Promoting the Application of Off-Site Construction in China’s Residential Building Industry from the Angle of Ecosystem

Abstract

1. Introduction

2. Methodology

2.1. Research Agenda

2.2. Conceptualizing the RBI-ECO of China and Proposing Hypotheses

2.2.1. The Key Concepts of Ecosystem

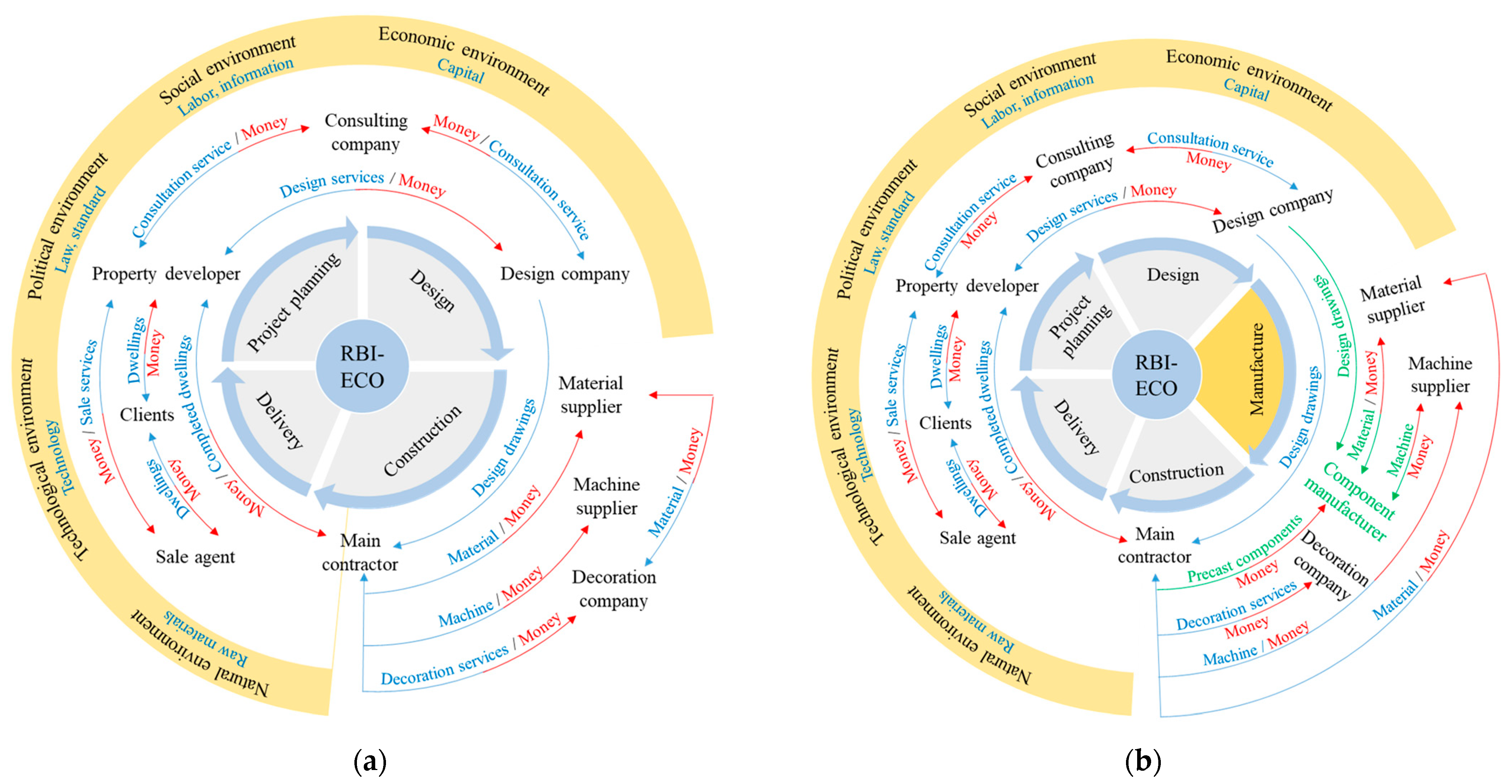

2.2.2. China’s RBI-ECO

- Composition

- Networks

- Interactions

2.2.3. Hypotheses

2.3. Survey and Semi-Structured Interviews

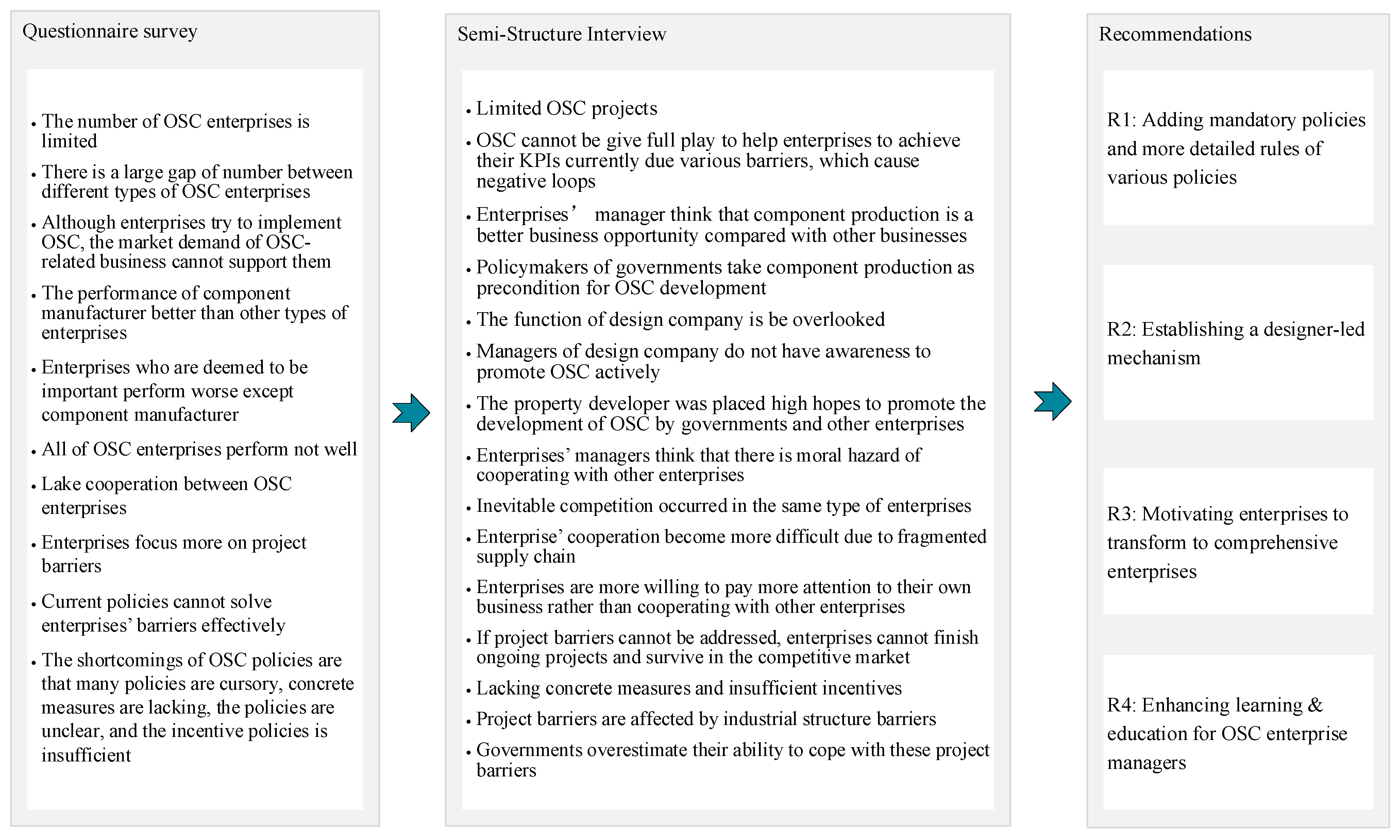

3. Analyzing Results and Discussing Hypotheses

3.1. The Status Quo Analysis of the Structure of China’s RBI-ECO to Verify H1

3.2. The Status Quo Analysis of Interactions between Enterprises to Verify H2

3.3. The Status Quo Analysis of Interactions between Enterprises and Environments to Verify H2 and H3

4. Towards a Sustainable RBI-ECO for OSC

4.1. Add Mandatory Policies and Concrete Measures (R1)

4.2. Establishing a Designer-Led Mechanism (R2)

4.3. Motivating Enterprises to Transform to Comprehensive Enterprises (R3)

4.4. Enhancing Learning and Education for OSC Enterprise Managers (R4)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Questionnaire and Interview

| This survey invites you to respond to the following questions. Your answers could help the research team to find the problems of OSC development in Chongqing. There are 13 questions in the questionnaire, which will take 10–15 min to finish. Your personal information will not be disclosed. |

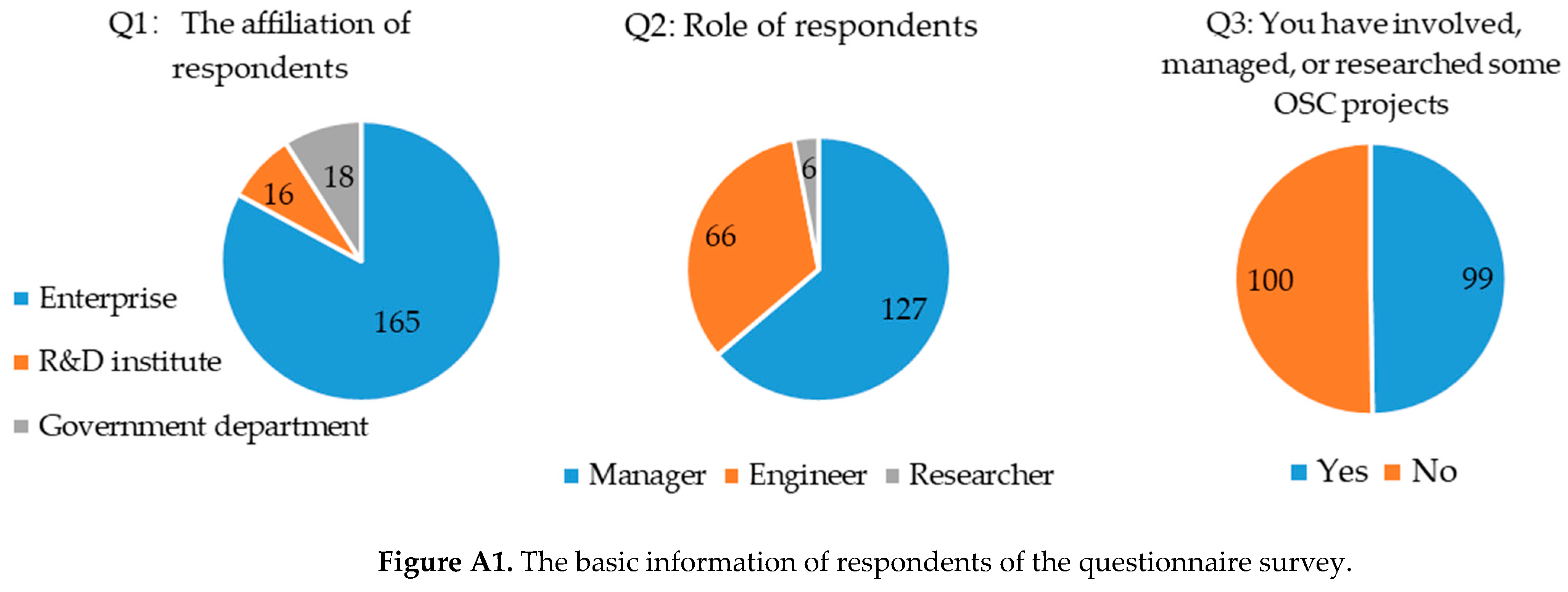

| Q1: Your affiliation: □ Enterprise □ R&D institute □ Government department |

| Q2: Your role: □ Manager □ Engineer □ Researcher |

| Q3: You have involved, managed, or researched some OSC projects: □ Yes □ No |

| Q4: You are working for: (respondents who have chosen “Enterprise” in Q1 should answer this question) □ Property developer □ Design company □ Component manufacturer □ Decoration company □ Consulting company □ Main contractor □ Comprehensive enterprise □ Machinery supplier □ Sale agent □ Material supplier □ Other |

| Q5: The driving force for enterprises to implement OSC: (multiple choice) □ Enterprises’ expectation of becoming a leader in OSC field □ The encouragement and requirement of the government □ There are abundant OSC projects in the building market □ Various advantages of OSC compared with the traditional method □ Other |

| Q6: The most important type of enterprise for promoting OSC: (multiple choice) □ Property developer □ Design company □ Component manufacturer □ Decoration company □ Consulting company □ Main contractor □ Comprehensive enterprise □ Machinery supplier □ Sale agent □ Material supplier |

| Q7: Grading the development level of different types of OSC enterprises: (The development level means that the number and ability of enterprises, score from 1 to 5, 1 = the lowest level, 5 = highest level) □ Property developer □ Design company □ Component manufacturer □ Decoration company □ Consulting company □ Main contractor □ Comprehensive enterprise □ Machinery supplier □ Sale agent □ Material supplier |

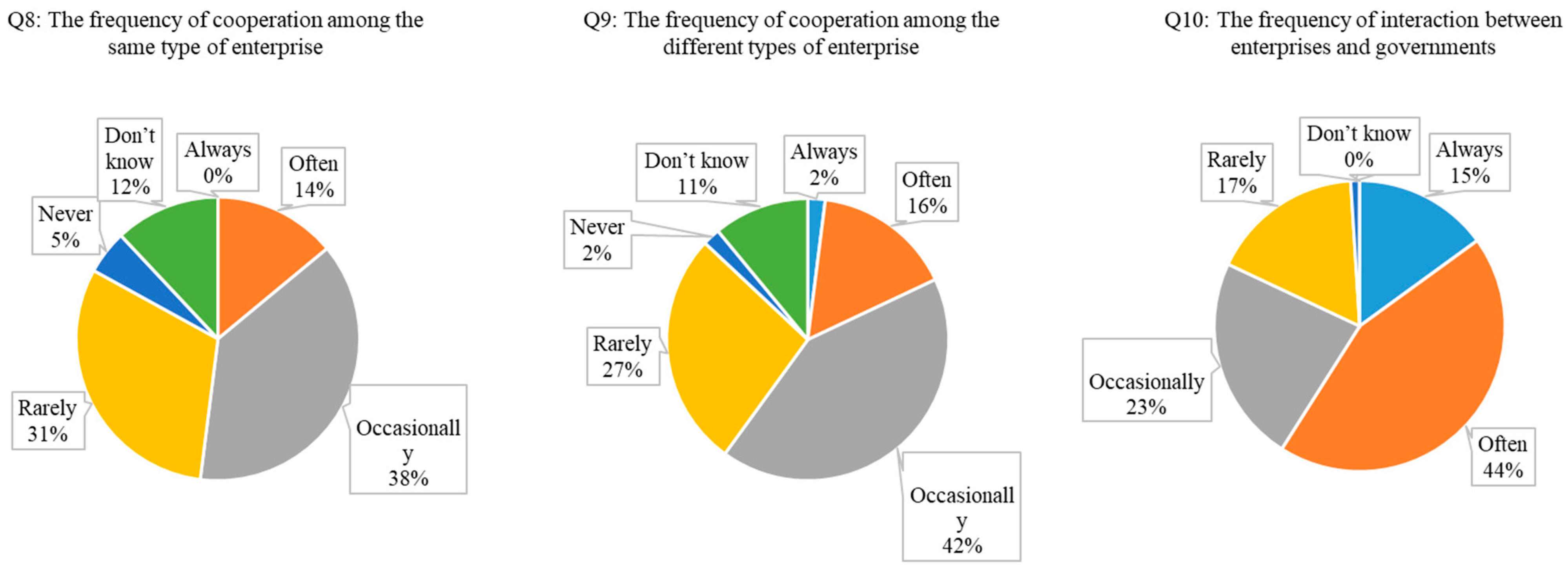

| Q8: The frequency of cooperation between the enterprises of the same type in forms of joint bidding, researching and developing new technologies, and building factories, and so on □ Always □ Often □ Occasionally □ Rarely □ Never □ Don’t know |

| Q9: The frequency of cooperation between different types of enterprises in forms of joint bidding, researching and developing new technologies, and building factories, and so on □ Always □ Often □ Occasionally □ Rarely □ Never □ Don’t know |

| Q10: The frequency with which enterprises ask the government for help to address OSC barriers □ Always □ Often □ Occasionally □ Rarely □ Never □ Don’t know |

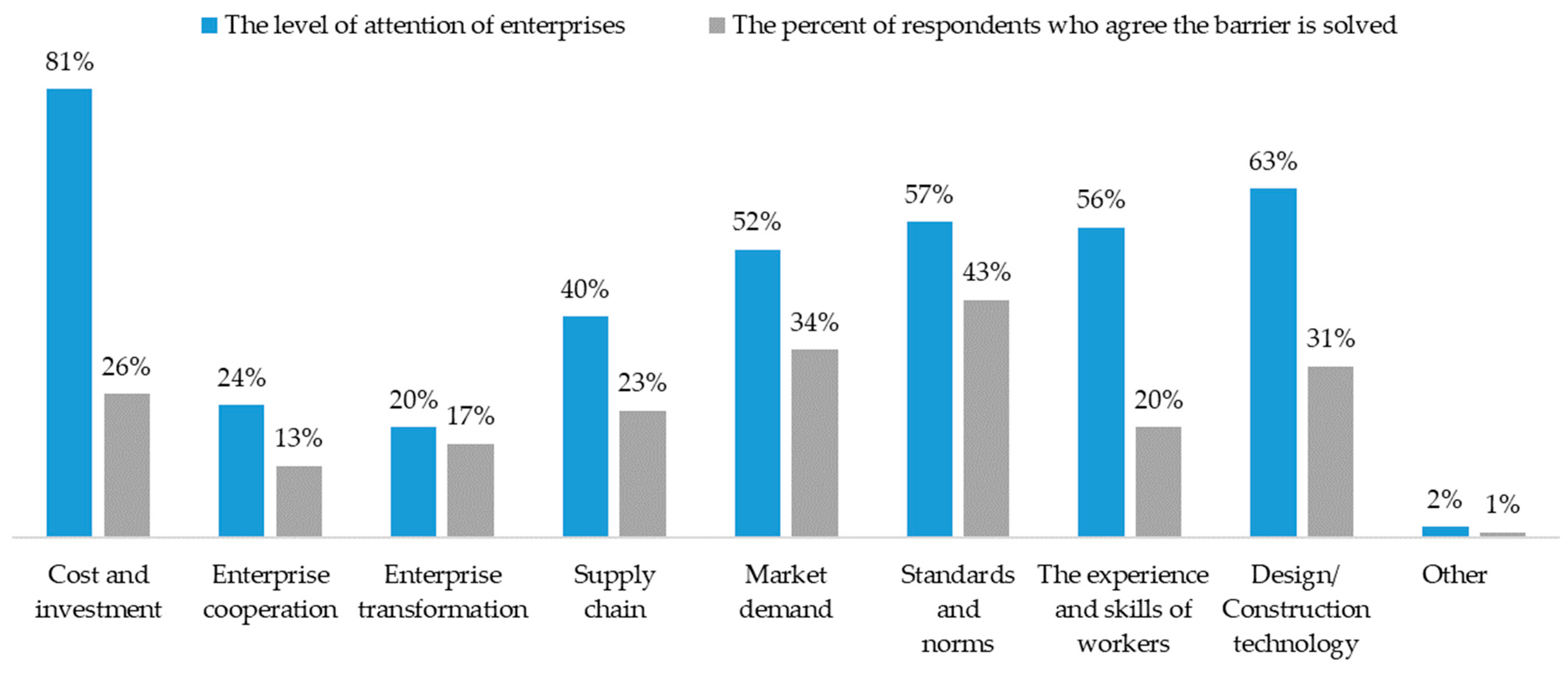

| Q11: The barriers that enterprises reported to the government include: (multiple choice) □ Cost and investment □ Design/Construction technology □ Supply chain □ Market demand □ Standards and norms □ Enterprise transformation □ The experience and skills of workers □ Enterprise cooperation □ Other |

| Q12: The barriers which can be effectively solved by current policies published include: (multiple choice) □ Cost and investment □ Design/Construction technology □ Supply chain □ Market demand □ Standards and norms □ Enterprise transformation □ The experience and skills of workers □ Enterprise cooperation □ Other |

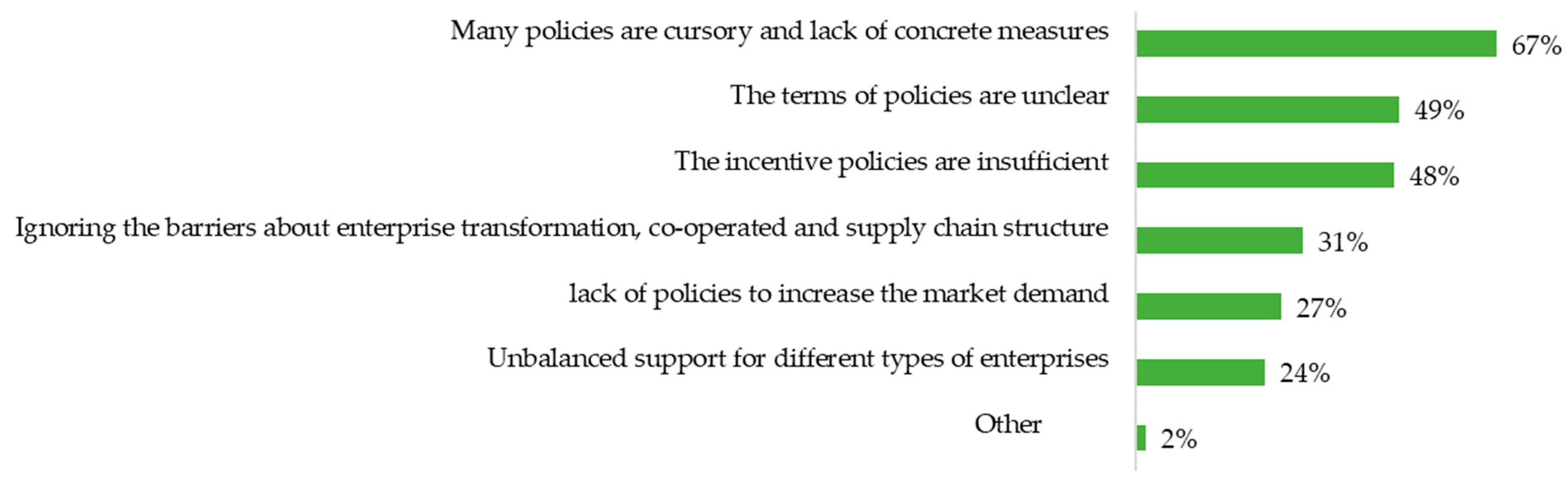

| Q13: The shortcomings of OSC policies published by the government are: (multiple choice) □ Many policies are cursory and concrete measures are lacking □ The policies are unclear □ Unbalanced support for different types of enterprises □ The incentive of policies is insufficient □ Ignoring the barriers about enterprise transformation, co-operation, and supply chain structure □ Lack of policies to increase the market demand □ Other |

| This survey invites you to respond to the following questions. Your answers could help the research team to explain, validate, or refute the conclusions of the questionnaire. Each interview will last for circa 30–40 min. Data collected will be used for the research team to conduct a deep analysis of the status and problems of implementation of off-site construction (OSC) in Chongqing and formulate some recommendations. Your personal information will not be disclosed. |

| Name: ...................................................................................... Affiliation: ............................................................................... Title/Role: ............................................................................... |

| I1: The results of the questionnaire show that the number of OSC enterprises is limited and the capacity of OSC enterprises is poor. What caused this situation? |

| I2: The results of the questionnaire show that the development of different types of enterprises is uncoordinated, and the development of the component manufacturer far exceeds other types of enterprises. What do you think about this phenomenon? |

| I3: The results of the questionnaire show that there is rare cooperation between enterprises, whether they are the same type of enterprise or different types of enterprises. What caused this problem? |

| I4: According to the results of the questionnaire, why do enterprises pay more attention to the barriers about cost, construction/design technology, the experience and skills of workers, standards and norms, and market demand? |

| I5: According to the results of the questionnaire, why cannot government’s policies effectively solve these barriers frequently reflected by enterprises? |

Appendix B. The Results of Questionnaire

Appendix C. The Findings of the Questionnaire and Interviews

| Questions | Findings |

|---|---|

| Q3 |

|

| Q4 |

|

| Q5 |

|

| Q6 |

|

| Q7 |

|

| Q8 |

|

| Q9 |

|

| Q10 |

|

| Q11 |

|

| Q12 |

|

| Q13 |

|

| Questions | Findings |

|---|---|

| I1 |

|

| I2 |

|

| I3 |

|

| I4 |

|

| I5 |

|

References

- Chiang, Y.-H.; Chan, E.H.-W.; Lok, L.K.-L. Prefabrication and barriers to entry—A case study of public housing and institutional buildings in Hong Kong. Habitat Int. 2006, 30, 482–499. [Google Scholar] [CrossRef]

- Mydin, M.O.; Sani, N.; Phius, A. Investigation of Industrialised Building System Performance in Comparison to Conventional Construction Method. MATEC Web Conf. 2014, 10, 04001. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Blismas, N. Off-Site Manufacture in Australia: Current State and Future Directions; Cooperative Research Centre for Construction Innovation: Gold Coast, Australia, 2007; pp. 1–51. [Google Scholar]

- Pasco, J.; Lei, Z.; Aranas, C. Additive Manufacturing in Off-Site Construction: Review and Future Directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, Z.; Wu, S. Optimized flowshop scheduling of multiple production lines for precast production. Autom. Constr. 2016, 72, 321–329. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Costa, S.; Carvalho, M.S.; Pimentel, C.; Duarte, C. A Systematic Literature Review and Conceptual Framework of Construction Industrialization. J. Constr. Eng. Manag. 2023, 149, 03122013. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- U.S. Department of Housing and Urban Development. Offsite Construction for Housing: Research Roadmap; U.S. Department of Housing and Urban Development: Washington, DC, USA, 2023; p. 83.

- The People’s Republic of China. The 14th Five-Year Plan (2021–2025) for National Economic and Social Development and Vision 2035 of the People’s Republic of China; Xinhua News Agency: Beijing, China, 2021.

- Yue, Y.; Li, Q. Research on the development trend of China’s construction industry modernization: The case of Jiangsu, China. In Proceedings of the International Conference on Construction and Real Estate Management 2016, Edmonton, AB, Canada, 29 September–1 October 2016. [Google Scholar]

- Azhar, S.; Lukkad, M.Y.; Ahmad, I. An Investigation of Critical Factors and Constraints for Selecting Modular Construction over Conventional Stick-Built Technique. Int. J. Constr. Educ. Res. 2013, 9, 203–225. [Google Scholar] [CrossRef]

- Tam, V.W.; Fung, I.W.; Sing, M.C.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Nasereddin, M.; Price, A. Addressing the capital cost barrier to sustainable construction. Dev. Built Environ. 2021, 7, 100049. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Fan, C.; Xu, X.; Shen, G.Q. Schedule delay analysis of prefabricated housing production: A hybrid dynamic approach. J. Clean. Prod. 2018, 195, 1533–1545. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Han, Y.; Wang, L. Identifying Barriers to Off-Site Construction Using Grey Dematel Approach: Case of China. J. Civ. Eng. Manag. 2018, 24, 364–377. [Google Scholar] [CrossRef]

- Pan, W.; Sidwell, R. Demystifying the cost barriers to offsite construction in the UK. Constr. Manag. Econ. 2011, 29, 1081–1099. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.; Tan, J. A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Terzis, D. Monitoring innovation metrics in construction and civil engineering: Trends, drivers and laggards. Dev. Built Environ. 2022, 9, 100064. [Google Scholar] [CrossRef]

- Chourasia, A.; Singhal, S. Manivannan Prefabricated Volumetric Modular Construction: A Review on Current Systems, Challenges, and Future Prospects. Pract. Period. Struct. Des. Constr. 2023, 28, 03122009. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J.; Ma, X.; Xiong, W. Precast supply chain management in off-site construction: A critical literature review. J. Clean. Prod. 2019, 232, 1204–1217. [Google Scholar] [CrossRef]

- Gao, Y.; Tian, X.-L. Prefabrication policies and the performance of construction industry in China. J. Clean. Prod. 2020, 253, 120042. [Google Scholar] [CrossRef]

- Geels, F.W. From sectoral systems of innovation to socio-technical systems: Insights about dynamics and change from sociology and institutional theory. Res. Policy 2004, 33, 897–920. [Google Scholar] [CrossRef]

- Teng, Y.; Mao, C.; Liu, G.; Wang, X. Analysis of stakeholder relationships in the industry chain of industrialized building in China. J. Clean. Prod. 2017, 152, 387–398. [Google Scholar] [CrossRef]

- Arif, M.; Goulding, J.; Pour Rahimian, F. Promoting Off-Site Construction: Future Challenges and Opportunities. J. Arch. Eng. 2012, 18, 75–78. [Google Scholar] [CrossRef]

- Xiong, W.; Yang, J.; Wang, Z.; Hu, H.; Xu, F.; Zhang, J. Improving supply chain communications for off-site construction using process specification language. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction (ISARC), Berlin, Germany, 20–25 July 2018. [Google Scholar]

- Azarmi, D. Factors Affecting Technology Innovation and Its Commercialisation in Firms. Mod. Appl. Sci. 2016, 10, 36. [Google Scholar] [CrossRef]

- Rong, K.; Patton, D.; Chen, W. Business models dynamics and business ecosystems in the emerging 3D printing industry. Technol. Forecast. Soc. Change 2018, 134, 234–245. [Google Scholar] [CrossRef]

- Sagar, A.D.; Frosch, R.A. A perspective on industrial ecology and its application to a metals-industry ecosystem. J. Clean. Prod. 1997, 5, 39–45. [Google Scholar] [CrossRef]

- Decan, A.; Mens, T.; Grosjean, P. An empirical comparison of dependency network evolution in seven software packaging ecosystems. Empir. Softw. Eng. 2018, 24, 381–416. [Google Scholar] [CrossRef]

- Pulkka, L.; Ristimäki, M.; Rajakallio, K.; Junnila, S. Applicability and benefits of the ecosystem concept in the construction industry. Constr. Manag. Econ. 2016, 34, 129–144. [Google Scholar] [CrossRef]

- Aksenova, G.; Kiviniemi, A.; Kocaturk, T.; Lejeune, A. From Finnish AEC knowledge ecosystem to business ecosystem: Lessons learned from the national deployment of BIM. Constr. Manag. Econ. 2018, 37, 317–335. [Google Scholar] [CrossRef]

- Jabareen, Y. Building a conceptual framework philosophy, definitions, and procedure. Int. J. Qual. Methods 2009, 8, 49–62. [Google Scholar] [CrossRef]

- Basu, S.; Bale, C.S.E.; Wehnert, T.; Topp, K. A complexity approach to defining urban energy systems. Cities 2019, 95, 102358. [Google Scholar] [CrossRef]

- Durst, S.; Zieba, M. Knowledge risks inherent in business sustainability. J. Clean. Prod. 2019, 251, 119670. [Google Scholar] [CrossRef]

- Lee, M.S.N.; Masrom, M.A.N.; Mohamed, S.; Goh, K.; Sarpin, N.; Manap, N. Examining Risk as Guideline in Design Stage for Green Retrofits Projects: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 713, 012043. [Google Scholar] [CrossRef]

- WILLIS, A.J. Forum. Functional Ecol. 1997, 11. [Google Scholar] [CrossRef]

- Gordon, H.B. Coral reef primary productivity. A hierarchy of pattern and process. Trends Ecol. Evol. 1990, 5, 149–155. [Google Scholar] [CrossRef]

- Tansley, A.G. The Use and Abuse of Vegetational Concepts and Terms. Ecology 1935, 16, 284–307. [Google Scholar] [CrossRef]

- Fath, B. Encyclopedia of Ecology; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Tsujimoto, M.; Kajikawa, Y.; Tomita, J.; Matsumoto, Y. A review of the ecosystem concept—Towards coherent ecosystem design. Technol. Forecast. Soc. Change 2018, 136, 49–58. [Google Scholar] [CrossRef]

- Schowalter, T.D. Insect Ecology; Academic Press: Salt Lake City, UT, USA, 2011. [Google Scholar]

- Kent, M. Advanced Biology; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Ranganathan, S.; Nakai, K.; Schönbach, C. Encyclopedia of Bioinformatics and Computational Biology: ABC of Bioinformatics; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Johnson, E.A.; Miyanishi, K. Plant Disturbance Ecology; Academic Press: Cambridge, UK, 2007. [Google Scholar]

- Sahney, S.; Benton, M.J. Recovery from the most profound mass extinction of all time. Proc. R. Soc. B Boil. Sci. 2008, 275, 759–765. [Google Scholar] [CrossRef] [PubMed]

- Michalet, R. Disturbance, survival, and succession: Understanding ecological responses to the 1980 eruption of Mount St. Helens. Mt. Res. Dev. 2007, 27, 98–99. [Google Scholar] [CrossRef]

- Xiao, X. Green Supply Chain Management in the UK and China Construction Industry; University of East Anglia University of East Anglia: Norwich, UK, 2006. [Google Scholar]

- Hannan, M.T.; Carroll, G.R. Dynamics of Organizational Populations: Density, Legitimation, and Competition; Oxford University Press: New York, NY, USA, 1992. [Google Scholar]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Holstein, J.A.; Grubium, J.F. Narrative Practice and the Active Interview; SAGE Publications: Los Angeles, CA, USA, 2016. [Google Scholar]

- Bar-Yam, S. Mutualistic Relationships. Available online: https://necsi.edu/mutualistic-relationships (accessed on 2 March 2023).

- O’Brien, W.J.; Formoso, C.T.; Ruben, V.; London, K. Review of Organizational Approaches to the Construction Supply Chain; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Liu, G.; Li, K.; Zhao, D.; Mao, C. Business Model Innovation and Its Drivers in the Chinese Construction Industry during the Shift to Modular Prefabrication. J. Manag. Eng. 2017, 33, 04016051. [Google Scholar] [CrossRef]

| Composition | Types | Attribute |

|---|---|---|

| Organisms | Property developer | Buys land; plans projects; raises money; manages construction activities and sales; delivers and operates projects |

| Design company | Provides design services for the property developer | |

| Main contractor | Is responsible for the day-to-day oversight of a construction site; management of subcontractors and employed by the property developer | |

| Consulting firm | Provides various consulting services for various enterprises | |

| Decoration company | Provides decoration services for the main contractor | |

| Component manufacturer | Provides precast components for the main contractor | |

| Machinery supplier | Sells or rents machines for the main contractor and the component manufacturer | |

| Sale agent | Provides sale services for the property developer | |

| Material supplier | Provides materials for the main contractor and the component manufacturer | |

| Client | Can be any customer who would buy dwellings | |

| Environment | Natural environment | Is related to raw material, energy, land, environmental protection, geographical condition, and so on |

| Social environment | Is related to social values, social stability, public security, religion, social welfare, education, and so on | |

| Economic environment | Is related to the labor market, consumer preference, GDP, finance, productivity, demands, and so on | |

| Technological environment | Is related to technological research and development, technological creation, technological progress, and so on | |

| Political environment | Is related to laws, standards, policies, war, civil strife, and so on |

| Interviewees | Position | Years of Working | Authority | Attribute |

|---|---|---|---|---|

| Li YG | Engineer | 8 | CMCU Engineering Co., Ltd. | Design company |

| Liu CM | Manager | 7 | Chongqing Construction Engineering Group Corporation Limited | Manufacturer |

| Ma YH | Engineer | 8 | Greatech | Contractor |

| Xiao ZZ | Professor | 15 | Chongqing University/CCETG Chongqing Engineering Co., Ltd. | Academy/Design company |

| Yang YX | Engineer | 9 | Broad Group | Consultancy |

| Liu A | Officer | 5 | Ministry of Housing and Urban-Rural Development of Chongqing | Government |

| Fu Y | Associate professor | 9 | Chongqing University | Academy |

| Ding ZZ | Manager | 8 | Vanke | Property developer |

| Chen WK | Engineer | 13 | Chongqing Huirui Construction Technology Co., Ltd. | Contractor |

| Zhang YW | Officer | 6 | Ministry of Housing and Urban-Rural Development of Chongqing | Government |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, F.; Fu, X.; Huang, R. Promoting the Application of Off-Site Construction in China’s Residential Building Industry from the Angle of Ecosystem. Systems 2023, 11, 140. https://doi.org/10.3390/systems11030140

Xie F, Fu X, Huang R. Promoting the Application of Off-Site Construction in China’s Residential Building Industry from the Angle of Ecosystem. Systems. 2023; 11(3):140. https://doi.org/10.3390/systems11030140

Chicago/Turabian StyleXie, Fangyun, Xinyue Fu, and Ruopeng Huang. 2023. "Promoting the Application of Off-Site Construction in China’s Residential Building Industry from the Angle of Ecosystem" Systems 11, no. 3: 140. https://doi.org/10.3390/systems11030140

APA StyleXie, F., Fu, X., & Huang, R. (2023). Promoting the Application of Off-Site Construction in China’s Residential Building Industry from the Angle of Ecosystem. Systems, 11(3), 140. https://doi.org/10.3390/systems11030140