A Database of Static Thermal Insulation and Evaporative Resistance Values of Dutch Firefighter Clothing Items and Ensembles

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. The Thermal Manikin Tore

2.2. Manikin Calibration

2.3. Measurements of Clothing Surface Area Factor (fcl)

2.4. Thermal Insulation Measurements

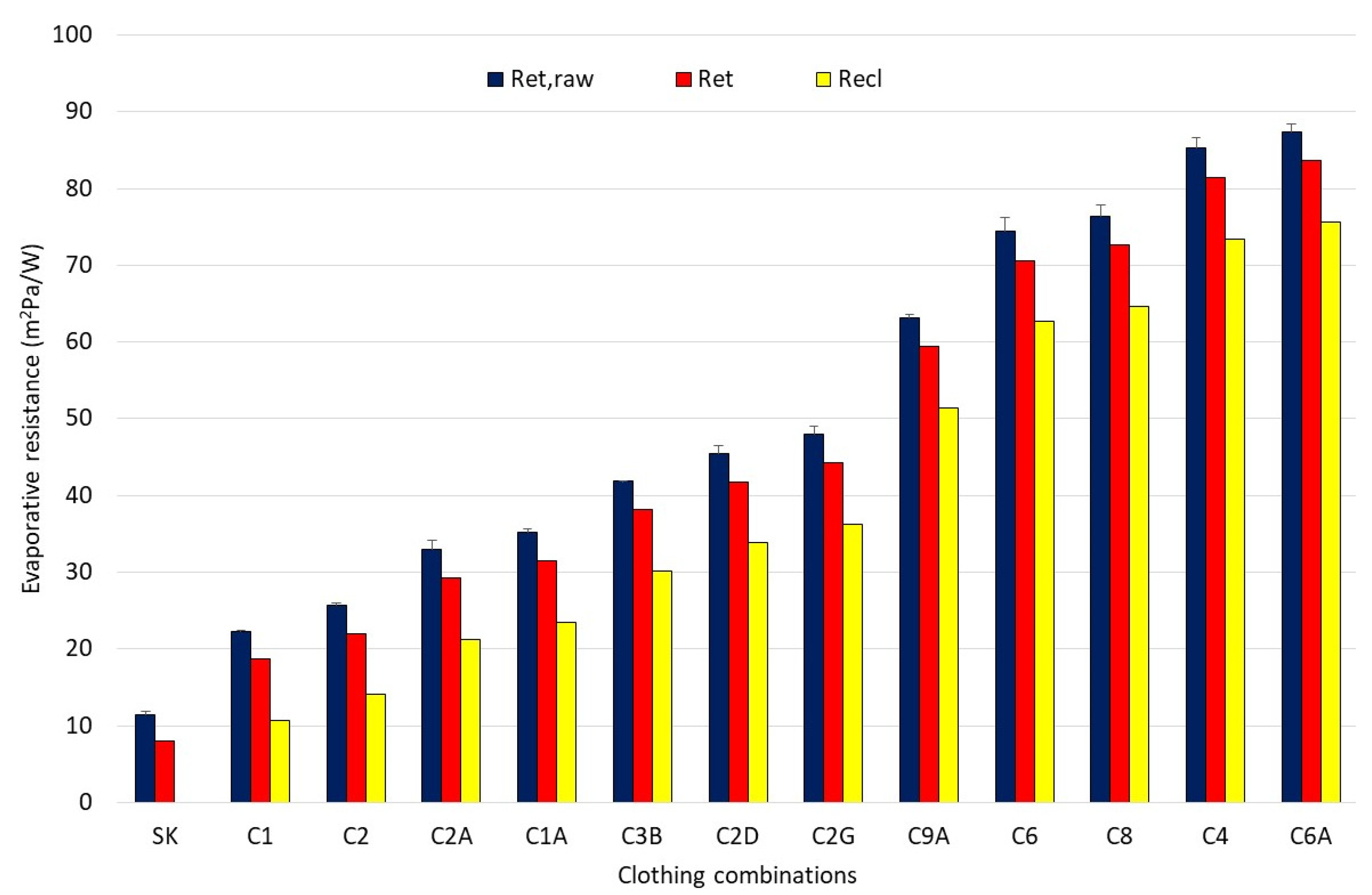

2.5. Evaporative Resistance Measurements

2.6. Calculations

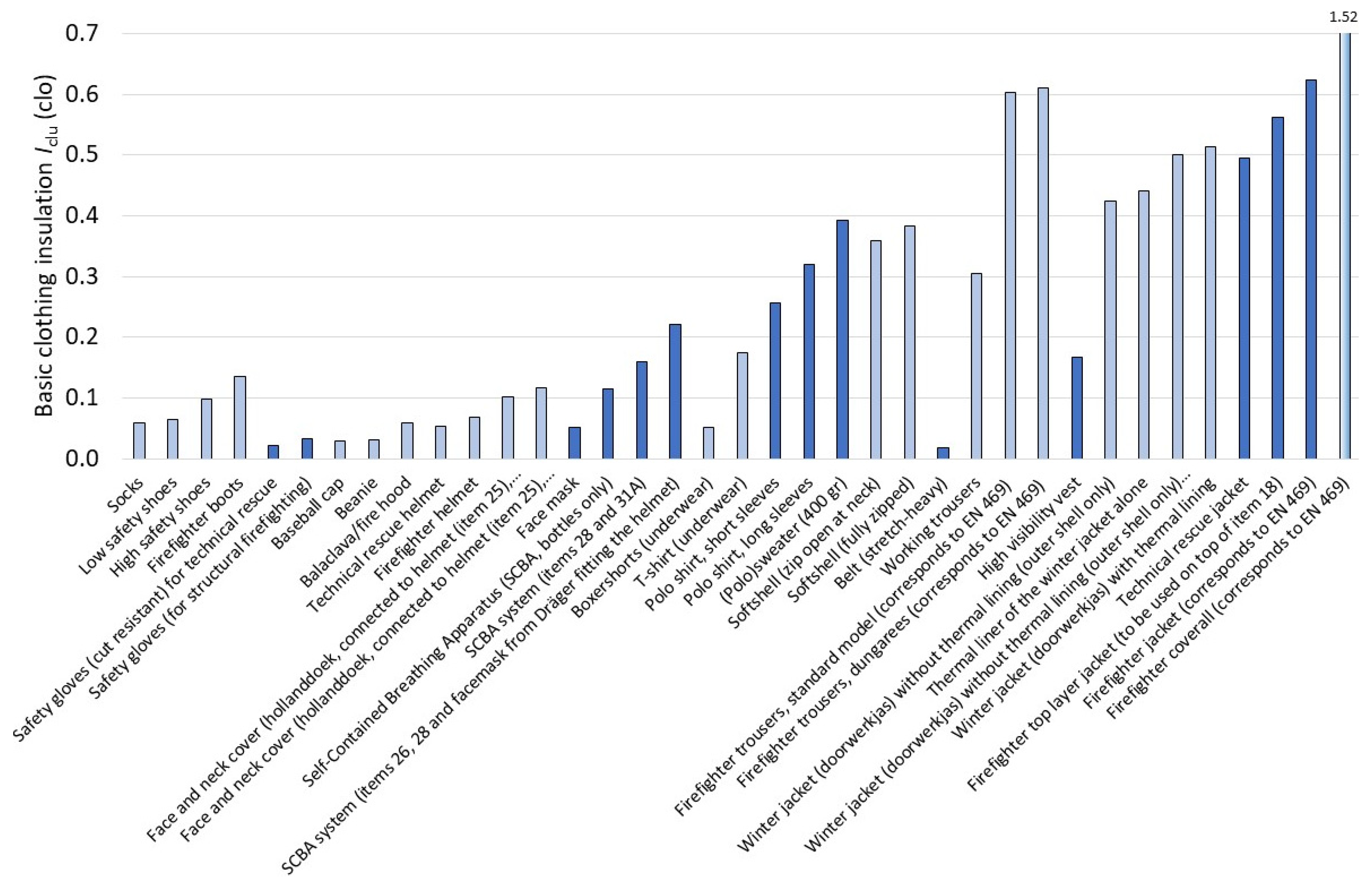

2.7. Clothing

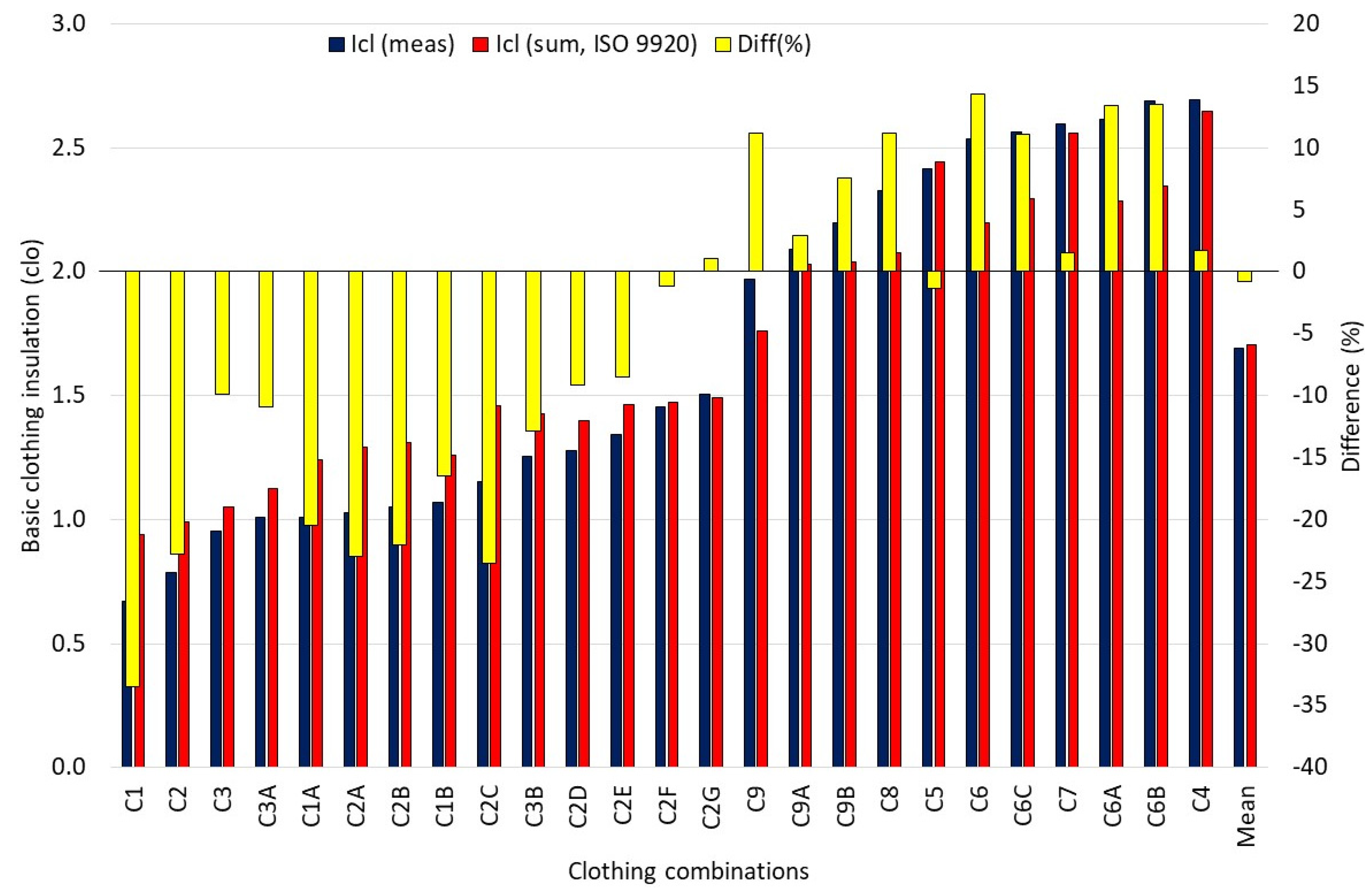

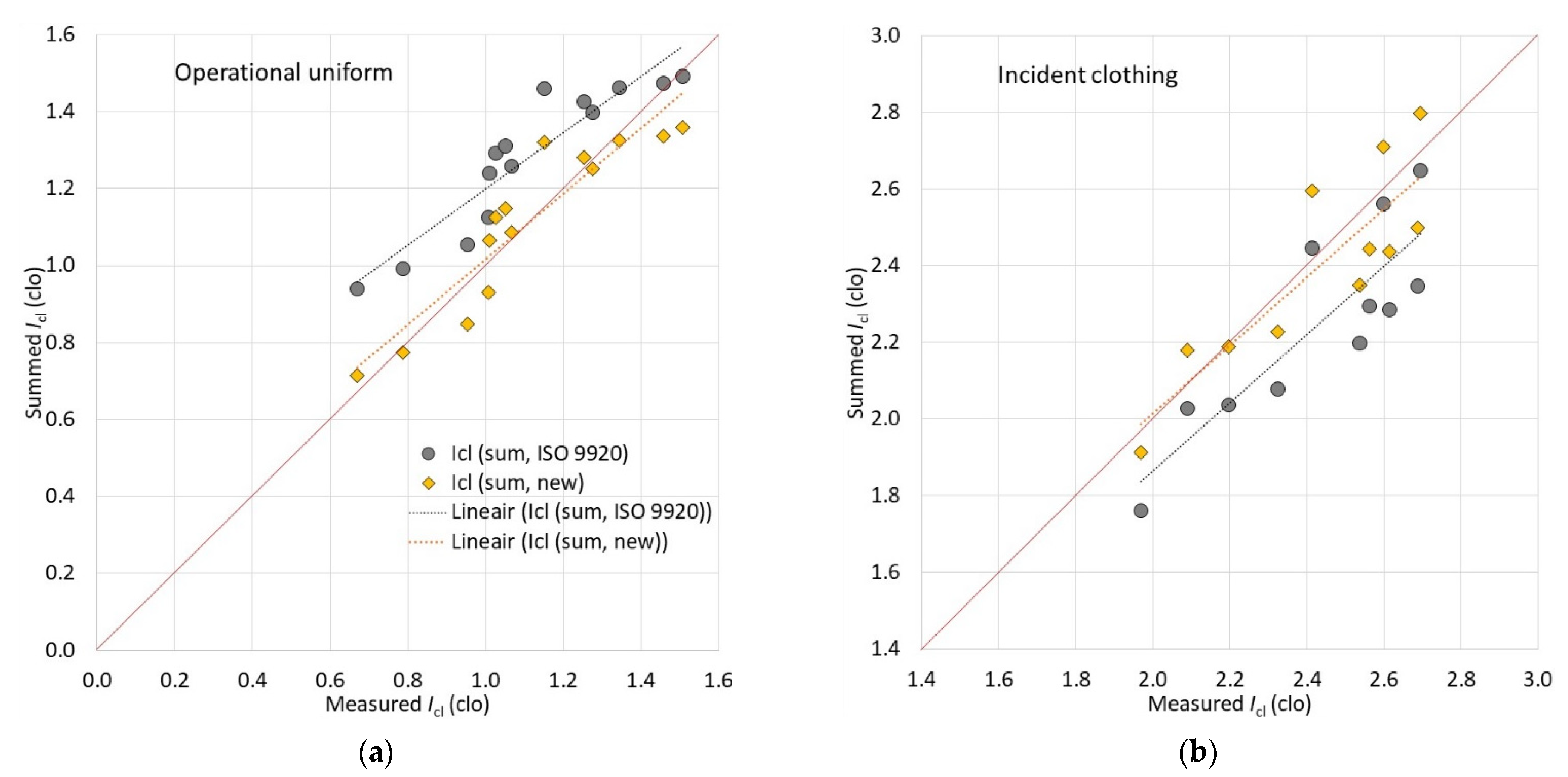

3. Results and Discussion

3.1. Relationship between Measured and Summed Basic Clothing Insulation (Icl)

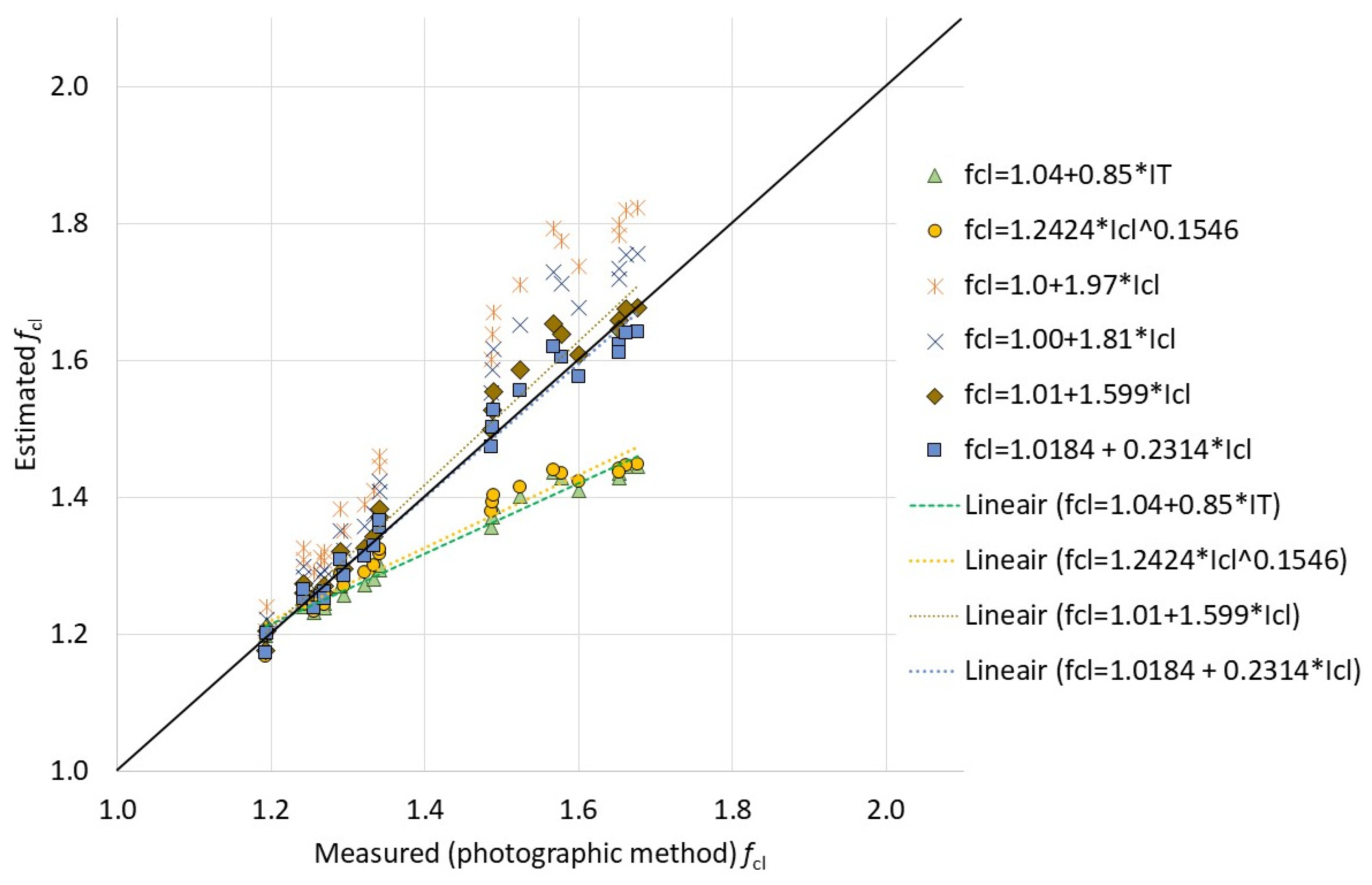

3.2. Clothing Surface Area Factor (fcl)

3.3. The Use of Collected Data

4. Conclusions and Future Perspectives

- Selection and recommendations of clothing combinations for the best performance and comfort under specific exposure conditions;

- Evaluation of the design aspects of the protective clothing and protective clothing systems;

- Modelling and prediction model validation, and the comparison of their deviation from human responses in realistic conditions with human subjects;

- Supporting the development of the firefighter’s modular protective clothing system of the future;

- Developing digital decision support tools for rescue services’ purposes;

- Creating educational and demonstration materials for optimal protection selection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Code | Head | Chest | Back | Abdomen | Buttocks | Torso | Upper Arms | Lower Arms | Arms | Hands | Thighs | Calves | Legs | Feet | Head, Hands and Feet Excluded |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AL | 0.106 | 0.113 | 0.097 | 0.095 | 0.076 | 0.097 | 0.119 | 0.105 | 0.113 | 0.101 | 0.097 | 0.082 | 0.090 | 0.108 | 0.097 |

| C1 | 0.101 | 0.279 | 0.251 | 0.304 | 0.267 | 0.263 | 0.211 | 0.104 | 0.156 | 0.101 | 0.230 | 0.174 | 0.201 | 0.264 | 0.207 |

| C1A | 0.098 | 0.413 | 0.388 | 0.469 | 0.472 | 0.419 | 0.360 | 0.232 | 0.302 | 0.100 | 0.255 | 0.186 | 0.222 | 0.268 | 0.294 |

| C1B | 0.105 | 0.451 | 0.405 | 0.520 | 0.498 | 0.448 | 0.368 | 0.244 | 0.312 | 0.103 | 0.260 | 0.191 | 0.227 | 0.270 | 0.305 |

| C2 | 0.101 | 0.238 | 0.214 | 0.329 | 0.285 | 0.246 | 0.278 | 0.205 | 0.247 | 0.117 | 0.246 | 0.179 | 0.214 | 0.267 | 0.233 |

| C2A | 0.099 | 0.387 | 0.347 | 0.531 | 0.438 | 0.397 | 0.385 | 0.278 | 0.337 | 0.110 | 0.254 | 0.175 | 0.215 | 0.266 | 0.292 |

| C2B | 0.098 | 0.389 | 0.357 | 0.526 | 0.455 | 0.404 | 0.394 | 0.287 | 0.345 | 0.122 | 0.253 | 0.174 | 0.214 | 0.273 | 0.294 |

| C2C | 0.101 | 0.456 | 0.425 | 0.639 | 0.574 | 0.480 | 0.411 | 0.295 | 0.360 | 0.112 | 0.245 | 0.208 | 0.228 | 0.285 | 0.321 |

| C2D | 0.155 | 0.468 | 0.342 | 0.597 | 0.500 | 0.431 | 0.435 | 0.338 | 0.391 | 0.123 | 0.248 | 0.206 | 0.228 | 0.282 | 0.317 |

| C2E | 0.211 | 0.461 | 0.340 | 0.597 | 0.496 | 0.427 | 0.439 | 0.338 | 0.394 | 0.124 | 0.248 | 0.205 | 0.228 | 0.284 | 0.316 |

| C2F | 0.166 | 0.581 | 0.508 | 0.680 | 0.680 | 0.577 | 0.602 | 0.484 | 0.550 | 0.121 | 0.242 | 0.209 | 0.226 | 0.274 | 0.361 |

| C2G | 0.157 | 0.626 | 0.554 | 0.742 | 0.702 | 0.623 | 0.624 | 0.489 | 0.560 | 0.136 | 0.245 | 0.206 | 0.227 | 0.284 | 0.370 |

| C3 | 0.101 | 0.280 | 0.248 | 0.443 | 0.453 | 0.302 | 0.329 | 0.261 | 0.299 | 0.155 | 0.241 | 0.180 | 0.211 | 0.275 | 0.259 |

| C3A | 0.143 | 0.269 | 0.232 | 0.427 | 0.411 | 0.286 | 0.314 | 0.238 | 0.280 | 0.152 | 0.231 | 0.202 | 0.218 | 0.268 | 0.255 |

| C3B | 0.145 | 0.414 | 0.378 | 0.601 | 0.598 | 0.442 | 0.410 | 0.297 | 0.358 | 0.123 | 0.249 | 0.219 | 0.235 | 0.272 | 0.319 |

| C4 | 0.276 | 0.706 | 0.609 | 0.764 | 0.601 | 0.660 | 0.526 | 0.414 | 0.480 | 0.259 | 0.618 | 0.434 | 0.528 | 0.354 | 0.560 |

| C5 | 0.207 | 0.670 | 0.534 | 0.585 | 0.529 | 0.581 | 0.551 | 0.389 | 0.480 | 0.262 | 0.545 | 0.439 | 0.497 | 0.341 | 0.523 |

| C6 | 0.207 | 0.730 | 0.529 | 0.793 | 0.764 | 0.657 | 0.578 | 0.419 | 0.506 | 0.259 | 0.602 | 0.421 | 0.514 | 0.345 | 0.560 |

| C6A | 0.281 | 0.644 | 0.542 | 0.730 | 0.622 | 0.614 | 0.522 | 0.392 | 0.466 | 0.264 | 0.613 | 0.425 | 0.521 | 0.348 | 0.539 |

| C6B | 0.315 | 0.654 | 0.520 | 0.722 | 0.608 | 0.603 | 0.520 | 0.402 | 0.470 | 0.280 | 0.631 | 0.432 | 0.533 | 0.352 | 0.542 |

| C6C | 0.272 | 0.642 | 0.549 | 0.720 | 0.579 | 0.607 | 0.500 | 0.413 | 0.462 | 0.258 | 0.597 | 0.418 | 0.510 | 0.342 | 0.531 |

| C7 | 0.207 | 0.812 | 0.623 | 0.842 | 0.783 | 0.735 | 0.535 | 0.419 | 0.485 | 0.255 | 0.613 | 0.426 | 0.521 | 0.350 | 0.578 |

| C8 | 0.198 | 0.626 | 0.454 | 0.717 | 0.734 | 0.576 | 0.471 | 0.387 | 0.437 | 0.250 | 0.585 | 0.424 | 0.507 | 0.344 | 0.513 |

| C9 | 0.155 | 0.545 | 0.411 | 0.777 | 0.772 | 0.537 | 0.401 | 0.349 | 0.379 | 0.155 | 0.565 | 0.426 | 0.499 | 0.340 | 0.478 |

| C9A | 0.153 | 0.664 | 0.447 | 0.796 | 0.734 | 0.590 | 0.479 | 0.390 | 0.441 | 0.147 | 0.586 | 0.433 | 0.514 | 0.351 | 0.521 |

| C9B | 0.154 | 0.638 | 0.436 | 0.727 | 0.777 | 0.574 | 0.468 | 0.388 | 0.435 | 0.247 | 0.590 | 0.426 | 0.511 | 0.348 | 0.513 |

Appendix B

| Code | All | Head | Chest | Back | Abdomen | Buttocks | Torso | Upper Arms | Lower Arms | Arms | Hands | Thighs | Calves | Legs | Feet | Head, Hands and Feet Excluded | Hands and Feet Excluded | Hands Excluded |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SK | 8.0 | 8.0 | 9.5 | 9.5 | 6.0 | 9.7 | 8.7 | 9.5 | 7.6 | 8.7 | 5.3 | 6.7 | 10.3 | 7.8 | 6.4 | 8.4 | 8.3 | 8.2 |

| C1 | 18.7 | 8.9 | 21.8 | 18.7 | 36.9 | 27.9 | 23.1 | 19.9 | 8.1 | 13.7 | 6.0 | 26.5 | 21.7 | 24.3 | 107.1 | 20.5 | 18.8 | 20.3 |

| C1A | 31.5 | 9.8 | 66.0 | 63.5 | 74.0 | 48.5 | 62.5 | 65.8 | 44.7 | 55.9 | 8.2 | 28.1 | 21.5 | 24.9 | 102.4 | 40.2 | 33.3 | 35.2 |

| C2 | 22.0 | 9.6 | 24.6 | 18.5 | 39.3 | 29.3 | 24.2 | 26.5 | 17.7 | 22.8 | 9.0 | 28.6 | 21.2 | 25.0 | 106.7 | 24.2 | 21.8 | 23.5 |

| C2A | 29.3 | 8.9 | 60.0 | 67.1 | 78.6 | 44.0 | 61.3 | 66.9 | 53.9 | 61.7 | 6.2 | 23.6 | 22.7 | 23.1 | 97.3 | 38.9 | 31.8 | 33.6 |

| C2D | 41.8 | 16.8 | 161.9 | 112.1 | 184.7 | 53.6 | 112.8 | 94.3 | 85.6 | 89.6 | 10.8 | 27.0 | 27.9 | 27.0 | 113.2 | 51.9 | 45.0 | 47.3 |

| C2G | 44.3 | 17.9 | 179.2 | 129.9 | 151.9 | 64.6 | 124.8 | 124.1 | 94.4 | 110.7 | 14.6 | 23.2 | 30.5 | 25.3 | 105.8 | 52.8 | 46.2 | 48.5 |

| C3B | 38.2 | 13.7 | 87.4 | 83.5 | 118.9 | 54.2 | 82.6 | 71.6 | 50.9 | 60.4 | 11.9 | 30.0 | 27.7 | 28.7 | 87.4 | 47.1 | 40.1 | 42.0 |

| C4 | 81.4 | 44.6 | 139.6 | 101.8 | 134.6 | 124.3 | 120.7 | 85.2 | 71.9 | 79.9 | 41.1 | 84.1 | 75.4 | 78.9 | 94.0 | 91.7 | 84.7 | 85.3 |

| C6 | 70.6 | 22.8 | 114.1 | 77.2 | 133.3 | 100.6 | 98.0 | 88.7 | 77.9 | 84.3 | 46.1 | 79.8 | 73.4 | 76.0 | 96.7 | 85.3 | 71.0 | 72.5 |

| C6A | 83.6 | 48.7 | 115.6 | 112.8 | 134.1 | 121.3 | 117.9 | 89.7 | 77.4 | 84.7 | 42.7 | 82.8 | 76.7 | 78.5 | 111.4 | 92.2 | 86.0 | 87.6 |

| C8 | 72.6 | 24.5 | 112.1 | 73.8 | 183.9 | 110.4 | 100.4 | 71.2 | 65.3 | 68.8 | 51.0 | 81.0 | 97.0 | 85.3 | 108.8 | 85.7 | 72.2 | 74.1 |

| C9A | 59.4 | 16.3 | 107.7 | 68.3 | 144.4 | 109.9 | 93.5 | 69.0 | 61.4 | 66.0 | 22.4 | 79.6 | 75.2 | 77.1 | 101.2 | 79.6 | 62.4 | 64.2 |

Appendix C. Visualisation and Ranking of Measured Insulation and Evaporative Resistance Values

References

- Kahn, S.A.; Patel, J.H.; Lentz, C.W.; Bell, D.E. Firefighter burn injuries: Predictable patterns influenced by turnout gear. J. Burn Care Res. 2012, 33, 152–156. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-H.; Kim, S.; Lee, J.-Y. An empirical investigation of firefighting personal protective equipment and burn injuries in Korea. Ind. Health 2022, 60, 2–15. [Google Scholar] [CrossRef]

- Chou, C.; Tochihara, Y.; Ismail, M.S.; Lee, J.Y. Physiological strains of wearing aluminized and non-aluminized firefighters’ protective clothing during exercise in radiant heat. Ind. Health 2011, 29, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kim, D.-H.; Lee, H.-H.; Lee, J.-Y. Frequency of firefighters’ heat-related illness and its association with removing personal protective equipment and working hours. Ind. Health 2019, 57, 370–380. [Google Scholar] [CrossRef] [PubMed]

- Taylor, N.A.S.; Lee, J.Y.; Kim, S.; Notley, S. Physiological interactions with personal-protective clothing, physically demanding work and global warming: An Asia-Pacific perspective. J. Therm. Biol. 2021, 97, 102858. [Google Scholar] [CrossRef] [PubMed]

- Dorman, L.E. The Effects of Protective Clothing and Its Properties on Energy Consumption during Different Activities. Doctoral’s Thesis, Loughborough University, Loughborough, UK, March 2007. [Google Scholar]

- Dorman, L.E.; Havenith, G. The effects of protective clothing on energy consumption during different activities. Eur. J. Appl. Physiol. 2009, 105, 463–470. [Google Scholar] [CrossRef]

- Teitlebaum, A.; Goldman, R.F. Increased energy cost with multiple clothing layers. J. Appl. Physiol. 1972, 32, 743–744. [Google Scholar] [CrossRef] [PubMed]

- Aljaroudi, A.M.; Bhattacharya, A.; Strauch, A.; Quinn, T.D.; Williams, W.J. Effect of cooling on static postural balance while wearing firefighter’s protective clothing in hot environment. Int. J. Occup. Saf. Ergon. 2022. online. [Google Scholar] [CrossRef] [PubMed]

- Son, S.Y.; Muraki, S.; Tochihara, Y. Exploring the appropriate test methods to examine the effects of firefighter personal protective equipment on mobility. Fash. Text. 2022, 9, 22. [Google Scholar] [CrossRef]

- Tochihara, Y.; Fujita, M.; Ogawa, T. Protective clothing—Related heat stress on firefighters in Japan. In Proceedings of the 11th International Conference on Environmental Ergonomics, Ystad, Sweden, 22–26 May 2005. [Google Scholar]

- Wang, S.; Park, J.; Wang, Y. Cross-cultural comparison of firefighters’ perception of mobility and occupational injury risks associated with personal protective equipment. Int. J. Occup. Saf. Ergon. 2021, 27, 664–672. [Google Scholar] [CrossRef] [PubMed]

- EN 469:2020; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Firefighting Activities. European Committee for Standardization: Brussels, Belgium, 2020.

- ISO 21942:2019; Station Uniform for Firefighters. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 11999 Series; PPE for Firefighters—Test Methods and Requirements for PPE Used by Firefighters Who Are at Risk of Exposure to High Levels of Heat and/or Flame While Fighting Fires Occurring in Structures. International Organization for Standardization: Geneva, Switzerland.

- ISO 11613:2017; Protective Clothing for Firefighter’s Who Are Engaged in Support Activities Associated with Structural Fire Fighting—Laboratory Test Methods and Performance. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 15384:2018; Protective Clothing for Firefighters—Laboratory Test Methods and Performance Requirements for Wildland Firefighting Clothing. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 16073 Series; Wildland Firefighting Personal Protective Equipment—Requirements and Test Methods. International Organization for Standardization: Geneva, Switzerland.

- ISO 18639 Series; PPE Ensembles for Firefighters Undertaking Specific Rescue Activities. International Organization for Standardization: Geneva, Switzerland.

- EN 16689:2017; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Technical Rescue. European Committee for Standardization: Brussels, Belgium, 2017.

- ISO 17491 Series; Protective Clothing—Test Methods for Clothing Providing Protection against Chemicals. International Organization for Standardization: Geneva, Switzerland.

- ISO 16602:2007; Protective Clothing for Protection against Chemicals—Classification, Labelling and Performance Requirements. International Organization for Standardization: Geneva, Switzerland, 2007.

- Kingma, B.R.M.; Steenhoff, H.; Toftum, J.; Daanen, H.A.M.; Folkerts, M.A.; Gerrett, N.; Gao, C.; Kuklane, K.; Petersson, J.; Halder, A.; et al. ClimApp–integrating personal factors with weather forecasts for individualised warning and guidance on thermal stress. Int. J. Environ. Res. Public Health 2021, 18, 11317. [Google Scholar] [CrossRef] [PubMed]

- Petersson, J.; Kuklane, K.; Gao, C. Is there a need to integrate human thermal models with weather forecasts to predict thermal stress? Int. J. Environ. Res. Public Health 2019, 16, 4586. [Google Scholar] [CrossRef]

- Xu, X.; Rioux, T.P.; Gonzalez, J.; Hansen, E.O.; Castellani, J.W.; Santee, W.R.; Karis, A.J.; Potter, A.W. Development of a cold injury prevention tool: The cold weather ensemble decision aid (CoWEDA). In USARIEM Technical Report No. T19-06; USARIEM: Natick, MA, USA, March 2019. [Google Scholar]

- Xu, X.; Rioux, T.P.; Gonzalez, J.; Hansen, E.O.; Castellani, J.W.; Santee, W.R.; Karis, A.J.; Potter, A.W. A digital tool for prevention and management of cold weather injuries–Cold Weather Ensemble Decision Aid (CoWEDA). Int. J. Biometeorol. 2021, 65, 1415–1426. [Google Scholar] [CrossRef] [PubMed]

- Parsons, K. Human Thermal Environments, 3rd ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2014. [Google Scholar]

- Taylor, N.A.S.; Machado-Moreira, C.A.; van den Heuvel, A.M.J.; Caldwell, J.N. Hands and feet: Physiological insulators, radiators and evaporators. Eur. J. Appl. Physiol. 2014, 114, 2037–2060. [Google Scholar] [CrossRef] [PubMed]

- Vanggaard, L.; Kuklane, K.; Holmer, I.; Smolander, J. Thermal responses to whole-body cooling in air with special reference to arteriovenous anastomoses in fingers. Clin. Physiol. Funct. Imaging 2012, 32, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Smith, C.J.; Havenith, G. Body mapping of sweating patterns in male athletes in mild exercise-induced hyperthermia. Eur. J. Appl. Physiol. 2011, 111, 1391–1404. [Google Scholar] [CrossRef] [PubMed]

- Smith, C.J.; Havenith, G. Body mapping of sweating patterns in athletes: A sex comparison. Med. Sci. Sports. Exerc. 2012, 44, 2350–2361. [Google Scholar] [CrossRef]

- Taylor, N.A.S.; Machado-Moreira, C.A. Regional variations in transepidermal water loss, eccrine sweat gland density, sweat secretion rates and electrolyte composition in resting and exercising humans. Extrem. Physiol. Med. 2013, 2, 4. [Google Scholar] [CrossRef]

- Wang, F.; Del Ferraro, S.; Molinaro, V.; Morrissey, M.; Rossi, R. Assessment of body mapping sportswear using a manikin operated in constant temperature mode and thermoregulatory model control mode. Int. J. Biometeorol. 2014, 58, 1673–1682. [Google Scholar] [CrossRef]

- Afanasieva, R.F. Hygienic Basis for Designing Cold Protective Clothing; Legkaja Industria: Moscow, Russia, 1977. (In Russian) [Google Scholar]

- Havenith, G.; Nilsson, H. Correction of clothing insulation for movement and wind effects, a meta-analysis. Eur. J. Appl. Physiol. 2004, 92, 636–640. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, F.; Wan, X.; Song, G.; Zhang, C.; Shi, W. Clothing resultant thermal insulation determined on a movable thermal manikin. Part II: Effects of wind and body movement on local insulation. Int. J. Biometeorol. 2015, 59, 1487–1498. [Google Scholar] [CrossRef] [PubMed]

- Veselá, S.; Psikuta, A.; Frijns, A.J.H. Local clothing thermal properties of typical office ensembles under realistic static and dynamic conditions. Int. J. Biometeorol. 2018, 62, 2215–2229. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; del Ferraro, S.; Lin, L.Y.; Sotto Mayor, T.; Ribeiro, M.; Gao, C.; Kuklane, K.; Holmér, I. Localised boundary air layer and clothing evaporative resistances for individual body segments. Ergonomics 2012, 55, 799–812. [Google Scholar] [CrossRef]

- Fojtlín, M.; Psikuta, A.; Fišer, J.; Toma, R.; Annaheim, S.; Jícha, M. Local clothing properties for thermo-physiological modelling: Comparison of methods and body positions. Build. Environ. 2019, 155, 376–388. [Google Scholar] [CrossRef]

- Havenith, G.; Fiala, D. Thermal indices and thermophysiological modeling for heat stress. In Comprehensive Physiology Wiley Online Library; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; Volume 6, pp. 255–302. [Google Scholar] [CrossRef]

- Joshi, A.; Wang, F.; Kang, Z.; Yang, B.; Zhao, D. A three-dimensional thermoregulatory model for predicting human thermophysiological responses in various thermal environments. Build. Environ. 2022, 207, 108506. [Google Scholar] [CrossRef]

- Psikuta, A.; Koelblen, B.; Mert, E.; Fontana, P.; Annaheim, S. An integrated approach to develop, validate and operate thermo-physiological human simulator for the development of protective clothing. Ind. Health 2017, 55, 500–512. [Google Scholar] [CrossRef] [PubMed]

- Psikuta, A.; Mert, E.; Annaheim, S.; Rossi, R.M. Local air gap thickness and contact area models for realistic simulation of human thermo-physiological response. Int. J. Biometeorol. 2018, 62, 1121–1134. [Google Scholar] [CrossRef]

- Takahashi, Y.; Nomoto, A.; Yoda, S.; Hisayama, R.; Ogata, M.; Ozeki, Y.; Tanabe, S. Thermoregulation model JOS-3 with new open source code. Energy Build. 2021, 231, 110575. [Google Scholar] [CrossRef]

- Chen, Y.S.; Fan, J.; Qian, X.; Zhang, W. Effect of garment fit on thermal insulation and evaporative resistance. Text. Res. J. 2004, 74, 742–748. [Google Scholar] [CrossRef]

- Jussila, K.; Kekäläinen, M.; Simonen, L.; Mäkinen, H. Determining the optimum size combination of three-layered cold protective clothing in varying wind conditions and walking speeds: Thermal manikin and 3D body scanner study. J. Fashion Technol. Textile Eng. 2015, 3, 1–9. [Google Scholar] [CrossRef]

- ASTM F1291-16; Standard Test Method for Measuring the Thermal Insulation of Clothing Using a Heated Manikin. American Society of Testing and Materials International (ASTM): Philadelphia, PA, USA, 2016.

- EN 342:2017; Protective Clothing—Ensembles and Garments for Protection against Cold. European Committee for Standardization: Brussels, Belgium, 2017.

- ISO 15831:2004; Clothing-Physiological Effects-Measurement of Thermal Insulation by Means of a Thermal Manikin. International Organisation for Standardisation: Geneva, Switzerland, 2004.

- ISO 9920:2009; Ergonomics of the Thermal Environment—Estimation of the Thermal Insulation and Evaporative Resistance of a Clothing Ensemble. International Standards Organisation: Geneva, Switzerland, 2009.

- ASTM F2370-16; Standard Test Method for Measuring the Evaporative Resistance of Clothing Using a Sweating Manikin. American Society of Testing and Materials International (ASTM): Philadelphia, PA, USA, 2016.

- EN 17528: 2022; Clothing—Physiological Effects—Measurement of Water Vapour Resistance by Means of a SWEATING manikin. European Committee for Standardization: Brussels, Belgium, 2022.

- Wang, F.M. Measurements of clothing evaporative resistance using a sweating thermal manikin: An overview. Ind. Health 2017, 55, 473–484. [Google Scholar] [CrossRef][Green Version]

- McCullough, E.A.; Jones, B.W.; Huck, J. A comprehensive data base for estimating clothing insulation (RP-411). ASHRAE Trans. 1985, 91, 29–47. [Google Scholar]

- McCullough, E.A.; Jones, B.W.; Tamura, T. A database for determining the evaporative resistance of clothing. ASHRAE Trans. 1989, 95, 316–328. [Google Scholar]

- Olesen, B.W.; Nielsen, R. Thermal insulation of clothing measured on a movable thermal manikin and on human subjects. In ECSC Programme Research Nr 7206/00/914; Technical University of Denmark: Copenhagen, Denmark, 1983. [Google Scholar]

- Al-ajmi, F.F.; Loveday, D.L.; Bedwell, K.H.; Havenith, G. Thermal insulation and clothing area factors of typical Arabian Gulf clothing ensembles for males and females: Measurements using thermal manikins. Appl. Ergon. 2008, 39, 407–414. [Google Scholar] [CrossRef] [PubMed]

- Havenith, G.; Kuklane, K.; Fan, J.; Hodder, S.; Ouzzahra, Y.; Lundgren, K.; Au, Y.; Loveday, D. A Database of Static Clothing Thermal Insulation and Vapor Permeability Values of Non-Western Ensembles for Use in ASHRAE Standard 55, ISO 7730, and ISO 9920. ASHRAE Trans. 2015, 121, 197–215. [Google Scholar]

- Wang, F.; Peng, H.; Shi, W. The relationship between air layers and evaporative resistance of male Chinese ethnic clothing. Appl. Ergon. 2016, 56, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Havenith, G.; Bröde, P.; den Hartog, E.; Kuklane, K.; Holmer, I.; Rossi, R.M.; Richards, M.; Farnworth, B.; Wang, X. Evaporative cooling: Effective latent heat of evaporation in relation to evaporation distance from the skin. J. Appl. Physiol. 2013, 114, 778–785. [Google Scholar] [CrossRef] [PubMed]

- Joshi, A.; Psikuta, A.; Bueno, M.A.; Annaheim, S.; Rossi, R.M. Effect of movement on convection and ventilation in a skin-clothing- environment system. Int. J. Therm. Sci. 2021, 166, 106965. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, F.; Wan, X.; Song, G.; Shi, W.; Zhang, C. Clothing resultant thermal insulation determined on a movable thermal manikin. Part I: Effects of wind and body movement on total insulation. Int. J. Biometeorol. 2015, 59, 1475–1486. [Google Scholar] [CrossRef]

- Smallcombe, J.; Hodder, S.; Loveday, D.; Kuklane, K.; Mlynarczyk, M.; Halder, A.; Petersson, J.; Havenith, G. Updated Database of Clothing Thermal Insulation and Vapor Permeability Values of Western Ensembles for Use in ASHRAE Standard 55, ISO 7730 and ISO 9920; Results of ASHRAE RP-1760. ASHRAE Trans. 2021, 127, 773–799. [Google Scholar]

- Rioux, T.P.; Karis, A.J.; Moore, B.A.; Xu, X. Biophysical evaluation of individual component levels and selected configurations of the United States Marine Corps cold-weather clothing ensemble. 01760. In Technical Report, T18-01; AD1046520; U.S. Army Research Institute of Environmental Medicine: Natick, MA, USA, 2018. [Google Scholar]

- Rioux, T.; Gonzalez, J.A.; Karis, A.; Potter, A.W.; Xu, X. Biophysical properties of five cold weather clothing systems and the predicted regional properties of ensembles. In USARIEM Technical Report T21-03; AD1115339; USARIEM: Natick, MA, USA, 2020. [Google Scholar]

- Šitvjenkins, I. Enhancement of Combat Individual Protection System. Doctoral’s Thesis, Riga Technical University, Riga, Latvia, 2014. [Google Scholar]

- Šitvjenkins, I.; Kuklane, K.; Vilumsone, A.; Abele, I. Development of the combat sleeping bag system of the Latvian National Armed Forces. In Proceedings of the 6th European Conference of Protective Clothing, Bruges, Belgium, 14–16 May 2014. [Google Scholar]

- Xu, X.; Rioux, T.P.; Pomerantz, N.; Tew, S. Effects of fabric on thermal and evaporative resistances of chemical protective ensembles: Measurement and quantification. Measurement 2019, 136, 248–255. [Google Scholar] [CrossRef]

- Xu, X.; Rioux, T.P.; Pomerantz, N.; Tew, S.; Blanchard, L.A. Heat strain in chemical protective ensembles: Effects of fabric thermal properties. J. Therm. Biol. 2019, 86, 102435. [Google Scholar] [CrossRef] [PubMed]

- Kuklane, K.; Toma, R. Validation of ISO 9920 clothing item insulation summation method based on an ambulance personnel clothing system. Ind. Health 2021, 59, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Kuklane, K.; Toma, R. Common clothing area factor estimation equations are inaccurate for highly insulating (Icl > 2 clo) and non-western loose-fitting clothing ensembles. Ind. Health 2021, 59, 107–116. [Google Scholar] [CrossRef]

- Anttonen, H.; Niskanen, J.; Meinander, H.; Bartels, V.; Kuklane, K.; Reinertsen, R.E.; Varieras, S.; Sołtyński, K. Thermal manikin measurements- exact or not? Int. J. Occup. Saf. Ergon. 2004, 10, 291–300. [Google Scholar] [CrossRef]

- Gavhed, D.; Kuklane, K.; Holmér, I. The influence of the number of thermal layers on the clothing insulation of a cold-protective ensemble. In Proceedings of the NOKOBETEF 6 and 1st European Conference on Protective clothing, Stockholm, Sweden, 7–10 May 2000. [Google Scholar]

- Gavhed, D.; Kuklane, K.; Holmér, I. Thermal insulation of multi-layer clothing ensembles measured on a thermal manikin and estimated by six individuals using the summation method in ISO 9920. In Proceedings of the NOKOBETEF 6 and 1st European Conference on Protective clothing, Stockholm, Sweden, 7–10 May 2000. [Google Scholar]

- Meinander, H.; Anttonen, H.; Bartels, V.; Holmér, I.; Reinertsen, R.E.; Sołtyński, K.; Varieras, S. Thermal insulation measurements of cold protective clothing using thermal manikins. In SUBZERO Project, Final Report (Report No. 4); Fibre Materials Science, Tampere University of Technology: Tampere, Finland, 2003. [Google Scholar]

- Oliveira, A.V.M.; Gaspar, A.R.; Quintela, D.A. Measurements of clothing insulation with a thermal manikin operating under the thermal comfort regulation mode. Comparative analysis of the calculation methods. Eur. J. Appl. Physiol. 2008, 104, 679–688. [Google Scholar] [CrossRef]

- Oliveira, A.V.M.; Gaspar, A.R.; Quintela, D.A. Dynamic clothing insulation. Measurements with a thermal manikin operating under the thermal comfort regulation mode. Appl. Ergon. 2011, 42, 890–899. [Google Scholar] [CrossRef]

- Kuklane, K.; Toma, R.; Lucas, R.A. Insulation and evaporative resistance of clothing for sugarcane harvesters and chemical sprayers, and their application in PHS model-based exposure predictions. Int. J. Environ. Res. Public Health 2020, 17, 3074. [Google Scholar] [CrossRef]

- Toma, R.; Kuklane, K.; Fojtlín, M.; Fišer, J.; Jícha, M. Using a thermal manikin to determine evaporative resistance and thermal insulation-a comparison of methods. J. Ind. Text. 2021, 50, 1493–1515. [Google Scholar] [CrossRef]

- ISO 11079:2007; Ergonomics of the Thermal Environment—Determination and Interpretation of Cold Stress when Using Required Clothing Insulation (IREQ) and Local Cooling Effects. International Organisation for Standardisation: Geneva, Switzerland, 2007.

- ISO 7933:2004; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Heat Stress Using Calculation of the Predicted Heat Strain. International Organisation for Standardisation: Geneva, Switzerland, 2004.

- ISO 7730:2005; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organisation for Standardisation: Geneva, Switzerland, 2005.

- Holmér, I. Assessment of cold stress in terms of required clothing insulation-IREQ. Int. J. Ind. Ergon. 1988, 3, 159–166. [Google Scholar] [CrossRef]

- Malchaire, J.; Kampmann, B.; Mehnert, P.; Gebhardt, H.; Piette, A.; Havenith, G.; Holmér, I.; Parsons, K.; Alfano, G.; Griefahn, B. Assessment of the risk of heat disorders encountered during work in hot conditions. Int. Arch. Occup. Environ. Health 2002, 75, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Malchaire, J.; Piette, A.; Kampmann, B.; Mehnert, P.; Gebhardt, H.; Havenith, G.; den Hartog, E.; Holmer, I.; Parsons, K.; Alfano, G.; et al. Development and validation of the predicted heat strain model. Ann. Occup. Hyg. 2001, 45, 123–135. [Google Scholar] [CrossRef] [PubMed]

- Hänel, S.E. A joint Nordic project to develop an improved thermal manikin for modeling and measuring human heat exchange. In The Medical and Biophysical Aspects on Protective Clothing; Centre de Recherches du Service de Santk des Armks: Lyon, France, 1983; pp. 280–282. [Google Scholar]

- Kuklane, K.; Heidmets, S.; Johansson, T. Improving thermal comfort in an orthopaedic aid: Better Boston Brace for scoliosis patients. In Proceedings of the 6th International Meeting on Manikins and Modelling (6I3M), Hong Kong, China, 16–18 October 2006; pp. 343–351. [Google Scholar]

- Kuklane, K.; Dejke, V. Testing sleeping bags according to EN 13537:2002: Details that make the difference. Int. J. Occup. Saf. Ergon. 2010, 16, 199–216. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Wang, F.; Havenith, G.; Mayor, T.S.; Kuklane, K.; Leonard, J.; Zwolinska, M.; Hodder, S.; Wong, C.; Kishino, J.; Dai, X. Clothing real evaporative resistance determined by means of a sweating thermal manikin: A new round-robin study. In Proceedings of the Ambience 14&10i3m: Scientific Conference for Smart and Functional Textiles, Well-Being, Thermal Comfort in Clothing, Design, Thermal Manikins and Modeling, Tampere, Finland, 7–9 September 2014. [Google Scholar]

- Psikuta, A.; Kuklane, K.; Bogdan, A.; Havenith, G.; Annaheim, S.; Rossi, R.M. Opportunities and constraints of presently used thermal manikins for thermo-physiological simulation of the human body. Int. J. Biometeorol. 2016, 60, 435–446. [Google Scholar] [CrossRef]

- Holmér, I.; Kuklane, K.; Gao, C. Test of firefighter’s turnout gear in hot and humid air exposure. Int. J. Occup. Saf. Ergon. 2006, 12, 297–305. [Google Scholar] [CrossRef]

- Gao, C.; Kuklane, K.; Holmér, I. Cooling vests with phase change material packs: The effects of temperature gradient, mass, and covering area. Ergonomics 2010, 53, 716–723. [Google Scholar] [CrossRef]

- Smolander, J.; Kuklane, K.; Gavhed, D.; Nilsson, H.; Holmér, I. Effectiveness of a light-weight ice-vest for cooling while wearing fire fighter’s protective clothing in the heat. Int. J. Occup. Saf. Ergon. 2004, 10, 111–117. [Google Scholar] [CrossRef]

- Huang, J. Calculation of thermal insulation of clothing from mannequin test. Meas. Tech. 2008, 51, 428–435. [Google Scholar] [CrossRef]

- Kuklane, K.; Gao, C.; Holmér, I.; Giedraityte, L.; Bröde, P.; Candas, V.; den Hartog, E.; Meinander, H.; Richards, M.; Havenith, G. Calculation of clothing insulation by serial and parallel methods: Effects on clothing choice by IREQ and thermal responses in the cold. Int. J. Occup. Saf. Ergon. 2007, 13, 103–116. [Google Scholar] [CrossRef]

- Kuklane, K.; Gao, C.; Wang, F.; Holmér, I. Parallel and serial methods of calculating thermal insulation in European manikin standards. Int. J. Occup. Saf. Ergon. 2012, 18, 171–179. [Google Scholar] [CrossRef]

- Lee, J.; Ko, E.; Lee, H.; Kim, J.; Choi, J. Validation of clothing insulation estimated by global and serial methods. Int. J. Cloth. Sci. Technol. 2011, 23, 184–198. [Google Scholar] [CrossRef]

- Wang, F.; Kuklane, K.; Gao, C.; Holmér, I. Development and validity of a universal empirical equation to predict skin surface temperature on thermal manikins. J. Therm. Biol. 2010, 35, 197–203. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, F.; Peng, H. Effect of two sweating simulation methods on clothing evaporative resistance in a so-called isothermal condition. Int. J. Biometeorol. 2016, 60, 1041–1049. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wang, F.; Peng, H.; Shi, W.; Song, G. Effect of sweating set rate on clothing real evaporative resistance determined on a sweating thermal manikin in a so-called isothermal condition (Tmanikin = Ta = Tr). Int. J. Biometeorol. 2016, 60, 481–488. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Lai, D.; Shi, W.; Fu, M. Effects of fabric thickness and material on apparent ‘wet’ conductive thermal resistance of knitted fabric ‘skin’ on sweating manikins. J. Therm. Biol. 2017, 70, 69–76. [Google Scholar] [CrossRef]

- Ueno, S.; Sawada, S. Correction of the evaporative resistance of clothing by the temperature of skin fabric on a sweating and walking thermal manikin. Text. Res. J. 2012, 82, 1143–1156. [Google Scholar] [CrossRef]

- Anttonen, H.; Hellsten, M.; Bartels, V.; Kuklane, K.; Niskanen, J. Report of the manikin measurements with analysis of the test results. In SUBZERO Project, D2; Oulu Regional Institute of Occupational Health: Oulu, Finland, 2002. [Google Scholar]

- Deaton, A.S.; Watson, K.; DenHartog, E.A.; Barker, R.L. Effectiveness of using a thermal sweating manikin coupled with a thermoregulation model to predict human physiological response to different firefighter turnout suits. In Performance of Protective Clothing and Equipment; Innovative Solutions to Evolving Challenges; Lehtonen, K., Shiels, B.P., Ormond, R.B., Eds.; ASTM International: West Conshohocken, PA, USA, 2020; Volume 11, pp. 222–236. [Google Scholar] [CrossRef]

- DenHartog, E.A.; Fang, X.; Deaton, A.S. Effects of total heat loss versus evaporative resistance of firefighter garments in a physiological heat strain trial. In Performance of Protective Clothing and Equipment; Innovative Solutions to Evolving Challenges; Lehtonen, K., Shiels, B.P., Ormond, R.B., Eds.; ASTM International: West Conshohocken, PA, USA, 2020; Volume 11, pp. 204–221. [Google Scholar] [CrossRef]

- Lee, J.; Choi, J. Estimation of regional body surface area covered by clothing. J. Hum. Environ. Syst. 2009, 12, 35–45. [Google Scholar] [CrossRef]

- Mert, E.; Psikuta, A.; Bueno, M.-A.; Rossi, R.M. The effect of body postures on the distribution of air gap thickness and contact area. Int. J. Biometeorol. 2017, 61, 363–375. [Google Scholar] [CrossRef]

- Ciuha, U.; Valenčič, T.; Mekjavic, I.B. Cooling efficiency of vests with different cooling concepts over 8-hour trials. Ergonomics 2021, 64, 625–639. [Google Scholar] [CrossRef]

- Krause, R.; Kuklane, K.; Kemmeren, M.; Gries, T. Europäische nutzerumfrage zu smarter persönliche schutzausrüstung für feuerwehreinsatzkräfte. Crisis Prev. 2021, 3, 34–39. (In German) [Google Scholar]

- Lee, J.-Y.; Park, J.; Park, H.; Coca, A.; Kim, J.-H.; Taylor, N.A.S.; Son, S.-Y.; Tochihara, Y. What do firefighters desire from the next generation of personal protective equipment? Outcomes from an international survey. Ind. Health 2015, 53, 434–444. [Google Scholar] [CrossRef] [PubMed]

- Havenith, G.; Heus, R. A test battery related to ergonomics of protective clothing. Appl. Ergon. 2004, 35, 3–20. [Google Scholar] [CrossRef] [PubMed]

- ISO/TS 20141:2022; Personal Safety—Personal Protective Equipment—Guidelines on Compatibility Testing of PPE. International Standards Organisation: Geneva, Switzerland, 2022.

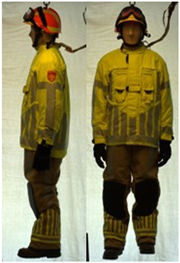

| Nr. | Item and Their Variation Description | Photo | Brand, Model | Size, Version | Weight (Grams) | Materials (Notes) | IT m2K/W | fcl n.d. | Iclu m2K/W |

|---|---|---|---|---|---|---|---|---|---|

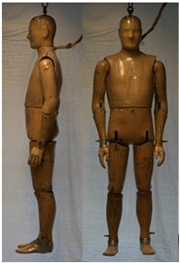

| AL | Nude manikin (air layer insulation—Ia) |  | 0.099 | 1.00 | 0.000 | ||||

| 1 | Socks |  | Groenendijk, Brandweer Nederland | 43–45 | 62.2 | 0.107 | 1.01 | 0.009 | |

| 2 | Low safety shoes |  | Neskrid, Crow S3 low | 45, W11 | 1554.1 | PU sole, leather uppers, fabric padding | 0.107 | 1.02 | 0.010 |

| 3 | High safety shoes |  | Haix, Airpower XR1 | 45 | 2153.4 | PU sole, leather uppers, fabric padding | 0.109 | 1.06 | 0.015 |

| 4 | Firefighter boots |  | Haix, Fire flash gamma | 44, W12 | 2939.3 | PU sole, leather uppers, fabric padding, Gore-Crosstech | 0.113 | 1.07 | 0.021 |

| 5 | Baseball cap |  | Groenendijk, Brandweer Nederland | one size | 91.3 | 50% cotton 48% polyester 2% elastane | 0.103 | 1.01 | 0.005 |

| 6 | Beanie |  | Groenendijk, Brandweer Nederland | one size | 49.5 | 80% Wool 20% Acrylic | 0.104 | 1.00 | 0.005 |

| 7 | Balaclava/fire hood |  | Viking Life Saving Equipment A/S, Type 1 | one size | 119.4 | 100% Aramid | 0.107 | 1.01 | 0.009 |

| 8 | Boxershorts (underwear) |  | GS Sport | XL | 69.4 | 95% Cotton 5% Elastane | 0.106 | 1.01 | 0.008 |

| 9 | T-shirt (underwear) |  | Narkonteks, Brandweer Nederland | L, regular | 182.1 | 60% Mode Acrylic 40% Cotton, Ribana, 190 g/m2 | 0.124 | 1.03 | 0.027 |

| 10 | Belt (stretch-heavy) |  | Groenendijk | 105 | 106.2 | 0.102 | 1.00 | 0.003 | |

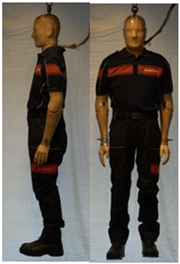

| 11 | Polo shirt, short sleeves |  | Narkonteks, Brandweer Nederland | L, regular | 345.8 | 60% Mode Acrylic 40% Cotton, Pique, 200 g/m2 | 0.131 | 1.08 | 0.040 |

| 12 | Polo shirt, long sleeves |  | Narkonteks, Brandweer Nederland | L, regular | 427.2 | 60% Mode Acrylic 40% Cotton, Pique, 200 g/m2 | 0.140 | 1.09 | 0.049 |

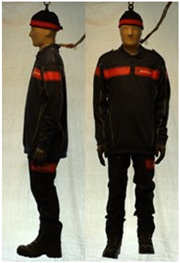

| 13 | (Polo)sweater (400 gr) |  | Narkonteks, Brandweer Nederland | L, regular | 842.1 | 50% Mode Acrylic 50% Cotton, three thread fleece, 400 g/m2 | 0.148 | 1.14 | 0.061 |

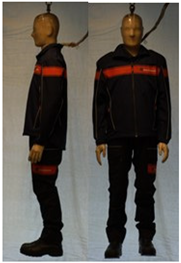

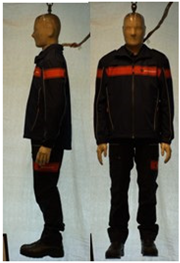

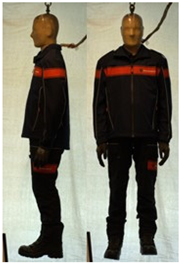

| 14 | Softshell (zip open at neck) |  | SIOEN, Brandweer Nederland | L, regular | 787.2 | 0.145 | 1.11 | 0.056 | |

| 14A | Softshell (fully zipped) |  | SIOEN, Brandweer Nederland | L, regular | 787.2 | 0.146 | 1.14 | 0.059 | |

| 15 | Working trousers |  | SIOEN, Brandweer Nederland | 52, regular | 697.7 | 42% modacrylic, 29% cotton 19% polyamide FR, 5% aramid 4% elastolefin, 1% antistatic (AST) yarn | 0.136 | 1.12 | 0.047 |

| 16 | Safety gloves (cut resistant) for technical rescue |  | GUIDE, 313 | 11 | 82.7 | 0.102 | 1.01 | 0.004 | |

| 17 | Safety gloves (for structural firefighting) |  | Eska, Helios E | 10 | 366.2 | 0.102 | 1.03 | 0.005 | |

| 18 | Technical rescue jacket |  | SIOEN, 233 Proviz/AS | L, regular | 1431.7 | OL: 54% Nomex®, 28% polyester 17% viscose FR, 1% AST Lining: 100% aramid laminated with bi-component ePTFE membrane + AST | 0.162 | 1.17 | 0.077 |

| 19 | Firefighter top layer jacket (to be used on top of item 18) |  | SIOEN, TL TWIN/AS | L, regular | 1312.0 | OL: 100% aramid + AST Lining: 50% aramid 50% viscose FR | 0.171 | 1.17 | 0.087 |

| 21 | Firefighter jacket (corresponds to EN 469) |  | SIOEN, 830 Twin/AS | L, regular | 1793.8 | OL: 100% aramid + AST ML: 100% aramid laminated with bi-component ePTFE membrane Lining: 100% aramid + AST | 0.177 | 1.23 | 0.097 |

| 22 | Firefighter trousers, standard model (corresponds to EN 469) |  | SIOEN | L, regular | 1712.5 | OL: 100% aramid + AST ML: 100% aramid laminated with bi-component ePTFE membrane Lining: 100% aramid + AST | 0.168 | 1.32 | 0.093 |

| 23 | Firefighter trousers, dungarees (corresponds to EN 469) |  | SIOEN | L, regular | 1795.3 | OL: 100% aramid + AST ML: 100% aramid laminated with bi-component ePTFE membrane Lining: 100% aramid + AST | 0.167 | 1.36 | 0.095 |

| 24 | Firefighter coverall (corresponds to EN 469) |  | SIOEN | L, regular | 2883.2 | OL: 100% aramid + AST ML: 100% aramid laminated with bi-component ePTFE membrane Lining: 100% aramid + AST | 0.303 | 1.47 | 0.236 |

| 25 | Firefighter helmet |  | Dräger, HPS 7000 H1 | 50–60 | 1621.3 | 0.103 | 1.07 | 0.011 | |

| 26 | Face and neck cover (hollanddoek, connected to helmet (item 25), closed in front) |  | Dräger | one size | 161.3 | 0.107 | 1.12 | 0.018 | |

| 26A | Face and neck cover (hollanddoek, connected to helmet (item 25), open in front, fixed at back side) |  | Dräger | one size | 161.3 | 0.105 | 1.10 | 0.016 | |

| 27 | Technical rescue helmet |  | MSA Gallet, F2 X-trem | 52–64 cm | 830.1 | 0.102 | 1.05 | 0.008 | |

| 28 | Self-Contained Breathing Apparatus (SCBA, bottles only) |  | Interspiro, V-RWS | XXL | 11,469.9 | Composite with 2 bottles. | 0.104 | 1.15 | 0.018 |

| 29 | High visibility vest |  | Coprit, V-RWS | XXL | 166.4 | 100% polyester | 0.117 | 1.08 | 0.026 |

| 30 | Winter jacket (doorwerkjas) with thermal lining |  | SIOEN, Brandweer Nederland | L, regular | 1594.3 | OL and lining: 100% Polyester Membrane: 100% Polyurethane Thermal liner: 100% Polyester insulation between 100% polyamide layers | 0.163 | 1.19 | 0.080 |

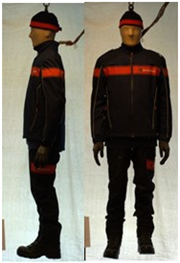

| 30A | Winter jacket (doorwerkjas) without thermal lining (outer shell only) |  | SIOEN, Brandweer Nederland | L, regular | 1253.1 | OL and lining: 100% Polyester Membrane: 100% Polyurethane | 0.151 | 1.16 | 0.066 |

| 30B | Winter jacket (doorwerkjas) without thermal lining (outer shell only) and with hood half way (it was not allowed to cut) |  | SIOEN, Brandweer Nederland | L, regular | 1353.0 | OL and lining: 100% Polyester Membrane: 100% Polyurethane | 0.161 | 1.19 | 0.078 |

| 30C | Thermal liner of the winter jacket alone |  | SIOEN, Brandweer Nederland | L, regular | 341.2 | 100% Polyester insulation between 100% polyamide layers | 0.156 | 1.13 | 0.068 |

| 31 | SCBA system (items 26, 28 and facemask from Dräger fitting the helmet) |  | Dräger, FPS 7000/Interspiro | M, HMC | 755.0 | Rubber/plastic glass | 0.113 | 1.26 | 0.034 |

| 31A | Face mask |  | Interspiro | 1228.7 | Rubber/plastic glass | 0.100 | 1.07 | 0.008 | |

| 31B | SCBA system (items 28 and 31A) |  | Interspiro | 12,698.6 | Rubber/plastic glass, composite | 0.106 | 1.22 | 0.025 |

| Code | Items in the Ensemble (See Table 1) | IT m2K/W | fcl n.d. | Icl m2K/W | Icl clo | Ret,raw m2Pa/W | Ret m2Pa/W | Recl m2Pa/W | im n.d. | im,cl n.d. |

|---|---|---|---|---|---|---|---|---|---|---|

| AL | Nude manikin (air layer insulation—Ia) | 0.099 | 1.00 | 0.000 | 0.00 | |||||

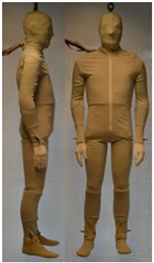

| SK | Manikin’s textile skin (cotton) | 0.131 | 1.03 | 0.040 | 0.26 | 11.5 | 8.0 | |||

| C1 | 1, 2, 8, 9, 10, 11, 15 | 0.187 | 1.19 | 0.104 | 0.67 | 22.3 | 18.7 | 12.0 | 0.61 | 0.52 |

| C1A | 1, 2, 8, 9, 10, 11, 14, 15 | 0.236 | 1.24 | 0.157 | 1.01 | 35.2 | 31.5 | 25.0 | 0.45 | 0.37 |

| C1B | 1, 2, 8, 9, 10, 11, 14, 15 The same as C1A but with softshell zip fully closed | 0.245 | 1.24 | 0.166 | 1.07 | |||||

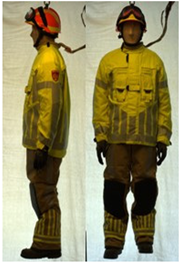

| C2 | 1, 2, 8, 9, 10, 12, 15 | 0.205 | 1.19 | 0.122 | 0.79 | 25.7 | 22.0 | 15.4 | 0.56 | 0.48 |

| C2A | 1, 2, 8, 9, 10, 12, 14, 15 | 0.237 | 1.26 | 0.159 | 1.03 | 32.9 | 29.3 | 23.0 | 0.49 | 0.42 |

| C2B | 1, 2, 8, 9, 10, 12, 14, 15, 16 | 0.241 | 1.27 | 0.163 | 1.05 | |||||

| C2C | 1, 3, 8, 9, 10, 12, 14, 15, 29 | 0.255 | 1.29 | 0.179 | 1.15 | |||||

| C2D | 1, 3, 6, 8, 9, 10, 12, 15, 30A | 0.273 | 1.32 | 0.198 | 1.28 | 45.5 | 41.8 | 35.7 | 0.40 | 0.33 |

| C2E | 1, 3, 6, 8, 9, 10, 12, 15, 30B | 0.282 | 1.33 | 0.208 | 1.34 | |||||

| C2F | 1, 3, 6, 8, 9, 10, 12, 15, 30 | 0.300 | 1.34 | 0.226 | 1.46 | |||||

| C2G | 1, 3, 6, 8, 9, 10, 12, 15, 16, 30 The same as C2F but with technical rescue gloves (Table 1, item 16) | 0.307 | 1.34 | 0.234 | 1.51 | 48.0 | 44.3 | 38.3 | 0.42 | 0.37 |

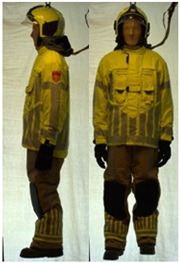

| C3 | 1, 2, 8, 9, 10, 13, 15 | 0.227 | 1.26 | 0.148 | 0.95 | |||||

| C3A | 1, 3, 6, 8, 9, 10, 13, 15, 16 | 0.234 | 1.27 | 0.156 | 1.01 | |||||

| C3B | 1, 3, 6, 8, 9, 10, 13, 14, 15, 16 | 0.271 | 1.29 | 0.194 | 1.25 | 41.9 | 38.2 | 32.0 | 0.43 | 0.36 |

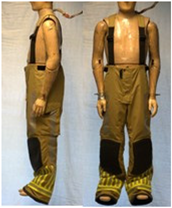

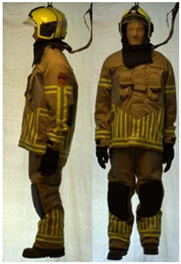

| C4 | 1, 4, 8, 9, 10, 12, 15, 17, 18, 19, 22, 31 (consisting of 26 (hollanddoek fixed to 25), 28 and facemask similar to 31A but fixed to helmet) | 0.477 | 1.68 | 0.418 | 2.69 | 85.3 | 81.4 | 76.7 | 0.35 | 0.33 |

| C5 | 1, 4, 8, 9, 10, 12, 15, 17, 24, 26 (as part of 25) | 0.436 | 1.60 | 0.374 | 2.41 | |||||

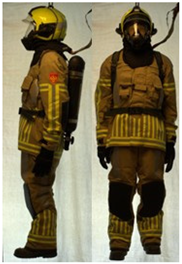

| C6 | 1, 4, 8, 9, 10, 12, 15, 17, 21, 22, 26 (as part of 25) | 0.456 | 1.58 | 0.393 | 2.54 | 74.4 | 70.6 | 65.6 | 0.39 | 0.36 |

| C6A | 1, 4, 8, 9, 10, 12, 15, 17, 21, 22, 31 (consisting of 26 (hollanddoek fixed to 25), 28 and facemask similar to 31A but fixed to helmet) | 0.465 | 1.65 | 0.405 | 2.62 | 87.4 | 83.6 | 78.8 | 0.34 | 0.31 |

| C6B | 1, 4, 7, 8, 9, 10, 12, 15, 17, 21, 22, 25, 28, 31A | 0.476 | 1.66 | 0.417 | 2.69 | |||||

| C6C | 1, 4, 8, 9, 10, 12, 15, 17, 21, 23, 31 (consisting of 26 (hollanddoek fixed to 25), 28 and facemask similar to 31A but fixed to helmet) | 0.457 | 1.65 | 0.397 | 2.56 | |||||

| C7 | 1, 4, 8, 9, 10, 12, 15, 17, 18, 19, 22, 26 (hollanddoek fixed to 25) | 0.466 | 1.57 | 0.403 | 2.60 | |||||

| C8 | 1, 4, 8, 9, 10, 12, 15, 17, 18, 22, 26A (hollanddoek front open fixed to 25) | 0.425 | 1.52 | 0.361 | 2.33 | 76.4 | 72.6 | 67.4 | 0.36 | 0.32 |

| C9 | 1, 4, 8, 9, 10, 15, 16, 18, 22, 27 | 0.372 | 1.49 | 0.305 | 1.97 | |||||

| C9A | 1, 4, 8, 9, 10, 12, 15, 16, 18, 22, 27 | 0.390 | 1.49 | 0.324 | 2.09 | 63.2 | 59.4 | 54.0 | 0.40 | 0.36 |

| C9B | 1, 4, 8, 9, 10, 12, 15, 17, 18, 22, 27 | 0.407 | 1.49 | 0.341 | 2.20 |

| AL | SK | ||

|  | ||

| C1 | C1A | C2 | C2A |

|  |  |  |

| C2B | C2C | C2D | C2E |

|  |  |  |

| C2F | C3 | C3A | C3B |

|  |  |  |

| C4 | C5 | C6 | C6A |

|  |  |  |

| C6B | C6C | C7 | C8 |

|  |  |  |

| C9 | C9A | C9B | |

|  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuklane, K.; Eggeling, J.; Kemmeren, M.; Heus, R. A Database of Static Thermal Insulation and Evaporative Resistance Values of Dutch Firefighter Clothing Items and Ensembles. Biology 2022, 11, 1813. https://doi.org/10.3390/biology11121813

Kuklane K, Eggeling J, Kemmeren M, Heus R. A Database of Static Thermal Insulation and Evaporative Resistance Values of Dutch Firefighter Clothing Items and Ensembles. Biology. 2022; 11(12):1813. https://doi.org/10.3390/biology11121813

Chicago/Turabian StyleKuklane, Kalev, Jakob Eggeling, Maurice Kemmeren, and Ronald Heus. 2022. "A Database of Static Thermal Insulation and Evaporative Resistance Values of Dutch Firefighter Clothing Items and Ensembles" Biology 11, no. 12: 1813. https://doi.org/10.3390/biology11121813

APA StyleKuklane, K., Eggeling, J., Kemmeren, M., & Heus, R. (2022). A Database of Static Thermal Insulation and Evaporative Resistance Values of Dutch Firefighter Clothing Items and Ensembles. Biology, 11(12), 1813. https://doi.org/10.3390/biology11121813