Artificial Intelligence Applications in Risk Management Within Integrated Management Systems: A Review

Abstract

1. Introduction

2. Research Methodology

2.1. Methodology

- What are the strategies implemented for using AI in IMS risk management?

- What challenges arise in integrating AI into IMS?

- What are the opportunities generated by implementing IMS using AI?

- What are the advantages of integrating artificial intelligence into IMS in industrial organizations?

- What are the risks associated with using AI?

- What are the barriers to using AI in IMS risk management?

- Are Internet of Things (IoT) devices and technologies suitable for data collection and IMS risk management using AI?

- What are the main emerging risks encountered when using AI?

- What are the critical factors in IMS risk management using AI?

- What algorithms and technologies are used for risk management of IMS using AI?

- How is IMS risk management using AI achieved in the management of documents developed by industrial organizations?

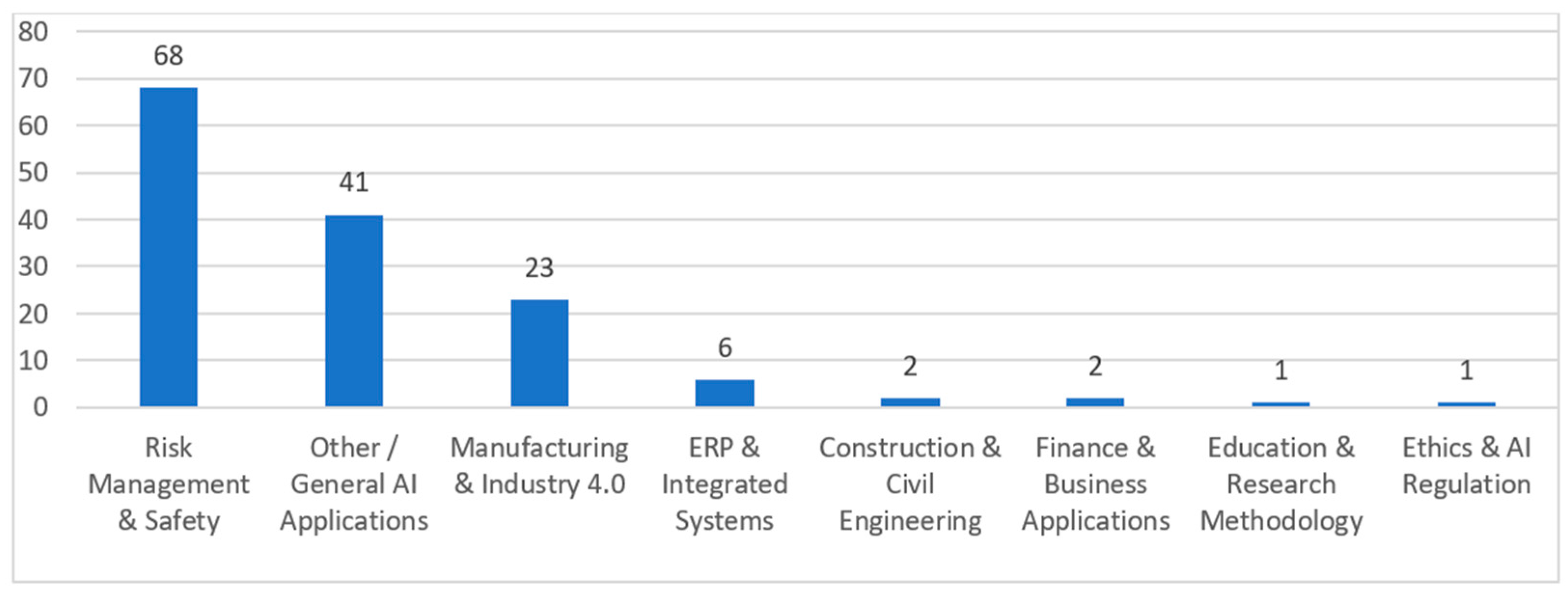

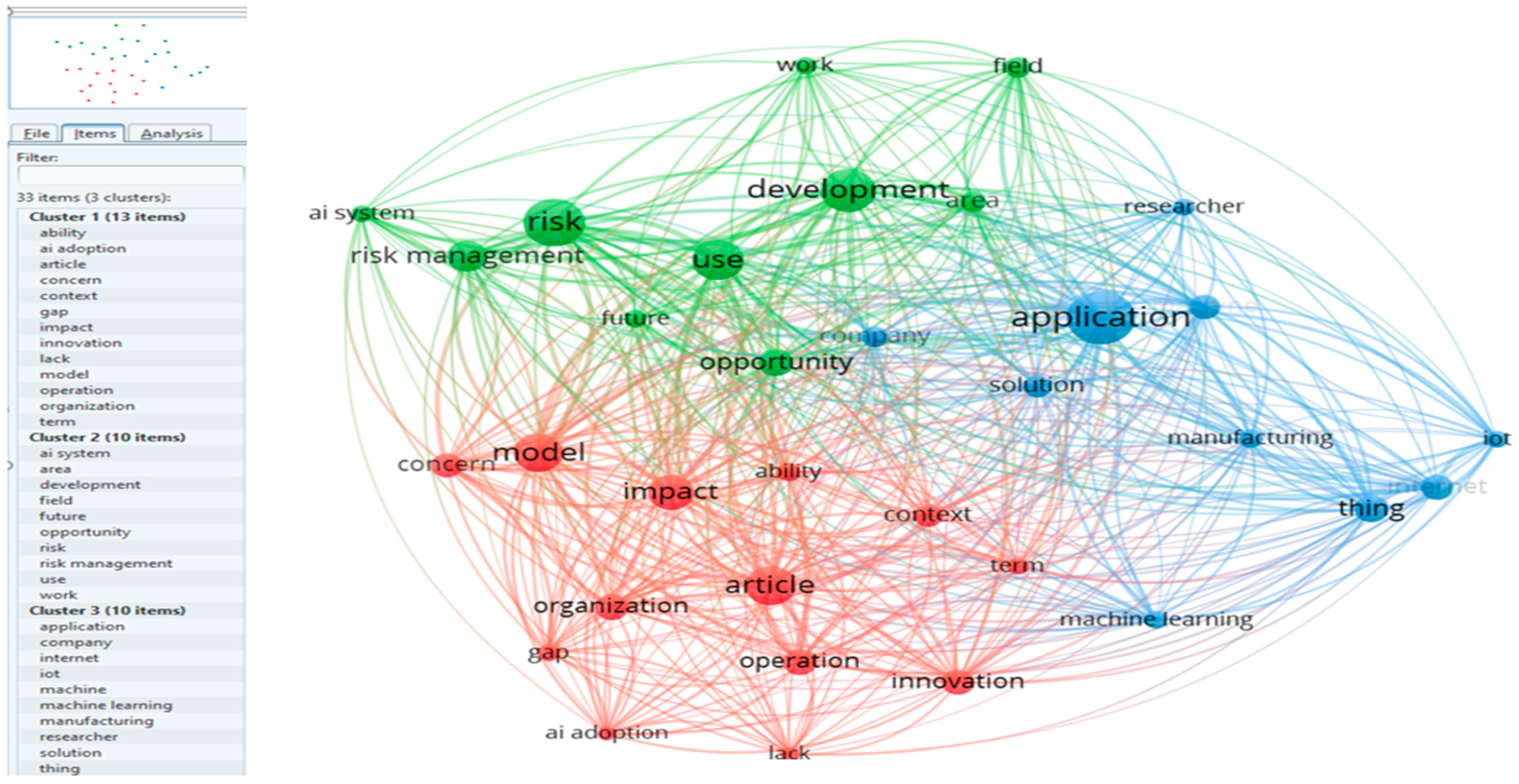

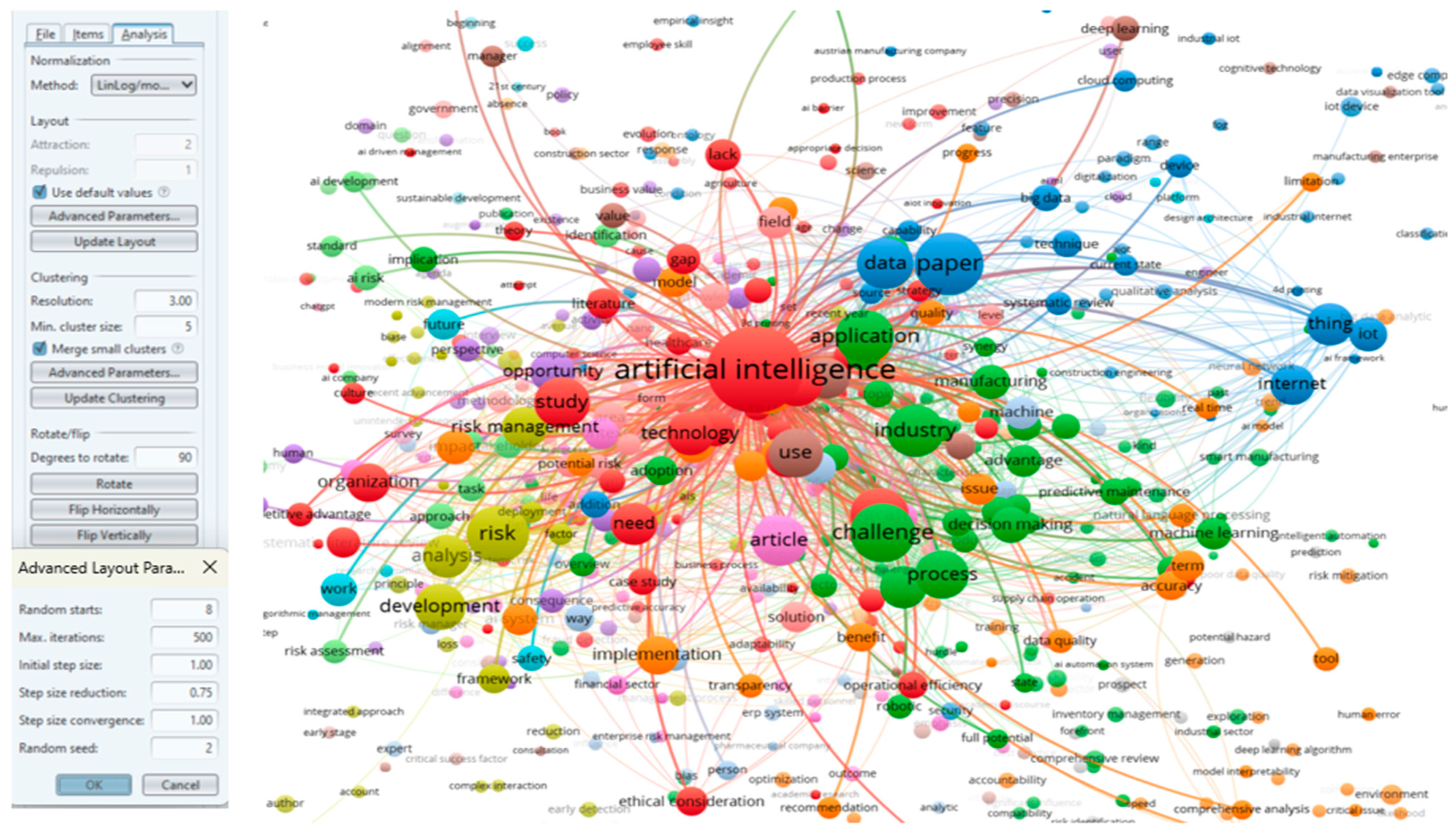

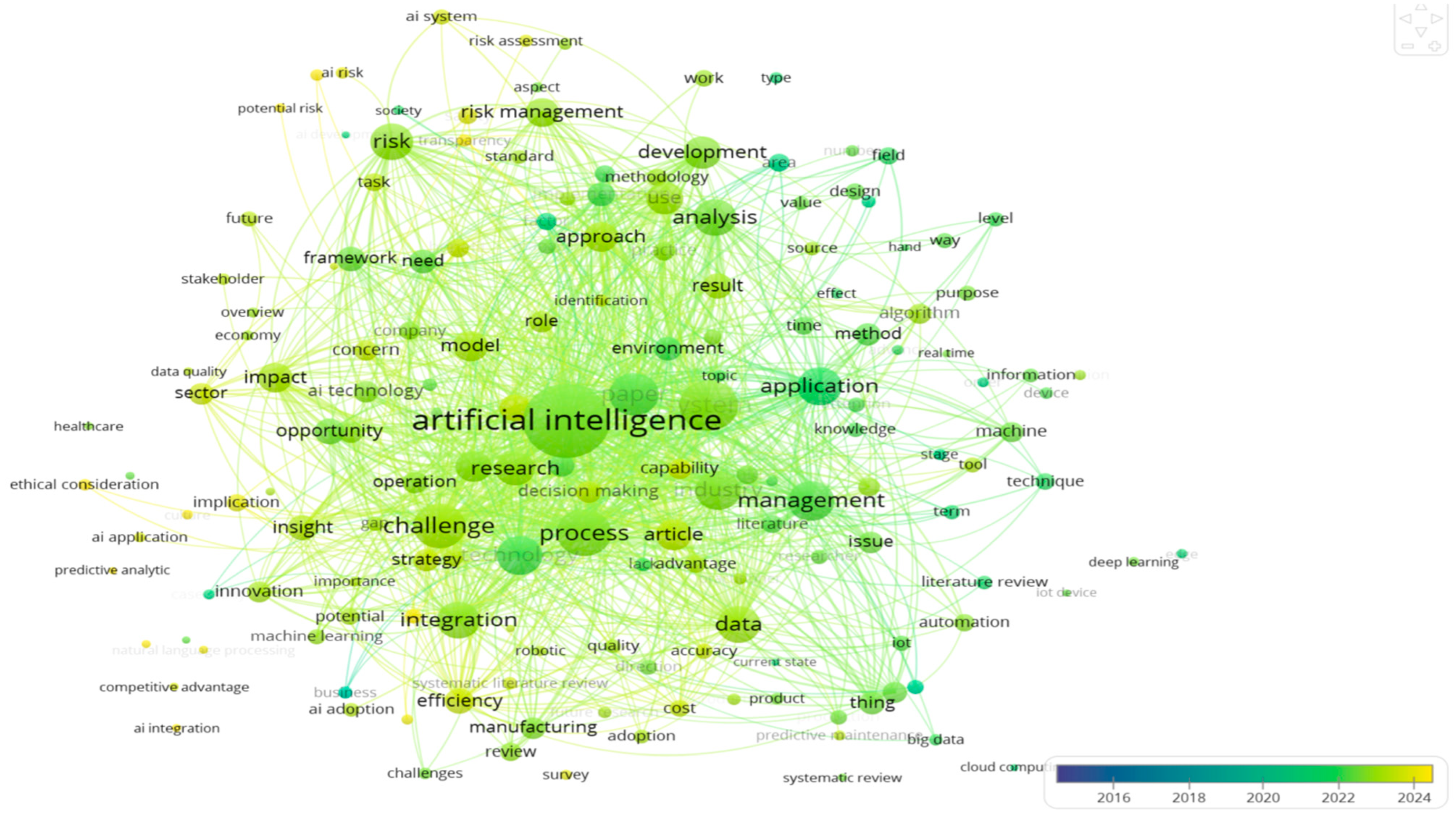

2.2. Bibliometric Analyses

3. Results and Discussion

- Opacity and inaccuracy: AI can introduce risks of opacity and inaccuracy into risk assessments, which can lead to operational inefficiencies and incorrect risk assessments [92].

- Resources and interactions: Proper resource allocation and efficient interaction between departments are crucial for risk prevention [118].

- Technical and social factors: Risk assessment should include both technical (e.g., equipment failures) and social (e.g., regulations, organizational factors) factors [135].

- Decision support systems: They use AI to integrate causal and predictive networks, multi-criteria analysis, and knowledge engineering techniques for industrial risk management [32].

- Learning automation platforms: Platforms like the engineering machine-learning automation platform (EMAP) use advanced AI/machine learning (ML) algorithms to support decisions at every stage of engineering projects, from bidding to maintenance [122].

- AI-enhanced project management systems: They optimize resource allocation and risk mitigation through big data analysis and decision-making automation [33].

- The use of algorithms and technologies for risk management of IMS using AI offers considerable advantages for optimizing resources in the field of industrial organizations, such as:

- Real-time monitoring and prediction: AI enables continuous monitoring of hazardous conditions and predictive analysis of historical data to anticipate risks [31].

- Risk management in supply chains: AI improves supply chain agility by modeling scenarios and optimizing decisions [127].

- Process automation and optimization: Integrating AI with other soft computing methods, such as artificial neural networks, improves accuracy and efficiency in construction and risk management [139].

- Safety risks and discrimination: The use of AI in industrial and human resources environments can lead to safety and discrimination risks, which must be managed through technical standards and legal regulations [142].

- Social and legal risks: AI can affect fundamental rights and create social and legal risks, requiring a regulatory approach that includes ongoing stakeholder participation and a contextual risk assessment [143].

- EU AI Act: Proposes a risk-based approach to AI regulation, setting requirements for high-risk AI systems and promoting compliance with ISO standards [144].

- International and European Standards: play a crucial role in defining technical requirements for developing and testing AI systems, helping to mitigate risks [142].

Contributions to Research

4. Conclusions

5. Limitations of the Study and Literature

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| ERP | Enterprise resource planning |

| HSE | Health, safety, and environment |

| IMS | Integrated Management Systems |

| IoT | Internet of Things |

| MLOps | Machine Learning Operations Specialization |

| MS | Management system |

| NLP | Natural Language Processing |

| OHSMS | Occupational Health and Safety Management System |

| PHM | Prognostic Management |

| QMS | Quality Management System |

References

- Bleakley, C. Poems that Solve Puzzles: The History and Science of Algorithms; Oxford University Press: Oxford, UK, 2020; ISBN 0198853734. [Google Scholar] [CrossRef]

- Liu, J.; Kong, X.; Xia, F.; Bai, X.; Wang, L.; Qing, Q.; Lee, I. Artificial intelligence in the 21st century. IEEE Access 2018, 6, 34403–34421. [Google Scholar] [CrossRef]

- Ilyas, M. Emerging role of artificial intelligence. J. Syst. Cybern. Inform. 2022, 20, 58–65. [Google Scholar] [CrossRef]

- Duan, Y.; Edwards, J.S.; Dwivedi, Y.K. Artificial intelligence for decision making in the era of Big Data–evolution, challenges and research agenda. Int. J. Inf. Manag. 2019, 48, 63–71. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A. Artificial Intelligence (AI): Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice and policy. Int. J. Inf. Manag. 2021, 57, 101994. [Google Scholar] [CrossRef]

- Lu, H.; Li, Y.; Chen, M.; Kim, H.; Serikawa, S. Brain intelligence: Go beyond artificial intelligence. Mob. Netw. Appl. 2018, 23, 368–375. [Google Scholar] [CrossRef]

- Ferràs-Hernández, X.; Nylund, P.A.; Brem, A. The emergence of dominant designs in artificial intelligence. Calif. Manag. Rev. 2023, 65, 73–91. [Google Scholar] [CrossRef]

- Li, M.; Wang, W.; Zhou, K. Exploring the technology emergence related to artificial intelligence: A perspective of coupling analyses. Technol. Forecast. Soc. Change 2021, 172, 121064. [Google Scholar] [CrossRef]

- Sawilla, I.; Weber, C.; Schmidt, B.; Ulrich, M. Industrial challenges for AI systems engineering: Towards autonomous industrial systems. Automatisierungstechnik 2022, 70, 805–814. [Google Scholar] [CrossRef]

- Ispas, L.; Mironeasa, C. The Identification of Common Models Applied for the Integration of Management Systems: A Review. Sustainability 2022, 14, 3559. [Google Scholar] [CrossRef]

- Schrettenbrunnner, M.B. Artificial-intelligence-driven management. IEEE Eng. Manag. Rev. 2020, 48, 15–19. [Google Scholar] [CrossRef]

- Borges, A.F.S.; Laurindo, F.J.B.; Spínola, M.M.; Gonçalves, R.F.; Mattos, C.A. The strategic use of artificial intelligence in the digital era: Systematic literature review and future research directions. Int. J. Inf. Manag. 2021, 57, 102225. [Google Scholar] [CrossRef]

- ISO/IEC 42001; Information Technology—Artificial Intelligence—Management System. International Organization for Standardization: Geneva, Switzerland, 2023.

- Mytrofanova, H.; Yevtushenko, O.; Hlukhyy, A.; Lugovyy, M. Methodological principles of implementing artificial intelligence into organizational management system. Acad. Rev. 2024, 2, 173–189. [Google Scholar] [CrossRef]

- Masimov, O.; Hajiyev, Y. Integration of artificial intelligence (AI) in task management systems. PAHTEI-Proce. Azerbaijan High Tech. Educ. Inst. 2024, 41, 501–509. [Google Scholar] [CrossRef]

- Slattery, P.; Saeri, A.K.; Grundy, E.A.C.; Graham, J.; Noetel, M.; Uuk, R.; Dao, J.; Pour, S.; Casper, S.; Thompson, N. The AI risk repository: A comprehensive meta-review, database, and taxonomy of risks from artificial intelligence. arXiv 2024, arXiv:2408.12622. [Google Scholar] [CrossRef]

- Patel, M.; Patel, N. Exploring research methodology. Int. J. Res. Rev. 2019, 6, 48–55. [Google Scholar] [CrossRef]

- Božić, V. Integrated risk management and artificial intelligence in hospital. J. AI 2023, 7, 63–80. [Google Scholar] [CrossRef]

- Alchinov, A.I.; Avetisyan, K.R.; Druzhinina, T.Y. Artificial intelligence technologies in automation of corporate risk management. Proc. J. Phys. Conf. Ser. 2020, 1582, 12001. [Google Scholar] [CrossRef]

- Rahman, S.; Islam, M.; Hossain, I.; Ahmed, A. The role of AI and business intelligence in transforming organizational risk management. Int. J. Bus. Manag. Sci. 2024, 4, 7–31. [Google Scholar] [CrossRef]

- Shen, Q. AI-driven financial risk management systems: Enhancing predictive capabilities and operational efficiency. App. Comput. Eng. 2024, 69, 134–139. [Google Scholar] [CrossRef]

- Xu, H.; Niu, K.; Lu, T.; Li, S.; Lou, Q. Leveraging artificial intelligence for enhanced risk management in financial services: Current applications and future prospects. Acad. J. Sociol. Manag. 2024, 2, 38–53. [Google Scholar] [CrossRef]

- Daiya, H. AI-driven risk management strategies in financial technology. J. Artif. Intell. Gen. Sci. 2024, 5, 194–216. [Google Scholar] [CrossRef]

- Jan, Z.; Ahamed, F.; Mayer, W.; Patel, N.; Grossmann, G.; Stumptner, M.; Kuusk, A. Artificial intelligence for industry 4.0: Systematic review of applications, challenges, and opportunities. Expert Syst. Appl. 2023, 216, 119456. [Google Scholar] [CrossRef]

- Windmann, A.; Wittenberg, P.; Schieseck, M.; Niggemann, O. Artificial intelligence in Industry 4.0: A review of integration challenges for industrial systems. In Proceedings of the 2024 IEEE 22nd International Conference on Industrial Informatics (INDIN), Beijing, China, 18–20 August 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Samuels, A. Examining the integration of artificial intelligence in supply chain management from Industry 4.0 to 6.0: A systematic literature review. Front. Artif. Intell. 2025, 7, 1477044. [Google Scholar] [CrossRef] [PubMed]

- Kelíšek, A.; Studená, J.; Buganová, K.; Hudáková, M. The Degree of Risk Management Implementation in Enterprises in the Slovak Republic. Systems 2025, 13, 427. [Google Scholar] [CrossRef]

- Zdravković, M.; Panetto, H.; Weichhart, G. AI-enabled enterprise information systems for manufacturing. Enterp. Inf. Syst. 2022, 16, 668–720. [Google Scholar] [CrossRef]

- Biolcheva, P.; Molhova, M. Integration of AI supported risk management in ERP implementation. Comput. Inf. Sci. 2022, 15, 37. [Google Scholar] [CrossRef]

- Yang, M.; Petronijevic, J.; Etienne, A.; Siadat, A. A Framework Based on Natural Language Processing for Risk Management in Engineering. In Proceedings of the 2024 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 15–18 December 2024; pp. 968–973. [Google Scholar] [CrossRef]

- Aderamo, A.T.; Olisakwe, H.C.; Adebayo, Y.A.; Esiri, A.E. AI-driven HSE management systems for risk mitigation in the oil and gas industry. Compr. Res. Rev. Eng. Technol. 2024, 2, 1–22. [Google Scholar] [CrossRef]

- Skulimowski, A.M.J.; Łydek, P. Adaptive design of a cyber-physical system for industrial risk management decision support. In Proceedings of the 2022 17th International Conference on Control, Automation, Robotics and Vision (ICARCV), Singapore, 11–13 December 2022; pp. 90–97. [Google Scholar] [CrossRef]

- Nabeel, M.Z. AI-enhanced project management systems for optimizing resource allocation and risk mitigation: Leveraging big data analysis to predict project outcomes and improve decision-making processes in complex projects. Asian J. Multidiscip. Res. Rev. 2024, 5, 53–65. [Google Scholar] [CrossRef]

- Biolcheva, P.; Valchev, E. Roadmap for Risk Management Integration Using AI. J. Risk Control 2022, 9, 13–28. [Google Scholar] [CrossRef]

- Hajjaji, Y.; Boulila, W.; Farah, I.R.; Romdhani, I.; Hussain, A. Big data and IoT-based applications in smart environments: A systematic review. Comput. Sci. Rev. 2021, 39, 100318. [Google Scholar] [CrossRef]

- Ryabchykov, O.M. Using artificial intelligence for risk management in projects with the Scrum methodology. J. Strateg. Econ. Res. 2024, 1, 102–109. [Google Scholar] [CrossRef]

- Leach, N. Br (AI) n City: The AI-Enhanced City of the Future. In The Routledge Companion to Smart Design Thinking in Architecture & Urbanism for a Sustainable, Living Planet; Routledge: Oxfordshire, UK, 2024; pp. 212–220. [Google Scholar] [CrossRef]

- Tambe, P.; Cappelli, P.; Yakubovich, V. Artificial intelligence in human resources management: Challenges and a path forward. Calif. Manag. Rev. 2019, 61, 15–42. [Google Scholar] [CrossRef]

- Elahi, M.; Afolaranmi, S.O.; Martinez Lastra, J.L.; Perez Garcia, J.A. A comprehensive literature review of the applications of AI techniques through the lifecycle of industrial equipment. Discov. Artif. Intell. 2023, 3, 43. [Google Scholar] [CrossRef]

- Yu, Y.; Lakemond, N.; Holmberg, G. AI in the context of complex intelligent systems: Engineering management consequences. IEEE Trans. Eng. Manag. 2023, 71, 6512–6525. [Google Scholar] [CrossRef]

- Nozari, H.; Szmelter-Jarosz, A.; Ghahremani-Nahr, J. Analysis of the challenges of artificial intelligence of things (AIoT) for the smart supply chain (case study: FMCG industries). Sensors 2022, 22, 2931. [Google Scholar] [CrossRef]

- Shaw, J.; Rudzicz, F.; Jamieson, T.; Goldfarb, A. Artificial intelligence and the implementation challenge. J. Med. Internet Res. 2019, 21, e13659. [Google Scholar] [CrossRef]

- Anagnostou, M.; Karvounidou, O.; Katritzidaki, C.; Kechagia, C.; Melidou, K.; Mpeza, E.; Konstantinidis, I.; Kapantai, E.; Berberidis, C.; Magnisalis, I. Characteristics and challenges in the industries towards responsible AI: A systematic literature review. Ethics Inf. Technol. 2022, 24, 37. [Google Scholar] [CrossRef]

- Ahmadi, A. Implementing Artificial Intelligence in IT Management: Opportunities and Challenges. Asian J. Comput. Sci. Technol. 2023, 12, 18–23. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Implementing challenges of artificial intelligence: Evidence from public manufacturing sector of an emerging economy. Gov. Inf. Q. 2022, 39, 101624. [Google Scholar] [CrossRef]

- Cevallos, M.G.O.; Jaramillo, G.A.L.; Vélez, J.L.B.; Zambrano, M.I.U.; Montesdeoca, L.D.Z.; Palomeque, M.A.B. Implementation of artificial intelligence in quality management in SMEs: Benefits and challenges. Evol. Stud. Imag. Cult. 2024, 8, 1489–1500. [Google Scholar] [CrossRef]

- Bernardo, M.; Simon, A.; Tarí, J.J.; Molina-Azorín, J.F. Benefits of management systems integration: A literature review. J. Clean. Prod. 2015, 94, 260–267. [Google Scholar] [CrossRef]

- Dahlin, G.; Isaksson, R. Integrated management systems–interpretations, results, opportunities. TQM J. 2017, 29, 528–542. [Google Scholar] [CrossRef]

- Susilo, B.W.; Susanto, E. Employing artificial intelligence in management information systems to improve business efficiency. J. Manag. Inform. 2024, 3, 212–229. [Google Scholar] [CrossRef]

- Weng, Y.; Wu, J.; Kelly, T.; Johnson, W. Comprehensive overview of artificial intelligence applications in modern industries. arXiv 2024, arXiv:2409.13059. [Google Scholar] [CrossRef]

- Akbarpour, A. Challenges and Opportunities: Integrating AI into Resource Management Practices. J. Resour. Manag. Decis. Eng. 2023, 2, 1–3. [Google Scholar] [CrossRef]

- Amirabadi, M. Perspectives on Implementing AI in Resource Management. J. Resour. Manag. Decis. Eng. 2023, 2, 11–17. [Google Scholar] [CrossRef]

- Singh, N.; Adhikari, D. AI in inventory management: Applications, Challenges, and opportunities. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 2049–2053. [Google Scholar] [CrossRef]

- Shahzadi, G.; Jia, F.; Chen, L.; John, A. AI adoption in supply chain management: A systematic literature review. J. Manuf. Technol. Manag. 2024, 35, 1125–1150. [Google Scholar] [CrossRef]

- Eyo-Udo, N. Leveraging artificial intelligence for enhanced supply chain optimization. Open Access Res. J. Multidiscip. Stud. 2024, 7, 1–15. [Google Scholar] [CrossRef]

- Olutimehin, D.O.; Ofodile, O.C.; Ejibe, I.; Odunaiya, O.G.; Soyombo, O.T. Implementing AI in business models: Strategies for efficiency and innovation. Int. J. Manag. Entrep. Res. 2024, 6, 863–877. [Google Scholar] [CrossRef]

- Yams, N.B.; Richardson, V.; Shubina, G.E.; Albrecht, S.; Gillblad, D. Integrated AI and innovation management: The beginning of a beautiful friendship. Technol. Innov. Manag. Rev. 2020, 10, 5–18. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Z.; Liu, A.; Tao, F. Artificial intelligence in product lifecycle management. Int. J. Adv. Manuf. Technol. 2021, 114, 771–796. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Critical analysis of the impact of artificial intelligence integration with cutting-edge technologies for production systems. J. Intell. Manufact. 2025, 36, 61–93. [Google Scholar] [CrossRef]

- Jiang, X.; Jiang, X.; Sun, W.; Fan, W. How do manufacturing firms manage artificial intelligence to drive iterative product innovation? IEEE Trans. Eng. Manag. 2023, 71, 6090–6102. [Google Scholar] [CrossRef]

- Schnitzer, R.; Hapfelmeier, A.; Gaube, S.; Zillner, S. AI Hazard Management: A framework for the systematic management of root causes for AI risks. In Proceedings of the 1st International Conference on Frontiers of AI, Ethics, and Multidisciplinary Applications (FAIEMA), Athens, Greece, 25–26 September 2023; pp. 359–375. [Google Scholar] [CrossRef]

- Zhao, W. Implementation of Using AI to Manage Known and Unknown Risks in Risk Management. In Proceedings of the ICBAR 2023: 2023 3rd International Conference on Big Data, Artificial Intelligence and Risk Management, Chengdu, China, 24–26 November 2023; pp. 743–749. [Google Scholar] [CrossRef]

- Lee, J.; Ni, J.; Singh, J.; Jiang, B.; Azamfar, M.; Feng, J. Intelligent maintenance systems and predictive manufacturing. J. Manuf. Sci. Eng. 2020, 142, 110805. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Lin, X. Artificial Intelligence in the Industrial Engineering. Adv. Oper. Res. Prod. Manag. 2024, 1, 1–6. [Google Scholar] [CrossRef]

- Andronie, M.; Lăzăroiu, G.; Iatagan, M.; Uță, C.; Ștefănescu, R.; Cocoșatu, M. Artificial intelligence-based decision-making algorithms, internet of things sensing networks, and deep learning-assisted smart process management in cyber-physical production systems. Electronics 2021, 10, 2497. [Google Scholar] [CrossRef]

- Lodhi, S.K.; Gill, A.Y.; Hussain, I. AI-powered innovations in contemporary manufacturing procedures: An extensive analysis. Int. J. Multidiscip. Sci. Arts 2024, 3, 15–25. [Google Scholar] [CrossRef]

- Suvarna, M.; Yap, K.S.; Yang, W.; Li, J.; Ng, Y.T.; Wang, X. Cyber–physical production systems for data-driven, decentralized, and secure manufacturing—A perspective. Engineering 2021, 7, 1212–1223. [Google Scholar] [CrossRef]

- George, A.S.; George, A.S.H. A review of ChatGPT AI’s impact on several business sectors. Partn. Univers. Int. Innov. J. 2023, 1, 9–23. [Google Scholar] [CrossRef]

- Schöggl, J.-P.; Rusch, M.; Stumpf, L.; Baumgartner, R.J. Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector. Sustain. Prod. Consum. 2023, 35, 401–420. [Google Scholar] [CrossRef]

- Rakholia, R.; Suárez-Cetrulo, A.L.; Singh, M.; Carbajo, R.S. Advancing Manufacturing Through Artificial Intelligence: Current Landscape, Perspectives, Best Practices, Challenges and Future Direction. IEEE Access 2024, 12, 131621–131637. [Google Scholar] [CrossRef]

- Adenekan, O.A.; Solomon, N.O.; Simpa, P.; Obasi, S.C. Enhancing manufacturing productivity: A review of AI-Driven supply chain management optimization and ERP systems integration. Int. J. Manag. Entrep. Res. 2024, 6, 1607–1624. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Artificial intelligence applications for industry 4.0: A literature-based study. J. Ind. Integr. Manag. 2022, 7, 83–111. [Google Scholar] [CrossRef]

- Rizvi, A.T.; Haleem, A.; Bahl, S.; Javaid, M. Artificial intelligence (AI) and its applications in Indian manufacturing: A review. In Current Advances in Mechanical Engineering: Select Proceedings of ICRAMERD 2020; Springer: Singapore, 2021; pp. 825–835. [Google Scholar] [CrossRef]

- Rai, R.; Tiwari, M.K.; Ivanov, D.; Dolgui, A. Machine learning in manufacturing and industry 4.0 applications. Int. J. Prod. Res. 2021, 59, 4773–4778. [Google Scholar] [CrossRef]

- Inkulu, A.K.; Bahubalendruni, M.V.A.R.; Dara, A.; K, S. Challenges and opportunities in human robot collaboration context of Industry 4.0-a state of the art review. Ind. Robot Int. J. Rob. Res. Appl. 2022, 49, 226–239. [Google Scholar] [CrossRef]

- Adenekan, O.A.; Ezeigweneme, C.; Chukwurah, E.G. Strategies for protecting IT supply chains against cybersecurity threats. Int. J. Manag. Entrep. Res. 2024, 6, 1598–1606. [Google Scholar] [CrossRef]

- Williamson, S.; Vijayakumar, K. Artificial intelligence techniques for industrial automation and smart systems. Concurr. Eng. 2021, 29, 291–292. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, J.; Jin, Y. Artificial intelligence in recommender systems. Complex Intell. Syst. 2021, 7, 439–457. [Google Scholar] [CrossRef]

- Zhukov, A.; Berkutova, T.; Zhurenkov, D.; Tikhonov, A.; Khachaturyan, K.; Kartsan, I. Prospects for deployment of integrated production automation systems using artificial intelligence. In Proceedings of the IV International Conference on Geotechnology, Mining and Rational Use of Natural Resources (GEOTECH-2024), Navoi, Uzbekistan, 3–5 April 2024; Volume 525, p. 5006. [Google Scholar] [CrossRef]

- Akinsolu, M.O. Applied artificial intelligence in manufacturing and industrial production systems: PEST considerations for engineering managers. IEEE Eng. Manag. Rev. 2022, 51, 52–62. [Google Scholar] [CrossRef]

- Antonova, I.I.; Smirnov, V.A.; Efimov, M.G. Integrating artificial intelligence into ERP systems: Advantages, disadvantages and prospects. Russ. J. Econ. Law 2024, 18, 619–640. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Androniceanu, A.; Grecu, I.; Grecu, G.; Neguriță, O. Artificial intelligence-based decision-making algorithms, Internet of Things sensing networks, and sustainable cyber-physical management systems in big data-driven cognitive manufacturing. Oeconomia Copernic. 2022, 13, 1047–1080. [Google Scholar] [CrossRef]

- Luo, D.; Thevenin, S.; Dolgui, A. A state-of-the-art on production planning in Industry 4.0. Int. J. Prod. Res. 2023, 61, 6602–6632. [Google Scholar] [CrossRef]

- Kühne, T.; Song, X.; Caire, G.; Rasilainen, K.; Le, T.H.; Rossi, M.; Ndip, I.; Fager, C. Performance simulation of a 5G hybrid beamforming millimeter-wave system. In Proceedings of the WSA 2020; 24th International ITG Workshop on Smart Antennas, Hamburg, Germany, 18–20 February 2020; pp. 1–6. [Google Scholar]

- Ahmed, M.I.B.; Saraireh, L.; Rahman, A.; Al-Qarawi, S.; Mhran, A.; Al-Jalaoud, J.; Al-Mudaifer, D.; Al-Haidar, F.; AlKhulaifi, D.; Youldash, M. Personal protective equipment detection: A deep-learning-based sustainable approach. Sustainability 2023, 15, 13990. [Google Scholar] [CrossRef]

- Algarni, A.M.; Thayananthan, V. Cybersecurity for Analyzing Artificial Intelligence (AI)-Based Assistive Technology and Systems in Digital Health. Systems 2025, 13, 439. [Google Scholar] [CrossRef]

- Benbya, H.; Davenport, T.H.; Pachidi, S. Special Issue Editorial: Artificial Intelligence in Organizations: Current State and Future Opportunities. MIS Q. Exec. 2020, 19, 4. [Google Scholar] [CrossRef]

- Dey, P.K.; Chowdhury, S.; Abadie, A.; Vann Yaroson, E.; Sarkar, S. Artificial intelligence-driven supply chain resilience in Vietnamese manufacturing small-and medium-sized enterprises. Int. J. Produc. Res. 2024, 62, 5417–5456. [Google Scholar] [CrossRef]

- Fosso Wamba, S.; Queiroz, M.M.; Pappas, I.O.; Sullivan, Y. Artificial intelligence capability and firm performance: A sustainable development perspective by the mediating role of data-driven culture. Inf. Syst. Front. 2024, 26, 2189–2203. [Google Scholar] [CrossRef]

- Macrae, C. Managing risk and resilience in autonomous and intelligent systems: Exploring safety in the development, deployment, and use of artificial intelligence in healthcare. Risk Anal. 2025, 45, 910–927. [Google Scholar] [CrossRef]

- Metwally, A.B.M.; Ali, S.A.M.; Mohamed, A.T.I. Thinking responsibly about responsible AI in risk management: The darkside of AI in RM. In Proceedings of the 2024 ASU International Conference in Emerging Technologies for Sustainability and Intelligent Systems (ICETSIS), Manama, Bahrain, 28–29 January 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Steimers, A.; Schneider, M. Sources of risk of AI systems. Int. J. Environ. Res. Public Health 2022, 19, 3641. [Google Scholar] [CrossRef]

- Karim, H.; Gupta, D.; Sitharaman, S. Securing LLM workloads with NIST AI RMF in the internet of robotic things. IEEE Access 2025, 13, 69631–69649. [Google Scholar] [CrossRef]

- Gipiškis, R.; Joaquin, A.S.; Chin, Z.S.; Regenfuß, A.; Gil, A.; Holtman, K. Risk sources and risk management measures in support of standards for general-purpose AI systems. arXiv 2024, arXiv:2410.23472. [Google Scholar] [CrossRef]

- Ashta, A.; Herrmann, H. Artificial intelligence and fintech: An overview of opportunities and risks for banking, investments, and microfinance. Strat. Change 2021, 30, 211–222. [Google Scholar] [CrossRef]

- Jedličková, A. Ethical considerations in risk management of autonomous and intelligent systems. Ethics Bioeth. 2024, 14, 80–95. [Google Scholar] [CrossRef]

- Banja, J. How might artificial intelligence applications impact risk management? AMA J. Ethics 2020, 22, 945–951. [Google Scholar]

- Paté-Cornell, E. Preferences in AI algorithms: The need for relevant risk attitudes in automated decisions under uncertainties. Risk Anal. 2024, 44, 2317–2323. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.; Gupta, R.; Borg, M.; Engström, E.; Lysek, M. AI Act High-Risk Requirements Readiness: Industrial Perspectives and Case Company Insights. In Proceedings of the 25th International Conference on Product-Focused Software Process Improvement, Tartu, Estonia, 2–4 December 2024; pp. 67–83. [Google Scholar] [CrossRef]

- Marvin Imperial, J.; Jones, M.D.; Tayyar Madabushi, H. Standardizing Intelligence: Aligning Generative AI for Regulatory and Operational Compliance. arXiv 2025, arXiv:2503.04736. [Google Scholar] [CrossRef]

- Gill, S.S.; Xu, M.; Ottaviani, C.; Patros, P.; Bahsoon, R.; Shaghaghi, A.; Golec, M.; Stankovski, V.; Wu, H.; Abraham, A. AI for next generation computing: Emerging trends and future directions. Internet Things 2022, 19, 100514. [Google Scholar] [CrossRef]

- Enholm, I.M.; Papagiannidis, E.; Mikalef, P.; Krogstie, J. Artificial intelligence and business value: A literature review. Inf. Sys. Front. 2022, 24, 1709–1734. [Google Scholar] [CrossRef]

- Campos Zabala, F.J. The Barriers for Implementing AI. In Grow Your Business with AI: A First Principles Approach for Scaling Artificial Intelligence in the Enterprise; Springer: Berkeley, CA, USA, 2023; pp. 85–110. [Google Scholar] [CrossRef]

- Țîrcovnicu, G.-I.; Hațegan, C.-D. Integration of artificial intelligence in the risk management process: An analysis of opportunities and challenges. J. Financ. Stud. 2023, 8, 198–214. [Google Scholar] [CrossRef]

- Tariq, M.U.; Poulin, M.; Abonamah, A.A. Achieving operational excellence through artificial intelligence: Driving forces and barriers. Front. Psychol. 2021, 12, 686624. [Google Scholar] [CrossRef]

- ISO 9001; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 14001; Environmental Management Systems—Requirements with Guidance for Use 2015. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 45001; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Danielsson, J.; Macrae, R.; Uthemann, A. Artificial intelligence and systemic risk. J. Bank. Financ. 2022, 140, 106290. [Google Scholar] [CrossRef]

- Braganza, A.; Chen, W.; Canhoto, A.; Sap, S. Productive employment and decent work: The impact of AI adoption on psychological contracts, job engagement and employee trust. J. Bus. Res. 2021, 131, 485–494. [Google Scholar] [CrossRef] [PubMed]

- Bhargava, A.; Bester, M.; Bolton, L. Employees’ perceptions of the implementation of robotics, artificial intelligence, and automation (RAIA) on job satisfaction, job security, and employability. J. Technol. Behav. Sci. 2021, 6, 106–113. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Niu, X.; Chen, F.; Zhou, H. Does artificial intelligence promote or inhibit on-the-job learning? Human reactions to AI at work. Systems 2023, 11, 114. [Google Scholar] [CrossRef]

- Caiazzo, B.; Murino, T.; Petrillo, A.; Piccirillo, G.; Santini, S. An IoT-based and cloud-assisted AI-driven monitoring platform for smart manufacturing: Design architecture and experimental validation. J. Manuf. Technol. Manag. 2023, 34, 507–534. [Google Scholar] [CrossRef]

- Ren, H.; Anicic, D.; Runkler, T.A. Towards semantic management of on-device applications in industrial IoT. ACM Trans. Internet Technol. 2022, 22, 1–30. [Google Scholar] [CrossRef]

- Li, Y.-F.; Wang, H.; Sun, M. ChatGPT-like large-scale foundation models for prognostics and health management: A survey and roadmaps. Reliab. Eng. Sys. Saf. 2024, 243, 109850. [Google Scholar] [CrossRef]

- Sodhro, A.H.; Pirbhulal, S.; De Albuquerque, V.H.C. Artificial intelligence-driven mechanism for edge computing-based industrial applications. IEEE Trans. Ind. Inform. 2019, 15, 4235–4243. [Google Scholar] [CrossRef]

- Singh, S.K.; Rathore, S.; Park, J.H. Blockiotintelligence: A blockchain-enabled intelligent IoT architecture with artificial intelligence. Future Gener. Comput. Syst. 2020, 110, 721–743. [Google Scholar] [CrossRef]

- Li, X.; Xie, C.; Zhao, Z.; Wang, C.; Yu, H. Anomaly detection algorithm of industrial internet of things data platform based on deep learning. IEEE Trans. Green Commun. Netw. 2024, 8, 1037–1048. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Gedeon, T.; Rogalska, E.; Valaskova, K.; Nagy, M.; Musa, H.; Zvarikova, K.; Poliak, M.; Horak, J.; Crețoiu, R.I. Digital twin-based cyber-physical manufacturing systems, extended reality metaverse enterprise and production management algorithms, and Internet of Things financial and labor market technologies in generative artificial intelligence economics. Oeconomia Copernic. 2024, 15, 837–870. [Google Scholar] [CrossRef]

- Khowaja, S.A.; Dev, K.; Qureshi, N.M.F.; Khuwaja, P.; Foschini, L. Toward industrial private AI: A two-tier framework for data and model security. IEEE Wirel. Commun. 2022, 29, 76–83. [Google Scholar] [CrossRef]

- Choi, S.-W.; Lee, E.-B.; Kim, J.-H. The engineering machine-learning automation platform (emap): A big-data-driven ai tool for contractors’ sustainable management solutions for plant projects. Sustainability 2021, 13, 10384. [Google Scholar] [CrossRef]

- Bengio, Y.; Hinton, G.; Yao, A.; Song, D.; Abbeel, P.; Darrell, T.; Harari, Y.N.; Zhang, Y.-Q.; Xue, L.; Shalev-Shwartz, S. Managing extreme AI risks amid rapid progress. Science 2024, 384, 842–845. [Google Scholar] [CrossRef]

- McLean, S.; King, B.J.; Thompson, J.; Carden, T.; Stanton, N.A.; Baber, C.; Read, G.J.M.; Salmon, P.M. Forecasting emergent risks in advanced AI systems: An analysis of a future road transport management system. Ergonomics 2023, 66, 1750–1767. [Google Scholar] [CrossRef]

- Qureshi, N.I.; Garg, A.; Singh, P.; Retzlaff, N. AI and Corporate Risk Management: Identifying and Mitigating Technological and Ethical Risks. In Proceedings of the 2024 International Conference on Knowledge Engineering and Communication Systems (ICKECS), Chikkaballapur, India, 18–19 April 2024; Volume 1, pp. 1–5. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Wong, L.-W.; Tan, G.W.-H.; Ooi, K.-B.; Lin, B.; Dwivedi, Y.K. Artificial intelligence-driven risk management for enhancing supply chain agility: A deep-learning-based dual-stage PLS-SEM-ANN analysis. Int. J. Prod. Res. 2024, 62, 5535–5555. [Google Scholar] [CrossRef]

- Ispas, L.; Mironeasa, C.; Silvestri, A. Risk-based approach in the implementation of integrated management systems: A systematic literature review. Sustainability 2023, 15, 10251. [Google Scholar] [CrossRef]

- Gvozdev, E. Risk assessment methodology within the framework of integrated safety of industrial enterprises. In Proceedings of the International Scientific and Practical Symposium “The Future of the Construction Industry: Challenges and Development Prospects” (FCI-2023), Moscow, Russia, 18–22 September 2023; Volume 457, p. 2004. [Google Scholar] [CrossRef]

- Barbosa, A.d.S.; Bueno da Silva, L.; Morioka, S.N.; da Silva, J.M.N.; de Souza, V.F. Integrated management systems and organizational performance: A multidimensional perspective. Total Qual. Manag. Bus. Excell. 2023, 34, 1469–1507. [Google Scholar] [CrossRef]

- Grynko, T.; Gviniashvili, T.; Yuldashev, R. Analysis of risk management systems in enterprises. Ekon. Anal. 2024, 34, 223–236. [Google Scholar] [CrossRef]

- Berger, T.; Gleißner, W. Integrated management systems: Linking risk management and management control systems. Int. J. Risk Assess. Manag. 2018, 21, 215–231. [Google Scholar] [CrossRef]

- Nuhic-Meskovic, M.; Meskovic, A. Risk Management Culture, Structure, and Process: Theoretical Insights and Empirical Evidence. Int. Bus. Res. 2023, 16, 1–10. [Google Scholar] [CrossRef]

- Oliveira, K.; Méxas, M.; Meirino, M.; Drumond, G. Critical success factors associated with the implementation of enterprise risk management. J. Risk Res. 2019, 22, 1004–1019. [Google Scholar] [CrossRef]

- Jain, P.; Pasman, H.J.; Waldram, S.; Pistikopoulos, E.N.; Mannan, M.S. Process Resilience Analysis Framework (PRAF): A systems approach for improved risk and safety management. J. Loss Prev. Process. Ind. 2018, 53, 61–73. [Google Scholar] [CrossRef]

- Algheriani, N.M.S.; Kirin, S.; Spasojevic Brkic, V. Risk model for integrated management system. Teh. Vjesn. 2019, 26, 1833–1840. [Google Scholar]

- Ho, L.T.; Lin, G.C.I. Critical success factor framework for the implementation of integrated-enterprise systems in the manufacturing environment. Int. J. Prod. Res. 2004, 42, 3731–3742. [Google Scholar] [CrossRef]

- Su, C.; Ma, J.; Wang, C.; Deng, J.; Chen, W. Flood-induced coal mine disaster chain evolution and risk analysis. Nat. Hazard. 2025, 121, 21031–21058. [Google Scholar] [CrossRef]

- Cao, Y.; Zandi, Y.; Agdas, A.S.; Wang, Q.; Qian, X.; Fu, L.; Wakil, K.; Selmi, A.; Issakhov, A.; Roco-Videla, A. A review study of application of artificial intelligence in construction management and composite beams. Steel Compos. Struct. Int. J. 2021, 39, 685–700. [Google Scholar] [CrossRef]

- Hsiao, L.-S.; Huang, C.-J.; Liu, H.-T.; Lin, I.-L. An AHP-Based Assessment of the Relative Importance of Risk Factors in Project Management: Designing a Bid Preparation Checklist. Systems 2025, 13, 328. [Google Scholar] [CrossRef]

- Zeng, Y.; Klyman, K.; Zhou, A.; Yang, Y.; Pan, M.; Jia, R.; Song, D.; Liang, P.; Li, B. AI risk categorization decoded (AIR 2024): From government regulations to corporate policies. arXiv 2024, arXiv:2406.17864. [Google Scholar] [CrossRef]

- Becker, N.; Junginger, P.; Martinez, L.; Krupka, D.; Beining, L. AI at work—Mitigating safety and discriminatory risk with technical standards. arXiv 2021, arXiv:2108.11844. [Google Scholar] [CrossRef]

- Cantero Gamito, M.; Marsden, C.T. Artificial intelligence co-regulation? The role of standards in the EU AI Act. Int. J. Law Inf. Technol. 2024, 32, eaae011. [Google Scholar] [CrossRef]

- Golpayegani, D.; Pandit, H.J.; Lewis, D. Airo: An ontology for representing AI risks based on the proposed EU AI act and ISO risk management standards. In Towards a Knowledge-Aware AI; IOS Press: Amsterdam, The Netherlands, 2022; pp. 51–65. [Google Scholar] [CrossRef]

- Anderljung, M.; Barnhart, J.; Korinek, A.; Leung, J.; O’Keefe, C.; Whittlestone, J.; Avin, S.; Brundage, M.; Bullock, J.; Cass-Beggs, D. Frontier AI regulation: Managing emerging risks to public safety. arXiv 2023, arXiv:2307.03718. [Google Scholar] [CrossRef]

- Sherman, E.; Eisenberg, I. AI risk profiles: A standards proposal for pre-deployment AI risk disclosures. In Proceedings of the 38th AAAI Conference on Artificial Intelligence, Vancouver, BC, Canada, 20–27 February 2024; Volume 38, pp. 23047–23052. [Google Scholar] [CrossRef]

- Guihot, M.; Matthew, A.F.; Suzor, N.P. Nudging robots: Innovative solutions to regulate artificial intelligence. Vand. J. Ent. Tech. Law 2017, 20, 385. [Google Scholar] [CrossRef]

- Howard, J.; Schulte, P. Managing workplace AI risks and the future of work. Am. J. Ind. Med. 2024, 67, 980–993. [Google Scholar] [CrossRef]

- Agapiou, A. A systematic review of the socio-legal dimensions of responsible AI and its role in improving health and safety in construction. Buildings 2024, 14, 1469. [Google Scholar] [CrossRef]

| No. | Name of the Strategy for Implementation | Description of the Strategy | Authors |

|---|---|---|---|

| 1. | Using a dashboard to track AI progress | There must be a document that clearly shows the evolution of integrating AI into risk management. This should cover all stages, from raising awareness of the need for AI, to carrying out the necessary analyses and preparing for implementation, and finally ensuring the system is functioning properly. | [28,29] |

| 2. | Automatic extraction of risk factors from large volumes of textual data | Sing NLP (Natural Language Processing) algorithms to analyze documentation, audit reports, and legislation to update the risk matrix | [30] |

| 3. | Using AI technologies for monitoring and prediction | In industries such as oil and gas, AI can be integrated into health, safety, and environment (HSE) management systems to improve real-time monitoring and predictive risk management. This enables proactive risk identification and mitigation. | [31] |

| 4. | Automating and optimizing project management processes | AI can optimize resource allocation and mitigate risks in project management through big data analysis and scenario simulation. | [32,33] |

| 5. | Integration into ERP projects | AI can be used to enhance the risk assessment methodology employed in ERP projects, enabling managers to respond more swiftly to emerging threats. | [34] |

| 6. | Integration with IoT and Big Data | AI can correlate data from sensors and monitoring equipment, as well as human reports, to provide smart monitoring of identified environmental aspects. It can also monitor hazards and factors affecting employee health and safety. | [35] |

| 7. | Risk assessment in agile projects | In IT projects managed using the Scrum methodology, AI can improve the accuracy and depth of risk assessments, enabling proactive risk management. | [36] |

| 8. | Assessing the risks of implementing AI | Using an appropriate taxonomy in identifying and classifying risks that arise in AI systems. | [16] |

| No. | Opportunity | Details | Authors |

|---|---|---|---|

| 1. | Increasing the efficiency and quality of decisions | AI allows for the optimization of data and information flows used in decision-making and can improve decision-making processes by reducing time | [49,50] |

| 2. | Decision support | AI provides decision support by identifying patterns and anomalies in data | [44,49] |

| 3. | Improving operational efficiency | AI can automate routine tasks, optimize workflows, leading to increased operational efficiency, driving increased productivity and economic efficiency | [32,44,49] |

| 4. | Cost reduction | Implementing AI can reduce operational costs by optimizing resources and automating processes | [44,49] |

| 5. | Transforming resource management | AI transforms resource management practices through efficiency and innovation | [51,52] |

| 6. | Supply chain optimization | AI improves demand forecasting, inventory management, and logistics optimization | [53,54,55] |

| 7. | Strategic innovation | AI drives innovation by integrating advanced technologies such as machine learning and natural language processing | [55,56] |

| 8. | Innovation and continuous improvement | AI identifies new opportunities for product development and innovative processes | [57,58,59,60] |

| 9. | Improving customer satisfaction | AI can improve customer satisfaction through faster and more accurate decision-making processes | [49] |

| 10. | Sustainability and environmental management | AI contributes to sustainable practices by optimizing resource use, real-time monitoring for rapid identification of deviations, proposing solutions to reduce environmental impact, and reducing emissions and waste | [24,51,53] |

| 11. | Decision support and IMS risk management | AI allows for the identification of trends and the anticipation of operational, environmental, or OHSAS risks | [26,28,50,61,62] |

| No. | Advantages | Description of the Obtained Advantages | Authors |

|---|---|---|---|

| 1. | Predictive maintenance | Machine learning algorithms minimize downtime and optimize resource allocation. | [63,64,65,66,67] |

| 2. | Operational optimization | Real-time data analysis improves decision-making and resource utilization. | [65,68,69,70,71,72] |

| 3. | Quality control | Advanced image recognition and machine learning ensure higher standards. | [63,65,68,71,73,74,75] |

| 4. | Human–machine Collaboration | Collaborative robots and AI are improving production capabilities. | [63,76,77,78] |

| 5. | Process automation | Reducing human intervention increases product efficiency and innovation. | [78,79,80,81] |

| 6. | Accelerated financial analysis | AI improves budgeting accuracy and reduces planning time. | [65,82] |

| 7. | Productivity increase | Optimizing production processes and reducing equipment downtime. | [68,75,77,80,82] |

| 8. | Improving customer relations | Optimization of customer relationships and business processes. | [65,82] |

| 9. | Automation of logistics | AI improves production logistics and supplier interaction management. | [80,83] |

| 10. | Supply chain management | AI predicts demand, optimizes inventory, and streamlines routes. | [26,63,65,72,84] |

| 11. | Data-driven decisions | AI facilitates informed decision-making and agile response to market conditions. | [67,68,72] |

| 12. | Reducing inventory management costs | AI optimizes inventory management and reduces costs. | [67,82] |

| 13. | Improving transparency | AI increases transparency in supply chain processes. | [67,72] |

| 14. | Increasing flexibility | AI enables smarter and more flexible systems in production. | [67,71] |

| 15. | Improving cross-functional collaboration | ERP integration facilitates collaboration and real-time data exchange. | [68,72] |

| 16. | Intelligent process planning | AI assists intelligent process planning through deep learning. | [59,68,75,78,83] |

| 17. | Increasing customer satisfaction | Higher quality standards improve customer satisfaction. | [67,73,74,81] |

| 18. | Error reduction | AI improves accuracy and reduces errors at rates beyond human capacity. | [78,80] |

| 19. | Increasing sustainability | AI contributes to the creation of sustainable industrial value. | [66,68,75,80,85] |

| 20. | Improving data security | AI requires robust security elements to protect data. | [78,86,87] |

| No. | Description of the Risk | Detailing the Risk | Authors |

|---|---|---|---|

| 1. | Impact on organizational culture and employees | The use of AI can transform the organization by changing structure and authority; it can introduce additional complexity, which can increase resistance to change. | [88,89,90] |

| 2. | Errors in data processing and decision-making | AI can generate wrong decisions if the input information is incorrect, incomplete, or inaccurate. | [40,61] |

| 3. | Lack of transparency in data processing | AI can operate as a “black box”, making it difficult to understand how decisions are made; AI algorithms can be designed or trained on biased data. | [91,92] |

| 4. | Cybersecurity impact | AI systems can be vulnerable to cyberattacks, which can compromise data and system operation. | [26,92,93,94] |

| 5. | Inadequate implementation | AI can be a source of risks depending on the existing variant, the lifecycle of the IMS, and the interaction with it. | [61,93,95] |

| 6. | The quality of the data used | Insufficient data, of poor quality, unreliable, and with an uncertain prediction. | [25,45] |

| 7. | Algorithmic bias | AI algorithms can perpetuate or amplify existing biases or errors in training data, affecting the accuracy of decisions. | [93,95,96,97] |

| 8. | Privacy issues | The use of AI can lead to data privacy breaches, especially if data is used without consent. | [97,98] |

| 9. | Reduced human factor supervision | Excessive automation can reduce human oversight, increasing the risk of unnoticed errors. | [97] |

| 10. | Difficulties in managing large volumes of data | AI requires processing large amounts of data, which can be difficult to manage. | [20] |

| 11. | High implementation costs | Implementing and maintaining AI systems can be expensive. | [20,41] |

| 12. | Ethical challenges | Automated decisions carry ethical risks that can have negative impacts on individuals and society. | [43,97] |

| 13. | Uncertainties in data manipulation | There are risks related to the incorrect manipulation and interpretation of data. | [92,99] |

| 14. | Ensuring compliance with legal and regulatory requirements | Limitations in the design and sources of AI training can lead to non-compliance with legal and reputational impacts. | [100,101] |

| 15. | Regulatory challenges | Lack of clear regulations can lead to inappropriate use of AI. | [23,92] |

| 16. | Excessive dependence on technology | Decisions in the organization may neglect human intervention that requires the use of critical skills to analyze processes. | [54,102] |

| No. | Type | Category | Authors |

|---|---|---|---|

| 1. | Technological barriers | Quality and availability of data provided a. Lack of a standardized collection and storage system; b. Lack of data standardization, which complicates their processing and analysis by AI algorithms; c. Difficulties in integrating relevant historical data; d. Recording errors; e. Confidentiality. | [20,26,93,103,104,105] |

| Use of hardware, software, and data infrastructure a. Lack of MLOps platforms for “controlled” and auditable operation. b. The hardware is outdated and cannot support advanced computational algorithms; c. Lack of interoperability between different systems; d. Need for investments in IT infrastructure; e. AI integration requires an infrastructure with advanced resources, quality input data, and functional and robust processes. | |||

| Lack of transparency of computational algorithms a. Users’ distrust of AI recommendations; b. Ability to justify certain decisions to auditors or authorities; c. AI models are often opaque, which makes it difficult to audit, validate, and accept decisions; d. Lack of human validation of some decisions. | |||

| 2. | Organizational barriers | Lack of AI alignment with risk management objectives: a. Unclear objectives; b. Difficult mapping of processes and performance indicators; c. Management of AI-assisted decisions; d. Failure to assign responsibilities to the process owner; e. Lack of sufficient evidence for SMI audit and associated risks. | [20,26,104,106] |

| Lack of competencies in using AI and of specialists in the field a. Data science and machine learning; b. Cybersecurity; c. Risk management and auditing. | |||

| Integrating AI with existing processes: a. Organizations use traditional management methods using ISO 9001 [107], ISO 14001 [108], ISO 45001 [109], etc. b. Risk management related to bias, transparency and accountability; c. Over-reliance on AI for environmental and OHSAS hazard identification. | |||

| 3. | Legal, ethical and, security barriers | Regulatory compliance: a. There are no standards for auditing and validating AI systems b. Regulations on personal data protection; c. Regulations in certain areas such as transport, energy, pharmaceuticals, etc.; d. Ensuring legality regarding documented information control and confidentiality requirements. | [18,93,104,106] |

| Ethical and liability issues: a. Potential for discrimination due to data bias; b. Lack of control over decision-making using AI; c. Monitoring employee behavior. | |||

| Cybersecurity: a. Data poisoning; b. Attacks on hardware, software, and data infrastructure running AI. | |||

| 4. | Economic and resource barriers | Developing and implementing AI requires a. Purchasing hardware, software, data, consulting, and staff training; b. Purchasing licenses; c. Costs for integrating existing systems with AI; d. Infrastructure changes; e. Costs of specialized personnel; f. Uncertain return on investment. | [22,23,104,110] |

| Maintenance and update costs a. AI must be constantly updated to be able to detect potential risks. | |||

| 5. | Human barriers | Resistance to change a. Conservative organizational culture, b. Employee reluctance to use AI; c. Dilemma of ensuring job satisfaction; d. Concerns about new responsibilities and work tasks; e. Fear of replacement by AI; f. Communication and collaboration issues. | [103,104,111,112,113] |

| Uncertainties a. Lack of trust in the recommendations or decisions of an AI system; b. Overconfidence leading to loss of vigilance and critical analysis skills; c. Responsibility and accountability regarding the use of AI. |

| No. | IoT Devices and Technologies for Data Collection and IMS Risk Management | Detailed Description of IoT Devices and Technologies for Data Collection and IMS Risk Management | Authors |

|---|---|---|---|

| 1. | IoT and cloud-based monitoring platforms | Utilizing AI techniques such as auto-encoders and fuzzy inference systems, these platforms facilitate comprehensive production system health assessment and anomaly detection. | [114] |

| 2. | IoT devices with semantic management | Industrial IoT devices use on-device applications to analyze data in real time, facilitating decision-making at the edge through techniques like TinyML and complex event processing. | [115] |

| 3. | Operational and Prognostic Management (PHM) Systems | AI-based PHM technologies are used for condition monitoring, failure prediction, and equipment operability management in various industries. | [116] |

| 4. | Edge computing with AI | Integrating AI into edge computing improves the computing speed and energy efficiency of industrial IoT devices, making it essential for monitoring industrial platforms. | [117] |

| 5. | Intelligent IoT architectures with blockchain | IoT architectures that integrate blockchain and AI enable efficient big data analysis and ensure data security and privacy. | [118] |

| 6. | Anomaly detection algorithms | Deep learning algorithms to detect anomalies in industrial IoT data are used, improving the accuracy of predictions and reducing the risks of cyberattacks. | [119] |

| 7. | AI-based HSE management systems | These systems use AI to monitor safety in real-time and manage risks proactively in industries such as oil and gas. | [31] |

| 8. | Digital Twin Systems | Digital Twin and Generative AI technologies are used to simulate and manage assets in cyber-physical production environments. | [120] |

| 9. | Private AI Frameworks for Industrial IoT | Private AI frameworks combine continuous learning and encryption to ensure data and model security in industrial IoT environments. | [121] |

| 10. | Machine Learning-based automation platforms | Automation platforms use AI and big data technology to inform engineering project decisions, thereby improving risk management and work accuracy. | [122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ispas, L.; Mironeasa, C.; Severin, T.-L.; Cerlincă, D.-A.; Mironeasa, S. Artificial Intelligence Applications in Risk Management Within Integrated Management Systems: A Review. Systems 2025, 13, 967. https://doi.org/10.3390/systems13110967

Ispas L, Mironeasa C, Severin T-L, Cerlincă D-A, Mironeasa S. Artificial Intelligence Applications in Risk Management Within Integrated Management Systems: A Review. Systems. 2025; 13(11):967. https://doi.org/10.3390/systems13110967

Chicago/Turabian StyleIspas, Lucian, Costel Mironeasa, Traian-Lucian Severin, Delia-Aurora Cerlincă, and Silvia Mironeasa. 2025. "Artificial Intelligence Applications in Risk Management Within Integrated Management Systems: A Review" Systems 13, no. 11: 967. https://doi.org/10.3390/systems13110967

APA StyleIspas, L., Mironeasa, C., Severin, T.-L., Cerlincă, D.-A., & Mironeasa, S. (2025). Artificial Intelligence Applications in Risk Management Within Integrated Management Systems: A Review. Systems, 13(11), 967. https://doi.org/10.3390/systems13110967