The Systems Fusion Challenge: Intelligence vs. Manufacturing in Micro Smart Factories

Abstract

1. Introduction

- RQ1: How can an evaluation index system for intelligence and manufacturing be built in MSF?

- RQ2: What is the value of MSF in the context of intelligent manufacturing?

- RQ3: How can the coordinated development of intelligence and manufacturing in MSFs be promoted?

2. Literature Review

2.1. Manufacturing Capabilities of Manufacturing Companies

2.2. Intelligent Level of Manufacturing Enterprises

2.3. Intelligent Manufacturing Measurement Index Design

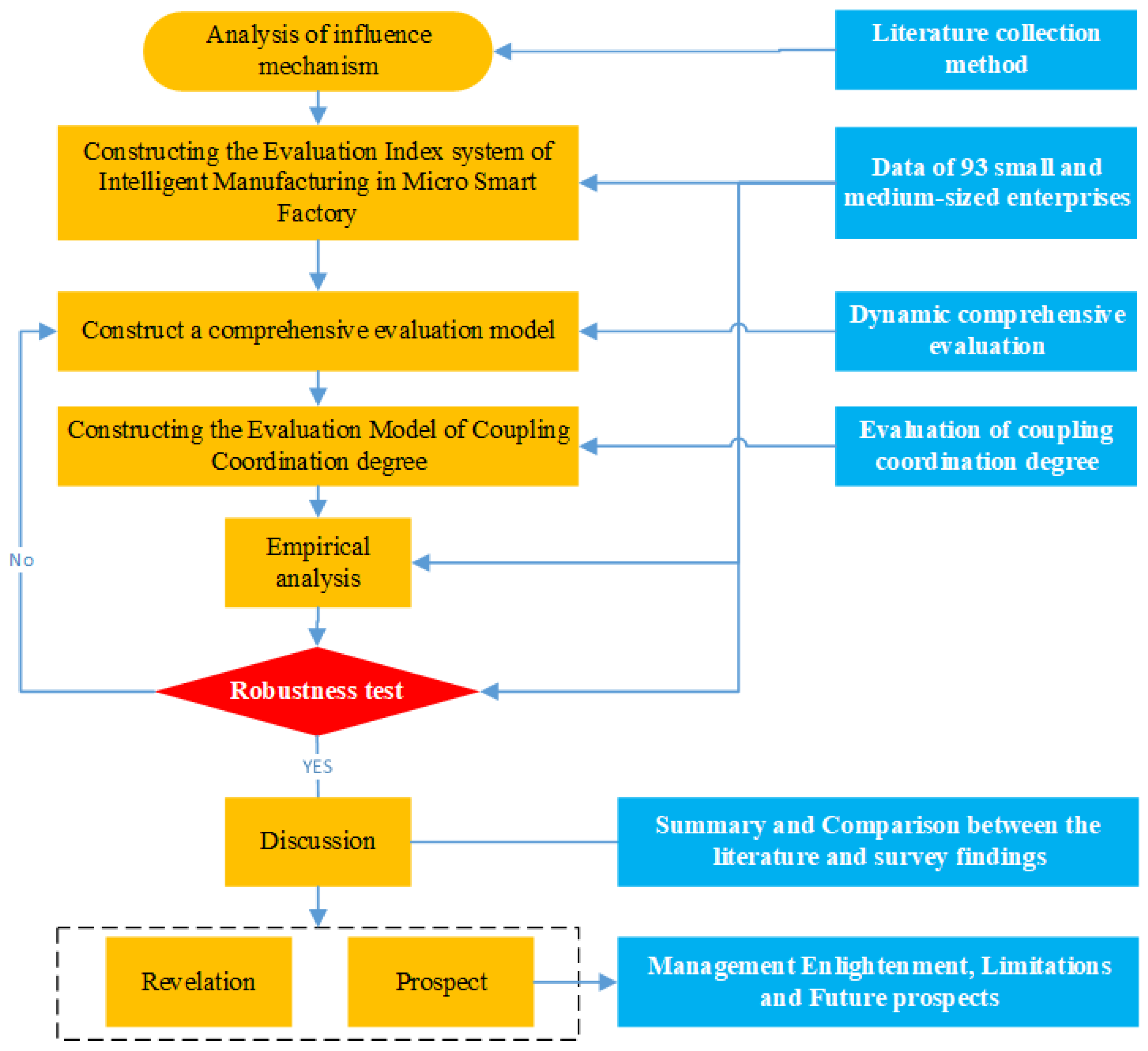

3. Research Method and Design

4. Model Building

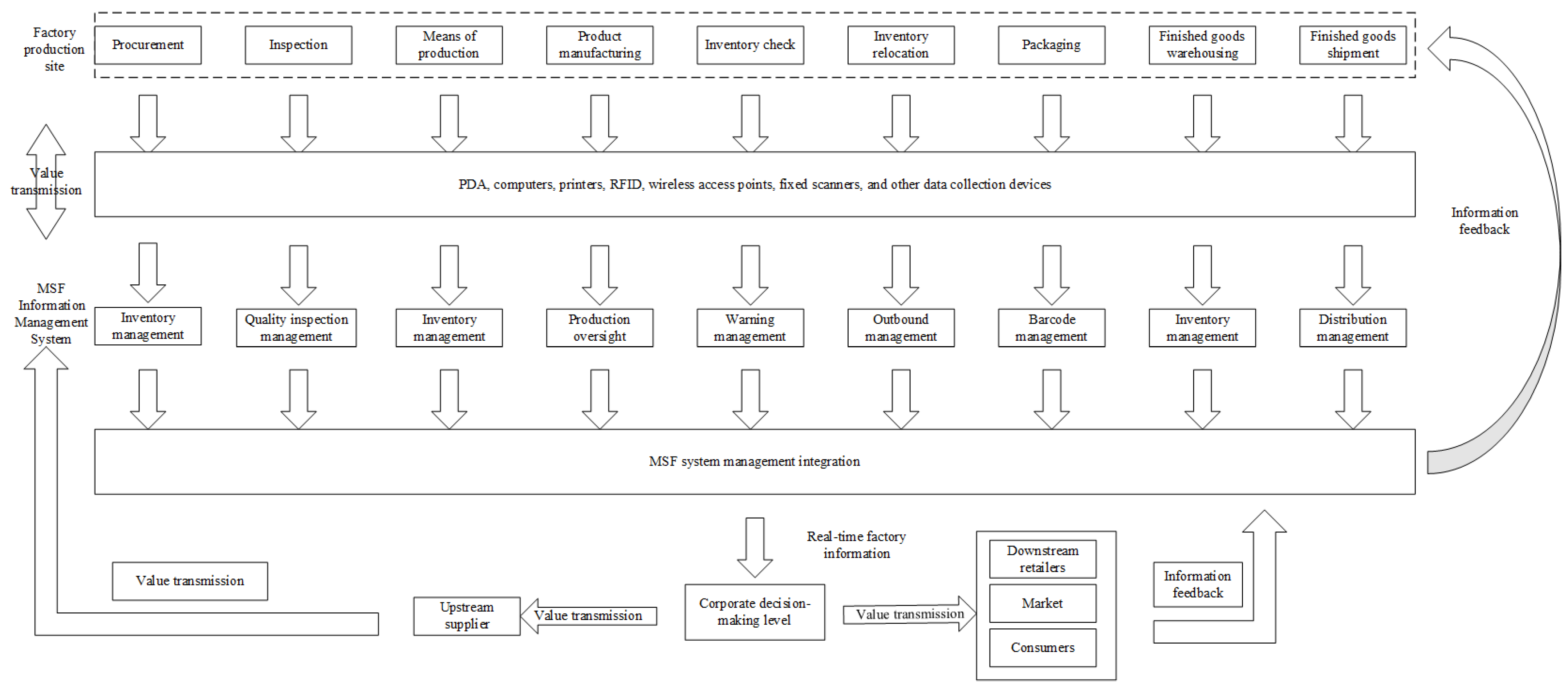

4.1. Analysis of the Influence Mechanism

4.2. Evaluation Index System for Intelligent Manufacturing in MSF

4.3. Constructing a Comprehensive Evaluation Model

4.4. Evaluation Model of the Degree of Coupling Coordination

5. Empirical Research

5.1. Sample Selection and Data Collection

5.2. Reliability and Validity Analysis

5.3. Measurement of Levels of Coupling and Coordinated Development

5.4. Discussion

6. Conclusions

6.1. Theoretical Significance

6.2. Management Implications

6.3. Limitations and Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Full Name | Abbreviation |

|---|---|

| Micro smart factory | MSF |

| Small and medium-sized enterprises | SMEs |

| Manufacturing dimensions | MD |

| Intelligence dimensions | ID |

| Manufacturing Capability Maturity Mode | CMMM |

| Indexes | LHS of the Equation | Representative Content | RHS of the Equation | Representative Content |

|---|---|---|---|---|

| Equation (1) | Xsi | The i-th incremental values of the ID. | Xsi(min) | The minimum value of ID. |

| Equation (2) | Xmi | The i-th incremental values of the MD. | Xmi(min) | The minimum value of MD. |

| Equation (3) | X′mi | The MD i-th indicator stock standardization result. | max (Xi) min (Xi) | The maximum values of Xi. The minimum values of Xi. |

| Equation (4) | ΔX′mi | The incremental standardized result of the i-th indicator of the MD. | Δmax (Xi) Δmin (Xi) | The maximum values of ΔXi. The minimum values of ΔXi. |

| Equation (5) | Ssi | The standard deviation of the stock. | Xij | The values of X in the MD and ID. |

| Equation (6) | βsi | The weight of the amount of information on the stock. | Sii Ssi | The standard deviation of the incremental amount. The standard deviation of the stock. |

| Equation (7) | βms | The comprehensive development level of stock. | βsi X′mi | The weight of the amount of information on the stock. The MD i-th indicator stock standardization result. |

| Equation (8) | βmi | The comprehensive development level of increment. | βii ΔX′mi | The weight of the incremental amount of information. The incremental standardized result of the i-th indicator of the MD. |

| Equation (9) | X′si | The ID i-th indicator stock standardization result. | max (Xi) min (Xi) | The maximum values of Xi. The minimum values of Xi. |

| Equation (10) | ΔX′si | The incremental standardized result of the i-th indicator of the ID. | Δmax (Xi) Δmin (Xi) | The maximum values of ΔXi. The minimum values of ΔXi. |

| Equation (11) | Sii | The standard deviation of the incremental amount. | ΔXij | The values of ΔX in the MD and ID. |

| Equation (12) | βii | The weight of the incremental amount of information. | Sii Ssi | The standard deviation of the incremental amount. The standard deviation of the stock. |

| Equation (13) | βss | The comprehensive development level of stock. | βsi X′si | The comprehensive development level of increment. The ID i-th indicator stock standardization result. |

| Equation (14) | βsi | The comprehensive development level of increment. | βii X′si | The weight of the incremental amount of information. The ID i-th indicator stock standardization result. |

| Equation (15) | φs | The development levels of enterprise ID, respectively. | βss βii | The comprehensive development level of stock. The weight of the incremental amount of information. |

| Equation (16) | φm | The development levels of enterprise MD, respectively. | βms βmi | The comprehensive development level of stock. The comprehensive development level of increment. |

| Equation (17) | C | The degree of coupling between the enterprise intelligence dimension and the manufacturing dimension. | φs φm | The development levels of enterprise ID, respectively. The development levels of enterprise MD, respectively. |

| Equation (18) | D | The coupling coordination degree between ID and MD. | C T | The degree of coupling between the enterprise intelligence dimension and the manufacturing dimension. Comprehensive coordination indicator. |

| Equation (19) | T | Comprehensive coordination indicator. | φs φm | The development levels of enterprise ID, respectively. The development levels of enterprise MD, respectively. |

References

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Chen, G.; Wang, P.; Feng, B.; Li, Y.; Liu, D. The framework design of smart factory in discrete manufacturing industry based on cyber-physical system. Int. J. Comput. Integr. Manuf. 2020, 33, 79–101. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, R.; Wang, J.; Wang, Y. Current and future lithium-ion battery manufacturing. IScience 2021, 24, 102332. [Google Scholar] [CrossRef]

- Min, H. Smart factory: A game changer or another fad in the era of fourth industrial revolution. Int. J. Technol. Manag. 2022, 89, 26–45. [Google Scholar] [CrossRef]

- Park, K.T.; Nam, Y.W.; Lee, H.S.; Im, S.J.; Noh, S.D.; Son, J.Y.; Kim, H. Design and implementation of a digital twin application for a connected micro smart factory. Int. J. Comput. Integr. Manuf. 2019, 32, 596–614. [Google Scholar] [CrossRef]

- Xie, Y.; Chen, X.; Liu, Z.; Wu, J. Construction of Practical Teaching Platform of Smart Factory. Res. Explor. Lab. 2020, 39, 174–178. (In Chinese) [Google Scholar]

- Wang, Y. Spatial–temporal evolution of “Production-Living-Ecologica” function and layout optimization Strategy in China: A case study of Liaoning Province, China. Environ. Sci. Pollut. Res. 2023, 30, 10683–10696. [Google Scholar] [CrossRef]

- Yu, Z.-J.; Shan, S.-H. Status, problems and countermeasures of smart equipment manufacturing in Liaoning Province. J. Shenyang Univ. Technol. (Soc. Sci. Ed.) 2020, 13, 46–49. (In Chinese) [Google Scholar]

- Lee, R. The effects of smart factory operational strategies and system management on the innovative performance of small-and medium-sized manufacturing firms. Sustainability 2021, 13, 3087. [Google Scholar] [CrossRef]

- Matt, D.T.; Rauch, E. SME 4.0: The role of small-and medium-sized enterprises in the digital transformation. In Industry 4.0 for SMEs; Palgrave Macmillan: Cham, Switzerland, 2020; pp. 3–36. [Google Scholar]

- Jin, Y.; Liu, J. Micro smart factory: Concept, research framework and future prospects. J. Shenyang Univ. Technol. (Soc. Sci. Ed.) 2024. (In Chinese) [Google Scholar]

- Won, J.Y.; Park, M.J. Smart factory adoption in small and medium-sized enterprises: Empirical evidence of manufacturing industry in Korea. Technol. Forecast. Soc. Change 2020, 157, 1201–1217. [Google Scholar] [CrossRef]

- Sarwar, Z.; Gao, J.; Khan, A. Nexus of digital platforms, innovation capability, and strategic alignment to enhance innovation performance in the Asia Pacific region: A dynamic capability perspective. Asia Pac. J. Manag. 2024, 41, 867–901. [Google Scholar] [CrossRef]

- Ogawa, Y.; Tokunaga, E.; Kobayashi, O.; Hirai, K.; Shibata, N. Current contributions of organofluorine compounds to the agrochemical industry. Iscience 2020, 23, 101467. [Google Scholar] [CrossRef]

- Du, J.; Yu, Y.; Zhao, N.; Xie, Z.; Fei, Z.; Pan, J. Evaluation modelling for maturity in intelligent manufacturing for multi-type clothing factories. J. Text. Res. 2021, 42, 162–167. (in Chinese). [Google Scholar] [CrossRef]

- Hosseini Tehrani, P.; Eslami, M.R. Two-dimensional time-harmonic dynamic coupled thermoelasticity analysis by boundary element method formulation. Eng. Anal. Bound. Elem. 1998, 22, 245–250. [Google Scholar] [CrossRef]

- GBT 39116-2020; Intelligent Manufacturing Capability Maturity Model. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2020. (In Chinese)

- Größler, A.; Grübner, A. An empirical model of the relationships between manufacturing capabilities. Int. J. Oper. Prod. Manag. 2006, 26, 458–485. [Google Scholar] [CrossRef]

- Swink, M.; Harvey Hegarty, W. Core manufacturing capabilities and their links to product differentiation. Int. J. Oper. Prod. Manag. 1998, 18, 374–396. [Google Scholar] [CrossRef]

- Cheng, H.; Xu, W.; Ai, Q.; Liu, Q.; Zhou, Z.; Pham, D.T. Manufacturing capability assessment for human-robot collaborative disassembly based on multi-data fusion. Procedia Manuf. 2017, 10, 26–36. [Google Scholar] [CrossRef]

- Lekurwale, R.; Akarte, M.; Raut, D. Framework to evaluate manufacturing capability using analytical hierarchy process. Int. J. Adv. Manuf. Technol. 2015, 76, 565–576. [Google Scholar] [CrossRef]

- Tuptuk, N.; Hailes, S. Security of smart manufacturing systems. J. Manuf. Syst. 2018, 47, 93–106. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, W.; Qin, Q.; Chen, K.; Wei, Y. Intelligent manufacturing management system based on data mining in artificial intelligence energy-saving resources. Soft Comput. 2023, 27, 4061–4076. [Google Scholar] [CrossRef]

- Hu, Y.; Jia, Q.; Yao, Y.; Lee, Y.; Lee, M.; Wang, C.; Zhou, X.; Xie, R.; Yu, F.R. Industrial internet of things intelligence empowering smart manufacturing: A literature review. IEEE Internet Things J. 2024, 11, 19143–19167. [Google Scholar] [CrossRef]

- Zhou, P.; Xiang, J.; Tang, D.; Li, J.; Obuobi, B. Intelligence level evaluation and influencing factors analysis of equipment manufacturing industry in the Yangtze River Delta. PLoS ONE 2024, 19, e0299119. [Google Scholar] [CrossRef]

- Blandino, G. How to measure stress in smart and intelligent manufacturing systems: A systematic review. Systems 2023, 11, 167. [Google Scholar] [CrossRef]

- Jiang, P.; Li, P. Shared factory: A new production node for social manufacturing in the context of sharing economy. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2020, 234, 285–294. [Google Scholar] [CrossRef]

- Farid, A.M. Measures of reconfigurability and its key characteristics in intelligent manufacturing systems. J. Intell. Manuf. 2017, 28, 353–369. [Google Scholar] [CrossRef]

- Chen, K.; Du, P.; Duan, W.-X.; Liu, J.-P. Research on the Evaluation Model and Its Application of Intelligent Construction Capability of Construction Enterprises Based on Maturity. J. Eng. Manag. 2022, 36, 37–42. (In Chinese) [Google Scholar]

- Bhavsar, S.P.; Diamond, M.L.; Gandhi, N.; Nilsen, J. Dynamic coupled metal transport-speciation model: Application to assess a zinc-contaminated lake. Environ. Toxicol. Chem. 2004, 23, 2410–2420. [Google Scholar] [CrossRef]

- Qu, S.; Shastry, V.; Curtin, W.; Miller, R.E. A finite-temperature dynamic coupled atomistic/discrete dislocation method. Model. Simul. Mater. Sci. Eng. 2005, 13, 1101. [Google Scholar] [CrossRef]

- Luongo, A. A unified perturbation approach to static/dynamic coupled instabilities of nonlinear structures. Thin-Walled Struct. 2010, 48, 744–751. [Google Scholar] [CrossRef]

- Zhang, S.; Pattipati, K.R.; Hu, Z.; Wen, X.; Sankavaram, C. Dynamic Coupled Fault Diagnosis with Propagation and Observation Delays. IEEE Trans. Syst. Man Cybern. Syst. 2013, 43, 1424–1439. [Google Scholar] [CrossRef]

- Lee, K.-L.; Roesinger, A.; Hommel, U. Development and Practice of Industrie 4.0 in China—Practical Experience of a German Industrial Software Company in China. Sci 2022, 4, 28. [Google Scholar] [CrossRef]

- Qu, Y.; Shi, Y.; Guo, K.; Zheng, Y. Has “Intelligent Manufacturing” Promoted the Productivity of Manufacturing Sector?--Evidence from China’s Listed Firms. Procedia Comput. Sci. 2018, 139, 299–305. [Google Scholar] [CrossRef]

- Lüthje, B. Platform Capitalism ‘Made in China’? Intelligent Manufacturing, Taobao Villages and the Restructuring of Work. Sci. Technol. Soc. 2019, 24, 199–217. [Google Scholar] [CrossRef]

- Zhou, D.; Xu, K.; Zhou, P.; Jiang, X. The production of large blast furnaces of China in 2018 and thoughts of intelligent manufacturing in the ironmaking process. Ironmak. Steelmak. 2020, 47, 650–654. [Google Scholar] [CrossRef]

- Qiao, F.; Kong, W.; Liu, M.; Wang, J.; Zhang, H. The Operation Management of Smart Factory for Intelligent Manufacturing. Manag. World 2023, 39, 216–225+239+226. (In Chinese) [Google Scholar] [CrossRef]

- Harrison, R.; Vera, D.; Ahmad, B. Engineering the smart factory. Chin. J. Mech. Eng. 2016, 29, 1046–1051. [Google Scholar] [CrossRef]

- Islam, F.B.; Nwakanma, C.I.; Tuli, E.A.; Lee, J.M.; Kim, D.S. Breathing Pattern Forecasting using Deep Learning in Smart Factory Environment. Proc. Acad. Conf. Korean Commun. Soc. 2021, 1358–1359. Available online: https://www.dbpia.co.kr/Journal/articleDetail?nodeId=NODE10587523 (accessed on 25 March 2025). (In Korean).

- Nieuwenhuis, P. Micro Factory Retailing: An Alternative, More Sustainable Automotive Business Model. IEEE Eng. Manag. Rev. 2018, 46, 39–46. [Google Scholar] [CrossRef]

- Bai, Y.; You, J.-B.; Lee, I.-K. Design and Optimization of Smart Factory Control System Based on Digital Twin System Model. Math. Probl. Eng. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- Jin, Q.; Ding, Z.; Zhang, Z. Capability knowledge Architecture of Service-oriented Manufacturing Model. Sci. Technol. Prog. Policy 2013, 30, 57–64. (In Chinese) [Google Scholar]

- Zhao, D.; Du, Q. The Impact of Dem and Information Updating on Sharing of Manufacturing Capacity in the Supply Chain. J. Syst. Manag. 2017, 26, 374–380. [Google Scholar]

- Wang, Y.-M.; Zhang, X.-W. Research on Intelligent Manufacturing Capability Maturity Index System of China’s Manufacturing Industry under Intelligent Economy. Sci. Decis.-Mak. 2021, 292, 118–132. (In Chinese) [Google Scholar]

- Shi, L.; Huang, K.; Liu, Y.; Ge, F.; Liu, S. Risk Assessment in Supplier Selection for Intelligent Manufacturing Systems Based on PLS-SEM. Appl. Sci. 2022, 12, 3998. [Google Scholar] [CrossRef]

- Rojanakit, P.; de Oliveira, R.T.; Dulleck, U. The sharing economy: A critical review and research agenda. J. Bus. Res. 2022, 139, 1317–1334. [Google Scholar] [CrossRef]

- Subramaniyam, M.; Park, S.; Choi, S.-I.; Song, J.-Y.; Park, J.K. Efficiency evaluation of micro factory for micro pump manufacture. J. Mech. Sci. Technol. 2009, 23, 498–503. [Google Scholar] [CrossRef]

- Zeng, D.; Hong, W. On the status quo and future prospect of STS: An interview with Michael Lynch. Stud. Sci. Sci. 2017, 35, 1409–1421. (In Chinese) [Google Scholar] [CrossRef]

- Ling, Y.-H. The influence of intellectual capital on organizational performance—Knowledge management as moderator. Asia Pac. J. Manag. 2013, 30, 937–964. [Google Scholar] [CrossRef]

- Kou, T.C.; Chiang, C.T.; Lee, B.C.Y. Enhancement of product design capability in the high-tech manufacturing industry. Int. J. Bus. Syst. Res. 2021, 15, 786–806. [Google Scholar] [CrossRef]

- Xue, J.; Swan, K.S. An investigation of the complementary effects of technology, market, and design capabilities on exploratory and exploitative innovations: Evidence from micro and small-sized tech enterprises in China. Creat. Innov. Manag. 2020, 29, 27–50. [Google Scholar] [CrossRef]

- Li, T. Cost control of mold enterprises under the trend of intelligence. J. Phys. Conf. Ser. 2019, 1237, 042056. [Google Scholar] [CrossRef]

- Anonymous. Expanded Production Capacity for Metal Finishing Industry. Prod. Finish. 2015, 79, 46. [Google Scholar]

- Keskin, H.; Akgün, A.E.; Esen, E.; Yilmaz, T. The manufacturing adaptive capabilities of firms: The role of technology, market and management systems-related adaptive capabilities. J. Manuf. Technol. Manag. 2022, 33, 1429–1449. [Google Scholar] [CrossRef]

- Khorram Niaki, M.; Nonino, F.; Tafakkori, K.; Torabi, S.A.; Kazemian, I. The influence of manufacturing contexts on additive manufacturing-enabled competitive capabilities. J. Manuf. Technol. Manag. 2022, 33, 1102–1123. [Google Scholar] [CrossRef]

- Xiao, W.; Fan, D. The “Simultaneous Development of Quantity and Quality”: Research on the Impact of the Digital Economy in Enabling Manufacturing Innovation. Systems 2024, 12, 470. [Google Scholar] [CrossRef]

- Yuan, F.-C.; Lee, C.-H. Intelligent sales volume forecasting using Google search engine data. Soft Comput. 2020, 24, 2033–2047. [Google Scholar] [CrossRef]

- Marzantowicz, Ł. The Impact of Uncertainty Factors on the Decision-Making Process of Logistics Management. Processes 2020, 8, 512. [Google Scholar] [CrossRef]

- Fayezi, S. Student-Centered Curriculum Design and Evaluation in Logistics Management. Logistics 2022, 6, 70. [Google Scholar] [CrossRef]

- Mridula, N.; Pant, T.K. The generation of post noon F3 layers over the dip equatorial location of Thiruvananthapuram- A new perspective. J. Atmos. Sol.-Terr. Phys. 2018, 170, 55–63. [Google Scholar] [CrossRef]

- Horbel, C.; Buck, C.; Diel, S.; Reith, R.; Walter, Y. Stadium visitors’ smartphone usage and digital resource integration. Sport Bus. Manag. Int. J. 2021, 11, 10–27. [Google Scholar] [CrossRef]

- Kim, H.G. Factors Affecting Purchase Intention on Smart Factory Manufactured Footwear in South Korea. Trade Res. 2021, 17, 99–111. [Google Scholar] [CrossRef]

- Jiao, P.; Tian, R. Research on the Mechanism of Deep Integration between Modern Service Industry and Advanced Manufacturing Industry Empowered by Digital Technology Innovation. J. Guangdong Univ. Financ. Econ. 2023, 38, 31–44. (In Chinese) [Google Scholar]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Zheng, X. The Application of Big Data Technology in Network Marketing. J. Phys. Conf. Ser. 2021, 1744, 042200. [Google Scholar] [CrossRef]

- Azeem, S.A. Convergence in future wireless network technology. Orient. J. Comput. Sci. Technol. 2017, 10, 41–46. [Google Scholar] [CrossRef]

- John, N.; Wellmann, M. Data security management and data protection for video conferencing software. Int. Cybersecur. Law Rev. 2020, 1, 39–50. [Google Scholar] [CrossRef]

- La Torre, M.; Dumay, J.; Rea, M.A. Breaching intellectual capital: Critical reflections on Big Data security. Meditari Account. Res. 2018, 26, 463–482. [Google Scholar] [CrossRef]

- Xue, X.; Wang, S.; Lu, B. Computational Experiment Approach to Controlled Evolution of Procurement Pattern in Cluster Supply Chain. Sustainability 2015, 7, 1516–1541. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X. A Smart system in Manufacturing with Mass Personalization (S-MMP) for blueprint and scenario driven by industrial model transformation. J. Intell. Manuf. 2023, 34, 1875–1893. [Google Scholar] [CrossRef]

- bin Islam, S.O.; Khan, L.A.; Khalid, A.; Lughmani, W.A. A smart micro factory design: An integrated approach. In Functional Reverse Engineering of Machine Tools; Khan, W.A., Edwin, C.A., Abbas, G., Rahman, K., Hussain, G., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 215–254. [Google Scholar]

- Kristoffersen, P.B. Reaping Benefits of Digital Age While Avoiding Cyber Threats. Pipeline Gas J. 2017, 244, 45–46. [Google Scholar]

- Miklautsch, P.; Hoffelner, M.; Woschank, M. Harmonizing “Smart” Life Cycle Assessment in Manufacturing Companies: Literature Review and Preliminary Morphological Analysis. IFAC Pap. 2022, 55, 1483–1490. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology, E.I.D. China Manufacturing Maturity Model; China Electronics Standardization Institute: Beijing, China, 2022. (In Chinese) [Google Scholar]

- Zhang, H.; He, Z.; Zheng, W. Quantifying the Emergence of Basic Research Capabilities in Cluster Enterprises: An Analytical Framework Based on Information Entropy. Systems 2024, 12, 473. [Google Scholar] [CrossRef]

- Hu, C. Analyzing dynamic coupling and coordination of modern service and advanced manufacturing industries in Guangdong–Hong Kong–Macao Greater Bay Area. Heliyon 2023, 9, e16565. [Google Scholar] [CrossRef] [PubMed]

- Ou, D.; Zhang, Q.; Wu, Y.; Qin, J.; Xia, J.; Deng, O.; Gao, X.; Bian, J.; Gong, S. Construction of a Territorial Space Classification System Based on Spatiotemporal Heterogeneity of Land Use and Its Superior Territorial Space Functions and Their Dynamic Coupling: Case Study on Qionglai City of Sichuan Province, China. Int. J. Environ. Res. Public Health 2021, 18, 9052. [Google Scholar] [CrossRef]

- Yan, M.; Chen, L. Analysis of the Dynamic Coupling Effect between the Development of Circulation Industry and the Agglomeration of Productive Service Industry. J. Commer. Econ. 2022, 11, 163–166. (In Chinese) [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Gao, L.; Ji, M.; Yang, J. Intelligent Manufacturing Capability Maturity Model of Small and Medium-sized Enterprises. Res. Sci. Technol. Manag. 2022, 42, 36–42. (In Chinese) [Google Scholar]

- Yang, W.; Yang, S.; Wang, Z. Research on the selection Mechanism of Enterprise Independent Innovation Mode based on Innovation capability intensity and matching-- taking Iron and Steel Enterprises as an example. Sci. Technol. Prog. Policy 2014, 31, 97–103. (In Chinese) [Google Scholar]

- Zhao, D.; Du, Q.; Xu, C. Strategies of Manufacturing Capability Sharing Based on Internet of Things Platform. J. Tianjin Univ. Soc. Sci. 2015, 17, 97–102. (In Chinese) [Google Scholar]

| First Level | Second Level | Third Level |

|---|---|---|

| MD | Intelligent design | Product design |

| Process planning (discrete) | ||

| Process optimization (process flow) | ||

| Intelligent production | Procurement | |

| Planning and scheduling | ||

| Production operation | ||

| Warehousing and distribution | ||

| Quality Control | ||

| Safety and environmental protection | ||

| Intelligent logistics | Logistics management | |

| Intelligent sales | Sales management | |

| Intelligent service | Customer service | |

| Products and services | ||

| Resource element | Strategy and organization | |

| Employee | ||

| Equipment | ||

| Energy | ||

| ID | Interconnection and inter-working | Network environment |

| network security | ||

| System integration | Application integration | |

| System security | ||

| Information fusion | Data fusion | |

| Data application | ||

| Data security | ||

| Capacity of emerging business forms | Personalized customization | |

| Remote operation and maintenance | ||

| Collaborative manufacturing | ||

| Other | Performance and evaluation | |

| Innovate |

| Coordination Level | Digital Interval | Coordination Degree | Relationship Between | Contrastive Relationship Coordination Level Type |

|---|---|---|---|---|

| 1 | (0,0.1] | Extreme disorder | Extreme disorder with intelligence | |

| Extreme disorder with intelligence and manufacturing | ||||

| Extreme disorder with manufacturing | ||||

| 2 | (0.1,0.2] | Severe disorder | Severe disorder with intelligence | |

| Severe disorder with intelligence and manufacturing | ||||

| Severe disorder with manufacturing | ||||

| 3 | (0.2,0.3] | Moderate disorder | Moderate disorder with intelligence | |

| Moderate disorder with intelligence and manufacturing | ||||

| Moderate disorder with manufacturing | ||||

| 4 | (0.3,0.4] | Mild disorder | Mild disorder with intelligence | |

| Mild disorder with intelligence and manufacturing | ||||

| Mild disorder with manufacturing | ||||

| 5 | (0.4,0.5] | On the verge of disorder | On the verge of disorder with intelligence | |

| On the verge of disorder with intelligence and manufacturing | ||||

| On the verge of disorder with manufacturing | ||||

| 6 | (0.5,0.6] | Barely coordinate | Barely coordinate with intelligence | |

| Barely coordinate with intelligence and manufacturing | ||||

| Barely coordinate with manufacturing | ||||

| 7 | (0.6,0.7] | Primary coordination | Primary coordination with intelligence | |

| Primary coordination with intelligence and manufacturing | ||||

| Primary coordination with manufacturing | ||||

| 8 | (0.7,0.8] | Intermediate coordination | Intermediate coordination with intelligence | |

| Intermediate coordination with intelligence and manufacturing | ||||

| Intermediate coordination with manufacturing | ||||

| 9 | (0.8,0.9] | Highly coordination | High coordination with intelligence | |

| High coordination with intelligence and manufacturing | ||||

| High coordination with manufacturing | ||||

| 10 | (0.9,1] | Superior coordination | Superior coordination with intelligence | |

| Superior coordination with intelligence and manufacturing | ||||

| Superior coordination with manufacturing |

| Variables | Indicators | Factor Loading | Explain Variance/% | AVE | Cronbach’s α |

|---|---|---|---|---|---|

| Manufacturing dimension | - | 69.873% | 0.822 | 0.972 | |

| Design | 0.725 | ||||

| Production | 0.893 | ||||

| Logistics | 0.864 | ||||

| Sales | 0.870 | ||||

| Service | 0.838 | ||||

| Resource elements | 0.909 | ||||

| Intelligent dimension | - | 65.799% | 0.804 | 0.950 | |

| Interconnection | 0.875 | ||||

| System integration | 0.899 | ||||

| Information fusion | 0.903 | ||||

| New forms of business | 0.762 | ||||

| Other | 0.698 | ||||

| KMO = 0.924; χ2/df = 1831.056; p = 0.000 *** < 0.010 | |||||

| Variables | Average | Std. | 1 | 2 |

|---|---|---|---|---|

| Manufacturing dimension | 1.516 | 1.148 | 0.928 (0.000 ***) | |

| Intelligent dimension | 1.882 | 2.435 | 0.756 (0.000 ***) | 0.822 (0.000 ***) |

| Variable | Stock Importance Coefficient | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | |

| Design | 0.128 | 0.176 | 0.224 | 0.272 | 0.320 | 0.368 | 0.416 | 0.464 | 0.512 | 0.560 |

| Production | 0.093 | 0.136 | 0.179 | 0.222 | 0.265 | 0.308 | 0.351 | 0.394 | 0.427 | 0.480 |

| Logistics | 0.093 | 0.136 | 0.179 | 0.222 | 0.265 | 0.308 | 0.351 | 0.394 | 0.427 | 0.480 |

| Sales | 0.0.95 | 0.130 | 0.165 | 0.200 | 0.235 | 0.270 | 0.305 | 0.340 | 0.375 | 0.410 |

| Service | 0.094 | 0.138 | 0.182 | 0.226 | 0.270 | 0.314 | 0.258 | 0.402 | 0.446 | 0.490 |

| Resource elements | 0.121 | 0.162 | 0.203 | 0.244 | 0.285 | 0.326 | 0.367 | 0.408 | 0.449 | 0.490 |

| Manufacturing dimension | 0.104 | 0.148 | 0.192 | 0.236 | 0.280 | 0.324 | 0.368 | 0.412 | 0.456 | 0.500 |

| Variable | Stock Importance Coefficient | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | |

| Interconnection | 0.191 | 0.232 | 0.273 | 0.314 | 0.355 | 0.396 | 0.437 | 0.478 | 0.519 | 0.560 |

| System integration | 0.148 | 0.186 | 0.224 | 0.262 | 0.300 | 0.338 | 0.376 | 0.414 | 0.452 | 0.490 |

| Information fusion | 0.301 | 0.322 | 0.343 | 0.364 | 0.385 | 0.406 | 0.427 | 0.448 | 0.469 | 0.490 |

| New forms of business | 0.381 | 0.382 | 0.383 | 0.384 | 0.385 | 0.386 | 0.387 | 0.388 | 0.389 | 0.390 |

| Performance and evaluation | 0.061 | 0.082 | 0.103 | 0.124 | 0.145 | 0.166 | 0.187 | 0.208 | 0.229 | 0.250 |

| Innovation | 0.091 | 0.102 | 0.113 | 0.124 | 0.135 | 0.146 | 0.157 | 0.168 | 0.179 | 0.190 |

| Intelligence dimension | 0.296 | 0.312 | 0.328 | 0.344 | 0.360 | 0.376 | 0.392 | 0.408 | 0.424 | 0.440 |

| Variable | Stock Importance Coefficient | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | |

| Design | 0.292 | 0.412 | 0.505 | 0.583 | 0.652 | 0.714 | 0.771 | 0.825 | 0.875 | 0.922 |

| Production | 0.190 | 0.268 | 0.328 | 0.379 | 0.423 | 0.464 | 0.502 | 0.536 | 0.569 | 0.600 |

| Logistics | 0.216 | 0.306 | 0.375 | 0.433 | 0.484 | 0.530 | 0.572 | 0.612 | 0.649 | 0.684 |

| Sales | 0.312 | 0.442 | 0.541 | 0.625 | 0.699 | 0.765 | 0.827 | 0.884 | 0.937 | 0.988 |

| Service | 0.227 | 0.321 | 0.394 | 0.455 | 0.508 | 0.558 | 0.601 | 0.643 | 0.682 | 0.719 |

| Resource elements | 0.273 | 0.387 | 0.474 | 0.547 | 0.611 | 0.670 | 0.723 | 0.773 | 0.820 | 0.865 |

| Manufacturing dimension | 0.201 | 0.284 | 0.348 | 0.401 | 0.449 | 0.492 | 0.531 | 0.568 | 0.602 | 0.635 |

| Interconnection | 0.211 | 0.298 | 0.365 | 0.422 | 0.472 | 0.517 | 0.558 | 0.597 | 0.633 | 0.667 |

| System integration | 0.217 | 0.307 | 0.376 | 0.434 | 0.485 | 0.532 | 0.574 | 0.614 | 0.651 | 0.687 |

| Information fusion | 0.222 | 0.314 | 0.385 | 0.444 | 0.496 | 0.544 | 0.587 | 0.628 | 0.666 | 0.702 |

| New forms of business | 0.183 | 0.259 | 0.317 | 0.366 | 0.409 | 0.448 | 0.484 | 0.517 | 0.589 | 0.579 |

| Performance and evaluation | 0.313 | 0.443 | 0.542 | 0.626 | 0.700 | 0.767 | 0.828 | 0.886 | 0.939 | 0.990 |

| Innovate | 0.316 | 0.447 | 0.547 | 0.632 | 0.706 | 0.774 | 0.836 | 0.894 | 0.948 | 0.999 |

| Intelligence dimension | 0.214 | 0.303 | 0.371 | 0.428 | 0.479 | 0.525 | 0.567 | 0.606 | 0.643 | 0.677 |

| Intelligent manufacturing | 0.100 | 0.347 | 0.476 | 0.581 | 0.668 | 0.744 | 0.815 | 0.878 | 0.939 | 0.995 |

| Variable | Stock Importance Coefficient | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | |

| Micro enterprise | 0.316 | 0.447 | 0.548 | 0.632 | 0.707 | 0.774 | 0.837 | 0.894 | 0.949 | 0.999 |

| Small enterprise | 0.316 | 0.447 | 0.548 | 0.632 | 0.707 | 0.775 | 0.837 | 0.894 | 0.949 | 0.999 |

| medium-sized enterprise | 0.240 | 0.339 | 0.415 | 0.480 | 0.536 | 0.588 | 0.635 | 0.679 | 0.720 | 0.759 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Liu, J.; Steenhuis, H.-J.; Homapour, E. The Systems Fusion Challenge: Intelligence vs. Manufacturing in Micro Smart Factories. Systems 2025, 13, 464. https://doi.org/10.3390/systems13060464

Jin Y, Liu J, Steenhuis H-J, Homapour E. The Systems Fusion Challenge: Intelligence vs. Manufacturing in Micro Smart Factories. Systems. 2025; 13(6):464. https://doi.org/10.3390/systems13060464

Chicago/Turabian StyleJin, Yuran, Jiahui Liu, Harm-Jan Steenhuis, and Elmina Homapour. 2025. "The Systems Fusion Challenge: Intelligence vs. Manufacturing in Micro Smart Factories" Systems 13, no. 6: 464. https://doi.org/10.3390/systems13060464

APA StyleJin, Y., Liu, J., Steenhuis, H.-J., & Homapour, E. (2025). The Systems Fusion Challenge: Intelligence vs. Manufacturing in Micro Smart Factories. Systems, 13(6), 464. https://doi.org/10.3390/systems13060464