Potential Utilization of Rice Waste in the Construction Sector: A Multi-Criteria Decision Analysis Approach

Abstract

1. Introduction

2. Materials and Methods

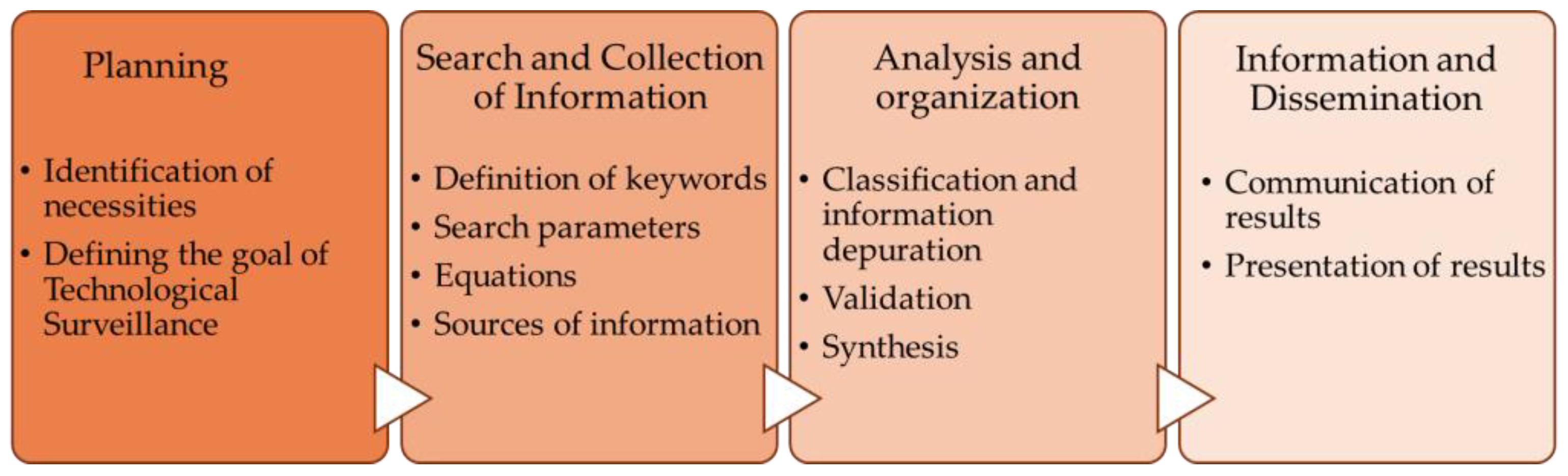

2.1. Exploration of Current Rice Waste Uses

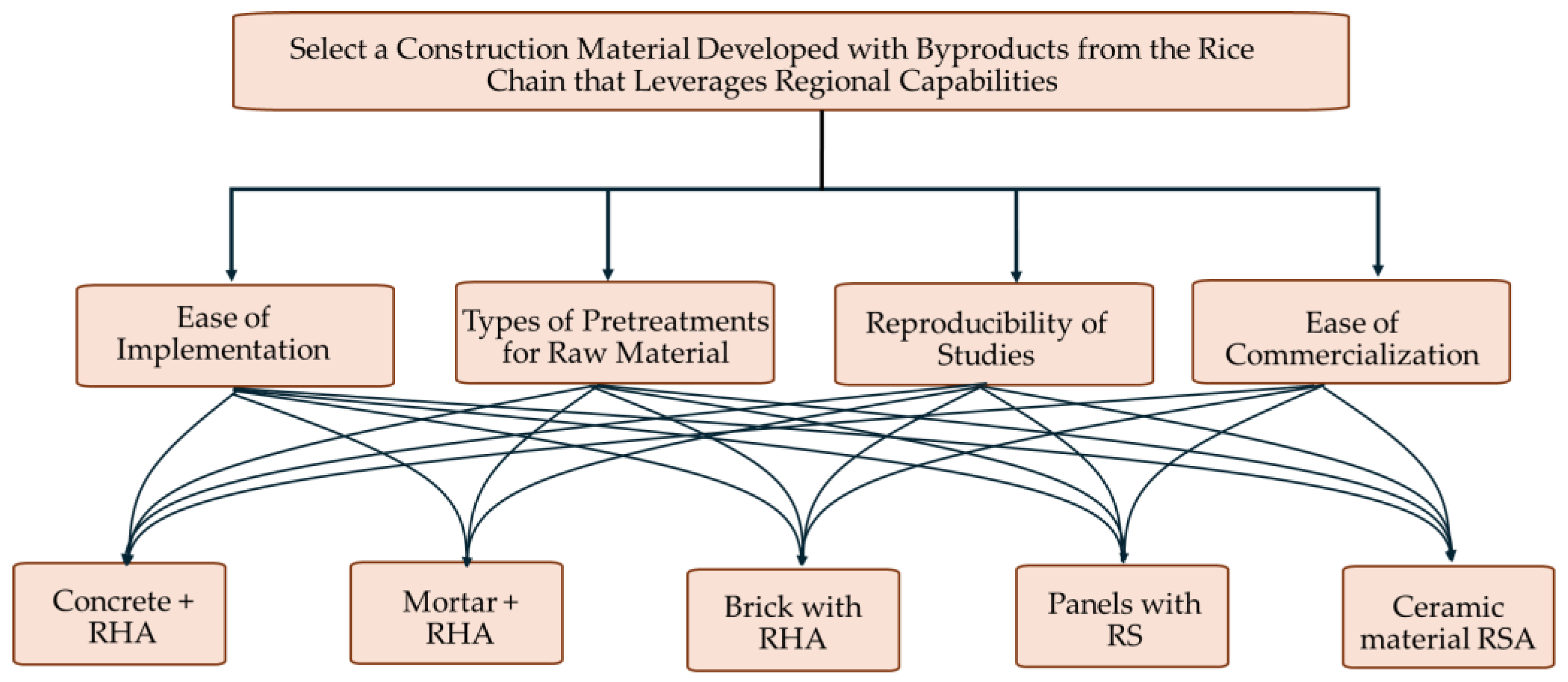

2.2. Analytic Hierarchy Process Methodology

3. Results

3.1. Exploration of Currect Rice Wastes Uses

3.2. Analytic Hierarchy Process Methodology

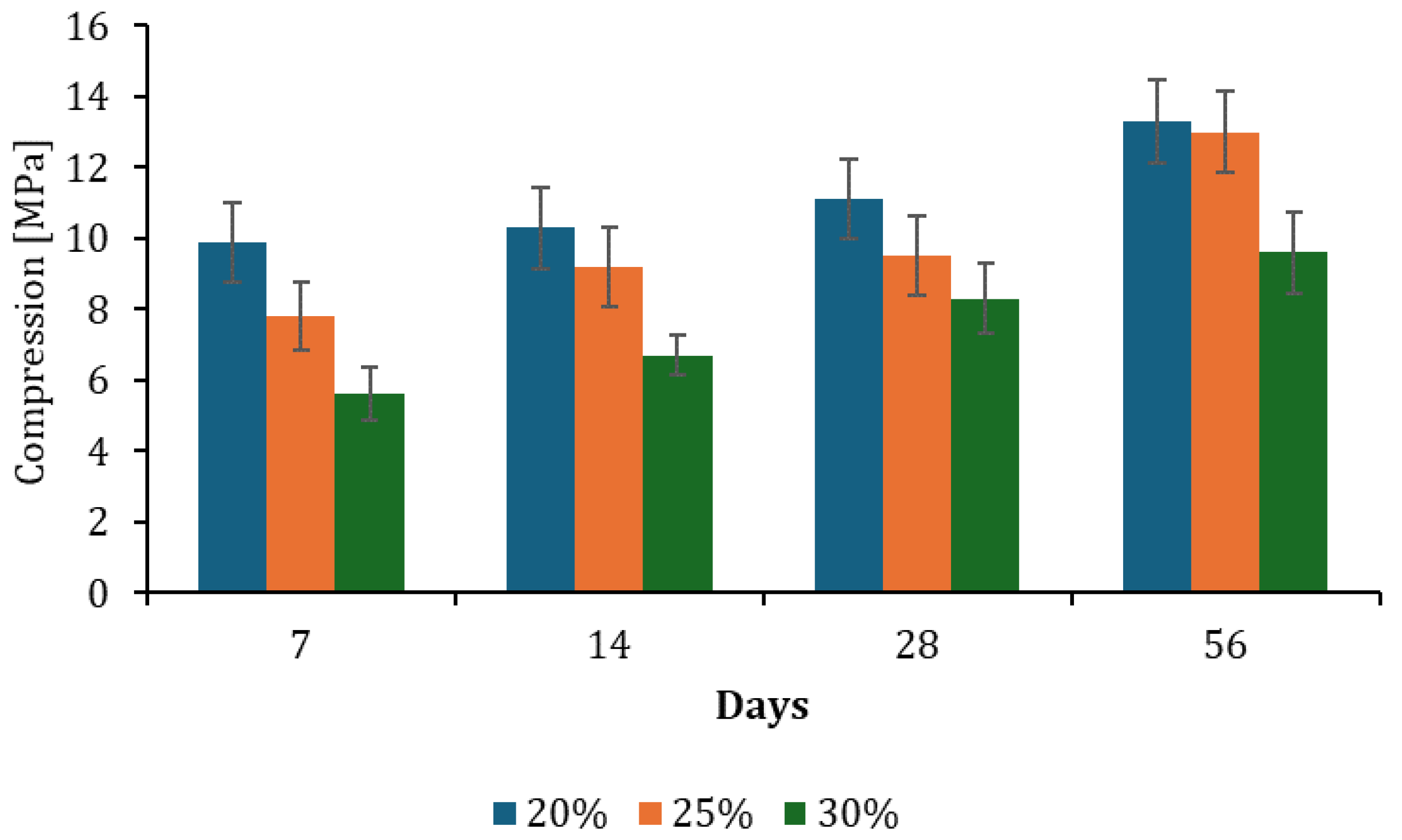

3.3. Performance of Pavers with Rice Husk Ash

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gáfaro, M.; Pellegrina, H.S. Political economy of roads: The role of access to cities in Colombia. J. Int. Econ. 2022, 137, 103598. [Google Scholar] [CrossRef]

- OECD. OECD Review of Agricultural Policies: Colombia 2015; OECD Publishing: Paris, France, 2015. [Google Scholar]

- FAOSTAT. Suite of Food Security Indicators. 2023. Available online: https://www.fao.org/faostat/en/#country/44 (accessed on 25 September 2024).

- Durand-Morat, A.; Bairagi, S. International Rice Outlook: International Rice Baseline Projections 2021–2031 (Research Reports and Research Bulletins); University of Arkansas: Fayetteville, AR, USA, 2022; Available online: https://scholarworks.uark.edu/cgi/viewcontent.cgi?article=1052&context=aaesrb (accessed on 10 July 2024).

- Phillips, J.; Durand-Morat, A.; Nalley, L.L.; Graterol, E.; Bonatti, M.; de la Pava, K.L.; Urioste, S.; Yang, W. Understanding demand for broken rice and its potential food security implications in Colombia. J. Agric. Food Res. 2024, 15, 100884. [Google Scholar] [CrossRef]

- Gobernación del Tolima. Tolima en Cifras 2022; Gobernación del Tolima: Tolima, Colombia, 2022. Available online: https://www.tolima.gov.co/tolima/cifras-y-estadisticas/tolima-en-cifras#2659-vigencia-2022 (accessed on 25 September 2024).

- Logroño, W.; Ramírez, G.; Recalde, C.; Echeverría, M.; Cunachi, A. Bioelectricity Generation from Vegetables and Fruits Wastes by Using Single Chamber Microbial Fuel Cells with High Andean Soils. Energy Procedia 2015, 75, 2009–2014. [Google Scholar] [CrossRef]

- Bayomy, H.M.; Alamri, E.S.; Albalawi, A.N.; Alharbi, R.; Ozaybi, N.A.; Rozan, M.A.; Shamsia, S.M. Production of Extruded Functional Snacks Based on Resistant Starch Using Waste Rice and Whey Milk. LWT-Food Sci. Technol. 2024, 197, 115871. [Google Scholar] [CrossRef]

- Tamilselvan, R.; Selwynraj, A.I. A novel g-C3N4 photocatalytic pretreatment for reducing silica and modifying the structure of rice straw for sustainable biofuel production. Process Saf. Environ. Prot. 2024, 187, 799–809. [Google Scholar] [CrossRef]

- Pandey, V.; Panda, S.K.; Singh, V.K. Preparation and characterization of high-strength insulating porous bricks by reusing coal mine overburden waste, red mud, and rice husk. J. Clean. Prod. 2024, 469, 143134. [Google Scholar] [CrossRef]

- Gupte, A.P.; Basaglia, M.; Casella, S.; Favaro, L. Rice Waste Streams as a Promising Source of Biofuels: Feedstocks, Biotechnologies, and Future Perspectives. Renew. Sustain. Energy Rev. 2022, 167, 112673. [Google Scholar] [CrossRef]

- Sobuz, M.H.R.; Al-Imran; Datta, S.D.; Jabin, J.A.; Aditto, F.S.; Hasan, N.M.S.; Hasan, M.; Zaman, A.A.U. Assessing the Influence of Sugarcane Bagasse Ash for the Production of Eco-Friendly Concrete: Experimental and Machine Learning Approaches. Case Stud. Constr. Mater. 2024, 20, e02839. [Google Scholar] [CrossRef]

- Saraswat, A.; Parashar, A.K.; Bahadur, R. Effect of Coconut Shell Ash Substitute with Cement on the Mechanical Properties of Cement Concrete. Mater. Today Proc. 2023. Available online: https://www.sciencedirect.com/science/article/pii/S2214785323050848 (accessed on 10 November 2023).

- Lejano, B.; Elevado, K.J.; Fandiño, M.A.; Ng, E.A.; Datinguinoo, Z.A.N.; Oliveros, S.B. Experimental Investigation of Utilizing Coconut Shell Ash and Coconut Shell Granules as Aggregates in Coconut Coir Reinforced Concrete. Clean. Eng. Technol. 2024, 21, 100779. [Google Scholar] [CrossRef]

- Xiong, G.; Cundy, A.; Guo, X. Utilization of Corn Cob Ash (CCA) to Prepare Geopolymer Grout: Reaction Mechanism, Crack Repair Effectiveness and Life Cycle Assessment. J. Clean. Prod. 2024, 476, 143741. [Google Scholar] [CrossRef]

- Ahmad, J.; Arbili, M.M.; Alabduljabbar, H.; Deifalla, A.F. Concrete Made with Partially Substituted Corn Cob Ash: A Review. Case Stud. Constr. Mater. 2023, 19, e01942. [Google Scholar]

- Ali, B.; Azab, M.; Ahmed, H.; Kurda, R.; El Ouni, M.H.; Elhag, A.B. Investigation of Physical, Strength, and Ductility Characteristics of Concrete Reinforced with Banana (Musaceae) Stem Fiber. J. Build. Eng. 2022, 61, 105364. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, E.; Wong, Y.C.; Horpibulsuk, S. Recycled plastic granules and demolition wastes as construction materials: Resilient moduli and strength characteristics. Constr. Build. Mater. 2017, 147, 639–647. [Google Scholar] [CrossRef]

- Sanchez-Echeverri, L.A.; Tovar-Perilla, N.J.; Suarez-Puentes, J.G.; Bravo-Cervera, J.E.; Rojas-Parra, D.F. Mechanical and Market Study for Sand/Recycled-Plastic Cobbles in a Medium-Size Colombian City. Recycling 2021, 6, 17. [Google Scholar] [CrossRef]

- Nyika, J.; Dinka, M. Recycling Plastic Waste Materials for Building and Construction: A Minireview. Mater. Today Proc. 2022, 62, 3257–3262. [Google Scholar] [CrossRef]

- Yousef, A.R.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P.; Alabduljabbar, H. Potential Use of Recycled Plastic and Rubber Aggregate in Cementitious Materials for Sustainable Construction: A Review. J. Clean. Prod. 2021, 329, 129736. [Google Scholar] [CrossRef]

- Ahmed, N. Utilizing Plastic Waste in the Building and Construction Industry: A Pathway towards the Circular Economy. Constr. Build. Mater. 2023, 383, 131311. [Google Scholar] [CrossRef]

- Poopalam, K.D.; Ismail, T.N.M.T.; Hanzah, N.A.; Alias, A.H.; Wahab, N.A.; Ibrahim, Z.; Subramaniam, V.; Armylisas, A.H.N.; Idris, Z. Utilization of Oil Palm Biomass and Polyurethanes as Sustainable Construction Materials: A Review. Dev. Built Environ. 2024, 17, 100380. [Google Scholar] [CrossRef]

- Monedero, E.; Hernández, J.J.; Collado, R.; Pazo, A.; Aineto, M.; Acosta, A. Evaluation of ashes from agro-industrial biomass as a component for producing construction materials. J. Clean. Prod. 2021, 318, 128517. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.C.; Arroja, L.; Dias, A.C. Environmental Assessment of Valorisation Alternatives for Woody Biomass Ash in Construction Materials. Resour. Conserv. Recycl. 2019, 148, 67–79. [Google Scholar] [CrossRef]

- Sathiparan, N.; Anburuvel, A.; Selvam, V.V. Utilization of agro-waste groundnut shell and its derivatives in sustainable construction and building materials—A review. J. Build. Eng. 2023, 66, 105866. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A.; Adesina, A. Possibilities for the Application of Agro-Industrial Wastes in Cementitious Materials: A Brief Review of the Brazilian Perspective. Clean. Mater. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice Husk Ash as a Partial Replacement of Cement in High Strength Concrete Containing Micro Silica: Evaluating Durability and Mechanical Properties. Case Stud. Constr. Mater. 2017, 7, 73–81. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Alaskar, A. Recycling of Rice Husk Waste for a Sustainable Concrete: A Critical Review. J. Clean. Prod. 2021, 312, 127734. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process—What It Is and How It Is Used. In The Analytic Hierarchy Process; Elsevier: Amsterdam, The Netherlands, 1980; pp. 161–167. [Google Scholar]

- Mardani, A.; Jusoh, A.; Nor, K.M.; Khalifah, Z.; Zakwan, N.; Valipour, A. Application of Multiple-Criteria Decision-Making Techniques and Approaches to Sustainable Energy Planning and Management: A Review. Renew. Sustain. Energy Rev. 2015, 56, 1457–1470. [Google Scholar]

- Zhang, C.; Qiao, P.; Fu, Q.; Zhang, J.; Shen, L. Evaluating Integrated Pest Management Strategies Using an Analytical Hierarchy Process (AHP). Comput. Electron. Agric. 2017, 136, 157–165. [Google Scholar] [CrossRef]

- Kumar, R.; Saroj, D.P.; Kumar, P.; Singh, P.; Kumar, P.; Singh, R.K. Evaluation of Water Conservation Strategies Using the Analytic Hierarchy Process for Sustainable Irrigation Management. J. Clean. Prod. 2020, 253, 118261. [Google Scholar] [CrossRef]

- Tovar-Perilla, N.J.; Bermeo-Andrade, H.P.; Torres-Delgado, J.F.; Gómez, M.I. Methodology to Support Decision-Making in Prioritization Improvement Plans Aimed at Agricultural Sector: Case Study. Dyna 2018, 85, 356–363. [Google Scholar] [CrossRef]

- Salazar-Camacho, N.A.; Delgadillo-Mirquez, L.; Sanchez-Echeverri, L.A.; Tovar-Perilla, N.J. Evaluating Sustainable Alternatives for Cocoa Waste Utilization Using the Analytic Hierarchy Process. Sustainability 2024, 16, 7817. [Google Scholar] [CrossRef]

- Alzate, B.A.; Giraldo, L.T.; Barbosa, A.F. Vigilancia Tecnológica: Metodologías y aplicaciones. Rev. GPT Gestión Pers. Tecnol. 2012, 5, 13. Available online: https://www.redalyc.org/pdf/4778/477847114019.pdf (accessed on 5 July 2024).

- Sánchez-Torres, J. Herramientas de software para la práctica en la empresa de la vigilancia tecnológica e inteligencia competitiva: Evaluación comparativa. Preface by E. Ríos Pita; Presentation by F. Palop Marro. 2002. Available online: https://www.researchgate.net/publication/31842359_Herramientas_de_software_para_la_practica_en_la_empresa_de_la_vigilancia_tecnologica_e_inteligencia_competitiva_evaluacion_comparativa_JM_Sanchez_Torres_pref_de_Eduardo_Rios_Pita_presen_de_Fernando_Pa (accessed on 25 September 2024).

- Carrillo-Zambrano, E.; Páez-Leal, M.C.; Suárez, J.M.; Luna-González, M.L. Modelo de vigilancia tecnológica para la gestión de un grupo de investigación en salud. MedUNAB 2018, 21, 84–99. [Google Scholar] [CrossRef]

- Silva, L.R.; de Carvalho Gama, K.N.; Salles, P.V.; Braga, F.C.S. Concrete with Rice Husk Ash and Construction and Demolition Wastes. Res. Soc. Dev. 2019, 8, 2684861. [Google Scholar] [CrossRef]

- Madandoust, R.; Ranjbar, M.M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical Properties and Durability Assessment of Rice Husk Ash Concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Jamil, M.; Kaish, A.B.M.A.; Raman, S.N.; Zain, M.F.M. Pozzolanic Contribution of Rice Husk Ash in Cementitious Systems. Constr. Build. Mater. 2013, 47, 588–593. [Google Scholar] [CrossRef]

- Adamu, M.; Jimoh, A.A.; Waziri, M.A. Experimental Investigation on Rice Husk Ash as Cement Replacement in Concrete Production. Constr. Build. Mater. 2016, 127, 353–362. [Google Scholar] [CrossRef]

- Vieira, A.P.; Toledo Filho, R.D.; Tavares, L.M.; Cordeiro, G.C. Effect of Particle Size, Porous Structure, and Content of Rice Husk Ash on the Hydration Process and Compressive Strength Evolution of Concrete. Constr. Build. Mater. 2020, 236, 117553. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Bahrami, N.; Vaezi, M.; Ozbakkaloglu, T. Optimum Rice Husk Ash Content and Bacterial Concentration in Self-Compacting Concrete. Constr. Build. Mater. 2019, 222, 796–813. [Google Scholar] [CrossRef]

- Safari, J.; Mirzaei, M.; Rooholamini, H.; Hassani, A. Effect of Rice Husk Ash and Macro-Synthetic Fibre on the Properties of Self-Compacting Concrete. Constr. Build. Mater. 2018, 175, 371–380. [Google Scholar] [CrossRef]

- Chopra, D.; Siddique, R.; Kunal. Strength, Permeability, and Microstructure of Self-Compacting Concrete Containing Rice Husk Ash. Biosyst. Eng. 2015, 130, 72–80. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Papadakis, V.G.; Tsimas, S. Rice Husk Ash (RHA) Effectiveness in Cement and Concrete as a Function of Reactive Silica and Fineness. Cem. Concr. Res. 2014, 61–62, 20–27. [Google Scholar] [CrossRef]

- Salas, A.; Delvasto, S.; Mejía de Gutiérrez, R. Developing High-Performance Concrete Incorporating Highly-Reactive Rice Husk Ash. Ing. Investig. 2013, 33, 49–55. [Google Scholar] [CrossRef]

- Cerutti, F.; Santilli, A. En Camino Hacia un hormigón sustentable: Uso de cementos puzolánicos en uruguay. Mem. Investig. Ing. 2017, 15, 37–42. [Google Scholar]

- Nguyen, V.T.; Ye, G.; van Breugel, K.; Fraaij, A.L.A.; Dai, B.D. The Study of Using Rice Husk Ash to Produce Ultra High Performance Concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Khan, R.; Jabbar, A.; Ahmad, I.; Khan, W.; Khan, A.N.; Mirza, J. Reduction in Environmental Problems Using Rice-Husk Ash in Concrete. Constr. Build. Mater. 2012, 30, 360–365. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A Life-Cycle Approach to Environmental, Mechanical, and Durability Properties of “Green” Concrete Mixes with Rice Husk Ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Kua, H.W.; Yu, L.N.; Chung, J.K.H. Study on Fresh Properties of Cementitious Materials Containing Rice Husk Ash for Construction 3D Printing. SSRN Electron. J. 2020, 32, 04020195. [Google Scholar]

- Munshi, S.; Sharma, R.P. Experimental Investigation on Strength and Water Permeability of Mortar Incorporate with Rice Straw Ash. Adv. Mater. Sci. Eng. 2016, 2016, 9696505. [Google Scholar] [CrossRef]

- Yuzer, N.; Cinar, Z.; Akoz, F.; Biricik, H.; Gurkan, Y.Y.; Kabay, N.; Kizilkanat, A.B. Influence of Raw Rice Husk Addition on Structure and Properties of Concrete. Constr. Build. Mater. 2013, 44, 54–62. [Google Scholar] [CrossRef]

- Chabi, E.; Doko, V.; Hounkpè, S.P.; Adjovi, E.C. Study of Cement Composites on Addition of Rice Husk. Case Stud. Constr. Mater. 2020, 12, e00345. [Google Scholar] [CrossRef]

- Fajardo Cárdenas, C.A.; Alvarado Loo, C. Lightweight Mortars with Rice Husk: Mix Design and Property Evaluation. Rev. Ing. Constr. 2011, 26, 273–282. [Google Scholar] [CrossRef][Green Version]

- Novoa-Galeano, M.A.; Becerra-Leon, L.D.; Vasquez-Piñeros, M.P. Rice husk ash and its effect on adhesive mortars. Av. Investig. En Ing. 2012, 9, 73–82. [Google Scholar] [CrossRef]

- Bie, R.-S.; Song, X.-F.; Liu, Q.-Q.; Ji, X.-Y.; Chen, P. Studies on Effects of Burning Conditions and Rice Husk Ash (RHA) Blending Amount on the Mechanical Behavior of Cement. Cem. Concr. Compos. 2015, 55, 162–168. [Google Scholar] [CrossRef]

- Hamzeh, Y.; Ziabari, K.P.; Torkaman, J.; Ashori, A.; Jafari, M. Study on the Effects of White Rice Husk Ash and Fibrous Materials Additions on Some Properties of Fiber-Cement Composites. J. Environ. Manag. 2013, 117, 263–267. [Google Scholar] [CrossRef]

- Pincha Tuabanda, A.; Valdivieso Pulgar, G. Ceniza de Cascarilla de Arroz en Mortero para Reducir las Patologías por Humedad en Enlucidos. Bachelor’s Thesis, Universidad Nacional de Chimborazo, Riobamba, Ecuador, 2023. [Google Scholar]

- Antiohos, S.K.; Tapali, J.G.; Zervaki, M.; Sousa-Coutinho, J.; Tsimas, S.; Papadakis, V.G. Low Embodied Energy Cement Containing Untreated RHA: A Strength Development and Durability Study. Constr. Build. Mater. 2013, 49, 455–463. [Google Scholar] [CrossRef]

- He, Z.; Hu, L.; Shao, Y.; Cai, X.; Zhang, S. Microstructure and Properties of Sustainable Cement-Based Materials Using Combustion Treated Rice Husk Ash. Constr. Build. Mater. 2021, 294, 123482. [Google Scholar] [CrossRef]

- Barbosa de Lima, P.C.; de Castro Xavier, G.; Lopes Pinheiro, I.; Albuquerque Tashima, M.M.; John, V.M.; Savastano, H., Jr. Evaluation of the use of cellulose pulp, residue from the paper industry, in combination with rice husk ash in the production of fiber cement. Constr. Build. Mater. 2014, 61, 46–50. [Google Scholar] [CrossRef]

- Liu, J.; Jia, C.; He, C. Flexural Properties of Rice Straw and Starch Composites. AASRI Procedia 2012, 3, 89–94. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; Almeida, J.; Antonio, J.; de Brito, J. Characterisation of Sustainable Building Walls Made from Rice Straw Bales. J. Build. Eng. 2020, 28, 101041. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Clausell, J.R.; Guillén-Guillamón, I.; Mendiguchia, F.A. Waste Valorization of Rice Straw as a Building Material in Valencia and its Implications for Local and Global Ecosystems. J. Clean. Prod. 2021, 318, 128507. [Google Scholar] [CrossRef]

- António, J.; Tadeu, A.; Marques, B.; Almeida, J.A.S.; Pinto, V. Application of Rice Husk in the Development of New Composite Boards. Constr. Build. Mater. 2018, 176, 432–439. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable Thermal Insulation Biocomposites from Rice Husk, Wheat Husk, Wood Fibers, and Textile Waste Fibers: Elaboration and Performance Evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Guzmán, Á.; Delvasto, S.; Sánchez, E.; Amigó, V. Use of Rice Straw Ash as a Substitute for Feldspar in the Production of Triaxial Porcelain. Bol. Soc. Esp. Ceram. Vidr. 2013, 52, 25–30. [Google Scholar] [CrossRef]

- Delgado-Trujillo, J.; Martínez-Chica, J.P.; Guzmán-Aponte, A.; Delvasto-Arjona, S.; Amigó-Borrás, V.; Sánchez-Vílchez, E. Reemplazo del cuarzo por ceniza de tamo de arroz en la manufactura de gres porcelánico. Rev. EIA 2015, 12, 41–50. [Google Scholar]

- Hwang, C.-L.; Huynh, T.-P. Investigation into the Use of Unground Rice Husk Ash to Produce Eco-Friendly Construction Bricks. Constr. Build. Mater. 2015, 93, 335–341. [Google Scholar] [CrossRef]

- Allam, M.E.; Garas, G.L.; El Kady, H.G. Recycled Chopped Rice Straw-Cement Bricks: Mechanical, Fire Resistance & Economical Assessment. Aust. J. Basic Appl. Sci. 2011, 5, 27–33. Available online: https://www.researchgate.net/publication/260793495 (accessed on 20 June 2024).

- Sandanayake, M.; Zhang, G.; Setunge, S. Environmental Impacts of Construction in Building Industry—A Review of Knowledge Advances, Gaps and Future Directions. Appl. Sci. 2019, 9, 2400. [Google Scholar] [CrossRef]

- Chen, L.; Huang, L.; Hua, J.; Chen, Z.; Wei, L.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Dong, L.; Yap, P.-S. Green construction for low-carbon cities: A review. Environ. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Pinzón Sanchez, A.M. Los Materiales más Usados para la Construcción en Colombia. 2021. Available online: https://contratistas.co/noticias/los-materiales-mas-usados-enconstruccion-colombia/ (accessed on 15 July 2024).

- Icontec. Norma Técnica Colombiana (NTC) 3819: Morteros para Albañilería; Instituto Colombiano de Normas Técnicas y Certificación (Icontec): Bogota, Colombia, 2010. [Google Scholar]

- Icontec. Norma Técnica Colombiana NTC 3829: Adoquín de Arcilla para Tránsito Peatonal y Vehicular Liviano; Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC): Bogotá, Colombia, 2004. [Google Scholar]

- Kumar, A.S.; Gopi, R. Strength and Durability Studies on Paver Blocks with Rice Husk Ash as Partial Replacement of Cement. Mater. Today Proc. 2022, 52, 683–688. [Google Scholar] [CrossRef]

- Guguloth, B.; Saravanan, M. Strength and Durability of Concrete Using Rice Husk Ash as a Partial Replacement of Cement. Mater. Today Proc. 2022, 52, 1606–1610. [Google Scholar] [CrossRef]

- Ma, W.; Wang, Y.; Huang, L.; Yan, L.; Kasal, B. Natural and Recycled Aggregate Concrete Containing Rice Husk Ash as Replacement of Cement: Mechanical Properties, Microstructure, Strength Model and Statistical Analysis. J. Build. Eng. 2023, 66, 105917. [Google Scholar] [CrossRef]

| Key Words | Searching Equations |

|---|---|

| Rice, subproducts, waste | (“rice”) AND (subproduc* OR waste*) |

| Rice straw, construction, concrete, ecomaterial | (“rice straw”) AND (construction OR concrete OR ecomaterial) NOT (food OR animals) |

| Rice husk, rice husk ashes, concrete, cement | concrete, cement (“rice”) AND (husk* OR husk ash*) AND (construction OR concrete) |

| Sustainable cement, rice husk, rice husk ashes | (sustainable cement) AND (rice husk OR rice husk ash* OR rice waste*) |

| Rice Waste | Construction Material | References |

|---|---|---|

| RH and RHA | Concrete | [28,29,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56] |

| RH, RSA and RHA | Mortar | [41,57,58,59,60,61,62,63] |

| RH and RS | Panels | [64,65,66,67,68,69,70,71] |

| RSA | Ceramic material | [70,71] |

| RS and RHA | Pavers | [10,72,73] |

| Criteria | Ease of Implementation | Types of Pretreatments | Reproducibility of Studies | Ease of Marketing |

|---|---|---|---|---|

| Ease of implementation | 1 | 0.14 | 7 | 3 |

| Types of Pretreatments | 7 | 1 | 7 | 7 |

| Reproducibility of studies | 0.14 | 0.14 | 1 | 0.14 |

| Ease of marketing | 0.33 | 0.14 | 7 | 1 |

| Criteria | Weight Criterion | Weight Criterion/Priority Vector |

|---|---|---|

| Ease of implementation | 0.26 | 4.462 |

| Types of Pretreatments | 0.51 | 7.697 |

| Reproducibility of studies | 0.03 | 5.162 |

| Ease of marketing | 0.20 | 2.989 |

| Average | 5.07 | |

| CI | CR | ||

|---|---|---|---|

| Criteria | 5.08 | 0.019 | 0.02 |

| Ease of implementation | 5.05 | 0.013 | 0.01 |

| Types of Pretreatments | 5.23 | 0.057 | 0.05 |

| Reproducibility of studies | 5.31 | 0.077 | 0.07 |

| Ease of marketing | 5.09 | 0.023 | 0.02 |

| Concrete | Mortar | Bricks | Panels | Ceramic | |

|---|---|---|---|---|---|

| Ease of implementation | 0.037 | 0.067 | 0.478 | 0.154 | 0.154 |

| Types of Pretreatments | 0.087 | 0.144 | 0.476 | 0.048 | 0.048 |

| Reproducibility of studies | 0.494 | 0.288 | 0.037 | 0.086 | 0.086 |

| Ease of marketing | 0.407 | 0.275 | 0.200 | 0.040 | 0.040 |

| Results | 0.15 | 0.15 | 0.41 | 0.07 | 0.21 |

| % RHA | Cement [kg] | Sand [m3] | Water [L] | RHA [kg] |

|---|---|---|---|---|

| 20 | 2.62 | 0.01 | 1.80 | 0.65 |

| 25 | 2.45 | 0.01 | 1.80 | 0.82 |

| 30 | 2.29 | 0.01 | 1.80 | 0.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Henao, D.; Sanchez-Echeverri, L.A.; Tovar-Perilla, N.J. Potential Utilization of Rice Waste in the Construction Sector: A Multi-Criteria Decision Analysis Approach. Resources 2024, 13, 139. https://doi.org/10.3390/resources13100139

Henao D, Sanchez-Echeverri LA, Tovar-Perilla NJ. Potential Utilization of Rice Waste in the Construction Sector: A Multi-Criteria Decision Analysis Approach. Resources. 2024; 13(10):139. https://doi.org/10.3390/resources13100139

Chicago/Turabian StyleHenao, Daniel, Luz Adriana Sanchez-Echeverri, and Nelson Javier Tovar-Perilla. 2024. "Potential Utilization of Rice Waste in the Construction Sector: A Multi-Criteria Decision Analysis Approach" Resources 13, no. 10: 139. https://doi.org/10.3390/resources13100139

APA StyleHenao, D., Sanchez-Echeverri, L. A., & Tovar-Perilla, N. J. (2024). Potential Utilization of Rice Waste in the Construction Sector: A Multi-Criteria Decision Analysis Approach. Resources, 13(10), 139. https://doi.org/10.3390/resources13100139