3.1. Transverse Loading—The Effect of Angle and Indenter Geometry

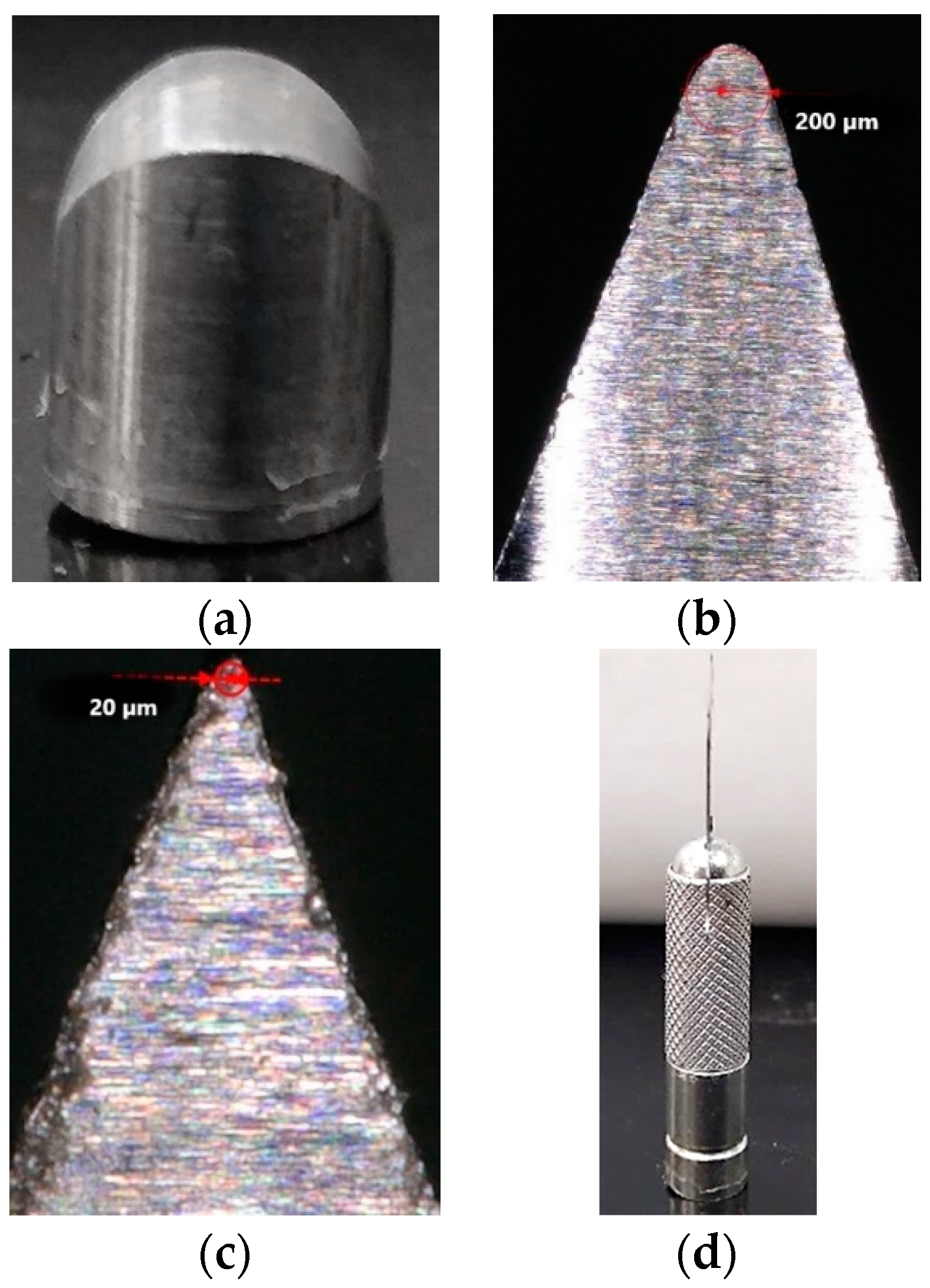

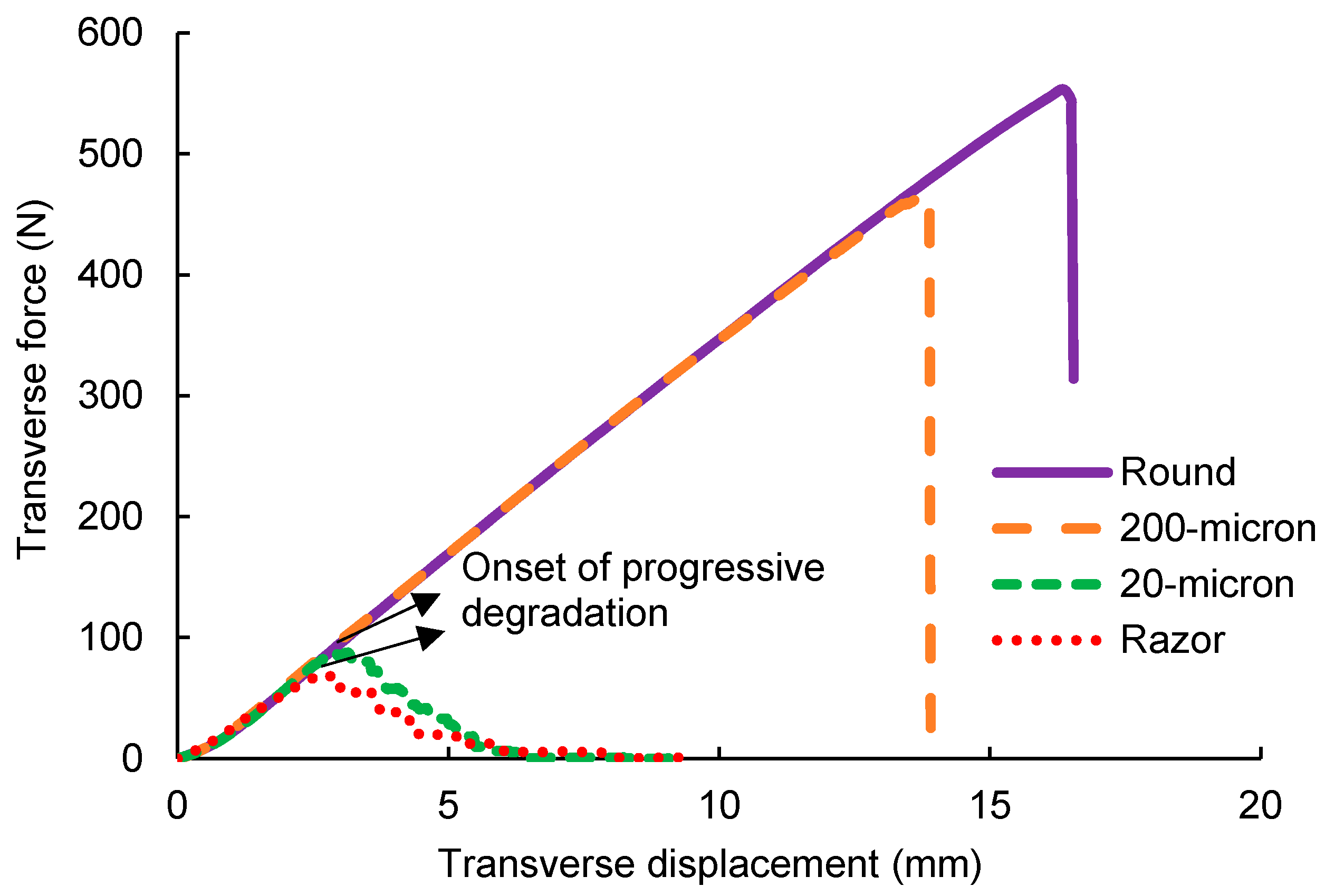

Figure 4 shows a force-displacement response for transverse loading for various indenter geometries. For conciseness, only a representative transverse force-displacement response at a starting angle of 25° is presented for the various indenter geometries. As seen from the figure, transverse failure loads decrease with increasing sharpness of the indenter geometry. A maximum transverse peak load is observed for the round projectile and is approximately 10 times higher than the peak load for the razor blade. Such a trend in transverse loads was also noted by Lim et al. [

16] for Twaron yarns subjected to transverse loading via various indenter geometries.

Figure 4 also highlights the differences in yarn failure observed for the different indenter geometries.

While instantaneous brittle failure is observed for the round projectile and 200-micron indenter on reaching the peak load, progressive failure occurs for the 20-micron indenter and razor blade. These differences in failure mode are more vividly captured in an experimental video which is attached to this study as supplementary information (see

Supplementary Materials). For the round projectile and 200-micron indenter, the yarn snaps back and forms a bulbous mass at failure. Such a failure was also observed for the uniaxial tensile failure of yarn in our previous study [

17]. Whereas for the 20-micron indenter and razor blade, individual fibers fail progressively in a cutting-type manner under transverse shear. For these indenters, two phenomena are observed during loading: progressive fiber failure and progressive degradation in load-carrying capacity of yarn as seen from

Figure 4. As the load increases, individual fibers start failing in a progressive manner and on reaching peak load, a cluster of fiber breaks is observed with progressive degradation in the load carrying capacity of the yarn.

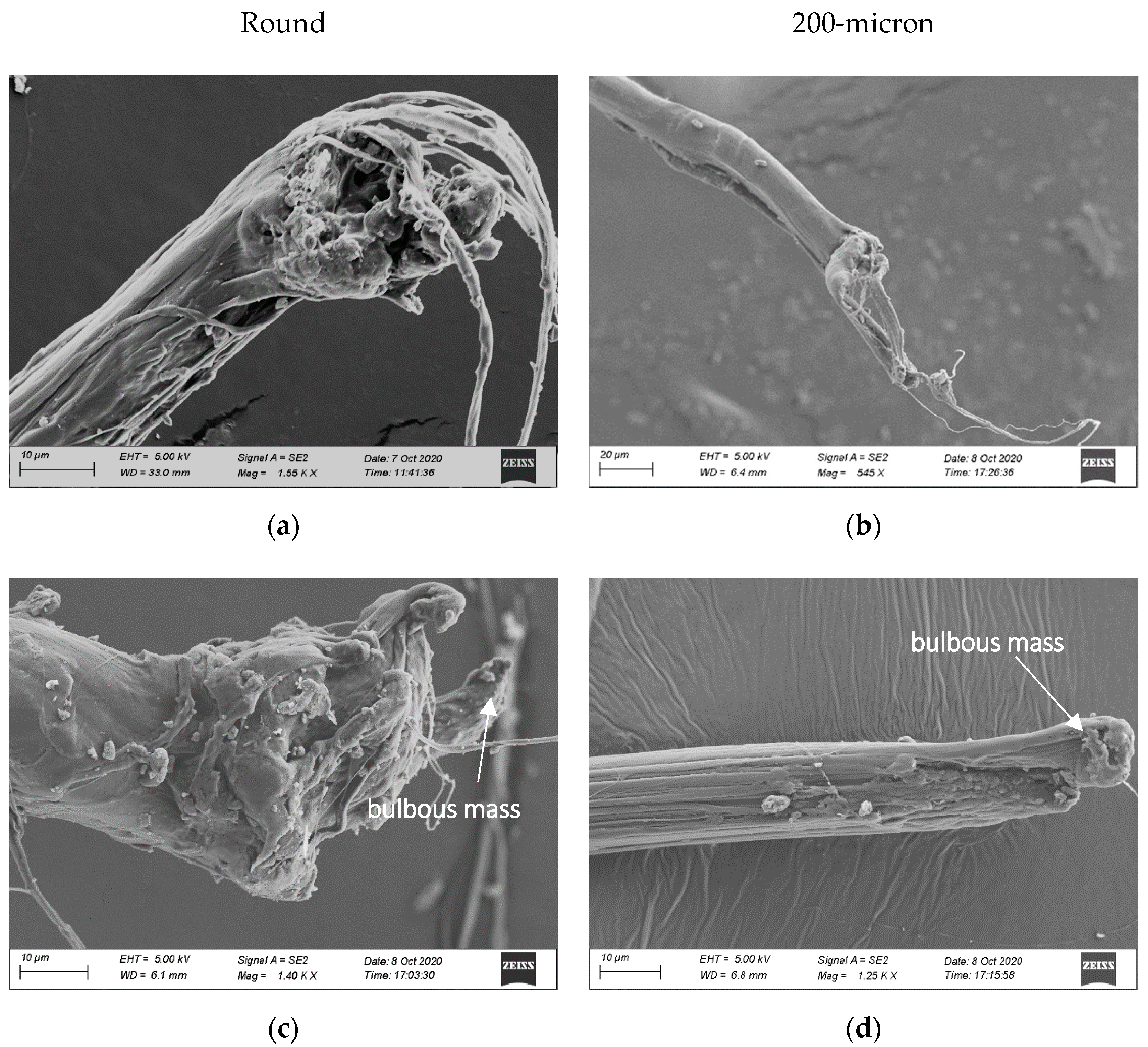

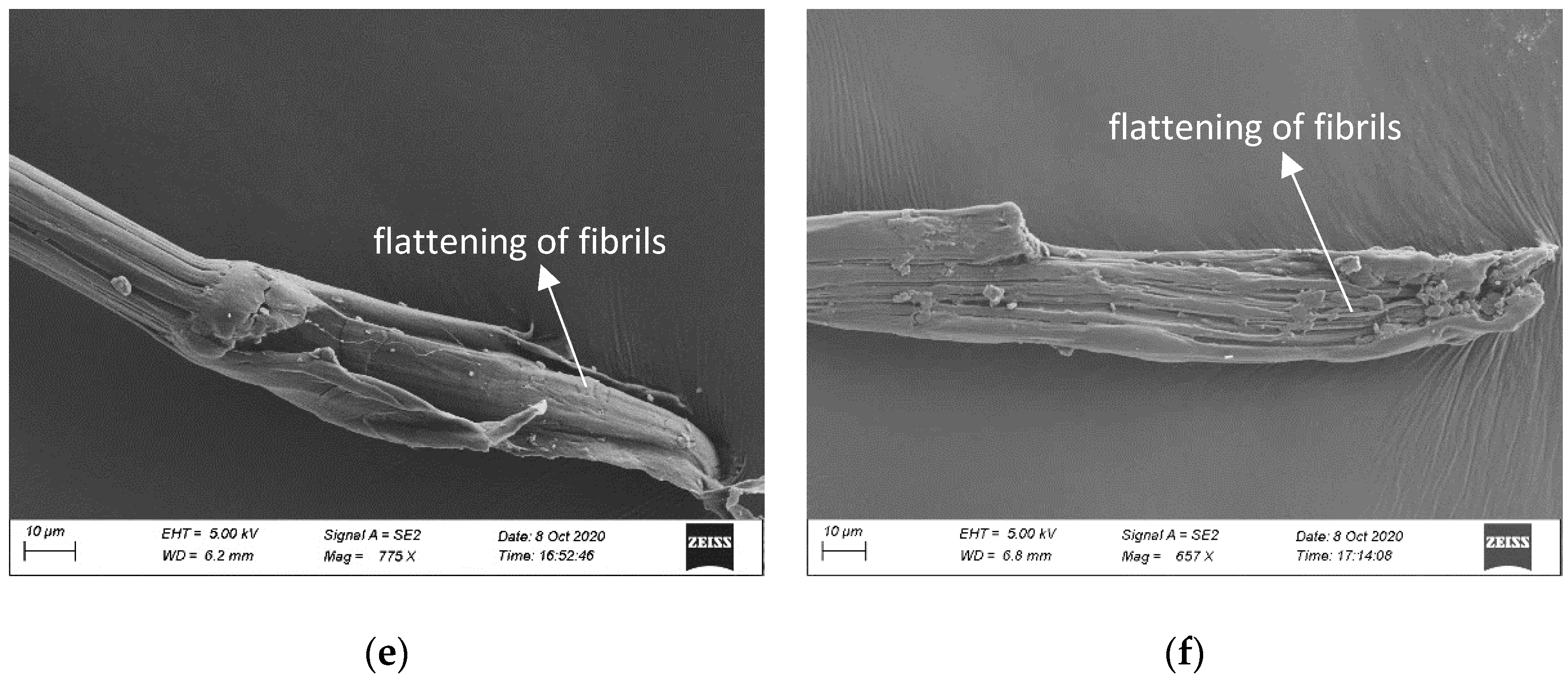

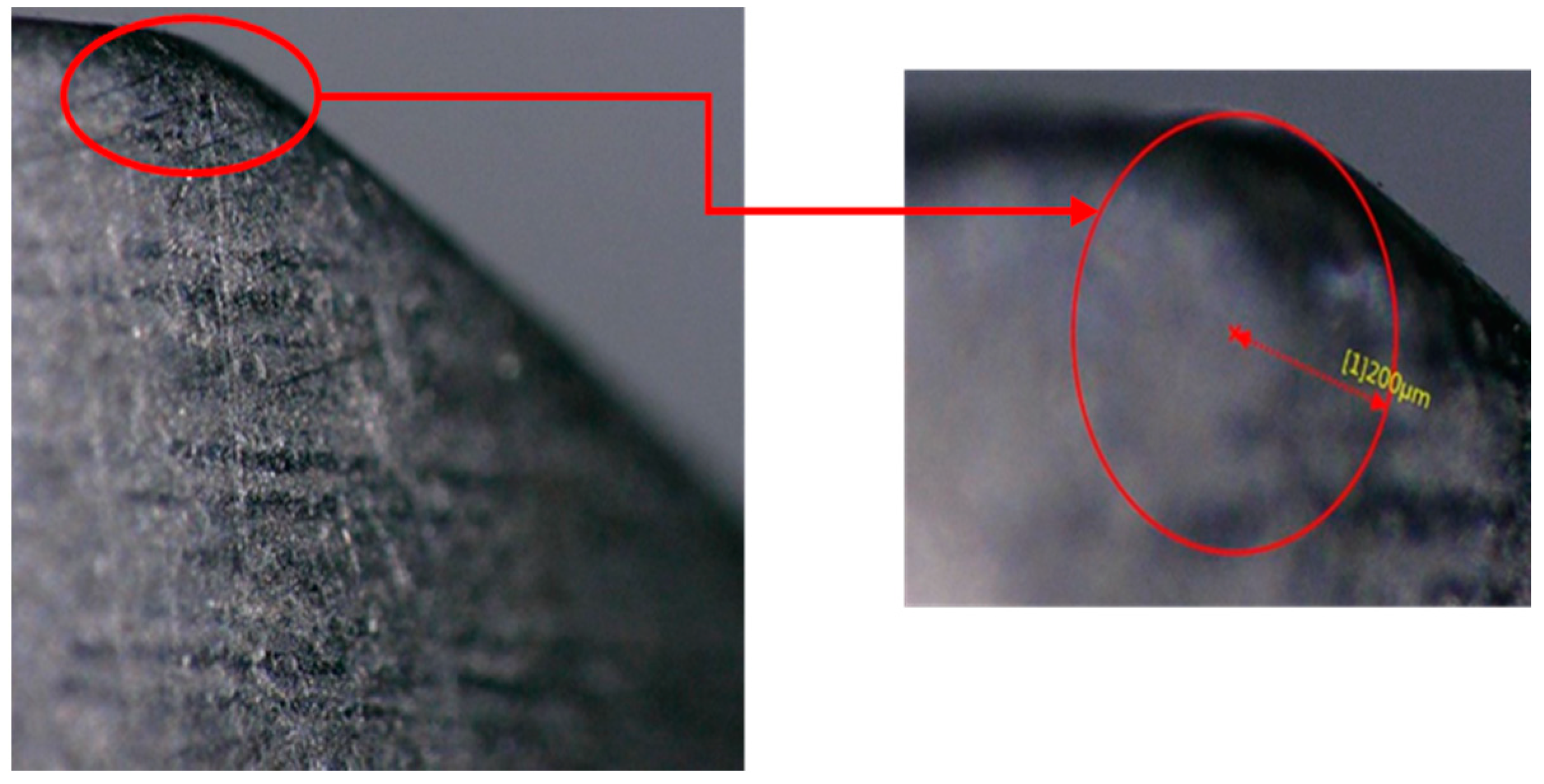

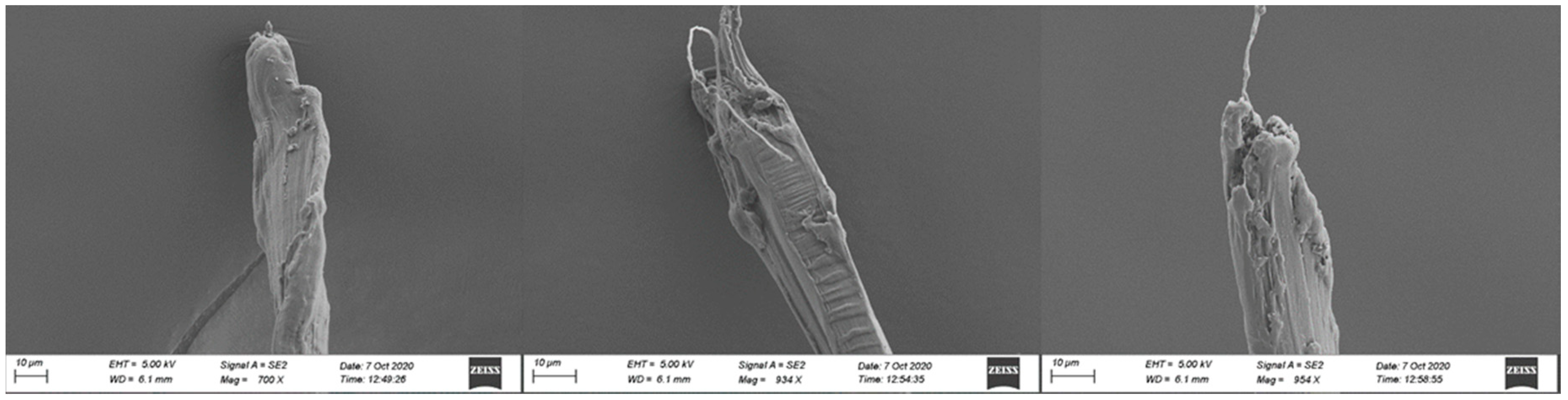

Figure 5 and

Figure 6 show post-mortem images of fiber failure surface for different indenter geometries for a starting angle of 25°. Multiple fibers are extracted from a failed yarn specimen and sputter-coated with gold-palladium (Au-Pd) particles before being imaged under a Zeiss FE 500 SEM acquired from Carl Zeiss Microscopy LLC, White Plains, NY, US. As seen from

Figure 5, for the round projectile fiber failure occurs mainly by axial splitting of fibrils or fibrillation. However, some fibers also show a flattening of fibrils along with fibrillation as depicted in

Figure 5e. Hudspeth et al. [

13] also report a similar failure surface for SK-76 single fibers transversely loaded by round projectile. For the 200-micron indenter, fibers mainly fail via flattening and fibrillation, as seen from

Figure 5b,d,f. Similar failure mechanisms are also observed for tensile failure of high modulus polyethylene fibers (HMPE) as reported by Languerand et al. [

25]. From the experimental video for the round projectile and 200-micron indenter it was observed that fibers snap back and form a bulbous mass at failure. This phenomenon can also be seen in the failure surface images for both indenters in

Figure 5c,d.

Post-mortem images of fiber failure surface for the 20-micron indenter and razor blade are very similar. For both geometries, fibrils seem to have been cut through via a localized transverse shear, as indicated by a flat failure surface. Although for the 20-micron indenter, a tensile failure of some fibrils is observed at one end of the failed fiber as shown in all its

Figure 6a,c,e. Gao et al. [

26,

27] and Hudspeth et al. [

13] have also reported similar failure images in their study on transverse failure of SK-76 fibers. However, the failure surfaces shown here for the 20-micron indenter (for failure angles ~26° (as shown later in Figure 9) are in contrast with those reported in [

13] for SK-76 single fibers which fail mainly via fibrillation for failure angles up to 40° and shear failure for failure angles at 50°. One potential reason for this could be the difference in fiber–indenter contact evolution when transversely loading yarns versus single fibers. Compared to single fibers, the contact conditions of the yarn are more complex involving several layers of fibers. A more detailed understanding of the contact conditions via three-dimensional finite element models is required to better understand this difference in failure mechanism between single fibers and yarns.

For the razor blade, however, the failure mechanism for the fiber seems to depend on the fiber location. Some fibers are completely cut through, as shown in

Figure 6b, whereas in some fibers, fibrils fail via both cutting (shearing) and fibrillation as shown in

Figure 6d,e. This type of a combined failure mechanism observed for both these indenters can be explained via the results of a three-dimensional finite element study of multi-axial loading of SK-76 single fiber conducted by Sockalingam et al. [

15]. Their results indicate that near the fiber–indenter contact interface the fiber experiences axial compression, transverse compression and transverse shear whereas away from the contact interface the fiber is under tension. This can explain why some fibrils at one end of the fiber fail via fibrillation or in tension whereas other fibrils are cut-through or sheared. Additionally, kink bands are observed on the fiber surface, as annotated in

Figure 6b. These kink bands are formed as a result of an axial compressive wave generated at the clamped end due to fiber recoil at failure [

28].

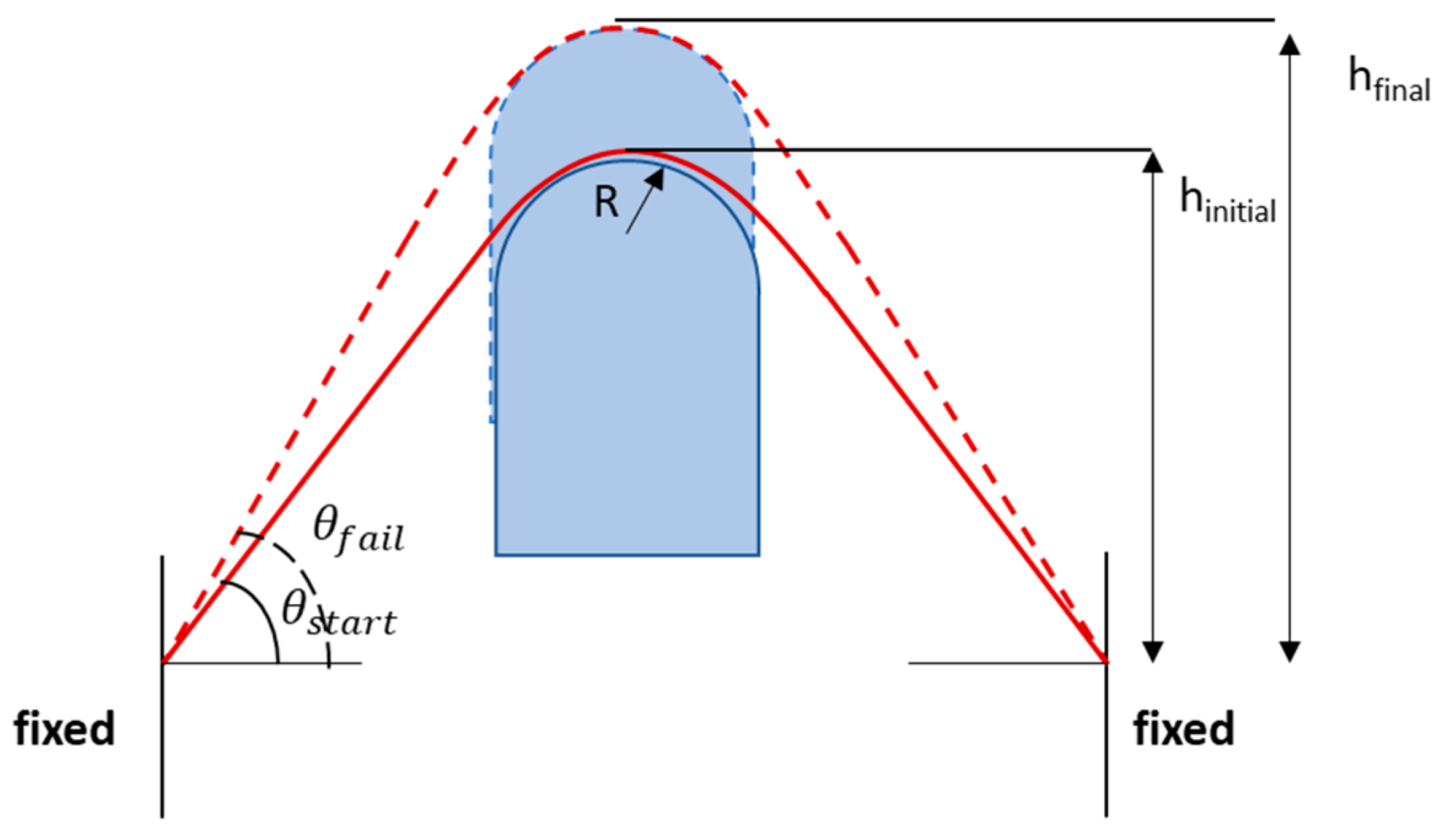

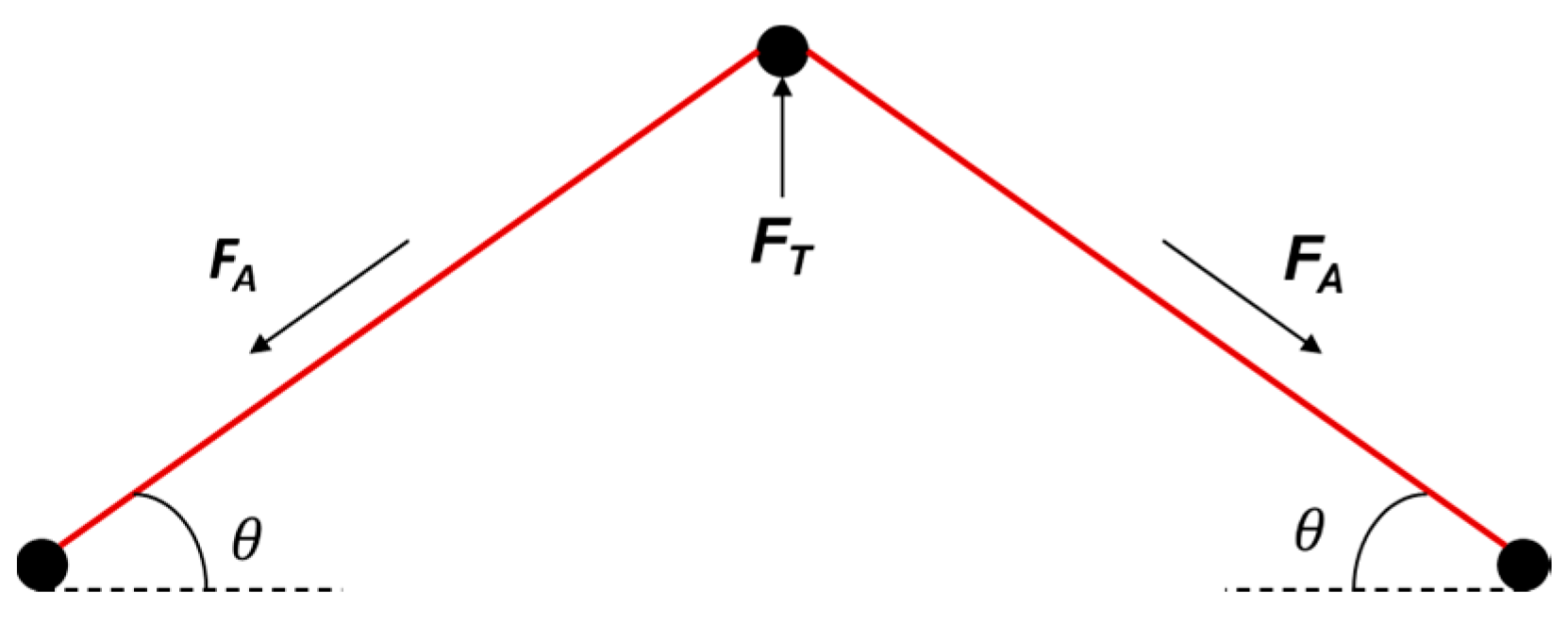

The effect of multi-axial loading on axial tensile properties is investigated by transforming the transverse load and displacement results to axial load and displacements in the fiber direction using the free body diagram shown in

Figure 7. Axial stress,

σ, is calculated as

, where

FA is the axial load given by

,

FT and

are the transverse load and current angle at a given time, respectively, and yarn cross-sectional area is taken as 0.1796 mm

2 (see

Table 1). Similarly, the output cross-head displacement is transformed to axial displacement to determine axial strain,

ε, as

, where

and

is the initial and final length of the yarn after being subjected to a transverse displacement, “u”, respectively.

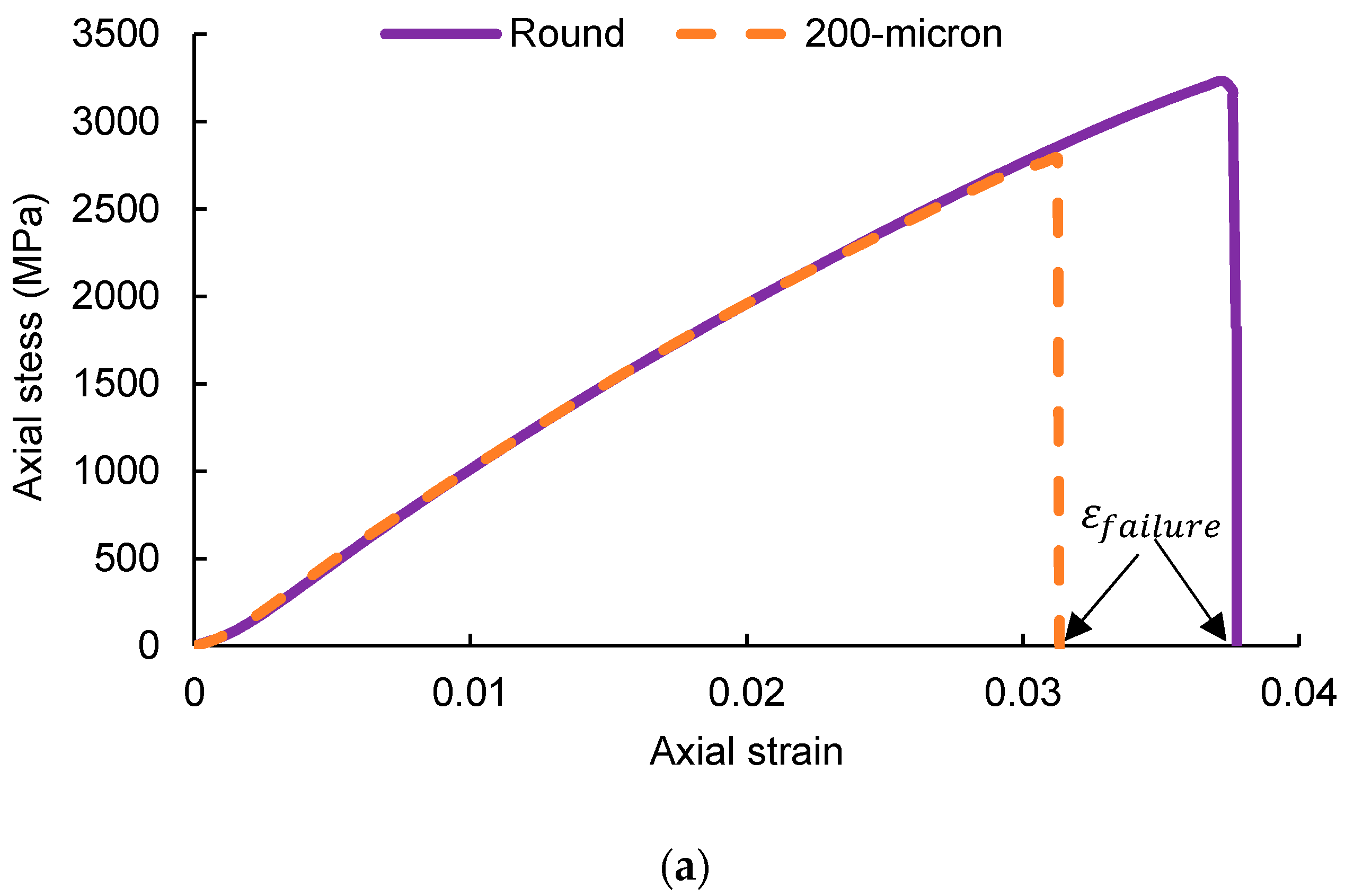

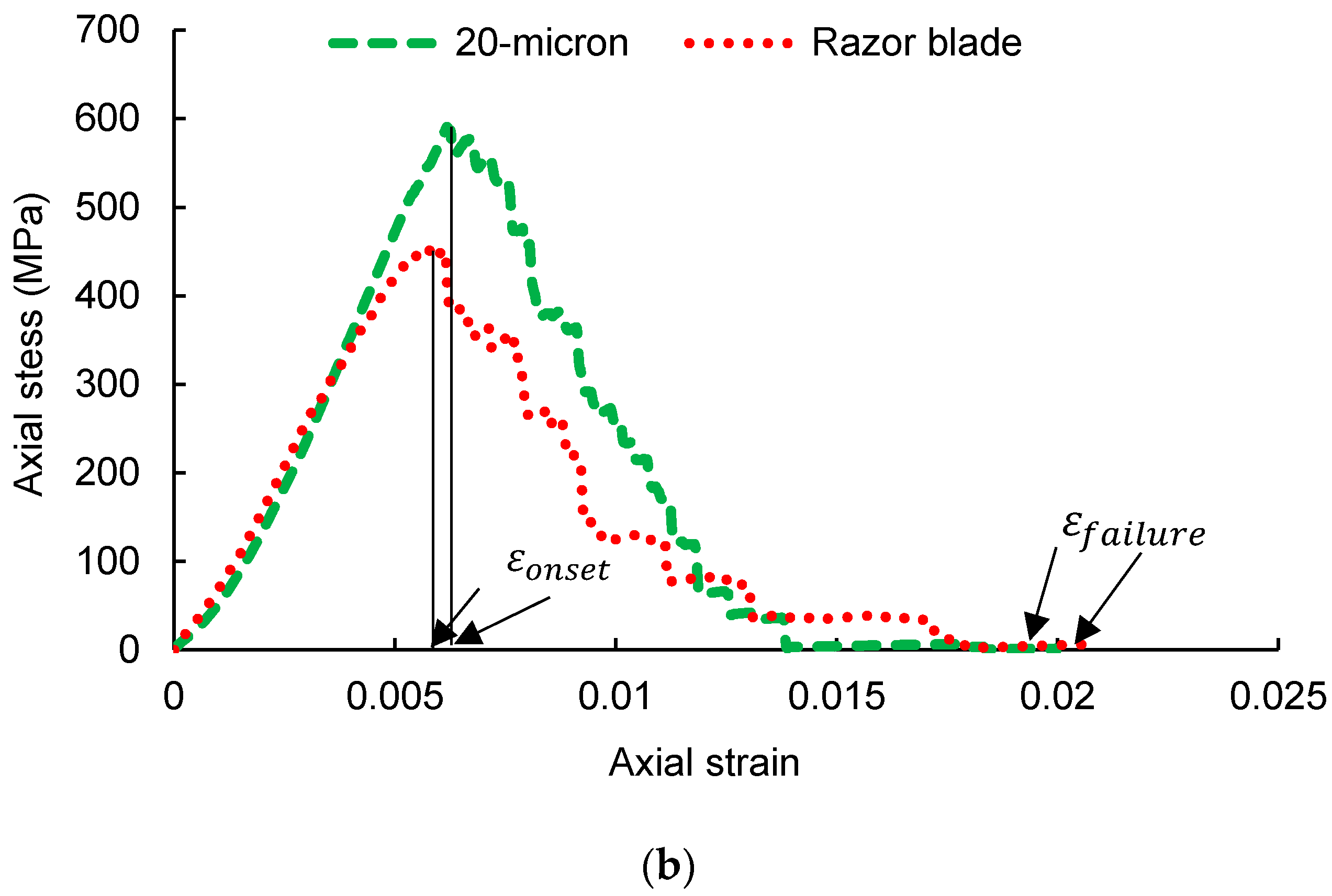

Figure 8 shows a representative axial stress vs. strain response for various indenter geometries at a starting angle of 25°. As observed for transverse loads, the peak axial stress decreases with increasing sharpness of the indenter geometry.

Figure 8 also delineates strains

and

on the stress–strain curves which will be useful for discussion in the later sections.

refers to the strain at complete failure of yarn and

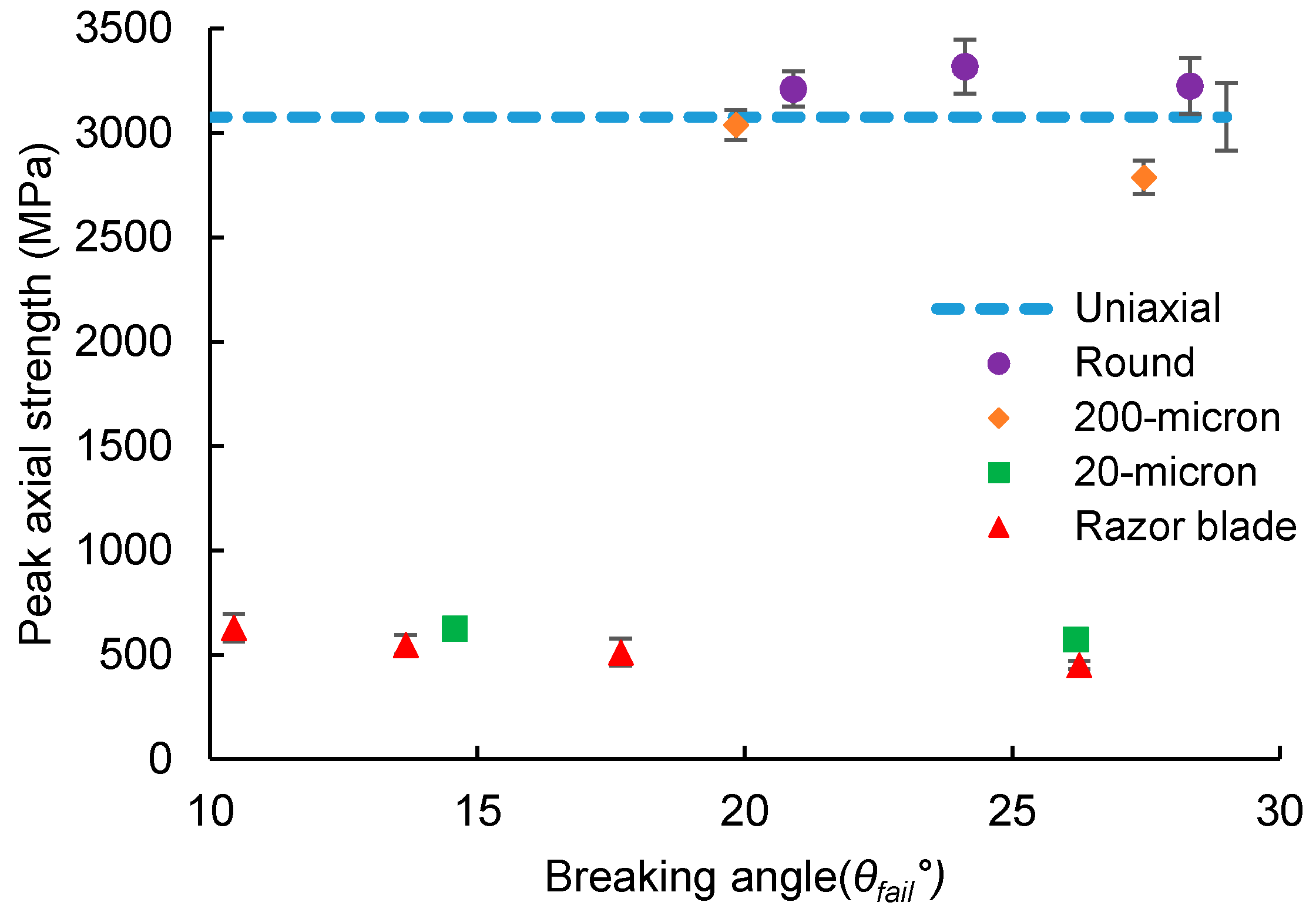

refers to the strain at onset of strength degradation observed in the yarns. The variation in axial strength with breaking angle for the different indenter geometries is shown in

Figure 9. Note that axial strength is calculated at peak load for all indenter geometries. The breaking angle, as described earlier, is the angle at which the yarn fails completely. Due to progressive fiber failure and strength degradation observed for the 20-micron indenter and razor blade, breaking angle for these indenters is determined at a point when the transverse load drops to 1 N.

As seen from

Figure 9, the yarn breaking angle has a negligible effect on axial strength for all indenter geometries. Further, transverse loading via the round projectile leads to no degradation in the axial failure strength compared to the uniaxial tensile strength of SK-76 yarn (3077 MPa). A slight decrease in axial strength is observed for the 200-micron indenter with an increase in the breaking angle, however, it may not be statistically significant. The greatest degradation in axial strength is observed for the 20-micron indenter and razor blade. Axial strength degrades by approximately 80% compared to the yarn uniaxial tensile strength for these geometries. The axial failure strain results for the different geometries are presented in

Figure 10.

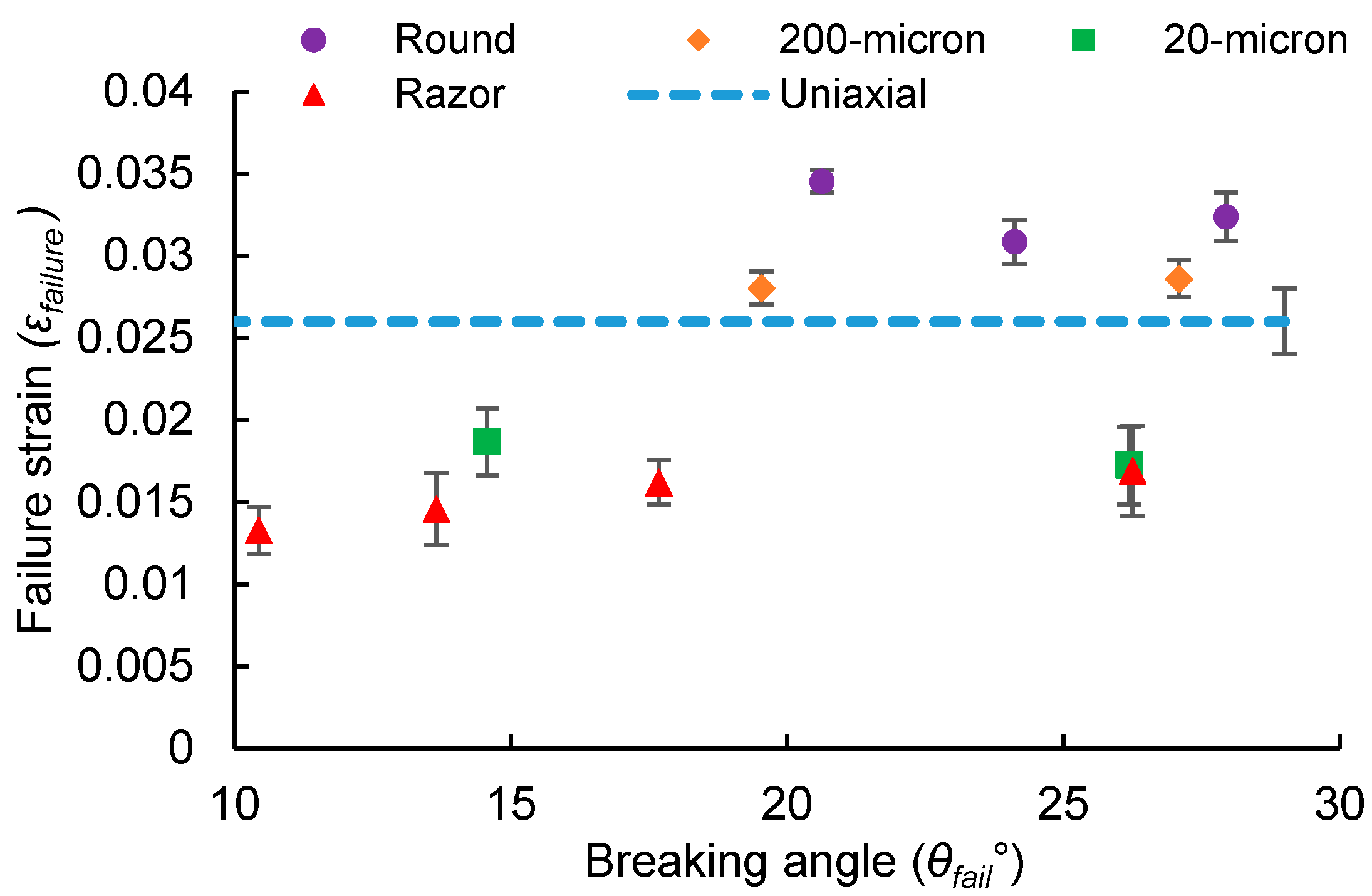

As seen from

Figure 10, yarn breaking angle has a negligible effect on the axial failure strain (

). As found for the axial strength results, transverse loading via the round projectile and the 200-micron indenter cause no degradation in the axial failure strain whereas for the 20-micron indenter and the razor blade, failure strain degrades to approximately ~1.8% and ~1.5% compared to the uniaxial tensile failure strain (compliance corrected) of 2.58%. It is important to note here that the failure strains presented in

Figure 10 for the round projectile and the 200-micron indenter represent compliance corrected strains. A compliance value of 0.0028 mm/N, the same as that found for tensile tests, was applied to correct the strains. It was not possible to correct the failure strains for the 20-micron indenter and the razor blade due to the progressive failure of yarns observed for these indenters. Although corrected for compliance, failure strains for the round projectile and the 200-micron indenter appear slightly higher than the uniaxial failure strain as the transverse experimental system is understood to be more compliant than the uniaxial system. In a transverse loading experiment, the bollard grips are arranged side by side (see

Figure 1) and thus do not contribute towards the total machine stiffness compared to an uniaxial tension system where the grips are arranged vertically and connected to the system crosshead.

The axial strength and failure strain results from

Figure 9 and

Figure 10 indicate that indenter geometry plays a significant role in the strength or strain degradation of yarns compared to yarn breaking angle. The tip radius of the 20-micron indenter and razor blade is on the same order as the average fiber diameter (17 µm) of a SK-76 single fiber. This causes a significant stress or strain concentration in the indenter–fiber contact zone unlike the 200-micron indenter and round projectile whose tip radii are significantly larger than the average fiber diameter and thus act as blunt indenters. This also explains the brittle and tension type of failure observed for the round projectile and the 200-micron indenter. It is worth noting here, that although the average failure strains are approximately ~1.8% and 1.5% for the 20-micron indenter and razor blade, the strength degradation of the yarn begins at much lower strains (

) of approximately 0.6–0.7% for both geometries, as depicted in

Figure 8. It is seen from the experimental video that progressive failure of fibers begins before the onset of strength degradation. This suggests that fibers which are initially in direct contact with the indenter tip begin to fail under transverse shear as the load increases. Whereas fibers away from the yarn–indenter contact region may experience a combined loading of transverse compression, shear and tension. This could lead to fibrillation of the fibers away from the contact region allowing the yarn to carry further load. This is also seen from the fiber failure surfaces presented in

Figure 6, which show that some fibers are cut through completely compared to others which fail in both shear and fibrillation. Therefore, the fibers initially in direct contact with the indenter control the peak load carried by the yarn under transverse shear, thereby characterizing the yarn strength in shear. The strength degradation and progressive final failure of fibers is probably controlled by the layers of the fiber away from the contact region experiencing a combined loading, thereby characterizing the yarn toughness in shear. A finite element model of yarn modeled as bundle of fibers subjected to transverse loading via the 20-micron indenter or the razor is required to establish more detailed insights into the yarn failure process for these indenter geometries.

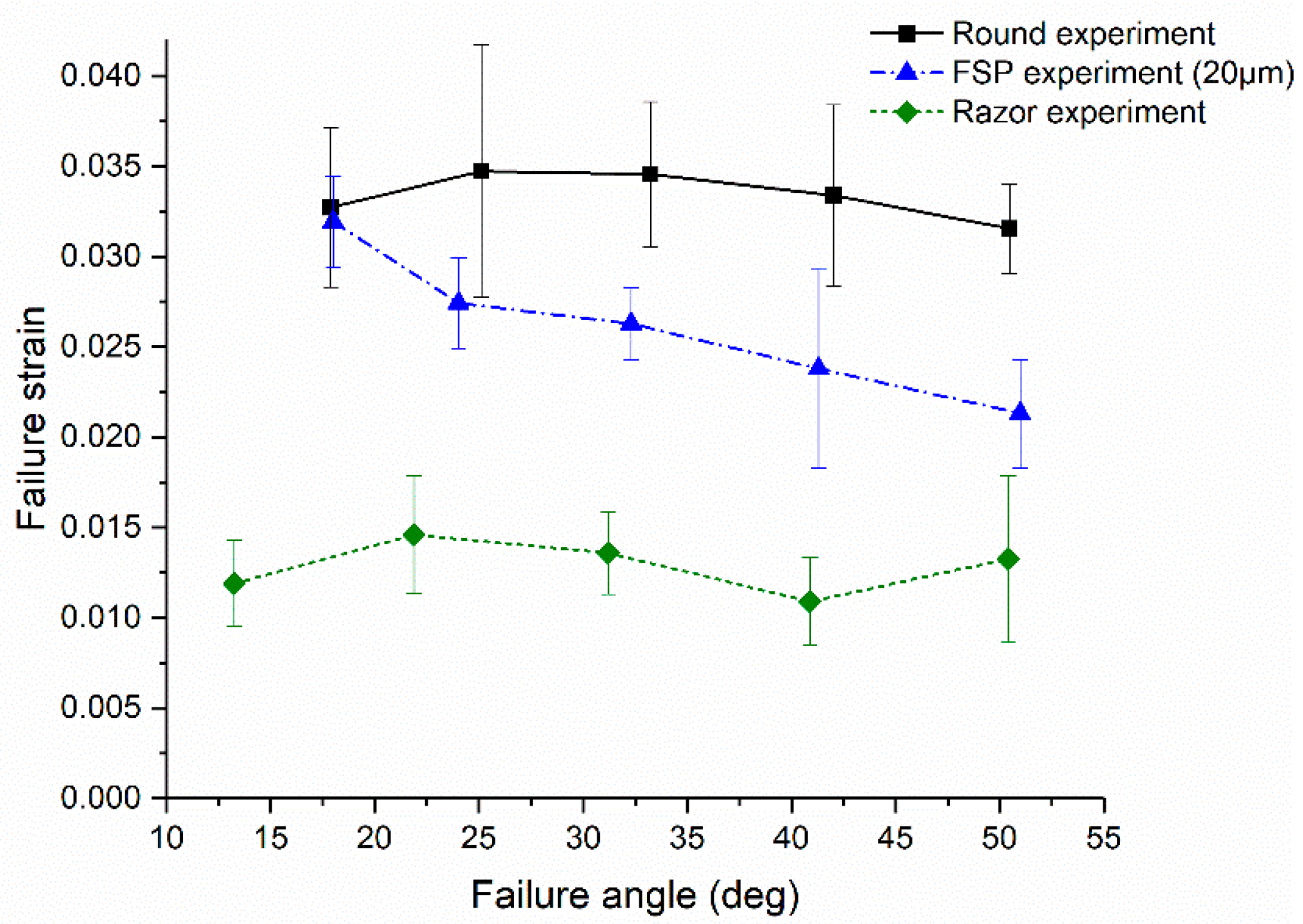

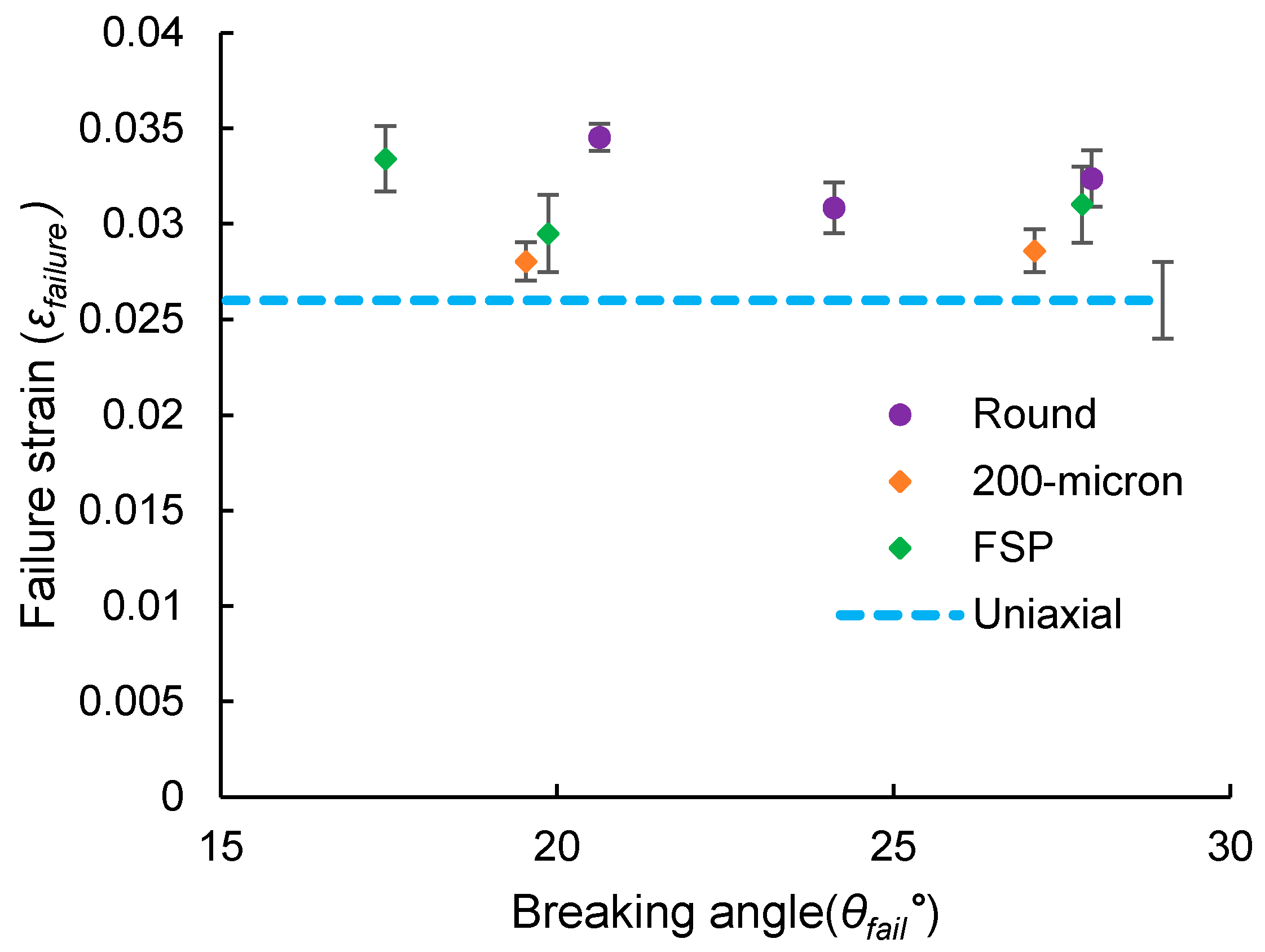

Figure 11 shows the failure strain results from SK-76 single fiber transverse loading experiments conducted by Hudspeth et al. [

13]. The reported failure strains in [

13] were also determined based on the transverse displacement output and geometry of the experimental system. Comparing

Figure 9 and

Figure 10, it is seen that round projectile and razor blade display similar trends with breaking angle for failure strain for both yarn and single fiber, respectively. A major difference in the failure strain response between the yarn and the single fiber is, however, observed for the 20-micron indenter or FSP geometry. As shown in

Figure 11, the FSP geometry used for single fiber experiments [

13], had a corner radius of 20 µm and is comparable with the 20-micron indenter investigated in this study. While progressive degradation in failure strain with an increase in breaking angle is observed for SK-The 76 single fiber breaking angle is seen to have a little effect on yarn failure strain for the 20-micron indenter. Yarn axial strength and strain results (

Figure 9 and

Figure 10) suggest that the tip radii ≥200 µm yarn exhibits a tensile failure, whereas for tip radii ≤ 20 µm the yarn exhibits a more complex failure process involving progressive failure and strength degradation. This may be the reason why a trend in failure strain with breaking angle is not observed for yarns for the 20-micron indenter unlike single fibers. Additional experimental data at a wide range of angles for a range of different tip geometries (20 µm < R < 200 µm) are also required along with finite element (FE) models to get better insights into yarn response under transverse loading.

3.3. Investigating Mark-Tracking Technique to Measure Strains

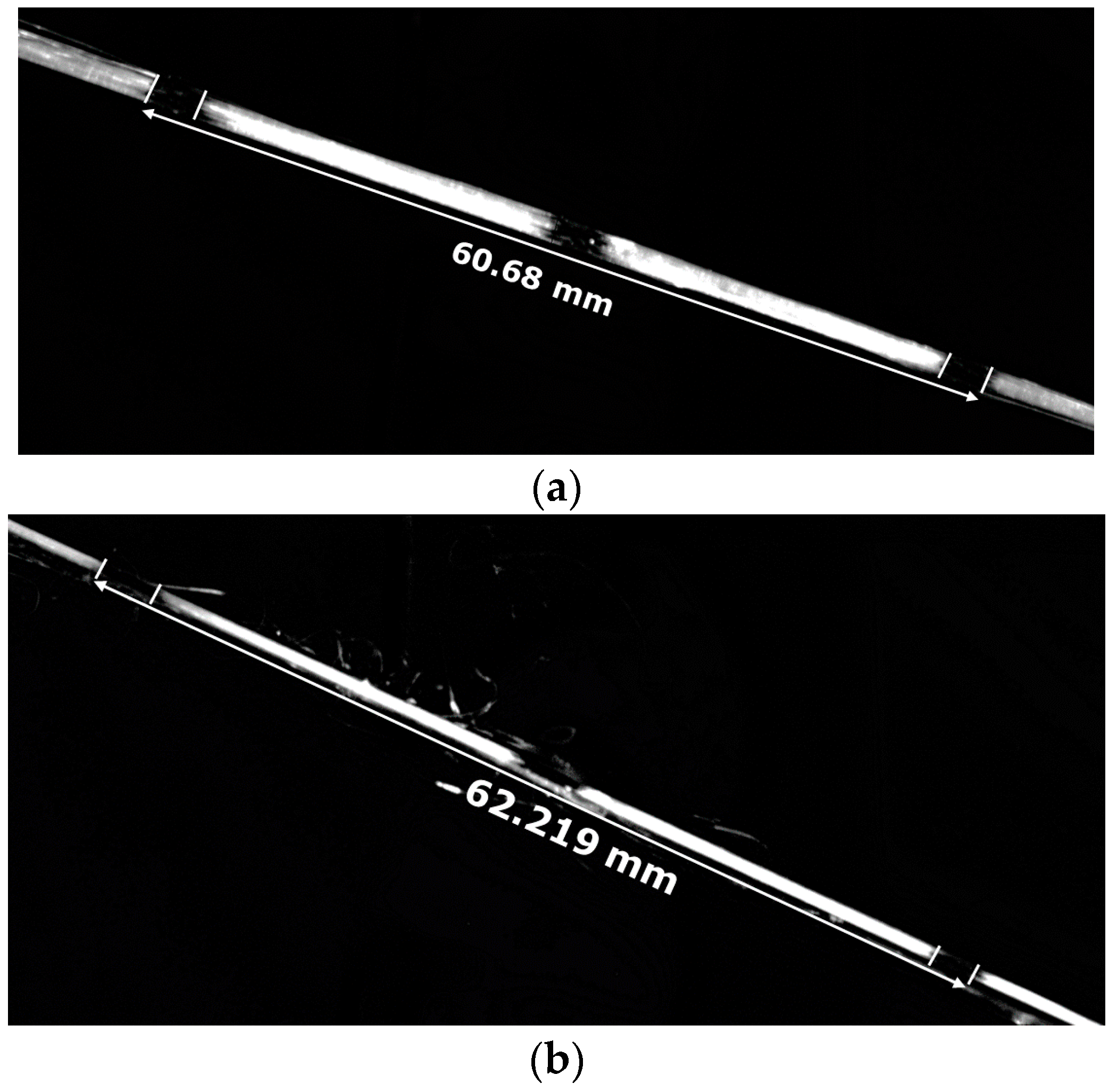

The failure strains presented so far in this work were calculated by transforming the output transverse displacements to axial displacements (displacement in the fiber direction) based on the geometry of the experimental system. However, directly measuring specimen displacement is a more accurate method of determining strains. Recently, Wang et al. [

29] used a mark-tracking technique to measure the tensile strains of spectra 1000 warp and weft yarns at different strain rates. It involved measuring tensile strains by capturing images of marked yarn specimens at regular intervals and then analyzing the captured images using ImageJ software. It offered a way of directly measuring the strains without having to correct for machine compliance.

Therefore, we sought to use the said mark-tracking (MT) technique and adapt it to our transverse loading experiments in order to obtain better estimates of yarn failure strain. Similar as the mark tracking technique described in [

29], three marks were placed on a Dyneema

® SK-76 yarn using a 0.30 mm tip SAKURA micron pen at approximately two inches from each other, as shown in

Figure 15. A Vernier caliper was used to measure the distance between the inside edges of the marks before the experiment for image calibration. A new series of five transverse loading experiments were conducted for the 200-micron indenter and the 20-micron indenter using the marked yarn specimens. A FLIR greyscale 12MP camera was used to capture the images of the yarn during the experiment at every 100 ms. Captured images were analyzed using ImageJ software to determine the displacement of the marks and hence calculate strains.

Figure 15 depicts two images: before the test and near failure for the 200-micron indenter. Since the images were captured at low resolution it was difficult to accurately measure the displacement of each mark. Thus, the strains were calculated based on the displacement of the outer edges of the first and the last mark, as shown in

Figure 15. It must be noted that the mark-tracking technique described here was used only for a preliminary study to investigate its viability for measuring strains during transverse loading. Hence for simplicity, effects of image noise, image distortion and out of plane displacement were not accounted for when calculating strains.

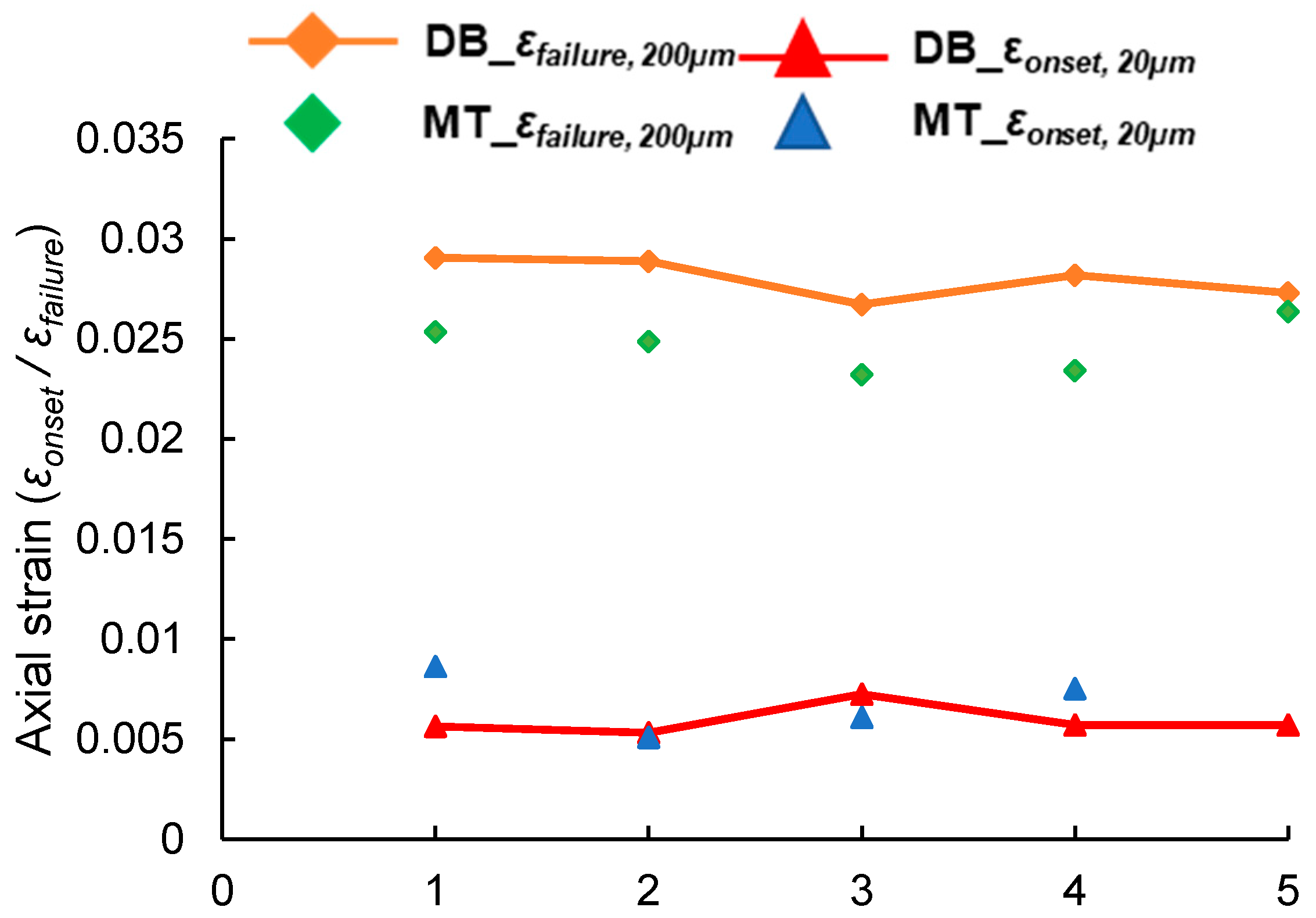

Figure 16 presents a comparison between the axial strains calculated using mark-tracking (MT) method and displacement-based (DB) method for 200-micron and 20-micron indenter at 15° and 25° starting angles, respectively. The mark-tracking and displacement-based method is referred to in the plot as MT and DB for brevity. Since compliance effects are minimized while employing MT technique, it results in more precise strain measurements for the 200-micron indenter compared to the DB technique. Failure strains measured for 200-micron indenter via MT technique are similar to the uniaxial tensile failure strain (2.58%) which is as expected given the tensile failure of yarn under transverse loading by this geometry.

For the 20-micron indenter, the images of the yarn near failure were not suitable for image analysis as the marks faded away with the progressive failure of fibers. Therefore, for the 20-micron indenter, an image close to the onset of strength degradation was analyzed and reported in

Figure 16 alongside onset strains obtained from the (DB) method (see

Figure 8b). As shown in

Figure 16, both the methods give similar strain results for the 20-micron indenter. This may be because the axial displacement of fibers is minimal during loading via the 20-micron indenter as it is found to fail in transverse shear. Besides, calculating the strains for the 20-micron indenter was difficult from images as the fibers seem to rotate during loading, which may be an effect of transverse shear. Thus, a more detailed investigation is required to develop an accurate method to measure strains based on the mark-tracking approach described here. Effects of image noise, image distortion and out of plane displacements due to loading need to be considered in order to obtain better measurements of axial strain.

3.4. Effect of Multi-Axial Stress States on Yarn Breaking Speeds

The axial failure strains determined in this study can be employed in Equation (1) from Smith theory to predict the yarn breaking speeds for different indenter geometries. However, this leads to significant over-prediction of the breaking speeds compared to the experimental breaking speeds [

12,

23], as these strains do not account for the dynamic effects due to impact.

Fiber scale impact models by Sockalingam et al. [

11] have shown that transverse impact onto yarns leads to fiber bounce and complicated wave kinematics in the form of flexural and spreading waves in fibers. This causes a significant increase in the axial strain concentration in the fiber cross-section at the location of failure. They have also shown via single fiber impact models [

30] that the dynamic strain concentration factors are approximately twice that of their static counterparts for Kevlar

® KM2. Besides, for UHMWPE Dyneema

® SK-76 fibers tensile failure strains decrease with increasing strain rates, as reported by Sanborn et al. [

31] and Thomas [

32]. Therefore, the dynamic failure strains for transverse loading are expected to be lower than the quasi-static strains found in this study.

To quantify the effects of dynamic loading on failure strain, quasi-static uniaxial tensile failure strains are compared with transverse dynamic failure strains for round projectile in literature. This is done with keeping in mind that the geometry effects of round projectile on failure strain are negligible and the degradation in failure strain compared to the uniaxial failure strain is due to the dynamic effects on impact. Hudspeth et al. [

12] and Phoenix et al. [

23] in the literature have reported failure strains of 1.37% and 1.3% for SK-76 yarns (1350 dtex and 1760 dtex, respectively) impacted via round and saddle-shaped projectiles compared to the quasi-static uniaxial failure strains of 2.68% and 2.6%, respectively. The saddle-shaped geometry used by Phoenix et al. in [

23] is a modified version of a round projectile to minimize slippage of the yarn from the projectile surface during impact.

Comparing the above-mentioned dynamic strains to the quasi-static uniaxial tensile failure strains gives a ratio of two between quasi-static to dynamic strains. The quasi-static axial failure strains in this study are corrected using this scale factor (

) and are used to predict the yarn breaking speeds, as shown in

Table 2.

Table 2 also shows the breaking speed predictions for the uniaxial failure strain found in this study. When corrected for dynamic effects, the breaking speed results for uniaxial (569 m/s) compare closely with the breaking speed reported for the saddle-shaped projectile (611 m/s) [

23]. This is expected as the saddle-shaped projectile induces negligible stress or strain concentration in the yarn due to its geometry. Results for the round projectile, 0.3 cal. The FSP and razor blade are compared against the experimental breaking speeds reported by Hudspeth et al. [

12] for the respective geometries. It must be noted here though that the 0.30 cal. FSP geometry used in [

12] had a tip radius of 87 µm compared to an FSP with tip radius of 200 µm used in this study. Breaking speeds for the said geometries compare very well with the experimental breaking speed regime as shown in

Table 2. Thus, the results indicate that multi-axial loading and dynamic effects due to are major contributors to the lower breaking speeds observed during transverse impact compared to Smith theory.