Abstract

Due to the high environmental burden of plastics, this study aimed to evaluate the environmental performance of chemical recycling of plastic waste through Life Cycle Assessment (LCA), focusing on pyrolysis oil production as the primary output. A pyrolysis plant in Almería, Spain, was chosen as a case study. The results indicate that the production of 1 L of pyrolysis oil from plastic waste generates about 0.032 kg CO2 eq and a water consumption of 0.031 m3, with other impact categories registering values of less than 0.1 kg/L or 0.01 m2a crop eq/L, reducing impacts in 17 out of 18 categories compared to fossil diesel. In addition, its chemical and physical properties, close to those of fossil diesel, suggest its suitability for internal combustion engines, although as a blend rather than a complete substitute. Chemical recycling also appears to be more environmentally favorable than incineration and landfilling in all 18 impact categories, achieving significant benefits, including a reduction in global warming of −3849 kg CO2 eq/ton, ionizing radiation of −22.4 kBq Co-60 eq/ton, and fossil resource consumption of −1807.5 kg oil eq/ton. These results, thus, highlight the potential dual role of chemical recycling of plastic waste, both in mitigating environmental impacts and in supporting circular economy goals by reducing demand for virgin plastics. However, although it appears to be a promising technology, challenges associated with high energy requirements, raw material variability, and scale infrastructure still need to be addressed to ensure industrial competitiveness and significant environmental benefits.

1. Introduction

According to the Organization for Economic Co-operation and Development (OECD), global plastic production in 2022 exceeded 450 million tons, a slight increase from the previous year. With current trends, it is predicted to exceed 1.2 billion tons by 2060 [1]. Annual global plastic production has grown significantly in just one generation: it has risen from 2 million tons in 1950 to over 450 million tons in 2022, excluding synthetic fibers [2], which implies that current figures represent a low estimate compared to actual production.

Between the 1950s and 2020, approximately 9.2 billion tons of plastics were produced (more than half of which were placed on the market after 2000). Over a quarter of these are still in use, while only 600 million tons have been recycled [3]. As stated by the recent data of Plasticeurope (2022) [4], around 20% of the global demand for plastics is for the production of Polypropylene (PP), used for plastic bottles, caps, lids, jars, and packaging for home furnishings and the automotive and medical sectors [5]. This is followed by Low-Density Polyethylene (LD-PE or PE-LD) with 14.4% widely used for the production of films and thin sheets, such as those for food packaging, shopping bags, garbage bags, and films for the agricultural industry [6]. Then, Polyvinyl Chloride (PVC) and High-Density Polyethylene (PE-HD) account for 12.9% and 12.5%, respectively. Other plastics of fossil origin are thermosets and other thermoplastics, each with a 7.1% share, polyethylene terephthalate (PET) with 6.2%, polyurethane (PUR) with 5.5% and polystyrene (PS) with 5.3%. On the other hand, circular plastics account for 9.7% of the market. Of these, recycled plastics represent the majority with 8.3%, while bio-based or bio-attributed plastics contribute 1.5%. This breakdown highlights the significant dominance of fossil-based plastics in the market while indicating the smaller but growing presence of circular options. This is because fossil plastics share key characteristics such as chemical resistance, durability, versatility, and low cost. However, while these traits are ideal for their intended uses, primarily in the packaging sector, they pose significant environmental challenges. Approximately 40% of all plastic products are discarded within a month of production, and over half of the 9.2 billion tons of plastic produced (about 5 billion tons) have ended up in landfills or dispersed in the environment [3]. Among these, it is estimated that between 5 and 13 million tons have reached the oceans, representing a severe waste of resources. The mechanical properties of plastics, which make them resistant and durable [7], have turned their disposal into a complex challenge [8]. The scientific community has long been aware of the environmental burden associated with plastics due to the well-documented impacts on marine pollution [9] and the risks to human health [10]. Adding to this are the environmental impacts of upstream activities in the plastic supply chain, particularly production processes, which rely predominantly on fossil fuels and require energy-intensive operations. Due to their fossil origin and the high energy consumption during refining, approximately 90% of the greenhouse gas emissions from plastics are attributable to production and processing stages. In 2019, total greenhouse gas emissions associated with the full life cycle of fossil-based plastics reached 1.8 Gt CO2 eq, representing 3.7% of global emissions. With the continued increase in plastic use and waste, these emissions are projected to double by 2060, reaching 4.3 Gt CO2 eq, or 4.5% of global greenhouse gas emissions, if no new policies are implemented [11]. In light of the above, the proper management of plastic waste, addressing both upstream and downstream impacts of the supply chain, represents a critical issue increasingly recognized at both international and national levels. It is a basic challenge to move toward a more sustainable future. These challenges are being addressed by transitioning to a circular economic development model that redesigns human-made systems to align economic and environmental well-being by recycling and circulating material flows [12]. The European Commission’s Circular Economy Package has set a recycling target of 55% for plastic packaging waste by 2030 [13]. Similarly, the United States and China promote policies to increase recycling rates and foster a circular economy [12]. Achieving efficient recycling of large volumes of plastic packaging waste requires adopting advanced technologies such as chemical recycling. This innovative technology allows plastics to be broken down into basic chemical components, converting packaging waste into new raw materials for the chemical industry [14]. This could, on the one hand, reduce dependence on limited fossil resources and reduce greenhouse gas emissions and, on the other hand, remove plastic waste from the environment, with the ultimate goal of conserving resources.

Furthermore, chemical recycling could have a further advantage, namely that of producing substances that are chemically identical to the source materials, or their fossil counterparts, including products such as fuels [15]. Fuels, e.g., diesel, petrol, and kerosene, can come from fossil sources such as oil, i.e., non-renewable resources because they are formed over very long geological timescales. They can also come from biological resources, which are called biofuels [16].

In more detail, they can come from agri-food raw materials (first-generation biofuels) [17], non-food raw materials and waste (second-generation biofuels) [18], genetically modified microalgae and plants (third-generation biofuels) [19], and microorganisms (including microalgae, yeasts, fungi, and cyanobacteria) genetically modified to photosynthesize CO2 into fuel (fourth-generation biofuels) [20].

More recently, research has also produced fuels from plastic waste, obtained by pyrolysis of PET, HDPE, LDPE, PP, and PS [15,21]. Through this thermochemical process, plastic waste is heated at high temperatures (usually between 300 and 600 °C) in an oxygen-free environment. This heating breaks down the long polymer chains in the plastic into smaller hydrocarbon molecules and could be an important technique for sustainable waste management [22]. The production and use of biofuels and fuels produced from waste could also fit into a particularly favorable decarbonization context, given that the energy sector is currently responsible for about ¾ of global greenhouse gas emissions, which have contributed to raising atmospheric CO2 concentrations to a record 449 parts per million (ppm) in 2019 [23]. These data represent the highest level in the past 2 million years, a staggering +50% increase compared to the time before the first steam engine was set in motion. However, the use of alternative fuels could support the decarbonization process, particularly in light of the upcoming ban on internal combustion engine car registrations, set to take effect in 2035. This stop will require European countries to register only vehicles powered by fuels that are lifecycle-neutral in terms of emissions.

In this context, the objective of this article was to assess the environmental performance of chemical recycling of plastic, with a specific case study focusing on pyrolysis oil as its output, which can be used as a fuel. On one hand, this study aims to evaluate the environmental performance of potential alternative fuels to fossil fuels, ensuring that such solutions effectively reduce environmental impacts by limiting greenhouse gas emissions and contributing to a more sustainable energy transition. On the other hand, it seeks to demonstrate the environmental compatibility of chemical recycling of plastic as an effective circular economy strategy capable of mitigating the depletion of natural resources. Then, the analysis focused on recycling technology by comparing chemical recycling with two other end-of-life options for plastic waste: landfill and incineration. The methodology used was Life Cycle Assessment (LCA), which complies with ISO 14040 [24] and ISO 14044 [25] standards and is widely used in the literature to assess the environmental impacts of a product or process throughout its life cycle. As a case study, the production of pyrolysis oil produced from plastic waste at Hintes Oil Europe’s pyrolysis plant in Almería was chosen. Although not globally representative, this case study could be relevant because it highlights how the pyrolysis of plastic waste can be a solution for waste disposal and a concrete opportunity to produce alternative and sustainable fuels and, thus, a circular economy.

2. Materials and Methods

2.1. Descriptions of Waste Conversion on a Laboratory Scale

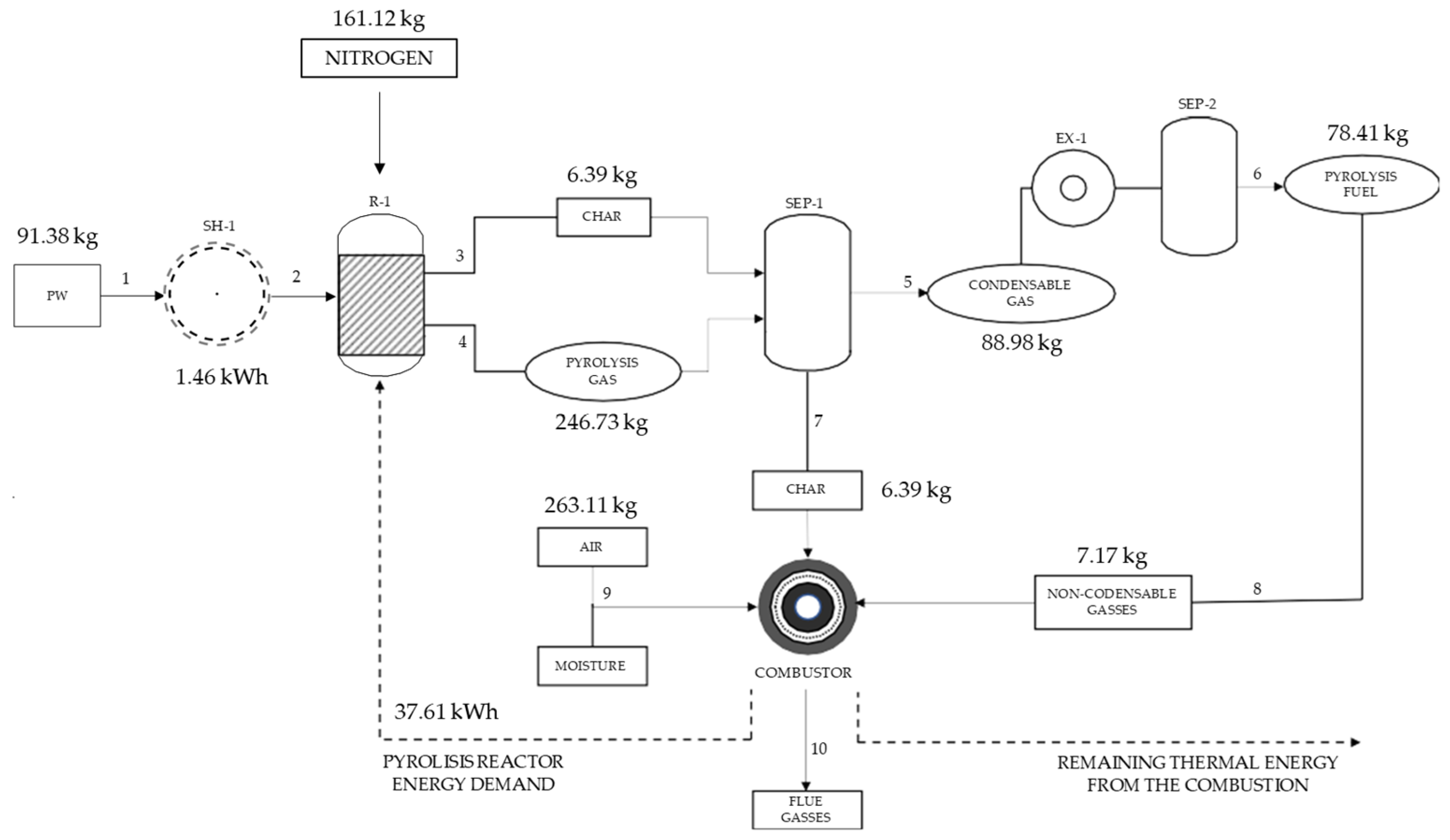

Laboratory-scale procedures for conversion processes are presented in this section. Laboratory experiments were conducted by the Department of Physical Chemistry and Applied Thermodynamics, at the University of Cordoba (Spain), to study different pathways for converting waste into oil. The industrial plant of Hintes Oil Europe (Almeria) was used to produce pyrolysis oil from plastic waste, as shown in Figure 1. The first stage is raw material pre-treatment. Specifically, to make, for example, 100 L of oil, it starts with 91.38 kg/h of plastic waste (PW). Specifically, this is about 46 kg of polyethylene (50%), 23 kg of polypropylene (25%), and 23 kg of polystyrene (25%). The proportion used is based on two premises. The first is the source of the raw material and the liquid fuel obtained, provided by a company located in Almería, whose main industry is agriculture. The second premise is to use proportions and conditions that are consistent with the analyzed fuel while maintaining a balance between light hydrocarbons from different fractions and aromatic elements. The output of pyrolysis, including pyrolysis oil, gas, and coal, is susceptible to the composition of the input feedstock because polyethylene contributes significantly to the oil fraction due to its high hydrogen/carbon ratio, resulting in lighter hydrocarbons. Polypropylene is similar to PE in its contribution to the oil but tends to produce slightly more gas due to its branched structure and polystyrene decomposes mainly into aromatic compounds, heavily influencing the composition of the pyrolytic oil (increasing the aromatic content) and potentially affecting its quality and applications. These features are in line with other literature studies, such as Anuar Sharuddin et al. (2016) [26], Al-Salem et al. (2017) [27], and Straka et al. (2017) [28]. This plastic is conveyed to a shredder (SH-1) and shredded into particles smaller than 2–3 mm. It should be noted that size reduction in biomass requires energy that depends mainly on the size of the final particles, the material to be ground, and the type of grinding. In this case, the maximum value of 1.46 kW was used as Piccinno et al. (2016) [29] suggested. The lower heating value (LHV) of the raw material, i.e., the energy content of plastic waste, was 44 MJ/kg. Next came fuel production: the plastic waste flakes conveyed to a reactor (R-1) filled with 161.12 kg of nitrogen to set the temperature at 550 °C.

Figure 1.

Industrial pyrolysis fuel production process from plastic waste (values from 1 to 10 represent the sequence of steps).

The temperatures used were a compromise between the conditions provided by the company and bibliographic references such as Straka et al. (2017) [28] findings, which demonstrated that temperatures above 500 °C are ideal for the pyrolysis of HDPE, PP, and PS mixtures. Such temperatures allow for the complete degradation of plastics (93–100%), driven by styrene radicals generated from PS, accelerating the decomposition of polyolefins. This range maximizes the production of high-calorific-value liquid oils (46–48 MJ/kg) and energy-rich gasses while minimizing solid residues. Additionally, it facilitates the formation of valuable chemical compounds such as aliphatic and aromatic hydrocarbons, optimizing the conversion yield into useful products and ensuring an efficient balance between quality, sustainability, and energy utilization. The plastic mixtures were selected following the company’s work protocol, which operates in the agricultural sector and is based on bibliographic references. It was determined then that the best mixture was polyethylene (50%), polypropylene (25%), and polystyrene (25%). In the case of this article, the temperature was increased to 550 °C due to the presence of organic residues. Therefore, it aims to enhance synergistic effects, as noted by Sánchez-Ávila et al. (2024) [30] where at 550 °C, the co-pyrolysis of OP with selected plastics generates positive synergistic effects, improving both the yield and quality of the products obtained, such as pyrolysis oils and gasses.

It should be noted that the start-up energy requirement to fire the reactor to the required temperature was not considered. What comes out of R-1 is 6.39 kg of solid carbon residues and 246.73 kg of pyrolysis vapors [31]. As shown in Figure 1, to increase the efficiency of the process, pyrolysis gasses are recycled back into the reactor, partially covering the heat requirement. Finally, for the fuel post-treatment stage, condensable gasses are separated from char in the separator (SEP-1). The 89.98 kg of pyrolysis vapors then pass through the fuel collection system, which consists of an exchanger (EX-1) and a separator (SEP-2). Then, 78.41 kg of condensed fuel is transferred to a tank to form 100 L of pyrolysis oil. By combining the pyrolysis by-products (6.39 kg of coal and 7.17 kg of non-condensable gas), 143.19 kW of thermal energy was provided for the endothermic reaction, since the pyrolysis reaction requires a constant source of energy. The total thermal energy of the pyrolysis reactor was 37.61 kW/h per 91.38 kg/h of PW. Therefore, no external heating source was needed. In conclusion, the plant produced 78.41 kg/h of pyrolysis oil with an energy content of 44.26 MJ/kg. The fraction of energy transferred from the plastic waste to the pyrolysis fuel is 1, indicating that all the energy contained in the plastic is conserved in the produced fuel. This was calculated by dividing the energy of the pyrolysis fuel by the energy contained in the plastic waste.

The fraction of energy in the plastic waste stored in the fuel was 1 MJ/kg, calculated by dividing the energy of the pyrolysis fuel and the energy content of the plastic waste. This represents the energy efficiency of the fuel [32]. The plant’s total electricity required 32.89 kW for every 91.38 kg/h of PW. It was possible to generate the flow using 279.63 kg/h of flue gas from the combustor, resulting in up to 105.58 kW. Overall, no external heating source other than the pre-treatment source was required in the entire process.

A set of specifications for bio-oil has been proposed since 1996 by the Pyrolysis Activity of the International Energy Agreement. The goal was to replicate, where possible, the main characteristics of those of crude oil. The specifications were based primarily on bio-oil’s kinematic viscosity and low heating value because of critical implications for end-use devices. The results of the current project (Table 1) have shown that the properties of pyrolytic oil conform to these values.

Table 1.

Physico-chemical properties of pyrolysis oil from plastic waste.

2.2. Life Cycle Assessment

The main steps of LCA carried out within this study are based on the standardized guidelines of ISO 14044:2006 [24] and ISO 14040:2006 [25] and are detailed in Table 2. The analysis aimed to assess the environmental compatibility of a chemical recycling solution for plastic waste. The functional unit (FU) chosen for this study was the production of 1 L of pyrolysis oil. This choice is based on literature studies, such as Dastjerdi et al. (2021) [33], which reviewed various approaches used in LCA studies on plastic recycling, showing that unitary functional units are currently the most commonly applied. The material inputs, energy use, and technological parameters for the production of pyrolysis oil were primarily obtained through technical visits to the facility, meetings with operators, and on-site inspections at the study’s case facility.

Table 2.

LCA steps for the environmental assessment of pyrolysis oil.

The main inputs and outputs of the two plants are detailed in Table 3. Modeling of various processes was performed using the software SimaPro 9.6. For LCI data, the Ecoinvent version 3.11 database was considered, which provides comprehensive data on energy production, transportation, and chemical production [34].

Table 3.

LCI of the pyrolysis oil process from PW.

For the assessment of environmental impacts, the ReCiPe 2016 Midpoint method was selected [35], following an individualistic perspective (20 years), focusing on short-term impacts. The ReCiPe methodology was selected because it is widely recognized and used in Life Cycle Assessment studies [36]. In addition, compared to other evaluation methods such as ILCD 2011, CML 2001, or TRACI, ReCiPe is distinguished by the inclusion of 18 impact categories, compared to 16 in ILCD 2011 MidPoint, 15 in IMPACT 2002+, 11 in CML-IA Baseline, and 9 in TRACI. This makes ReCiPe able to capture a broader, more holistic, and accurate spectrum of the environmental impacts of manufacturing processes. The 18 impact categories considered, grouped into four macro-areas, are as follows:

- Atmospheric Effects: Global Warming Potential (GWP); Stratospheric Ozone Depletion (SOD); Ionizing radiation (IR); Ozone Formation, Human Health (OFHH); Fine Particulate Matter Formation (FPMP); Ozone formation, Terrestrial ecosystems (OFTE); Terrestrial acidification Potential (TAP);

- Eutrophication: Freshwater Eutrophication Potential (FEP) and Marine Eutrophication Potential (MEP);

- Toxicity: Terrestrial Ecotoxicity (TEC); Freshwater Ecotoxicity (FEC); Marine Ecotoxicity (MEC); Human Carcinogenic Toxicity (HCT); Human Non-Carcinogenic Toxicity (HNCT);

- Abiotic Resources: Land Use (LU); Mineral Resources Scarcity (MRS); Fossil Resources Scarcity (FRS), Water Consumption (WC).

2.3. Scenario Analysis

Then, given the wide variability in chemical recycling processes, a scenario analysis was constructed to compare the chemical recycling process with the two most common and conventional end-of-life methods for plastics: landfilling and incineration. To facilitate and better target the evaluation of the environmental and technological aspects of each treatment process, the functional unit was adjusted from the generation of 1 L of pyrolysis oil to the treatment of 1000 kg of plastic waste. This adjustment aligns with other literature studies, such as Chhabra et al. (2021) [37] and Ahamed et al. (2020) [38]. The change in the functional unit, whose normalized inventory data for 1000 kg are shown in Table S1, aims to shift the focus from specific outputs (such as fuel) to the processes themselves and their efficiencies in handling large volumes of plastic waste. By concentrating on the treatment of 1000 kg of plastic, the analysis provides a clearer exploration of the different environmental impacts of each disposal method, offering a more comprehensive understanding of the potential role chemical recycling could play as an alternative to traditional waste management methods. The scenarios considered in this analysis are:

S1: Chemical Recycling. The treatment of 1000 kg of plastic waste (50% polyethylene, 25% polypropylene, and 25% polystyrene) to produce pyrolytic oil as the primary output.

S2: Landfill Disposal. The universal and widely used method of waste disposal globally, accounting for up to 42% of the world’s plastic waste [39]. This scenario evaluates the environmental impacts of storing plastic waste in a landfill.

S3: Incineration. The incineration of plastic waste under sufficient aerobic conditions at temperatures above 500 °C in a dedicated waste-to-energy (WTE) plant. This process thermally converts the waste into energy, such as electricity or heat [40].

3. Results

3.1. Life Cycle Assessment

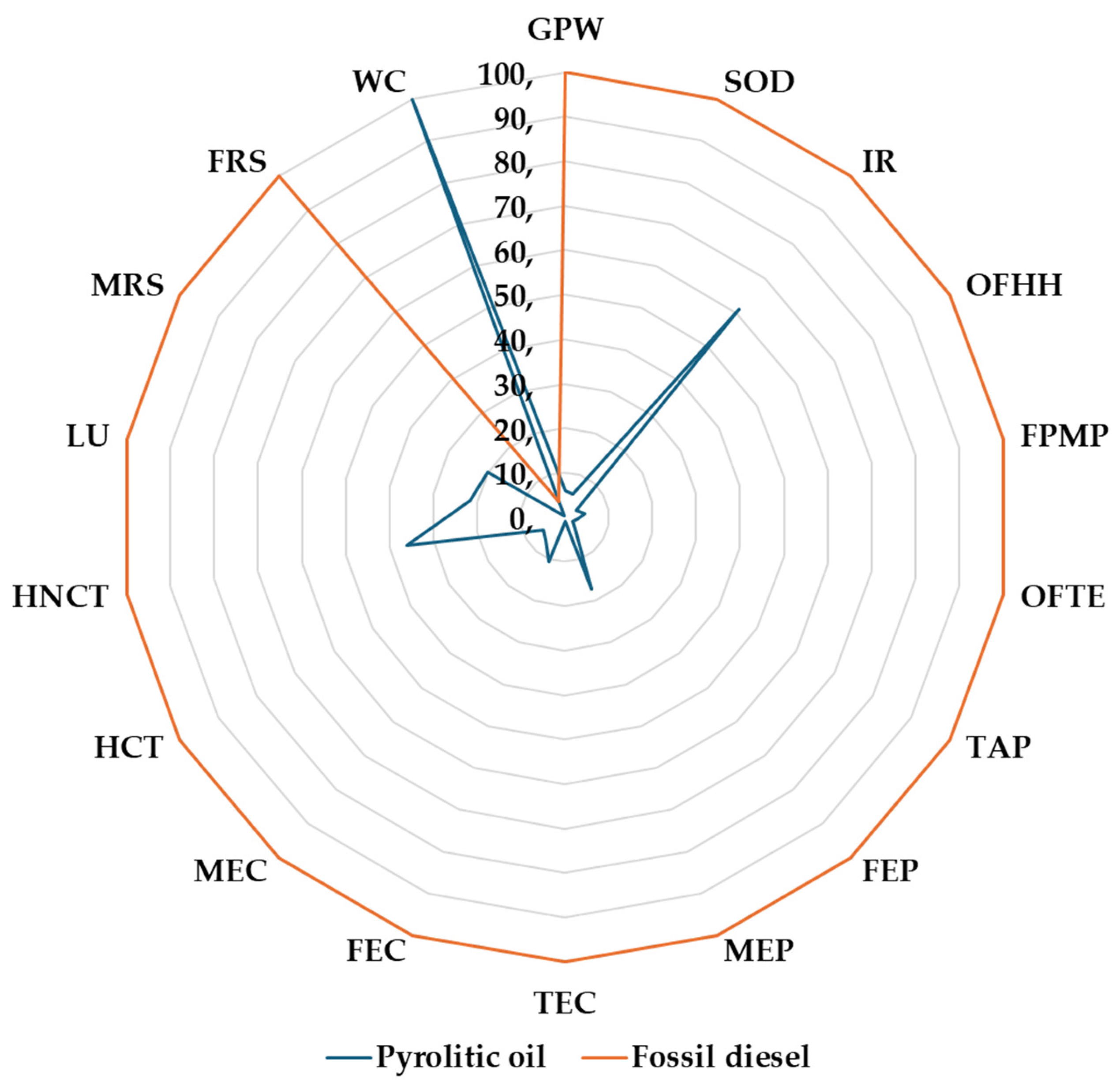

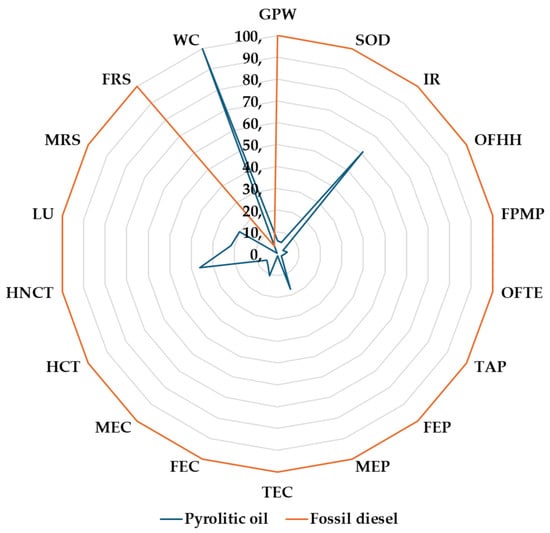

The results of the Life Cycle Assessment are shown in Table 4 and characterized in Figure 2. From the results in Table 4, it emerges that the highest value in all impact categories is Global Warming Potential with 0.032 kg CO2 eq/L, followed by Water Consumption with 0.031 m3/L. However, considering the eighteen impact categories, it emerges that in all cases the results present values of less than 0.1 kg/L, 0.1 m2/L, or 0.1 m3/L. The inputs impacting the pyrolysis process are nitrogen and electricity generation. In more detail, in the pyrolysis production process of the plastic in question, nitrogen is used both to maintain constant pressure and temperature conditions, which are essential for controlling the quality and composition of pyrolysis products [41] and because pyrolysis requires an oxygen-free environment to ensure that the plastic thermally decomposes rather than burns [42]. By purging the reaction chamber with nitrogen, oxygen was effectively removed, reducing the risk of material combustion and enabling controlled thermal decomposition into oil, gas, and char. However, as also noted by Erisman et al. (2011) [43], nitrogen can have significant climate effects, for example, through the formation of N2O during industrial processes, the creation of O3 and aerosols, and their influence on radiative forcing. Nitrogen-containing aerosols can have a direct cooling effect (in addition to an indirect cooling effect through cloud formation). On the other hand, electricity generation from fuels results in emissions such as CO2 and N2O, which can increase the GWP [44]. The liquid oil produced has a variety of applications, as demonstrated by Antelava et al. (2019) [45]. For instance, it can be used as an energy source or as a transportation fuel. Specifically, pyrolysis oil, when used in combination with diesel as a transportation fuel, has been successfully tested at various blending ratios in previous studies [46,47,48,49].

Table 4.

Life Cycle Assessment results.

Figure 2.

Comparison of the environmental results of pyrolytic oil and fossil diesel (GWP = Global Warming Potential; SOD = Stratospheric Ozone Depletion; IR = Ionizing Radiation; OFHH = Ozone Formation, Human Health; FPMF = Fine Particulate Matter Formation; TAP = Terrestrial Acidification Potential; FEP = Freshwater Eutrophication Potential; MEP = Marine Eutrophication Potential; TEC = Terrestrial Ecotoxicity; FEC = Freshwater Ecotoxicity; MEC = Marine Ecotoxicity; HCT = Human Carcinogenic Toxicity; HNCT = Human Non-Carcinogenic Toxicity; LU = Land Use; MRS = Mineral Resource Scarcity; FRS = Fossil Resource Scarcity; WC = Water Consumption).

Thus, pyrolytic oil from PW was compared to a fossil counterpart, specifically diesel, in the same unit (1 L). What is interesting to note is that pyrolytic oil from the production process has significantly lower environmental values than fossil diesel in 17 out of 18 impact categories, as shown in Table S2 and Figure 2. For example, pyrolytic oil could potentially lead to significant reductions ranging from −39% (Ozone formation, Human health) to −99% (Terrestrial ecotoxicity and Fossil resource scarcity) for all impact categories excluding WC. More in detail, reductions of −94.13%/L for GWP (3.28 × 10−2 kg CO2 eq/L for pyrolytic oil vs. 5.59 × 10−1 kg CO2 eq/L for fossil diesel), −98%/L for Terrestrial acidification (8.27 × 10−5 kg SO2 eq/L for pyrolytic oil vs. 4.14 × 10−3 kg SO2 eq/L for fossil diesel), and −78.45%/L for land use (1.11 × 10−2 m2a crop eq/L for pyrolytic oil vs. 5.15 × 10−2 m2 a crop eq/L for fossil diesel). Or −99.65% for FRS, with values of 4.01 × 10−3 kg oil eq/L for pyrolytic oil and 1.16 × 100 kg oil eq/L for fossil diesel (Table S2). This last value could be read as particularly significant because it emphasizes how the use of waste material for the production of alternative fuels could shift the problem of the depletion of fossil resources, the basic energy for human survival and societal development [50]. Their non-renewable nature and overconsumption have attracted increasing attention to addressing the depletion of fossil energy and concern over environmental problems. Therefore, the modern energy system, as supported by the LCA data in this research, could benefit from producing fuel from plastic waste. The process of refining diesel typically involves simple distillation. In this initial step, crude oil is separated into its fractions, the main categories of hydrocarbons that compose it. The crude oil is heated and introduced into a distillation column, where various products evaporate and can be collected at different temperatures. The lighter products, such as liquefied petroleum gas (LPG), naphtha, and gasoline, are extracted at lower temperatures. These are followed by middle distillates, including jet fuel, kerosene, and other distillates like diesel fuel [51].

In contrast, the production of fuel oil through recycling could, via simple pyrolysis, avoid the extraction of crude oil and, consequently, the emissions associated with it. The only impact category where fossil diesel exhibits higher values compared to pyrolytic oil from plastic waste is water consumption, with diesel’s water usage being 27 times greater (3.2 × 10−2 m3/L vs. 1.2 × 10−3 m3/L). This discrepancy is most likely due to the industrial processes required to separate and purify nitrogen from air using cryogenic or adsorption techniques, which demand significant energy to cool air to extremely low temperatures [52]. This may indirectly increase the consumption of water, which is required for cooling machinery and dissipating the heat produced by equipment [53]. The results of the LCA, thus, highlight how a fuel such as pyrolytic oil derived from plastic waste could have considerable potential for a partial replacement of fossil-derived diesel in modern ignition engines. Indeed, the characteristics of the output obtained, shown in Table 1, suggest that PW fuel oil may have the potential to be used successfully in endothermic engines. For instance, a density of 784.2 kg/m3, is close to that of conventional diesel, which generally ranges from 820 to 860 kg/m3.

A kinematic viscosity of 2.04 mm2/s at 40 °C also falls within the acceptable range for diesel (typically between 2 and 4.5 mm2/s), suggesting a flow behavior similar to diesel. Or, a calorific value of 46.16 MJ/kg, indicating an energy content comparable to that of diesel, which usually ranges from 42 to 46 MJ/kg [54]. These results support the research of Ahamed et al. (2020) [38], who show that their pyrolysis oil produced from plastic has similar properties to fossil fuels, due to both the absence of water in the plastic (which increases its calorific value) and the absence of oxygen content (which makes the fuel non-acidic and non-corrosive, unlike biofuels). However, its low flash point (15 °C) (i.e., the minimum temperature at which a heated fuel produces a momentary flash in the presence of an ignition source), which is lower than that of standard diesel (typically 52–96 °C) [55], make it not fully suitable for total replacement of fossil diesel. However, it could still be blended in varying percentages with it, contributing significantly to reducing pollutant emissions and decreasing dependence on fossil fuels. Indeed, it is important to consider that only a few blends with low alternative fuel content, generally up to 10% by volume (v/v), are compatible with large-scale applications and in current commercial engines without requiring substantial modifications to the fuel system or engine performance [56]. This is true for almost all biofuels and fuels produced from waste, due to their low aromatics content [57], which compromises their viscosity and other properties. Thus, consistent with this, the resulting fuel oil may require further upgrading and blending with diesel to enhance its characteristics. However, this solution could still represent an intermediate step, and these results could be particularly significant because they show the potential of the chemical recycling of plastics, which, instead of being destined for landfill, could instead be directed into circular economy practices, producing output with high added value, avoiding the depletion of new resources on the one hand, and the production of new waste on the other.

Consistent with the difficulties documented by Stančin et al. (2023) [58], comparing the results obtained in this research with those of other studies is difficult for several reasons, such as different impact assessment methods, inventory data, different system models and boundaries, and the use of different functional units. There are those who, for example, consider the output to be FU, such as Stančin et al. (2023) [58] who study the production of 1 ton of pyrolysis oil. Or those who consider, for example, the processing of 1000 kg of plastic, such as Tsangas et al. (2024) [59], who consider the production of pyrolysis oil from used tires). Azam et al. (2022) [60] consider chemical recycling of HDPE plastic waste with a conversion capacity of 1000 kg/h as a functional unit. Or, finally, Chhabra et al. (2021) [37] consider the processing of 1 ton of municipal solid waste in India. Quite simply, on international databases such as Scopus, most recent LCA studies on the subject have different methodological frameworks behind them, or often deal with biomass or pyrolysis of plastics of different origins (used tires, mix of PP and PE, PS only, etc.), and the values obtained are difficult to compare.

In this research, to obtain 1 L of pyrolysis oil, approximately 0.46 kg of polyethylene, 0.23 kg of polypropylene, and 0.23 kg of waste polystyrene are pyrolyzed, producing a GWP of approximately 0.03 kg CO2 eq/L, which is ten times lower than, for example, the 0.34 kg CO2 eq/L of Stančin et al. (2023) [58], who, however, also include the transport of raw materials, as well as a different electricity mix. Similarly, they are lower than the 0.22–0.36 kg CO2 eq/L of Kulas et al. (2023) [61], who, however, consider different inputs than the results provided by this research. The same applies to other studies in the literature. Therefore, although methodological differences and different system boundaries make direct comparisons between studies complex, the results, nonetheless, suggest that the pyrolysis process for plastic recycling can significantly reduce GWP and other emissions compared to traditional fossil fuels.

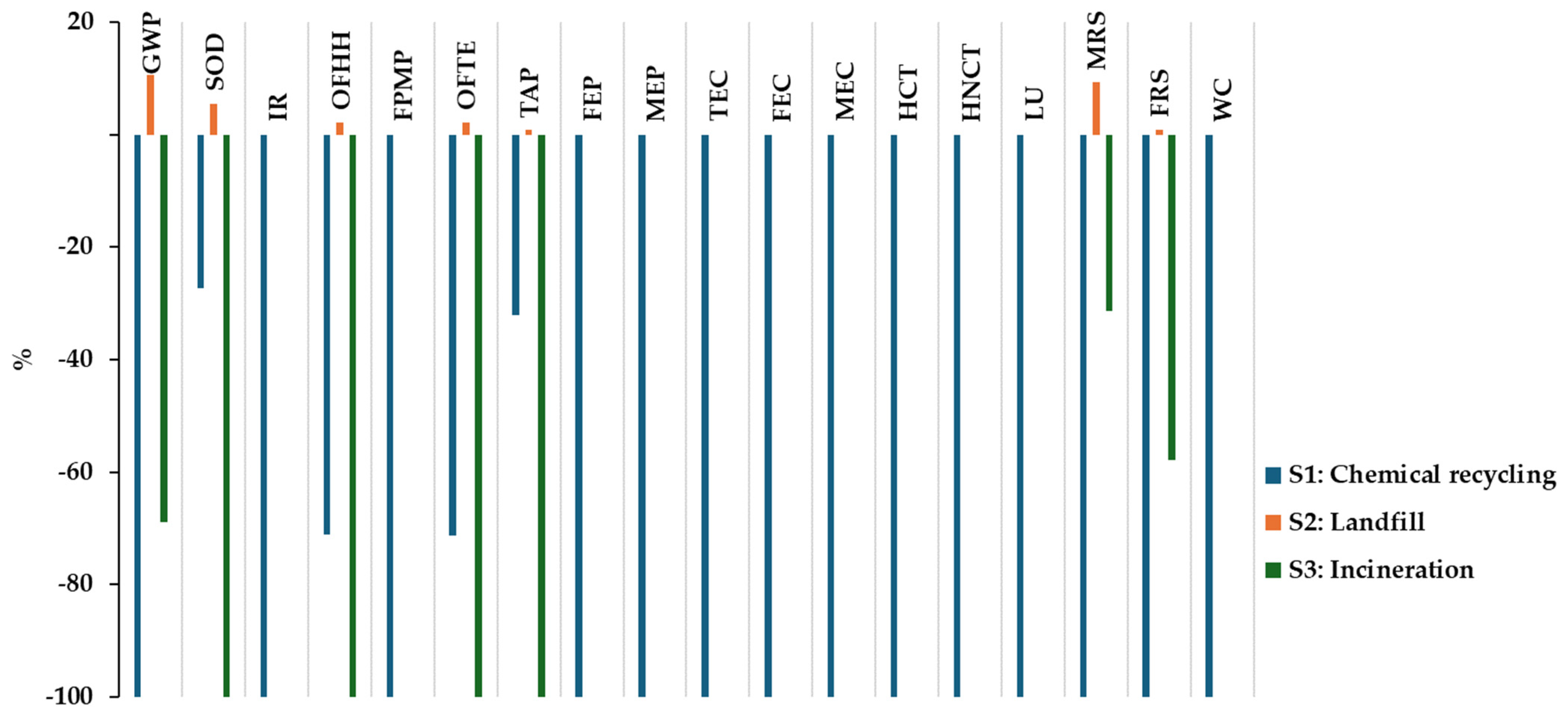

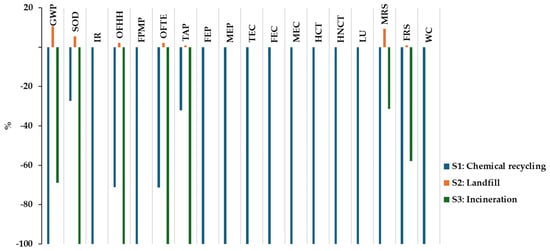

3.2. Scenario Analysis

The results of the scenario analysis are shown in Figure 3 and Table S3. Negative numbers (i.e., when the bar in the graph goes down) indicate environmental benefits due to avoided burdens through plastic recycling, while positive numbers (when the bar goes up) refer to environmental burdens from direct and indirect emissions.

Figure 3.

Comparison of the three scenarios considered (GWP = Global Warming Potential; SOD = Stratospheric Ozone Depletion; IR = Ionizing Radiation; OFHH = Ozone Formation, Human Health; FPMF = Fine Particulate Matter Formation; TAP = Terrestrial Acidification Potential; FEP = Freshwater Eutrophication Potential; MEP = Marine Eutrophication Potential; TEC = Terrestrial Ecotoxicity; FEC = Freshwater Ecotoxicity; MEC = Marine Ecotoxicity; HCT = Human Carcinogenic Toxicity; HNCT = Human Non-Carcinogenic Toxicity; LU = Land Use; MRS = Mineral Resource Scarcity; FRS = Fossil Resource Scarcity; WC = Water Consumption).

What emerges is that, of the three disposal types, chemical recycling (S1) may be the most favorable, compared to incineration (S3) and landfill (S2), as it produces greater environmental credits than both. In particular, S3 is, as widely expected, the least favorable from an environmental perspective, as it produces significant impacts in the following seven impact categories: GWP (408 kg CO2 eq/1000 kg), SOD (4.71 × 10−5 kg CFC11 eq/1000 kg), OFHH and OFTE (0.15 kg NOx eq/1000 kg), MRS (0.26 kg Cu eq/1000 kg), and FRS (14.8 kg oil eq/1000 kg). More specifically, plastic disposal in landfills could contribute to GWP due to the degradation of organic matter (since landfills are not exclusively for plastic waste but are often mixed with organic waste) [62].

Additionally, it could impact OFHH and OFTE categories due to indirect emissions from vehicles used for waste management, including transportation, compaction, and covering activities [63]. Although these emissions do not result directly from decomposing plastic waste, they could still be accounted for in the total landfill contribution to NOx emissions. However, what is interesting to note is that both landfilling (S2) and incineration (S3) have zero impacts in 11 out of 11 categories (IR, FPMP, FEP, MEP, TEC, FEC, MEC, HCT, HNCT, LU, WC), in fact showing that both may contribute neither positively nor negatively to these specific impacts (or that their contributions are negligible). This could be due to different factors, such as the fact that both landfilling and incineration generally do not recover materials that can compensate for resource extraction or prevent environmental impacts in the same way as chemical recycling processes (or other forms of recycling) which, on the other hand, can recover resources. Incineration of plastic waste, for example, might produce energy, but generally does not generate resources such as chemicals that would offset ecotoxicity, land use, or eutrophication of fresh and marine water. Landfills, on the other hand, do not produce outputs that would offset impacts such as water consumption or toxicity.

Or, for other categories such as FEP, MEP, or IR, landfilling and incineration may have negligible contributions, or their emissions may not be significant enough to be recorded in these impact categories. For example, the incineration process might produce mainly CO2 and other greenhouse gasses but not necessarily contribute directly to IR or MEP. What is noteworthy, finally, is that the modeling result of the landfill of plastic waste process does not consider toxicity, although landfills are important sources of microplastics, which could contain and transport persistent organic pollutants (POPs) and heavy metals, which can be harmful to human health [64]. When ingested, these substances can accumulate in human tissues, potentially leading to chronic illnesses such as cancer, neurological disorders, and hormonal imbalances [64]. International databases, such as Ecoinvent, likely still have limited quantitative data on how to accurately model these impacts in LCA studies. This limitation explains why these databases may not yet include robust data on the toxicity of microplastics, particularly regarding their long-term effects on ecosystems and human health [65]. Moreover, current LCA models are typically designed for chemical pollutants, which are easier to quantify in terms of concentration and toxicity. In contrast, microplastics exhibit complex behaviors and pathways that are more challenging to model and quantify effectively. Therefore, the environmental impacts of landfilling plastic waste are likely underestimated. From this perspective, research and databases must focus on identifying the behavior of microplastics to accurately quantify their real impacts on toxicity. Conversely, chemical recycling (S1) demonstrates environmental benefits in all 18 impact categories and emerges as the most environmentally favorable end-of-life option among the three scenarios. For instance, it provides particularly significant environmental benefits in GWP with −3849 kg CO2 eq/1000 kg, IR with −22.4 kBq Co-60 eq, TEC with −58.9 kg 1,4-DCB, LU with −174 m2a crop eq, and FRS with −1807.5 kg oil eq, as compensatory effects for avoiding virgin plastic extraction. In comparison, S3 (incineration) shows environmental benefits in 7 out of 7 categories, yet its overall impact is less favorable than S1. Consequently, S1, representing chemical recycling to produce pyrolytic oil, appears to be a particularly favorable recycling technology for plastics, standing out as a promising circular economy strategy for managing plastic waste efficiently and sustainably.

4. Conclusions

This research aimed to analyze the environmental performance of chemical recycling of plastic waste using Life Cycle Assessment, with a particular focus on the production of pyrolytic oil as the main output of the process. The pyrolysis plant of Hintes Oil Europe, located in Almería (Spain), was selected as a case study. This system represents a concrete example of the industrial application of chemical recycling, capable of highlighting both the potential and the challenges associated with this technology. Therefore, the main findings of the study can be summarized as follows:

- The production of 1 L of pyrolysis oil from plastic waste could generate a Global Warming Potential of about 0.032 kg CO2 eq and water consumption of 0.031 m3, with the other impact categories registering values of less than 0.1 kg/L or 0.01 m2a crop eq/L;

- Compared with fossil diesel, pyrolytic oil shows reduced impacts in 17 out of 18 impact categories, demonstrating its potential as a viable alternative to conventional diesel;

- The chemical and physical characteristics of the resulting pyrolysis oil, similar to those of fossil diesel, suggest how it is potentially usable in endothermic engines, although not as a complete replacement for conventional diesel. However, pyrolysis oil could be blended with fossil diesel in different percentages, thus, offering a practical option to reduce pollutant emissions during the life cycle and decrease dependence on fossil resources;

- For the same amount of plastic processed (1000 kg), chemical recycling appears to be a more environmentally favorable solution than incineration and landfilling. This process achieves environmental benefits in all eighteen impact categories considered, reducing global warming by −3849 kg CO2 eq per ton of plastic processed, ionizing radiation by −22.4 kBq Co-60 eq/1000 kg, terrestrial toxicity by −58.9 kg 1.4-DCB/1000 kg, land use by −174 m2a crop eq/1000 kg, and fossil resource consumption by −1807.5 kg oil eq/1000 kg. These results indicate that chemical recycling could not only contribute to the reduction in environmental impacts related to waste disposal but could also provide a substantial offsetting effect by reducing the demand for virgin plastic and promoting the circular economy.

In conclusion, the results of this study showed how chemical recycling of plastics by pyrolysis could be a promising way both to reduce the environmental presence of plastic waste and to mitigate the problem of depletion of fossil resources, which are essential for economic and social development, offering in fact, an intermediate solution between waste management and alternative fuel production. However, it is always important to consider certain limitations, such as the high energy requirements of the process, the dependence on the quality and composition of incoming plastic waste, and the need for an adequate infrastructure to scale chemical recycling to an industrial level while ensuring real economic competitiveness and an effective reduction in environmental impacts.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/resources13120176/s1, Table S1. Normalized inventory data according to chemical recycling of 1000 kg of plastics; Table S2. Comparison data between 1 L of pyrolysis oil and 1 L of fossil diesel; Table S3. Comparative results of the scenario analysis. S1: Chemical recycling, S2: Landfill, S3: Incineration. Data related to the treatment of 1000 kg of input material.

Author Contributions

Conceptualization, G.V., S.P. and D.P.; methodology, G.V., L.G., M.C.-C. and M.R.; software, G.V., M.R. and D.P.; validation, G.V., S.P. and L.G.; formal analysis, D.P.; investigation, D.P.; resources, G.V. and L.G.; data curation, G.V., L.G., M.C.-C. and S.P.; writing—original draft preparation, D.P., M.C.-C. and M.R.; writing—review and editing, G.V., M.C.-C. and M.R.; visualization, L.G.; supervision, G.V., L.G. and S.P.; project administration, G.V.; funding acquisition, G.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data processed within the article are available upon request to the corresponding author.

Acknowledgments

The authors would like to express their gratitude to Sapienza University of Rome (Sistema Gestione Bandi, protocol number RM1221816C19200A) for funding the research of which this project is a part.

Conflicts of Interest

Daniela Porcaro was employed by the company BDO Italia SPA. via Ludovisi 16, 00187, Rome (Italy). The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- OECD. Global Plastics Production: Annual Production of Polymer Resin and Fibers. 2022. Available online: https://ourworldindata.org/plastic-pollution (accessed on 29 April 2024).

- United Nations Environment Programme. From Pollution to Solution: A Global Assessment of Marine Litter and Plastic Pollution. Nairobi. 2021. Available online: https://www.unep.org/resources/pollution-solution-global-assessment-marine-litter-and-plastic-pollution (accessed on 3 November 2024).

- Plastic Soup Foundation. Plastic Facts and Figures. 2023. Available online: https://www.plasticsoupfoundation.org/en/plastic-facts-and-figures/#vervuilers (accessed on 3 November 2024).

- Plasticeurope. Plastics—The Facts. 2022. Available online: https://plasticseurope.org/wp-content/uploads/2022/10/PE-PLASTICS-THE-FACTS_V7-Tue_19-10-1.pdf (accessed on 3 November 2024).

- Sin, L.T.; Tueen, B.S. Eco-profile of plastics. In Plastics and Sustainability; Elsevier: Amsterdam, The Netherlands, 2023; pp. 45–89. [Google Scholar] [CrossRef]

- Speight, J.G. Monomers, Polymers, and Plastics. In Handbook of Industrial Hydrocarbon Processes; Gulf Professional Publishing: Houston, TX, USA, 2011; pp. 499–537. [Google Scholar] [CrossRef]

- Deshmukh, K.; Kovářík, T.; Muzaffar, A.; Ahamed, M.B.; Pasha, S.K.K. Mechanical analysis of polymers. In Polymer Science and Innovative Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 117–152. [Google Scholar] [CrossRef]

- Moharir, R.V.; Kumar, S. Challenges associated with plastic waste disposal and allied microbial routes for its effective degradation: A comprehensive review. J. Clean. Prod. 2019, 208, 65–76. [Google Scholar] [CrossRef]

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M.N. Plastic waste and its management strategies for environmental sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Lee, Y.; Cho, J.; Sohn, J.; Kim, C. Health Effects of Microplastic Exposures: Current Issues and Perspectives in South Korea. Yonsei Med. J. 2023, 64, 301–308. [Google Scholar] [CrossRef]

- OECD. Climate Change and Plastics Pollution: Synergies Between Two Crucial Environmental Challenges. 2022. Available online: https://www.oecd.org/environment/plastics/Policy-Highlights-Climate-change-and-plastics-pollution-Synergies-between-two-crucial-environmental-challenges.pdf (accessed on 3 November 2024).

- Meys, R.; Frick, F.; Westhues, S.; Sternberg, A.; Klankermayer, J.; Bardow, A. Towards a circular economy for plastic packaging wastes—The environmental potential of chemical recycling. Resour. Conserv. Recycl. 2020, 162, 105010. [Google Scholar] [CrossRef]

- European Commission. Packaging Waste: EU Rules on Packaging and Packaging Waste, Including Design and Waste Management. 2018. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en (accessed on 3 November 2024).

- Kaminsky, W. Chemical recycling of plastics by fluidized bed pyrolysis. Fuel Commun. 2021, 8, 100023. [Google Scholar] [CrossRef]

- Ndiaye, N.K.; Derkyi, N.S.A.; Amankwah, E. Pyrolysis of plastic waste into diesel engine-grade oil. Sci. Afr. 2023, 21, e01836. [Google Scholar] [CrossRef]

- Sosnina, D.; Altynov, A.; Kirgina, M.; Bogdanov, I. Production of motor fuel components by processing vegetable oils using a CoMo/Al2O3 hydrotreating catalyst and a ZSM-5 zeolite catalyst. Resources 2024, 13, 96. [Google Scholar] [CrossRef]

- Bhaskar, T.; Pandey, A. Advances in Thermochemical Conversion of Biomass—Introduction. In Recent Advances in Thermochemical Conversion of Biomass; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3–30. [Google Scholar] [CrossRef]

- Dahman, Y.; Syed, K.; Begum, S.; Roy, P.; Mohtasebi, B. Biofuels: Their characteristics and analysis. In Biomass, Biopolymer-Based Materials, and Bioenergy; Woodhead Publishing: Sawston, UK, 2019; pp. 277–325. [Google Scholar] [CrossRef]

- Renzaho, A.M.N.; Kamara, J.K.; Toole, M. Biofuel production and its impact on food security in low- and middle-income countries: Implications for the post-2015 sustainable development goals. Renew. Sustain. Energy Rev. 2017, 78, 503–516. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Shu, C.M.; Sarangi, P.K.; Shadangi, K.P.; Rakshit, S.; Kennedy, J.F.; Gupta, V.K.; Sharma, M. Catalytic hydrodeoxygenation of bio-oil and model compounds—Choice of catalysts, and mechanisms. Renew. Sustain. Energy Rev. 2023, 187, 113700. [Google Scholar] [CrossRef]

- Faisal, F.; Rasul, M.G.; Jahirul, M.I.; Chowdhury, A.A. Waste plastics pyrolytic oil as a source of diesel fuel: A recent review on diesel engine performance, emissions, and combustion characteristics. Sci. Total Environ. 2023, 886, 163756. [Google Scholar] [CrossRef]

- Seah, C.C.; Tan, C.H.; Arifin, N.A.; Hafriz, R.S.R.M.; Salmiaton, A.; Nomanbhay, S.; Shamsuddin, A.H. Co-pyrolysis of biomass and plastic: Circularity of wastes and comprehensive review of synergistic mechanism. Results Eng. 2023, 17, 100989. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Changing State of the Climate System. In Climate Change 2021—The Physical Science Basis: Working Group I Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2023; pp. 287–422. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 13 November 2024).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 13 November 2024).

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Straka, P.; Bičáková, O.; Šupová, M. Thermal conversion of polyolefins/polystyrene ternary mixtures: Kinetics and pyrolysis on a laboratory and commercial scales. J. Anal. Appl. Pyrolysis 2017, 128, 196–207. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Sánchez-Ávila, N.; Cardarelli, A.; Carmona-Cabello, M.; Dorado, M.P.; Pinzi, S.; Barbanera, M. Kinetic and thermodynamic behavior of co-pyrolysis of olive pomace and thermoplastic waste via thermogravimetric analysis. Renew. Energy 2024, 230, 120880. [Google Scholar] [CrossRef]

- Ringer, M.; Putsche, V.; Scahill, J. Large-Scale Pyrolysis Oil Production: A Technology Assessment and Economic Analysis; National Renewable Energy Laboratory: Golden, CO, USA, 2006. Available online: http://www.osti.gov/bridge (accessed on 12 November 2024).

- Fivga, A.; Dimitriou, I. Pyrolysis of plastic waste for the production of heavy fuel substitute: A techno-economic assessment. Energy 2018, 149, 865–874. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. A systematic review on life cycle assessment of different waste-to-energy valorization technologies. J. Clean. Prod. 2021, 290, 125747. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Veronese, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Schmidt Rivera, X.C.; Gallego-Schmid, A.; Najdanovic-Visak, V.; Azapagic, A. Life cycle environmental sustainability of valorization routes for spent coffee grounds: From waste to resources. Resour. Conserv. Recycl. 2020, 157, 104751. [Google Scholar] [CrossRef]

- Chhabra, V.; Parashar, A.; Shastri, Y.; Bhattacharya, S. Techno-economic and life cycle assessment of pyrolysis of unsegregated urban municipal solid waste in India. Ind. Eng. Chem. Res. 2021, 60, 1473–1482. [Google Scholar] [CrossRef]

- Ahamed, A.; Veksha, A.; Yin, K.; Weerachanchai, P.; Giannis, A.; Lisak, G. Environmental impact assessment of converting flexible packaging plastic waste to pyrolysis oil and multi-walled carbon nanotubes. J. Hazard. Mater. 2020, 390, 121449. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, S.; Yang, S.; Zhang, R.; Shi, X.; Song, L. A landfill serves as a critical source of microplastic pollution and harbors diverse plastic biodegradation microbial species and enzymes: Study in large-scale landfills, China. J. Hazard. Mater. 2023, 457, 131676. [Google Scholar] [CrossRef]

- Sharma, B.; Goswami, Y.; Sharma, S.; Shekhar, S. Inherent roadmap of conversion of plastic waste into energy and its life cycle assessment: A frontrunner compendium. Renew. Sustain. Energy Rev. 2021, 146, 111070. [Google Scholar] [CrossRef]

- Guo, S.; Li, Y.; Tang, S.; Zhang, T. The nitrogen transformation behavior based on the pyrolysis products of wheat straw. Chin. J. Chem. Eng. 2024, 71, 58–65. [Google Scholar] [CrossRef]

- Saad, J.M.; Williams, P.T.; Zhang, Y.S.; Yao, D.; Yang, H.; Zhou, H. Comparison of waste plastics pyrolysis under nitrogen and carbon dioxide atmospheres: A thermogravimetric and kinetic study. J. Anal. Appl. Pyrolysis 2021, 156, 105135. [Google Scholar] [CrossRef]

- Erisman, J.W.; Galloway, J.; Seitzinger, S.; Bleeker, A.; Butterbach-Bahl, K. Reactive nitrogen in the environment and its effect on climate change. Curr. Opin. Environ. Sustain. 2011, 3, 281–290. [Google Scholar] [CrossRef]

- Nieuwlaar, E. Life Cycle Assessment and Energy Systems. Ref. Module Earth Syst. Environ. Sci. 2013, 3, 647–654. [Google Scholar] [CrossRef]

- Antelava, A.; Damilos, S.; Hafeez, S.; Manos, G.; Al-Salem, S.M.; Sharma, B.K.; Kohli, K.; Constantinou, A. Plastic Solid Waste (PSW) in the Context of Life Cycle Assessment (LCA) and Sustainable Management. Environ. Manag. 2019, 64, 230–244. [Google Scholar] [CrossRef]

- Demirbas, A. Pyrolysis of municipal plastic wastes for recovery of gasoline range hydrocarbons. J. Anal. Appl. Pyrolysis 2004, 72, 97–102. [Google Scholar] [CrossRef]

- Gardy, J.; Hassanpour, A.; Lai, X.; Rehan, M. The influence of blending process on the quality of rapeseed oil-used cooking oil biodiesels. J. Environ. Sci. 2014, 3, 233–240. [Google Scholar]

- Islam, M.R.; Parveen, M.; Haniu, H.; Sarker, M.I. Innovation in pyrolysis technology for management of scrap tire: A solution of Energy and Environment. J. Environ. Dev. 2010, 1, 89. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Nizami, A.S. Effect of plastic waste types on pyrolysis liquid oil. Int. Biodeterior. Biodegrad. 2017, 119, 239–252. [Google Scholar] [CrossRef]

- Sun, P.; Wang, Z.; Li, C.; Tang, B.; Peng, C. Catalytic conversion of lignin and its derivatives to alkanes over multifunctional catalysts: A review. Fuel 2024, 361, 130726. [Google Scholar] [CrossRef]

- Kochaphum, C.; Gheewala, S.H.; Vinitnantharat, S. Environmental comparison of straight run diesel and cracked diesel. J. Clean. Prod. 2012, 37, 142–146. [Google Scholar] [CrossRef]

- Bulfin, B.; Buttsworth, L.; Lidor, A.; Steinfeld, A. High-purity nitrogen production from air by pressure swing adsorption combined with SrFeO3 redox chemical looping. Chem. Eng. J. 2021, 421, 127734. [Google Scholar] [CrossRef]

- Karmann, C.; Mágrová, A.; Jeníček, P.; Bartáček, J.; Kouba, V. Advances in nitrogen removal and recovery technologies from reject water: Economic and environmental perspectives. Bioresour. Technol. 2024, 391, 129888. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, K. Properties and use of jatropha curcas oil and diesel fuel blends in compression ignition engine. Renew. Energy 2003, 28, 239–248. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. A critical review on available models to predict engine fuel properties of biodiesel. Renew. Sustain. Energy Rev. 2022, 155, 111925. [Google Scholar] [CrossRef]

- Tipanluisa, L.; Prati, M.V.; Costagliola, M.A. Impact of diesel/renewable fuels blend on gaseous and particle emissions of a light-duty vehicle under real driving emissions. Renew. Energy 2024, 230, 120819. [Google Scholar] [CrossRef]

- Tan, S.X.; Lim, S.; Ong, H.C.; Pang, Y.L. State of the art review on development of ultrasound-assisted catalytic transesterification process for biodiesel production. Fuel 2019, 235, 1121–1127. [Google Scholar] [CrossRef]

- Stančin, H.; Strezov, V.; Mikulčić, H. Life cycle assessment of alternative fuel production by co-pyrolysis of waste biomass and plastics. J. Clean. Prod. 2023, 414, 137676. [Google Scholar] [CrossRef]

- Tsangas, M.; Papamichael, I.; Loizia, P.; Voukkali, I.; Salman Raza, N.; Vincenzo, N.; Zorpas, A.A. Life cycle assessment of electricity generation by tire pyrolysis oil. Process Saf. Environ. Prot. 2024, 186, 376–387. [Google Scholar] [CrossRef]

- Azam, M.U.; Vete, A.; Afzal, W. Process Simulation and Life Cycle Assessment of Waste Plastics: A Comparison of Pyrolysis and Hydrocracking. Molecules 2022, 27, 8084. [Google Scholar] [CrossRef]

- Kulas, D.G.; Zolghadr, A.; Chaudhari, U.S.; Shonnard, D.R. Economic and environmental analysis of plastics pyrolysis after secondary sortation of mixed plastic waste. J. Clean. Prod. 2023, 384, 135542. [Google Scholar] [CrossRef]

- Manfredi, S.; Tonini, D.; Christensen, T.H.; Scharff, H. Landfilling of waste: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 8. [Google Scholar] [CrossRef] [PubMed]

- Peña, D.; Dorronsoro, B.; Ruiz, P. Sustainable waste collection optimization using electric vehicles. Sustain. Cities Soc. 2024, 105, 105343. [Google Scholar] [CrossRef]

- Singh, S.; Malyan, S.K.; Maithani, C.; Kashyap, S.; Tyagi, V.K.; Singh, R.; Malhotra, S.; Sharma, M.; Kumar, A.; Panday, B.K.; et al. Microplastics in landfill leachate: Occurrence, health concerns, and removal strategies. J. Environ. Manag. 2023, 342, 118220. [Google Scholar] [CrossRef] [PubMed]

- Jiao, H.; Ali, S.S.; Alsharbaty, M.H.M.; Elsamahy, T.; Abdelkarim, E.; Schagerl, M.; Al-Tohamy, R.; Sun, J. A critical review on plastic waste life cycle assessment and management: Challenges, research gaps, and future perspectives. Ecotoxicol. Environ. Saf. 2024, 271, 115942. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).