Model for Assessing Efficiency of Processing Geo-Resources, Providing Full Cycle for Development—Case Study in Russia

Abstract

1. Introduction

- Disturbance of the stress–strain state under the weight of the industrial mass, which causes changes in the hydrogeological regime [20].

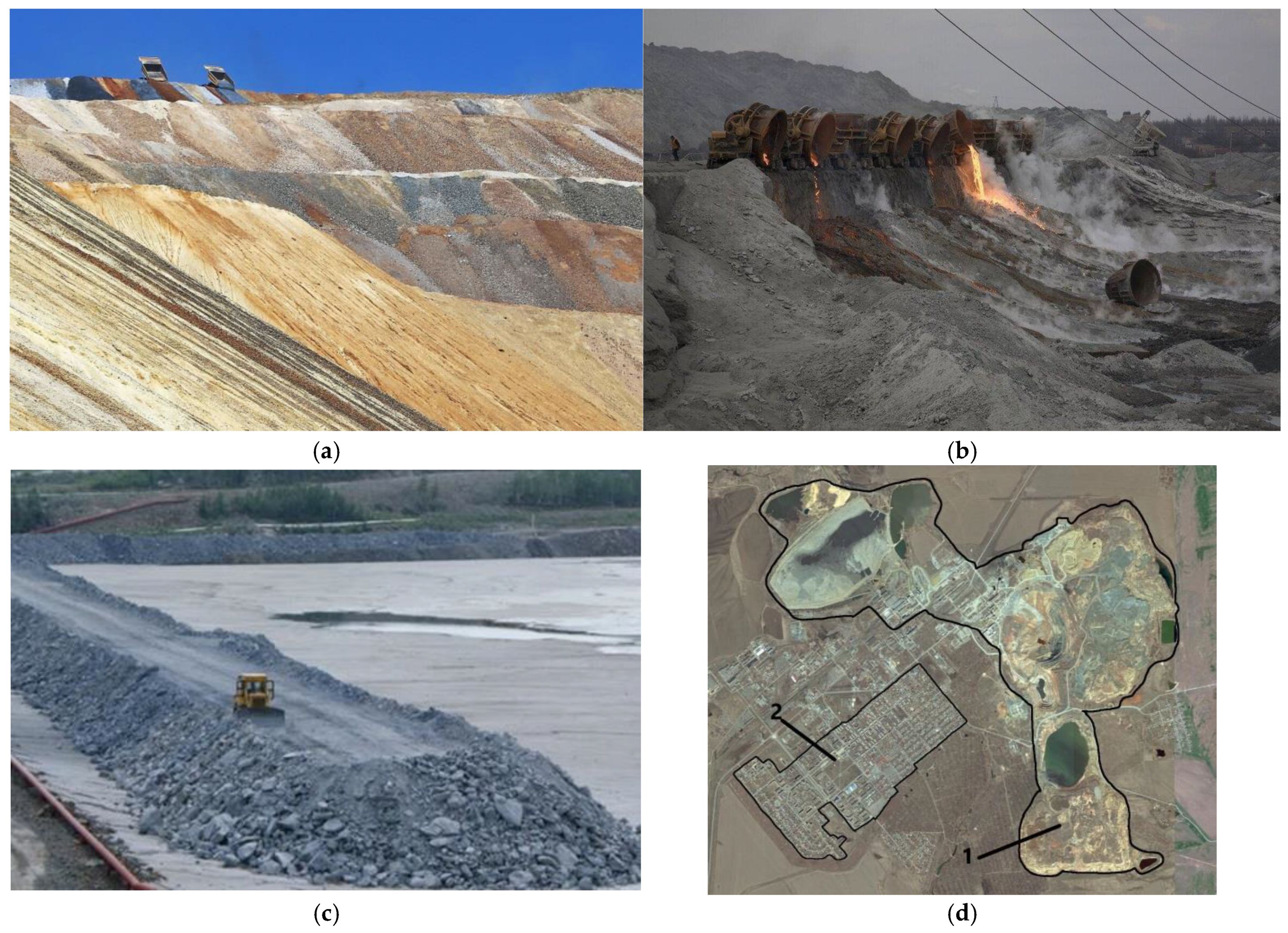

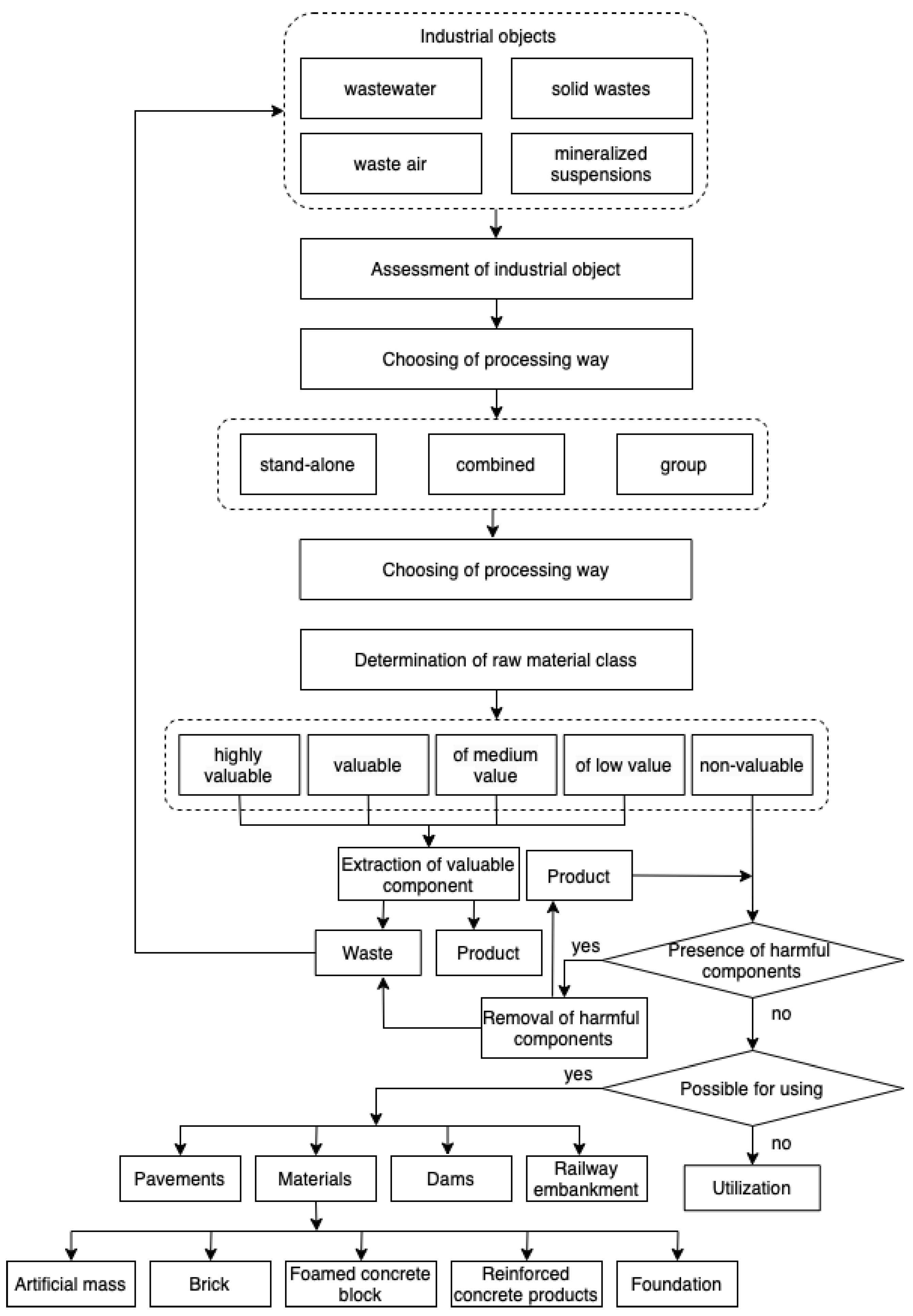

2. Materials and Methods

- The utilization of substandard ores and rocks from stripping and drivage operations;

- The utilization of tailings and metallurgical slags;

- Wastewater treatment;

- Waste air treatment;

- The reuse of mine workings and pit space.

- The mining of out-of-balance or low-grade ores;

- The mining of ores located in the subsurface or dumps of complex material composition;

- The extraction of valuable components from industrial waste to a zero level;

- A reduction in harmful components in industrial waste to sanitary norms;

- The extraction of valuable components from wastewater;

- The extraction of valuable components from electromelting dust;

- The use of “cleaned” industrial waste in various industrial sectors;

- The use of “cleaned” industrial waste in a closed cycle of mining production.

- An increase in the demand for mined mineral raw materials and in the consumption of raw material products;

- The depletion of the mineral resource base of the mining enterprise and mineral deposits;

- A sharp increase in industrial waste, which leads to an increase in the negative environmental impact of both the formations themselves and the mining industry as a whole.

- The globalization of the economy and increased competition in the international market;

- Condition reduction through the introduction of innovative technologies for the extraction of valuable components;

- The need for workplaces during the closure of mining town-forming enterprises.

- Considering industrial formations and systematizing them, preliminarily defining unified assessment criteria;

- Assessing the material and chemical–physical composition of industrial masses (the presence/absence of valuable, associated, and harmful components);

- Identifying possibilities for the commercial and economic utilization of industrial waste;

- Performing process mapping;

- Developing and implementing technology for the comprehensive exploitation of industrial geo-resources and the extraction of valuable components with subsequent involvement in a closed cycle or manufacturing;

- Developing technical and organizational schemes and logistic flows of the comprehensive exploitation of industrial resources;

- Identifying the main criteria for assessing the economic and environmental efficiency of the proposed technology, involving industrial waste in processing and utilization;

- Developing an economic and mathematical model for assessing the efficiency of the comprehensive exploitation of industrial waste;

- Proposing an option for the rational and effective use of “cleaned” industrial waste or a method for its utilization.

3. Results and Discussion

3.1. Factors for Assessing the Efficiency of Industrial Geo-Resource Recycling

- The development and implementation of economically feasible technologies for the extraction of valuable components from industrial raw materials;

- The search for efficient solvents that will ensure the selective transformation and ion intensity of the valuable components in the pregnant leach solution;

- The creation of prototype installations that facilitate the extraction of valuable components from industrial geo-resources, their production testing, and their industrial implementation;

- The direct recycling of industrial raw materials and extraction of valuable components;

- Logistics costs regarding the storage location or shipment to the customer.

- Profits from the sale of additional valuable raw materials;

- A reduction in or even the elimination of costs for the placement and maintenance of industrial masses;

- The elimination of reclamation costs;

- A reduction in rent payments (land seizure, etc.);

- A reduction in expenses for the purchase of backfill components, etc.

- Minimal total costs of major capital investments and additional costs of the recycling and utilization of industrial geo-resources;

- Environmental requirements of production (minimum environmental impact);

- Obligatory positive economic effects.

- The total volume of industrial geo-resources stored in tailings ponds, dumps, etc.;

- The total volume of industrial geo-resources that is technically feasible to recycle and economically valuable;

- The availability and degree of operational readiness of industrial objects;

- The amounts of different types of valuable components expected to be recovered in the process of industrial geo-resource recycling;

- The total annual volume of industrial mass intended for recycling and utilization;

- The extraction ratios of separate valuable components;

- The need to remove harmful components;

- The possibility of the subsequent use of “cleaned” raw materials in a closed production cycle or the manufacturing of additional products.

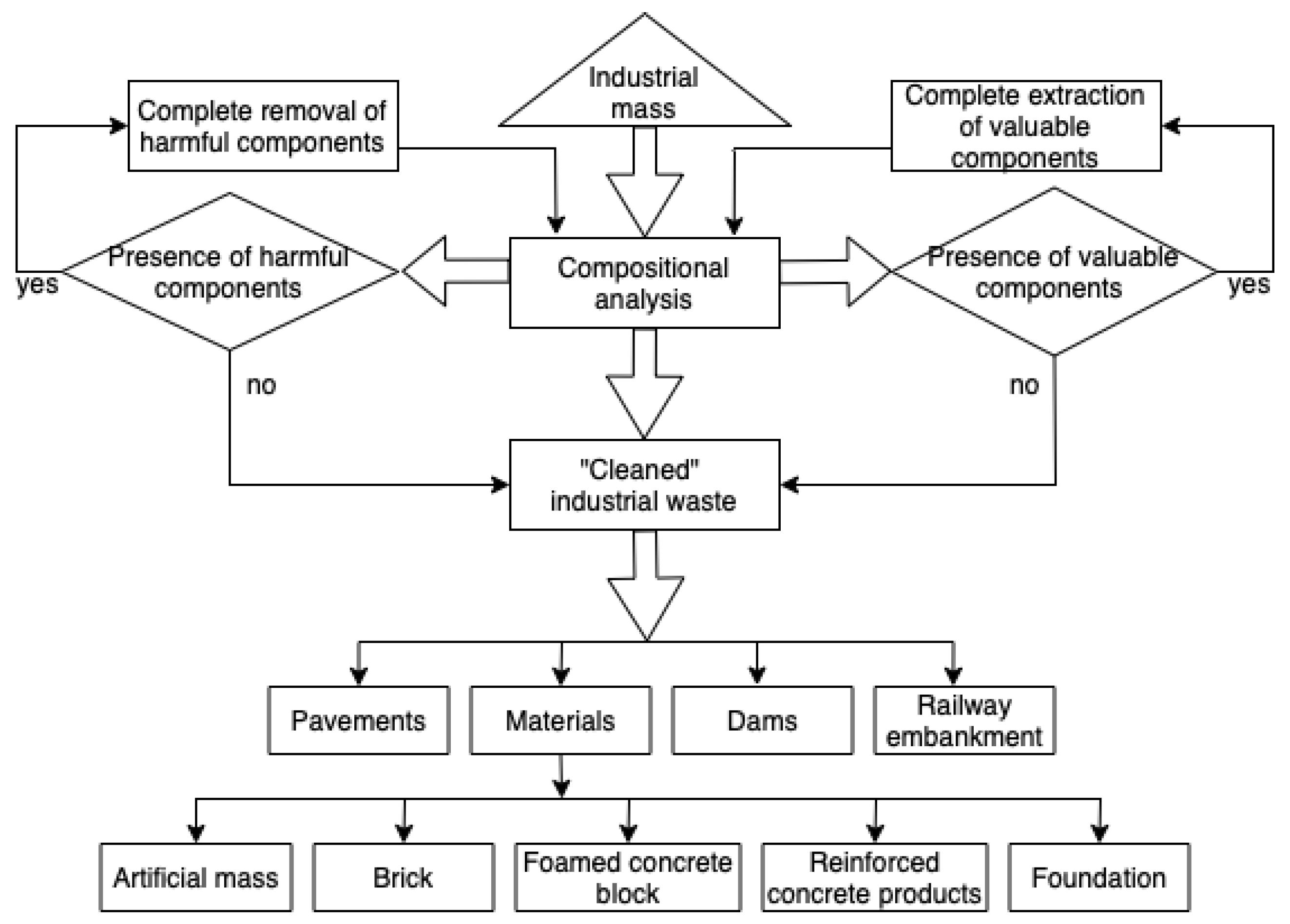

3.2. Assessment of Production Efficiency of Industrial Geo-Resources’ Involvement in a Closed Waste-Free (Low-Waste) Cycle

- The assessment of the chemical and material composition of industrial raw materials;

- Analyzing the content of harmful components in industrial raw materials for their subsequent reduction to sanitary norms;

- Analyzing the content of valuable components in industrial raw materials for the assessment of the technical and economic feasibility of their extraction;

- The assessment of the possibility of the subsequent use of “cleaned” industrial raw materials or their safe utilization.

3.3. Model of Environmental and Economic Assessment of Efficiency of Industrial Waste Recycling

3.4. Economic Efficiency of Industrial Geo-Resources’ Exploitation in the Example of Tailings of the Ural Mining and Metallurgical Company

- Backfill,

- Construction material,

- Pavement,

- Embankments for dams, roads, railways, etc.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, N.; Shi, B.; Kang, R. Analysis of the coupling effect and space-time difference between China’s digital economy development and carbon emissions reduction. Int. J. Environ. Res. Public Health 2023, 20, 872. [Google Scholar] [CrossRef]

- Adigamov, A.E.; Yudenkov, A.V.; Noginova, L.Y. Generalized mathematical model of the main problems of the elasticity theory for anisotropic bodies. Sustain. Dev. Mt. Territ. 2024, 16, 358–367. [Google Scholar] [CrossRef]

- Zubov, V.P.; Trofimov, A.V.; Kolganov, A.V. Influence of ground control features on indicators of dilution in mines of the Talanakh ore province. MIAB Min. Inf. Anal. Bull. 2024, 12, 87–106. [Google Scholar]

- Oliveira, M.L.S.; Valença, G.O.; Pinto, D.; Moro, L.D.; Bodah, B.W.; de Vargas Mores, G.; Grub, J.; Adelodun, B.; Neckel, A. Hazardous Elements in Sediments Detected in Former Decommissioned Coal Mining Areas in Colombia: A Need for Environmental Recovery. Sustainability 2023, 15, 8361. [Google Scholar] [CrossRef]

- Tost, M.; Ammerer, G.; Kot-Niewiadomska, A.; Gugerell, K. Mining and Europe’s World Heritage Cultural Landscapes. Resources 2021, 10, 18. [Google Scholar] [CrossRef]

- Tyulyaeva, Y.S.; Khayrutdinov, A.M.; Gorelkina, E.I. Increasing Classification of georesources in the paradigm of their integrated development. Russ. Min. Ind. 2024, 6, 140–143. [Google Scholar] [CrossRef]

- Öhlander, B.; Chatwin, T.; Alakangas, L. Management of Sulfide-Bearing Waste, a Challenge for the Mining Industry. Minerals 2012, 2, 1–10. [Google Scholar] [CrossRef]

- Jastrzębska, M.; Kazimierowicz-Frankowska, K.; Chiaro, G.; Rybak, J. New Frontiers in Sustainable Geotechnics. Appl. Sci. 2023, 13, 562. [Google Scholar] [CrossRef]

- Nikitin, V.I. Mathematical modeling of drilling fluid filter penetration into the bottom-hole of formation taking into account oil viscoplastic properties. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2023, 334, 130–137. [Google Scholar] [CrossRef]

- Agafonov, Y.G.; Dudchenko, O.L.; Fedorov, G.B. Infrasonic methods and technology: Innovative approach to intensify mining practices. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2014, 2, 99–104. [Google Scholar]

- Alieva, L.; Zhukov, I.A. Upgrading rotary-percussion drilling of high-strength rocks by improving the structure of a rock-crushing blade-free tool. Sustain. Dev. Mt. Territ. 2024, 16, 1681–1694. [Google Scholar]

- Aleksandrova, T.N.; Kuznetsov, V.V.; Prokhorova, E.O. Investigation of Interfacial Characteristics as a Key Aspect of the Justification of the Reagent Regime for Coal Flotation. Minerals 2025, 15, 76. [Google Scholar] [CrossRef]

- Bacova, D.; Khairutdinov, A.M.; Gago, F. Cosmic geodesy contribution to geodynamics monitoring. IOP Conf. Ser. Earth Environ. Sci. 2021, 906, 012074. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B. Influence of mine water on the strength of artificial mass based on industrial waste. Ugol 2024, 12, 75–78. [Google Scholar]

- Korshak, A.A.; Pshenin, V.V. Modeling of Water Slug Removal from Oil Pipelines by Methods of Computational Fluid Dynamics. Neft. Khozyaystvo—Oil Ind. 2023, 10, 117–122. [Google Scholar] [CrossRef]

- Gendler, S.G.; Kryukova, M.S.; Alferova, E.L. Investigation of thermodynamic parameters of the air environment in subway lines with single-track and double-track tunnels. Min. Sci. Technol. 2024, 9, 250–262. [Google Scholar] [CrossRef]

- Repin, S.V.; Afanasyev, A.S.; Dobromirov, V.N.; Barsukov, V.O. Innovative method for disposal of waste of monolithic building structures. Sustain. Dev. Mt. Territ. 2023, 15, 771–783. [Google Scholar] [CrossRef]

- Rodríguez-Pacheco, R.; García, G.; Caparrós-Ríos, A.V.; Robles-Arenas, V.; García-García, C.; Millán, R.; Pérez-Sanz, A.; Alcolea-Rubio, L.A. Mineralogy, Geochemistry and Environmental Hazards of Different Types of Mining Waste from a Former Mediterranean Metal Mining Area. Land 2023, 12, 499. [Google Scholar] [CrossRef]

- Woźniak, J.; Pactwa, K. Overview of Polish Mining Wastes with Circular Economy Model and Its Comparison with Other Wastes. Sustainability 2018, 10, 3994. [Google Scholar] [CrossRef]

- Carmo, F.F.; Lanchotti, A.O.; Kamino, L.H.Y. Mining Waste Challenges: Environmental Risks of Gigatons of Mud, Dust and Sediment in Megadiverse Regions in Brazil. Sustainability 2020, 12, 8466. [Google Scholar] [CrossRef]

- Klyuev, R.V.; Martyushev, N.V.; Kukartsev, V.V.; Kukartsev, V.A.; Brigida, V. Analysis of geological information toward sustainable performance of geotechnical systems. MIAB Min. Informational Anal. Bull. 2024, 5, 144–157. [Google Scholar] [CrossRef]

- Huang, J.; Tian, C.; Xing, L.; Bian, Z.; Miao, X. Green and Sustainable Mining: Underground Coal Mine Fully Mechanized Solid Dense Stowing-Mining Method. Sustainability 2017, 9, 1418. [Google Scholar] [CrossRef]

- Ayuk, E.T.; Pedro, A.M.; Ekins, P.; Gatune, J.; Milligan, B.; Oberle, B.; Christmann, P.; Ali, S.; Kumar, S.V.; Bringezu, S.; et al. Mineral Resource Governance in the 21st Century: Gearing Extractive Industries Towards Sustainable Development; A Report by the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2019; Available online: http://www.resourcepanel.org/reports (accessed on 13 March 2025).

- European Commission. Best Available Techniques (BAT) Reference Document for the Management of Waste from Extractive Industries, in Accordance with Directive 2006/21/EC; JRC109657; EUR 28963 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-77178-1. [Google Scholar] [CrossRef]

- Directorate-General for Environment; Van Keer, I.; Laenen, B.; Bronders, J.; Lagrou, D.; Campling, P.; Maraboutis, P.; Poulimenou, N.; Hebestreit, C.; Drielsma, J.; et al. Study Supporting the Development of General Guidance on the Implementation of the Extractive Waste Directive–Final Report; Publications Office of the European Union: Luxembourg, 2021; Available online: https://data.europa.eu/doi/10.2779/147984 (accessed on 13 March 2025).

- Hamilton, C.; Hutchison, I.; Trimble, R.; Slate, B.; Zyl, D.V. Guidelines for Mine Waste Management Facilities. 2023. Available online: https://yukon.ca/sites/default/files/emr/emr-guidelines-mine-waste-management-facilities.pdf (accessed on 13 March 2025).

- Khalil, A.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Applied Methodological Approach for the Assessment of Soil Contamination by Trace Elements around Abandoned Coal Mines—A Case Study of the Jerada Coal Mine, Morocco. Minerals 2023, 13, 181. [Google Scholar] [CrossRef]

- Bučinskas, A. Proposal for Feasibility Assessment Model for Landfill Mining and Its Implementation for Energy Generation Scenarios. Sustainability 2018, 10, 2882. [Google Scholar] [CrossRef]

- Avksentiev, S.Y.; Semenov, P.A.; Afanasyev, A.S. Comprehensive solutions for tailings management at the Usolsky potash plant. Sustain. Dev. Mt. Territ. 2024, 16, 7–18. [Google Scholar] [CrossRef]

- Goncharenko, S.N.; Lachihina, A.B. Modeling protected geological and geotechnical information system in mining industry. Mining Inf. Anal. Bull. 2023, 6, 39–55. [Google Scholar] [CrossRef]

- Padró, J.-C.; Cardozo, J.; Montero, P.; Ruiz-Carulla, R.; Alcañiz, J.M.; Serra, D.; Carabassa, V. Drone-Based Identification of Erosive Processes in Open-Pit Mining Restored Areas. Land 2022, 11, 212. [Google Scholar] [CrossRef]

- Zotov, V.V.; Mnatsakanyan, V.U.; Bazlin, M.M.; Lakshinsky, V.S.; Dyatlova, E.V. Extending the service life of centrifugal dewatering pump impellers in mines. Gorn. Promyshlennost 2024, 2, 143–146. [Google Scholar] [CrossRef]

- Sekhohola-Dlamini, L.M.; Keshinro, O.M.; Masudi, W.L.; Cowan, A.K. Elaboration of a Phytoremediation Strategy for Successful and Sustainable Rehabilitation of Disturbed and Degraded Land. Minerals 2022, 12, 111. [Google Scholar] [CrossRef]

- Guéablé, Y.K.D.; Bezrhoud, Y.; Moulay, H.; Moughli, L.; Hafidi, M.; El Gharouss, M.; El Mejahed, K. New Approach for Mining Site Reclamation Using Alternative Substrate Based on Phosphate Industry By-Product and Sludge Mixture. Sustainability 2021, 13, 10751. [Google Scholar] [CrossRef]

- Koval, V.; Kryshtal, H.; Udovychenko, V.; Soloviova, O.; Froter, O.; Kokorina, V.; Veretin, L. Review of mineral resource management in a circular economy infrastructure. Min. Miner. Depos. 2023, 17, 61–70. [Google Scholar] [CrossRef]

- Upadhyay, A.; Laing, T.; Kumar, V.; Dora, M. Exploring barriers and drivers to the implementation of circular economy practices in the mining industry. Resour. Policy 2021, 72, 102037. [Google Scholar] [CrossRef]

- Bakesheva, A.T.; Fetisov, V.G.; Pshenin, V.V. A refined algorithm for leak location in gas pipelines with determination of quantitative parameters. Int. J. Eng. Res. Technol. 2019, 12, 2867–2869. [Google Scholar]

- Tyulyaeva, Y.S.; Khayrutdinov, A.M.; Galachieva, I.D.; Totrukova, I.K. Creation of a high-strength backfill composite based on sulfide-bearing technogenic waste from mining production. Sustain. Dev. Mt. Territ. 2024, 16, 1384–1396. [Google Scholar] [CrossRef]

- Golik, V.I.; Gashimova, Z.A.; Liskova, M.Y.; Kongar-Syuryun, C.B. To the problem of minimizing the volume of mobile dust in the development of pits. Bezop. Tr. V Promyshlennosti 2021, 11, 28–33. [Google Scholar] [CrossRef]

- Zglinicki, K. Critical Minerals from Post-Processing Tailing. A Case Study from Bangka Island, Indonesia. Minerals 2021, 11, 352. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Malashkevych, D.; Bulat, I.; Popovych, V.; Sai, K. Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Min. Miner. Depos. 2021, 15, 122–129. [Google Scholar] [CrossRef]

- Maksarov, V.V.; Minin, A.O.; Vasilkov, D.V. The use of high-frequency wave action as part of the process to ensure the quality of boring surfaces in products made of corrosion-resistant aluminum alloys. Tsvetnye Met. 2025, 1, 76–83. [Google Scholar] [CrossRef]

- Kovalskiy, E.R.; Kongar-Syuryun, C.B.; Sirenko, Y.G.; Mironov, N.A. Modeling of rheological deformation processes for room and pillar mining at the Verkhnekamsk potash salt deposit. Sustain. Dev. Mt. Territ. 2024, 16, 1017–1030. [Google Scholar] [CrossRef]

- de Carvalho, F.A.; Nobre, J.N.P.; Cambraia, R.P.; Silva, A.C.; Fabris, J.D.; dos Reis, A.B.; Prat, B.V. Quartz Mining Waste for Concrete Production: Environment and Public Health. Sustainability 2022, 14, 389. [Google Scholar] [CrossRef]

- Tyulyaeva, Y.S.; Khayrutdinov, A.M. Creation of a backfill composite based on coal industry waste. Ugol 2024, 10, 24–27. [Google Scholar]

- Petlovanyi, M.; Sai, K. Research into cemented paste backfill properties and options for its application: Case study from a Kryvyi Rih Iron-ore Basin, Ukraine. Min. Miner. Depos. 2024, 18, 162–179. [Google Scholar] [CrossRef]

- Bazaluk, O.; Petlovanyi, M.; Sai, K.; Chebanov, M.; Lozynskyi, V. Comprehensive assessment of the earth’s surface state disturbed by mining and ways to improve the situation: Case study of Kryvyi Rih Iron-ore Basin, Ukraine. Front. Environ. Sci. 2024, 12, 1480344. [Google Scholar] [CrossRef]

- Safiullin, R.N.; Afanasyev, A.S. Integrated assessment of methods for calculating harm caused by vehicles in transport of heavy cargoes. IOP Conf. Ser. Earth Environ. Sci. 2018, 194, 072011. [Google Scholar] [CrossRef]

- Khalifa, A.A.; Bazhin, V.Y.; Vadimovna, K.Y.; Abdelrahim, A.; Ahmed, Y.M.Z. Study the recycling of red mud in iron ore sintering process. J. Ecol. Eng. 2021, 22, 191–201. [Google Scholar] [CrossRef]

- Egoshin, A.M.; Afanasyev, A.S.; Alekseev, S.V. Procedure of mineral delivery system selection based on economic analysis of alternatives. MIAB Min. Inf. Anal. Bull. 2024, 6, 135–148. [Google Scholar] [CrossRef]

- Ministry of Natural Resources and Environment of the Russia. Order of the Ministry of Natural Resources and Environment of Russia No. 581 dated 11.08.2020 ‘On Approval of the Methodology for the Development (Calculation) and Establishment of Standards for Permissible Emissions of Pollutants into the Atmospheric Air; Ministry of Natural Resources and Environment of the Russia: Moscow, Russia, 2020.

- Ministry of Natural Resources and Environment of the Russia. Order of the Ministry of Natural Resources and Environment of Russia No. 22-r Dated 28.06.2021 ‘List of Methods for Calculating Emissions of Harmful (Polluting) Substances into the Atmospheric Air by Stationary Sources’; Ministry of Natural Resources and Environment of the Russia: Moscow, Russia, 2021.

- Ministry of Natural Resources and Environment of the Russian Federatio. Order of the Ministry of Natural Resources and Environment of the Russian Federation No. 238 Dated 8 July 2010 ‘On Approval of the Methodology for Calculating the Amount of Damage Caused to Soils as an Object of Environmental Protection’; Ministry of Natural Resources and Environment of the Russian Federation: Moscow, Russia, 2010.

- Emelyanova, V.P.; Lobchenko, E.E. Method of Complex Assessment of Surface Water Pollution Degree by Hydrochemical Indicators; Gidrometeoizdat: Rostov on Don, Russia; Hydrometeoizdat: Saint Petersburg, Russia, 2022; 55p. [Google Scholar]

- Kaung, P.A.; Zotov, V.V.; Gadzhiev, M.A.; Artemov, S.I.; Gireev, I.A. Formalization of selection procedure of mineral mining technologies. MIAB Min. Inf. Anal. Bull. 2022, 2, 124–138. [Google Scholar] [CrossRef]

- Alekseenko, A.V.; Drebenstedt, C.; Bech, J. Assessment and abatement of the eco-risk caused by mine spoils in the dry subtropical climate. Environ. Geochem. Health 2022, 44, 1581–1603. [Google Scholar] [CrossRef]

- Brigida, V.; Golik, V.I.; Voitovich, E.V.; Kukartsev, V.V.; Gozbenko, V.E.; Konyukhov, V.Y.; Oparina, T.A. Technogenic Reservoirs Resources of Mine Methane When Implementing the Circular Waste Management Concept. Resources 2024, 13, 33. [Google Scholar] [CrossRef]

- Kazanin, O.I.; Sidorenko, A.A.; Evsiukova, A.A.; Liu, Z. Justification of the longwall panel entries support technology when mining gently inclined coal seams at large depths. MIAB Min. Inf. Anal. Bull. 2023, 9, 5–21. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Evaluations of existing waste recycling methods: A Hong Kong study. Build. Environ. 2006, 41, 1649–1660. [Google Scholar] [CrossRef]

- Sobierajewicz, P.; Adamczyk, J.; Dylewski, R. Ecological and Economic Assessment of the Reuse of Steel Halls in Terms of LCA. Appl. Sci. 2023, 13, 1597. [Google Scholar] [CrossRef]

- Nevskaya, M.; Seleznev, S.; Masloboev, V.; Klyuchnikova, E.; Makarov, D. Involving small and medium-sized mining industry businesses in mining waste processing in the Russian Federation. Miner. Econ. 2021, 34, 81–86. [Google Scholar] [CrossRef]

- Kaung, P.F.; Semikin, A.A.; Khayrutdinov, A.M.; Dekhtyarenko, A.A. Recycling of industrial waste is a paradigm of resource provision for sustainable development. Sustain. Dev. Mt. Territ. 2023, 15, 385–397. [Google Scholar] [CrossRef]

- Golik, V.I.; Mitsik, M.F.; Aleksakhina, Y.V.; Alenina, E.E.; Ruban-Lazareva, N.V.; Kruzhkova, G.V.; Kondratyeva, O.A.; Trushina, E.V.; Skryabin, O.O.; Khayrutdinov, M.M. Comprehensive Recovery of Metals in Tailings Utilization with Mechanochemical Activation. Resources 2023, 12, 113. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B.; Aleksakhin, A.V.; Eliseeva, E.N.; Zhaglovskaya, A.V.; Klyuev, R.V.; Petrusevich, D.A. Modern Technologies Providing a Full Cycle of Geo-Resources Development. Resources 2023, 12, 50. [Google Scholar] [CrossRef]

| Recovery Period, Year | k1 | Recovery Period, Year | k1 |

|---|---|---|---|

| 1 | 0.9 | 8–10 | 5.6 |

| 2 | 1.7 | 11–15 | 7 |

| 3 | 2.5 | 16–20 | 8.2 |

| 4 | 3.2 | 21–25 | 8.9 |

| 5 | 3.8 | 26–30 | 9.3 |

| 6–7 | 4.6 | >31 | 10 |

| Depth of Pollution, cm | k2 |

|---|---|

| 0–20 | 1 |

| 0–50 | 1.3 |

| 0–100 | 1.5 |

| 0–150 | 1.7 |

| 0->150 | 2 |

| Economic Zoning of Russia | k3 |

|---|---|

| Northern (N) | 1.3 |

| Northwestern (N/W) | 1.4 |

| Central (C) | 1.8 |

| Volga-Vyatka (V/V) | 1.5 |

| Central Black Earth (C/B) | 2 |

| Volga (V) | 1.9 |

| North Caucasian (N/K) | 1.9 |

| Ural (U) | 1.7 |

| West Siberian (W/N) | 1.2 |

| East Siberian (E/S) | 1.1 |

| Far Eastern (F/E) | 1.1 |

| Level | Probability | |

|---|---|---|

| 0 | None | 0 |

| 1 | Unlikely | 0.075 |

| 2 | Acceptable | 0.15 |

| 3 | Weak | 0.3 |

| 4 | Moderate | 0.6 |

| 5 | Probable | 1.5 |

| 6 | Very likely | 2 |

| Factor | N | N/W | C | V/V | C/B | V | N/K | U | W/N | E/S | F/E |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Earthquake | 1.0 | 1.1 | 1.0 | 1.0 | 1.0 | 1.1 | 1.4 | 1.2 | 1.3 | 1.4 | 1.6 |

| Volcano | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.1 | 1.1 | 1.1 | 1.2 | 1.5 |

| Relief | 1.0 | 1.2 | 1.0 | 1.0 | 1.0 | 1.0 | 1.3 | 1.1 | 1.2 | 1.3 | 1.3 |

| Tailing Dumps of the Processing Plant | Copper | Zinc | Iron | Gold | Silver | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Reserves [62] | Extraction [63] | Reserves [62] | Extraction [63] | Reserves [62] | Extraction [63] | Reserves [62] | Extraction [63] | Reserves [62] | Extraction [63] | |

| Thousand Tons | Tons | |||||||||

| Sibay | 34.5 | 33.637 | 90.0 | 88.92 | 5900.0 | 5811.5 | 13.9 | 11.0 | 344.0 | 305.5 |

| Uchaly | 90.0 | 87.75 | 257.0 | 253.9 | 8050.0 | 7929.2 | 16.5 | 13.1 | 232.0 | 206.0 |

| Buribai | 25.0 | 24.375 | 11.6 | 11.46 | 1280.0 | 1260.8 | 6.60 | 5.24 | 56.8 | 50.5 |

| Guy | 120.0 | 117.0 | 92.0 | 90.9 | 5550.0 | 5466.8 | 32.0 | 25.4 | 160.0 | 142.1 |

| Steps | Quarter | Capital Investments, RUB Million | |||||||

|---|---|---|---|---|---|---|---|---|---|

| I | II | II | IV | V | VI | VII | VIII | ||

| Geological mapping of tailing dump and study its raw materials. Feasibility study of investments. | X | X | 350 | ||||||

| Development of technical assignment and design-and-operational documents. Adaptation of technology. | X | X | X | 550 | |||||

| Development of a production project. Experimental design works. | X | X | X | 600 | |||||

| Production of non-standard technological equipment. | X | X | X | 4000 | |||||

| Complete by standard equipment. | X | X | 2800 | ||||||

| Performing construction and installation work. | X | X | 1700 | ||||||

| Testing and commissioning. | X | 1200 | |||||||

| Total: | 11,200 | ||||||||

| Tailing Dumps of the Processing Plant | Waste Volumes [47], Million Tons | Productivity, Thousand Tons/Month | Annual Revenue, Million USD/Month | Payback, Month | IRR, % | Raw Material Class | Term of the Work, Year |

|---|---|---|---|---|---|---|---|

| Sibay | 28.5 | 200 | 14.898 | 8.28 | 21.9 | Highly valuable | 142.5 |

| Uchaly | 40.8 | 200 | 15.264 | 8.13 | 22.3 | Highly valuable | 204 |

| Buribai | 5.5 | 200 | 14.815 | 8.38 | 21.4 | Highly valuable | 27.5 |

| Guy | 40 | 200 | 10.108 | 12.28 | 18.5 | Valuable | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kongar-Syuryun, C.; Babyr, N.; Klyuev, R.; Khayrutdinov, M.; Zaalishvili, V.; Agafonov, V. Model for Assessing Efficiency of Processing Geo-Resources, Providing Full Cycle for Development—Case Study in Russia. Resources 2025, 14, 51. https://doi.org/10.3390/resources14030051

Kongar-Syuryun C, Babyr N, Klyuev R, Khayrutdinov M, Zaalishvili V, Agafonov V. Model for Assessing Efficiency of Processing Geo-Resources, Providing Full Cycle for Development—Case Study in Russia. Resources. 2025; 14(3):51. https://doi.org/10.3390/resources14030051

Chicago/Turabian StyleKongar-Syuryun, Cheynesh, Nikita Babyr, Roman Klyuev, Marat Khayrutdinov, Vladislav Zaalishvili, and Valery Agafonov. 2025. "Model for Assessing Efficiency of Processing Geo-Resources, Providing Full Cycle for Development—Case Study in Russia" Resources 14, no. 3: 51. https://doi.org/10.3390/resources14030051

APA StyleKongar-Syuryun, C., Babyr, N., Klyuev, R., Khayrutdinov, M., Zaalishvili, V., & Agafonov, V. (2025). Model for Assessing Efficiency of Processing Geo-Resources, Providing Full Cycle for Development—Case Study in Russia. Resources, 14(3), 51. https://doi.org/10.3390/resources14030051