Class E ZVS Resonant Inverter with CLC Filter and PLL-Based Resonant Frequency Tracking for Ultrasonic Piezoelectric Transducer

Abstract

1. Introduction

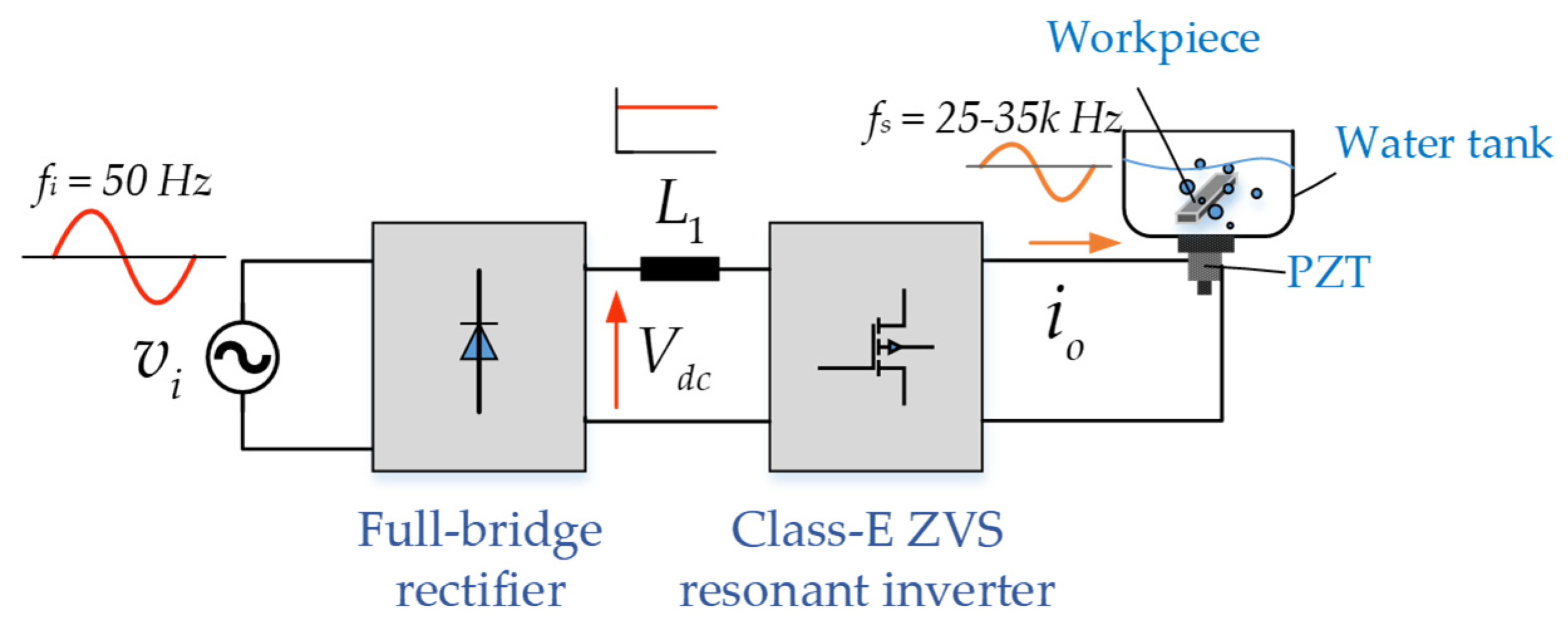

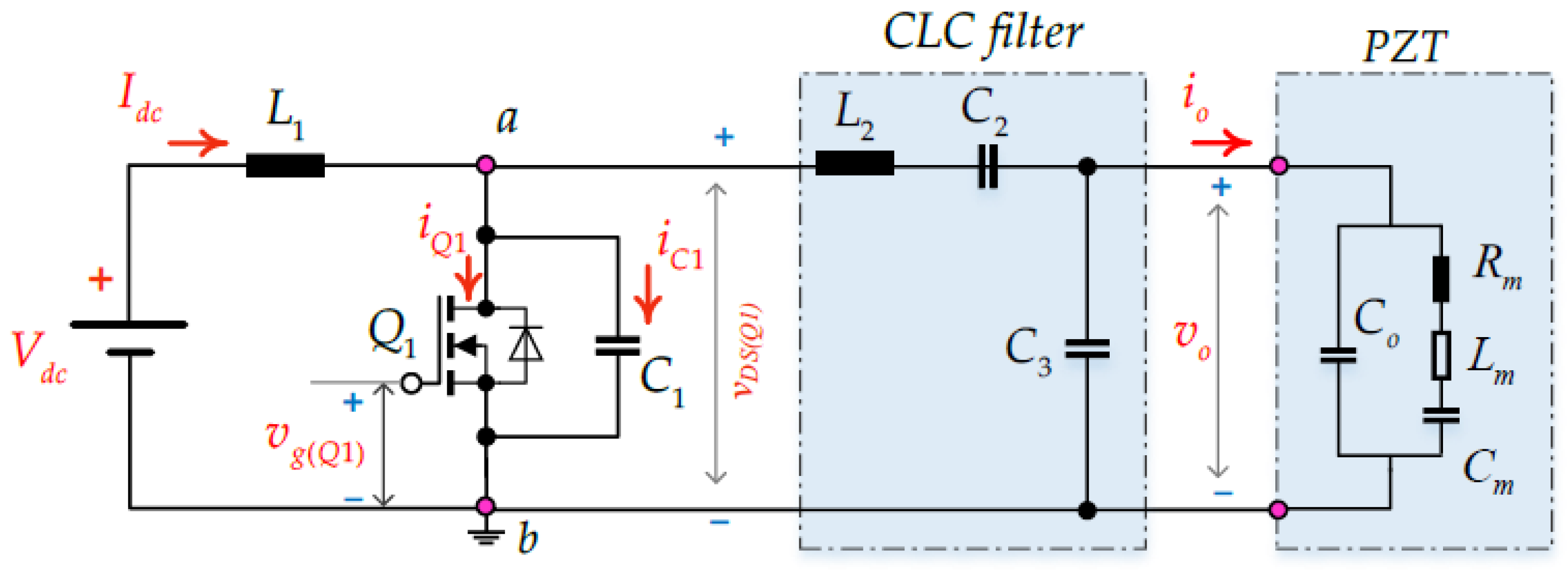

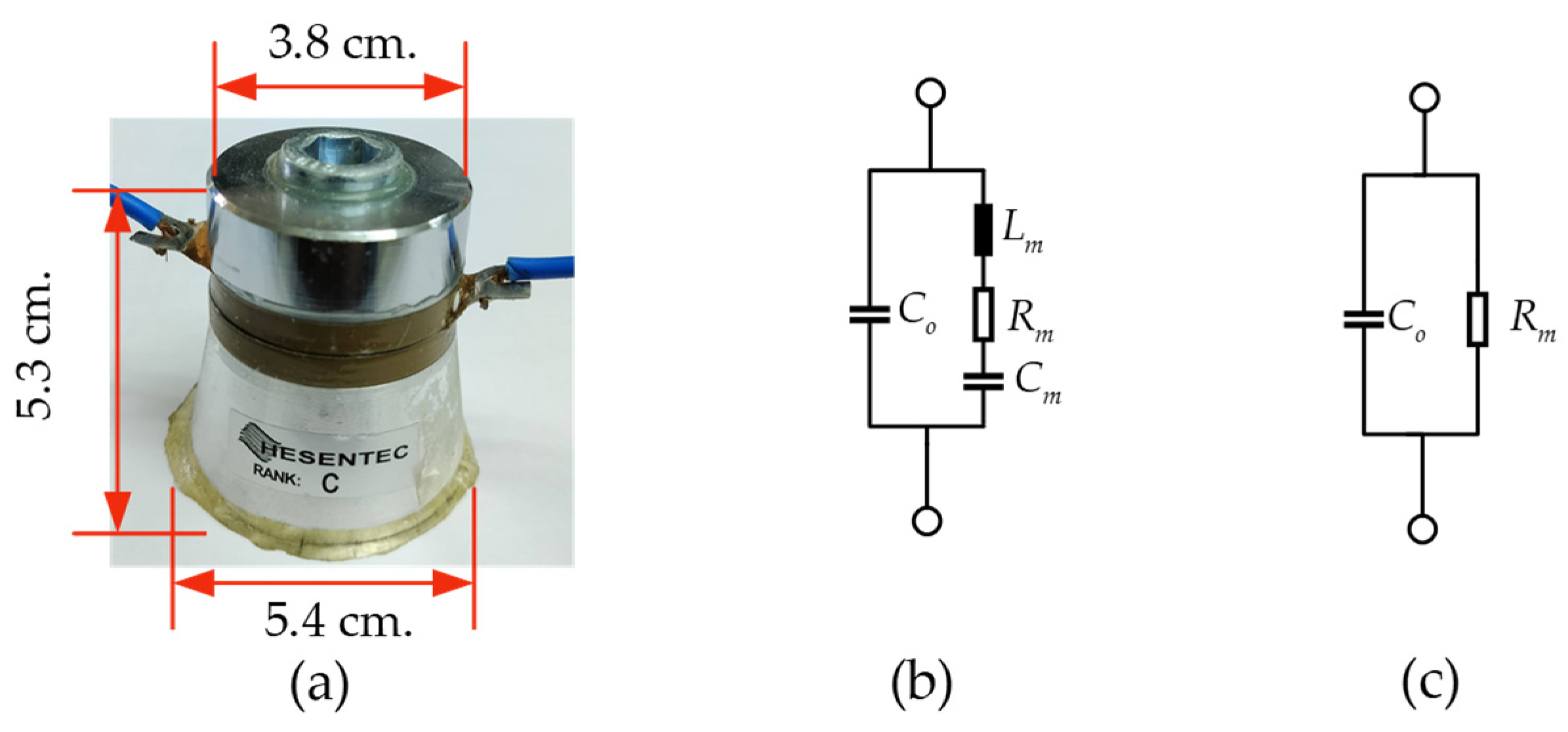

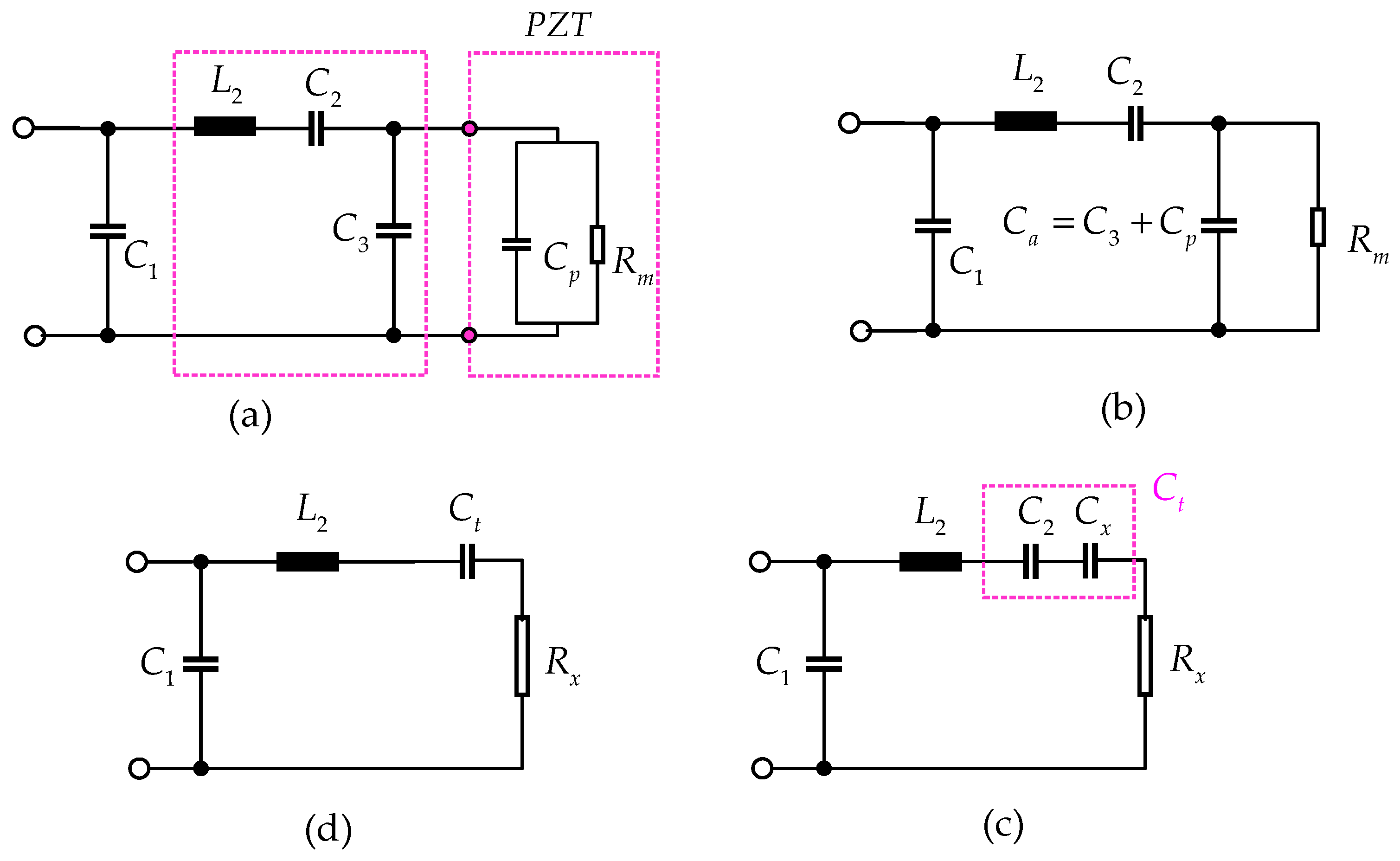

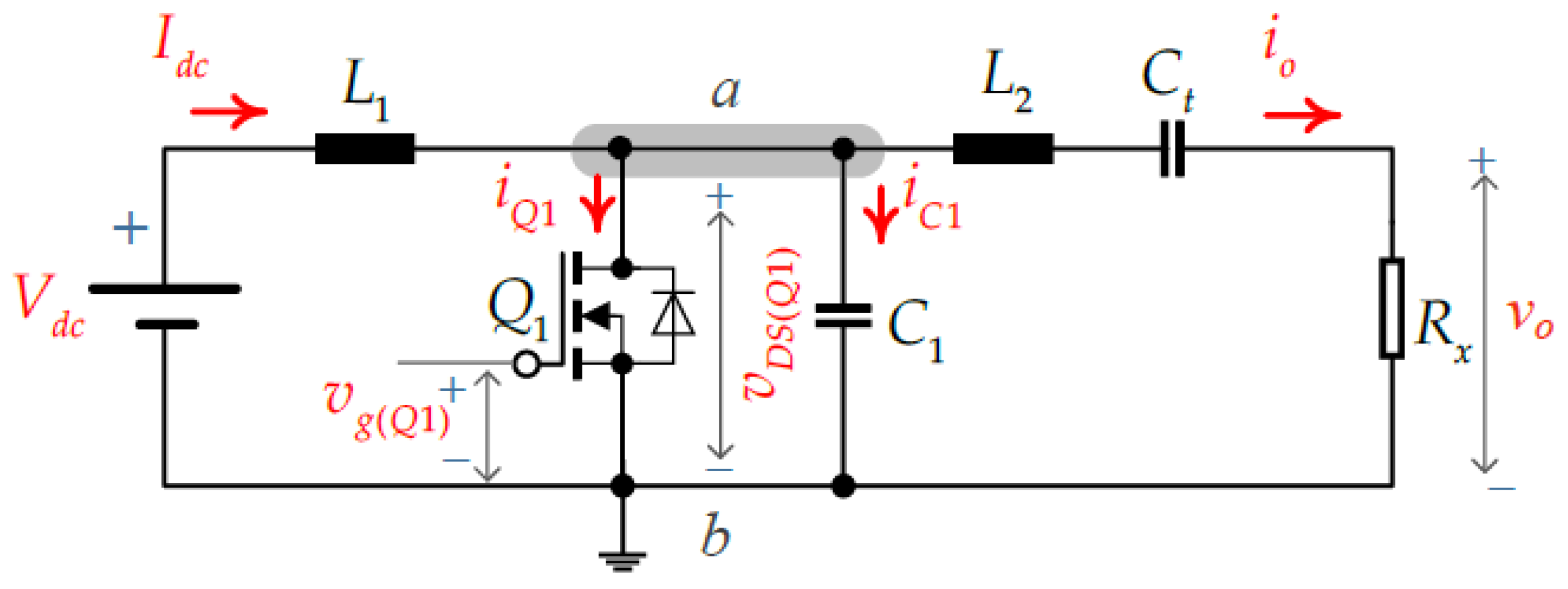

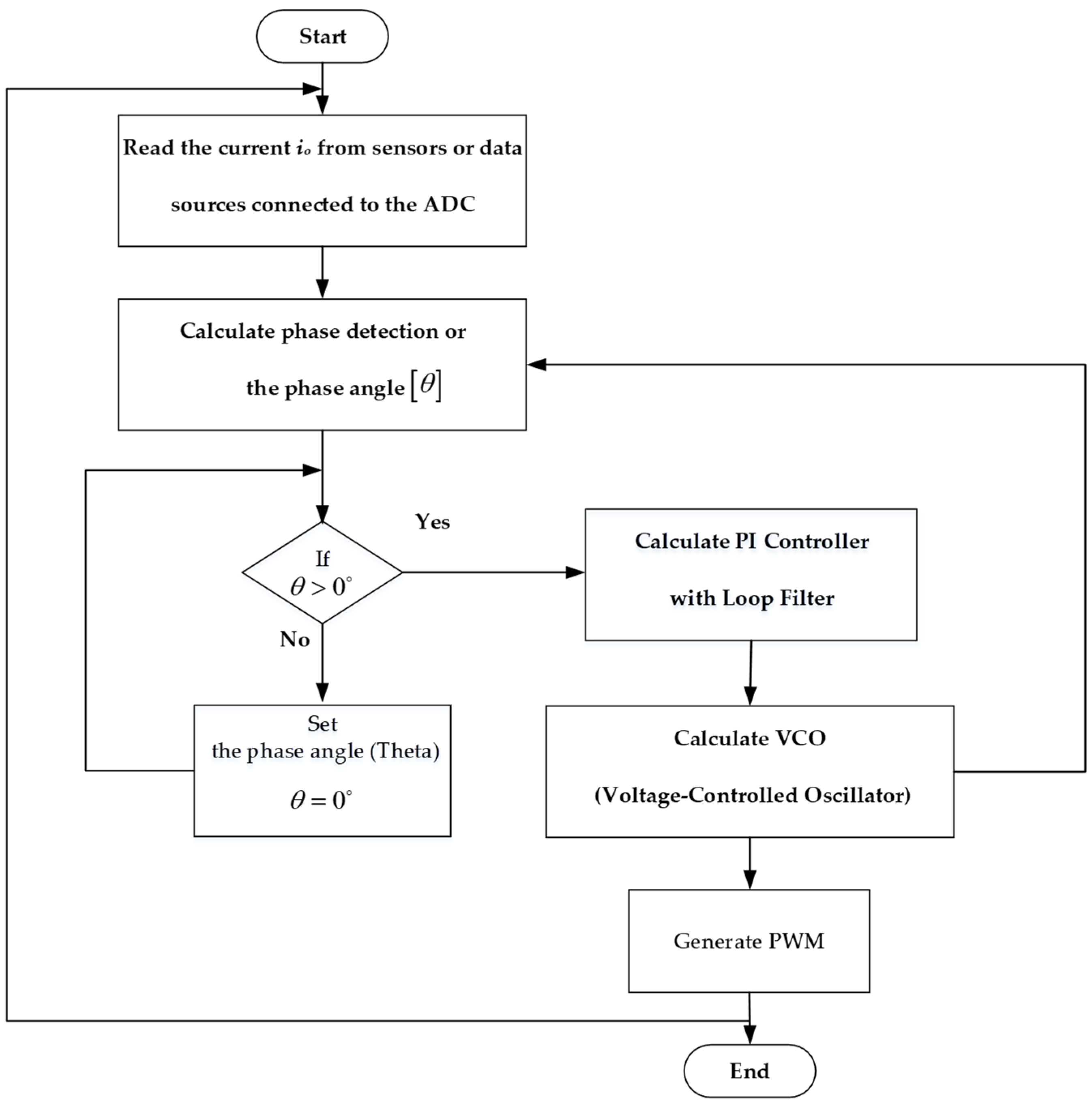

2. Proposed System

3. Circuit Analysis

- The analysis of the proposed Class E ZVS resonant inverter is based on the following assumptions:

- The power MOSFETs operate as ideal switches.

- The quality factor of the series resonant load is sufficiently high, ensuring a nearly sinusoidal output current .

- The input current is considered constant due to the large choke inductor .

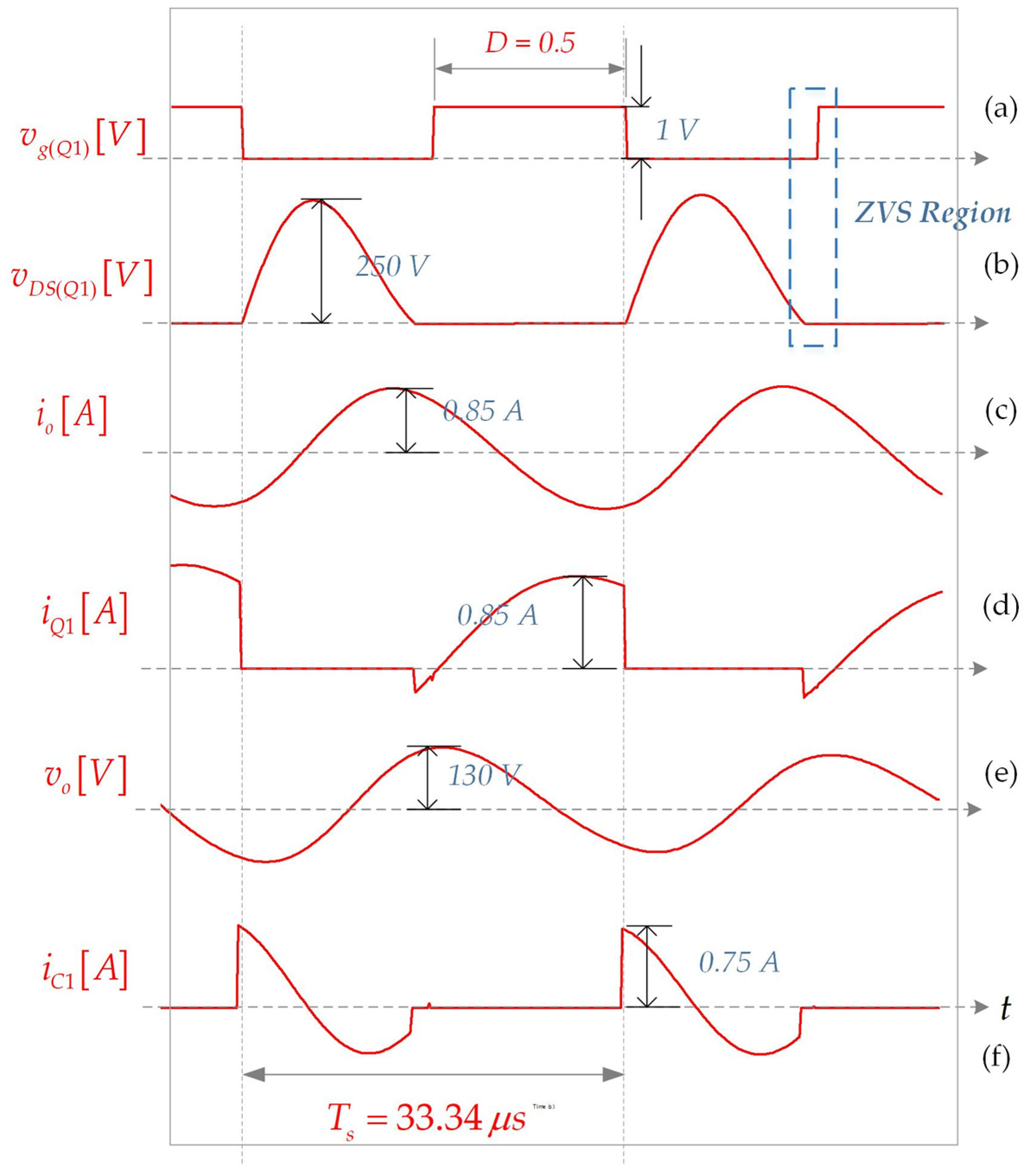

- : gate drive signal of the MOSFET.

- : drain–source voltage of .

- : current through switch .

- : current through the shunt capacitor .

- : output current delivered to the load.

- : voltage across the load.

- is turned ON when the capacitor current becomes zero at , ensuring ZVS.

- During the ON interval , the current through , , is

- (1)

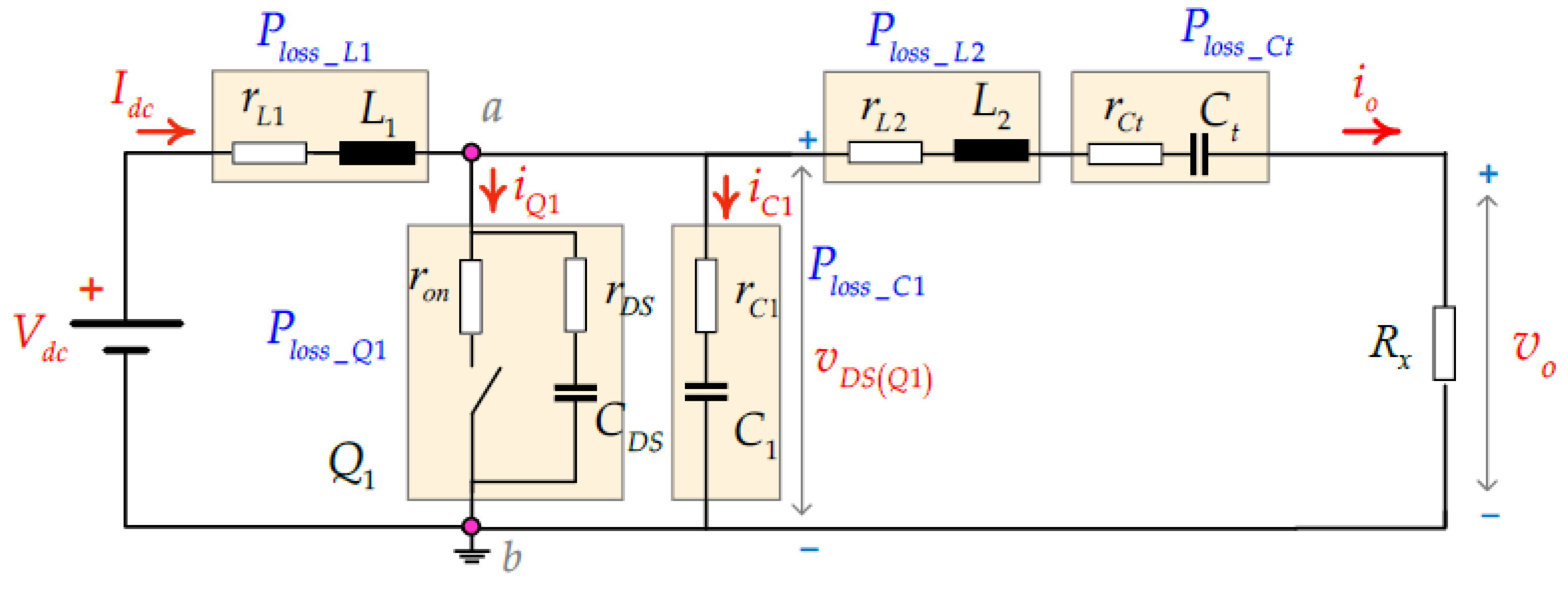

- The power losses due to the parasitic resistance of the power MOSFET occur in two stages: the power loss when the power MOSFET conducts current depends on the MOSFET on-resistance, , and the power loss due to the internal resistance (ESR or equivalent series resistance) of the capacitance between the drain and source in the MOSFET , . The power loss equations for both cases can be expressed as follows:

- (2)

- The switching loss is caused by energy stored in the parasitic capacitance during the transition of the switch from the off state to the on state. The total loss is calculated as the average of the energy stored during the switching cycle, which affects the circuit’s efficiency, especially at high switching frequencies. This loss can be reduced by improving the control of the switching process. Therefore, the power loss during the turn-on of the power MOSFET iswhere the energy stored during the switching cycle is

- (3)

- The power losses caused by the parasitic resistances of the inductor and capacitors include the power loss of inductor , ; power loss of capacitor , ; power loss of inductor , ; and power loss of capacitor , . Therefore, the power losses due to the parasitic resistances of the inductor and capacitors are expressed by the following equations:where is the parasitic resistance of the inductorwhere is the parasitic resistance of the capacitorwhere is the parasitic resistance of the inductor , and is the parasitic resistance of the capacitor

4. Implementation and Results

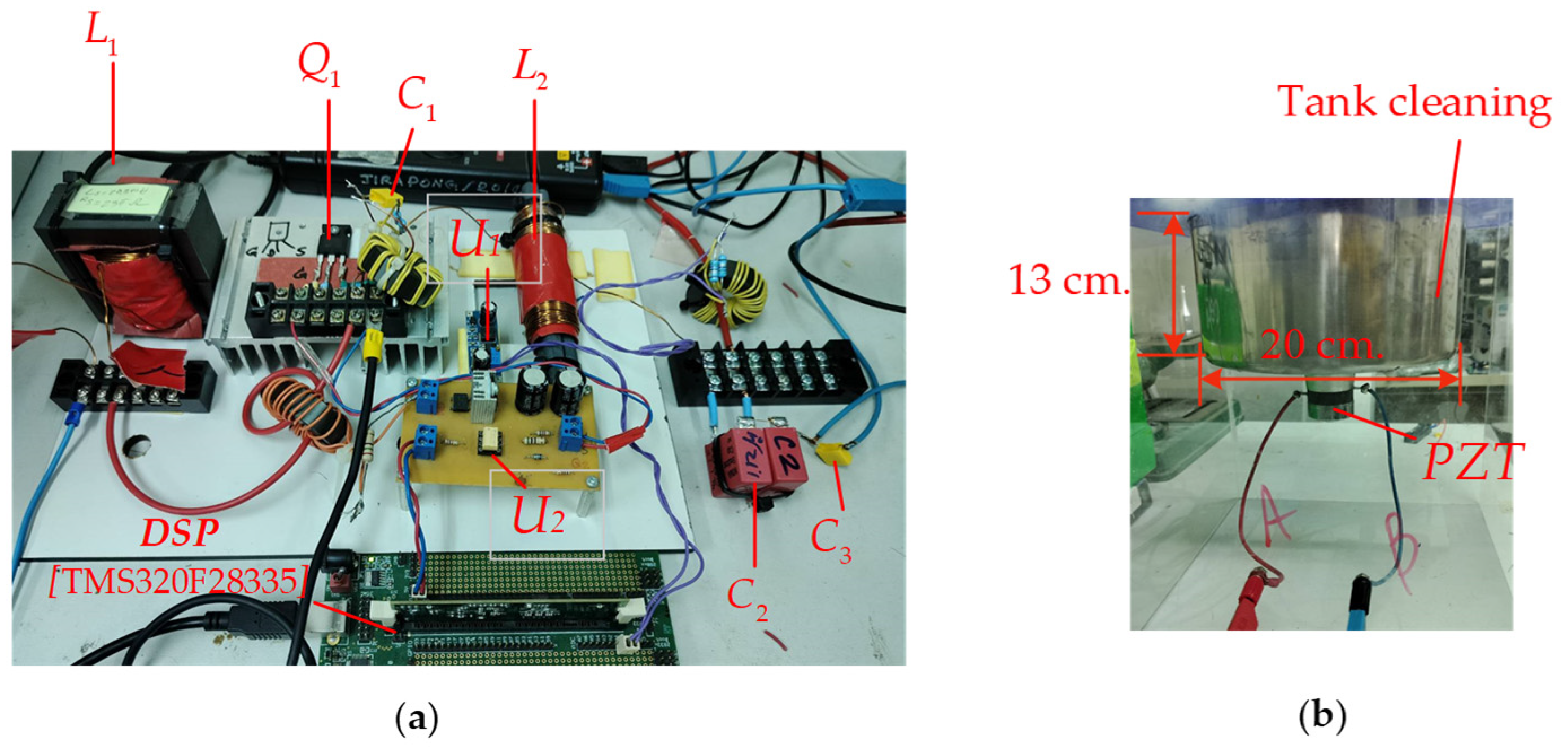

4.1. Implementation

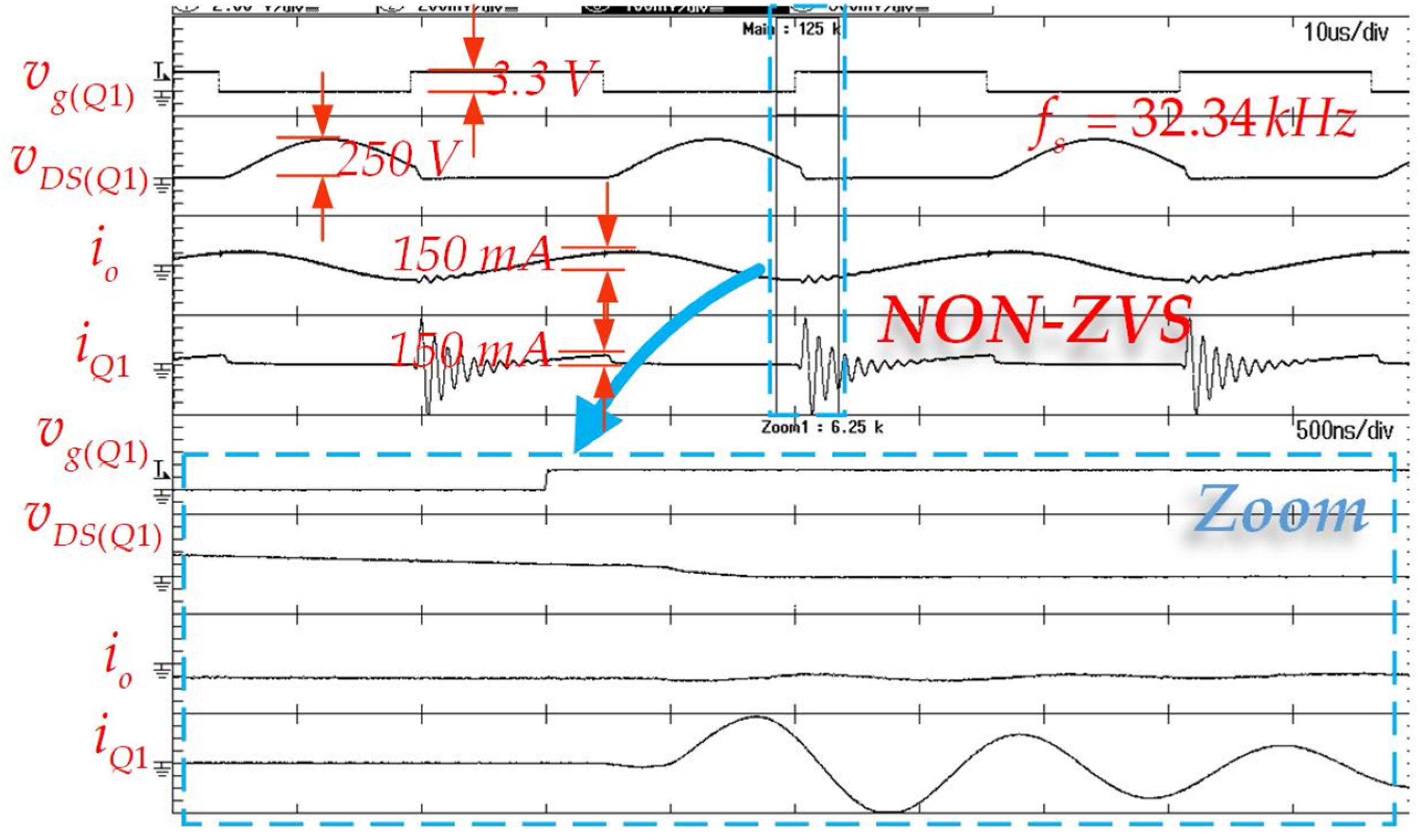

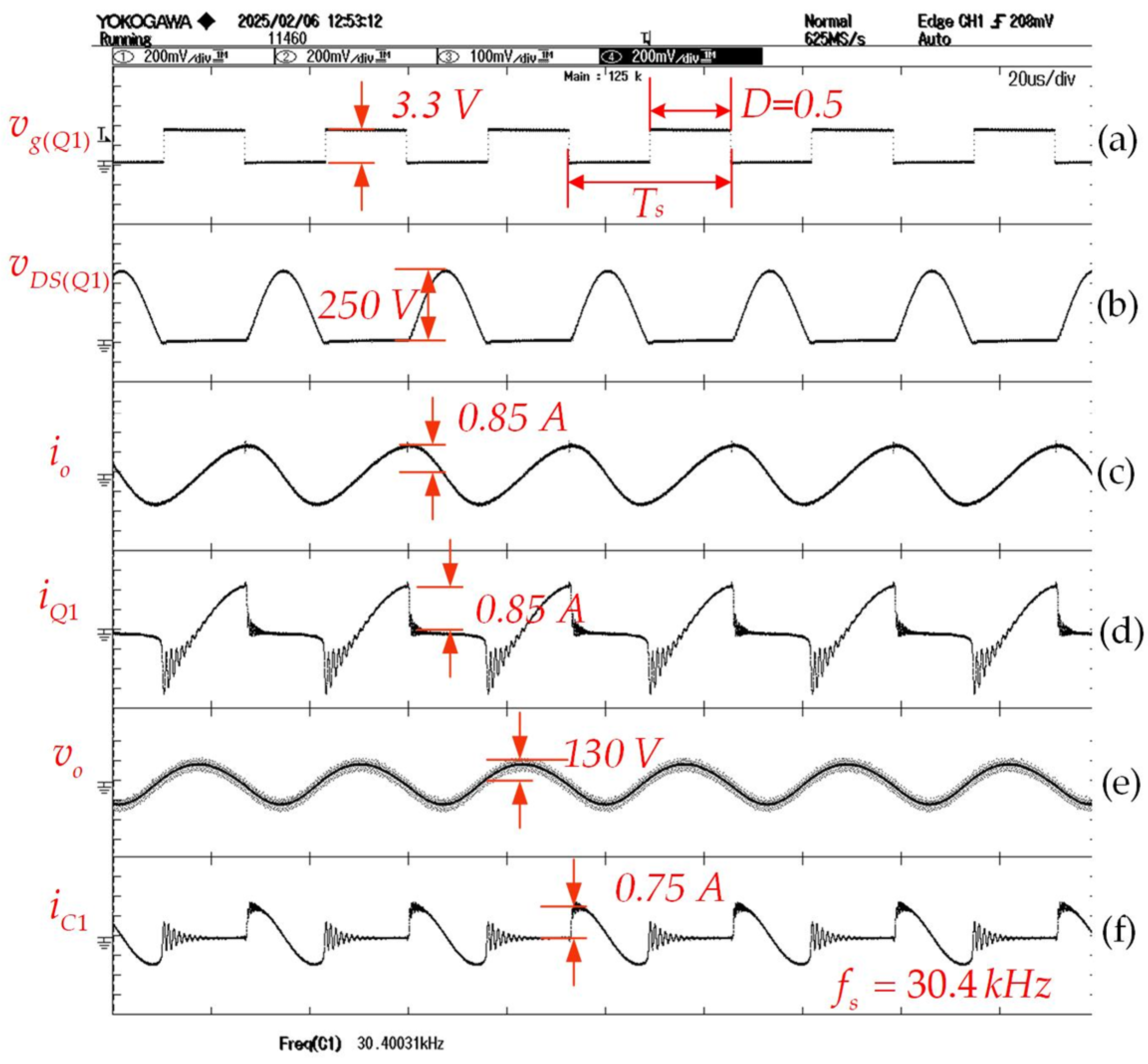

4.2. Results

5. Conclusions

- The Class E ZVS resonant inverter successfully maintains zero-voltage switching (ZVS) across a range of resonant frequencies and varying load conditions.

- The CLC filter effectively smooths the output voltage and current waveforms, improving waveform quality and reducing harmonic distortion.

- The inverter achieves lower switching losses and offers a compact design, making it suitable for space-constrained applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- Core loss and AC copper loss in and the transformer rise with frequency, increasing the thermal burden.

- Switching loss, dv/dt stress, and EMI all increase, potentially requiring added snubbers/filters.

| Name | Theory | Simulation | Experiment |

|---|---|---|---|

| 3.34 mH | 3.34 mH | 3.5 mH | |

| 765 | 765 | 768 | |

| 8.45 nF | 8.45 nF | 8.5 nF | |

| 424 nF | 424 nF | 450 nF | |

| 6.17 nF | 6.17 nF | 6.5 nF |

- -

- The power loss of due to conduction can be determined from Equation (13).

- -

- The power loss of the MOSFET drain–source capacitance ESR can be calculated using Equation (14).

- -

- The turn-on loss of the power MOSFET can be calculated using Equation (15).where

- -

- The power loss of inductor can be calculated from Equation (16) as follows:where the measured current is 1.05 A.

- -

- The power loss of capacitor can be calculated from Equation (17) as follows:

- -

- Equation (18) provides the calculation of losses arising from the parasitic resistances of inductor and capacitor , as shown below:

- -

- Thus, the total power loss of the proposed system can be calculated from Equation (19) as follows:

- -

- Consequently, the efficiency of the Class E resonant inverter can be calculated from Equation (20) as follows:

References

- Wang, Z.; Saoud, C.; Wangsiricharoen, S.; James, A.W.; Popel, A.S.; Sulam, J. Label cleaning multiple instance learning: Refining coarse annotations on single whole-slide images. IEEE Trans. Med. Imaging 2022, 41, 3952–3968. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Xu, Q.; Tam, L.M. A survey on techniques and applications of window-cleaning robots. IEEE Access 2021, 9, 111518–111532. [Google Scholar] [CrossRef]

- Rymansaib, Z.; Kurt, P.; Zhang, Y.; Roscow, J.I.; Bowen, C.R.; Hunter, A.J. Ultrasonic transducers made from freeze-cast porous piezoceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 1100–1111. [Google Scholar] [CrossRef]

- Niyomthai, S.; Sangswang, A.; Naetiladdanon, S.; Mujjalinvimut, E. A predictive control of class E resonant inverter for ultrasonic cleaners. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 6319–6324. [Google Scholar]

- Zhang, Z.; Guan, Y.; Zhao, Q.; Wang, F. Early warning on mass imbalance and clean-in-place strategy for rotor of rotating packed bed. IEEE Access 2020, 8, 44503–44510. [Google Scholar] [CrossRef]

- Jittakort, J.; Kitcharoenwat, S. Adjusted power of class d-zvs resonant inverter controlled by buck converter for LCLC resonant tank. J. Power Electron. 2023, 23, 1907–1918. [Google Scholar] [CrossRef]

- Srathonghuam, K.; Wonganu, B.; Busayaporn, W.; Thongsri, J. Vibration analysis and development of a submersible ultrasonic transducer for an application in the inhibitory activity of pathogenic bacteria. IEEE Access 2021, 9, 142362–142373. [Google Scholar] [CrossRef]

- Astashev, V.K.; Pichugin, K.A.; Li, X.; Meadows, A.; Babitsky, V.I. Resonant tuning of langevin transducers for ultrasonically assisted machining applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 1888–1896. [Google Scholar] [CrossRef]

- Lematre, M.; Ul, R.; Tran-Huu-Hue, L.P.; Lethiecq, M. Electromechanical behavior of a doped barium titanate piezoceramic under mechanical stress: Modeling and comparison with experimental measurements. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 350–355. [Google Scholar] [CrossRef]

- Li, X.; Stritch, T.; Manley, K.; Lucas, M. Limits and opportunities for miniaturizing ultrasonic surgical devices based on a langevin transducer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 2543–2553. [Google Scholar] [CrossRef]

- Shanmugam, Y.; Narayanamoorthi, R. Receiver side-controlled load-independent s-lcc/sp-compensated multi-leg inverter powered dynamic charging system. IEEE Trans. Ind. Electron. 2024, 71, 15694–15703. [Google Scholar] [CrossRef]

- Zawada, T.; Bove, T.; Lou-Møller, R.; Ringgaard, E. Head-to-head comparison of acoustic properties of lead-free and pzt-based hifu transducers operating at 12 MHz. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2024, 71, 16–26. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Ngo, K. An improved class-e current inverter with two coupled inductors for isolation and power scaling without affecting switch voltage stress. IEEE Trans. Ind. Electron. 2024, 71, 9947–9950. [Google Scholar] [CrossRef]

- Cheng, C.; Zheng, X.; Zhang, Y.; Hua, W. Load-independent class-e inverter with dual quasi-constant outputs. IEEE Trans. Power Electron. 2024, 39, 14015–14026. [Google Scholar] [CrossRef]

- Jittakort, J.; Chudjuarjeen, S.; Karnjanapiboon, C.; Kitcharoenwat, S. Enhanced half bridge series resonant inverter for induction cap sealing with controlled load adaptation. Przegląd Elektrotechniczny 2024, 5, 198–204. [Google Scholar] [CrossRef]

- Ayachit, A.; Corti, F.; Reatti, A.; Kazimierczuk, M.K. Zero-voltage switching operation of transformer class-e inverter at any coupling coefficient. IEEE Trans. Ind. Electron. 2019, 66, 1809–1819. [Google Scholar] [CrossRef]

- Cheng, C.; Zhang, Y.; Zheng, X.; Hua, W. A full-range soft-switching class-e inverter achieving quasi-constant voltage output. IEEE Trans. Power Electron. 2025, 40, 7663–7667. [Google Scholar] [CrossRef]

- Li, H.; Wang, H.; Liang, J.; Fu, M. EMI suppression in inductive power transfer systems using class e inverters. IEEE Trans. Power Electron. 2024, 39, 15474–15478. [Google Scholar] [CrossRef]

- Li, Y.; Ruan, X.; Zhang, L.; Dai, J.; Jin, Q. Variable switching frequency on–off control for class e dc–dc converter. IEEE Trans. Power Electron. 2019, 34, 8859–8870. [Google Scholar] [CrossRef]

- Li, Y.; Watson, A.J.; Kaya, M. A class-e-based multichannel auxiliary power supply with individual hysteresis control. IEEE J. Emerg. Sel. Topics Power Electron. 2023, 11, 3335–3347. [Google Scholar] [CrossRef]

- Saxena, V.K.; Kumar, K.; Lulbadda, K.T.; Williamson, S. A comprehensive analysis of gan-hemt-based class e resonant inverter using modified resonant gate driver circuit. IEEE Trans. Ind. Appl. 2024, 60, 7098–7110. [Google Scholar] [CrossRef]

- Shinde, K.; Koizumi, H. Capacitive power transfer system using a load-independent class e zero voltage switching parallel resonant inverter and a class d voltage-driven rectifier. IEEE Trans. Circuits Syst. II Exp. Briefs. 2024, 71, 4366–4370. [Google Scholar] [CrossRef]

- Li, D.; Wu, X.; An, C.; Gao, J.; Gao, W. Implementation of zvs for double-sided lcc inductive coupled wireless power transfer system under constant current/constant voltage operation mode. IEEE Access 2023, 11, 29726–29743. [Google Scholar] [CrossRef]

- Aiello, O. Design of an Ultra-low voltage bias current generator highly immune to electromagnetic interference. J. Low Power Electron. Appl. 2021, 11, 6. [Google Scholar] [CrossRef]

- Ren, S.; Yang, P.; Wang, X.; Xu, J.; Ma, H. LCL/CLC resonant rectifier-based inductive power transfer systems with integrated coil structure and inherent cc and cv battery-charging profile. IEEE Trans. Transport. Electrific. 2024, 10, 5037–5048. [Google Scholar] [CrossRef]

- Wang, J.; Pei, W.; Hu, J.; Zhao, S.; Zhuang, J. Five-phase llc resonant dc/dc converter utilizing clc filter for current sharing. IEEE Trans. Ind. Electron. 2023, 70, 8634–8644. [Google Scholar] [CrossRef]

- Svoboda, M.; Sotner, R.; Polak, L.; Jerabek, J.; Jaikla, W.; Andriukaitis, D. Design of phase-locked loop using special analog multipliers and voltage buffers: Demodulation of transposed signals from sensors. IEEE Trans. Instrum. Meas. 2024, 73, 2006511. [Google Scholar] [CrossRef]

- Yang, H.; Yang, L.; Chen, S.; Shi, J.; Jin, A. A frequency adaptive control strategy for grid-connected inverters without ac voltage sensor based on an improved finite position set-phase locked loop. IEEE Trans. Power Electron. 2025, 40, 3938–3951. [Google Scholar] [CrossRef]

- Gulipalli, S.C.; Chou, P.H.; Chen, Y.M.; Liu, T.I.; Chu, C.C. Frequency-locked loop based new automatic phase-shift method for active islanding detection of three-phase microgrid. IEEE Trans. Ind. Appl. 2023, 59, 5257–5268. [Google Scholar] [CrossRef]

- Kashif, M.; Singh, B. Multi-resonant third-order generalized integrator based pll for seamless control of solar-battery fed grid synchronized water pumping system. IEEE Trans. Energy Convers. 2023, 38, 355–366. [Google Scholar] [CrossRef]

- Jittakort, J.; Sangswang, A.; Naetiladdanon, S.; Koompai, C.; Chudjuarjeen, S. Full bridge resonant inverter using asymmetrical control with resonant-frequency tracking for ultrasonic cleaning applications. J. Power Electron. 2017, 17, 1150–1159. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| 320.05 | ||

| 85.25 | mH | |

| 170.15 | pF | |

| 2.52 | nF |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aurasopon, A.; Sriboonrueng, B.; Jittakort, J.; Chudjuarjeen, S. Class E ZVS Resonant Inverter with CLC Filter and PLL-Based Resonant Frequency Tracking for Ultrasonic Piezoelectric Transducer. J. Low Power Electron. Appl. 2025, 15, 54. https://doi.org/10.3390/jlpea15030054

Aurasopon A, Sriboonrueng B, Jittakort J, Chudjuarjeen S. Class E ZVS Resonant Inverter with CLC Filter and PLL-Based Resonant Frequency Tracking for Ultrasonic Piezoelectric Transducer. Journal of Low Power Electronics and Applications. 2025; 15(3):54. https://doi.org/10.3390/jlpea15030054

Chicago/Turabian StyleAurasopon, Apinan, Boontan Sriboonrueng, Jirapong Jittakort, and Saichol Chudjuarjeen. 2025. "Class E ZVS Resonant Inverter with CLC Filter and PLL-Based Resonant Frequency Tracking for Ultrasonic Piezoelectric Transducer" Journal of Low Power Electronics and Applications 15, no. 3: 54. https://doi.org/10.3390/jlpea15030054

APA StyleAurasopon, A., Sriboonrueng, B., Jittakort, J., & Chudjuarjeen, S. (2025). Class E ZVS Resonant Inverter with CLC Filter and PLL-Based Resonant Frequency Tracking for Ultrasonic Piezoelectric Transducer. Journal of Low Power Electronics and Applications, 15(3), 54. https://doi.org/10.3390/jlpea15030054