Design Aspects of a Single-Output Multi-String WLED Driver Using 40 nm CMOS Technology

Abstract

:1. Introduction

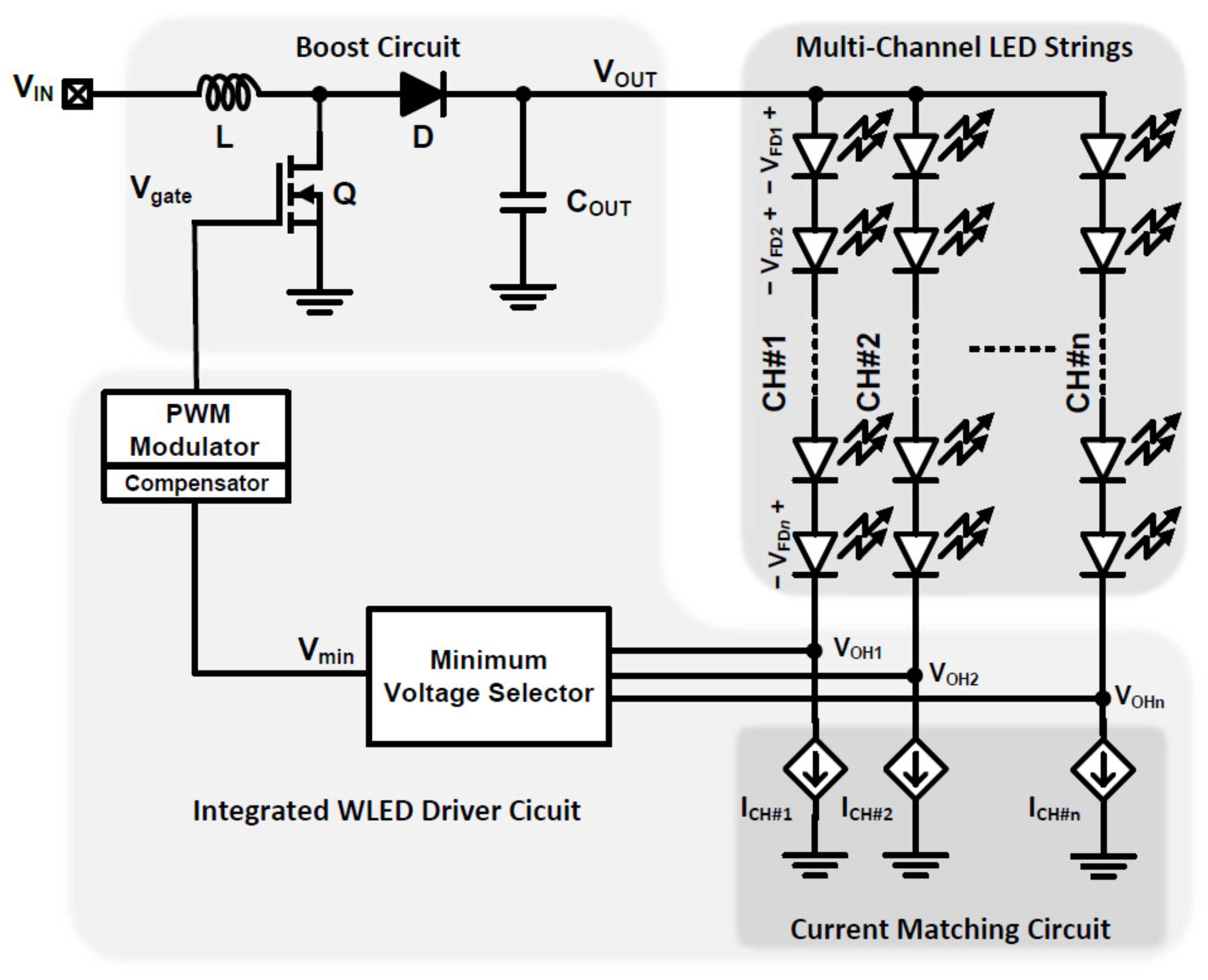

2. Features, Issues and Proposed Circuit Implementation

2.1. Efficiency Optimization

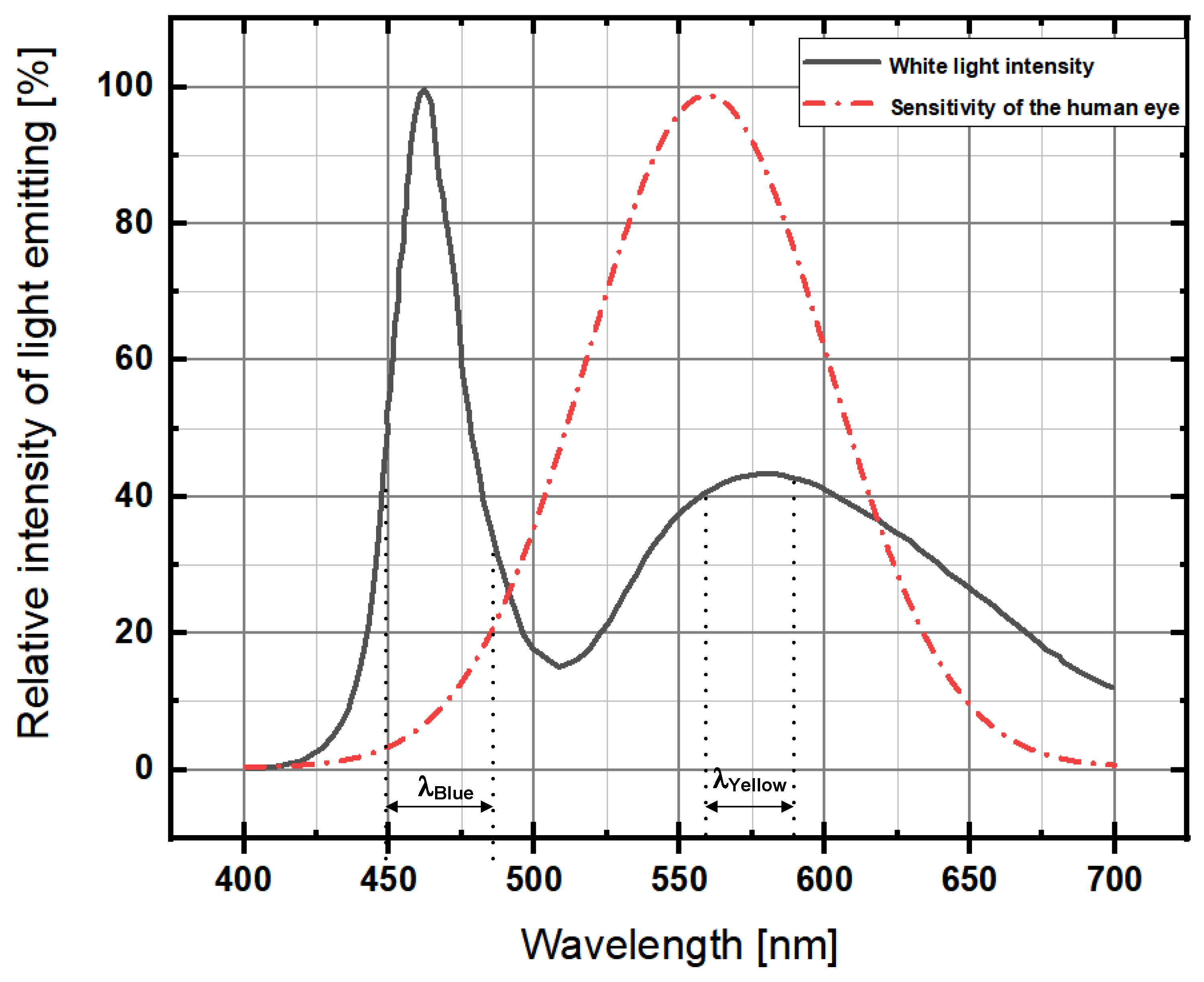

2.1.1. WLED Arrangement

2.1.2. Voltage Feedback Sensing

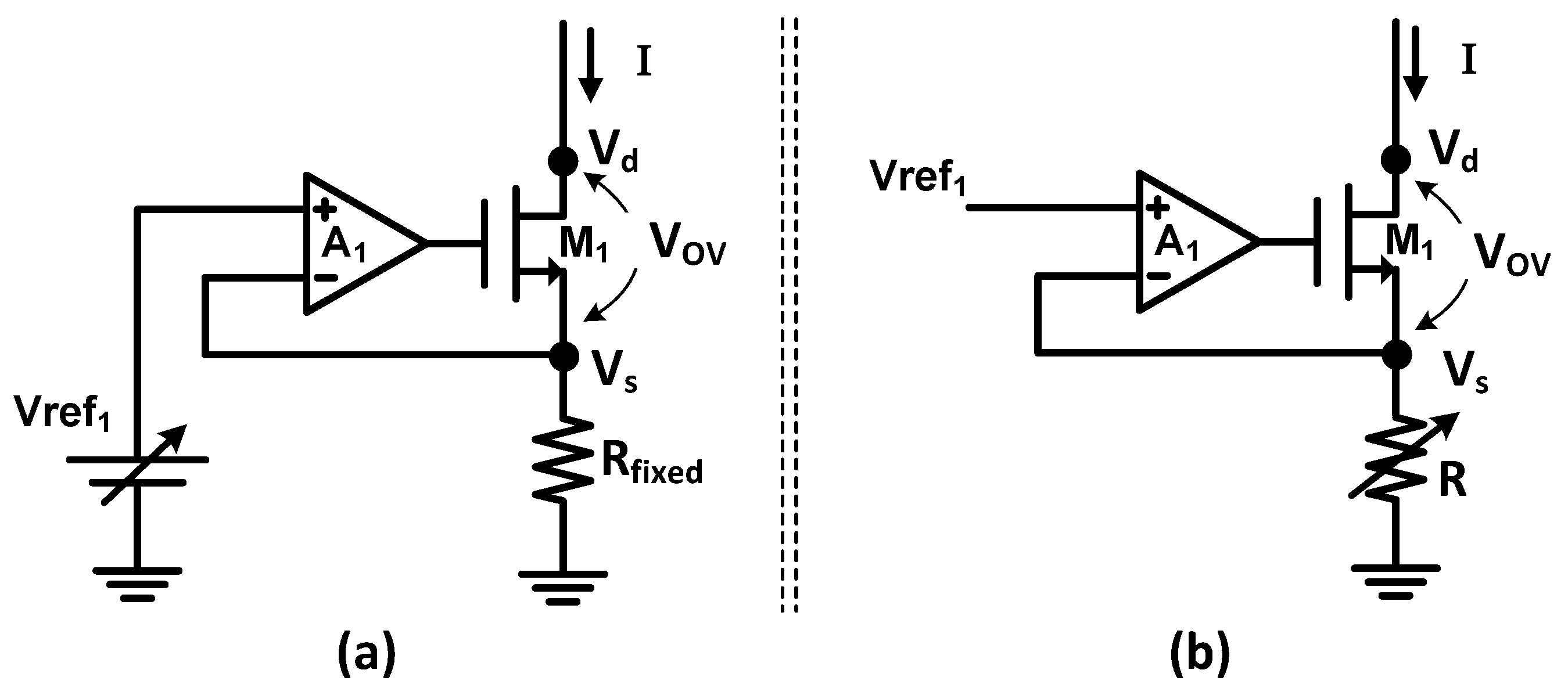

2.2. Current Sink Programmability

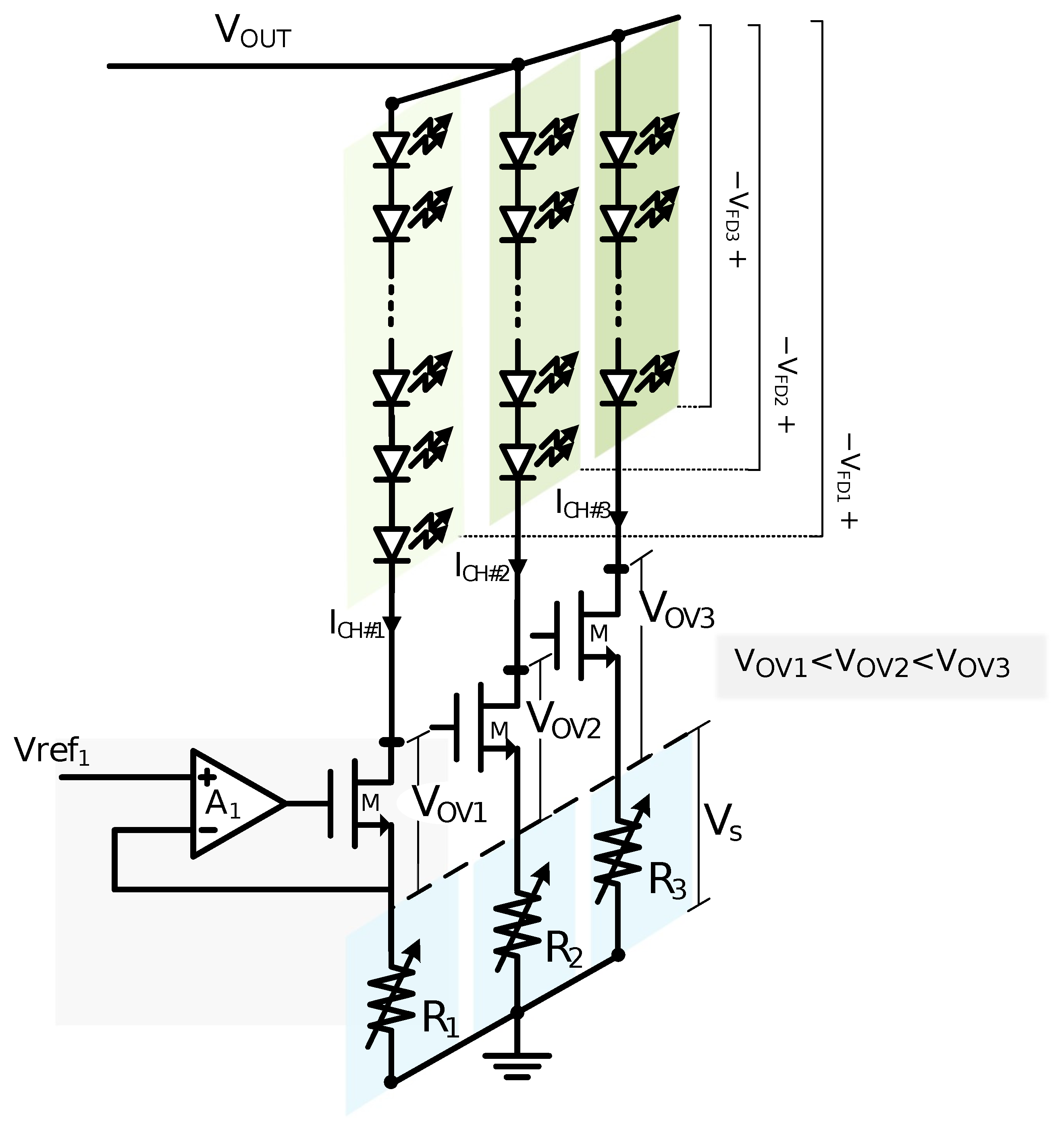

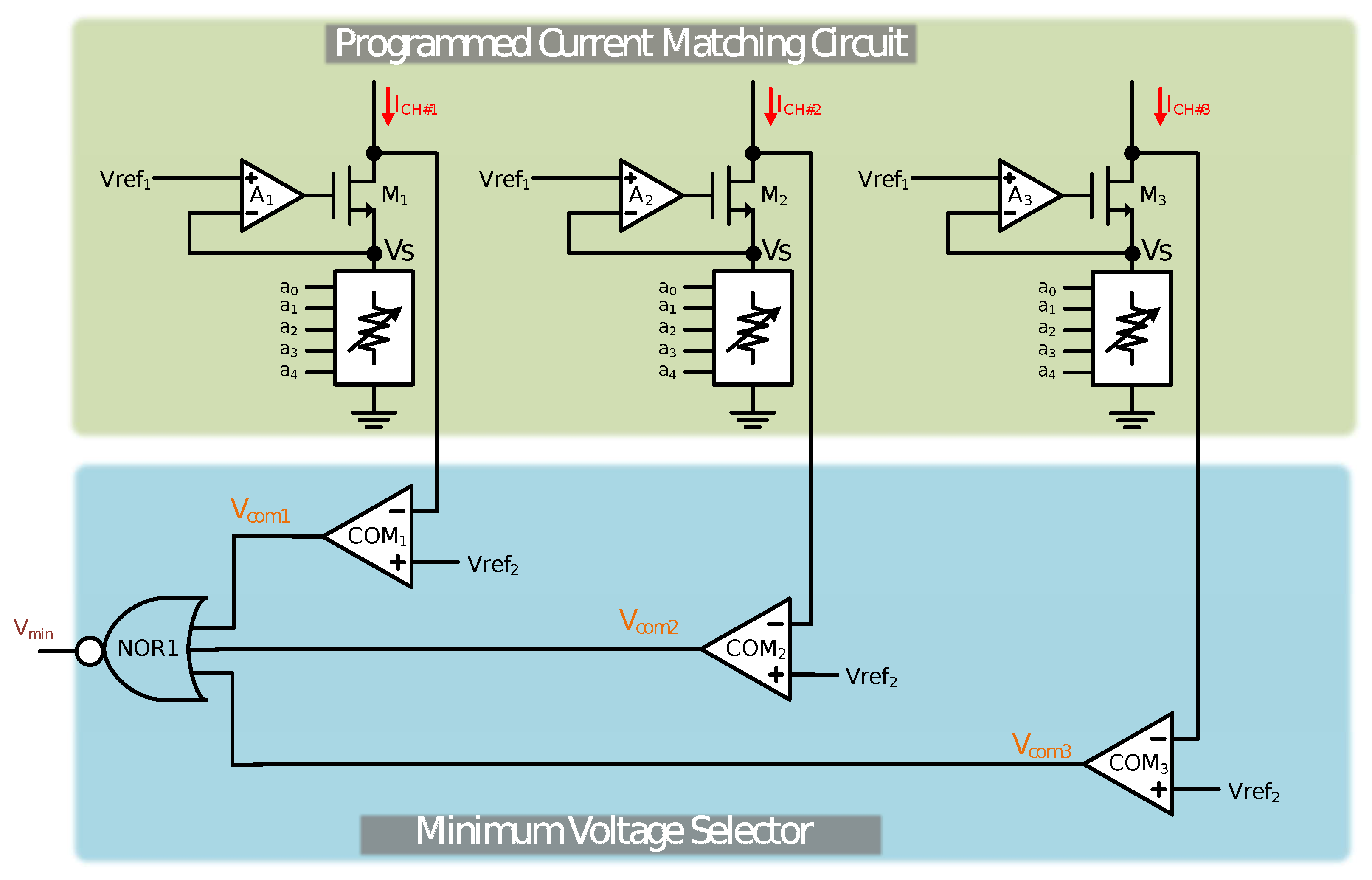

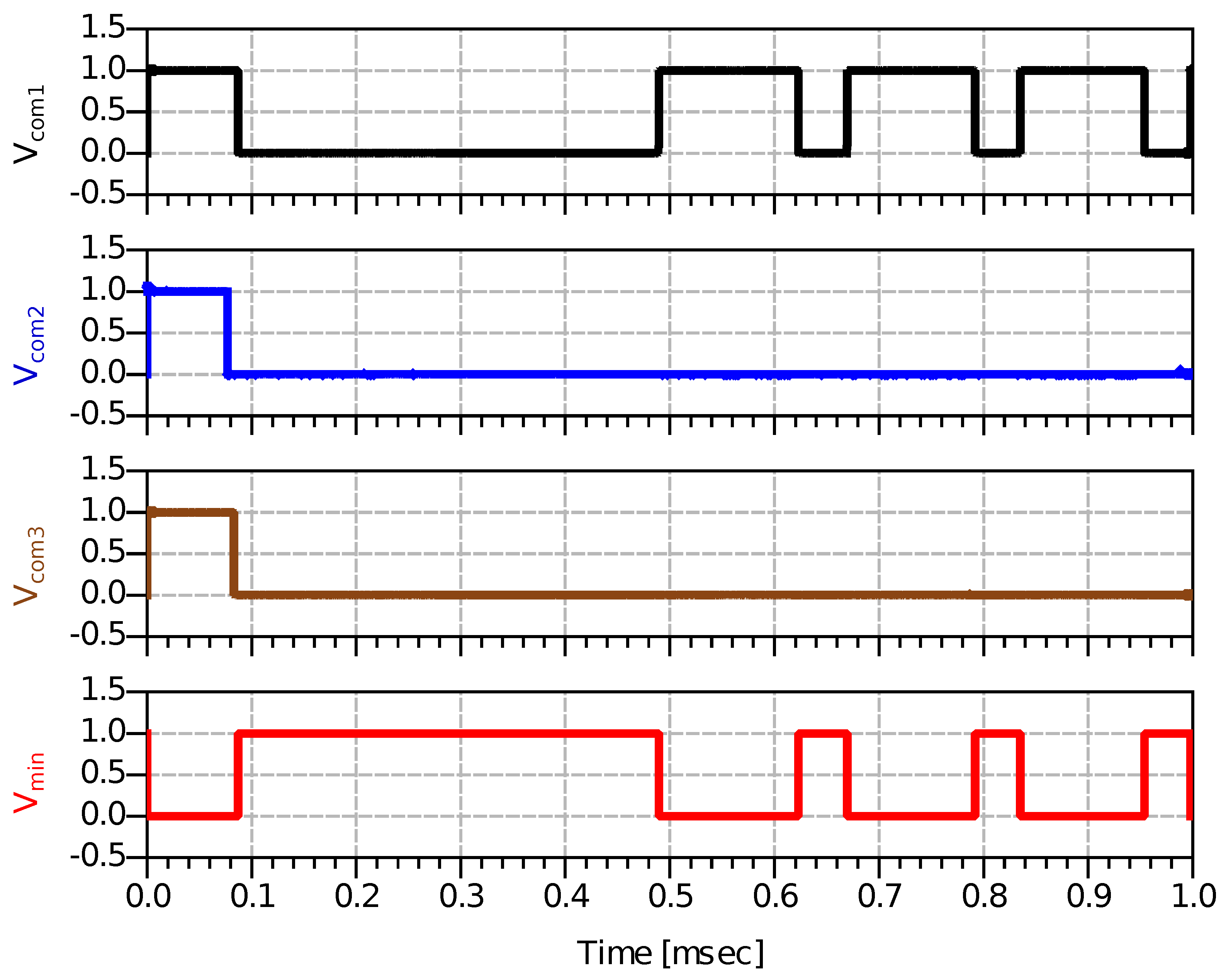

2.3. Programmable Current Matching and Minimum Voltage Selector Circuitry

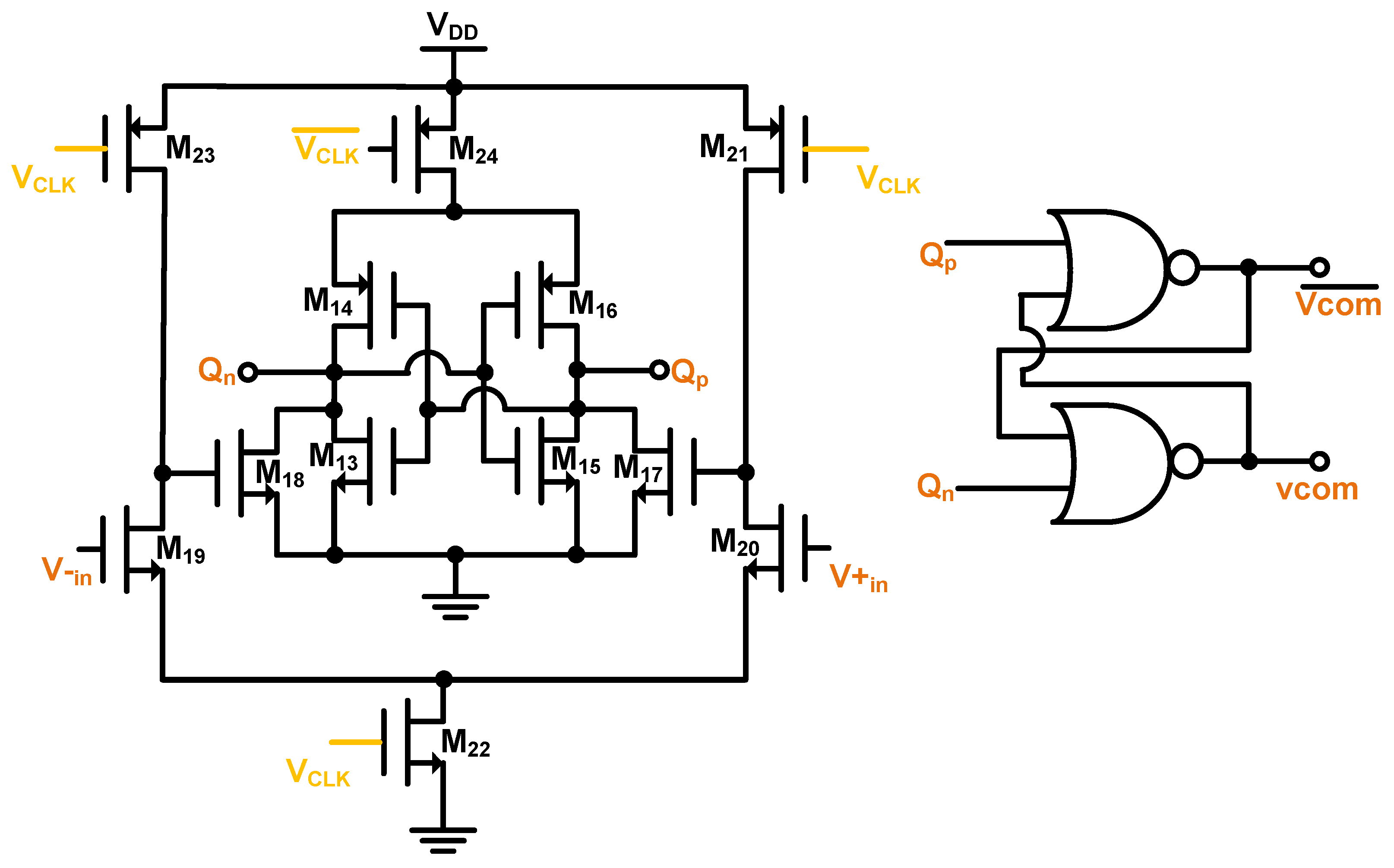

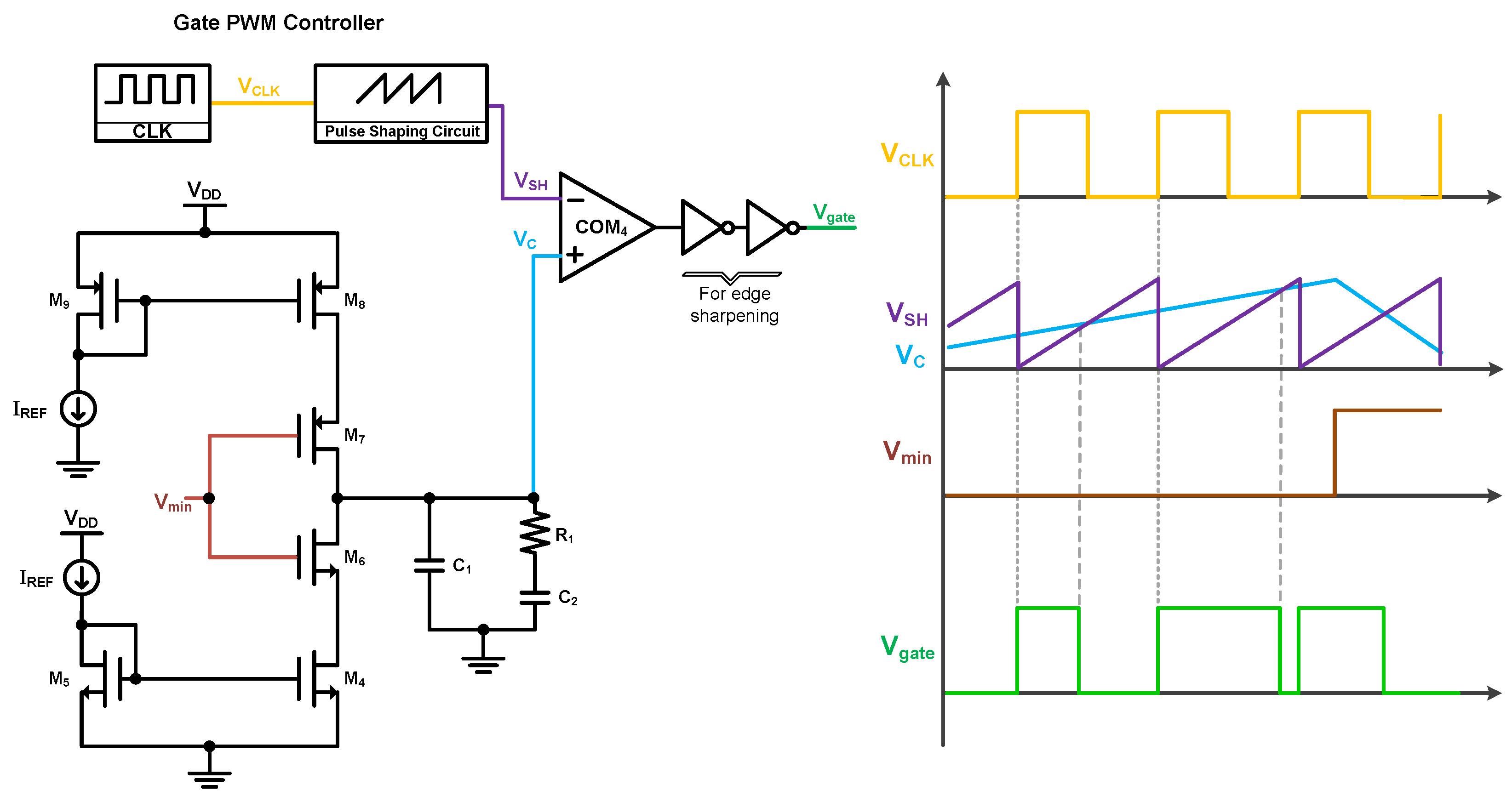

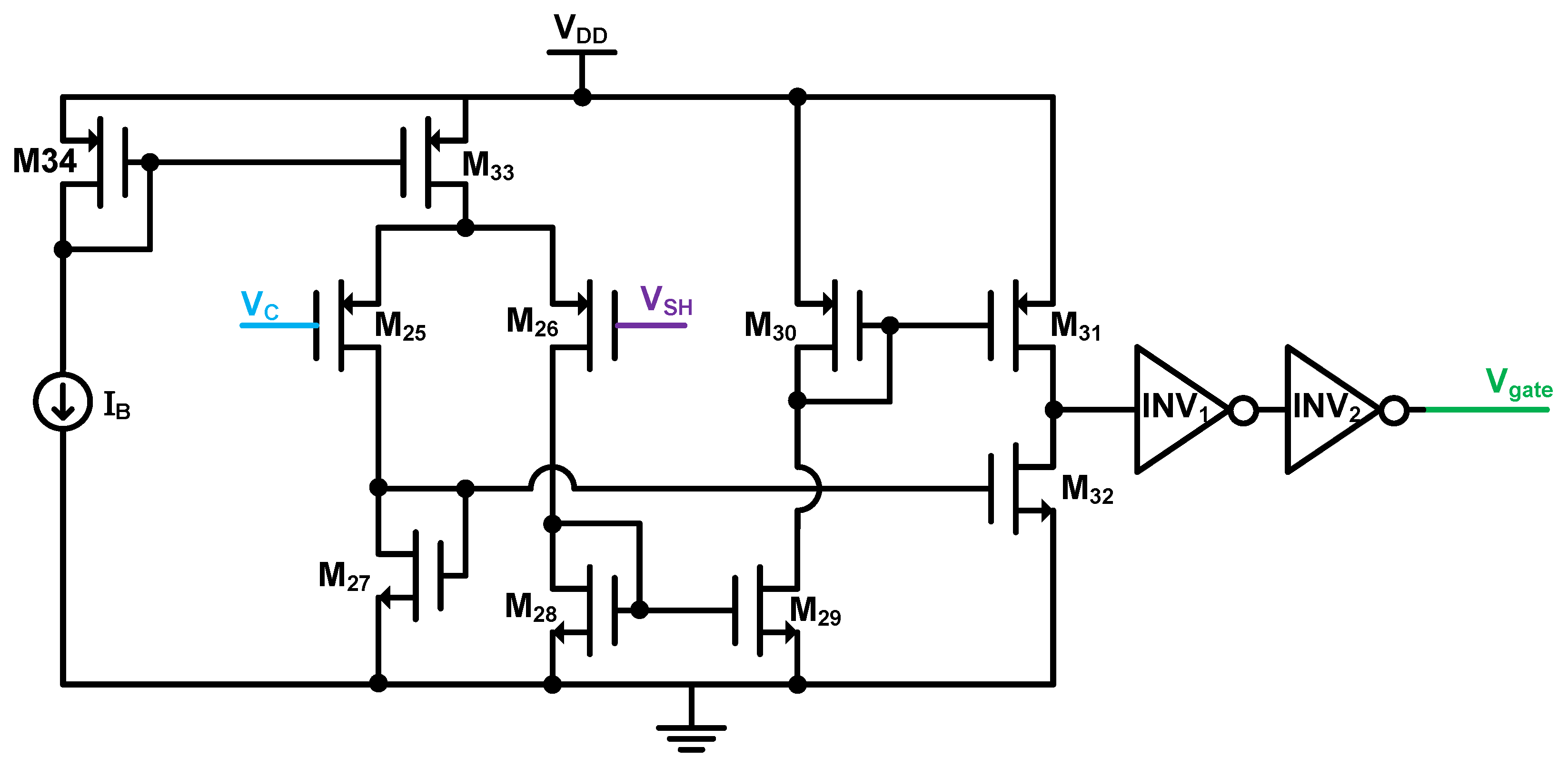

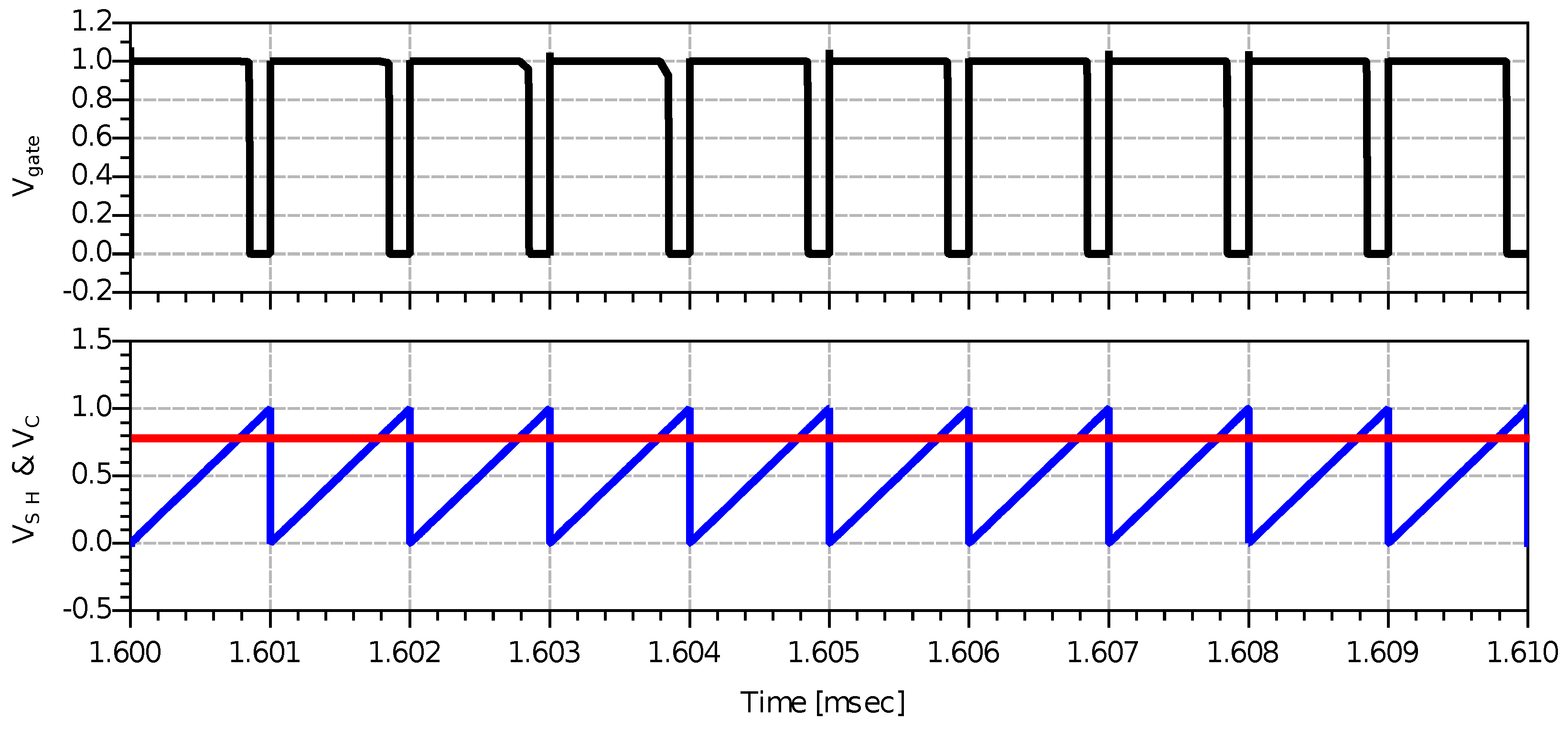

2.4. Compensator and PWM Modulator Circuitry

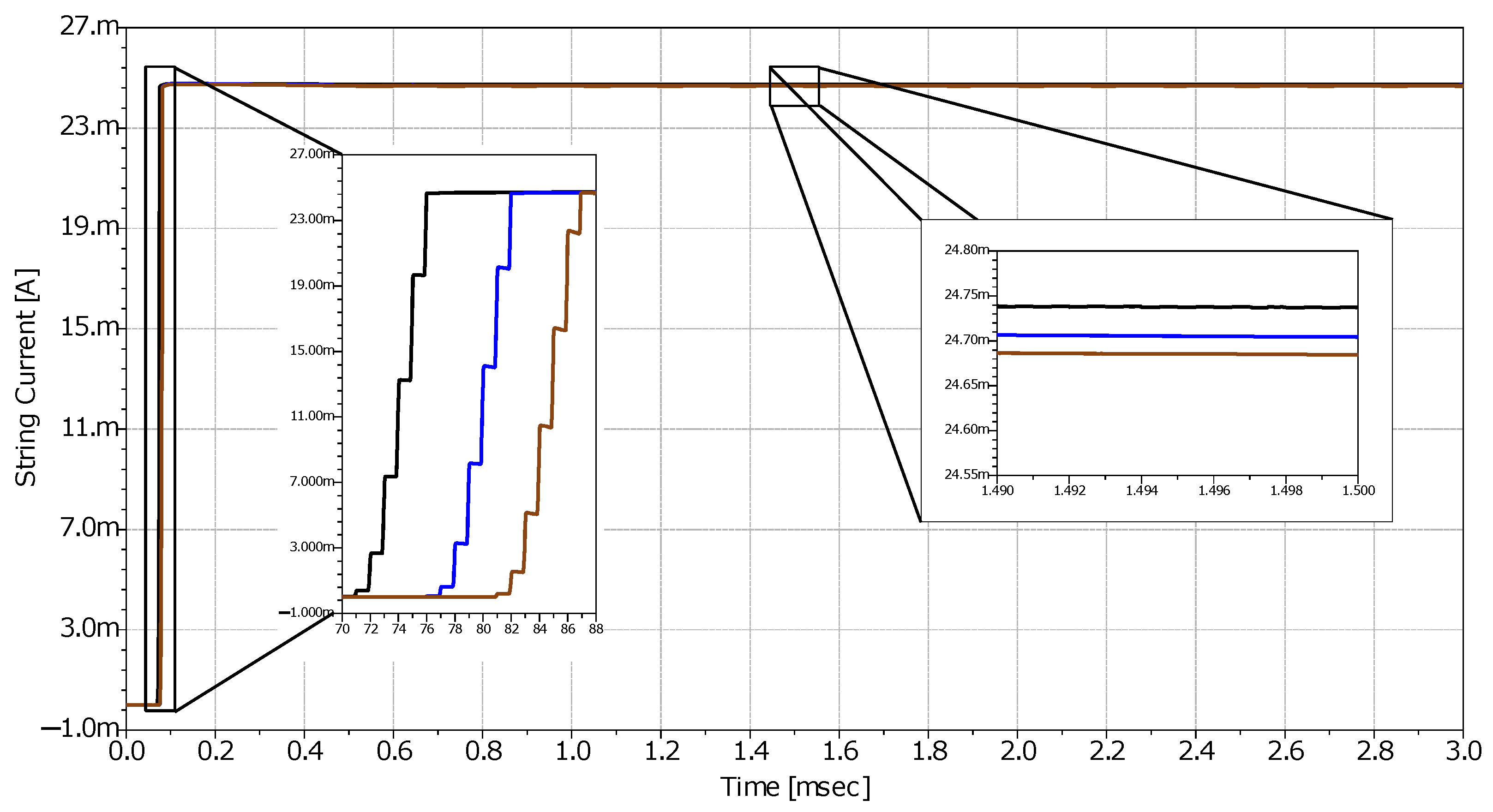

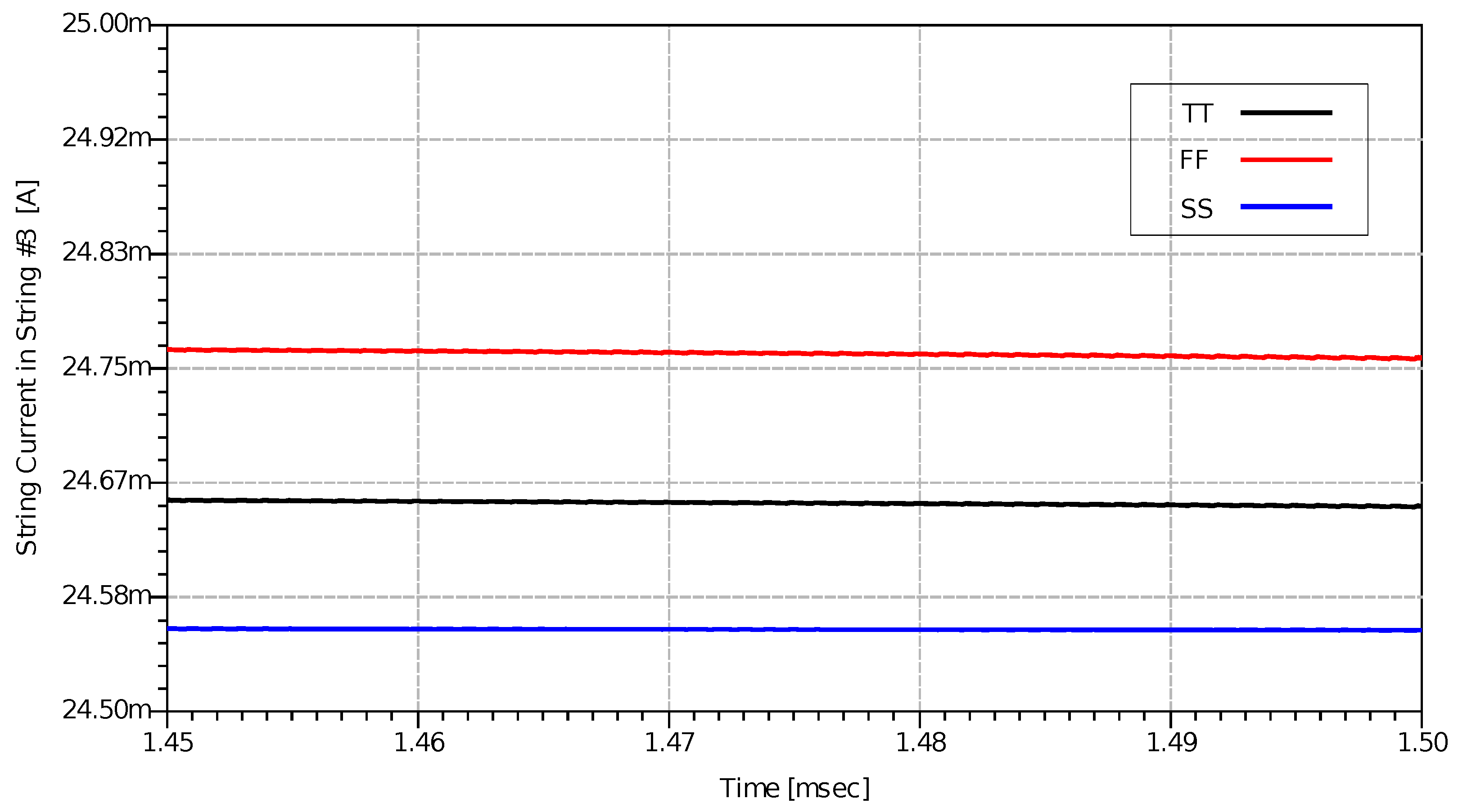

3. Simulation Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CMOS | Complementary metal–oxide–semiconductor |

| WLED | White Light-Emitting Diode |

| CCM | Continuous Conduction Modes |

| DCM | Discontinuous Conduction Modes |

References

- Ahmad, H.H.; Shahroury, F.R. Design of a High Efficiency WLED Driver in 40 nm CMOS Technology. In Proceedings of the 2020 32nd International Conference on Microelectronics (ICM), Aqaba, Jordan, 14–17 December 2020; pp. 1–4. [Google Scholar]

- Eguchi, K.; Shibata, A.; Do, W.; Asadi, F. An LED driver connecting a nested-type SC converter and an SI buck-boost converter in parallel. In Proceedings of the 2021 3rd Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 26–29 March 2021; pp. 255–258. [Google Scholar]

- Branas, C.; Azcondo, F.J.; Alonso, J.M. Solid-state lighting: A system review. IEEE Ind. Electron. Mag. 2013, 7, 6–14. [Google Scholar] [CrossRef]

- Ahmad, H.H.; Shahroury, F.R.; Abuishmais, I. A Multi-Output Multi-String High-Efficiency WLED Driver Using 40 nm CMOS Technology. J. Low Power Electron. Appl. 2021, 11, 47. [Google Scholar] [CrossRef]

- Kim, H.C.; Yoon, C.S.; Jeong, D.K.; Kim, J. A single-inductor, multiple-channel current-balancing LED driver for display backlight applications. IEEE Trans. Ind. Appl. 2014, 50, 4077–4081. [Google Scholar] [CrossRef]

- Han, H.; Zhang, F.; Liu, M. PWM dimming method for capacitor-clamped current-sharing circuit in LED backlight system. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1190–1197. [Google Scholar] [CrossRef]

- Guo, Y.; Li, S.; Lee, A.T.L.; Tan, S.; Lee, C.K.; Hui, S.Y.R. Single-Stage AC/DC Single-Inductor Multiple-Output LED Drivers. IEEE Trans. Power Electronics 2016, 31, 5837–5850. [Google Scholar] [CrossRef]

- Kang, E.C.; Yeon, J.E.; Kim, D.S.; Kwon, D. Sequential low-voltage detecting method for multistring LED BLU circuit. Electron. Lett. 2010, 46, 839–840. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, N.; Guan, Y.; Cecati, C.; Xu, D. A single-stage LED driver based on SEPIC and LLC circuits. IEEE Trans. Ind. Electron. 2016, 64, 5766–5776. [Google Scholar] [CrossRef]

- Reddy, U.R.; Narasimharaju, B. A cost-effective zero-voltage switching dual-output led driver. IEEE Trans. Power Electron. 2016, 32, 7941–7953. [Google Scholar] [CrossRef]

- Hwu, K.I.; Jiang, W.Z. Input-current-ripple-free two-channel LED driver. IEEE Trans. Ind. Electron. 2016, 64, 5865–5874. [Google Scholar] [CrossRef]

- Doshi, M.; Zane, R. Digital architecture for driving large LED arrays with dynamic bus voltage regulation and phase shifted PWM. In Proceedings of the APEC 07-Twenty-Second Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 25 February–1 March 2007; pp. 287–293. [Google Scholar]

- Hong, S.i.; Han, J.W.; Kim, D.H.; Kwon, O.K. A double-loop control LED backlight driver IC for medium-sized LCDs. In Proceedings of the 2010 IEEE International Solid-State Circuits Conference-(ISSCC), San Francisco, CA, USA, 7–11 February 2010; pp. 116–117. [Google Scholar]

- Oh, T.J.; Cho, A.; Ki, S.L.; Hwang, I.C. A low-power and low-cost digitally-controlled boost LED driver IC for backlights. In Proceedings of the 2012 IEEE Asian Solid State Circuits Conference (A-SSCC), Kobe, Japan, 12–14 November 2012; pp. 237–240. [Google Scholar]

- Zhang, H.J. Basic Concepts of Linear Regulator and Switching Mode Power Supplies. Available online: https://www.analog.com/en/app-notes/an-140.html (accessed on 2 December 2021).

- Burgyan, L.; Prinz, F. High Efficiency LED Driver. U.S. Patent 6,690,146, 10 February 2004. [Google Scholar]

- Modepalli, K.; Parsa, L. A scalable N-color LED driver using single inductor multiple current output topology. IEEE Trans. Power Electron. 2015, 31, 3773–3783. [Google Scholar] [CrossRef]

- Hiramoto, T. Five nanometre CMOS technology. Nat. Electron. 2019, 2, 557–558. [Google Scholar] [CrossRef]

- Bianchi, R.; Monsieur, F.; Blanchet, F.; Raynaud, C.; Noblanc, O. High voltage devices integration into advanced CMOS technologies. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2008; pp. 1–4. [Google Scholar]

- Erickson, R.W.; Maksimovic, D. Fundamentals of Power Electronics, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- NICHIA Corporation. Specification for White LED; Cat. No. 201008; NICHIA Corporation: Tokushima, Japan, 2019. [Google Scholar]

- Yao, K.; Moyer, J.C. Control of Multi-String LED Array. U.S. Patent 8,410,716, 4 February 2013. [Google Scholar]

- Hsieh, Y.T.; Liu, B.D.; Wu, J.F.; Fang, C.L.; Tsai, H.H.; Juang, Y.Z. A high-dimming-ratio LED driver for LCD backlights. IEEE Trans. Power Electron. 2012, 27, 4562–4570. [Google Scholar] [CrossRef]

- Schinkel, D.; Mensink, E.; Klumperink, E.; Van Tuijl, E.; Nauta, B. A double-tail latch-type voltage sense amplifier with 18ps setup+ hold time. In Proceedings of the 2007 IEEE international solid-state circuits conference. Digest of technical papers, San Francisco, CA, USA, 11–15 February 2007; pp. 314–605. [Google Scholar]

- Nikolic, B.; Oklobdzija, V.G.; Stojanovic, V.; Jia, W.; Chiu, J.K.S.; Leung, M.M.T. Improved sense-amplifier-based flip-flop: Design and measurements. IEEE J. Solid-State Circuits 2000, 35, 876–884. [Google Scholar] [CrossRef]

- Wicht, B.; Nirschl, T.; Schmitt-Landsiedel, D. Yield and speed optimization of a latch-type voltage sense amplifier. IEEE J. Solid-State Circuits 2004, 39, 1148–1158. [Google Scholar] [CrossRef]

- Sedra, A.; Smith, K.; Carusone, T.C.; Gaudet, V. Microelectronic Circuits 8th Edition. Chapter 2020, 14, 1235–1236. [Google Scholar]

- Allen, P.E.; Holberg, D.R. CMOS Analog Circuit Design; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Yang, W.H.; Yang, H.A.; Huang, C.J.; Chen, K.H.; Lin, Y.H. A high-efficiency single-inductor multiple-output buck-type LED driver with average current correction technique. IEEE Trans. Power Electron. 2017, 33, 3375–3385. [Google Scholar] [CrossRef]

- Qu, Y.; Wang, Z. Soft-switching techniques for single-inductor multiple-output led drivers. IEEE Trans. Power Electron. 2020, 35, 13748–13756. [Google Scholar] [CrossRef]

| Configuration | Efficiency % |

|---|---|

| 1S, 18 WLEDs | 88.58 |

| 18S, 1 WLED | 85.00 |

| 2S, 9 WLEDs | 90.57 |

| 9S, 2 WLEDs | 89.02 |

| 6S, 3 WLEDs | 90.22 |

| 3S, 6 WLEDs | 90.90 |

| Ref. | [17] | [29] | [5] | [6] | [7] | [30] | This Work |

|---|---|---|---|---|---|---|---|

| Switching Frequency (kHz) | 50 | 1200 | 93.75 | 100 | 75 | 2000 | 1000 |

| Process Technology | Discreet | 0.5 μm HV | Discreet | Discreet | Discreet | Integrated circuit | 40 nm CMOS standard technology |

| Efficiency | 91% | 96% | 85.6% | 98.5% | 93.5% | 96.2% | 90.9 % |

| Current Accuracy Among Strings | 12.5% | N/A | 2.04% | 1.39% | N/A | N/A | 0.2% |

| Dimming | PWM 200 kHz | PWM 3 kHz | No dimming | PWM 1 kHz | PWM 25 kHz | PWM 3 kHz | Individual digital dimming (with 1 mA resolution) |

| Input Voltage (V) | 48 | 16–24 | 9–12 | 138 | 7.8 | 15 | 3.2–4.2 |

| String vs. WLEDs | 3 × 3 | 4 × 1 | 3 × 6 | 3 × 11 | 3 × 7 | 1 × 4 | 3 × 6 |

| Mode of Operation | CCM | CCM | CCM | CCM | CCM & DCM | BCM | CCM & DCM |

| Current Sensing Technique | Switch mode current driver | External resistance | External resistance | Capacitor-clamped current sharing | External resistance | On-chip bidirectional current sensor | On-chip programmable resistor |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahroury, F.R.; Ahmad, H.H.; Abuishmais, I. Design Aspects of a Single-Output Multi-String WLED Driver Using 40 nm CMOS Technology. J. Low Power Electron. Appl. 2022, 12, 5. https://doi.org/10.3390/jlpea12010005

Shahroury FR, Ahmad HH, Abuishmais I. Design Aspects of a Single-Output Multi-String WLED Driver Using 40 nm CMOS Technology. Journal of Low Power Electronics and Applications. 2022; 12(1):5. https://doi.org/10.3390/jlpea12010005

Chicago/Turabian StyleShahroury, Fadi R., Hani H. Ahmad, and Ibrahim Abuishmais. 2022. "Design Aspects of a Single-Output Multi-String WLED Driver Using 40 nm CMOS Technology" Journal of Low Power Electronics and Applications 12, no. 1: 5. https://doi.org/10.3390/jlpea12010005

APA StyleShahroury, F. R., Ahmad, H. H., & Abuishmais, I. (2022). Design Aspects of a Single-Output Multi-String WLED Driver Using 40 nm CMOS Technology. Journal of Low Power Electronics and Applications, 12(1), 5. https://doi.org/10.3390/jlpea12010005