [CrossRef]

- Khan, A.; Ahmad, S.; Amjad, A.; Khan, I.A.; Ibraheem, W. Development of a Statistical Model for Predicting the Dimensional Stability of Socks during Wet Processing. J. Text. Sci. Eng. 2017, 7, 1000304. [Google Scholar] [CrossRef]

- Demirak, M.Ş.Ş.; Canpolat, E. Plant-Based Bioinsecticides for Mosquito Control: Impact on Insecticide Resistance and Disease Transmission. Insects 2022, 13, 162. [Google Scholar] [CrossRef]

- Adeyemi, A.D.; Oluigbo, C.C.; Esan, A.O.; Bello, M.O.; Oladoye, S.O.; Emmanuel, C.P.; Effiong, E. Chemical composition and antimicrobial activity of the essential oils of 14 known ficus species—A concise review. Biointerface Res. Appl. Chem. 2022, 12, 8003–8034. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).