Temperature Dependent Strain/Damage Monitoring of Glass/Epoxy Composites with Graphene as a Piezoresistive Interphase

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

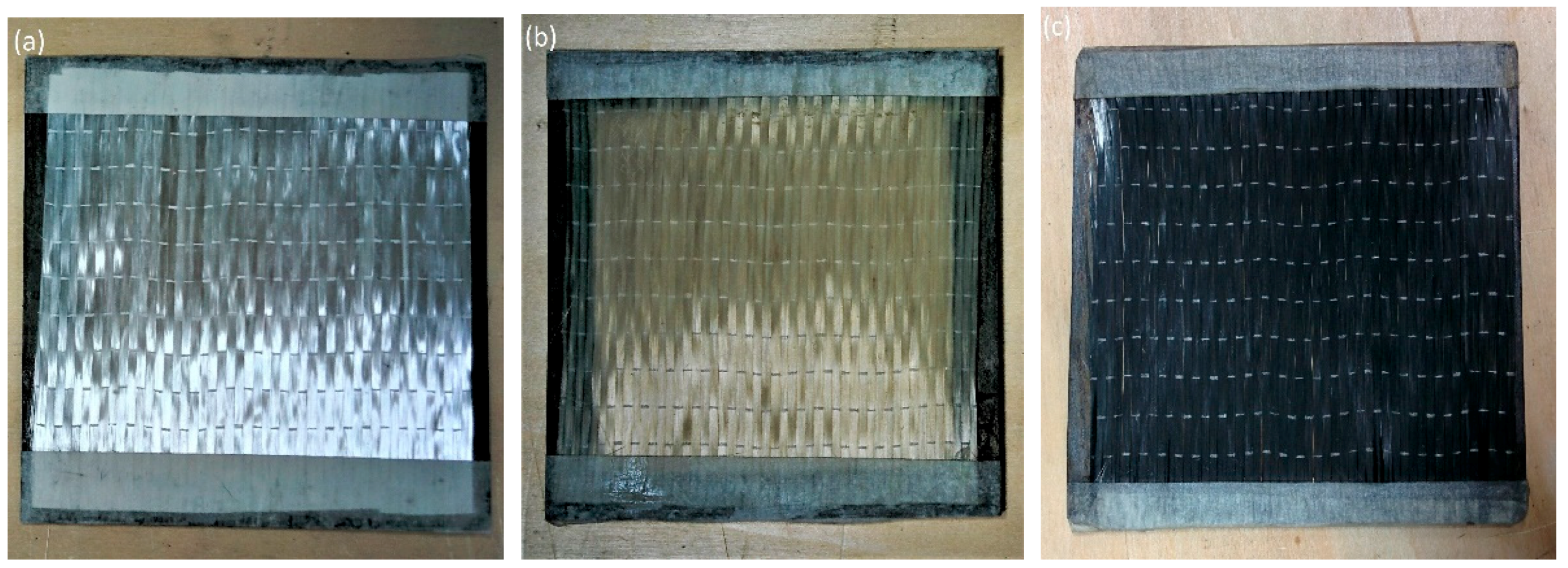

2.2. Samples Preparation

2.3. Experimental Techniques

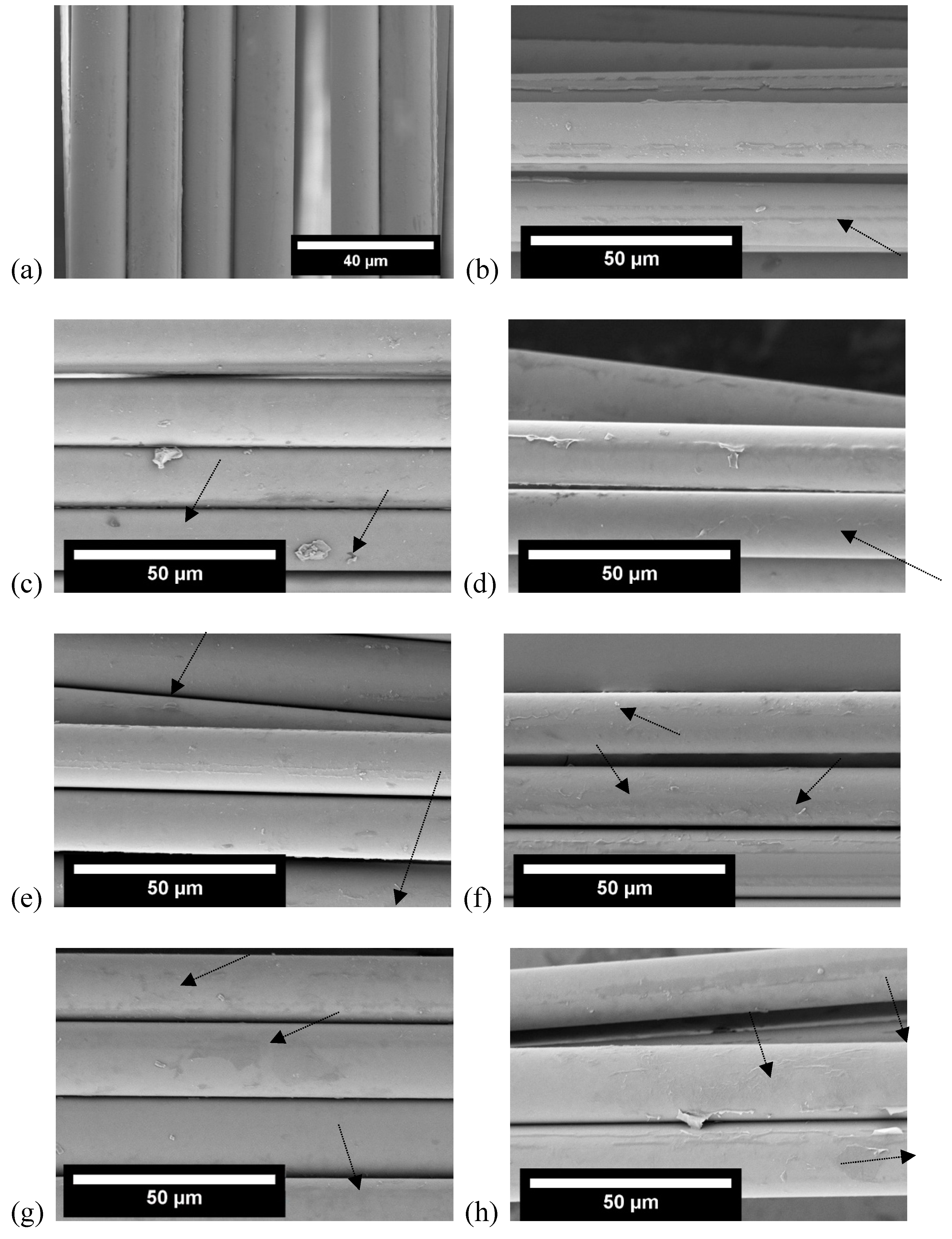

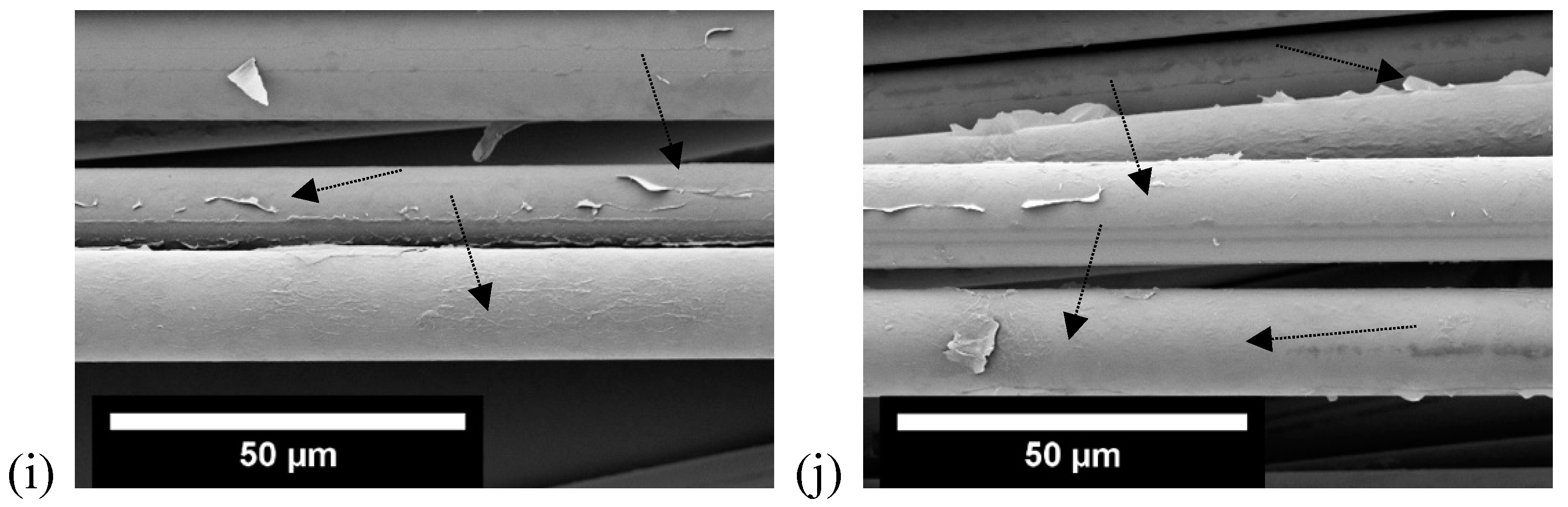

2.3.1. Characterization of the Fibers

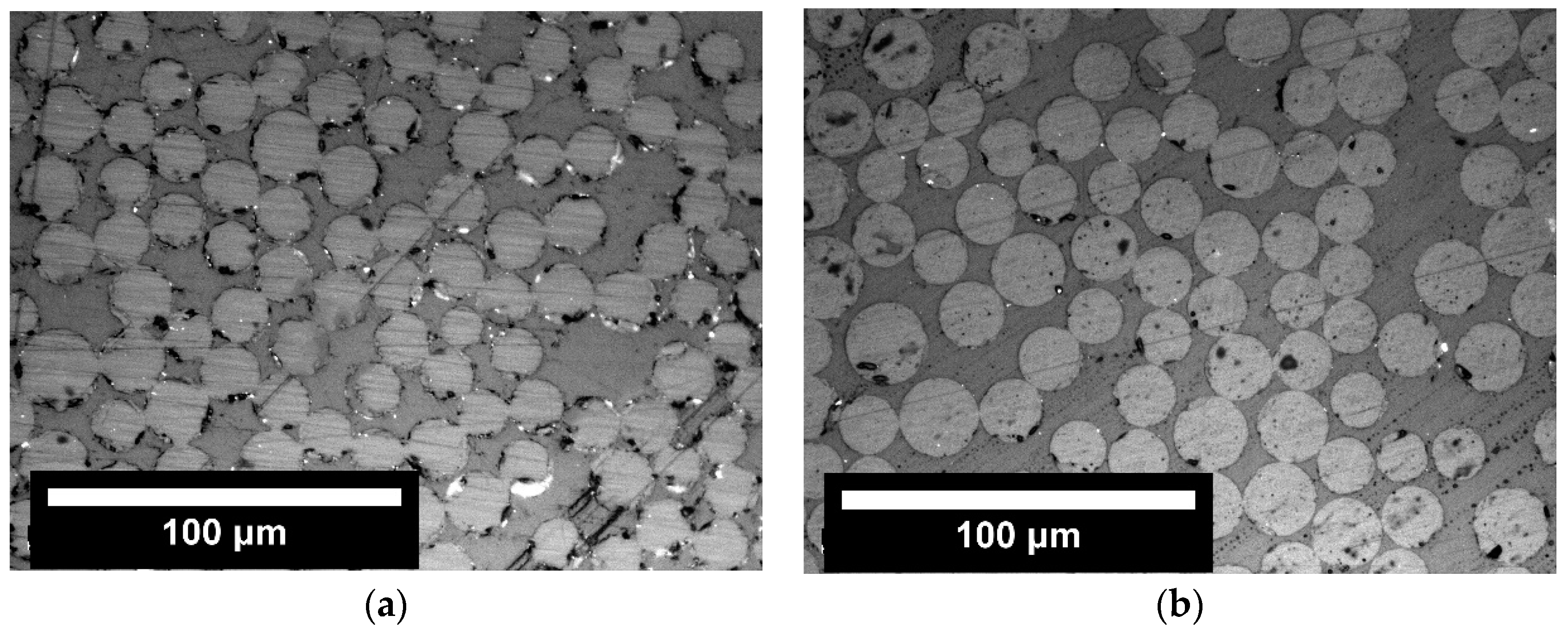

2.3.2. Characterization of the Composites

3. Results and Discussion

3.1. Characterization of the Fibers

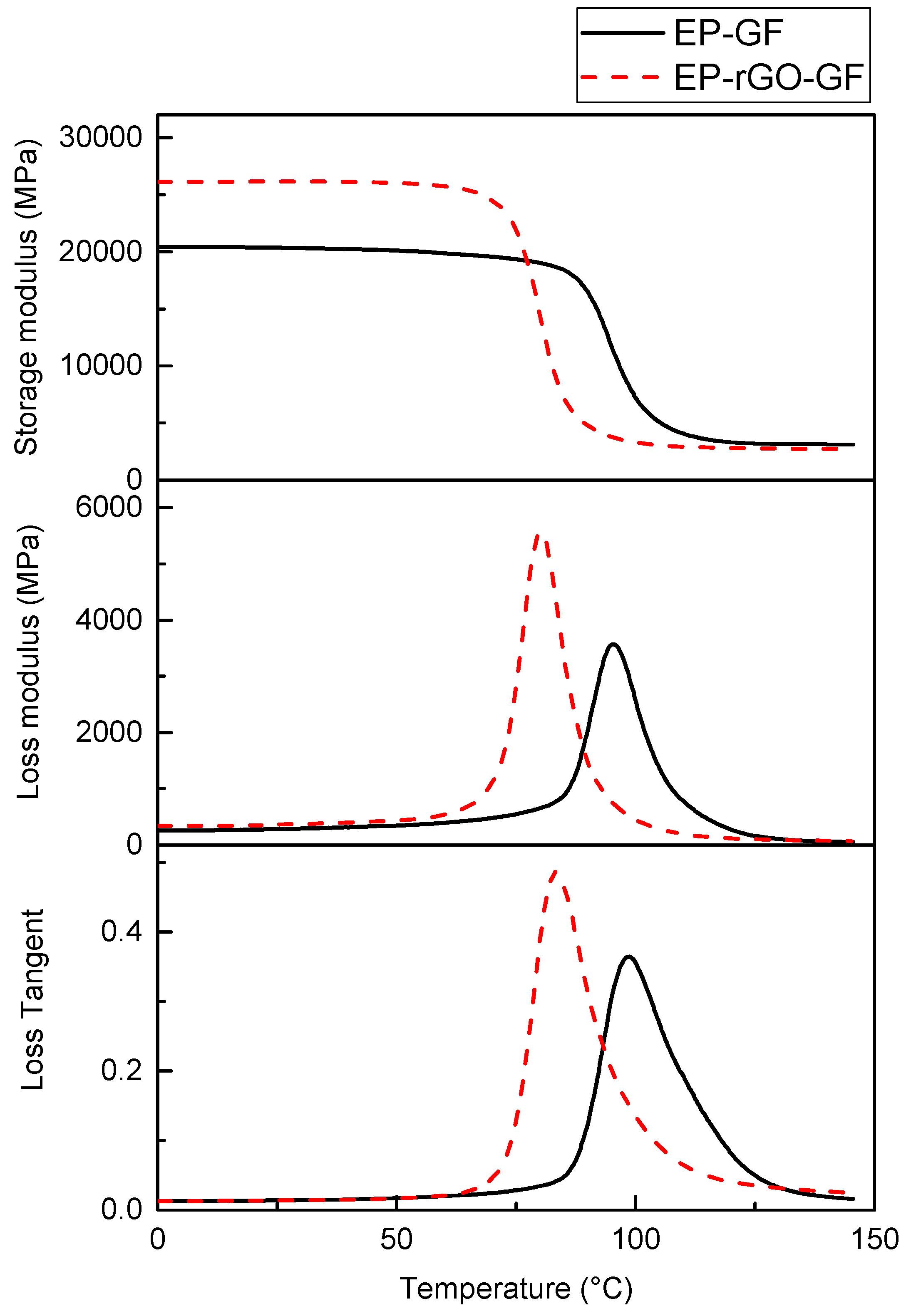

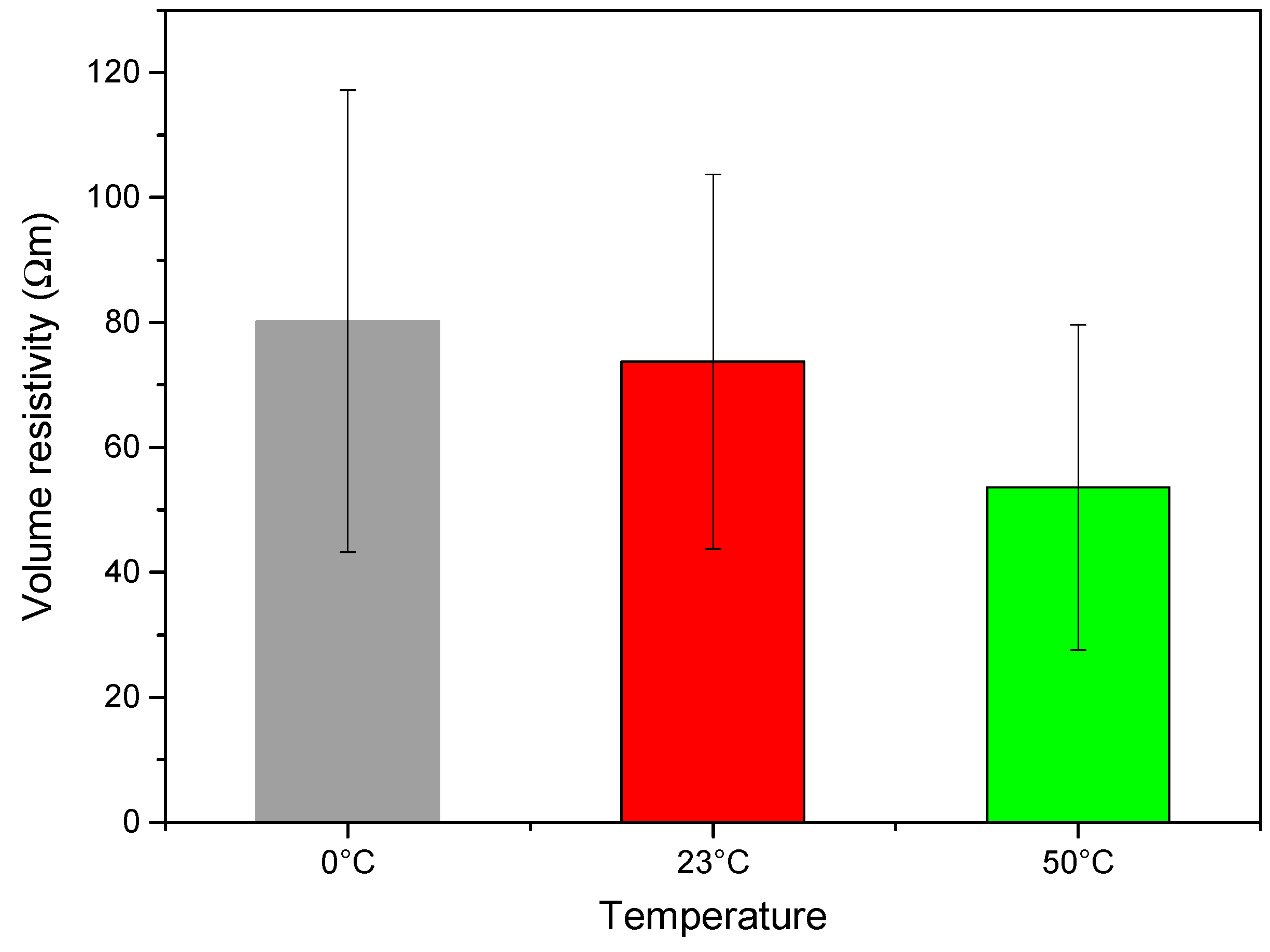

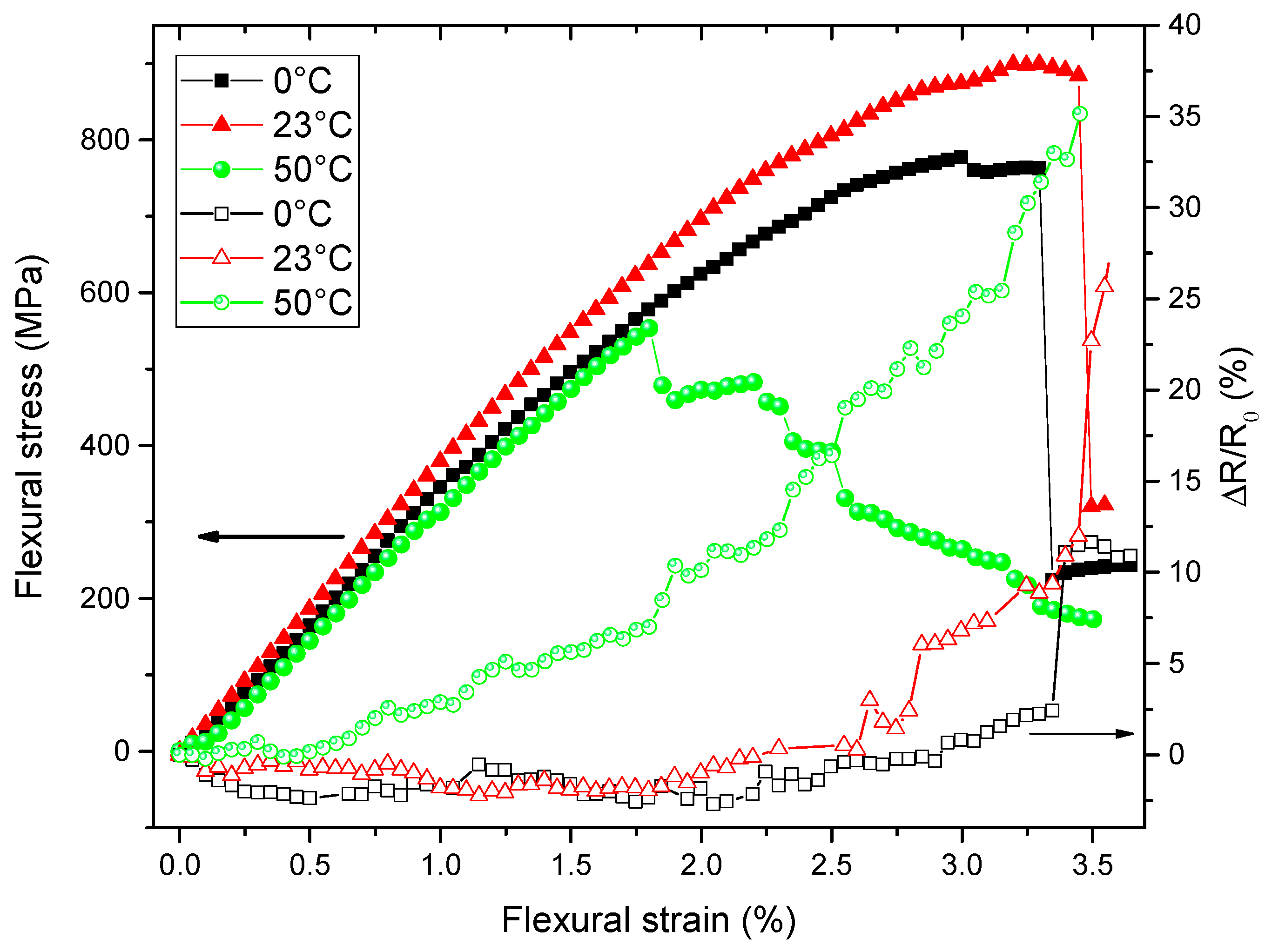

3.2. Characterization of the Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pegoretti, A.; Karger-Kocsis, J. Editorial corner—A personal view Interphase engineering in polymer composites: Challenging the devil. Express Polym. Lett. 2015, 9, 838. [Google Scholar] [CrossRef]

- Jones, F.R. A Review of Interphase Formation and Design in Fibre-Reinforced Composites. J. Adhes. Sci. Technol. 2010, 24, 171–202. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2015, 73, 1–43. [Google Scholar] [CrossRef]

- Dorigato, A.; Brugnara, M.; Pegoretti, A. Novel polyamide 12 based nanocomposites for industrial applications. J. Polym. Res. 2017, 24, 96. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Effects of carbonaceous nanofillers on the mechanical and electrical properties of crosslinked poly(cyclooctene). Polym. Eng. Sci. 2017, 57, 537–543. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.H.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Pegoretti, A.; Dorigato, A.; Biani, A.; Slouf, M. Cyclic olefin copolymer-silica nanocomposites foams. J. Mater. Sci. 2016, 51, 3907–3916. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Dorigato, A.; Conti, T.; Vanzetti, L.; Bersani, M.; Pegoretti, A. Liquid crystalline polymer nanocomposites reinforced with in-situ reduced graphene oxide. Express Polym. Lett. 2015, 9, 709–720. [Google Scholar] [CrossRef]

- Dorigato, A.; Sebastiani, M.; Pegoretti, A.; Fambri, L. Effect of Silica Nanoparticles on the Mechanical Performances of Poly(Lactic Acid). J. Polym. Environ. 2012, 20, 713–725. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kennel, E.; Kim, K.-J. Polymer Nanocomposites Handbook; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Hua, Y.; Li, F.; Liu, Y.; Huang, G.-W.; Xiao, H.-M.; Li, Y.-Q.; Hu, N.; Fu, S.-Y. Positive synergistic effect of graphene oxide/carbon nanotube hybrid coating on glass fiber/epoxy interfacial normal bond strength. Compos. Sci. Technol. 2017, 149, 294–304. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Sun, X.; Sun, H.; Li, H.; Peng, H. Developing polymer composite materials: Carbon nanotubes or graphene? Adv. Mater. 2013, 25, 5153–5176. [Google Scholar] [CrossRef] [PubMed]

- Chizari, K.; Arjmand, M.; Liu, Z.; Sundararaj, U.; Therriault, D. Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications. Mater. Today Commun. 2017, 11, 112–118. [Google Scholar] [CrossRef]

- Cataldi, P.; Ceseracciu, L.; Marras, S.; Athanassiou, A.; Bayer, I.S. Electrical conductivity enhancement in thermoplastic polyurethane-graphene nanoplatelet composites by stretch-release cycles. Appl. Phys. Lett. 2017, 110, 121904. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.H.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Tan, L.; Wang, C.; Zeng, M.; Fu, L. Graphene: An Outstanding Multifunctional Coating for Conventional Materials. Small 2017, 13, 1603337. [Google Scholar] [CrossRef] [PubMed]

- Cataldi, P.; Athanassiou, A.; Bayer, I. Graphene Nanoplatelets-Based Advanced Materials and Recent Progress in Sustainable Applications. Appl. Sci. 2018, 8, 1438. [Google Scholar] [CrossRef]

- Chang, L.; Friedrich, K. Enhancement effect of nanoparticles on the sliding wear of short fiber-reinforced polymer composites: A critical discussion of wear mechanisms. Tribol. Int. 2010, 43, 2355–2364. [Google Scholar] [CrossRef]

- Vlasveld, D.P.N.; Parlevliet, P.P.; Bersee, H.E.N.; Picken, S.J. Fibre-matrix adhesion in glass-fibre reinforced polyamide-6 silicate nanocomposites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1–11. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, D.; Jin, X.; Wang, C.C.; Wang, D.Z.; Ge, H.Y. Modifying glass fibers with graphene oxide: Towards high-performance polymer composites. Compos. Sci. Technol. 2014, 97, 41–45. [Google Scholar] [CrossRef]

- Mahmood, H.; Tripathi, M.; Pugno, N.; Pegoretti, A. Enhancement of interfacial adhesion in glass fiber/epoxy composites by electrophoretic deposition of graphene oxide on glass fibers. Compos. Sci. Technol. 2016, 126, 149–157. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Samad, Y.A.; Liao, K.; Cantwell, W. Graphene coated piezo-resistive fabrics for liquid composite molding process monitoring. Compos. Sci. Technol. 2017, 148, 106–114. [Google Scholar] [CrossRef]

- Moriche, R.; Sánchez, M.; Jiménez-Suárez, A.; Prolongo, S.G.; Ureña, A. Strain monitoring mechanisms of sensors based on the addition of graphene nanoplatelets into an epoxy matrix. Compos. Sci. Technol. 2016, 123, 65–70. [Google Scholar] [CrossRef]

- Mahmood, H.; Vanzetti, L.; Bersani, M.; Pegoretti, A. Mechanical properties and strain monitoring of glass-epoxy composites with graphene-coated fibers. Compos. Part A Appl. Sci. Manuf. 2018, 107, 112–123. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Dorigato, A.; Pegoretti, A. Monitoring the mechanical behaviour of electrically conductive polymer nanocomposites under ramp and creep conditions. J. Nanosci. Nanotechnol. 2012, 12, 4093–4102. [Google Scholar] [CrossRef] [PubMed]

- Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Prolongo, S.G.; Ureña, A. Graphene nanoplatelets coated glass fibre fabrics as strain sensors. Compos. Sci. Technol. 2017, 146, 59–64. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Balasubramaniam, K.; Ramaprabhu, S. Functionalized graphene reinforced thermoplastic nanocomposites as strain sensors in structural health monitoring. J. Mater. Chem. 2011, 21, 12626–12628. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Dorigato, A.; Pegoretti, A. Monitoring the mechanical behavior under ramp and creep conditions of electrically conductive polymer composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1285–1292. [Google Scholar] [CrossRef]

- Wang, X.; Liu, H.; Fang, P.; Liao, L.; Pan, C.; Liew, K.M. Interface enhancement of glass fiber/vinyl ester composites with carbon nanotubes synthesized from ethanol flames. J. Nanosci. Nanotechnol. 2010, 10, 948–955. [Google Scholar] [CrossRef]

- Zhang, J.E.; Zhuang, R.C.; Liu, J.W.; Mader, E.; Heinrich, G.; Gao, S.L. Functional interphases with multi-walled carbon nanotubes in glass fibre/epoxy composites. Carbon 2010, 48, 2273–2281. [Google Scholar] [CrossRef]

- Lv, P.; Feng, Y.Y.; Zhang, P.; Chen, H.M.; Zhao, N.Q.; Feng, W. Increasing the interfacial strength in carbon fiber/epoxy composites by controlling the orientation and length of carbon nanotubes grown on the fibers. Carbon 2011, 49, 4665–4673. [Google Scholar] [CrossRef]

- Tzounis, L.; Kirsten, M.; Simon, F.; Mader, E.; Stamm, M. The interphase microstructure and electrical properties of glass fibers covalently and non-covalently bonded with multiwall carbon nanotubes. Carbon 2014, 73, 310–324. [Google Scholar] [CrossRef]

- Böger, L.; Wichmann, M.H.G.; Meyer, L.O.; Schulte, K. Load and health monitoring in glass fibre reinforced composites with an electrically conductive nanocomposite epoxy matrix. Compos. Sci. Technol. 2008, 68, 1886–1894. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T.W. Sensing of damage mechanisms in fiber-reinforced composites under cyclic loading using carbon nanotubes. Adv. Funct. Mater. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A.; Bondioli, F.; Messori, M. Improving Epoxy Adhesives with Zirconia Nanoparticles. Compos. Interface 2010, 17, 873–892. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. The role of alumina nanoparticles in epoxy adhesives. J. Nanopart. Res. 2011, 13, 2429–2441. [Google Scholar] [CrossRef]

- Shen, J.F.; Huang, W.S.; Wu, L.P.; Hu, Y.Z.; Ye, M.X. The reinforcement role of different amino-functionalized multi-walled carbon nanotubes in epoxy nanocomposites. Compos. Sci. Technol. 2007, 67, 3041–3050. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Li, W.Z.; Wang, D.Z.; Ren, Z.F.; Chou, T.W. Carbon nanotube/carbon fiber hybrid multiscale composites. J. Appl. Phys. 2002, 91, 6034–6037. [Google Scholar] [CrossRef]

- Mei, L.; He, X.D.; Li, Y.B.; Wang, R.G.; Wang, C.; Peng, Q.Y. Grafting carbon nanotubes onto carbon fiber by use of dendrimers. Mater. Lett. 2010, 64, 2505–2508. [Google Scholar] [CrossRef]

- Bekyarova, E.; Thostenson, E.T.; Yu, A.; Kim, H.; Gao, J.; Tang, J.; Hahn, H.T.; Chou, T.W.; Itkis, M.E.; Haddon, R.C. Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites. Langmuir 2007, 23, 3970–3974. [Google Scholar] [CrossRef]

- Besra, L.; Liu, M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater. Sci. 2007, 52, 1–61. [Google Scholar] [CrossRef]

- Thomas, B.; Boccaccini, A.; Shaffer, M. Multi-Walled Carbon Nanotube Coatings Using Electrophoretic Deposition (EPD). J. Am. Ceram. Soc. 2005, 88, 980–982. [Google Scholar] [CrossRef]

- Cho, J.; Konopka, K.; Rozniatowski, K.; Garcia-Lecina, E.; Shaffer, M.S.P.; Boccaccini, A.R. Characterisation of carbon nanotube films deposited by electrophoretic deposition. Carbon 2009, 47, 58–67. [Google Scholar] [CrossRef]

- Mahmood, H.; Unterberger, S.; Pegoretti, A. Tuning electrical and thermal properties in epoxy/ glass composites by graphene-based interphase. J. Compos. Sci. 2017, 1, 12. [Google Scholar] [CrossRef]

- Wang, X.; Yang, H.Y.; Song, L.; Hu, Y.; Xing, W.Y.; Lu, H.D. Morphology, mechanical and thermal properties of graphene-reinforced poly(butylene succinate) nanocomposites. Compos. Sci. Technol. 2011, 72, 1–6. [Google Scholar] [CrossRef]

- Pissis, P. Thermoset Nanocomposites for Engineering Applications; iSmithers Rapra Publishing: Shawbury, UK, 2007. [Google Scholar]

- Wei, J.; Vo, T.; Inam, F. Epoxy/graphene nanocomposites—Processing and properties: A review. RSC Adv. 2015, 5, 73510–73524. [Google Scholar] [CrossRef]

- Tripathi, M.; Mahmood, H.; Novel, D.; Iacob, E.; Vanzetti, L.; Bartali, R.; Speranza, G.; Pegoretti, A.; Pugno, N. Nanoscale friction of graphene oxide over glass-fibre and polystyrene. Compos. Part B 2018, 148, 272–280. [Google Scholar] [CrossRef]

- Traina, M.; Pegoretti, A.; Penati, A. Time-temperature dependence of the electrical resistivity of high density polyethylene—Carbon black composites. J. Appl. Polym. Sci. 2007, 106, 2065–2074. [Google Scholar] [CrossRef]

- Shao, Q.; Liu, G.; Teweldebrhan, D.; Balandin, A.A. High-temperature quenching of electrical resistance in graphene interconnects. Appl. Phys. Lett. 2008, 92, 202108. [Google Scholar] [CrossRef]

- Das, N.C.; Chaki, T.K.; Khastgir, D. Effect of processing parameters, applied pressure and temperature on the electrical resistivity of rubber-based conductive composites. Carbon 2002, 40, 807–816. [Google Scholar] [CrossRef]

- Hao, B.; Ma, Q.; Yang, S.D.; Mader, E.; Ma, P.C. Comparative study on monitoring structural damage in fiber-reinforced polymers using glass fibers with carbon nanotubes and graphene coating. Compos. Sci. Technol. 2016, 129, 38–45. [Google Scholar] [CrossRef]

| Code. | GO Concentration in Water (wt%) | Applied Electric Field (V/cm) |

|---|---|---|

| 0A | 0.005 | 0.5 |

| 0B | 0.005 | 1.0 |

| 0C | 0.005 | 1.5 |

| 1A | 0.01 | 0.5 |

| 1B | 0.01 | 1.0 |

| 1C | 0.01 | 1.5 |

| 2A | 0.02 | 0.5 |

| 2B | 0.02 | 1.0 |

| 2C | 0.02 | 1.5 |

| Sample | Resistivity (Ω·m) |

|---|---|

| Uncoated GF | 1.5 × 1014 |

| 0A | 6449 ± 241 |

| 0B | 5439 ± 368 |

| 0C | 2073 ± 562 |

| 1A | 1154 ± 146 |

| 1B | 887 ± 203 |

| 1C | 222 ± 54 |

| 2A | 41 ± 7 |

| 2B | 51 ± 18 |

| 2C | 52 ± 14 |

| Sample | Fiber Fraction (vol%) | Theoretical Density ρt (g/cm3) | Experimental Density ρe (g/cm3) | Void Content (vol%) |

|---|---|---|---|---|

| EP | - | 1.1470 | 1.1470 ± 0.0014 | - |

| EP-GF | 65.0 | 2.1056 | 1.9960 ± 0.0068 | 5.20 ± 0.32 |

| EP-rGO-GF | 65.3 | 2.1095 | 2.0363 ± 0.0404 | 3.47 ± 1.91 |

| Parameter | EP | EP-GF | EP-rGO-GF |

|---|---|---|---|

| T5% | 306.6 | 332.5 | 346.5 |

| Tonset | 335.1 | 347.0 | 332.1 |

| Td | 346.7 | 375.7 | 367.3 |

| rm | 7.35 | 77.4 | 81.6 |

| Sample | Flexural Modulus (MPa) | Flexural Strength (MPa) | Flexural Strain at Break (%) | ILSS (MPa) |

|---|---|---|---|---|

| EP-GF | 38.2 ± 0.7 | 687 ± 55 | 2.1 ± 0.2 | 44 ± 5 |

| EP-rGO-GF | 38.6 ± 0.8 | 888 ± 22 | 3.0 ± 0.1 | 57 ± 13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, H.; Dorigato, A.; Pegoretti, A. Temperature Dependent Strain/Damage Monitoring of Glass/Epoxy Composites with Graphene as a Piezoresistive Interphase. Fibers 2019, 7, 17. https://doi.org/10.3390/fib7020017

Mahmood H, Dorigato A, Pegoretti A. Temperature Dependent Strain/Damage Monitoring of Glass/Epoxy Composites with Graphene as a Piezoresistive Interphase. Fibers. 2019; 7(2):17. https://doi.org/10.3390/fib7020017

Chicago/Turabian StyleMahmood, Haroon, Andrea Dorigato, and Alessandro Pegoretti. 2019. "Temperature Dependent Strain/Damage Monitoring of Glass/Epoxy Composites with Graphene as a Piezoresistive Interphase" Fibers 7, no. 2: 17. https://doi.org/10.3390/fib7020017

APA StyleMahmood, H., Dorigato, A., & Pegoretti, A. (2019). Temperature Dependent Strain/Damage Monitoring of Glass/Epoxy Composites with Graphene as a Piezoresistive Interphase. Fibers, 7(2), 17. https://doi.org/10.3390/fib7020017