Abstract

This study investigates innovation performance through the lens of the Internet of Things (IoT) and in the context of supply chain globalization. For theoretical support this study employs dynamic capabilities theory; however, data analysis was performed using SPSS. Results demonstrate that IoT capabilities (i.e., smart environmental creation, data processing) have both direct and indirect relations with innovation performance. Perceived business force (competition and policies) and environmental uncertainty are both moderating variables in the proposed research framework, whereas supply chain integration and supply chain agility are demonstrated to be positive mediators between IoT and innovation performance. These results extend the application of dynamic capability theory in the context of the digital supply chain and offer actionable insights for managers seeking to leverage IoT capabilities to drive innovation under uncertain business environments.

1. Introduction

As globalization affects supply chains, it also brings problems and risks that make these networks weaker [1]. Another issue that businesses need to face is that modern consumers have more diverse consumer needs. Product customization is becoming a demand of consumers and they are unwilling to accept long delivery times and large orders [2]. Therefore, enterprises need to take measures to achieve rapid response to market changes. Research describes that IoT technology is a helpful tool to improve supply chain processes [3].

IoT is an Industry 4.0 application that brings a lot of opportunities for enterprises to extend their business [4]. It makes products easier to track and verify throughout their lifecycle, which makes the entire supply chain management system safer and clearer, and counterfeit products are also easier to pick out [3]. There are many cases that have shown the importance of IoT in the contemporary world. For example, the latest IoT technology improves the efficiency of logistics costs and provides consumers with a customized logistics experience [5]. Using IoT technology for collecting and monitoring real-time data during the production process makes production time timelier and more precise [6].

IoT capability helps businesses to strengthen the supply chain integration in terms of raw materials purchasing, production, distribution, retail and customer support [7]. IoT technology also affects supply chain visibility. Applying Industry 4.0 technologies like IoT in supply chains is critical for increasing transparency in the way of creating a smart and advanced supply chain with predictive ability that makes supply chain visibility more efficient [8]. IoT can improve business performance by affecting the whole supply chain. It helps in three areas: finance, society, and the environment. This is done by connecting everyone involved, both inside and outside the company [9]. Moreover, IoT helps companies to get short-term competitive benefits and this effect is further improved by building dynamic capabilities [9].

Supply chain integration (SCI) encourages its partners to create strategic cooperation, bringing operational and strategic advantages, and its main and final goal is to achieve customer satisfaction [9]. SCI allows businesses to focus on their core strength and professional field, and it also connects with other supply chain participants who have different kinds of resources, technologies, and professional knowledge [10], providing accurate, reliable, and timely information between both internal and external supply chain partners. SCI facilitates businesses to enhance integration between various supply chain units to sustain supply chain performance [10]. On the other hand, supply chain agility (SCA) refers to stable internal coordination and strong collaboration between partners [11]. Therefore, digital transformation is very important in improving the supply chain’s ability to handle unexpected events [12].

Perceived business force plays a significant role in the integration of the IoT, which enhances efficiency and effectiveness in firms’ performance. These enhancements lead to improved integration of retail supply chains, positively affecting cost, quality, delivery, and flexibility, thereby improving firms’ financial, social, and environmental sustainability [13]. Moreover, perceived business pressure strengthens the influence of digital transformation on supply chain integration [14]. Furthermore, perceived business force has various sources, such as consumers, suppliers, stockholders, industry rivals, and financial organizations. Thus, perceived business force influences the adoption of IoT technologies in supply chains by pushing for more integrated, secure, and efficient systems.

This study also introduces environmental uncertainty to examine innovation performance. Environmental uncertainty refers to the intensity of market shifts in industry [15]. It has various impacts on innovation performance to develop advanced strategies and innovative practices. These effects of uncertainty vary based on the context and the strategic approaches adopted by firms.

Existing research focuses on IoT in supply chain integration and visibility, and its impact on business, economic, and environmental performance. However, there is a lack of research on IoT’s impact on innovation performance. In today’s volatile business environment, the urgency and novelty of emphasizing innovation over operational performance for achieving a competitive advantage are gaining importance in both research and practical settings. Global events such as pandemics and trade disruptions have exposed the limitations of traditional business models as well as operational strategies. Therefore, the world should focus on shifting from traditional business models to innovation and technology to survive in such environments. Thus, innovation has become a foundation for maintaining competitive edges in an uncertain environment. Recent research demonstrates that businesses are integrating innovation into their strategies to sustain their competitive advantages [16]. As a result, they generate new ideas and solutions to address challenges. This highlights the need for continuous progress and adaptation in products and processes to meet the current market demands. One study demonstrates that innovative firms are in a better position to address challenges and neutralize external pressure (i.e., environmental and economic shifts) effectively [17]. To adapt the culture of innovation within the organization, where the environment is dynamic and competitive, not only supports the development of unique capabilities but also ensures the continuous flow of new ideas. These ideas not only help in organizational growth but also facilitate the organizations to develop the quality of resilience against environmental challenges. Moreover, ref. [18] argued that developing dynamic capabilities through innovation enhances a firm’s agility and adaptability to rapid environmental challenges.

Therefore, to contribute to the innovation performance literature, this study further introduces SCI and SCA as mediators. This study stresses the novel contribution of SCA in innovation performance. From a strategic perspective, many studies have explored the antecedents of SCA; however, there is limited research from a strategic perspective [19]. This study addresses the research gap by arguing that strategic orientation enhances SCA and subsequently innovation performance. In view of offering comprehensive frameworks [20], this study synthesizes SCA with technologies that contribute to innovation performance. SCA as a contextual factor (i.e., product complexity) plays a role in adaptability, which is missing in the prior literature [21]. We further demonstrate that SCA improves firms’ innovation performance. When firms focus on customer service, they establish an environment in which they focus on the business environment and consumer demands. They can better enhance the innovation performance of their firms. This study also examines the significant role of SCA. Literature on strategic integration [22] identified the research gap of SCI affecting innovation performance. To address this gap, the current study contributes to the literature by introducing IoT, which helps firms in learning and exploration for further understanding of the market environment in the digital age. This will not only help in product development but also bring further innovation within the industry. There is limited research that investigates the role of technology in SCI [23]. The advancement of this study in supply chain literature is to link supply chain integration with the IoT to achieve innovation performance.

Perceived business force has been used to study the effect of digital transformation. This study proposes perceived business force and environmental uncertainty. These two variables cover several aspects of industry, for example, policies, competition and uncertainty for achieving innovation performance. These aspects have both positive and negative influences on innovation performance.

This study is based on the following research questions:

- What is the role of IoT capabilities for enhancing innovation performance?

- Do supply chain integration and agility mediate the relationship between IoT capability and innovation performance?

- Do environmental uncertainty and perceived business force moderate the relationship between IoT capability and supply chain integration, and innovation performance?

To answer these research questions, this research first provides a comprehensive literature review. The literature provides a solid theoretical background and related literature to support this study. Second, this study proposes a hypothesis that advances the literature on innovation performance. Third, for empirical evidence, the study uses survey data to answer the above research questions. Then, the study answers the questions and compares with prior studies. Finally, the study provides the authors’ conclusion and future research.

2. Literature Review

2.1. Dynamic Capabilities Theory

The conceptual framework of the dynamic capabilities was proposed by Teece Et Al. [24]. This theoretical framework has become an influential perspective within contemporary management literature [25]. At the initial stages, this framework addresses the limited static nature of the resource-based view. However, recently, dynamic capabilities have been widely acknowledged as an extension of the resource-based view [26]. Dynamic capabilities further argue that a firm must evolve on a continuous basis to ensure a sustained competitive advantage [25]. Firms in more static markets also need dynamic capabilities to better respond to unexpected changes in the business environment [27].

Recently, dynamic capabilities offered a fitting conceptual framework for understanding digital transformation. For example, adaptability to rapid changes [28,29]; this capability helps firms’ agility to reconfigure both internal and external resources in dynamic environments. This characteristic is important for the evolving landscape of digital transformation driven by technological advancements [30]. Second, these capabilities are involved in strategic renewal [31], by identifying opportunities, resource allocation, and organizational transformation. Third, dynamic capabilities cover numerous aspects, including technology, organizational practices, and business factors [32], which are important for digital transformation, technological adoption, and aligning internal structures, processes, and organizational culture [32]. Fourth, these capabilities emphasize resource flexibility [27,31,33], which is important for experimenting with new technologies, innovation, and sustaining digital transformation. These can be achieved by effective utilization of resources, for example, human capital, financial investments, and technological assets [28,34]. Fifth, dynamic capabilities deal with strategic goals [27,31,35], including digital transformation, harmonizing internal capabilities with external opportunities [34,36]. Sixth, dynamic capabilities stress continuous learning and improvement activities [31], more specifically firms’ environment in which individuals continuously learn, get customers’ feedback, and address market shifts [30,37]. Finally, dynamic capabilities are significantly associated with innovation and entrepreneurship [31,38,39]. This capability is important in digital transformation, aligning with innovation in services, adapting emerging technologies, and developing an entrepreneurial mindset to explore new business models [36].

Dynamic capability theory deals with the firm’s capability to combine, develop, and modify abilities for surviving in a dynamic environment, and create new and unique patterns of competitive advantage [24]. There are three different aspects of dynamic capabilities. First, the ability to identify and form opportunities and threats. Second, the ability to grasp the opportunities, and finally, the ability to maintain competitiveness by improving, integrating, protecting, and reallocating the firm’s resources [40]. When related to supply chain management, supply chains must continually change existing static capabilities and develop new dynamic capabilities to enhance long-term sustainability in a quickly changing environment [41]. In addition, companies’ capacity to identify and use opportunities, and allocate resources, as well as the fundamental changes in organizational structure and culture, are helpful in facilitating the usage of Industry 4.0 technologies, such as the Industrial Internet of Things [8]. Dynamic capabilities that depend on IoT adoption play a significant role in decision-making by providing real-time data and end-to-end visibility across the supply chain [42]. The literature of dynamic capabilities [43] argues that the patient and appropriate implementation of dynamic capabilities contribute to continuous innovation. Another study [44] demonstrates that dynamic capabilities are the firm’s behavior integrating with competitive advantages for developing innovation performance.

2.2. Internet of Things (IoT) Capability

IoT is a system of equipment that is linked by the internet [45]. IoT capability refers to a kind of improved ability achieved by the supply chain with daily items equipped with technologies. That enables identification, detection, networking, and handling abilities to exchange information with other services and equipment through the internet [46]. As a digital technology, IoT improves the supply chain in various ways. In terms of the manufacturing aspect, using RFID’s wireless detection network and widespread data access offered by IoT, items and materials can be detected and transmit the information to servers through the internet, and provide real-time information [47]. In addition, this method also simplifies the complicated assembling process by providing correct materials and precise positions, such as the specific columns and rows of the storage shelves [47]. Ullah, et al. [48] argue that IoT system helps businesses in order completion, align consumers’ demands, and product processing. About transportation, IoT offers a method to gather and transmit important data to nearby or far base stations. It then applies complex algorithms to produce timely and accurate decisions [49]. Vehicles that apply IoT technology can interact with and use smart transportation systems to achieve advanced services, for example, real-time tracking along the distribution paths [49]. After transportation, IoT is also applied in the retail sector. When IoT technology is used in stores, it improves the shopping experience for consumers. For instance, it enables shoppers to interact with goods or services in various ways [13]. For online retailers, IoT predicts consumer needs and assists in selecting and provides delivery options customized to their special preferences [13]. Thus, the adoption of IoT offers benefits like better productivity because the time spent in the traditional supply chain is allocated to other tasks; also, there is improved communication within the supply chain, and more efficient product monitoring.

2.3. Supply Chain Integration

Supply chain integration is the strategic cooperation between all the engaged participants in the value-creating processes that offer goods, services, and information to the end user; this includes product development, purchasing, production, assembly, inventory management, sales, and delivery [50]. Supply chain integration can also be defined as the degree to which a company coordinates and manages the business operations in its supply chain. It has two different parts: internal and external integration. Internal integration refers to the degree of cooperation between various organizational departments in the company. It is a critical operational capacity to remove functional obstacles and improve information exchange between different departments [51]. External integration involves association with consumers and suppliers [52].

Supplier integration means working closely with important suppliers, aligning supply chain activities like information exchange, planning and prediction, and product innovation [53] that improves the efficiency of data exchange, quick production schedule adaptation, and rapid material distribution. Thus, the companies can shorten supply cycle time, lower inventory levels, and prevent unexpected conflicts. Customer integration is the extent to which a company can work closely with its key customers to organize its cross-organizational strategies, practices, processes, and actions into coordinated, harmonized, and controllable steps to satisfy customer needs [54]. By customer integration, companies have a deeper insight into consumers’ needs, improving their knowledge and understanding of their goods, and market environment. That enables companies to meet customer needs and demands more preciously and specifically [54].

2.4. Supply Chain Agility

Supply chain agility refers to a firm’s capacity to achieve a competitive advantage by adapting to market uncertainties in an effective way. In addition, it also allows companies to address issues in the supply chain more effectively and economically [55]. SCA enables companies to align supply and demand levels and minimize inventory and logistics expenses [56]. That helps companies to adapt to the shifting demand trends and meet the growing information requirements both internally and externally within the supply chain [56,57]. In addition, by SCA, companies can instantly react to changes, and establish and adjust collaborative relationships. SCA also enables partners to get useful insights and resources for facing unpredictable conditions or market shifts [58]. Supply chain agility has the ability to promote the adjustment of operational processes, so it supports the reallocation of organizational resources and increases the company’s ability to identify changes [59]. Moreover, SCA makes the supply chain more adaptable and flexible, so the supply chain participants are able to address the supply chain disruptions through adjusting to market changes and environmental fluctuations [60].

2.5. Innovation Performance

Innovation performance is the extent to which companies apply new technologies and acquire advanced equipment to enhance the quality of their goods through innovation [61]. Product innovation is a continuous process, and it combines business operations, management practices, production activities, and technological design. Businesses uses these improved processes to launch new products in the market [62]. In addition to product innovation performance, process innovation represents new methods for manufacturing and distributing products [63], bringing improvement in cost efficiency and performance characteristics.

2.6. Environmental Uncertainty

Environmental uncertainty is the lack of ability to accurately assess how external factors impact achievement and failure when making decisions [64]. Environmental uncertainty includes numerous dimensions, for example, technology uncertainty that refers to substantial and new changes in the features of goods or services and operational methods unique to a particular department [65]. Environmental uncertainty creates an information imbalance when making decisions. This also makes trade more complex and difficult, which then influences the anticipated collaboration means and goals of the participants [66].

2.7. Perceived Business Force

Perceived business force refers to the firm’s internal and external factors that businesses recognize as influential to their operations as well as strategies. Perceived business force includes market dynamics, competitive pressures, socio-economic conditions, and regulatory environments contribute to both success and challenges. Various studies [67,68] investigate perceived business force by developing relationships between business perception and strategy development. Perceived business force can significantly enhance green supply chain integration, especially when perceived institutional forces support environmental goals [69]. In the context of global economic policies, uncertainty emerges, affecting risk management strategies. These perceptions guide organizations based on the supply chain in developing mitigation strategies. These strategies facilitate businesses to reduce risks in both natural and man-made events [70].

From the above literature, we have found that IoT, supply chain integration, supply chain agility, perceived business force, and environmental uncertainty play important roles in innovative performance. This study proposes a framework in which supply chain integration and supply chain agility play an important role in fostering innovation performance. We know that all these variables are important for innovation performance; however, the literature highlights that IoT capability enhances supply chain processes by improving visibility, coordination, and real-time information sharing. That in turn develops integration and agility across operations. In this vein, this study tries to demonstrate empirical confirmation of these theoretical relationships, that IoT strengthens both supply chain integration and agility and enhances innovation performance. In addition, the prior studies emphasized the influence of external factors—for example, environmental uncertainty—on organizational performance. Whereas our study supports that view by showing that higher environmental uncertainty further amplifies the positive impact of IoT capability on innovation performance. In a similar vein, the perceived business force validates the literature’s discussion of market pressures as catalysts for technological adoption and integration. Our study thus extends the prior research by offering empirical evidence of translating IoT-driven capabilities into superior innovation performance.

3. Theoretical Framework and Hypotheses

3.1. Internet of Things (IoT) Capability and Innovation Performance

Systems that apply IoT facilitate real-time supervision, management of manufacturing activities, improve quality control, and reduce cost [71]. IoT expertise and IoT capability offer important data processing abilities for market-driven companies, supporting resource collection and combination, and the result is better innovation [72]. IoT provides opportunities for companies to develop a new series of products, particularly in the manufacturing industry where manufacturing activities are interconnected and link different supply chain units [73]. IoT as an advanced digital technology is very important in improving dynamic capabilities, because it enables companies to expand or limit their operations rapidly, efficiently, and cost-effectively [74]. From a dynamic capabilities perspective, IoT significantly enhances innovation performance by enabling firms to sense and adapt to changes, fostering a robust framework for continuing innovation and competitive advantages [75,76]. Therefore, this study proposes the following hypothesis:

H1.

IoT directly influences innovation performance.

3.2. IoT Capability and Supply Chain Integration

IoT builds a linked and smart supply chain network that combines procedures and systems. That creates new opportunities to make the supply chain more transparent and visible for all stakeholders, including retailers, producers, shoppers, and suppliers. It also supports decision-making and makes the supply chain more productive and better [74]. To any company, IoT capabilities can boost supply chain integration in both demand and supplier aspects, and this combination allows an organization to get better performance, achieve a sustainable circular economy, and finally improve profitability [77]. By integrating IoT information from manufacturers, retailers, wholesalers, and logistics companies, partners are able to learn about the entire supply chain network [78]. This kind of shared view and information results in more effective cooperation, information exchange, and decision-making. In addition, supply chains become more efficient and consistent [78]. From the perspective of dynamic capabilities theory, organizations can strategically integrate IoT technology to achieve superior supply chain integration. That enables organizational adaptation to market changes and consumer demands. Therefore, this study proposes the following hypothesis:

H2.

IoT directly influences supply chain integration.

3.3. IoT Capability and Supply Chain Agility

The adoption of IoT in an agile supply chain supports both detection and reaction functions by generating information effectively, such as identifying an object at a particular moment [79]. IoT enhances and strengthens supply chain agility through functions like real-time monitoring, data-driven analytics, and automated processes [80]. Moreover, digital technologies provide various approaches to improve supply chain agility and make it more visible and transparent. For example, sensors, 5G technology, and RFID technology enable real-time tracking of inventory and logistics situations [81]. This kind of improvement enables companies to rapidly detect and react to unexpected things and changes [81]. However, from the lens of dynamic capabilities theory, IoT’s role is very important, including real-time data analytics, predictive maintenance, inventory management, and collaborating stakeholders [82,83]. In addition, dynamic capabilities theory provides a framework for understanding the impact of IoT on supply chain agility, positioning firms to develop in dynamic conditions. Therefore, this study proposes the following hypothesis:

H3.

IoT directly influences supply chain agility.

3.4. Supply Chain Integration and Innovation Performance

Supply chain integration provides better coordination for different units of the supply chain. That includes suppliers and manufacturers, as well as customers. By improving these processes, firms enhance operational efficiencies that contribute to the innovation capabilities of the firm [84,85]. In addition, firms engage more effectively in collaborative innovation activities with their supply chain partners. These activities and collaborations are important for innovation performance. These collaborations provide access to new technologies, markets, and competencies [86]. Moreover, supply chain integration contributes to a firm’s innovative abilities (i.e., responsive and adaptive) by developing dynamic capabilities [85,87]. From the dynamic capabilities theory perspective, supply chain integration functions as a strategic source to enhance innovation performance. These innovations include green innovation, particularly the green supply chain, by implementing innovative products and processes [87]. Product innovation, in which dynamic capability helps firms to develop product innovation capability [85]. In addition, operational performance in which dynamic capabilities within supply chain integration improve operational processes to support innovation [88]. Thus, this study proposes the following hypothesis:

H4.

Supply chain integration directly influences innovation performance.

3.5. Supply Chain Agility and Innovation Performance

Supply chain agility is important for the rapid response to dynamic market demand as well as technological advancements. Firms derive benefits from such responses in various dimensions, such as the characterization of environments into instability and uncertainty. This helps firms to enhance their innovation outcomes and easily adjust their strategies according to the situation [89]. Moreover, agility also facilitates in ongoing advancement of the firm’s processes. This capability of the firm is very important in terms of operational efficiencies that contribute to innovation capabilities. It also serves in the acquisition and implementation of new technologies. For example, digitalization enhances a firm’s innovation capabilities. These technological advancements lead to improved innovation outcomes by aligning operations as well as developing products and services [81,90]. Supply chain agility also supports strategic flexibility that allows firms to rapidly reconfigure their processes in terms of innovative solutions. This flexibility helps maintain competitive advantages and is essential for developing a culture of continuous innovation within the organization [19]. From a dynamic capabilities perspective, supply chain agility is an important enabler of innovation performance. It enables firms to effectively respond to environmental uncertainties and technological advancements, thus fostering an innovative culture and driving sustainable growth. Literature supports the positive role of supply chain agility from the lens of dynamic capabilities theory for sustaining competitive and uncertain business situations. The literature argues that supply chain agility enhances innovation performance by providing flexibility and responsiveness [87] to explore new opportunities and adapt to challenges in a dynamic market environment. In addition, this agility supports an innovative culture by integrating new technologies and procedures [91,92]. Thus, this study proposes the following hypothesis:

H5.

Supply chain agility directly influences innovation performance.

3.6. Supply Chain Integration as a Mediator

When there are fewer obstacles between different departments, the company’s internal process becomes more efficient, and obtains better innovation performance [93]. Better supply chain integration influences external operation performance in a positive way because customers gain good services when supply chain processes are effectively structured [94]. Customer integration helps customers to form strategic alliances that makes them more competitive at reduced trade expense, and the result is that there are greater market opportunities to enhance a company’s innovation performance [93]. Moreover, SCI, influenced by IoT, enables businesses to better manage information processing. For example, one study shows that IoT-driven integration is a strategic innovation initiative facilitating businesses to deal with supply chain risks [95]. Thus, supply chain integration aligns a firm’s internal resources and processes with external opportunities. That enables firms to respond effectively to market changes, a hallmark of dynamic capabilities. This integration, however, supports strategic flexibility that allows firms to innovate processes, products, and services [96]. This study proposes the following hypothesis:

H6.

Supply chain integration significantly mediates between IoT and innovation performance.

3.7. Supply Chain Agility as a Mediator

Although many companies can manufacture goods and provide services in a standard way, those with better SCA are more likely to realize the significance of innovative solutions and establish management systems that promote both innovation and efficiency, and the result is improved innovation performance [97]. In a market that includes a lot of competition, agility allows the supply chain to adjust to fluctuating customer requirements and various product preferences, rapidly meet customer orders, launch new products consistently and efficiently, and establish strategic partnerships with their collaborators in a short time [98]. SCA serves as a critical mediator that helps translate resource optimization into innovative capabilities, leading to better innovation performance [99]. Strong cooperation with supply chain participants leads to the generation of creative solutions that are essential for obtaining SCA. Then it is used to handle market fluctuations and manage unexpected environmental disruptions [100]. From the dynamic capability perspective, IoT technology significantly contributes to the supply chain, contributing to enhanced supply chain agility [42]. By enhancing agility, businesses can pursue innovative products and services in a more efficient way. Thus, dynamic capabilities frameworks emphasize the reconfiguration and adaptation of resources in dynamic environments [96]. This study proposes the following hypothesis:

H7.

Supply chain agility significantly mediates between IoT and innovation performance.

3.8. The Moderating Role of Perceived Business Force

The competition in society, governmental policies, and other social factors are different sources of outside pressure that prompt companies to apply new technologies [101]. Pressure and stimuli from the government mean using policies and mandates in a suitable way as a driver to promote companies to adopt and apply IoT technology [102]. About how business forces relate to supply chain integration, institutional pressure may impact a company to consider the extent of integration between suppliers and consumers [103]. Perceived Business Force, on the other hand, acts as a moderating element that influences the relationship between capabilities like IoT and supply chain integration. The perceived force of external business pressures can heighten the urgency with which a firm senses and responds to environmental changes. When businesses perceive strong external pressures, there is an increased necessity to integrate IoT capabilities to enhance supply chain agility, which boosts the firm’s ability to sense, seize, and reconfigure effectively [104]. From the literature, we can conclude that supply chain agility is directly linked with the dynamic capabilities framework, in which SCA represents the organization’s ability to adapt to the changes. This is a key aspect of reconfiguring ability in the dynamic capabilities framework. Based on this ability, organizations restructure their supply chain processes to respond to environmental changes. A recent study argues that the ability to reconfigure is important for maintaining competitiveness and achieving operational success in dynamic environments [105]. Thus, this study proposes the following hypothesis:

H8.

Perceived business force moderates between IoT and supply chain agility.

3.9. The Moderating Role of Environmental Uncertainty

Companies operate in a specific context that includes market fluctuation, economic policies, political conflicts, social situations, etc., which are the fundamentals of uncertainty in the business environment. An uncertain situation significantly impacts how a firm plans its strategy and manages decisions. Forecasting analytics enabled by digital transformation, the IoT sensor application can also be employed by a car producer to control supplier performance [106]. Companies are willing to accept innovation between organizations when facing environmental uncertainty, and the purpose is to improve data sharing and reduce uncertainty within their business partners [107]. From the dynamic capabilities theory perspective, environmental uncertainty impacts innovation performance in several ways. For example, adaptation to change; under conditions of environmental uncertainty, the ability to dynamically sense, seize, and configure capabilities is very important [75]. In addition, competitive advantage [75], operational resilience [108], and strategic decision-making [109] can be achieved by using IoT strategically. Therefore, this study proposes the following hypothesis:

H9.

Environmental uncertainty moderates between IOT and innovation performance.

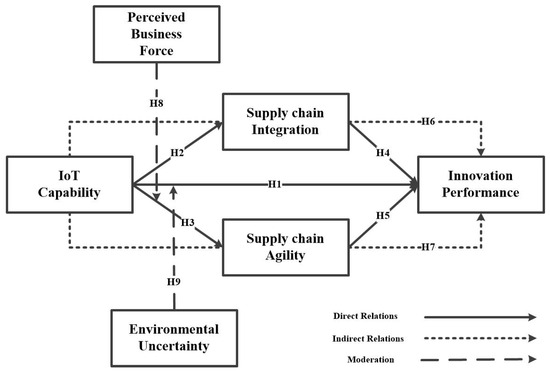

All the hypotheses are shown in Figure 1.

Figure 1.

Research Framework.

4. Methodology

4.1. Data Collection and Measures

This study employs the quantitative approach for which the data was collected through questionnaire surveys. The survey subjects are enterprise employees from different industries, positions, and educational backgrounds. The questionnaire begins with the demographic information of the respondents (such as age, gender, educational background, industry, position, and company size). Next are the scale questions related to the research variables. The questionnaire was distributed online and expressed through social media in China. A total of 500 questionnaires were sent. After collecting the questionnaires, effective screening and sorting were conducted, and finally, a total of 385 valid questionnaires were obtained, which makes 77% of the total questionnaires. Overall, the respondents were mainly between 31 and 35 years old, accounting for 54.81%. This indicates that the sample of this study was mainly composed of middle-aged working people with certain work experience. About education level, the majority of respondents had an undergraduate degree, with a percentage of 54.03%. This means most respondents have received higher education. About the industry, the types of industries are very different, which helps to enhance the applicability of this study’s conclusions. About positions, front-line employees take the highest proportion, reaching 84.42%. Finally, in terms of company size, the majority of respondents came from medium-sized enterprises (100–300 people), with a percentage of 49.61%. (see Table 1).

Table 1.

Demographic Information of the respondents.

In terms of variable measurement, all the variables in the questionnaires of this study were scored using the Likert 7-point scale, with the scale ranging from 1 (strongly disagree) to 7 (strongly agree). All scale items refer to the existing literature to ensure the reliability and validity of the measurement. This study made a quantitative analysis by using SPSS V.25 and the PROCESS plugin.

4.2. Measures, Reliability, and Validity Tests

This study followed the benchmarking of the factor analysis using dimension reduction [110,111]. For the reliability of the data, Cronbach’s α was used [112]. Whereas, for average variance extracted (AVE), we followed [113], and for composite reliability (CR), we followed the benchmark of [114]. These studies set the benchmark to decide whether the items show a significant relation with their respective measures or not.

Independent measure: This study employs IoT as an independent measure and adapted the measures from the study of [46]. The measure included various dimensions such as identification of items, units, tracking and monitoring, supply chain activities (remotely), decision-making, real-time information, and operations. A total of twelve items were adapted to measure the overall IoT. However, the results show above the benchmark α = 0.950. The factor loading also shows an excellent range of 0.750 to 0.796. On the other hand, CR (0.812) is above the benchmark, and the average AVE is (0.793) above the benchmark of 0.50, demonstrating a significant relationship between the items.

Mediators: This study employs two mediators, supply chain integration adapted and supply chain agility adapted from [14]. To measure the supply chain integration, the questionnaire included five items. These items included integration of supply chain operations, minimizing answering time, enhancing the activities of the supply chain, improving interaction, and developing communication and information systems. The reliability results show Cronbach’s α = 0.888 above the benchmark. Whereas factor-loading ranged between 0.759 and 0.803. CR (0.901) is above the benchmark, and the average AVE is (0.877) above the benchmark of 0.50, demonstrating a significant relationship between the items. Supply chain agility is used as a second mediator. A total of five items were adapted. These items included statements related to improved services, quick response to market change, timely response to the environment, modifications in portfolio, and adaptations to new changes. The reliability results show Cronbach’s α = 0.878 above the benchmark, whereas factor loading ranged between 0.746 and 0.809. CR (0.889) is above the benchmark, and the average AVE is (0.712) above the benchmark of 0.50, demonstrating a significant relationship between the items.

Moderators: This study also proposes the two moderators. First, regarding environmental uncertainty, the measures were adapted from [15]. A total of six items were adapted to measure the overall measure of environmental uncertainty. The items included dimensions, for example, quick changes in consumer demand, technological advancements in the market, anticipating market trends, and competition in the market. The reliability results show Cronbach’s α = 0.905 above the benchmark. Whereas factor-loading ranged between 0.770 and 0.803. However, CR (0.856) is above the benchmark, and the average AVE is (0.812) above the benchmark of 0.50, demonstrating a significant relationship between the items. Second, perceived business force is used as a moderator in this study. The authors of this study adapted five items from [14] to measure the overall perceived business force. These items included the dimensions of customers, suppliers, shareholders, industry competition, and financial organizations affecting operational problems. The reliability results show Cronbach’s α = 0.884 above the benchmark. Whereas factor loading ranged between 0.767 and 0.795. In addition, CR (0.973) is above the benchmark, and the average AVE is (0.766) above the benchmark of 0.50, demonstrating a significant relationship between the items.

Dependent: innovation performance plays the role of a dependent variable in this study. Authors of this study adapted items from [114]. A total of six items were adapted to measure the overall innovation performance. The items included dimensions such as innovation in products/services, process innovations, improved processes, and increased flexibility. Reliability results shows Cronbach’s α = 0.897 above the benchmark, whereas factor loading ranged between 0.763 and 0.785. Additionally, CR (0.966) was above the benchmark, and the average AVE was (0.742) above the benchmark of 0.50, demonstrating a significant relationship between the items (See Table 2).

Table 2.

Factor Loading.

The selection of these scales was based on their theoretical relevance, empirical validation, and frequent application in prior studies by addressing technology adoption and supply chain management. These scales cover multiple dimensions of the supply chain. For example, technological integration and operational performance is associated with IoT. To cover the dimensions of collaboration, flexibility and responsiveness, supply chain integration and agility adapted. In the environmental and competitive dynamic literature perspective, environmental uncertainty and perceived business force captured the contextual factors. That captures the contextual factors affecting strategic and technological adaptation. Contributing to rich innovation management research innovation performance (measure) provides comprehensive coverage of product, process, and service innovation dimensions. Overall, these scales were selected for their conceptual alignment, proven reliability, and consistent use in related empirical contexts. To ensure both measurement validity and comparability with prior studies.

Table 3 shows the correlation analysis results for these six variables. It also shows the significance of the linear relationship between the variables through the Pearson correlation coefficient [115]. It is obvious that there is a significant positive relationship between IoT capability and supply chain integration (0.313, p < 0.01), supply chain agility (0.333, p < 0.01) and innovation performance (0.327, p < 0.01). There is also a significant positive relationship between supply chain integration and innovation performance (0.325, p < 0.01) and supply chain agility and innovation performance (0.327, p < 0.01). These results provide primary support for the tests of some hypotheses.

Table 3.

Pearson Correlation Analysis.

5. Results

5.1. Direct Effect

Table 4 demonstrates the direct relationship between the variables. The first hypothesis this study proposes is the direct relation between IoT and innovation performance. To verify it, this study took IoT capability as the independent variable to make a regression analysis of innovation performance. Results show that β = 0.326, p < 0.005, and t-value 6.773, which means IoT has a positive impact on INP, thus supporting H1. Hypothesis 2 suggests that IoT influences supply chain agility, result β = 0.329, p < 0.005, t-value 6.460 indicates that IoT also has a significant positive impact on the level of SCA. Therefore, this supports H2. The third hypothesis predicts that IoT has a positive relation with supply chain integration. Results show that β = 0.401, p < 0.001, and t-value 9.366, which means IoT has a positive impact on SCI, and supports H3. The fourth hypothesis predicted that supply chain integration has a positive relationship with innovation performance. Results show that β = 0.421, p < 0.001, and t-value 8.657, which means SCI has a positive impact on INP, and supports H4. The fourth hypothesis predicted that supply chain agility has a positive relationship with innovation performance. Results show that β = 0.437, p < 0.001, and t-value 10.231, which means SCA has a positive impact on INP and supports H5.

Table 4.

Structural equation modelling (SEM) for direct links between the variables.

5.2. Mediating Effects

Table 5 demonstrates the mediation effect of SCI and SCA by employing Hayes Process modelling. First, SCI mediates the relationship between IOT and INP. The following are the results: coefficient 0.235, p-value 0.001, and t-value 36.921. where the upper and lower levels are 0.041 and 0.120, respectively, shows no 0 between the lower and upper confidence levels. These results support the positive mediator role of SCI between IoT and INP. Second, supply chain agility plays a mediator role between IoT and INP. The results show a coefficient of 0.247, a p-value of 0.001, and a t-value of 36.547. where the upper and lower levels, 0.045 and 0.125, show no 0 between the lower and upper confidence levels. Thus, this supports the mediating role of SCA.

Table 5.

Mediation effect of supply chain integration and supply chain agility.

5.3. Moderating Effects

The authors employed Hayes process modelling to examine the moderating effects. The first moderate variable is the perceived business force affecting the relationship between IoT and SCI. The results show that the interaction between IOT and PBF is 0.134, p-value = 0.001, and t-value 3.846. In addition, environmental uncertainty is the second moderator in the conceptual framework. The results show that the interaction between IOT and ENU is 0.113, p-value = 0.005, t-value 2.649. Whereas there is no 0 between LLCI and ULCI, showing the positive effect of ENU (see Table 6).

Table 6.

Moderating effect of perceived business force and environmental uncertainty.

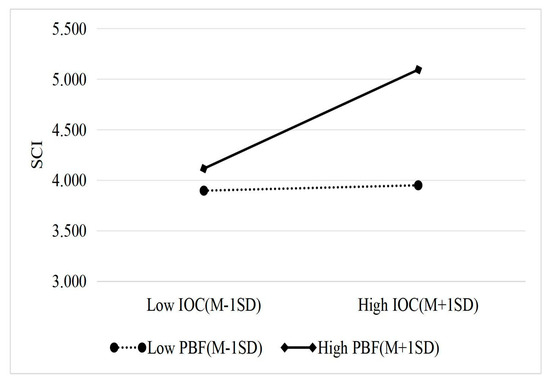

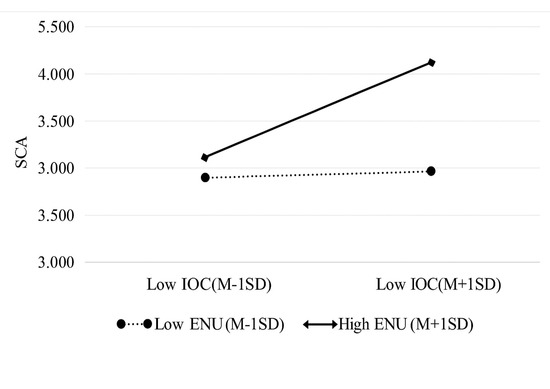

Figure 2 provides a visual demonstration of the moderating role of perceived business force. In the Figure, the horizontal axis is IoT capability, and the vertical axis shows SCI. This study uses the average value plus or minus one standard deviation (M ± 1SD) to represent “Low IOC” and “High IOC”. These two curves represent the regression trends in the situations of “Low PBF” and “High PBF”. In a high PBF situation, the impact of IoT capabilities on SCI shows a positive trend. The slope is positive. That means SCI rises when IoT capability enhances, and this effect is obvious. In a low PBF situation, the slope is still positive but not obvious. These results further explain the moderating effect of PBF. Figure 3 shows the moderating effect of ENU on the relationship between IoT capability and innovation performance. The horizontal axis is still IoT capability, and the vertical axis is INP. These two curves indicate the regression trends in the situation of “Low ENU” and “High ENU”. In a high ENU situation, the slope is positive and steep. This means there is a positive relationship between IOC and INP. In the low ENU situation, the slope is still positive but relatively more stable. This figure also further explains the moderating effect of ENU.

Figure 2.

The moderating effect of PBF on the relationship between IoT capability and supply chain integration (SCI).

Figure 3.

The moderating effect of ENU on the relationship between IoT capability and innovation performance (INP).

5.4. Common Method Bias

This study was conducted Via a questionnaire survey. However, studies in the field of business have adopted four Post Hoc statistical methods to examine the common method variance and common method bias. Therefore, data that is self-reported has a big threat of common method bias and common method variance [116]. Method biases, however, are the main sources of measurement errors that threaten the validity as well as conclusions [111]. However, these errors in prior research are linked with random systemic components [117,118,119]. The literature shows the reason [120], that it provides an alternative explanation for the observed relationships between various constructs. Therefore, to avoid these issues, we in this study follow Harman’s one-factor test [120], suggested by Podsakoff and Organ. In this test, the percentage of variance should be less than 50 percent, showing no threat of the common method bias. In this study, we load all the variables into one factor; however, the results show 41 percent variance (see Table 7). That demonstrates no threat of common method bias.

Table 7.

Harman’s one-factor test.

6. Discussion

First and foremost, this study confirmed that IoT has a significant direct positive effect on innovation performance, β = 0.326, p = 0.001. If one company has high IoT capability, it has better performance in innovation, such as product innovation. For example, a company can obtain user behavior data and their feedback by using IoT technology. This helps the company to design new products to satisfy its users. The positive relation between IoT and innovation performance in this study is aligned with the existing research. The relationship between IoT and innovation performance in the perspective of digital transformation [121], extension of Industry 4.0 [122], improved efficiency and reduced cost [123], and addressing challenges through improved IoT infrastructure [124]. Our results are aligned with these studies and support the positive relationship. The results also indicate that IoT capability promotes supply chain integration and agility significantly, β = 0.329, p = 0.001, and β = 401, p = 0.000. Regarding supply chain integration, high IoT capability helps companies to collaborate on processes and share data with upstream and downstream partners. Thus, there is more frequent and effective information communication and efficient departmental collaboration.

IoT capability is a kind of bridge that helps the company to do business with other suppliers, manufacturers, and distributors. In terms of supply chain agility, IoT capability helps the company to identify and respond to various unexpected situations, like sudden fluctuations in market demand and delays in raw material supply. IoT equipment allows changes and adjustments to the production plans to fit the current market situation. This study also predicts the positive direct relation between supply chain integration and innovation performance. Results of this study are aligned with the prior studies in terms of enhanced connectivity and real-time data [13], operational advantages and performance improvement [96], green and sustainable supply chains [125], and strategic competitive advantage [42,126]. Results show that β = 0.421, p = 0.000. Supply chain integration involves coordinating and aligning processes among different parts of the supply chain—internally within the organization and externally with suppliers and customers. This coordination is shown to positively affect operational and innovation performance by enabling a more efficient flow of information and materials. For instance, strong customer and supplier integration strengthens supply chain agility and enhances performance in terms of cost-effectiveness, order fulfilment rates, and business process innovation [127]. There is also a direct relation predicted by this study between supply chain agility and innovation performance. The results of this study aligned with the prior studies in terms of facilitating knowledge for enhancing product innovation capability [85], promoting green innovation [87,128], and operational excellence and competitive advantage [129]. Results show that β = 0.437, p = 0.000. That means the agility component significantly boosts firm performance by enabling quick adaptation to technological changes and market demands, helping in achieving innovation outcomes [81]. IoT capability is also able to promote innovation performance positively through both supply chain integration and agility. If a company’s IoT capability can be transformed into supply chain integration, such as optimizing cross-organizational collaboration and achieving resource sharing, it can achieve better innovation performance in product, production, and distribution. About supply chain agility, a company is able to use improved IoT capability to better identify market and environmental changes more quickly and adjust strategies and resources through an agile supply chain. Finally, it achieves better innovation performance. Supply chain agility helps the company to react to the market at a lower cost and achieve innovative results. The empirical results of this study are aligned with the existing studies in terms of digital transformation [90,92], organizational input and process innovation [87], flexibility and responsiveness [99], and competitive capabilities (as strategic asset) [21].

As the mediating result shows β = 0.235, p = 0.000, and β = 0.247, p = 0.000 positive benchmarking, this study supports the positive role of both variables. In different levels of perceived business force, the degree of impact of IoT capability on supply chain integration also changes. The results of this study emphasize the positive mediating role of supply chain integration and supply chain agility [81,99]. This study demonstrates aligned results with the prior studies in terms of integration and innovation [88], dynamic capabilities and performance [83,92], customized performance and technology enables [11] the support of innovation in organizations.

Results demonstrate β = 0.134, p = 0.000, the positive role of perceived business force between IoT capability and SCI. That means when the perceived business force gets stronger, the impact also gets more obvious. Perceived business force motivates companies to make more efficient use of their existing resources to enhance the whole supply chain integration. When facing rapid market fluctuation, companies have a greater demand for obtaining information, accurately judging trends, and quickly adjusting strategies. Then, a high IoT capability enables companies to achieve these goals and improve their innovation performance. Our study supports the results of the prior studies by emphasizing the moderating role of perceived business force in terms of influencing strategic integration [69], and competitive advantage [130]. This study also supports the positive role of environmental uncertainty between IoT capability and innovation performance, β = 0.113, p = 0.001. Our results support the effective role played by environmental uncertainty in several ways, including interaction with innovation strategies and controls [131], organizational flexibility [132], and different effects in innovation dimensions [133]. Overall, we can see that firms need dynamic capabilities to sustain innovation performance. These capabilities help firms to be sustained in a perceived business force and an uncertain business environment.

6.1. Theoretical Implications

Beyond verifying the applicability of dynamic capabilities theory our research extended the theory by showing IoT capability functions as a digitally enabling dynamic capability to transform its traditional mechanisms (i.e., sensing, seizing, and reconfiguring). This theoretical contribution not only identifies firms’ ability to sense environmental changes but also foster continuous sensing. In this continuous learning process real-time data allows firms to scan the environment for rapid opportunity recognition. That is an underexplored aspect in the original dynamic capabilities theory framework. The use of IoT in supply chains shows how digital tools change the way we work together and make decisions (i.e., seizing). It systematizes these tasks, making it easier to find and take advantage of new opportunities. Reconfiguration in digital supply chains is recursive rather than episodic, in which firms continuously adjust operations in response to feedback loops. Furthermore, the theoretical implications of this study suggest that the effectiveness of dynamic capabilities depends on contextual pressure. The more the environment is uncertain the more firms try to learn (search and apply new information into supply chains) for the development of innovation performance. Therefore, the contribution of this study enriches the theoretical understanding of dynamic capabilities in the digital sphere, where these capabilities evolve through digital tools, organizational learning, and inter-firm collaboration.

The direct positive impact of IoT capability on innovation performance is supported by existing research. About manufacturing, there are several aspects that benefit from IoT implementation, such as factory transparency, supply chain interconnection, manufacturing planning and adjusting, predictive maintenance, extra quality outside the factory, sustainability, and other targeted uses [134]. The return process is also promoted by higher IoT capability. An advanced model uses IoT technology to enhance purchasing, manufacturing, and decision-making on product recall, fixing a price, and return strategies [134]. This study quantified the influence of IoT capability on innovation performance and provided more support for this relationship.

Moreover, this study also analyzed how IoT capability indirectly contributes to company innovation performance through supply chain integration and agility. About supply chain integration, a study stated that the level of innovation is strongly shaped by supply chain collaborations and partnerships, and it also promotes both internal integration in the organization and external integration across the whole supply chain [135]. In addition, external supply chain integration helps companies to coordinate plans and solve problems, and it is crucial in developing new products. Through external integration, suppliers and customers can develop new products more closely, and there are also specific steps and procedures to discuss and coordinate critical product design decisions [136]. Supply chain agility enables firms to rapidly adapt to market changes, satisfy customer demands, and handle both current and future disruptions in exporting [137]. In addition, supply chain agility also enhances operational performance in many ways. For instance, rapid replacement of materials and services, swift and adaptable production changing, and flexible inventory repositioning contribute to short lead time and more efficient customer distribution handling [21]

In terms of moderation, the moderating effect of perceived business force is also confirmed. One research study states that market competition, including pressure from rivals, cost reduction, productivity enhancement, and dynamic competitive conditions, drives companies to make digital transformations [138]. This study found that when companies deal with external pressure, they will more actively use technological resources to obtain integration capability. Regarding environmental uncertainty, companies need to adjust their marketing strategies more frequently to meet the changing customer demands when facing a quickly changing environment, and one example is building big data analysis technology [139]. This supports the result that the impact of IoT capability on innovation performance is significantly enhanced under high environmental uncertainty.

Based on dynamic capabilities theory, this study analyzes the effect of IoT capabilities on innovation performance through supply chain integration and agility. This also includes perceived business force and environmental uncertainty as a moderator. Under this theory, the findings verify the application of dynamic capabilities theory in the supply chain. Dynamic capabilities theory has three important dimensions: sensing, seizing, and reconfiguring [40]. Firstly, the results indicate that IoT capability is an important part of a company’s dynamic capabilities, especially in the “sensing” part. Because IoT technology can provide companies with more accurate data through sensor networks and real-time monitors and it also enhances the perception ability of companies. Regarding “seizing”, this study finds that IoT can improve supply chain integration by promoting the information and process connection between different partners. This finally improves the innovation performance. In the dimension of “reconfiguring”, IoT capability can improve companies’ flexible response ability when facing fluctuations and then build an agile supply chain structure. In addition, the introduction of perceived business force and environmental uncertainty helps to verify the different adaptations of the dynamic capability theory in different environmental situations. The results (i.e., positive impact of IoT in supply chain integration and agility and innovation performance) show that dynamic capability will be activated and have a greater impact when facing difficult situations.

6.2. Managerial Implications

First and foremost, managers should focus on IoT deployments in supply chain processes. Due to uncertainty in business environments, managers should focus more on dynamic capabilities by integrating intellectual capabilities with technologies. IoT adoption will help managers to monitor different areas of the supply chain, including internal processes, supply chain interactions, and customer relationships. Moreover, managers should focus on the development of data-driven decision-making capabilities to enhance the value of IoT-generated data. Managers should further integrate the IoT insights with advanced business intelligence systems for enhanced strategic planning as more businesses nowadays are adopting technologies for information sharing; therefore, managers should strengthen cybersecurity and data governance frameworks and provide protection to sensitive operational and customer data. Supply chain managers can reduce waste, monitor energy usage, and optimize resource consumption by employing IoT. This will not only help businesses to monitor resources but also contribute to sustainability and environmental protection responsibilities. To bring customer-centric innovation managers need to understand customers’ behavior that can be possible by effectively utilizing IoT data. This data allows managers to enhance responsiveness, tailor products, and improve satisfaction, whereas strategic investment decisions should be guided by evaluating the return on investment of IoT initiatives and prioritizing high-impact areas. From the supply chain agility and resilience perspective, IoT allows managers to anticipate disruption and reconfigure networks dynamically. Managers should foster partnerships with technology providers and supply chain collaborators to enhance innovation ecosystems and accelerate digital transformation. Managers should encourage employees to engage in continuous learning by effective implementation of IoT. This continuous learning will bring improvement both in organizational and individual performance by utilizing real-time data.

In addition, companies should deploy devices such as sensors, cameras, RFID, and GPS locations in important business links. Then, equip cutting-edge computers to primarily analyze the data and build a data acquisition system to collect and monitor the equipment operation situation comprehensively. Second, companies can try to establish a shared platform, like a supply chain management system and blockchain platform, with other suppliers and distributors. Companies can enhance information sharing with partners, including order status, inventory level, and transportation information. After this, companies can introduce flexible planning and adjustment to face complex markets. The key is to build a flexible adjustment system. For example, companies can use real data from the IoT system to adjust an optimal distribution route to improve operational flexibility. Companies should provide professional training for employees to master multiple skills, such as being able to handle orders and manage inventory at the same time. This will decrease the burden on individuals caused by rapid change and increase the adaptability of employees. Finally, companies should apply IoT technologies in processes that are significantly affected by fluctuations. Therefore, companies can achieve maximum effect with limited resources.

7. Conclusions

This study focuses on how IoT capability affects innovation performance through supply chain integration and agility. It also takes perceived business force and environmental uncertainty as moderating variables. This study builds a model under dynamic capabilities theory and conducts a quantitative analysis. This study finds that IoT Capability not only directly promotes innovation performance but also improves it indirectly through supply chain integration and supply chain agility. Our study advances the literature in terms of innovation performance, which is not discussed in prior research from the IoT perspective. In this vein, the current study contributes to the literature by introducing supply chain integration and agility. To support the organizations from several perspectives, for example, data processing, information sharing, real-time inventory management, quality control, improving service delivery, real-time responsiveness, boosting overall efficiency, continuous learning, improving, and innovation. Thus, this study further provides empirical support for these two variables as mediators. It also confirms the moderating effect of perceived business force and environmental uncertainty: The higher the perceived business force, the more significant the impact of IoT capability on supply chain integration is; When existing in a situation with high environmental uncertainty, the promoting effect of IoT capability on innovation is also more significant. This study points out that companies should regard technological capabilities as an important part of their capabilities. They can transfer technological advantages into better performance by achieving integration and agility. This approach helps companies adapt to market changes and achieve continuous innovation.

8. Limitations and Future Research

One limitation is that the sample size is not very large. This may affect the applicability of the study result. It may lead to insufficient persuasiveness. In terms of future research suggestions, future research can further explore more potential mediating and moderating variables to enrich how IoT capability influences company innovation performance. For example, active promotion by the manager helps implement IoT equipment. Future research can construct a more complex model to explore the potential influence mechanism. Another limitation of this study is that the larger number of the targeted group is frontline workers, as indicated by 84.42%; there might be potential perceptual bias regarding strategic-level outcomes, for example, firm-level innovation. However, it is important to recognize the importance of frontline employees due to their different scopes of visibility and influence compared to senior management. Frontline employees are more involved in operational and immediate customer services where strategic activities are more related to top management. On the other hand, we can see that frontline employees play a significant role in innovation with interactions with customers and in service delivery processes. This might help in gathering information or customer feedback but making decisions on how to implement those ideas is still an area for top management. In a similar vein, frontline employees may contribute to innovation and creative engagement, but they often lack the resources or authority to make strategic decisions. Therefore, future research should focus more on top management, people involved in strategic decision-making, IT managers, and those who are responsible for overseeing overall supply chain processes.

Author Contributions

Conceptualization and overall study have been developed by F.K. and K.U.K.; software and data analysis have been done by F.A.; finally, F.A. and K.U.K. funded this article. All authors have read and agreed to the published version of the manuscript.

Funding

Wenzhou-Kean University 2023 Internal Faculty/Staff Start-Up Research Grant ISRG2023007 and Wenzhou-Kean University 2024 Internal Faculty/Staff Research Support Programs-IRSPC2024002.

Data Availability Statement

Available on demand.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Iftikhar, A.; Purvis, L.; Giannoccaro, I.; Wang, Y. The impact of supply chain complexities on supply chain resilience: The mediating effect of big data analytics. Prod. Plan. Control 2023, 34, 1562–1582. [Google Scholar] [CrossRef]

- Jafari, T.; Zarei, A.; Azar, A.; Moghaddam, A. The impact of business intelligence on supply chain performance with emphasis on integration and agility–a mixed research approach. Int. J. Product. Perform. Manag. 2023, 72, 1445–1478. [Google Scholar] [CrossRef]

- Taj, S.; Imran, A.S.; Kastrati, Z.; Daudpota, S.M.; Memon, R.A.; Ahmed, J. IoT-based supply chain management: A systematic literature review. Internet Things 2023, 24, 100982. [Google Scholar] [CrossRef]

- Al-Khatib, A.W. Internet of things, big data analytics and operational performance: The mediating effect of supply chain visibility. J. Manuf. Technol. Manag. 2023, 34, 1–24. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Lee, S.Y. A research on users’ behavioral intention to adopt Internet of Things (IoT) technology in the logistics industry: The case of Cainiao Logistics Network. J. Int. Logist. Trade 2023, 21, 41–60. [Google Scholar] [CrossRef]

- Mu, X.; Antwi-Afari, M.F. The applications of Internet of Things (IoT) in industrial management: A science mapping review. Int. J. Prod. Res. 2024, 62, 1928–1952. [Google Scholar] [CrossRef]

- Argyropoulou, M.; Garcia, E.; Nemati, S.; Spanaki, K. The effect of IoT capability on supply chain integration and firm performance: An empirical study in the UK retail industry. J. Enterp. Inf. Manag. 2024, 37, 875–902. [Google Scholar] [CrossRef]

- AL Khatib, A.W. The impact of dynamic capabilities on circular economy: The mediating effect of the industrial Internet of things. J. Manuf. Technol. Manag. 2023, 34, 873–895. [Google Scholar] [CrossRef]

- Billah, M.M.; Alam, S.S.; Masukujjaman, M.; Ali, M.H.; Makhbul, Z.K.M.; Salleh, M.F.M. Effects of Internet of Things, supply chain collaboration and ethical sensitivity on sustainable performance: Moderating effect of supply chain dynamism. J. Enterp. Inf. Manag. 2023, 36, 1270–1295. [Google Scholar] [CrossRef]

- Malhotra, G. Impact of circular economy practices on supply chain capability, flexibility and sustainable supply chain performance. Int. J. Logist. Manag. 2024, 35, 1500–1521. [Google Scholar] [CrossRef]

- Eslami, M.H.; Jafari, H.; Achtenhagen, L.; Carlbäck, J.; Wong, A. Financial performance and supply chain dynamic capabilities: The Moderating Role of Industry 4.0 technologies. Int. J. Prod. Res. 2021, 62, 8092–8109. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Blome, C.; Dwivedi, Y.K.; Childe, S.J.; Foropon, C. Alliances and digital transformation are crucial for benefiting from dynamic supply chain capabilities during times of crisis: A multi-method study. Int. J. Prod. Econ. 2024, 269, 109166. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J. Iot in supply chain management: A narrative on retail sector sustainability. Int. J. Logist. Res. Appl. 2020, 24, 605–624. [Google Scholar] [CrossRef]

- Meng, J.; Hao, Z.; Yang, J.; Hong, Y. How does digital transformation affect organisational sustainable performance: The mediating roles of supply chain agility and integration. Int. J. Logist. Res. Appl. 2023, 28, 860–885. [Google Scholar] [CrossRef]

- Lissillour, R.; Cui, Y.; Guesmi, K.; Chen, W.; Chen, Q. Value network and firm performance: The role of knowledge distance and environmental uncertainty. J. Knowl. Manag. 2024, 28, 44–68. [Google Scholar] [CrossRef]

- Delhi, A.; Sana, E.; Bisty, A.A.; Husain, A. Innovation in Business Management Exploring the Path to Competitive Excellence. APTISI Trans. Manag. (ATM) 2024, 8, 58–65. [Google Scholar] [CrossRef]

- Urbancova, H. Competitive Advantage Achievement through Innovation and Knowledge. J. Compet. 2013, 5, 82–96. [Google Scholar] [CrossRef]

- Jiao, H.; Alon, I.; Cui, Y. Environmental dynamism, innovation, and dynamic capabilities: The case of China. J. Enterprising Communities People Places Glob. Econ. 2011, 5, 131–144. [Google Scholar] [CrossRef]

- Zhu, M.; Gao, H. The antecedents of supply chain agility and their effect on business performance: An organizational strategy perspective. Oper. Manag. Res. 2021, 14, 166–176. [Google Scholar] [CrossRef]

- Wu, L.; Huang, J.; Wang, M.; Kumar, A. Unleashing supply chain agility: Leveraging data network effects for digital transformation. Int. J. Prod. Econ. 2024, 277, 109402. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. Int. J. Prod. Res. 2014, 53, 3028–3046. [Google Scholar] [CrossRef]

- Stank, T.P.; Dittmann, J.P.; Autry, C.W. The new supply chain agenda: A synopsis and directions for future research. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 940–955. [Google Scholar] [CrossRef]

- Güler, M.; Büyüközkan, G. A Survey of Digital Government: Science Mapping Approach, Application Areas, and Future Directions. Systems 2023, 11, 563. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Di Stefano, G.; Peteraf, M.; Verona, G. The organizational drivetrain: A road to integration of dynamic capabilities research. Acad. Manag. Perspect. 2014, 28, 307–327. [Google Scholar] [CrossRef]

- Schilke, O.; Hu, S.; Helfat, C.E. Quo vadis, dynamic capabilities? A contentanalytic review of the current state of knowledge and recommendations for future research. Acad. Manag. Ann. 2017, 12, 390–439. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J.A. Dynamic capabilities: What are they? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Gong, Y.; Yang, J.; Shi, X. Towards a comprehensive understanding of digital transformation in government: Analysis of flexibility and enterprise architecture. Gov. Inf. Q. 2020, 37, 101487. [Google Scholar] [CrossRef]

- Teece, D.J. The foundations of enterprise performance: Dynamic and ordinary capabilities in an (Economic) theory of firms. Acad. Manag. Perspect. 2014, 23, 328–352. [Google Scholar] [CrossRef]

- Lee, J.; Wewege, L.; Thomsett, M.C. Disruptions and digital banking trends. J. Appl. Financ. Bank. 2020, 10, 15–56. [Google Scholar]

- Teece, D.; Peteraf, M.; Leih, S. Dynamic capabilities and organizational agility: Risk, Uncertainty, and Strategy in the Innovation Economy. Rev. Calif. Manag. Rev. 2016, 58, 13–35. [Google Scholar] [CrossRef]

- Lee, C.-H.; Liu, C.-L.; Trappey, A.J.C.; Mo, J.P.T.; Desouza, K.C. Understanding digital transformation in advanced manufacturing and engineering: A bibliometric analysis, topic modeling and research trend discovery. Adv. Eng. Inform. 2021, 50, 101428. [Google Scholar] [CrossRef]

- Pezeshkan, A.; Fainshmidt, S.; Nair, A.; Lance Frazier, M.; Markowski, E. An empirical assessment of the dynamic capabilities-performance relationship. J. Bus. Res. 2016, 69, 2950–2956. [Google Scholar] [CrossRef]

- Ellstrom, D.; Holtstrom, J.; Berg, E.; Josefsson, C. Dynamic capabilities for digital transformation. J. Strategy Manag. 2022, 15, 272–286. [Google Scholar] [CrossRef]

- Hutterer, P. Dynamic Capabilities; Springer: Wiesbaden, Germany, 2013; pp. 181–244. [Google Scholar]

- Warner, K.S.R.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Naeem, M.; Ozuem, W.; Ward, P. Understanding the accessibility of retail mobile banking during the COVID-19 pandemic. Int. J. Retail Distrib. Manag. 2022, 50, 860–879. [Google Scholar] [CrossRef]

- Posen, H.E.; Ross, J.M.; Wu, B.; Benigni, S.; Cao, Z. Reconceptualizing imitation: Implications for dynamic capabilities, innovation, and competitive advantage. Acad. Manag. Ann. 2023, 17, 74–112. [Google Scholar] [CrossRef]

- Heubeck, T.; Meckl, R. More capable, more innovative? An empirical inquiry into the effects of dynamic managerial capabilities on digital fims’ innovativeness. Eur. J. Innov. Manag. 2022, 25, 892–915. [Google Scholar] [CrossRef]