How to Facilitate Safety Performance of Human–Robot Collaboration in High-Rise Construction Scenarios: An Empirical Model

Abstract

1. Introduction

- Q1: What are the core components of the HTRA model in high-rise HRC? Specifically, how do the three dyadic interactions (i.e., task–human fit (THA), task–robot alignment (TRA), and human–robot alignment (HRA)) manifest in such scenarios?

- Q2: Does HTRA influence safety performance in HRC? If so, what are the underlying impact mechanisms?

2. Literature Review

2.1. Human–Robot Collaboration (HRC) Safety

- (1)

- Robotic optimization for safety.

- (2)

- Task assignment and scheduling

- (3)

- Human safety training

2.2. Factors Influencing Safety Behavior Performance

3. Theoretical Background and Research Hypotheses

3.1. Task–Technology Fit Theory

3.2. Research Model and Hypotheses

3.2.1. Task–Robot Alignment (TRA)

3.2.2. Task–Human Alignment (THA)

3.2.3. Human–Robot Alignment (HRA)

3.2.4. Safety Constructs

4. Research Method

4.1. Questionnaire Design

- I always use appropriate personal protective equipment (e.g., safety harness, helmet, gloves).

- I strictly follow safety procedures to ensure my own and other workers’ safety.

- I always equip the robot with appropriate protective measures (e.g., collision protection, cushioning or buffer pads).

- I strictly follow safety construction procedures to ensure the robot is not damaged.

4.2. Data Collection and Analysis

5. Results

5.1. Descriptive Results

5.2. Measurement Model Test

5.3. Structural Model Test

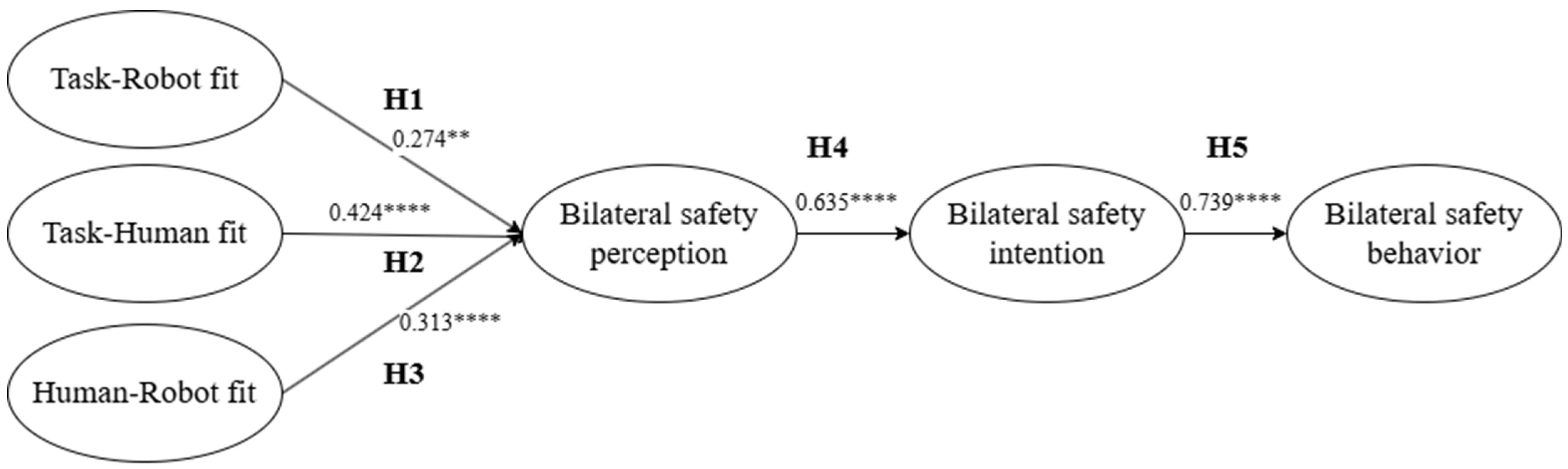

5.3.1. Original Structural Model

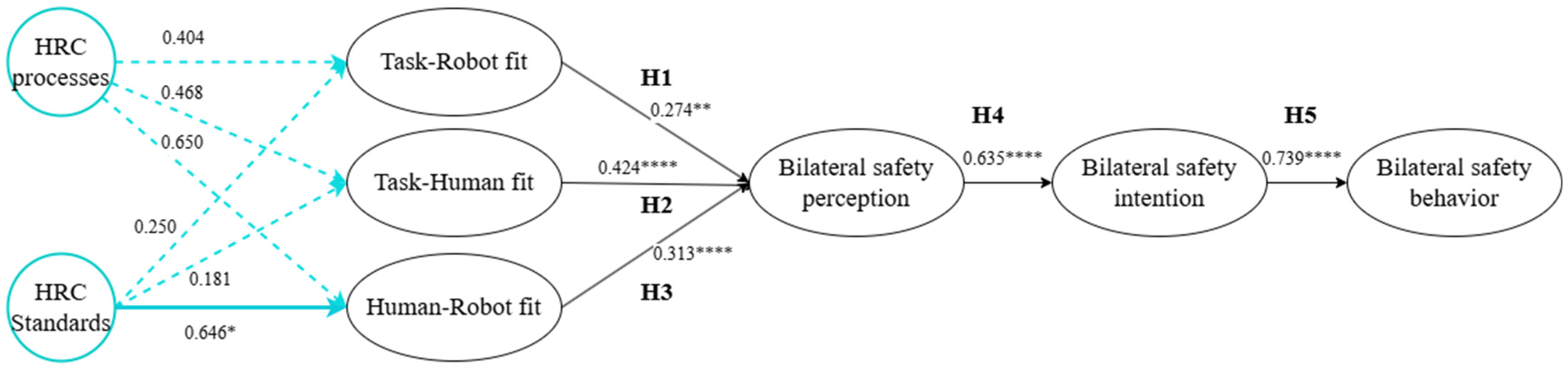

5.3.2. Control Variable Experiment

6. Discussion

6.1. HTRA Model

6.2. Bilateral Safety Behavior Performance Model

6.3. Implication for Theory and Practice

- (1)

- Human–robot role division and authority boundaries, specifying which tasks are executed autonomously by robots and which require human supervision or joint control.

- (2)

- Interface and communication protocols, defining how information, warnings, and task updates are exchanged between human operators and robotic systems.

- (3)

- Emergency response and recovery procedures, ensuring rapid and coordinated actions in case of system failure, near misses, or hazardous events.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Construct | Indicator | Indicator Reliability | Internal Reliability | Consistency | Convergent Validity | ||

|---|---|---|---|---|---|---|---|

| Loading | t-Value | p-Value | Cronbach’s a | CR | AVE | ||

| BSB | BSB1 | 0.885 | 21.369 | 0.000 | 0.935 | 0.946 | 0.690 |

| BSB2 | 0.871 | 15.054 | 0.000 | ||||

| BSB3 | 0.852 | 17.713 | 0.000 | ||||

| BSB4 | 0.861 | 22.330 | 0.000 | ||||

| BSB5 | 0.866 | 27.429 | 0.000 | ||||

| BSB6 | 0.878 | 22.271 | 0.000 | ||||

| BSI | BSI1 | 0.838 | 14.996 | 0.000 | 0.933 | 0.947 | 0.749 |

| BSI2 | 0.934 | 33.636 | 0.000 | ||||

| BSI3 | 0.867 | 16.755 | 0.000 | ||||

| BSI4 | 0.782 | 9.861 | 0.000 | ||||

| BSI5 | 0.875 | 16.308 | 0.000 | ||||

| BSI6 | 0.889 | 18.055 | 0.000 | ||||

| BSP | BSP1 | 0.784 | 8.702 | 0.000 | 0.811 | 0.877 | 0.643 |

| BSP2 | 0.879 | 22.211 | 0.000 | ||||

| BSP3 | 0.722 | 4.109 | 0.000 | ||||

| BSP4 | 0.848 | 19.762 | 0.000 | ||||

| HRA | HRA1 | 0.823 | 20.022 | 0.000 | 0.891 | 0.925 | 0.755 |

| HRA2 | 0.848 | 34.112 | 0.000 | ||||

| HRA3 | 0.853 | 12.063 | 0.000 | ||||

| HRA4 | 0.804 | 9.332 | 0.000 | ||||

| THA | THA1 | 0.823 | 15.655 | 0.000 | 0.852 | 0.900 | 0.693 |

| THA2 | 0.848 | 25.632 | 0.000 | ||||

| THA3 | 0.853 | 30.346 | 0.000 | ||||

| THA4 | 0.804 | 4.977 | 0.000 | ||||

| TRA | TRA1 | 0.885 | 6.148 | 0.000 | 0.848 | 0.908 | 0.767 |

| TRA2 | 0.840 | 7.471 | 0.000 | ||||

| TRA3 | 0.901 | 5.778 | 0.000 | ||||

| BSB | BSI | BSP | HRA | THA | TRA | |

|---|---|---|---|---|---|---|

| BSB | 0.830 * | |||||

| BSI | 0.739 | 0.865 * | ||||

| BSP | 0.705 | 0.635 | 0.802 * | |||

| HRA | 0.706 | 0.618 | 0.664 | 0.869 * | ||

| THA | 0.674 | 0.703 | 0.745 | 0.778 | 0.879 * | |

| TRA | 0.682 | 0.593 | 0.741 | 0.763 | 0.738 | 0.876 * |

| Path | Coefficient | t-Value | p-Value |

|---|---|---|---|

| HRA > BSP | 0.313 | 3.528 | 0.000 |

| TRA > BSP | 0.274 | 2.823 | 0.004 |

| THA > BSP | 0.424 | 3.294 | 0.000 |

| BSP > BSI | 0.635 | 6.709 | 0.000 |

| BSI > BSB | 0.739 | 9.586 | 0.000 |

| Standards > HRA | 0.646 | 2.277 | 0.022 |

| Standards > RTF | 0.250 | 0.758 | 0.448 |

| Standards > THA | 0.181 | 0.549 | 0.583 |

| Process > HRA | 0.650 | n/a | n/a |

| Process > TRA | 0.404 | n/a | n/a |

| Process > THA | 0.468 | n/a | n/a |

References

- Yoo, S.; Joo, I.; Hong, J.; Park, C.; Kim, J.; Kim, H.S.; Seo, T. Unmanned High-Rise Façade Cleaning Robot Implemented on a Gondola: Field Test on 000-Building in Korea. IEEE Access 2019, 7, 30174–30184. [Google Scholar] [CrossRef]

- Sugiyama, Y. Device for Horizontally Moving an Apparatus Working at a High Location. United States Patent 4811819, 14 March 1989. [Google Scholar]

- Yokota, T.; Nishiyama, Y.; Takasaki, T. Horizontally Moving Automatic Outer Surface Cleaning. U.S. Patent US4809384A, 7 March 1989. [Google Scholar]

- Ji, R.; Xu, A.; Zhao, J.; Li, L. Spray Robot 2019. China Patent CN109972825A, 5 July 2019. Available online: https://patents.google.com/patent/CN109972825A/en (accessed on 28 October 2025).

- Iturralde, K.; Feucht, M.; Illner, D.; Hu, R.; Pan, W.; Linner, T.; Bock, T.; Eskudero, I.; Rodriguez, M.; Gorrotxategi, J.; et al. Cable-Driven Parallel Robot for Curtain Wall Module Installation. Autom. Constr. 2022, 138, 104235. [Google Scholar] [CrossRef]

- Yu, S.N.; Lee, S.Y.; Han, C.S.; Lee, K.Y.; Lee, S.H. Development of the Curtain Wall Installation Robot: Performance and Efficiency Tests at a Construction Site. Auton. Robot. 2007, 22, 281–291. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Kim, S.-H.; Gil, M.-S.; Lee, S.-H.; Kang, M.-S.; Jang, S.-H.; Yu, B.-H.; Ryu, B.-G.; Hong, D.; Han, C.-S. The Study on the Integrated Control System for Curtain Wall Building Façade Cleaning Robot. Autom. Constr. 2018, 94, 39–46. [Google Scholar] [CrossRef]

- Thale, S.; Sawant, P.; Bagwe, S.; Chandrashekhar, N.S. Design of External Wall Painting Robot for High-Rise Buildings. In Advances in Mechanical and Materials Technology; Govindan, K., Kumar, H., Yadav, S., Eds.; Springer Nature: Singapore, 2022; pp. 1021–1031. [Google Scholar]

- Okpala, I.; Nnaji, C.; Gambatese, J. Assessment Tool for Human-Robot Interaction Safety Risks during Construction Operations. J. Constr. Eng. Manag. 2023, 149, 04022158. [Google Scholar] [CrossRef]

- Sun, Y.; Jeelani, I.; Gheisari, M. Safe Human-Robot Collaboration in Construction: A Conceptual Perspective. J. Safety Res. 2023, 86, 39–51. [Google Scholar] [CrossRef]

- Jeelani, I.; Gheisari, M. Safety Challenges of Human-Drone Interactions on Construction Jobsites. In Automation and Robotics in the Architecture, Engineering, and Construction Industry; Jebelli, H., Habibnezhad, M., Shayesteh, S., Asadi, S., Lee, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 143–164. ISBN 978-3-030-77163-8. [Google Scholar]

- Namian, M.; Khalid, M.; Wang, G.; Turkan, Y. Revealing Safety Risks of Unmanned Aerial Vehicles in Construction. Transp. Res. Rec. 2021, 2675, 334–347. [Google Scholar] [CrossRef]

- Qian, Z.-Y.; Zhao, Y.-Z.; Fu, Z.; Cao, Q.-X. Design and Realization of a Non-Actuated Glass-Curtain Wall-Cleaning Robot Prototype with Dual Suction Cups. Int. J. Adv. Manuf. Technol. 2006, 30, 147–155. [Google Scholar] [CrossRef]

- Liu, Y.; Habibnezhad, M.; Jebelli, H. Brain-Computer Interface for Hands-Free Teleoperation of Construction Robots. Autom. Constr. 2021, 123, 103523. [Google Scholar] [CrossRef]

- Adami, P.; Rodrigues, P.B.; Woods, P.J.; Becerik-Gerber, B.; Soibelman, L.; Copur-Gencturk, Y.; Lucas, G. Impact of VR-Based Training on Human-Robot Interaction for Remote Operating Construction Robots. J. Comput. Civ. Eng. 2022, 36, 04022023. [Google Scholar] [CrossRef]

- Onososen, A.; Musonda, I.; Dzuwa, C. Enhancing Human-Robot Teaming in Construction through the Integration of Virtual Reality-Based Training in Human-Robot Collaboration. In Proceedings of the International Association for Automation and Robotics in Construction (IAARC), Lille, France, 3–7 June 2024; pp. 623–630. [Google Scholar]

- Lee, D.; Lee, S.; Masoud, N.; Krishnan, M.S.; Li, V.C. Digital Twin-Driven Deep Reinforcement Learning for Adaptive Task Allocation in Robotic Construction. Adv. Eng. Inform. 2022, 53, 101710. [Google Scholar] [CrossRef]

- Aaquib, T. Mediating Trust and Influence in Human-Robot Teams via Multimodal Communication and Explanation for Mental Model Alignment; University of Colorado at Boulder: Boulder, CO, USA, 2024. [Google Scholar]

- Wong, C.Y.; Seet, G. Workload, Awareness and Automation in Multiple-Robot Supervision. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417710463. [Google Scholar] [CrossRef]

- Goodhue, D.L.; Thompson, R.L. Task-Technology Fit and Individual Performance. MIS Q. 1995, 19, 213–236. [Google Scholar] [CrossRef]

- Thompson, P.; Yates, T.; Inan, E.; Ananiadou, S. Semantic Annotation for Improved Safety in Construction Work. In Proceedings of the Twelfth Language Resources and Evaluation Conference, Marseille, France, 11–16 May 2020; Calzolari, N., Béchet, F., Blache, P., Choukri, K., Cieri, C., Declerck, T., Goggi, S., Isahara, H., Maegaard, B., Mariani, J., et al., Eds.; European Language Resources Association: Marseille, France, 2020; pp. 1990–1999. [Google Scholar]

- Guiochet, J.; Machin, M.; Waeselynck, H. Safety-Critical Advanced Robots: A Survey. Robot. Auton. Syst. 2017, 94, 43–52. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, R.; Wu, H.; Pan, J.; Luo, X. Human-Robot Collaboration for on-Site Construction. Autom. Constr. 2023, 150, 104812. [Google Scholar] [CrossRef]

- Xu, Y.; Turkan, Y.; Karakhan, A.A.; Liu, D. Exploratory Study of Potential Negative Safety Outcomes Associated with UAV-Assisted Construction Management. In Construction Research Congress 2020: Computer Applications; ASCE: New York, NY, USA, 2020; pp. 1223–1232. [Google Scholar] [CrossRef]

- Eraliev, O.M.U.; Lee, K.-H.; Shin, D.-Y.; Lee, C.-H. Sensing, Perception, Decision, Planning and Action of Autonomous Excavators. Autom. Constr. 2022, 141, 104428. [Google Scholar] [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent Advancements of Robotics in Construction. Autom. Constr. 2022, 144, 104591. [Google Scholar] [CrossRef]

- Amani, M.; Akhavian, R. Intelligent Ergonomic Optimization in Bimanual Worker-Robot Interaction: A Reinforcement Learning Approach. Autom. Constr. 2024, 168, 105741. [Google Scholar] [CrossRef]

- Duan, K.; Zou, Z. Safety-Constrained Deep Reinforcement Learning Control for Human–Robot Collaboration in Construction. Autom. Constr. 2025, 174, 106130. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, Y.; Park, M.; Ahn, C.R. Effects of Spatial Characteristics on the Human–Robot Communication Using Deictic Gesture in Construction. J. Constr. Eng. Manag. 2023, 149, 04023049. [Google Scholar] [CrossRef]

- Morato, C.; Kaipa, K.N.; Zhao, B.; Gupta, S.K. Toward Safe Human Robot Collaboration by Using Multiple Kinects Based Real-Time Human Tracking. J. Comput. Inf. Sci. Eng. 2014, 14, 011006. [Google Scholar] [CrossRef]

- You, H.; Zhou, T.; Zhu, Q.; Ye, Y.; Du, E.J. Embodied AI for Dexterity-Capable Construction Robots: DEXBOT Framework. Adv. Eng. Inform. 2024, 62, 102572. [Google Scholar] [CrossRef]

- Lee, J.S.; Ham, Y. The Effect of Time Pressure on Human-Robot Interaction Performance during Excavator Teleoperation; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2024; pp. 505–512. [Google Scholar]

- Liau, Y.Y.; Ryu, K. Genetic Algorithm-Based Task Allocation in Multiple Modes of Human–Robot Collaboration Systems with Two Cobots. Int. J. Adv. Manuf. Technol. 2022, 119, 7291–7309. [Google Scholar] [CrossRef]

- Dianatfar, M.; Latokartano, J.; Lanz, M. Concept for Virtual Safety Training System for Human-Robot Collaboration. Procedia Manuf. 2020, 51, 54–60. [Google Scholar] [CrossRef]

- Shayesteh, S.; Ojha, A.; Liu, Y.; Jebelli, H. Human-Robot Teaming in Construction: Evaluative Safety Training through the Integration of Immersive Technologies and Wearable Physiological Sensing. Saf. Sci. 2023, 159, 106019. [Google Scholar] [CrossRef]

- Han, Y.; Li, J.; Cao, X.; Jin, R. Structural Equation Modeling Approach to Studying the Relationships among Safety Investment, Construction Employees’ Safety Cognition, and Behavioral Performance. J. Constr. Eng. Manag. 2020, 146, 04020065. [Google Scholar] [CrossRef]

- Heinrich, H. Industrial Accident Prevention: A Scientific Approach, 4th ed.; McGraw-Hill Book Company: New York, NY, USA, 1959. [Google Scholar]

- Griffin, M.A.; Hu, X. How Leaders Differentially Motivate Safety Compliance and Safety Participation: The Role of Monitoring, Inspiring, and Learning. Saf. Sci. 2013, 60, 196–202. [Google Scholar] [CrossRef]

- Liang, Q.; Zhou, Z.; Ye, G.; Shen, L. Unveiling the Mechanism of Construction Workers’ Unsafe Behaviors from an Occupational Stress Perspective: A Qualitative and Quantitative Examination of a Stress–Cognition–Safety Model. Saf. Sci. 2022, 145, 105486. [Google Scholar] [CrossRef]

- Love, P.E.D.; Edwards, D.J.; Irani, Z. Work Stress, Support, and Mental Health in Construction. J. Constr. Eng. Manag. 2010, 136, 650–658. [Google Scholar] [CrossRef]

- Xia, N.; Zou, P.X.W.; Liu, X.; Wang, X.; Zhu, R. A Hybrid BN-HFACS Model for Predicting Safety Performance in Construction Projects. Saf. Sci. 2018, 101, 332–343. [Google Scholar] [CrossRef]

- Xia, N.; Ding, S.; Ling, T.; Tang, Y. Safety Climate in Construction: A Systematic Literature Review. Eng. Constr. Archit. Manag. 2023, 31, 3973–4000. [Google Scholar] [CrossRef]

- Zhang, Q.; Chan, A.P.C.; Yang, Y.; Guan, J.; Choi, T.N.Y. Influence of Learning from Incidents, Safety Information Flow, and Resilient Safety Culture on Construction Safety Performance. J. Manag. Eng. 2023, 39, 04023007. [Google Scholar] [CrossRef]

- Zhu, Q.; Wei, P.; Shi, Y.; Du, J. Cognitive Benefits of Human-Robot Collaboration in Complex Industrial Operations: A Virtual Reality Experiment. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020; pp. 129–138. [Google Scholar] [CrossRef]

- Wang, L. Collaborative Robot Monitoring and Control for Enhanced Sustainability. Int. J. Adv. Manuf. Technol. 2015, 81, 1433–1445. [Google Scholar] [CrossRef]

- Shin, M.; Lee, H.-S.; Park, M.; Moon, M.; Han, S. A System Dynamics Approach for Modeling Construction Workers’ Safety Attitudes and Behaviors. Accid. Anal. Prev. 2014, 68, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Fuller, R.M.; Dennis, A.R. Does Fit Matter? The Impact of Task-Technology Fit and Appropriation on Team Performance in Repeated Tasks. Inf. Syst. Res. 2009, 20, 2–17. [Google Scholar] [CrossRef]

- Alyoubi, B.A.; Yamin, M.A. The Impact of Task Technology Fit on Employee Job Performance. Mark. Manag. Innov. 2019, 4, 146–158. [Google Scholar] [CrossRef]

- Hoehle, H.; Huff, S. Advancing Task-Technology Fit Theory: A Formative Measurement Approach to Determining Task-Channel Fit for Electronic Banking Channels. In Information Systems Foundations: Theory Building in Information Systems; Hart, D.N., Gregor, S.D., Eds.; ANU Press: Canberra, Australia, 2012; pp. 133–170. ISBN 978-1-921862-93-9. [Google Scholar]

- Liu, Y.; Lee, Y.; Chen, A.N.K. Evaluating the Effects of Task–Individual–Technology Fit in Multi-DSS Models Context: A Two-Phase View. Decis. Support Syst. 2011, 51, 688–700. [Google Scholar] [CrossRef]

- Suhail, F.; Adel, M.; Al-Emran, M.; AlQudah, A.A. Are Students Ready for Robots in Higher Education? Examining the Adoption of Robots by Integrating UTAUT2 and TTF Using a Hybrid SEM-ANN Approach. Technol. Soc. 2024, 77, 102524. [Google Scholar] [CrossRef]

- Wang, K.; Guo, F.; Zhang, C.; Hao, J.; Wang, Z. Unlocking Determinants of Smart Construction: An Integrated Model of UTAUT2, TTF, and Perceived Risk for IoT Acceptance in AEC Industry. Eng. Constr. Archit. Manag. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Ma, X.; Mao, C.; Liu, G. Can Robots Replace Human Beings?—Assessment on the Developmental Potential of Construction Robot. J. Build. Eng. 2022, 56, 104727. [Google Scholar] [CrossRef]

- Furneaux, B. Task-Technology Fit Theory: A Survey and Synopsis of the Literature. In Information Systems Theory: Explaining and Predicting Our Digital Society, Vol. 1; Dwivedi, Y.K., Wade, M.R., Schneberger, S.L., Eds.; Springer: New York, NY, USA, 2012; pp. 87–106. ISBN 978-1-4419-6108-2. [Google Scholar]

- Jarvenpaa, S.L. The Effect of Task Demands and Graphical Format on Information Processing Strategies. Manag. Sci. 1989, 35, 285–303. [Google Scholar] [CrossRef]

- Vessey, I. Cognitive Fit: A Theory-Based Analysis of the Graphs Versus Tables Literature. Decis. Sci. 1991, 22, 219–240. [Google Scholar] [CrossRef]

- Vessey, I.; Galletta, D. Cognitive Fit: An Empirical Study of Information Acquisition. Inf. Syst. Res. 1991, 2, 63–84. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S.; Wang, H. Construction Automation and Robotics for High-Rise Buildings: Development Priorities and Key Challenges. J. Constr. Eng. Manag. 2020, 146, 04020096. [Google Scholar] [CrossRef]

- Ngcobo, N.; Akinradewo, O. Revolutionising High-Rise Building Construction: The Role of Robotics in South Africa’s Construction Industry. J. Constr. Proj. Manag. Innov. 2023, 13, 93–102. [Google Scholar]

- Emaminejad, N.; Kath, L.; Akhavian, R. Assessing Trust in Construction AI-Powered Collaborative Robots Using Structural Equation Modeling. J. Comput. Civ. Eng. 2024, 38, 04024011. [Google Scholar] [CrossRef]

- Chauhan, H.; Pakbaz, A.; Jang, Y.; Jeong, I. Analyzing Trust Dynamics in Human–Robot Collaboration through Psychophysiological Responses in an Immersive Virtual Construction Environment. J. Comput. Civ. Eng. 2024, 38, 04024017. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, Y.; Zhou, X.; Hao, S.; Li, J. Identifying the Risk Factors and Their Interactions of Human–Robot Collaboration Implementation during Engineering Project Construction: Evidence from China. Eng. Constr. Archit. Manag. 2023, 30, 3073–3094. [Google Scholar] [CrossRef]

- Caldwell, D.F.; O’Reilly, C.A. Measuring Person-Job Fit with a Profile-Comparison Process. J. Appl. Psychol. 1990, 75, 648–657. [Google Scholar] [CrossRef]

- de Beer, L.T.; Rothmann, S., Jr.; Mostert, K. The Bidirectional Relationship between Person-Job Fit and Work Engagement: A Three-Wave Study. J. Pers. Psychol. 2016, 15, 4–14. [Google Scholar] [CrossRef]

- Olukanni, E.; Akanmu, A.; Jebelli, H.; Ammar, A.; Okunola, A. Competencies for Human–Robot Collaboration in the Construction Industry: Perspectives from Academia and Industry. Constr. Robot. 2025, 9, 15. [Google Scholar] [CrossRef]

- Edwards, J.R. Person-Job Fit: A Conceptual Integration, Literature Review, and Methodological Critique. In International Review of Industrial and Organizational Psychology; International Review of Industrial and Organizational Psychology; John Wiley & Sons: Oxford, UK, 1991; Volume 6, pp. 283–357. ISBN 978-0-471-92819-5. [Google Scholar]

- Lin, J.-R.; Wu, M.-H. Exploiting the Power of Human-Robot Collaboration: Coupling and Scale Effects in Bricklaying. arXiv 2022, arXiv:2212.05181. [Google Scholar] [CrossRef]

- Goodhue, D.L.; Klein, B.D.; March, S.T. User Evaluations of IS as Surrogates for Objective Performance. Inf. Manag. 2000, 38, 87–101. [Google Scholar] [CrossRef]

- Koppenborg, M.; Nickel, P.; Naber, B.; Lungfiel, A.; Huelke, M. Effects of Movement Speed and Predictability in Human–Robot Collaboration. Hum. Factors Ergon. Manuf. Serv. Ind. 2017, 27, 197–209. [Google Scholar] [CrossRef]

- Rubagotti, M.; Tusseyeva, I.; Baltabayeva, S.; Summers, D.; Sandygulova, A. Perceived Safety in Physical Human–Robot Interaction—A Survey. Robot. Auton. Syst. 2022, 151, 104047. [Google Scholar] [CrossRef]

- Johannsmeier, L.; Haddadin, S. A Hierarchical Human-Robot Interaction-Planning Framework for Task Allocation in Collaborative Industrial Assembly Processes. IEEE Robot. Autom. Lett. 2017, 2, 41–48. [Google Scholar] [CrossRef]

- Lasota, P.A.; Shah, J.A. Analyzing the Effects of Human-Aware Motion Planning on Close-Proximity Human–Robot Collaboration. Hum. Factors 2015, 57, 21–33. [Google Scholar] [CrossRef]

- Sanfilippo, F.; Zafar, M.H.; Wiley, T.; Zambetta, F. From Caged Robots to High-Fives in Robotics: Exploring the Paradigm Shift from Human–Robot Interaction to Human–Robot Teaming in Human–Machine Interfaces. J. Manuf. Syst. 2025, 78, 1–25. [Google Scholar] [CrossRef]

- Liu, Y.; Habibnezhad, M.; Jebelli, H. Brainwave-Driven Human-Robot Collaboration in Construction. Autom. Constr. 2021, 124, 103556. [Google Scholar] [CrossRef]

- Eagly, A.H.; Chaiken, S. The Psychology of Attitudes; Harcourt Brace Jovanovich College Publishers: Orlando, FL, USA, 1993; p. 794. ISBN 978-0-15-500097-1. [Google Scholar]

- Xu, Z.; Zhang, K.; Min, H.; Wang, Z.; Zhao, X.; Liu, P. What Drives People to Accept Automated Vehicles? Findings from a Field Experiment. Transp. Res. Part C Emerg. Technol. 2018, 95, 320–334. [Google Scholar] [CrossRef]

- Ajzen, I. The Theory of Planned Behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Baraglia, J.; Cakmak, M.; Nagai, Y.; Rao, R.; Asada, M. Initiative in Robot Assistance during Collaborative Task Execution. In Proceedings of the 2016 11th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Christchurch, New Zealand, 7–10 March 2016; pp. 67–74. [Google Scholar]

- Cai, J.; Li, Z.; Dou, Y.; Li, T.; Yuan, M. Understanding Adoption of High Off-Site Construction Level Technologies in Construction Based on the TAM and TTF. Eng. Constr. Archit. Manag. 2022, 30, 4978–5006. [Google Scholar] [CrossRef]

- Lin, C.-P.; Bhattacherjee, A. Elucidating Individual Intention to Use Interactive Information Technologies: The Role of Network Externalities. Int. J. Electron. Commer. 2008, 13, 85–108. [Google Scholar] [CrossRef]

- Neal, A.; Griffin, M.A. A Study of the Lagged Relationships among Safety Climate, Safety Motivation, Safety Behavior, and Accidents at the Individual and Group Levels. J. Appl. Psychol. 2006, 91, 946–953. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Ye, G.; Feng, Y. Workers’ Safety Behaviors in the off-Site Manufacturing Plant. Eng. Constr. Archit. Manag. 2019; ahead-of-print. [Google Scholar] [CrossRef]

- Saks, A.M.; Ashforth, B.E. A Longitudinal Investigation of the Relationships Between Job Information Sources, Applicant Perceptions of Fit, and Work Outcomes. Pers. Psychol. 1997, 50, 395–426. [Google Scholar] [CrossRef]

- Biernacki, P.; Waldorf, D. Snowball Sampling: Problems and Techniques of Chain Referral Sampling. Sociol. Methods Res. 1981, 10, 141–163. [Google Scholar] [CrossRef]

- Xie, L.; Xu, T.; Ju, T.; Xia, B. Explaining the Alienation of Megaproject Environmental Responsibility Behavior: A Fuzzy Set Qualitative Comparative Analysis Study in China. Eng. Constr. Archit. Manag. 2022, 30, 2794–2813. [Google Scholar] [CrossRef]

- Chen, G.; Yan, Z.; Ruan, C.; Li, Q.; Tang, L. How Digital Technologies Contribute to Prefabricated Construction Supply Chain Resilience: An Asset Orchestration Perspective. Eng. Constr. Archit. Manag. 2025, 1–22. [Google Scholar] [CrossRef]

- Acheampong, A.; Adjei, E.K.; Adade-Boateng, A.; Acheamfour, V.K.; Afful, A.E.; Boateng, E. Impact of Construction Workers Informal Safety Communication (CWISC) on Safety Performance on Construction Sites. Eng. Constr. Archit. Manag. 2024, 32, 4338–4356. [Google Scholar] [CrossRef]

- Anderson, J.C.; Gerbing, D.W. Structural Equation Modeling in Practice: A Review and Recommended Two-Step Approach. Psychol. Bull. 1988, 103, 411–423. [Google Scholar] [CrossRef]

- Hair, J.F. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); SAGE: Thousand Oaks, CA, USA, 2014; ISBN 978-1-4522-1744-4. [Google Scholar]

- Bagozzi, R.P.; Yi, Y.; Phillips, L.W. Assessing Construct Validity in Organizational Research. Adm. Sci. Q. 1991, 36, 421–458. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Routledge: New York, NY, USA, 2013; ISBN 978-0-203-77158-7. [Google Scholar]

- Du, S.; Du, M.; Gao, Y.; Yang, M.; Hu, F.; Weng, Y. Optimized Motion Planning for Mobile Robots in Dynamic Construction Environments with Low-Feature Mapping and Pose-Based Positioning. Autom. Constr. 2025, 177, 106334. [Google Scholar] [CrossRef]

- Hopko, S.; Wang, J.; Mehta, R. Human Factors Considerations and Metrics in Shared Space Human-Robot Collaboration: A Systematic Review. Front. Robot. AI 2022, 9, 799522. [Google Scholar] [CrossRef]

- Liang, C.-J.; Kamat, V.R.; Menassa, C.C. Teaching Robots to Perform Quasi-Repetitive Construction Tasks through Human Demonstration. Autom. Constr. 2020, 120, 103370. [Google Scholar] [CrossRef]

- Chen, M.; Nikolaidis, S.; Soh, H.; Hsu, D.; Srinivasa, S. Planning with Trust for Human-Robot Collaboration. In Proceedings of the 2018 ACM/IEEE International Conference on Human-Robot Interaction, Chicago, IL, USA, 5–8 March 2018; Association for Computing Machinery: New York, NY, USA, 2018; pp. 307–315. [Google Scholar]

- Liang, C.-J.; Wang, X.; Kamat, V.R.; Menassa, C.C. Human–Robot Collaboration in Construction: Classification and Research Trends. J. Constr. Eng. Manag. 2021, 147, 03121006. [Google Scholar] [CrossRef]

- You, S.; Kim, J.-H.; Lee, S.; Kamat, V.; Robert, L.P. Enhancing Perceived Safety in Human–Robot Collaborative Construction Using Immersive Virtual Environments. Autom. Constr. 2018, 96, 161–170. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, T.; Han, J. A Fast Transfer Reinforcement Learning Model for Transferring Force-Based Human Speed Adjustment Skills to Robots for Collaborative Assembly Posture Alignment. Adv. Eng. Inform. 2024, 62, 102836. [Google Scholar] [CrossRef]

| Construct | Item | Codes | Measurement | Sources |

|---|---|---|---|---|

| HRA | Human–Robot Alignment | HRA1 | I collaborate smoothly with the robot during construction tasks. | [80] |

| HRA2 | I work efficiently with robots on site. | |||

| HRA3 | I can rely on the robot to complete assigned tasks. | |||

| HRA4 | I trust the information and feedback provided by the robot. | |||

| TRA | Task–Robot Alignment | TRA1 | The facade spraying robot meets the safety requirements for high-altitude operations. | [81,82] |

| TRA2 | The facade spraying robot improves the efficiency of high-altitude operations. | |||

| TRA3 | The facade spraying robot meets the precision requirements for high-altitude tasks. | |||

| THA | Task–Human Alignment | THA1 | I possess the necessary skills for facade spraying tasks (e.g., robot operation or assistance). | [84] |

| THA2 | I possess the necessary abilities for facade spraying tasks (e.g., identifying on-site risks). | |||

| THA3 | I have relevant experience in facade spraying tasks (e.g., handling emergencies). | |||

| THA4 | I have a strong safety awareness and sense of responsibility in facade spraying operations. | |||

| BSP | Bilateral Safety Perception | BSP1 | Most of the time, I feel safe when working with robots on site. | [76] |

| BSP2 | Most of the time, I believe the robot will not be damaged during the collaboration. | |||

| BSP3 | Most of the time, I feel relaxed and not nervous or fearful when working with robots. | |||

| BSP4 | Most of the time, I do not worry about the robot being damaged during operations. | |||

| BSP5 | I always wear appropriate personal protective equipment to protect myself during human–robot collaboration (e.g., safety harness, helmet, gloves). | |||

| BSP6 | I always ensure that the robot is equipped with suitable protective devices to prevent damage or collisions (e.g., bumpers, cushioning pads). | |||

| BSI | Bilateral Safety Intention | BSI1 | I intend to always follow safety procedures during high-altitude work to protect myself and coworkers. | [83] |

| BSI2 | I intend to always follow safety procedures to avoid damage to the robot during high-altitude tasks. | |||

| BSI3 | I intend to ensure maximum safety for myself during future high-altitude operations. | |||

| BSI4 | I intend to prevent robot damage to the greatest extent during future high-altitude operations. | |||

| BSI5 | I intend to actively participate in safety training or meetings to enhance worker safety. | |||

| BSI6 | I intend to actively participate in training or meetings to prevent robot-related damage. | |||

| BSB | Bilateral Safety Behavior Performance | BSB1 | I strictly follow safety procedures to prevent harm to myself and other workers. | [79] |

| BSB2 | I strictly follow safety procedures to prevent damage to the robot. | |||

| BSB3 | I actively participate in safety training to learn how to protect myself and my coworkers. | |||

| BSB4 | I actively participate in safety training to learn how to prevent damage to the robot. | |||

| BSB5 | I proactively suggest ways to improve worker safety on site. | |||

| BSB6 | I proactively suggest ways to improve robot safety during operations. |

| Characteristic | Category | Frequency | Percentage |

|---|---|---|---|

| Organization | Construction company | 40 | 47.62% |

| Project owner/client | 8 | 9.52% | |

| Robot supplier | 22 | 26.19% | |

| University or research institution | 14 | 16.67% | |

| Work experience | 1–5 years | 44 | 52.38% |

| 6–10 years | 28 | 33.33% | |

| 11–15 years | 9 | 10.72% | |

| >15 years | 3 | 3.57% | |

| Role | Project manager | 22 | 26.19% |

| Robot operator | 13 | 15.48% | |

| Traditional construction worker (HRC assistant) | 5 | 5.95% | |

| On-site safety manager | 8 | 9.52% | |

| Robotics development engineer | 27 | 32.14% | |

| Researcher | 9 | 10.72% |

| Hypothesis | Path | Coefficient | t-Value | p-Value | f2 | R2 | Result |

|---|---|---|---|---|---|---|---|

| H1 | HRA > BSP | 0.313 | 3.536 | p < 0.0001 | 0.429 | 0.944 | Supported |

| H2 | TRA > BSP | 0.274 | 2.823 | p < 0.0005 | 0.169 | Supported | |

| H3 | THA > BSP | 0.424 | 3.294 | p < 0.0001 | 0.434 | Supported | |

| H4 | BSP > BSI | 0.635 | 6.708 | p < 0.0001 | 0.675 | 0.453 | Supported |

| H5 | BSI > BSB | 0.739 | 9.586 | p < 0.0001 | 1.203 | 0.546 | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, P.; Chen, G.; Zeng, N.; Li, Q. How to Facilitate Safety Performance of Human–Robot Collaboration in High-Rise Construction Scenarios: An Empirical Model. Systems 2025, 13, 1000. https://doi.org/10.3390/systems13111000

Lin P, Chen G, Zeng N, Li Q. How to Facilitate Safety Performance of Human–Robot Collaboration in High-Rise Construction Scenarios: An Empirical Model. Systems. 2025; 13(11):1000. https://doi.org/10.3390/systems13111000

Chicago/Turabian StyleLin, Peng, Guangchong Chen, Ningshuang Zeng, and Qiming Li. 2025. "How to Facilitate Safety Performance of Human–Robot Collaboration in High-Rise Construction Scenarios: An Empirical Model" Systems 13, no. 11: 1000. https://doi.org/10.3390/systems13111000

APA StyleLin, P., Chen, G., Zeng, N., & Li, Q. (2025). How to Facilitate Safety Performance of Human–Robot Collaboration in High-Rise Construction Scenarios: An Empirical Model. Systems, 13(11), 1000. https://doi.org/10.3390/systems13111000