Abstract

This paper investigates single-machine scheduling with a deteriorating maintenance activity, where the processing time of a job depends on whether it is handled before or after the maintenance activity. Under common and slack due date assignments, the aim is to find the optimal job schedule, position of the maintenance activity, and optimal value of the common due date (flow-allowance) so that the linear weighted sum of earliness, tardiness and common due date (flow-allowance) value is minimized, where the weights are location-dependent (position-dependent) weights. Through a series of optimal properties, a polynomial time algorithm is proposed and it is then proven that the problem is polynomially solvable.

1. Introduction

Traditional scheduling problems consider that the machine is always available, while actually, if a maintenance (rate-modifying) activity is carried out on the machine, it becomes unavailable, and it reverts to its original condition after the maintenance activity is finished (see Lee and Leon [1]; Ma et al. [2]; Strusevich and Rustogi [3]). In 2006, Mosheiov and Oron [4] considered single-machine scheduling with a rate-modifying activity (denoted ). Under the common due-date (denoted ) assignment, the goal is to minimize the total earliness, tardiness and due-date cost. They proved that the problem can be solved in polynomial time. In 2010, Wang and Wang [5] addressed single-machine scheduling with and slack due-date (denoted ) assignment. They showed that the non-regular objective minimization is polynomially solvable. In 2012, Yin et al. [6] studied single-machine batch delivery scheduling with the and assignment, with the goal of minimizing the sum of earliness, tardiness, due-date, holding and delivery cost. They proved that some special cases of the problem can be solved in polynomial time. In 2014, Bai et al. [7] studied the single-machine problem with deteriorating jobs and . Under the allocation, the objective is to minimize the weighted sum of earliness, tardiness and the common flow allowance cost. They showed that the problem is polynomially solvable. In 2018, Cheng et al. [8] discussed single-machine batch problems with variable maintenance activities. For the minimization of makespan (total completion time), they demonstrated that the problem can be solved in polynomial time in a special case. In 2019, Detti et al. [9] addressed the single-machine problem with a flexible maintenance activity. In 2021, Wang et al. [10] considered the single-machine problem with and a common due-window. For the generalized earliness/tardiness penalties, they showed that the problem is polynomially solvable. In 2022, Zhao et al. [11] studied the single-machine resource allocation problem with an aging effect as well as and assignment. In 2023, Sun et al. [12] delved into single-machine scheduling with worsening effects. With the maintenance activity, they showed that some regular objective minimizations are polynomially solvable. For total weighted completion time minimization, they suggested several heuristic and branch-and-bound algorithms. In addition, in 2014, Ji et al. [13] and Fan and Zhao [14] considered due-date assignment scheduling with a deteriorating maintenance activity (denoted ), i.e., the maintenance duration (time) is a linear deteriorating function of the starting time of this maintenance activity. In 2015, Mor and Mosheiov [15] studied single-machine scheduling with . Under the due-window assignment, they proved that some non-regular minimizations can be solved in polynomial time. In 2017, Li and Chen [16] investigated the single-machine problems with job-rejection and , and they showed that the makespan, total completion time and due-date assignment minimizations are polynomially solvable. Zhu et al. [17] explored single-machine scheduling with a general (including worsening and resource-dependent) maintenance activity. They showed that the problem can be solved in polynomial time for a number of regular and non-regular objectives. Wang et al. [18] addressed identical parallel machine scheduling with . They illustrated that the total completion time minimization can be solved in polynomial time. More recent papers which have studied scheduling problems with and include He et al. [19], Jia et al. [20], liu et al. [21] and Zou et al. [22].

At the same time, in modern manufacturing, more and more industries are adopting due-date assignment systems (see Gordon et al. [23,24], Qian and Zhan [25], Lu et al. [26], Wang [27]) and location-dependent (position-dependent) weights (Brucker [28], Liu et al. [29], Wang et al. [30], Wang et al. [31]). Recently, Jiang et al. [32] investigated proportionate flowshop problems with location-dependent weights. Under the and assignments, they showed that the non-regular objective minimization is polynomially solvable (i.e., time is , where n is the number of jobs). Liu et al. [33] studied single-machine scheduling with resource allocation, worsening jobs and location-dependent weights. Under the and assignments, they provided a bi-criteria analysis for the scheduling cost (including the weighted sum of the absolute value in lateness and common due date (flow-allowance) cost) and the resource consumption cost. They proved that three versions of these two costs can be solved in polynomial time. In 2021, Lv and Wang [34] considered the same problems as Jiang et al. [32], and they demonstrated that both problems can be addressed by using a lower-order algorithm (i.e., time is )). Wang et al. [35] and Wang et al. [36] investigated single-machine scheduling with setup times associated with past sequences and weights related to location. Under the and assignments, Wang et al. [35] demonstrated that the weighted sum of earliness, tardiness and due-date cost minimization is polynomially solvable. Wang et al. [36] demonstrated that the weighted sum of lateness, number of early and delayed jobs, and due-date cost minimization is also polynomially solvable.

In real production processes, the location-dependent (position-dependent) weights can be found in services and logistics systems (e.g., in Didi taxi dispatching, Sun et al. [37]). Hence, the work of () assignment and will be continued by considering the location-dependent weights, i.e., we investigate single-machine due-date assignment scheduling with and location-dependent weights. Under the and assignments, the aim of the article is to find the job schedule, location of the maintenance activity, and optimal value of common due-date (flow-allowance) so as to minimize the linear weighted sum of the earliness, tardiness and due date assignment costs, where the weights are related to the location. We demonstrate that the problem can be solved in polynomial time, i.e., time complexity is . For a comparison with other similar papers (see Table 1; the related symbols are given later), this article extends the results of Mosheiova and Oron [4], Wang and Wang [5], Brucker [28], and Liu et al. [29], by scrutinizing a more general scheduling model. The rest of this article is structured as below. In Section 2, we introduce the problem. In Section 3 and Section 4, we explore the main details of common due-date and slack due-date assignments. In Section 5, an example and computational experiments are reported to verify the effectiveness of the algorithms. Section 6 presents the conclusion of the problem.

Table 1.

Summary of and results.

2. Problem Description

In this article, the problem can be described as: n independent jobs can be usable at time 0 for handling on a single-machine and they are not preemptive. The machine stops working when a maintenance activity is being carried out, if the job is handled before the maintenance activity, the corresponding normal processing time (i.e., basic processing time that is not affected by other factors) is defined as , and its actual processing time is . If the job is processed after the maintenance activity, the corresponding actual processing time is defined as , where is the modified rate of the job , and it satisfies . Meanwhile, the machine only has a deteriorating maintenance activity, and its maintenance time is: , where is the basic maintenance time, is the rate of deterioration, and is the starting time of . We consider two different types of due-dates that include and . As for the model, all the jobs have the same due date, i.e., , in which is a decision variable. For the model, the due date of job is equivalent to the sum of the actual processing time and the common flow-allowance , i.e., , and the common flow-allowance is a decision variable. For a known schedule , the completion (resp. starting) time of the job is (resp. ), the earliness (resp. tardiness) cost of the job is (resp. ). Let be the job being arranged at the ith position in the schedule, then our goal is: (1) to determine the optimal job schedule; (2) to determine where to carry out the maintenance activity of the machine; (3) to determine the value of the common due date and the common flow-allowance; (4) to minimize the objective function: and , where , , are weights of the ith location in a schedule, i.e., the weights are the location-dependent weights rather than the weights connected with the job . With three-field notation, the scheduling can be expressed as:

3. Results of

Assuming that the maintenance activity occurs exactly before the job , its starting time is equivalent to the completion time of the job , i.e., . For the sake of simplicity, let j be the location of the maintenance activity.

Lemma 1.

If , then , if , then .

Proof.

For a given schedule , if , we can get . Similarly, if , we can also get . □

From Lemma 1, it can be seen that the jobs before the job are the early jobs, and the jobs after the job are the late jobs.

Lemma 2.

For a known schedule , the optimal value of the common due date is equal to the completion time of the hth job, i.e., , where h satisfies both

Proof.

See Appendix A. □

Remark 1.

For a given schedule, if h satisfies both the above inequalities, the optimal common due date can be determined by Lemma 2. But h may not meet the above both inequalities, so we need to set .

Lemma 3

(Hardy et al. [38]). For , if the sequence is in non-decreasing order and the sequence is in non-increasing order, or vice versa, it is the smallest.

Next, we consider the problem . Under Lemmas 1–3, the following cases should be considered.

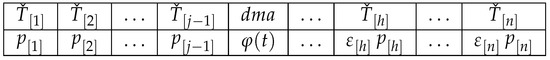

Case 1. If , the schedule is shown in Figure 1.

Figure 1.

If .

Where and . Then the objective function is expressed as

where is a constant (if j is given),

is only related to the location j of the maintenance activity. Therefore, for a known j, minimizing is equivalent to minimizing . Let

can be minimized by solving the next assignment problem:

where is a 0 or 1 variable, if the job is at location l, , otherwise .

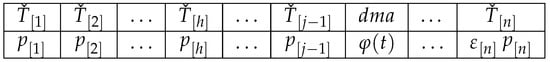

Case 2. If , the schedule is shown Figure 2.

Figure 2.

If .

Where , and . Then the objective function is expressed as

where is only related to and it is a constant,

is only related to the location j of the maintenance activity. Similarly to Case 1 (i.e., ), let

then, the problem can be translated into the assignment problem below:

where is a 0 or 1 variable, when the job is at position l, , otherwise .

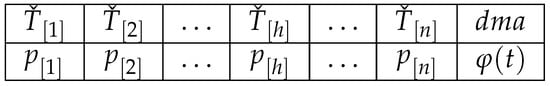

Case 3. If , the schedule is shown Figure 3.

Figure 3.

If .

where and . This means that there is no maintenance activity on the machine. In this case, the objective function is

where

The optimal schedule as well as the minimum value of can be acquired by matching the minimum weight with the maximum processing time by using rule (see Lemma 3).

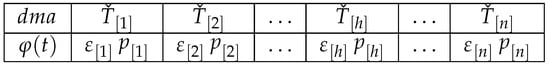

Case 4. if , the schedule is shown Figure 4.

Figure 4.

If .

where , and . This means that the maintenance activity occurs before the jobs are processed. In this case, the objective function is

where is only related to and it is a constant. Similarly, the optimal schedule of this case can be obtained through Lemma 3.

From the above cases, the optimal solution of the problem can be obtained by using the following algorithm.

Theorem 1.

The optimal solution of can be obtained in time by using Algorithm 1.

Proof.

The correctness of Algorithm 1 follows from the above analysis. For each j, the complexity of the assignment problem is , and it takes times. So the time complexity of Algorithm 1 is . □

| Algorithm 1: Solution of |

| Initialization: Let , , and . Step 1: Calculate h from Lemma 2. Step 2: For If , then obtain the minimum value and the schedule by using (3)–(6); If , then let , , and ; If , then obtain the minimum value and the schedule by using (7)–(10); If , then let , , and ; If , then acquire the optimal value of and the schedule by the rule; Calculate ; If , then obtain the optimal value of and the schedule by the rule; Calculate . Step 3: Choose the minimum value , and obtain the corresponding schedule , and . |

4. Results of

Lemma 4.

If , then , if , then .

Proof.

For a given schedule , under the model, we have . If , we can get , i.e., . Similarly, if , we can also get , i.e., . □

Lemma 5.

For a given schedule , the optimal value of the common flow-allowance is decided by the start time of the hth job, i.e., , where h satisfies both

Proof.

Similar to the proof of Lemma 2. □

Remark 2.

Similarly, if h does not meet the above both inequalities, we need to set .

Next, we investigate the problem . Under Lemmas 3–5, the following cases will be considered.

Case 5. If , the schedule is identical to Case 1, where and . Then the objective function is expressed as

where is the same as it in Case 1, and

is only related to the position of j. Therefore, for a known j, minimizing is identical to minimizing , and can be minimized by resolving the assignment problem. Let represent the weight of job at location l, i.e.,

The problem can be translated into the assignment problem below:

where is a 0 or 1 variable, if the job is at position l, , otherwise .

Case 6. If , the schedule is the same as Case 2, where , and . Then the objective function is stated as

where same as it in Case 2, and

is only related to the location of the maintenance activity. Similarly to Case 5 (i.e., ), let

The problem can be translated into the assignment problem below:

where is a 0 or 1 variable, when the job is at position l, , otherwise .

Case 7. If , the schedule is equal to Case 3, where , and . In this case, the objective function is

where

The optimal schedule and the minimum value of the objective function can be found by matching the minimum weight with the maximum processing time by using Lemma 3.

Case 8. If , the schedule is identical with Case 4, where and . In this case, the objective function is

where is the same as it in Case 4. Similar to Case 7, the minimum weight with the maximum can minimize the objective function by using Lemma 3.

From above cases, the optimal solution of can be obtained by the next algorithm.

Theorem 2.

The optimal solution of can be obtained in time by using Algorithm 2.

Proof.

Similar to the proof of Theorem 1. □

| Algorithm 2: Solution of . |

| Initialization: Let , , and . Step 1: Calculate h from Lemma 5. Step 2: For If , then obtain the minimum value and the schedule by using (14)–(17); If , then let , , and ; If , then obtain the minimum value and the schedule by using (18)–(21); If , then let , , and ; If , then acquire the optimal value of and the schedule by the rule; Calculate ; If , then obtain the optimal value of and the schedule by the rule; Calculate . Step 3: Choose the minimum value , and obtain the corresponding schedule , and . |

5. An Example and Computational Experiments

5.1. An Example

Let , , , , respectively are 7, 4, 3, 1, 5, 13, 2, and the remaining data are given in Table 2.

Table 2.

The remaining data.

Solution: according to Lemmas 2 and 5, we can get and , , , , , , .

First, we consider the case of the common due date .

Case 9.: from Equation (5), we can get

and it is easy to see that

;

;

;

;

;

.

Similarly, the rest of the values of are given in Table 3,

Table 3.

The values of .

We can obtain the optimal schedule by solving the assignment problem (6), and , , , , so .

: Similarly, we can easily find the values of from Equation (5), and solve the assignment problem (6) to obtain the optimal schedule , and , , , , so .

: Similarly, we can easily find the values of from Equation (5), and solve the assignment problem (6) to obtain the optimal schedule , and , , , , so .

Case 10. : from Equation (9), the values of are known, similarly, we can obtain the optimal schedule by solving the assignment problem (10), and , , , , so .

: Similarly, we can obtain the values of from Equation (9) and tackle the assignment problem (10) to get the optimal schedule , and , , , , so .

: Similarly, we can get the values of from Equation (9) and tackle the assignment problem (10) to acquire the optimal schedule , and , , , , so .

Case 11. : From (12), we can obtain , according to the rule the optimal schedule is , , and , , .

Case 12. : Similar to Case 11, we can know , meanwhile , using the rule the optimal schedule is , , and , , , so .

Next, we consider the case of the common flow allowance .

Case 13. : Similar to Case 9, the values of can been gathered from (16), and we can obtain the optimal schedule by solving the assignment problem (17), and , , , , so .

: Similarly, we can easily find the values of from (16), and solve the assignment problem (17) so that we can obtain the optimal schedule , and , , , , so .

: Similarly, we can obtain the values of from (16), and tackle the assignment problem (17) to acquire the optimal schedule , and , , , , so .

Case 14. : from (20), the values of are given, similarly, we can get the optimal schedule by solving the assignment problem (21), and , , , , so .

: Similarly, we can obtain the values of from (20), and tackle the assignment problem (21) to know the optimal schedule , and , , , , so .

: Similarly, we can obtain the values of from (20), and tackle the assignment problem (21) to acquire the optimal schedule , and , , , , so .

Case 15.: From (23), we can get , according to the rule the optimal schedule is , , and , , .

Case 16. : Similar to Cases 12 and 15, we can obtain and , and according to the rule the optimal schedule is , , and , , , so .

After the above calculation, the results are shown in Table 4.

Table 4.

The results of the example.

We can see that the optimal solution to the question about is , , , , and the optimal solution to the question about is , , .

5.2. Computational Experiments

To test the validity of Algorithms 1 and 2, the examples are generated randomly. Microsoft visual C++ 2022 was applied to code Algorithms 1 and 2. For every problem size, 20 cases were created and coded on a PC with a 3.10 GHz CPU and 8.00 GB RAM. The features of the examples are listed below:

- (1)

- , and ;

- (2)

- () is evenly distributed over [1, 100];

- (3)

- () is evenly distributed over [0.5, 0.95];

- (4)

- and () are evenly distributed over [1, 50].

The computational tests for Algorithms 1 and 2 are given as follows. The minimum (min), average (mean) and maximum (max) CPU times (milliseconds (ms)) are shown in Table 5. From Table 5, we can see that Algorithms 1 and 2 are effective and their CPU times increase moderately as n increases from 30 to 200, and the maximum CPU time is 830,682.20 ms for .

Table 5.

CPU times of algorithms.

6. Conclusions

In this paper, we studied the single-machine due-date assignment problem with a deteriorating maintenance activity. Under the common and slack due-date assignments, the purpose of the problem is to find the optimal job schedule, the position of the maintenance activity, the optimal value of the common due date or the optimal value of the common flow-allowance so that the linear weighted sum of earliness, tardiness and due-date assignment cost is minimized. The problem is proved to be solved in polynomial time. Through computational complexity analysis and experimentation, we demonstrated that the proposed algorithm (approach) performs very well. In the future, other non-regular objectives with deteriorating maintenance activity can be studied, or multi-machine (flexible job shop, see Zhang et al. [39] and Song et al. [40]) due-date assignment problems with deteriorating maintenance activity can be addressed.

Author Contributions

Conceptualization, W.W., D.-Y.L. and J.-B.W.; methodology, W.W. and D.-Y.L.; investigation, J.-B.W.; writing, review and editing, W.W. and D.-Y.L.; supervision, J.-B.W.; writing-original draft preparation, W.W.. All authors have read and agreed to the published version of the manuscript.

Funding

This Work was supported by LiaoNing Revitalization Talents Program (grant no. XLYC2002017).

Data Availability Statement

The data used to support this paper are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Proof.

When , we first consider a schedule , and the common due date satisfies , is the corresponding value of objective function, let , (), and are the corresponding objective function values of and , respectively, therefore

Obviously, if , , otherwise , this means that is equal to the completion time of some job.

We assume that the value of coincides with the completion time of the job at the hth position, i.e., , then for , the common due date shifted unit to the left, and it is obtained

we have

If the common due date shifted unit to the right, we have

and

Thus, h satisfies

Similarly, the above result can be obtained when , i.e., for any given schedule, . □

References

- Lee, C.Y.; Leon, V.J. Machine scheduling with a rate-modifying activity. Eur. J. Oper. Res. 2001, 128, 119–128. [Google Scholar] [CrossRef]

- Ma, Y.; Chu, C.; Zuo, C. A survey of scheduling with deterministic machine availability constraints. Comput. Ind. Eng. 2010, 58, 199–211. [Google Scholar] [CrossRef]

- Strusevich, V.A.; Rustogi, K. Scheduling with Time-Changing Effects and Rate-Modifying Activities; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Mosheiova, G.; Oron, D. Due-date assignment and maintenance activity scheduling problem. Math. Comput. Model. 2006, 44, 1053–1057. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Wang, M.-Z. Single machine common flow allowance scheduling with a rate-modifying activity. Comput. Ind. Eng. 2010, 59, 898–902. [Google Scholar] [CrossRef]

- Yin, Y.; Cheng, T.C.E.; Xu, D.; Wu, C.-C. Common due date assignment and scheduling with a rate-modifying activity to minimize the due date, earliness, tardiness, holding, and batch delivery cost. Comput. Ind. Eng. 2012, 63, 223–234. [Google Scholar] [CrossRef]

- Bai, J.; Li, Z.-R.; Wang, J.-J.; Huang, X. Single machine common flow allowance scheduling with deteriorating jobs and a rate-modifying activity. Appl. Math. Model. 2014, 38, 5431–5438. [Google Scholar] [CrossRef]

- Cheng, M.; Xiao, S.; Luo, R.; Lian, Z. Single-machine scheduling problems with a batch-dependent aging effect and variable maintenance activities. Int. J. Prod. Res. 2018, 56, 7051–7063. [Google Scholar] [CrossRef]

- Detti, P.; Nicosia, G.; Pacifici, A.; De Lara, G.Z.M. Robust single machine scheduling with a flexible maintenance activity. Comput. Oper. Res. 2019, 107, 19–31. [Google Scholar] [CrossRef]

- Wang, J.-B.; Hu, Y.; Zhang, B. Common due-window assignment for single-machine scheduling with generalized earliness/tardiness penalties and a rate-modifying activity. Eng. Optim. 2021, 53, 496–512. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, J.; Wang, J.-B.; Li, L. Bicriteria common flow allowance scheduling with aging effect, convex resource allocation, and a rate-modifying activity on a single machine. Asia-Pac. J. Oper. Res. 2022, 39, 2150046. [Google Scholar] [CrossRef]

- Sun, X.; Liu, T.; Geng, X.-N.; Hu, Y.; Xu, J.-X. Optimization of scheduling problems with deterioration effects and an optional maintenance activity. J. Sched. 2023. [Google Scholar] [CrossRef]

- Ji, P.; Li, G.; Huo, Y.; Wang, J.-B. Single-machine common flow allowance scheduling with job-dependent aging effects and a deteriorating maintenance activity. Optim. Lett. 2014, 8, 1389–1400. [Google Scholar] [CrossRef]

- Fan, Y.P.; Zhao, C.-L. Single machine scheduling with multiple common due date assignment and aging effect under a deteriorating maintenance activity consideration. J. Appl. Math. Comput. 2014, 46, 51–66. [Google Scholar] [CrossRef]

- Mor, B.; Mosheiov, G. Scheduling a deteriorating maintenance activity and due-window assignment. Comput. Oper. Res. 2015, 57, 33–40. [Google Scholar] [CrossRef]

- Li, S.-S.; Chen, R.X. Scheduling with rejection and a deteriorating maintenance activity on a single machine. Asia-Pac. J. Oper. Res. 2017, 34, 1750010. [Google Scholar] [CrossRef]

- Zhu, H.; Li, M.; Zhou, Z.J. Machine scheduling with deteriorating and resource-dependent maintenance activity. Comput. Ind. Eng. 2015, 88, 479–486. [Google Scholar] [CrossRef]

- Wang, J.-J.; Wang, J.-B.; Liu, F. Parallel machines scheduling with a deteriorating maintenance activity. J. Oper. Res. Soc. 2011, 62, 1898–1902. [Google Scholar] [CrossRef]

- He, H.; Hu, Y.; Liu, W.-W. Scheduling with deterioration effects and maintenance activities under parallel processors. Eng. Optim. 2021, 53, 2070–2087. [Google Scholar] [CrossRef]

- Jia, X.; Lv, D.-Y.; Hu, Y.; Wang, J.-B.; Wang, Z.; Wang, E. Slack due-window assignment scheduling problem with deterioration effects and a deteriorating maintenance activity. Asia-Pac. J. Oper. Res. 2022, 39, 2250005. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Li, L.; Zhao, P. A maintenance activity scheduling with time-and-position dependent deteriorating effects. Math. Biosci. Eng. 2022, 19, 11756–11767. [Google Scholar] [CrossRef]

- Zou, J.; Sui, Y.-K.; Gao, J.; Zhang, X.-Z. Parallel machines scheduling with deteriorating maintenance activities and job rejection. Asia-Pac. J. Oper. Res. 2023, 40, 2240013. [Google Scholar] [CrossRef]

- Gordon, V.S.; Proth, J.-M.; Chu, C.B. A survey of the state-of-the-art of common due date assignment and scheduling research. Eur. J. Oper. Res. 2002, 139, 1–25. [Google Scholar] [CrossRef]

- Gordon, V.S.; Proth, J.-M.; Chu, C.B. Due date assignment and scheduling: SLK, TWK and other due date assignment models. Prod. Plan. Control 2002, 13, 117–132. [Google Scholar] [CrossRef]

- Qian, J.; Zhan, Y. The due date assignment scheduling problem with delivery times and truncated sum-of-processing-times-based learning effect. Mathematics 2021, 9, 3085. [Google Scholar] [CrossRef]

- Lu, Y.-Y.; Wang, T.-T.; Wang, R.-Q.; Li, Y. A note on due-date assignment scheduling with job-dependent learning effects and convex resource allocation. Eng. Optim. 2021, 53, 1273–1281. [Google Scholar] [CrossRef]

- Wang, W. Single-machine due-date assignment scheduling with generalized earliness/tardiness penalties including proportional setup times. J. Appl. Math. Comput. 2022, 68, 1013–1031. [Google Scholar] [CrossRef]

- Brucker, P. Scheduling Algorithms; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Liu, W.; Hu, X.; Wang, X. Single machine scheduling with slack due dates assignment. Eng. Optim. 2017, 49, 709–717. [Google Scholar] [CrossRef]

- Wang, S.-H.; Lv, D.-Y.; Wang, J.-B. Research on position-dependent weights scheduling with delivery times and truncated sum-of-processing-times-based learning effect. J. Ind. Manag. Optim. 2023, 19, 2824–2837. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Wang, S.-H.; Wang, J.-B. Resource allocation scheduling with position-dependent weights and generalized earliness-tardiness cost. Mathematics 2023, 11, 222. [Google Scholar] [CrossRef]

- Jiang, C.; Zou, D.; Bai, D.; Wang, J.-B. Proportionate flowshop scheduling with position-dependent weights. Eng. Optim. 2020, 52, 37–52. [Google Scholar] [CrossRef]

- Liu, W.; Yao, Y.; Jiang, C. Single-machine resource allocation scheduling with due-date assignment, deterioration effect and position-dependent weights. Eng. Optim. 2020, 52, 701–714. [Google Scholar] [CrossRef]

- Lv, D.Y.; Wang, J.-B. Study on proportionate flowshop scheduling with due-date assignment and position-dependent weights. Optim. Lett. 2021, 15, 2311–2319. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Huang, X.; Liu, W.-W.; Wu, Y.; Wang, J.-B. Scheduling with position-dependent weights, due-date assignment and past-sequence-dependent setup times. Rairo-Oper. Res. 2021, 55, S2747–S2758. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Li, L.; Zhao, P.; Zhang, R. Due date assignment scheduling with positional-dependent weights and proportional setup times. Math. Biosci. Eng. 2022, 19, 5104–5119. [Google Scholar] [CrossRef]

- Sun, X.; Geng, X.-N.; Liu, T. Due-window assignment scheduling in the proportionate flow shop setting. Ann. Oper. Res. 2020, 292, 113–131. [Google Scholar] [CrossRef]

- Hardy, G.H.; Littlewood, J.E.; Polya, G. Inequalities; Cambridge University Press: Cambridge, UK, 1976. [Google Scholar]

- Zhang, H.; Qin, C.; Zhang, W.; Xu, Z.; Xu, G.; Gao, Z. Energy-saving scheduling for flexible job shop problem with AGV transportation considering emergencies. Systems 2023, 11, 103. [Google Scholar] [CrossRef]

- Song, L.; Xu, Z.; Wang, C.; Su, J. A new decision method of flexible job shop rescheduling based on WOA-SVM. Systems 2023, 11, 59. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).