Non-Invasive On-Site pXRF Analysis of Coloring Agents of Under- and Over-Glazes: Variability and Representativity of Measurements on Porcelain

Abstract

:1. Introduction

2. Materials and Methods

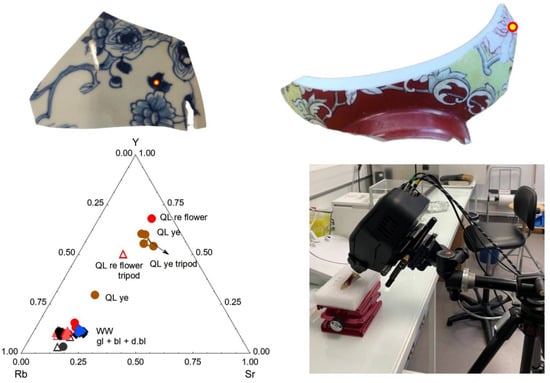

2.1. Samples

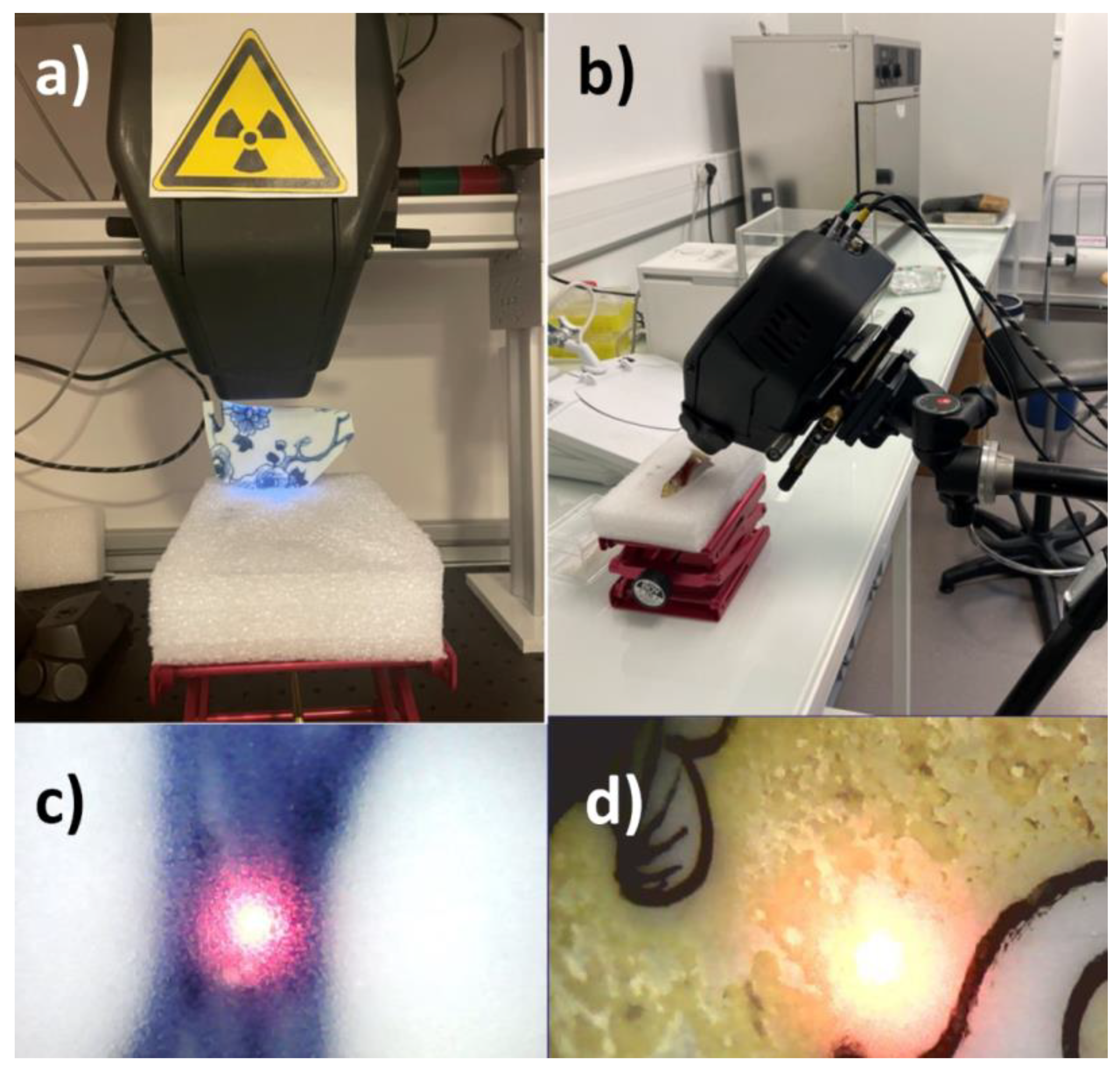

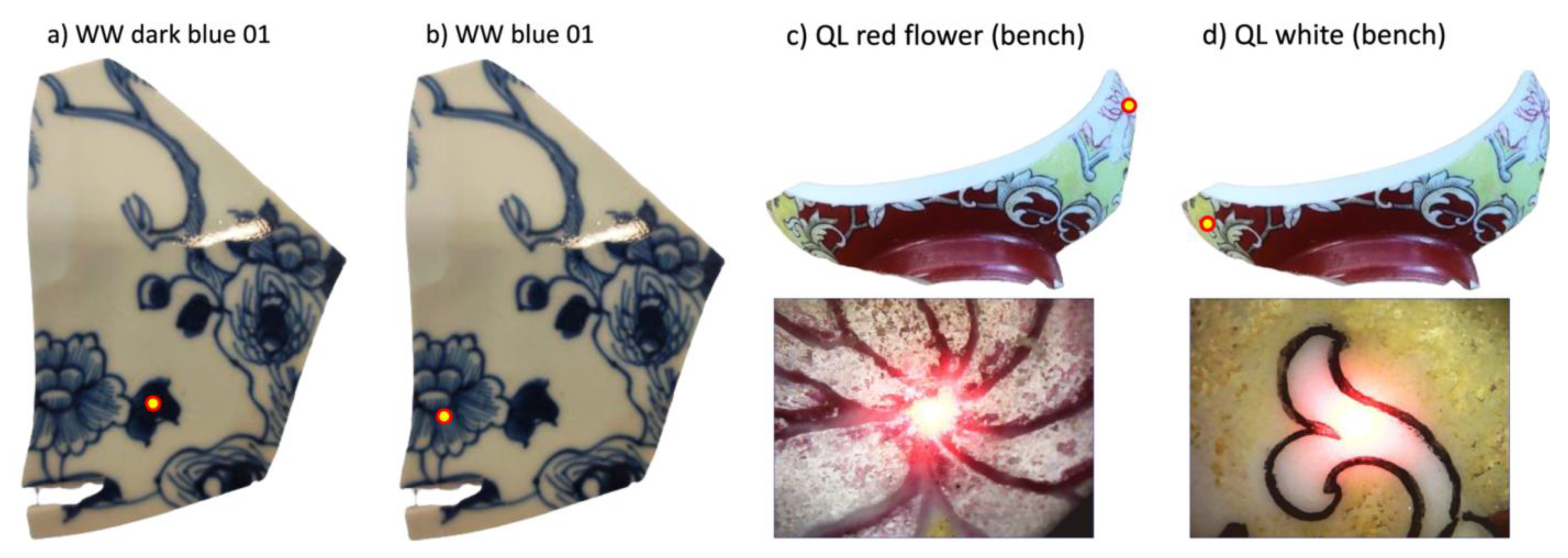

2.2. Experimental

2.3. XRF Data Processing

3. Results

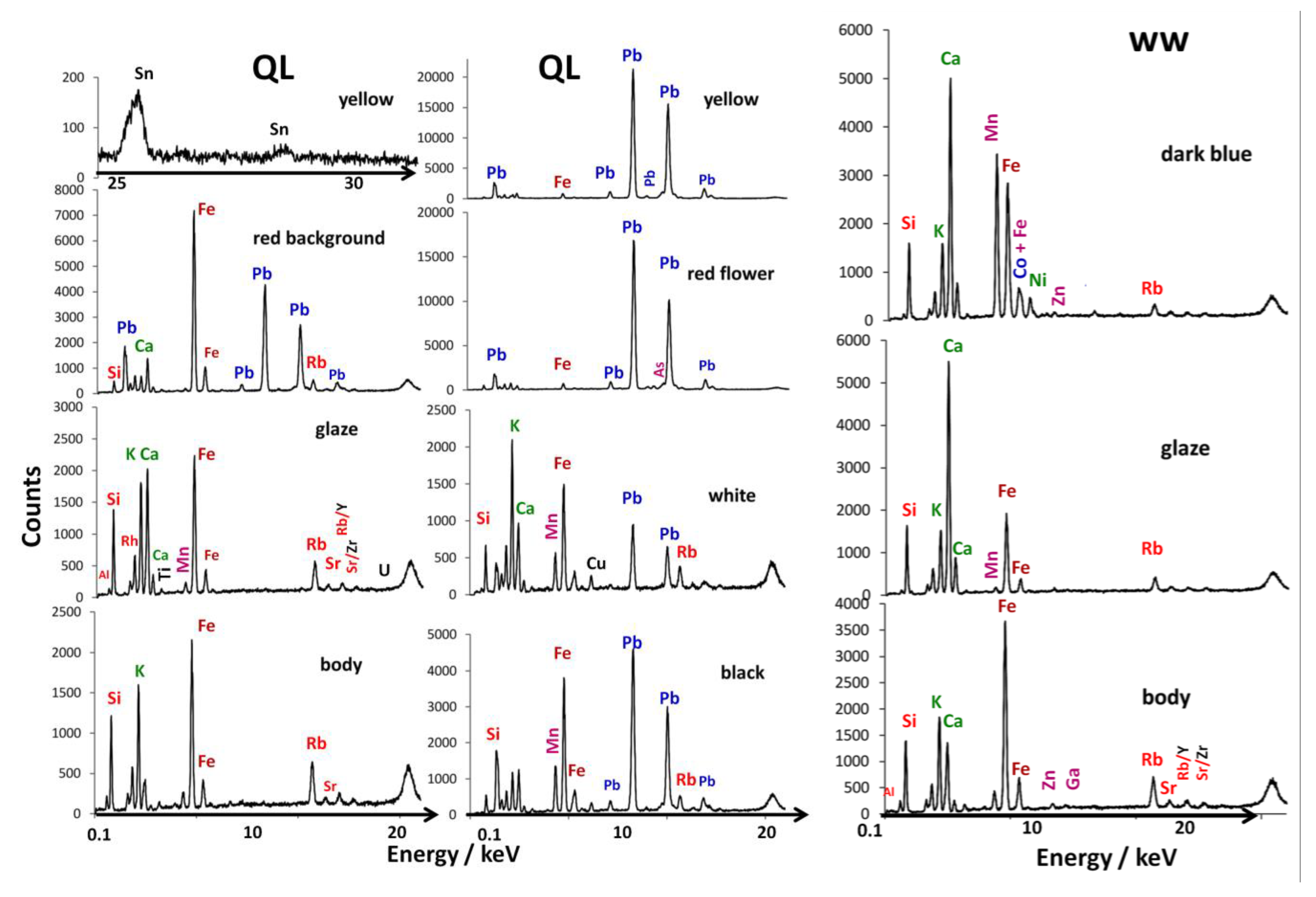

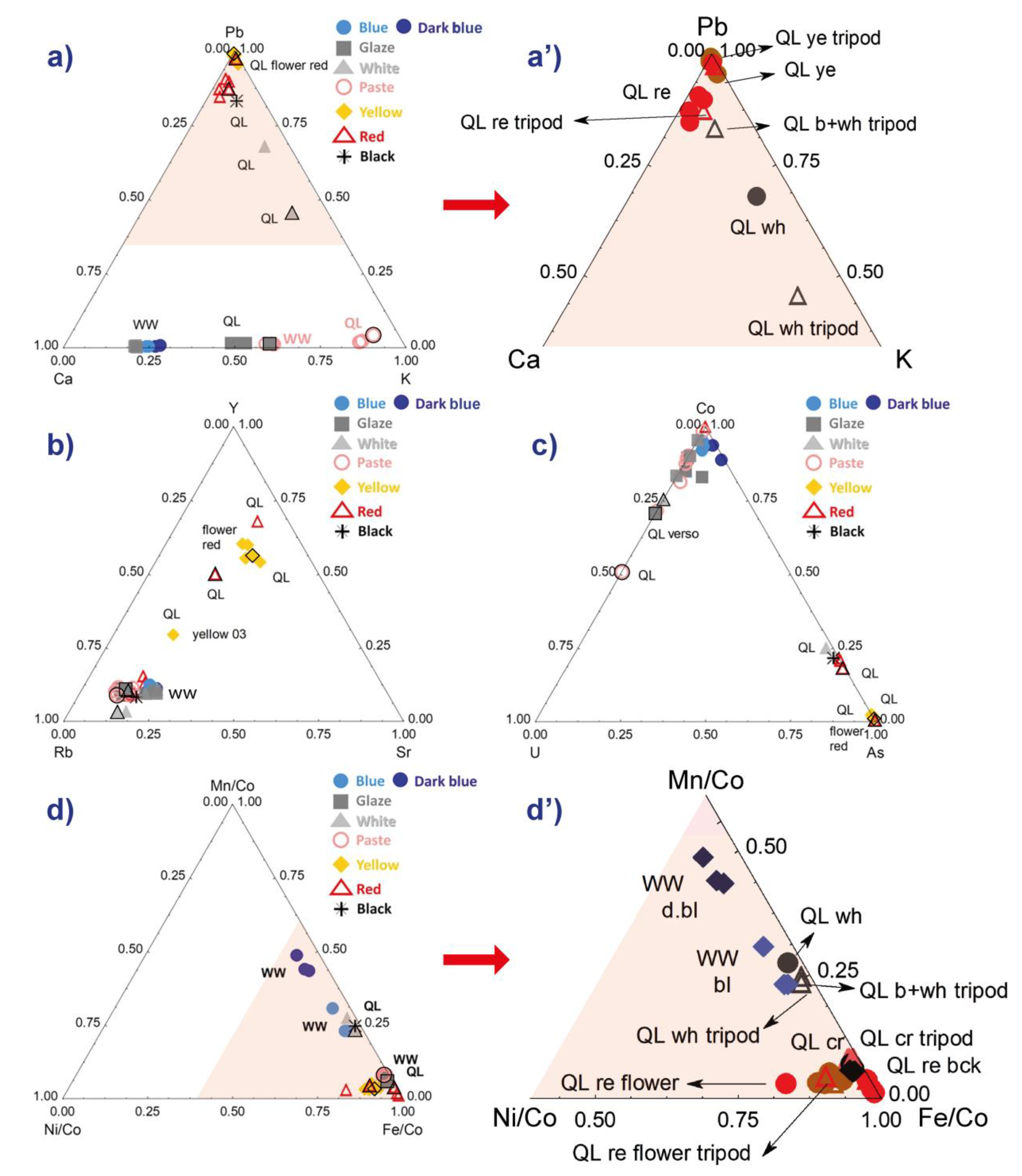

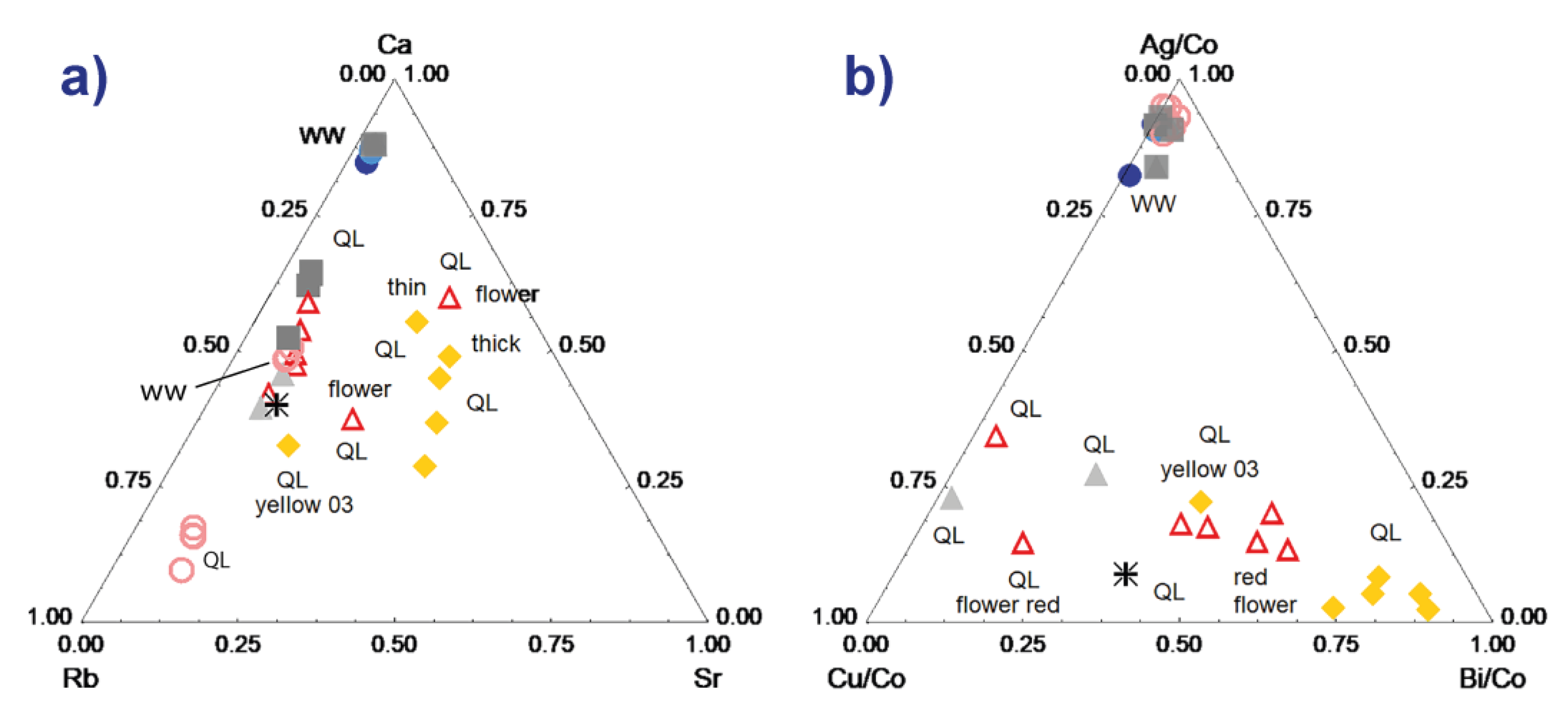

3.1. XRF Fingerprint

3.2. Silicate Matrix

3.3. Coloring and Associated Elements

4. Discussion: Intrinsic Heterogeneity vs. Measurement Error

4.1. Effects of the Surface Geometry

4.2. Tripod vs. Bench: The Case of Sample QL

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Finlay, R. 1. The Porcelain City: Jingdezhen in the Eighteenth Century. In The Pilgrim Art: Cultures of Porcelain in World History; University of California Press: Berkeley, CA, USA, 2010; pp. 17–46. ISBN 978-0-520-94538-8. [Google Scholar]

- Huang, E.C. From the Imperial Court to the International Art Market: Jingdezhen Porcelain Production as Global Visual Culture. J. World Hist. 2012, 23, 115–145. [Google Scholar] [CrossRef]

- Pierson, S. True Beauty of Form and Chaste Embellishment. Summer Palace Loot and Chinese Porcelain Collecting in Nineteenth-Century Britain. In Collecting and Displaying China’s “Summer Palace” in the West—The Yuanmingyuan in Britain and France, The Histories of Material Culture and Collecting, 1700–1950; Tythacott, L., Ed.; Routledge: London, UK, 2018; pp. 72–86. [Google Scholar]

- Pierson, S. True or False? Defining the Fake in Chinese Porcelain. Les Cahiers de Framespa 2019, 31. [Google Scholar] [CrossRef]

- Catalogue Porcelain with Painted Enamels of Qing Period; National Palace Museum: Taipei, Taiwan, 2013.

- Cai, H. Special Exhibition of Ch’ing Dynasty Enamelled Procelains of the Imperial Ateliers; National Palace Museum, Ed.; National Palace Museum: Taipei, Taiwan, 1992; ISBN 978-957-562-125-4. [Google Scholar]

- Landry-Deron, I. Les Mathématiciens Envoyés En Chine Par Louis XIV En 1685. Arch. Hist. Exact Sci. 2001, 55, 423–463. [Google Scholar] [CrossRef]

- Loehr, G. Missionary-Artists at the Manchu Court. Trans. Orient. Ceram. Soc. 1963, 34, 51–67. [Google Scholar]

- Shih, C.-F. Evidence of East-West Exchange in the Eighteenth Century: The Establishment of Painted Enamel Art at the Qing Court in the Reign of Emperor Kangxi. Natl. Palace Mus. Res. Q. 2017, 24, 45–94. [Google Scholar]

- Xu, X. Europe-China-Europe: The Transmission of the Craft of Painted Enamel in the Seventeenth and Eighteenth Centuries. In Goods from the East, 1600–1800 Trading Eurasia; Berg, M., Gottmann, F., Hodacs, H., Nierstrasz, C., Eds.; Palgrave Macmillan: London, UK, 2015; pp. 92–106. [Google Scholar]

- Colomban, P.; Zhang, Y.; Zhao, B. Non-Invasive Raman Analyses of Chinese Huafalang and Related Porcelain Wares. Searching for Evidence for Innovative Pigment Technologies. Ceram. Int. 2017, 43, 12079–12088. [Google Scholar] [CrossRef]

- Ma, H.; Henderson, J.; Cui, J.; Chen, K. Glassmaking of the Qing Dynasty: A Review, New Data, and New Insights. Adv. Archaeomater. 2020, 1, 27–35. [Google Scholar] [CrossRef]

- Curtis, E.B. Aspects of a Multi-Faceted Process: The Circulation of Enamel Wares between the Vatican and Kangxi’s Court. In Des Arts Diplomatiques. Les Cadeaux Diplomatiques Entre la Chine et l’Europe aux XVIIe-XVIIIe Siècles. Pratiques et Enjeux; Zhao, B., Landry-Deron, I., Simon, F., Eds.; Extrême-Orient, Extrême-Occident; Presses Universitaires de Vincennes: Vincennes, France, 2019; pp. 29–39. [Google Scholar]

- Xu, Y. Painted Enamel on Ceramics—The Encounter of Dutch and Chinese Pottery. Available online: https://www.aronson.com/painted-enamel-on-ceramic-the-encounter-of-dutch-and-chinese-pottery/ (accessed on 23 November 2022).

- Bellemare, J. A New Palette: Reassessing the Development of Enamel Colors in Early Eighteenth-Century China. J. Glass Stud. 2022, 64, 147–167. [Google Scholar]

- Treasures from Oversea Countries, Exhibition Catalogue of Kulangsu Gallery of Foreign Artefacts from the Palace Museum Collection; Palace Museum (Ed.) Gugong Chubanshe: Beijing, China, 2011. [Google Scholar]

- Kleutghen, K. Chinese Occidenterie: The Diversity of “Western” Objects in Eighteenth-Century China. Eighteenth-Century Stud. 2014, 47, 117–135. [Google Scholar] [CrossRef]

- De Rochebrunne, M.L. Les Porcelaines de Sèvres Envoyées En Guise de Cadeaux Diplomatiques à l’empereur de Chine Par Les Souverains Français Dans La Seconde Moitié Du XVIIIe Siècle. In Des Arts Diplomatiques. Les Cadeaux Diplomatiques Entre la Chine et l’Europe aux XVIIe-XVIIIe Siècles. Pratiques et Enjeux; Zhao, B., Landry-Deron, I., Simon, F., Eds.; Extrême-Orient, Extrême-Occident; Presses Universitaires de Vincennes: Vincennes, France, 2019; pp. 81–92. [Google Scholar]

- Finlay, J. Henri Bertin and Louis XV’s Gifts to the Qianlong Emperor. In Des Arts Diplomatiques. Les Cadeaux Diplomatiques Entre la Chine et l’Europe aux XVIIe-XVIIIe Siècles. Pratiques et Enjeux; Zhao, B., Landry-Deron, I., Simon, F., Eds.; Extrême-Orient, Extrême-Occident; Presses Universitaires de Vincennes: Vincennes, France, 2019; pp. 93–112. [Google Scholar]

- Guo, F. Presents and Tribute: Exploration of the Presents Given to the Qianlong Emperor by the British Macartney Embassy. In Des Arts Diplomatiques. Les Cadeaux Diplomatiques Entre la Chine et l’Europe aux XVIIe-XVIIIe Siècles. Pratiques et Enjeux; Zhao, B., Landry-Deron, I., Simon, F., Eds.; Extrême-Orient, Extrême-Occident; Presses Universitaires de Vincennes: Vincennes, France, 2019; pp. 143–172. [Google Scholar]

- Colomban, P.; Kırmızı, B.; Gougeon, C.; Gironda, M.; Cardinal, C. Pigments and Glassy Matrix of the 17th–18th Century Enamelled French Watches: A Non-Invasive on-Site Raman and PXRF Study. J. Cult. Herit. 2020, 44, 1–14. [Google Scholar] [CrossRef]

- Zhang, F. The Origin and Development of Traditional Chinese Glazes and Decorative Ceramics Color. In Ancient Technology to Modern Science; Kingery, W.D., Ed.; The American Ceramic Society: Colombus, OH, USA, 1985; Volume 1, pp. 163–180. [Google Scholar]

- Kingery, W.D.; Vandiver, P.B. The Eighteenth-Century Change in Technology and Style from the Famille-Verte Palette to the Famille-Rose Palette. In Technology and Style; Kingery, W.D., Ed.; Ceramics and Civilization; The American Ceramic Society: Colombus, OH, USA, 1986; Volume 2, pp. 363–381. [Google Scholar]

- Colomban, P.; Ambrosi, F.; Ngo, A.T.; Lu, T.A.; Feng, X.L.; Chen, S.; Choi, C.L. Comparative Analysis of Wucai Chinese Porcelains Using Mobile and Fixed Raman Microspectrometers. Ceram. Int. 2017, 43, 14244–14256. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, J.; Ji, L.; Shan, Y.; Jiang, S.; Chen, G.; Sciau, P.; Wang, W.; Wang, C. Study of Arsenic in Famille Rose Porcelain from the Imperial Palace of Qing Dynasty, Beijing, China. Ceram. Int. 2018, 44, 1627–1632. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, X.; Kang, B.; Wang, G.; Qu, L.; Lei, Y. Non-Destructive Analysis and Deterioration Study of a Decorated Famille Rose Porcelain Bowl of Qianlong Reign from the Forbidden City. Stud. Conserv. 2019, 64, 311–322. [Google Scholar] [CrossRef]

- Li, Y.; Sciau, P.; Zhu, J.; Ji, L.; Shan, Y.; Song, G. Microscopic Analysis of Overglaze Green Pigment on Chinese famille rose Porcelain from the Imperial Palace. Microsc. Res. Tech. 2021, 84, 1106–1114. [Google Scholar] [CrossRef] [PubMed]

- Colomban, P.; Kırmızı, B.; Zhao, B.; Clais, J.B.; Yang, Y.; Droguet, V. Investigation of the Pigments and Glassy Matrix of Painted Enamelled Qing Dynasty Chinese Porcelains by Noninvasive On-Site Raman Microspectrometry. Heritage 2020, 3, 915–940. [Google Scholar] [CrossRef]

- Colomban, P.; Gironda, M.; Vangu, D.; Kırmızı, B.; Zhao, B.; Cochet, V. The Technology Transfer from Europe to China in the 17th–18th Centuries: Non-Invasive On-Site XRF and Raman Analyses of Chinese Qing Dynasty Enameled Masterpieces Made Using European Ingredients/Recipes. Materials 2021, 14, 7434. [Google Scholar] [CrossRef]

- Colomban, P.; Simsek Franci, G.; Gironda, M.; d’Abrigeon, P.; Schumacher, A.C. PXRF Data Evaluation Methodology for On-Site Analysis of Precious Artifacts: Cobalt Used in the Blue Decoration of Qing Dynasty Overglazed Porcelain Enameled at Customs District (Guangzhou), Jingdezhen and Zaobanchu (Beijing) Workshops. Heritage 2022, 5, 1752–1778. [Google Scholar] [CrossRef]

- Colomban, P. The Discovery and Comparison of the Manufacturing Secrets of Enamelled Masterpieces. Orientations 2022, 53, 92–96. [Google Scholar]

- Colomban, P.; Gironda, M.; Simsek Franci, G.; d’Abrigeon, P. Distinguishing Genuine Imperial Qing Dynasty Porcelain from Ancient Replicas by On-Site Non-Invasive XRF and Raman Spectroscopy. Materials 2022, 15, 5747. [Google Scholar] [CrossRef]

- Van Pevenage, J.; Lauwers, D.; Herremans, D.; Verhaeven, E.; Vekemans, B.; De Clercq, W.; Vincze, L.; Moens, L.; Vandenabeele, P. A Combined Spectroscopic Study on Chinese Porcelain Containing Ruan-Cai Colours. Anal. Methods 2014, 6, 387–394. [Google Scholar] [CrossRef]

- Giannini, R.; Freestone, I.C.; Shortland, A.J. European Cobalt Sources Identified in the Production of Chinese famille rose Porcelain. J. Archaeol. Sci. 2017, 80, 27–36. [Google Scholar] [CrossRef]

- Norris, D.E.; Braekmans, D.; Domoney, K.; Shortland, A. The Composition and Technology of Polychrome Enamels on Chinese Ruby-Backed Plates Identified Through Nondestructive Micro-X-ray Fluorescence. X-ray Spectrom. 2020, 49, 502–510. [Google Scholar] [CrossRef]

- Colomban, P.; Ngo, A.T.; Fournery, N. Non-Invasive Raman Analysis of 18th Century Chinese Export/Armorial Overglazed Porcelain: Identification of the Different Enameling Techniques. Heritage 2022, 5, 233–259. [Google Scholar] [CrossRef]

- Colomban, P. On-Site Raman Identification and Dating of Ancient Glasses: A Review of Procedures and Tools. J. Cult. Herit. 2008, 9, e55–e60. [Google Scholar] [CrossRef]

- Colomban, P. The On-site/Remote Raman Analysis with Mobile Instruments: A Review of Drawbacks and Success in Cultural Heritage Studies and Other Associated Fields. J. Raman Spectrosc. 2012, 43, 1529–1535. [Google Scholar] [CrossRef]

- Colomban, P. On-Site Raman Study of Artwork: Procedure and Illustrative Examples. J. Raman Spectrosc. 2018, 49, 921–934. [Google Scholar] [CrossRef]

- Colomban, P.; Milande, V.; Le Bihan, L. On-Site Raman Analysis of Iznik Pottery Glazes and Pigments. J. Raman Spectrosc. 2004, 35, 527–535. [Google Scholar] [CrossRef]

- Shackley, M.S. Is There Reliability and Validity in Portable X-ray Fluorescence Spectrometry (PXRF)? SAA Archaeol. Rec. 2010, 10, 17–20. [Google Scholar]

- Liritzis, I.; Zacharias, N. Portable XRF of Archaeological Artifacts: Current Research, Potentials and Limitations. In X-ray Fluorescence Spectrometry (XRF) in Geoarchaeology; Schackley, M.S., Ed.; Springer: New York, NY, USA, 2011; pp. 109–142. [Google Scholar]

- Goodale, N.; Bailey, D.G.; Jones, G.T.; Prescott, C.; Scholz, E.; Stagliano, N.; Lewis, C. PXRF: A Study of Inter-Instrument Performance. J. Archaeol. Sci. 2012, 39, 875–883. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.H.; Fu, Q.; Gan, F.X.; Xiong, Z.M. Application of a Portable XRF Spectrometer for Classification of Potash Glass Beads Unearthed from Tombs of Han Dynasty in Guangxi, China: Application of PXRF for Potash Glass Found in Guangxi, China. X-ray Spectrom. 2013, 42, 470–479. [Google Scholar] [CrossRef]

- Forster, N.; Grave, P. Effects of Elevated Levels of Lead in Ceramics on Provenancing Studies Using Non-Destructive PXRF: A Case Study in Byzantine Cypriot Glazed Ceramics: Effects of Elevated Levels of Lead in Ceramics on Non-Destructive PXRF. X-ray Spectrom. 2013, 42, 480–486. [Google Scholar] [CrossRef]

- Frahm, E. Validity of “off-the-Shelf” Handheld Portable XRF for Sourcing Near Eastern Obsidian Chip Debris. J. Archaeol. Sci. 2013, 40, 1080–1092. [Google Scholar] [CrossRef]

- Xu, W.; Niziolek, L.C.; Feinman, G.M. Sourcing Qingbai Porcelains from the Java Sea Shipwreck: Compositional Analysis Using Portable XRF. J. Archaeol. Sci. 2019, 103, 57–71. [Google Scholar] [CrossRef]

- Demirsar Arlı, B.; Simsek Franci, G.; Kaya, Ş.; Arli, H.; Colomban, P. Portable X-ray Fluorescence (p-XRF) Uncertainty Estimation for Glazed Ceramic Analysis: Case of Iznik Tiles. Heritage 2020, 3, 1302–1329. [Google Scholar] [CrossRef]

- BRUKER Information Depth. Available online: https://xrfcheck.bruker.com/InfoDepth (accessed on 23 November 2022).

- Govindaraju, K. Report (1967–1981) on Four ANRT Rock Reference Samples: Diorite DR-N, Serpentine UB-N, Bauxite BX-N and Disthene DT-N. Geostand. Geoanal. Res. 1982, 6, 91–159. [Google Scholar] [CrossRef]

- Govindaraju, K. 1995 Working Values with Confidence Limits for Twenty-Six CRPG, ANRT and IWG-GIT Geostandards. Geostand. Geoanal. Res. 1995, 19, 1–32. [Google Scholar] [CrossRef]

- Colomban, P. Full Spectral Range Raman Signatures Related to Changes in Enameling Technologies from the 18th to the 20th Century: Guidelines, Effectiveness and Limitations of the Raman Analysis. Materials 2022, 15, 3158. [Google Scholar] [CrossRef]

- Burlot, J.; Bellot-Gurlet, L.; Lemasson, Q.; Pichon, L.; Colomban, P. Bore/Lithium-based flux in 18th Century Chinese porcelain enamels: PIXE/PIGE study. In Proceedings of the 18th ECerS Conf., Lyon, France, 2–6 July 2023. submitted. [Google Scholar]

- Colomban, P.; Kırmızı, B.; Simsek Franci, G. Cobalt and Associated Impurities in Blue (and Green) Glass, Glaze and Enamel: Relationships between Raw Materials, Processing, Composition, Phases and International Trade. Minerals 2021, 11, 633. [Google Scholar] [CrossRef]

- Kissin, S.A. Five-Element (Ni-Co-As-Ag-Bi) Veins. Geosci. Can. 1992, 19, 113–124. [Google Scholar]

| Area | Bench Setup | Tripod Setup | ||

|---|---|---|---|---|

| Spot Number | Part of the Shard Analyzed | Spot Number | Part of the Shard Analyzed | |

| Falangcai bowl (QL) | ||||

| Body | 7, 11, 12 | Cross-section | 35 | Cross-section |

| Glaze | 8, 9, 10 | Inner surface | 34 | Inner surface |

| Black line | Outer surface | 37 | Outer surface | |

| White | 5 | 33 | ||

| Red background | 3, 4, 13, 14 | 32 | ||

| Red flower | 6 | 36 | ||

| Yellow “regular” | 2, 15, 16, 18 | 31 | ||

| Yellow “thick” | 17 | _ | ||

| Blue-and-white plate (ww) | ||||

| Body | 28, 29, 30 | Cross-section | _ | |

| Glaze | 25, 26, 27 | Outer surface | ||

| Blue (hatched motif) | 22, 23, 24 | |||

| Dark blue | 19, 20, 21 | |||

| Ca | Pb | K | Ca | Pb | K | Ca | Pb | K | Ca | Pb | K | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Paste (n = 3) | Glaze (n = 3) | Yellow (n = 5) | Red background (n = 4) | |||||||||

| Mean | 0.122 | 0.020 | 0.858 | 0.484 | 0.014 | 0.501 | 0.008 | 0.980 | 0.012 | 0.092 | 0.880 | 0.028 |

| Diff. | 0.009 | 0.004 | 0.005 | 0.043 | 0.001 | 0.043 | 0.009 | 0.038 | 0.031 | 0.053 | 0.061 | 0.015 |

| Std | 0.005 | 0.002 | 0.003 | 0.022 | 0.000 | 0.022 | 0.004 | 0.015 | 0.013 | 0.026 | 0.027 | 0.008 |

| Paste * (n = 4) | Glaze * (n = 4) | Yellow * (n = 6) | Red background * (n = 5) | |||||||||

| Mean | 0.110 | 0.026 | 0.864 | 0.461 | 0.014 | 0.525 | 0.008 | 0.981 | 0.011 | 0.090 | 0.878 | 0.032 |

| Diff. | 0.052 | 0.024 | 0.028 | 0.111 | 0.002 | 0.112 | 0.009 | 0.038 | 0.031 | 0.053 | 0.061 | 0.028 |

| Std | 0.025 | 0.011 | 0.013 | 0.050 | 0.001 | 0.050 | 0.004 | 0.014 | 0.012 | 0.023 | 0.024 | 0.012 |

| Rb | Sr | Y | Rb | Sr | Y | Rb | Sr | Y | Rb | Sr | Y | |

| Paste (n = 3) | Glaze (n = 3) | Yellow (n = 5) | Red background (n = 4) | |||||||||

| Mean | 0.786 | 0.104 | 0.111 | 0.780 | 0.120 | 0.100 | 0.239 | 0.244 | 0.517 | 0.722 | 0.161 | 0.117 |

| Diff. | 0.018 | 0.005 | 0.013 | 0.005 | 0.016 | 0.021 | 0.379 | 0.133 | 0.308 | 0.072 | 0.024 | 0.064 |

| Std | 0.010 | 0.002 | 0.008 | 0.003 | 0.008 | 0.011 | 0.163 | 0.049 | 0.128 | 0.035 | 0.010 | 0.030 |

| Paste * (n = 4) | Glaze * (n = 4) | Yellow * (n = 6) | Red background * (n = 5) | |||||||||

| Mean | 0.789 | 0.106 | 0.105 | 0.776 | 0.122 | 0.102 | 0.227 | 0.249 | 0.524 | 0.729 | 0.157 | 0.114 |

| Diff. | 0.020 | 0.012 | 0.028 | 0.020 | 0.017 | 0.021 | 0.379 | 0.133 | 0.308 | 0.072 | 0.035 | 0.064 |

| Std | 0.010 | 0.005 | 0.013 | 0.009 | 0.008 | 0.010 | 0.149 | 0.046 | 0.116 | 0.035 | 0.013 | 0.027 |

| Co | As | U | Co | As | U | Co | As | U | Co | As | U | |

| Paste (n = 3) | Glaze (n = 3) | Yellow (n = 5) | Red background (n = 4) | |||||||||

| Mean | 0.800 | 0.009 | 0.190 | 0.858 | 0.032 | 0.111 | 0.016 | 0.984 | 0.000 | 0.407 | 0.593 | 0.000 |

| Diff. | 0.160 | 0.021 | 0.165 | 0.065 | 0.075 | 0.038 | 0.015 | 0.015 | 0.000 | 0.794 | 0.794 | 0.000 |

| Std | 0.081 | 0.011 | 0.085 | 0.034 | 0.039 | 0.020 | 0.006 | 0.006 | 0.000 | 0.395 | 0.395 | 0.000 |

| Paste * (n = 4) | Glaze * (n = 4) | Yellow * (n = 6) | Red background * (n = 5) | |||||||||

| Mean | 0.727 | 0.007 | 0.266 | 0.820 | 0.024 | 0.156 | 0.015 | 0.985 | 0.000 | 0.362 | 0.637 | 0.001 |

| Diff. | 0.368 | 0.021 | 0.371 | 0.189 | 0.075 | 0.199 | 0.015 | 0.015 | 0.000 | 0.819 | 0.814 | 0.005 |

| Std | 0.161 | 0.010 | 0.166 | 0.081 | 0.035 | 0.093 | 0.006 | 0.006 | 0.000 | 0.357 | 0.356 | 0.002 |

| Mn/Co | Ni/Co | Fe/Co | Mn/Co | Ni/Co | Fe/Co | Mn/Co | Ni/Co | Fe/Co | Mn/Co | Ni/Co | Fe/Co | |

| Paste (n = 3) | Glaze (n = 3) | Yellow (n = 5) | Red background (n = 4) | |||||||||

| Mean | 0.078 | 0.019 | 0.903 | 0.063 | 0.018 | 0.919 | 0.038 | 0.070 | 0.892 | 0.026 | 0.006 | 0.969 |

| Diff. | 0.002 | 0.001 | 0.002 | 0.008 | 0.001 | 0.008 | 0.023 | 0.048 | 0.043 | 0.024 | 0.001 | 0.025 |

| Std | 0.001 | 0.001 | 0.001 | 0.005 | 0.001 | 0.004 | 0.009 | 0.019 | 0.016 | 0.012 | 0.001 | 0.012 |

| Paste * (n = 4) | Glaze * (n = 4) | Yellow * (n = 6) | Red background * (n = 5) | |||||||||

| Mean | 0.078 | 0.018 | 0.904 | 0.061 | 0.017 | 0.922 | 0.037 | 0.069 | 0.894 | 0.028 | 0.005 | 0.966 |

| Diff. | 0.004 | 0.006 | 0.003 | 0.012 | 0.004 | 0.016 | 0.023 | 0.048 | 0.043 | 0.027 | 0.002 | 0.026 |

| Std | 0.002 | 0.002 | 0.001 | 0.005 | 0.002 | 0.006 | 0.008 | 0.017 | 0.015 | 0.012 | 0.001 | 0.012 |

| Ca | Rb | Sr | Ca | Rb | Sr | Ca | Rb | Sr | Ca | Rb | Sr | |

| Paste (n = 3) | Glaze (n = 3) | Yellow (n = 5) | Red background (n = 4) | |||||||||

| Mean | 0.163 | 0.739 | 0.098 | 0.634 | 0.317 | 0.049 | 0.404 | 0.283 | 0.313 | 0.523 | 0.389 | 0.088 |

| Diff. | 0.017 | 0.010 | 0.008 | 0.026 | 0.017 | 0.009 | 0.265 | 0.339 | 0.237 | 0.114 | 0.077 | 0.038 |

| Std | 0.009 | 0.005 | 0.004 | 0.014 | 0.009 | 0.005 | 0.112 | 0.136 | 0.098 | 0.051 | 0.035 | 0.016 |

| Paste * (n = 4) | Glaze * (n = 4) | Yellow * (n = 6) | Red background * (n = 5) | |||||||||

| Mean | 0.146 | 0.753 | 0.102 | 0.606 | 0.340 | 0.054 | 0.411 | 0.270 | 0.319 | 0.502 | 0.409 | 0.088 |

| Diff. | 0.078 | 0.059 | 0.019 | 0.123 | 0.099 | 0.024 | 0.265 | 0.339 | 0.237 | 0.169 | 0.147 | 0.038 |

| Std | 0.035 | 0.027 | 0.008 | 0.057 | 0.046 | 0.011 | 0.102 | 0.126 | 0.089 | 0.064 | 0.055 | 0.014 |

| Ag/Co | Cu/Co | Bi/Co | Ag/Co | Cu/Co | Bi/Co | Ag/Co | Cu/Co | Bi/Co | Ag/Co | Cu/Co | Bi/Co | |

| Paste (n = 3) | Glaze (n = 3) | Yellow (n = 5) | Red background (n = 4) | |||||||||

| Mean | 0.933 | 0.046 | 0.021 | 0.955 | 0.047 | -0.002 | 0.080 | 0.184 | 0.737 | 0.213 | 0.374 | 0.413 |

| Diff. | 0.026 | 0.022 | 0.023 | 0.021 | 0.021 | 0.002 | 0.199 | 0.267 | 0.463 | 0.210 | 0.369 | 0.571 |

| Std | 0.013 | 0.011 | 0.012 | 0.011 | 0.011 | 0.001 | 0.082 | 0.114 | 0.185 | 0.091 | 0.172 | 0.258 |

| Paste * (n = 4) | Glaze * (n = 4) | Yellow * (n = 6) | Red background * (n = 5) | |||||||||

| Mean | 0.924 | 0.054 | 0.022 | 0.945 | 0.055 | 0.000 | 0.075 | 0.180 | 0.744 | 0.206 | 0.381 | 0.413 |

| Diff. | 0.048 | 0.039 | 0.023 | 0.049 | 0.042 | 0.007 | 0.199 | 0.267 | 0.463 | 0.210 | 0.369 | 0.571 |

| Std | 0.020 | 0.017 | 0.010 | 0.022 | 0.019 | 0.003 | 0.074 | 0.103 | 0.167 | 0.080 | 0.150 | 0.224 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burlot, J.; Gallet, X.; Simsek Franci, G.; Bellot-Gurlet, L.; Colomban, P. Non-Invasive On-Site pXRF Analysis of Coloring Agents of Under- and Over-Glazes: Variability and Representativity of Measurements on Porcelain. Colorants 2023, 2, 42-57. https://doi.org/10.3390/colorants2010004

Burlot J, Gallet X, Simsek Franci G, Bellot-Gurlet L, Colomban P. Non-Invasive On-Site pXRF Analysis of Coloring Agents of Under- and Over-Glazes: Variability and Representativity of Measurements on Porcelain. Colorants. 2023; 2(1):42-57. https://doi.org/10.3390/colorants2010004

Chicago/Turabian StyleBurlot, Jacques, Xavier Gallet, Gulsu Simsek Franci, Ludovic Bellot-Gurlet, and Philippe Colomban. 2023. "Non-Invasive On-Site pXRF Analysis of Coloring Agents of Under- and Over-Glazes: Variability and Representativity of Measurements on Porcelain" Colorants 2, no. 1: 42-57. https://doi.org/10.3390/colorants2010004

APA StyleBurlot, J., Gallet, X., Simsek Franci, G., Bellot-Gurlet, L., & Colomban, P. (2023). Non-Invasive On-Site pXRF Analysis of Coloring Agents of Under- and Over-Glazes: Variability and Representativity of Measurements on Porcelain. Colorants, 2(1), 42-57. https://doi.org/10.3390/colorants2010004