Development of a SEM-EDS-XRD Protocol for the Physicochemical and Automated Mineralogical Characterisation of Coal Dust Particles

Abstract

1. Introduction

2. Protocol Description and Setup

2.1. Approach

2.2. Outline of Particle Characteristics Investigated

2.2.1. Mineral and Element Distributions

2.2.2. Particle Size

2.2.3. Particle Shape

2.2.4. Particle Roughness

2.2.5. Mineral Liberation and Association

2.3. Instrumentation

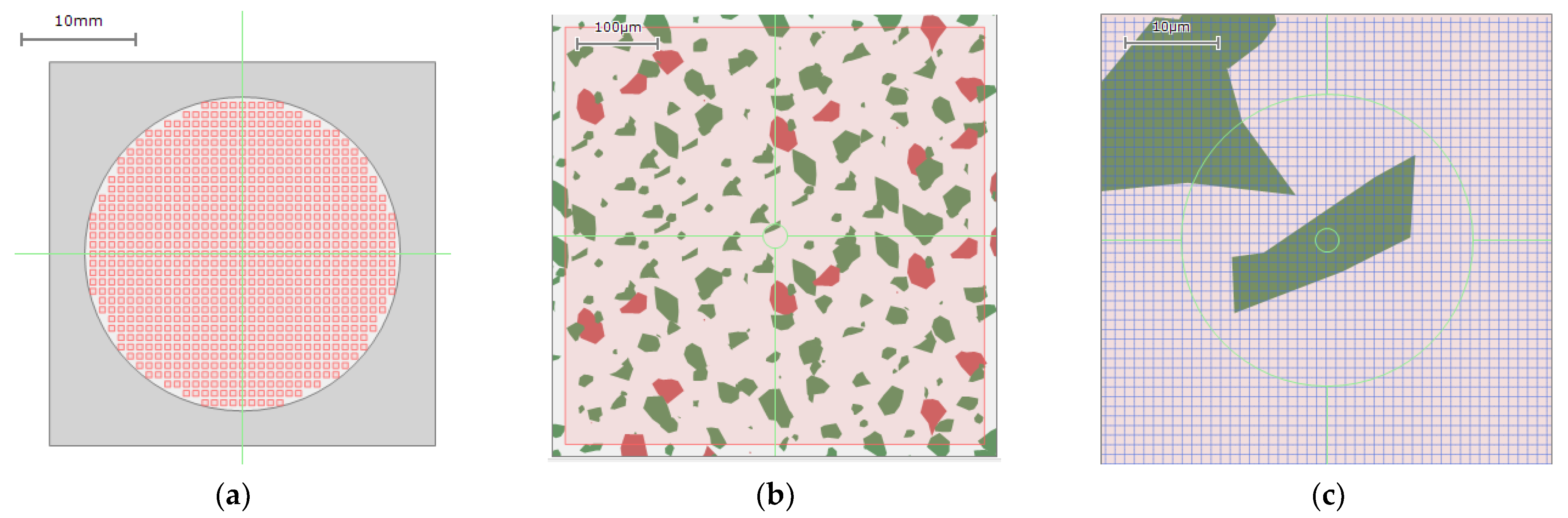

2.4. Measurement Setup

2.4.1. Sample Mounting Methodology

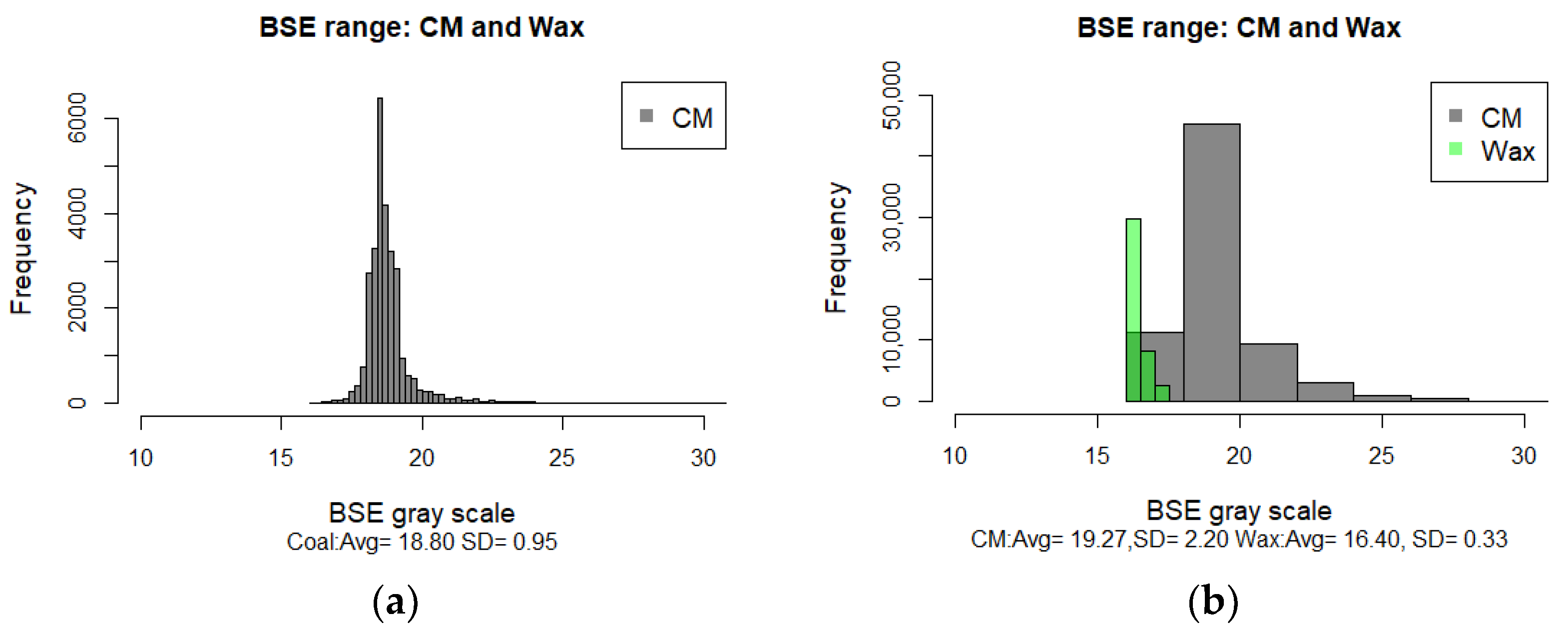

2.4.2. SEM Measurement Conditions

2.4.3. Optimising Mineral Identification: Development of Pixel Classifiers

2.5. Complementary XRF and XRD Data

3. Application and Evaluation of the Auto-SEM-EDS-XRD Protocol: A Case Study

3.1. Sample Description and Preparation

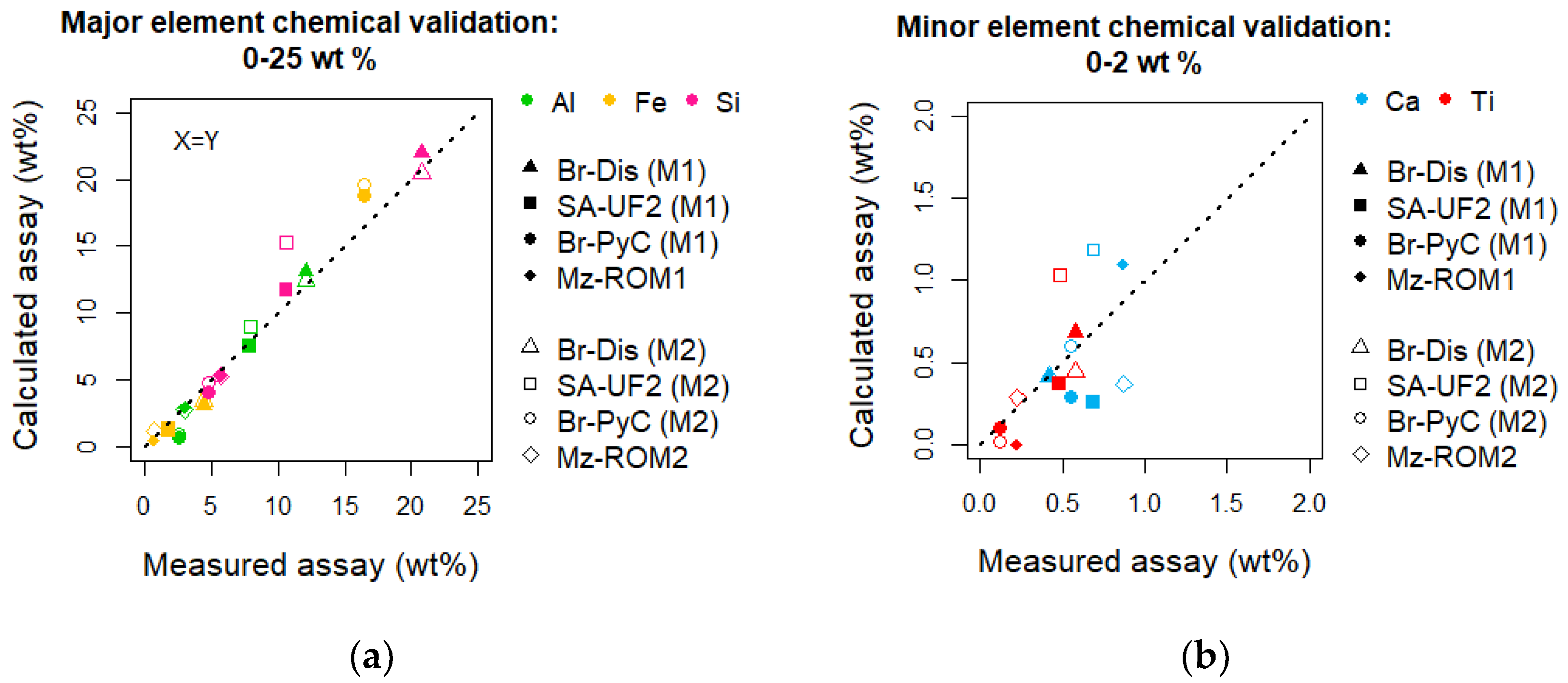

3.2. Measurement Validation

3.3. Elemental Distributions

3.4. General Particle Characteristics

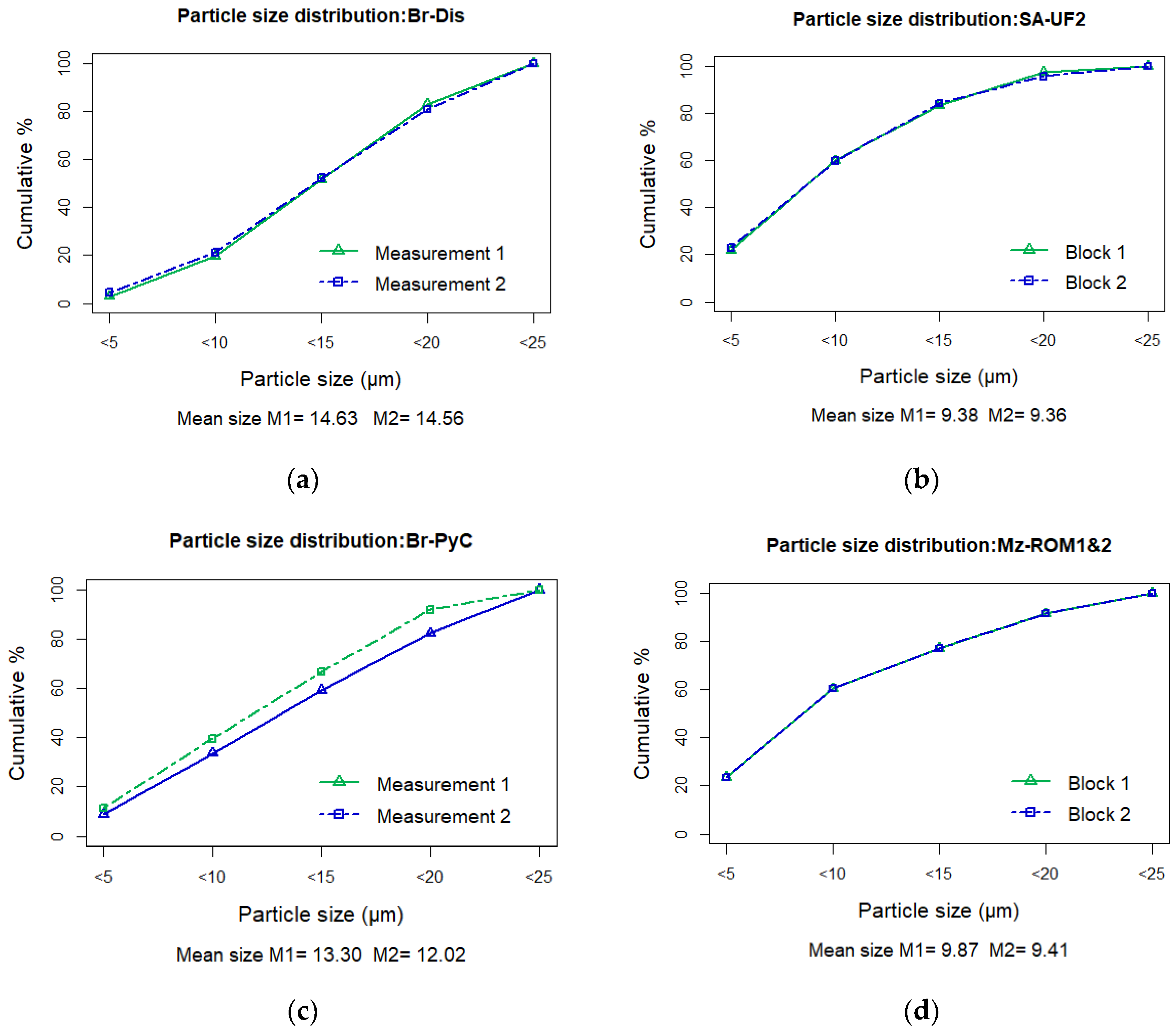

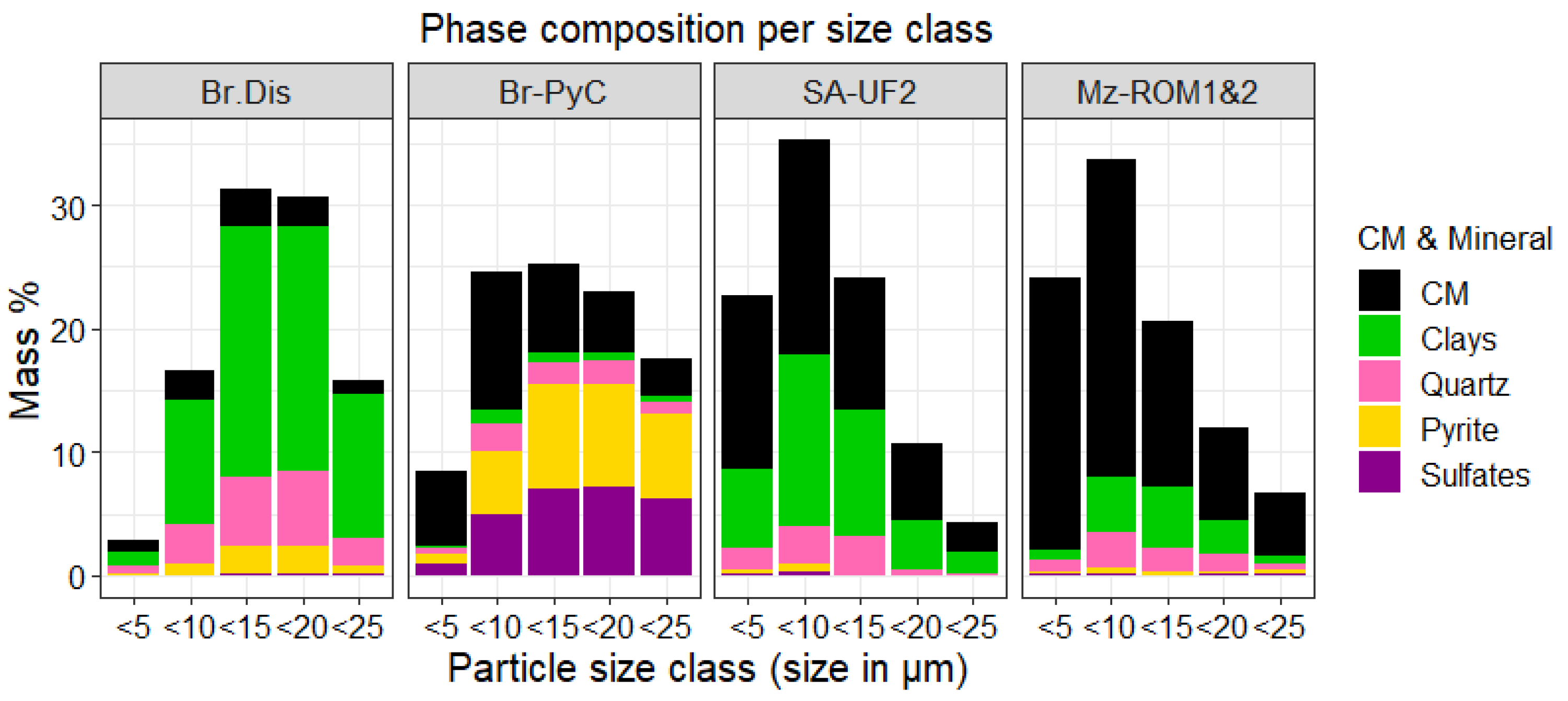

3.4.1. Size Distributions

3.4.2. Shape and Roughness

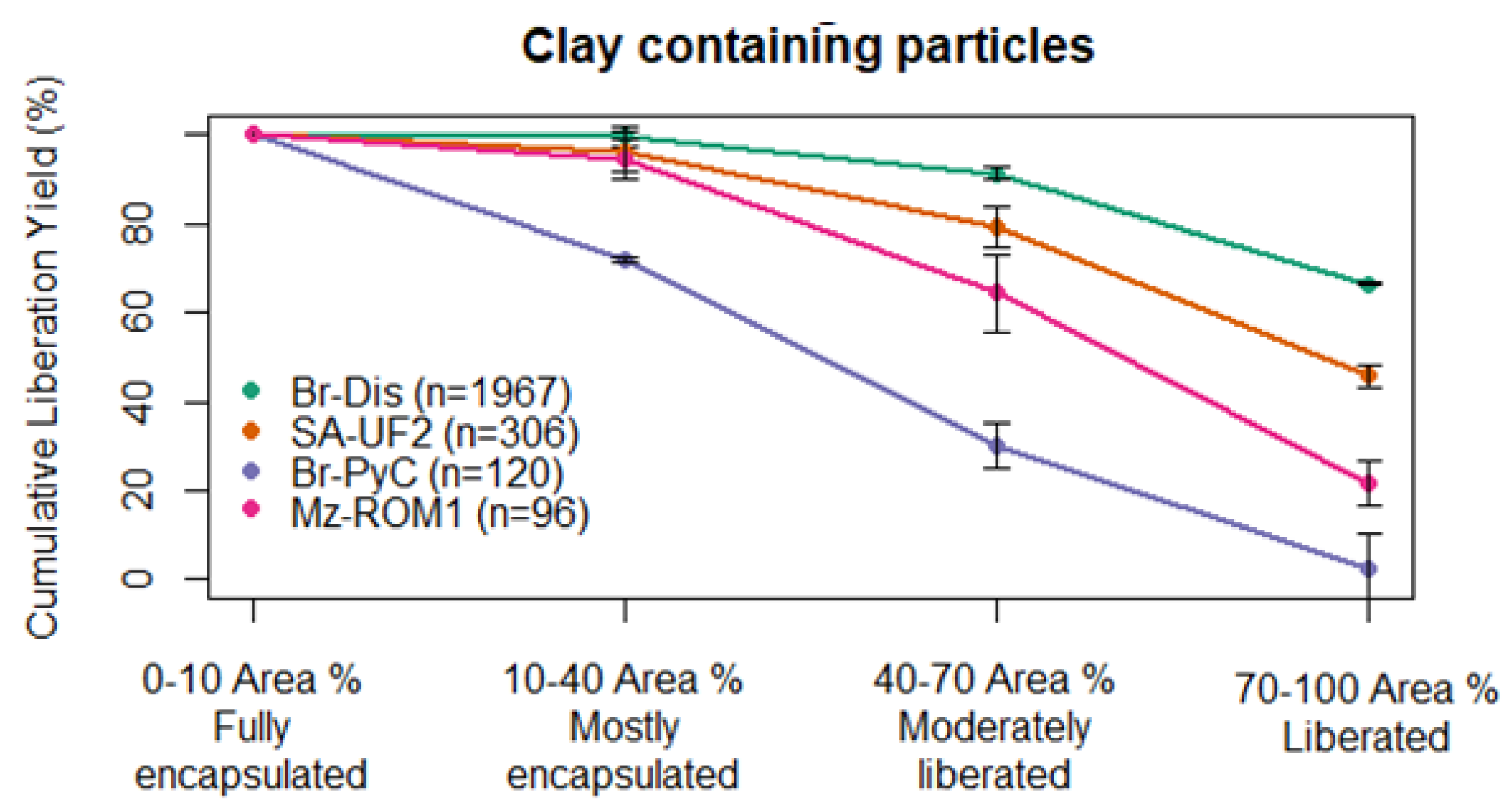

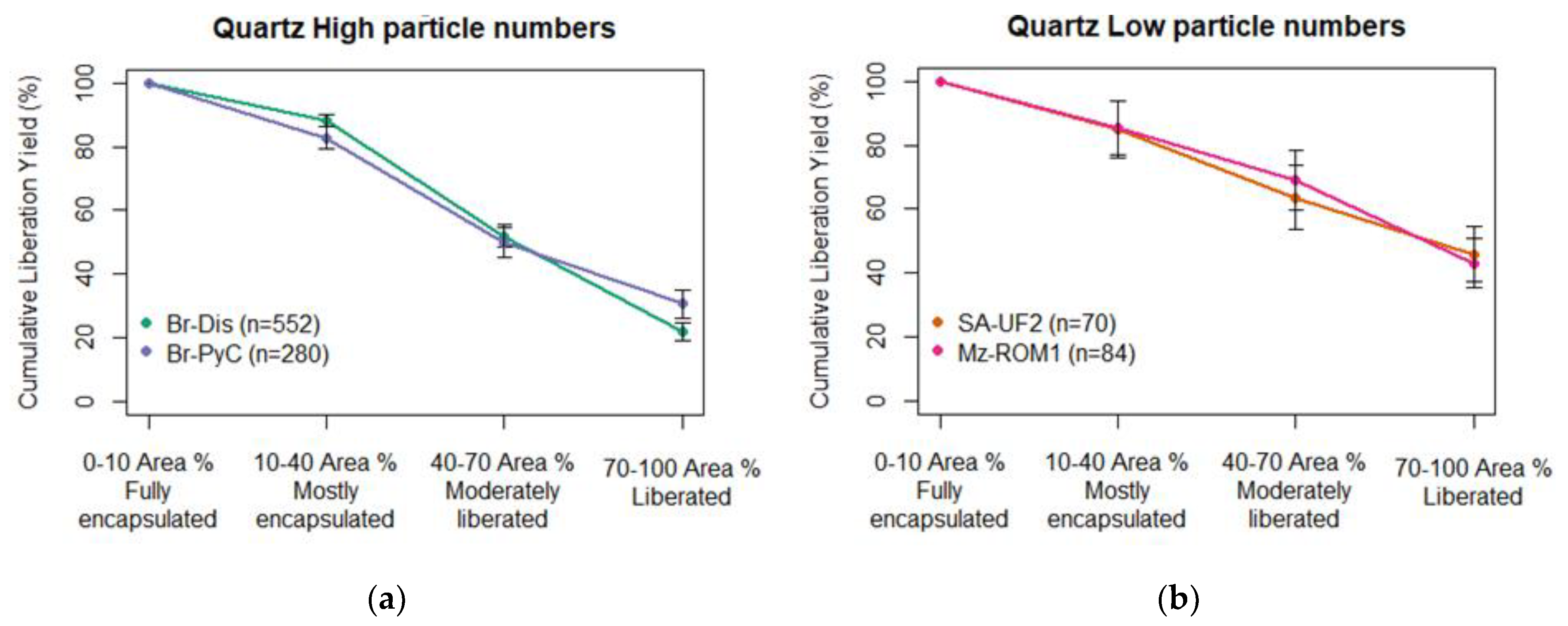

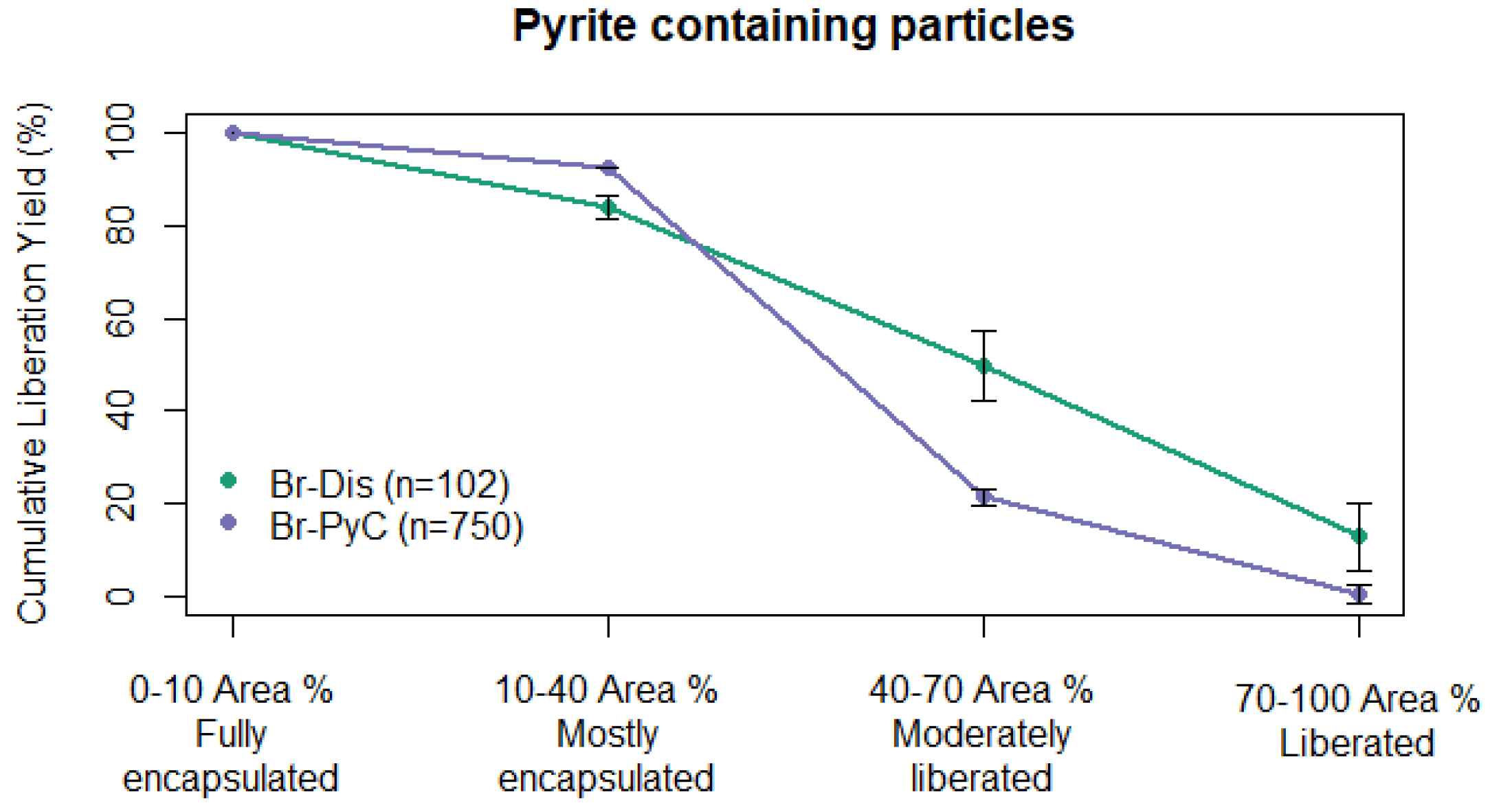

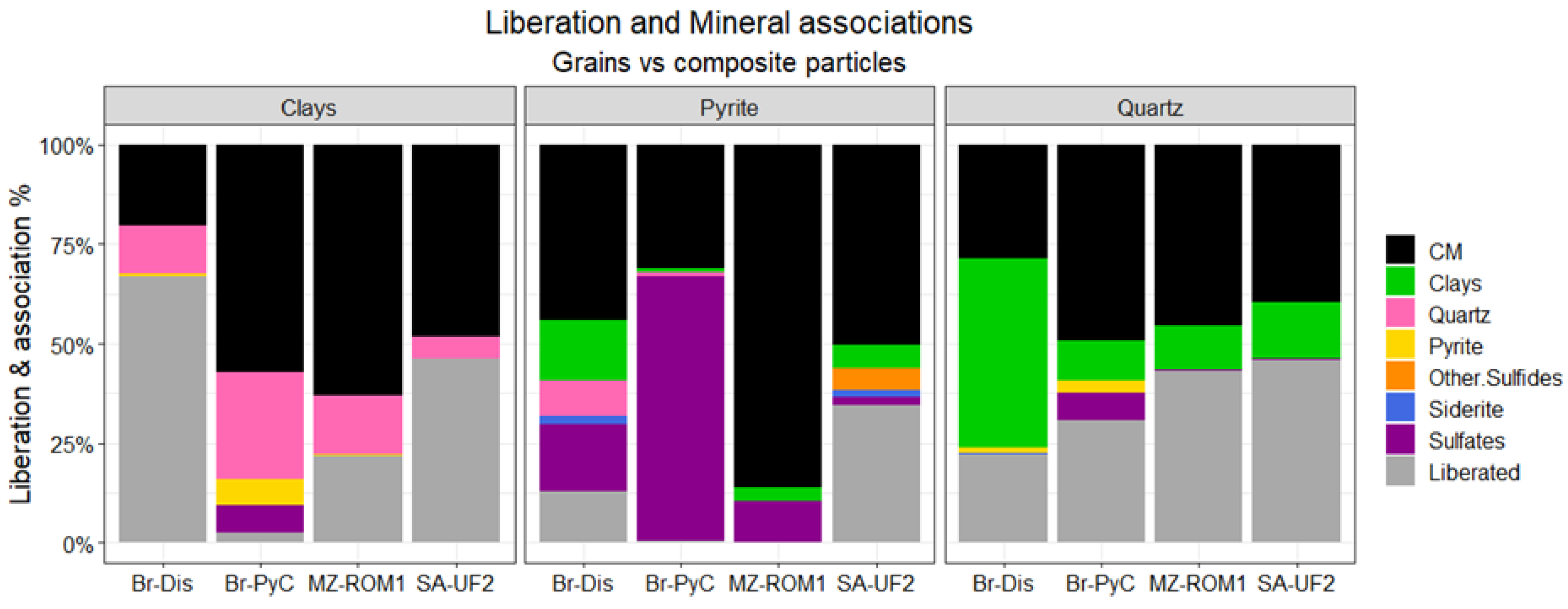

3.5. Mineral Specific Particle Characteristics: Liberation and Association

3.6. Limitations and Broader Implications of the Dataset

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leonard, R.; Zulfikar, R.; Stansbury, R. Coal Mining and Lung Disease in the 21st Century. Curr. Opin. Pulm. Med. 2020, 26, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Hurley, J.F.; Burns, J.; Copland, L.; Dodgson, J.; Jacobsen, M. Coalworkers’ Simple Pneumoconiosis and Exposure to Dust at 10 British Coalmines. Br. J. Ind. Med. 1982, 39, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Heppleston, A.G. Coal Workers’ Pneumoconiosis: A Historical Perspective on Its Pathogenesis. Am. J. Ind. Med. 1992, 22, 905–923. [Google Scholar] [CrossRef]

- Petsonk, E.L.; Rose, C.; Cohen, R. Coal Mine Dust Lung Disease: New Lessons from an Old Exposure. Am. J. Respir. Crit. Care Med. 2013, 187, 1178–1185. [Google Scholar] [CrossRef] [PubMed]

- Cohen, R.A. Resurgent Coal Mine Dust Lung Disease: Wave of the Future or a Relic of the Past? Occup. Environ. Med. 2016, 73, 715–717. [Google Scholar] [CrossRef]

- Vallyathan, V.; Shi, X.; Dalal, N.S.; Irr, W.; Castranova, V. Generation of Free Radicals from Freshly Fractured Silica Dust. Potential Role in Acute Silica-Induced Lung Injury. Am. Rev. Respir. Dis. 1988, 138, 1213–1219. [Google Scholar] [CrossRef]

- Harrington, A.D.; Tsirka, S.E.; Schoonen, M.A.A. Inflammatory Stress Response in A549 Cells as a Result of Exposure to Coal: Evidence for the Role of Pyrite in Coal Workers’ Pneumoconiosis Pathogenesis. Chemosphere 2013, 93, 1216–1221. [Google Scholar] [CrossRef][Green Version]

- Harrington, A.D.; Smirnov, A.; Tsirka, S.E.; Schoonen, M.A. Metal-Sulfide Mineral Ores, Fenton Chemistry and Disease—Particle Induced Inflammatory Stress Response in Lung Cells. Int. J. Hyg. Environ. Health 2015, 218, 19–27. [Google Scholar] [CrossRef][Green Version]

- Castranova, V.; Vallyathan, V. Silicosis and Coal Workers’ Pneumoconiosis. Environ. Health Perspect. 2000, 108, 675–684. [Google Scholar]

- Vallyathan, V.; Shi, X.; Castranova, V. Reactive Oxygen Species: Their Relation to Pneumoconiosis and Carcinogenesis. Environ. Health Perspect. 1998, 106, 1151–1155. [Google Scholar]

- Cohn, C.A.; Laffers, R.; Simon, S.R.; O’Riordan, T.; Schoonen, M.A. Role of Pyrite in Formation of Hydroxyl Radicals in Coal: Possible Implications for Human Health. Part. Fibre Toxicol. 2006, 3, 1–10. [Google Scholar] [CrossRef]

- Harrington, A.D.; Hylton, S.; Schoonen, M.A. Pyrite-Driven Reactive Oxygen Species Formation in Simulated Lung Fluid: Implications for Coal Workers’ Pneumoconiosis. Environ. Geochem. Health 2012, 34, 527–538. [Google Scholar] [CrossRef]

- Zhang, Q.; Dai, J.; Ali, A.; Chen, L.; Huang, X. Roles of Bioavailable Iron and Calcium in Coal Dust-Induced Oxidative Stress: Possible Implications in Coal Workers Lung Disease. Free Radic. Res. 2002, 36, 285–294. [Google Scholar] [CrossRef]

- Schoonen, M.A.; Harrington, A.D.; Laffers, R.; Strongin, D.R. Role of Hydrogen Peroxide and Hydroxyl Radical in Pyrite Oxidation by Molecular Oxygen. Geochim. Cosmochim. Acta 2010, 74, 4971–4987. [Google Scholar] [CrossRef]

- Gormley, I.P.; Collings, P.; Davis, J.M.G.; Ottery, J. An Investigation into the Cytotoxicity of Respirable Dusts from British Collieries. Br. J. Exp. Path. 1979, 60, 526–536. [Google Scholar]

- Reisner, M.T.R.; Bruch, J.; Hilscher, W.; Kriegseis, W.; Prajsnar, D.; Robock, K.; Rosmanith, J.; Scharmann, A.; Schlipköter, H.W.; Strübel, G.; et al. Specific Harmfulness of Respirable Dusts from West German Coal Mines VI: Comparison of Experimental and Epidemiological Results. Ann. Occup. Hyg. 1982, 26, 527–539. [Google Scholar] [CrossRef]

- Bouffant, L.L.; Bruyet, B.; Daniel, H.; Demarez, J.; Kovacs, P.; Martin, J.C.; Addison, J.; Bolton, R.E.; Bruch, J.; Davis, J.M.G.; et al. Compared in Vitro and in Vivo Toxicity of Coalmine Dusts. Relationship with Mineralogical Composition. Ann. Occup. Hyg. 1988, 32, 611–620. [Google Scholar] [CrossRef]

- Zosky, G.R.; Bennett, E.J.; Pavez, M.; Beamish, B.B. No Association between Pyrite Content and Lung Cell Responses to Coal Particles. Sci. Rep. 2021, 11, 8193. [Google Scholar] [CrossRef]

- Sun, Y.; Kinsela, A.S.; Waite, T.D. Elucidation of Alveolar Macrophage Cell Response to Coal Dusts: Role of Ferroptosis in Pathogenesis of Coal Workers’ Pneumoconiosis. Sci. Total Environ. 2022, 823, 153727. [Google Scholar] [CrossRef]

- Huertas, J.I.; Huertas, M.E.; Solis-Casados, D.A. Characterization of Airborne Particles in an Open Pit Mining Region. Sci. Total Environ. 2012, 423, 39–46. [Google Scholar] [CrossRef]

- Trechera, P.; Moreno, T.; Córdoba, P.; Moreno, N.; Zhuang, X.; Li, B.; Li, J.; Shangguan, Y.; Kandler, K.; Dominguez, A.O.; et al. Mineralogy, Geochemistry and Toxicity of Size-Segregated Respirable Deposited Dust in Underground Coal Mines. J. Hazard. Mater. 2020, 399, 122935. [Google Scholar] [CrossRef]

- Ram, S.S.; Majumdar, S.; Chaudhuri, P.; Chanda, S.; Santra, S.C.; Maiti, P.K.; Sudarshan, M.; Chakraborty, A. SEMEDS: An Important Tool for Air Pollution Bio-Monitoring. Micron 2012, 43, 490–493. [Google Scholar] [CrossRef]

- Liu, T.; Liu, S. The Impacts of Coal Dust on Miners’ Health: A Review. Environ. Res. 2020, 190, 109849. [Google Scholar] [CrossRef] [PubMed]

- Sellaro, R.; Sarver, E.; Baxter, D. A Standard Characterization Methodology for Respirable Coal Mine Dust Using SEM-EDX. Resources 2015, 4, 939–957. [Google Scholar] [CrossRef]

- Johann-Essex, V.; Keles, C.; Sarver, E. A Computer-Controlled SEM-EDX Routine for Characterizing Respirable Coal Mine Dust. Minerals. 2017, 7, 15. [Google Scholar] [CrossRef]

- Bharti, S.K.; Kumar, D.; Anand, S.; Poonam; Barman, S.C.; Kumar, N. Characterization and Morphological Analysis of Individual Aerosol of PM10 in Urban Area of Lucknow, India. Micron 2017, 103, 90–98. [Google Scholar] [CrossRef] [PubMed]

- Petruk, W. Applied Mineralogy in the Mining Industry. In Applied Mineralogy in the Mining Industry; Elsevier: Amsterdam, The Netherlands, 2000; pp. 198–199. [Google Scholar]

- Petruk, W.; Skinner, H.C.W. Characterizing Particles in Airborne Dust by Image Analysis. Rev. Extr. Process. 1997, 49, 58–61. [Google Scholar] [CrossRef]

- LaBranche, N.; Keles, C.; Sarver, E.; Johnstone, K.; Cliff, D. Characterization of Particulates from Australian Underground Coal Mines. Minerals 2021, 11, 447. [Google Scholar] [CrossRef]

- LaBranche, N.; Teale, K.; Wightman, E.; Johnstone, K.; Cliff, D. Characterization Analysis of Airborne Particulates from Australian Underground Coal Mines Using the Mineral Liberation Analyser. Minerals 2022, 12, 796. [Google Scholar] [CrossRef]

- Elmes, M.; Delbem, I.; Gasparon, M.; Ciminelli, V. Single-Particle Analysis of Atmospheric Particulate Matter Using Automated Mineralogy: The Potential for Monitoring Mine-Derived Emissions. Int. J. Environ. Sci. Technol. 2020, 17, 2743–2754. [Google Scholar] [CrossRef]

- French, D.; Ward, C.; Butcher, A.R. QEMSCAN for Characterisation of Coal and Coal Utilisation By-Products, Cooperative Research Centre for Coal in Sustainable Development. Aust. Res. Rep. 2008, 93, 20088. [Google Scholar]

- French, D.; Ward, C.R. The Application of Advanced Mineralogical Techniques to Coal Combustion Product Characterisation. In Proceedings of the 2009 World of Coal Ash Conference, Lexington, Kentucky, 5 May 2009. [Google Scholar]

- Pirrie, D.; Rollinson, G.K. Unlocking the Applications of Automated Mineral Analysis. Geol. Today 2011, 27, 226–235. [Google Scholar] [CrossRef]

- Schulz, B.; Sandmann, D.; Gilbricht, S. Sem-Based Automated Mineralogy and Its Application in Geo-and Material Sciences. Minerals 2020, 10, 1004. [Google Scholar] [CrossRef]

- Vickery, K.; Eckardt, F. A Closer Look at Mineral Aerosol Emissions from the Makgadikgadi Pans, Botswana, Using Automated SEM-EDS (QEMSCAN®). S. Afr. Geogr. J. 2021, 103, 7–21. [Google Scholar] [CrossRef]

- Little, L.; Becker, M.; Wiese, J.; Mainza, A.N. Auto-SEM Particle Shape Characterisation: Investigating Fine Grinding of UG2 Ore. Miner. Eng. 2015, 82, 92–100. [Google Scholar] [CrossRef]

- Williamson, B.J.; Rollinson, G.; Pirrie, D. Automated Mineralogical Analysis of PM10: New Parameters for Assessing PM Toxicity. Environ. Sci. Technol. 2013, 47, 5570–5577. [Google Scholar] [CrossRef]

- Schoonen, M.A.; Roemer, E.J.; Simon, S. Mineral-Induced Formation of Reactive Oxygen Species Chemistry of Surfaces and Nanoparticles View Project. Rev. Mineral. Geochem. 2006, 64, 179–222. [Google Scholar] [CrossRef]

- Bair, W. The ICRP Human Respiratory Tract Model for Radiological Protection. Radiat. Prot. Dosim. 2000, 60, 307–310. [Google Scholar] [CrossRef]

- Maynard, A.D.; Kuempel, E.D. Airborne Nanostructured Particles and Occupational Health. J. Nanoparticle Res. 2005, 7, 587–614. [Google Scholar] [CrossRef]

- Fubini, B.; Otero Areán, C. Chemical Aspects of the Toxicity of Inhaled Mineral Dusts. Chem. Soc. Rev. 1999, 28, 373–381. [Google Scholar] [CrossRef]

- Plumlee, G.; Morman, S.; Ziegler, T. The Toxicological Geochemistry of Earth Materials: An Overview of Processes and the Interdisciplinary Methods Used to Understand Them. Rev. Mineral. Geochem. 2006, 64, 5–57. [Google Scholar] [CrossRef]

- Ruby, M.V.; Schoof, R.; Brattin, W.; Goldade, M.; Post, G.; Harnois, M.; Mosby, E.; Casteel, S.W.; Berti, W.; Carpenter, M.; et al. Advances in Evaluating the Oral Bioavailability of Inorganics in Soil for Use in Human Health Risk Assessment. Environ. Sci. Technol. 1999, 33, 3697–3705. [Google Scholar] [CrossRef]

- Plumlee, G.S.; Ziegler, T.L. The Medical Geochemistry of Dusts, Soils, and Other Earth Materials, 9th ed.; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Li, M.; Wilkinson, D.; Patchigolla, K. Comparison of Particle Size Distributions Measured Using Different Techniques. Part. Sci. Technol. 2005, 23, 265–284. [Google Scholar] [CrossRef]

- Johann-Essex, V.; Keles, C.; Rezaee, M.; Scaggs-Witte, M.; Sarver, E. Respirable Coal Mine Dust Characteristics in Samples Collected in Central and Northern Appalachia. Int. J. Coal Geol. 2017, 182, 85–93. [Google Scholar] [CrossRef]

- Little, L. The Development and Demonstration of a Practical Methodology for Fine Particle Shape Characterisation in Minerals Processing; University of Cape Town: Cape Town, South Africa, 2016. [Google Scholar]

- Barbery, G. Liberation 1, 2, 3: Theoretical Analysis of the Effect of Space Dimension on Mineral Liberation by Size Reduction. Miner. Eng. 1992, 5, 123–141. [Google Scholar] [CrossRef]

- Fandrich, R.; Gu, Y.; Burrows, D.; Moeller, K. Modern SEM-Based Mineral Liberation Analysis. Int. J. Miner. Process. 2007, 84, 310–320. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Brough, I. High Resolution Electron Backscatter Diffraction with a Field Emission Gun Scanning Electron Microscope. J. Microsc. 1999, 195, 6–9. [Google Scholar]

- Gatti, E.; Rehak, P.; Walton, J.T. Silicon Drift Chambers-First Results and Optimum Processing of Signals. Nucl. Inst. Methods Phys. Res. A 1984, 226, 129–141. [Google Scholar] [CrossRef]

- Straszheim, W.E.; Younkin, K.A.; Greer, R.T.; Markuszewski, R.; Younkinl, K.A. Mounting Materials for Automated Image Analysis of Coals Using Backscattered Electron Imaging. Scanning Microsc. Int. 1988, 2, 1257–1264. [Google Scholar]

- Haberlah, D.; Owen, M.; Botha, P.W.S.K.; Gottlieb, P. SEM-EDS-based protocol of subsurface drilling mineral identification and petrological classification. In Proceedings of the 10th International Congress for Applied Mineralogy (ICAM), Trondheim, Norway, 20 March 2012; pp. 265–266. [Google Scholar]

- Ward, C.R. Analysis, Origin and Significance of Mineral Matter in Coal: An Updated Review. Int. J. Coal Geol. 2016, 165, 1–27. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Füllmann, T.; Gallucci, E.; Walenta, G.; Bermejo, E. Quantitative Study of Portland Cement Hydration by X-Ray Diffraction/Rietveld Analysis and Independent Methods. Cem. Concr. Res. 2004, 34, 1541–1547. [Google Scholar] [CrossRef]

- Ward, C.R.; Spears, D.A.; Booth, C.A.; Staton, I.; Gurba, L.W. Mineral Matter and Trace Elements in Coals of the Gunnedah Basin, New South Wales, Australia. Int. J. Coal Geol. 1999, 40, 281–308. [Google Scholar] [CrossRef]

- Barthelmy, D. Webmineral-Mineralogy Database. Available online: https://www.webmineral.com (accessed on 20 March 2019).

- Kaya, E.; Hogg, R.; Mutmansky, J.M. Evaluation of Procedures for Production of Dust Samples for Biomedical Research. Appl. Occup. Environ. Hyg. 1996, 11, 745–750. [Google Scholar] [CrossRef]

- León-Mejía, G.; Silva, L.F.O.; Civeira, M.S.; Oliveira, M.L.S.; Machado, M.; Villela, I.V.; Hartmann, A.; Premoli, S.; Corrêa, D.S.; Da Silva, J.; et al. Cytotoxicity and Genotoxicity Induced by Coal and Coal Fly Ash Particles Samples in V79 Cells. Environ. Sci. Pollut. Res. 2016, 23, 24019–24031. [Google Scholar] [CrossRef] [PubMed]

- Dalal, N.; Suryan, M.; Vallyathan, V.; Green, F.; Jafari, B.; Wheeler, R. Detection of Reactive Free Radicals In Fresh Coal Mine Dust and Their Implication for Pulmonary Injury. Ann. Occup. Hyg. 1989, 33, 79–84. [Google Scholar] [CrossRef]

- Van der Plas, L.; Tobi, A.C. A Chat for Judging the Reliability of Point Counting Results. Am. J. Sci. 1965, 263, 87–90. [Google Scholar] [CrossRef]

- Semsari, P.P.; Parian, M.; Rosenkranz, J. Breakage Process of Mineral Processing Comminution Machines—An Approach to Liberation. Adv. Powder Technol. 2020, 31, 3669–3685. [Google Scholar] [CrossRef]

- Little, L.; Mainza, A.N.; Becker, M.; Wiese, J.G. Using Mineralogical and Particle Shape Analysis to Investigate Enhanced Mineral Liberation through Phase Boundary Fracture. Powder Technol. 2016, 301, 794–804. [Google Scholar] [CrossRef]

- Leigh, G.M.; Sutherland, D.N.; Gottlieb, P. Confidence Limits for Liberation Measurements. Miner. Eng. 1993, 6, 155–161. [Google Scholar] [CrossRef]

- Blannin, R.; Frenzel, M.; Tuşa, L.; Birtel, S.; Ivăşcanu, P.; Baker, T.; Gutzmer, J. Uncertainties in Quantitative Mineralogical Studies Using Scanning Electron Microscope-Based Image Analysis. Miner. Eng. 2021, 167, 106836. [Google Scholar] [CrossRef]

- Little, L.; Becker, M.; Wiese, J.; Yorath, G.; Mainza, A.; Tonzetic, I. Shape Characterisation: Can Different Devices Produce Comparable Data for Particulate Samples? In Proceedings of the XXVIII the International Mineral Processing Congress, Quebec City, QC, Canada, 11 September 2016. [Google Scholar]

- Rasheed, M.A.; Rao, P.L.S.; Boruah, A.; Hasan, S.Z.; Patel, A.; Velani, V.; Patel, K. Geochemical Characterization of Coals Using Proximate and Ultimate Analysis of Tadkeshwar Coals, Gujarat. Geosciences 2015, 5, 113–119. [Google Scholar] [CrossRef]

- Deer, W.A.; Howie, R.A.; Zussman, J. An Introduction to the Rock Forming Minerals, 2nd ed.; Pearson Parentice Hall: Hoboken, NJ, USA, 1992; ISBN 0-582-30094-0. [Google Scholar]

| Characteristics Investigated | Relevance to Respiratory Toxicity and Inflammation | References |

|---|---|---|

| Mineral and element distributions | Minerals serve as hosts for reactive elements as well as providing surface reactive sites potentially producing harmful bio-reactive compounds. Elements can also be leached into the lung fluids where they can biogeochemically react depending on their form | [12,13,39] |

| General particle characteristics | ||

| Particle size | Determines the probability of where the particle may be deposited and potentially phagocytosed (digestion of foreign material by defence cells called macrophages) | [40,41] |

| Particle roughness and shape | Surface texture and particle shape have been found to impact phagocytosis irrespective of the size and volume of the particles | [42,43] |

| Mineral specific characteristics | ||

| Liberation and association | Phases which are encapsulated and/or associated with non-reactive phases will be rendered inert, thus the degree to which a phase is liberated will impact its potential bio-reactivity | [44,45] |

| Descriptor | Description | Formula | Visual Description |

|---|---|---|---|

| Roundness | The ratio of the surface area of an object over the area of a circle with a diameter equal to the maximum diameter of the object. Scaled to values between 0 and 1 |  | |

| Aspect ratio (inverse) | The ratio of an object’s length over width. The inverse of such can be taken to scale the values between 0 and 1 |  |

| Shape Category | Round | Elongate and Smooth | Equant | Angular | Elongate and Angular |

|---|---|---|---|---|---|

|  |  |  |  | |

| Aspect ratio | 0.5–1 | 0–0.5 | 0.5–1 | 0.5–1 | 0–0.5 |

| Roundness | 0.75–1 | 0.4–0.75 | 0.4–0.75 | 0–0.4 | 0–0.4 |

| Liberation Classes | Percentage Area Range of Target Phase | Example of False Colour Particles (MOI-Quartz) |

|---|---|---|

| Liberated | % Area MOI ≤ 100 and% Area MOI ≥ 70 |  |

| Moderately liberated | % Area MOI < 70 and% Area MOI ≥ 40 |  |

| Mostly encapsulated | % Area MOI < 40 and% Area MOI ≥ 10 |  |

| Fully encapsulated | % Area MOI < 10 and% Area MOI ≥ 0 |  |

| Sample Name | Replicate Type | Description | D50 (µm) |

|---|---|---|---|

| Br-Dis | Single block with duplicate scans | Brazilian coal discard | 7.70 |

| SA-UF2 | Repeat block was made, blocks represent two separate sampling batches of the parental coal | South African ultrafine thickener underflow | 9.53 |

| Br-PyC | Single block with duplicate scans | Brazilian coal pyrite concentrate (waste product) | 10.42 |

| Mz-ROM1 *,† | Repeat block was made, blocks represent a single batch of the parental coal sub-samples into two splits | Mozambican coal run of mine | - |

| Mz-ROM2 *,† | Mozambican coal run of mine | - |

| Mean Element Distribution: Si (% in total) | ||||

|---|---|---|---|---|

| Minerals | Br-Dis | SA-UF2 | BR-PyC | Mz-ROM1&2 |

| Clays | 61.91 (±0.32) | 62.43 (±0.51) | 18.11 (±0.11) | 4.13 (±0.00) |

| Quartz | 38.09 (±0.32) | 37.57 (±0.51) | 81.87 (±0.11) | 1.53 (±0.00) |

| Mean Element Distribution: Fe (% in total) | ||||

| Ankerite | 0.02 | - | - | - |

| Chalcopyrite *,† | 0.03 | 1.27 (±0.03) | <0.01 | - |

| Goethite *,† | 0.27 (±0.01) | 0.36 (±0.01) | <0.01 * | - |

| Hematite † | 0.49 (±0.01) | 8.89 (±0.22) | 0.06 (±0.01) | - |

| Jarosite | 0.19 | - | 0.03 | - |

| Pyrite | 89.18 (±0.22) | 40.15 (±0.17) | 79.24 (±0.37) | 74.93 (±0.00) |

| Rhomboclase | 5.52 (±0.13) | 2.00 (±0.04) | 15.75 (±0.19) | 3.87 (±0.00) |

| Siderite † | 3.19 (±0.00) | 46.14 (±0.02) | 0.09 (±0.00) | 18.85 (±0.00) |

| Sphalerite *,† | 0.03 (±0.00) | 0.30 | <0.01 | - |

| Szomolnokite | 2.30 | 1.05 (±0.02) | 4.83 (±0.18) | 2.31 (±0.00) |

| Mean Element Distribution: Ca (% in total) | ||||

| Ankerite † | 0.26 | - | - | - |

| Apatite † | 6.33 (±0.02) | 0.36 | - | 0.48 |

| Calcite | 85.57 (±0.00) | 50.44 (±0.03) | 35.85 (±0.17) | 87.91 (±0.00) |

| Dolomite | - | 0.36 (±0.00) | 0.17 | 4.50 (±0.00) |

| Gypsum | 7.97 (±0.01) | 49.02 (±0.03) | 64.06 (±0.17) | 7.12 (±0.00) |

| Particle Population: Distributed by Mean% Abundance Reporting to Shape Classes | ||||

|---|---|---|---|---|

| Particle Classes | Br-Dis | SA-UF2 | Br-PyC | Mz-ROM1&2 |

| % Round | 0.03 (±0.01) | 0.72 (±0.30) | 0.18 (±0.05) | 0.42 (±0.01) |

| % Equant | 47.26 (±5.08) | 70.50 (±4.57) | 65.84 (±5.44) | 71.74 (±0.77) |

| % Elongate and smooth | 0.02 (±0.00) | 0.11 (±0.04) | 0.04 (±0.00) | 0.13 (±0.00) |

| % Elongate and angular | 8.27 (±1.37) | 8.92 (±1.55) | 5.06 (±1.83) | 7.72 (±1.34) |

| % Angular | 44.43 (±3.70) | 19.78 (±2.76) | 28.91 (±3.73) | 19.97 (±0.58) |

| Total% abundance | 100 (±0.00) | 100 (±0.00) | 100 (±0.00) | 100 (±0.00) |

| Particle Population: Distributed by Mean% Abundance of Reporting to Particle Roughness Classes | ||||

|---|---|---|---|---|

| Roughness Classes | Br-Dis | SA-UF2 | Br-PyC | Mz-ROM1&2 |

| % Jagged | 83.03 (±5.06) | 51.96 (±10.87) | 78.46 (±2.43) | 54.92 (±1.40) |

| % Intermediate | 12.94 (±3.09) | 29.59 (±2.70) | 15.97 (±2.61) | 29.75 (±0.61) |

| % Smooth | 4.04 (±1.97) | 18.45 (±8.16) | 5.58 (±0.18) | 15.33 (±2.01) |

| Total% abundance | 100 (±0.00) | 100 (±0.00) | 100 (±0.00) | 100 (±0.00) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamanzi, C.; Becker, M.; Von Holdt, J.; Broadhurst, J. Development of a SEM-EDS-XRD Protocol for the Physicochemical and Automated Mineralogical Characterisation of Coal Dust Particles. Resources 2022, 11, 114. https://doi.org/10.3390/resources11120114

Kamanzi C, Becker M, Von Holdt J, Broadhurst J. Development of a SEM-EDS-XRD Protocol for the Physicochemical and Automated Mineralogical Characterisation of Coal Dust Particles. Resources. 2022; 11(12):114. https://doi.org/10.3390/resources11120114

Chicago/Turabian StyleKamanzi, Conchita, Megan Becker, Johanna Von Holdt, and Jennifer Broadhurst. 2022. "Development of a SEM-EDS-XRD Protocol for the Physicochemical and Automated Mineralogical Characterisation of Coal Dust Particles" Resources 11, no. 12: 114. https://doi.org/10.3390/resources11120114

APA StyleKamanzi, C., Becker, M., Von Holdt, J., & Broadhurst, J. (2022). Development of a SEM-EDS-XRD Protocol for the Physicochemical and Automated Mineralogical Characterisation of Coal Dust Particles. Resources, 11(12), 114. https://doi.org/10.3390/resources11120114