Investigation of Chemical and Physical Surface Changes of Thermally Conditioned Glass Fibres

Abstract

1. Introduction

2. Materials and Methods

3. Results

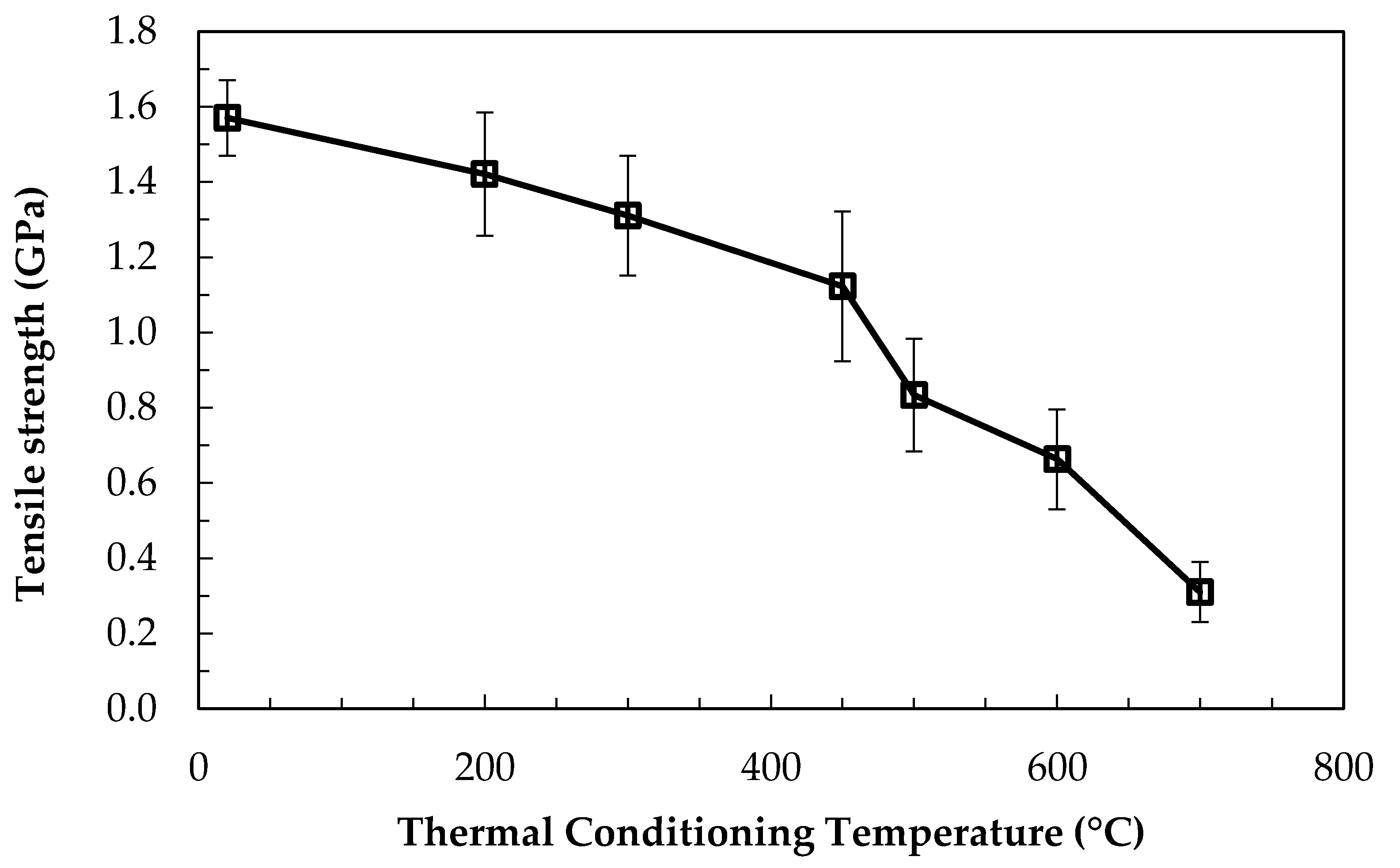

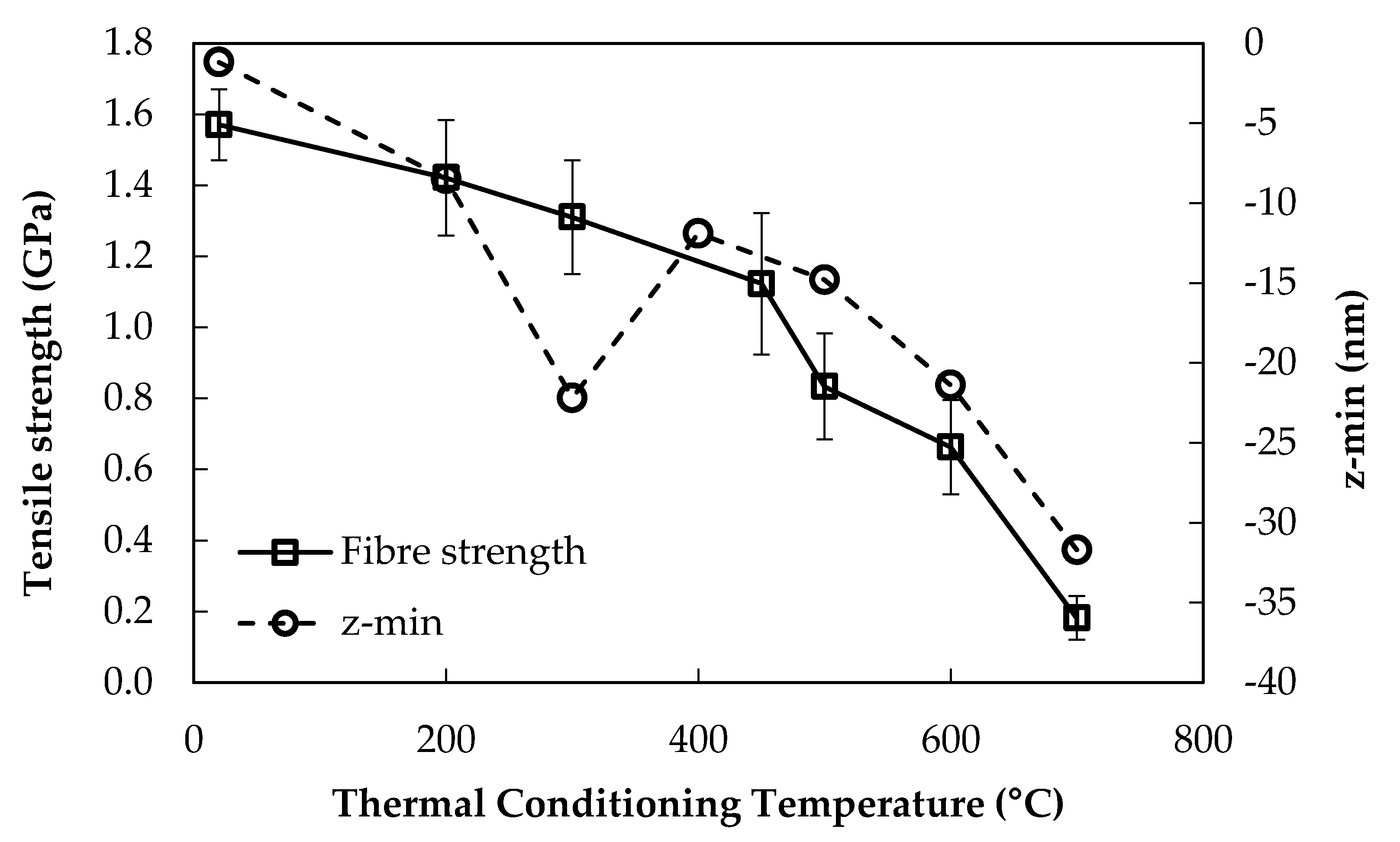

3.1. Tensile Strength of Heat-Treated Fibres

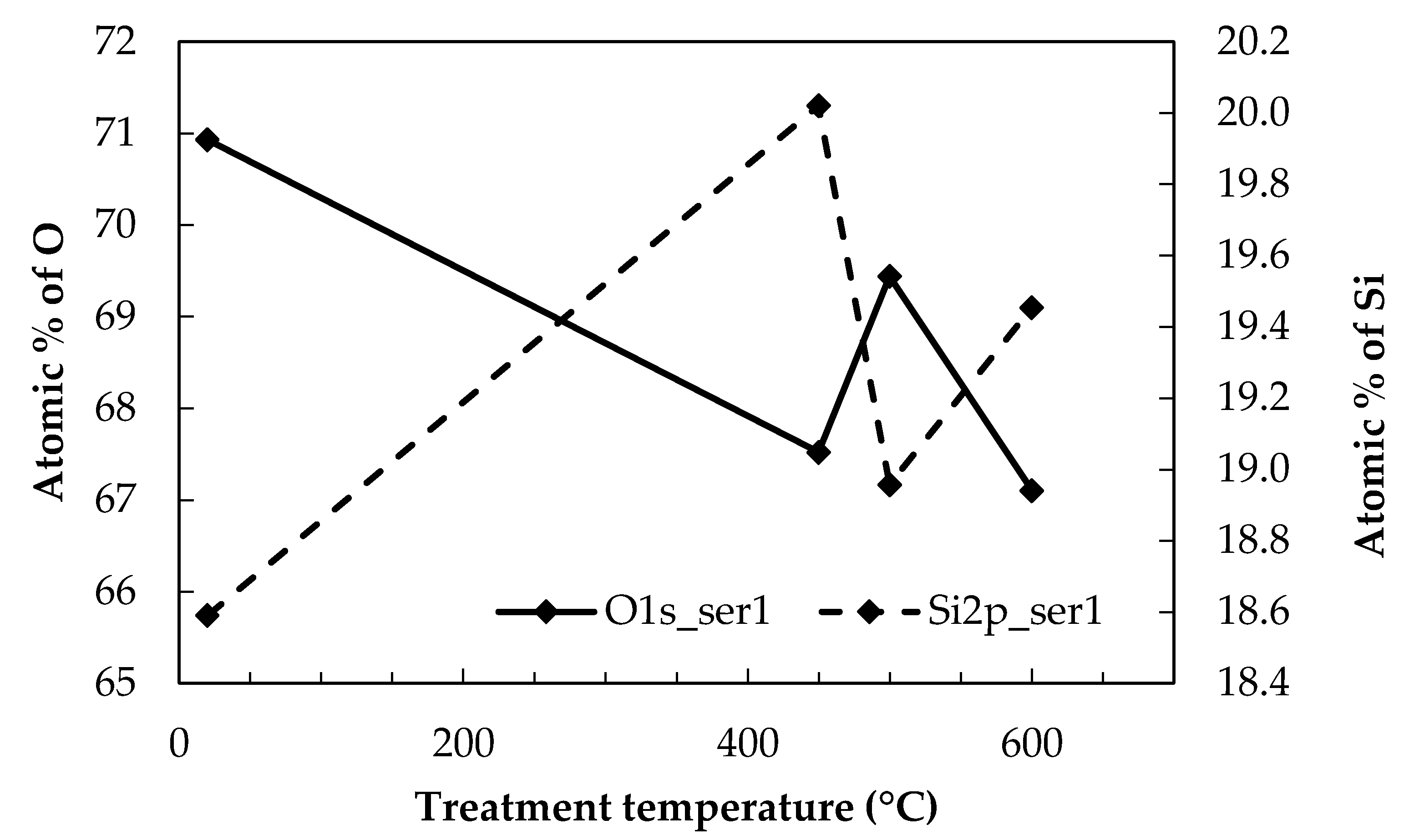

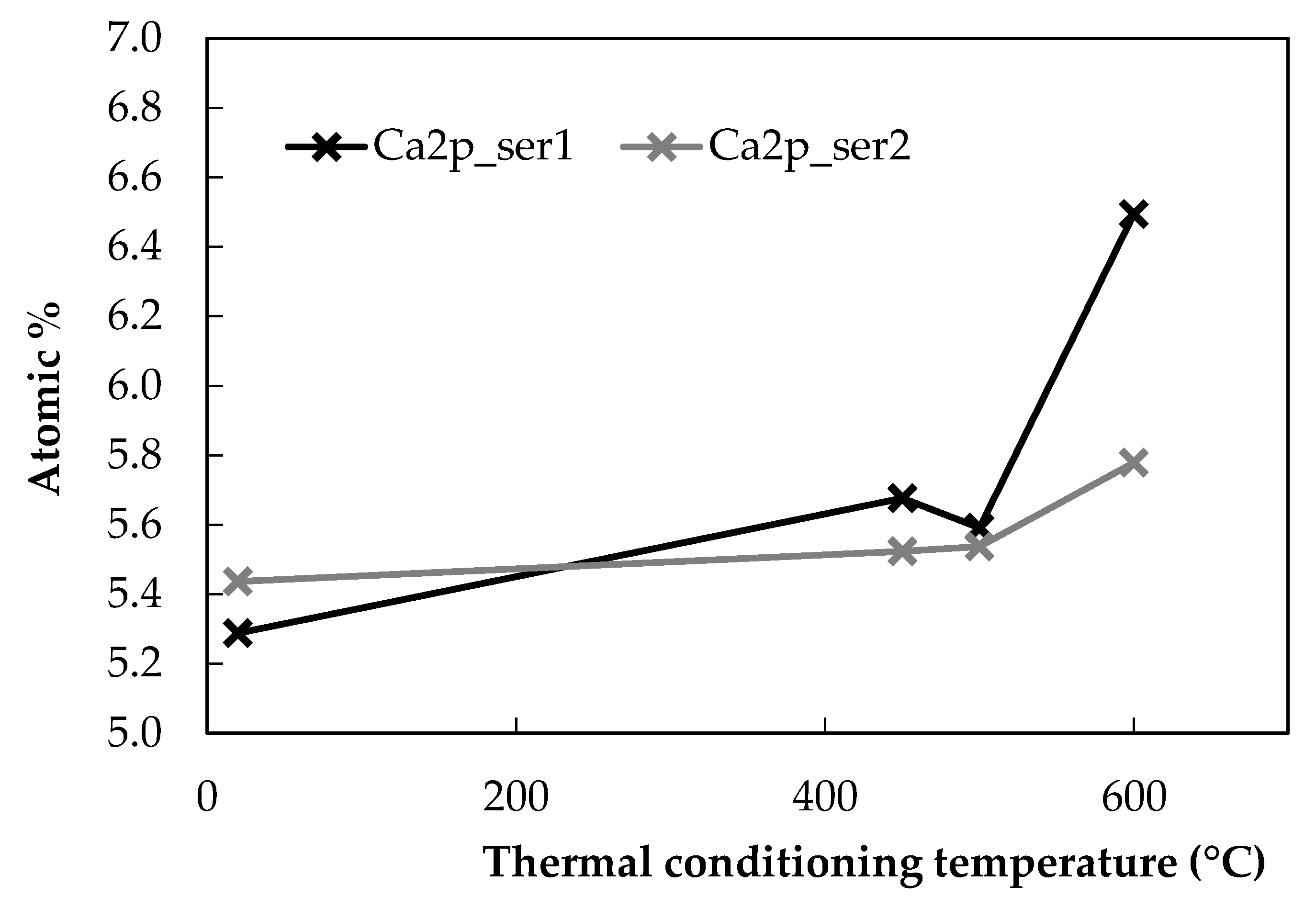

3.2. X-Ray Photoelectron Spectroscopy

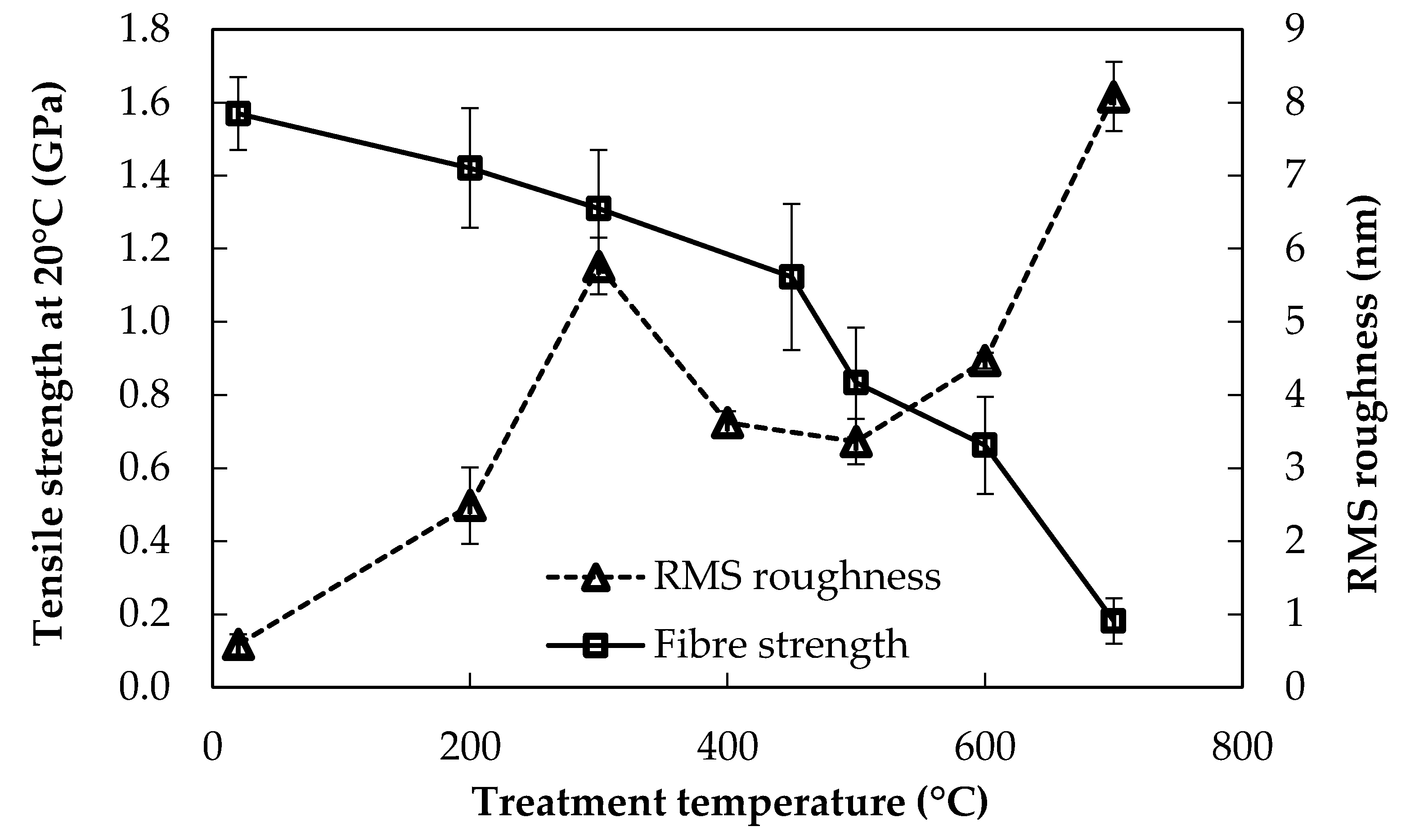

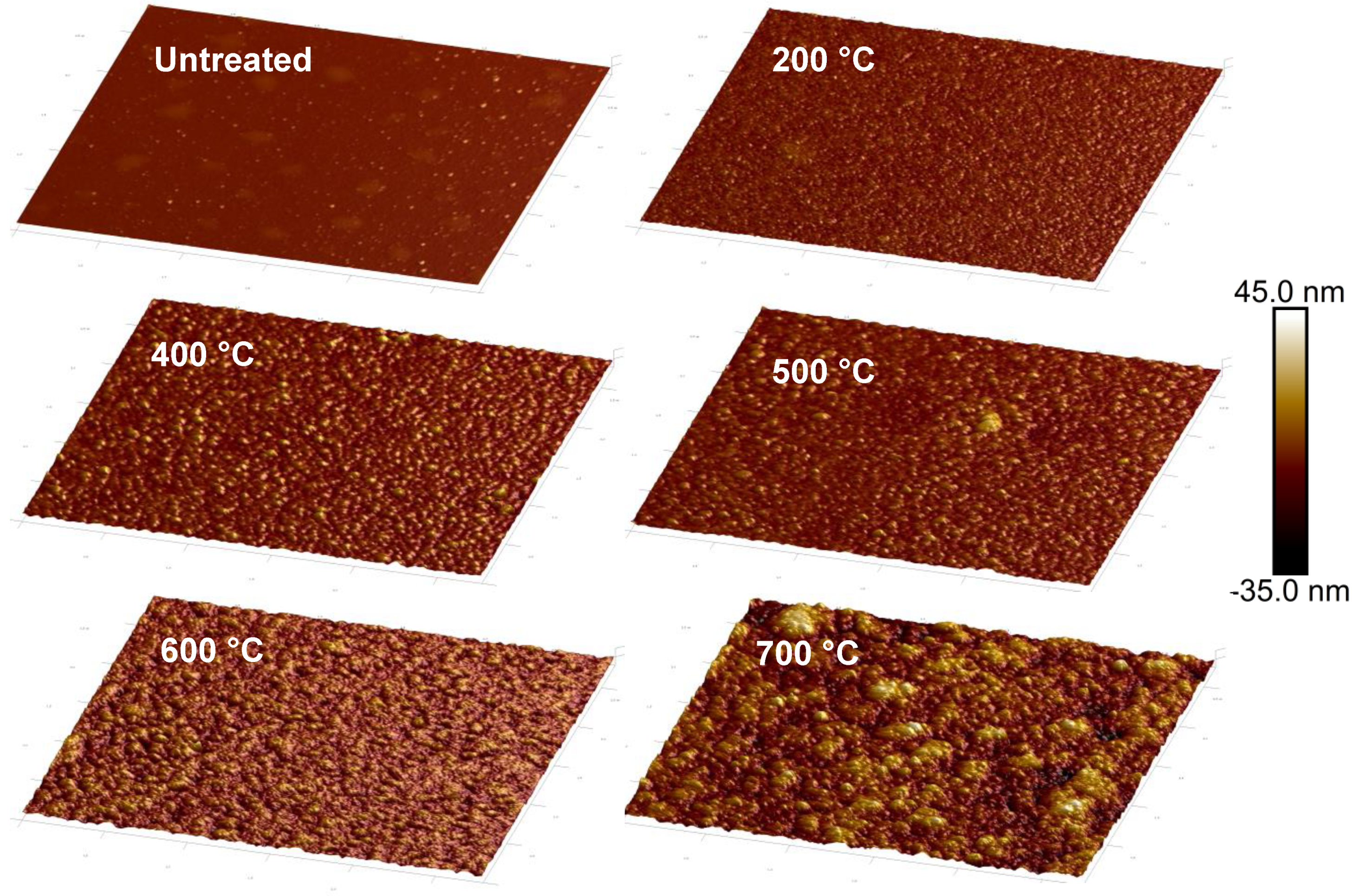

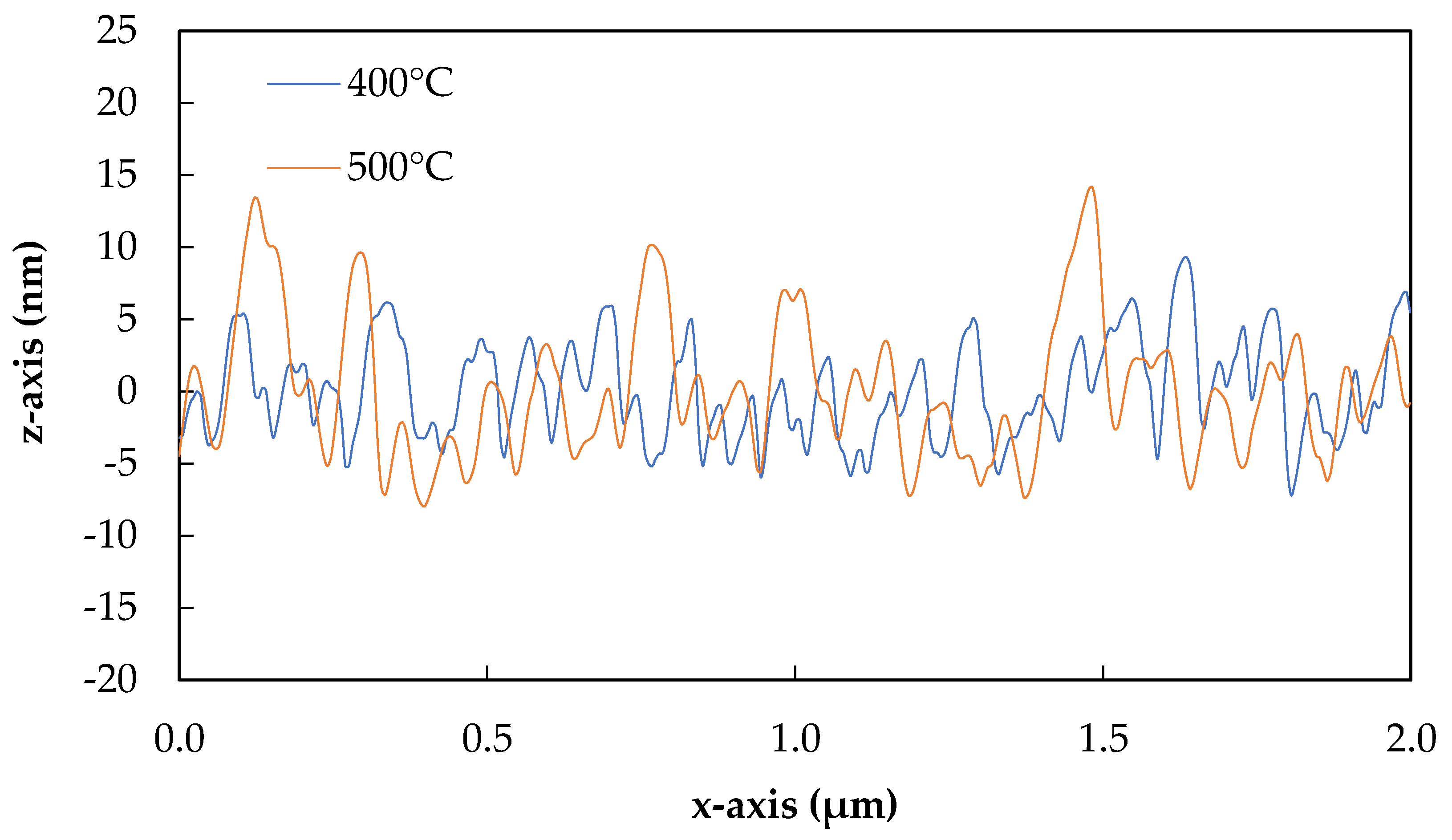

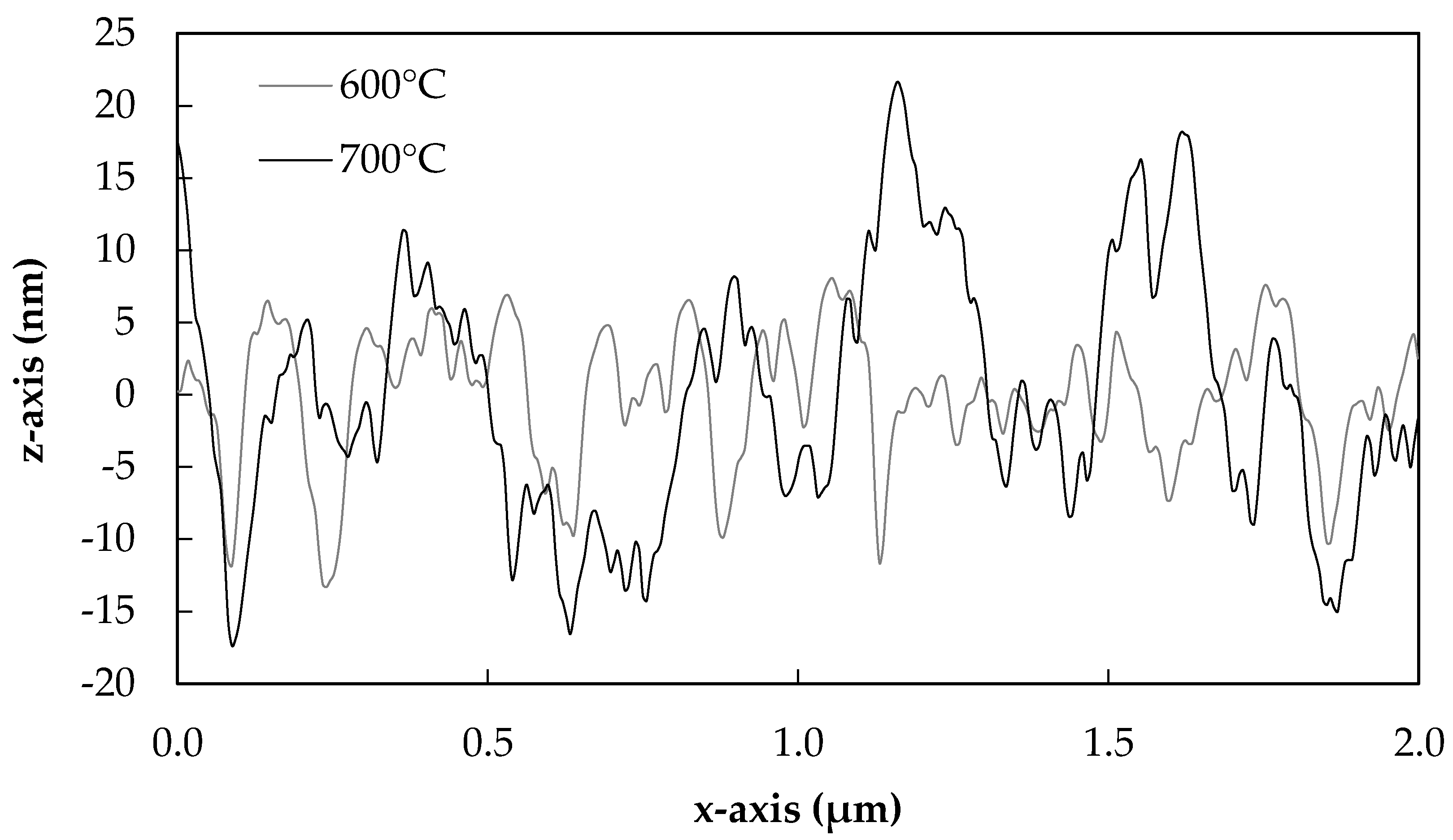

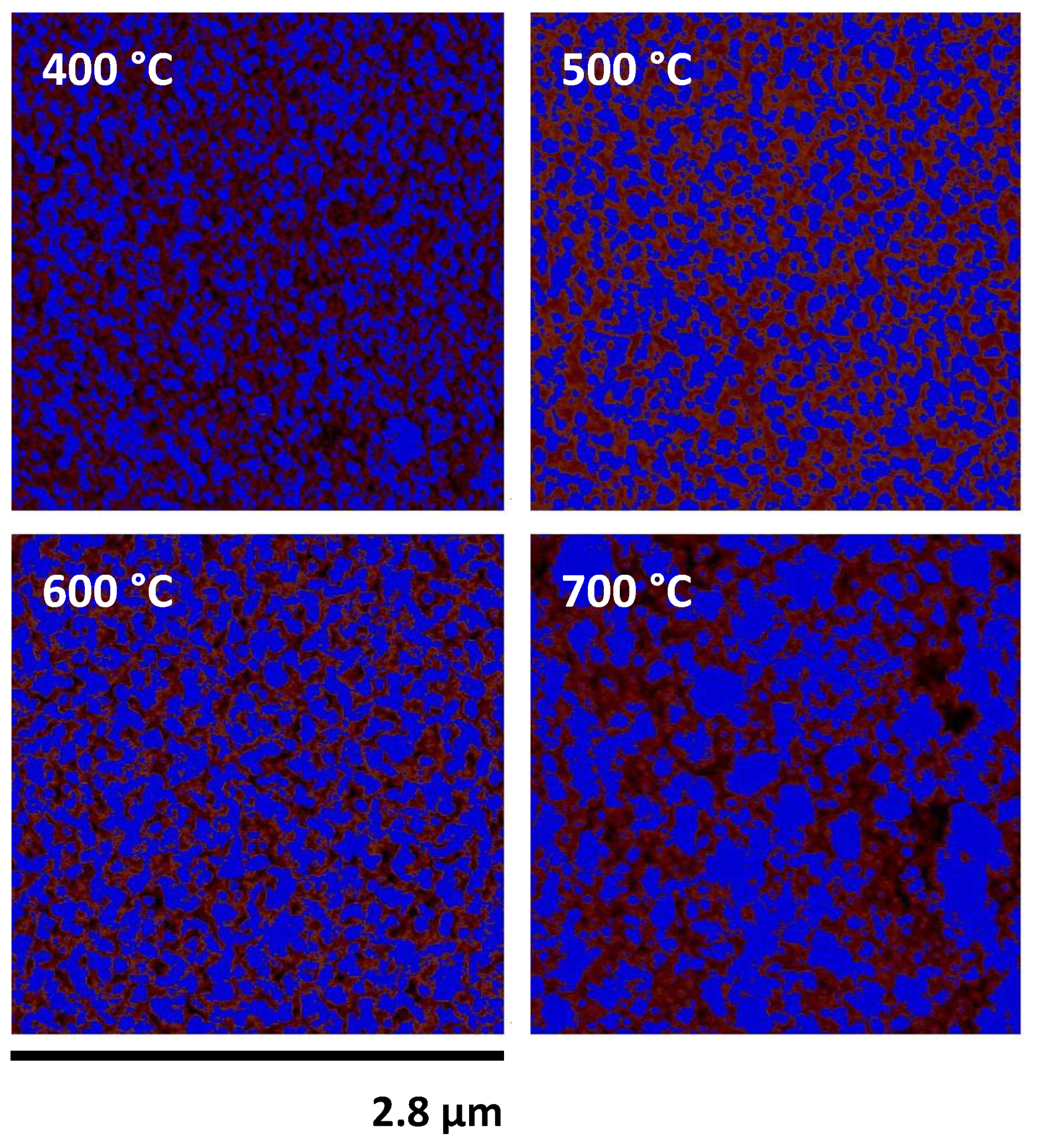

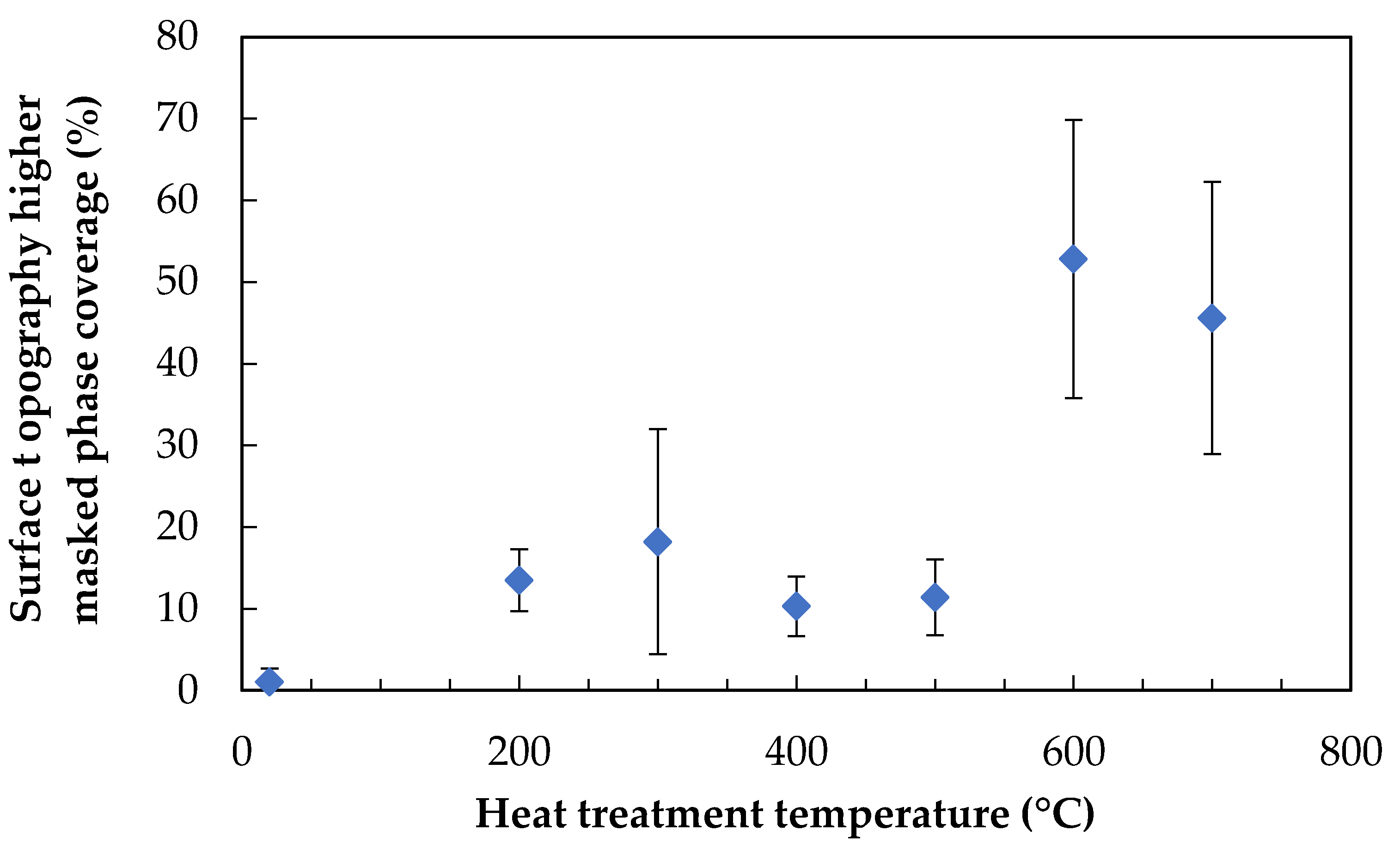

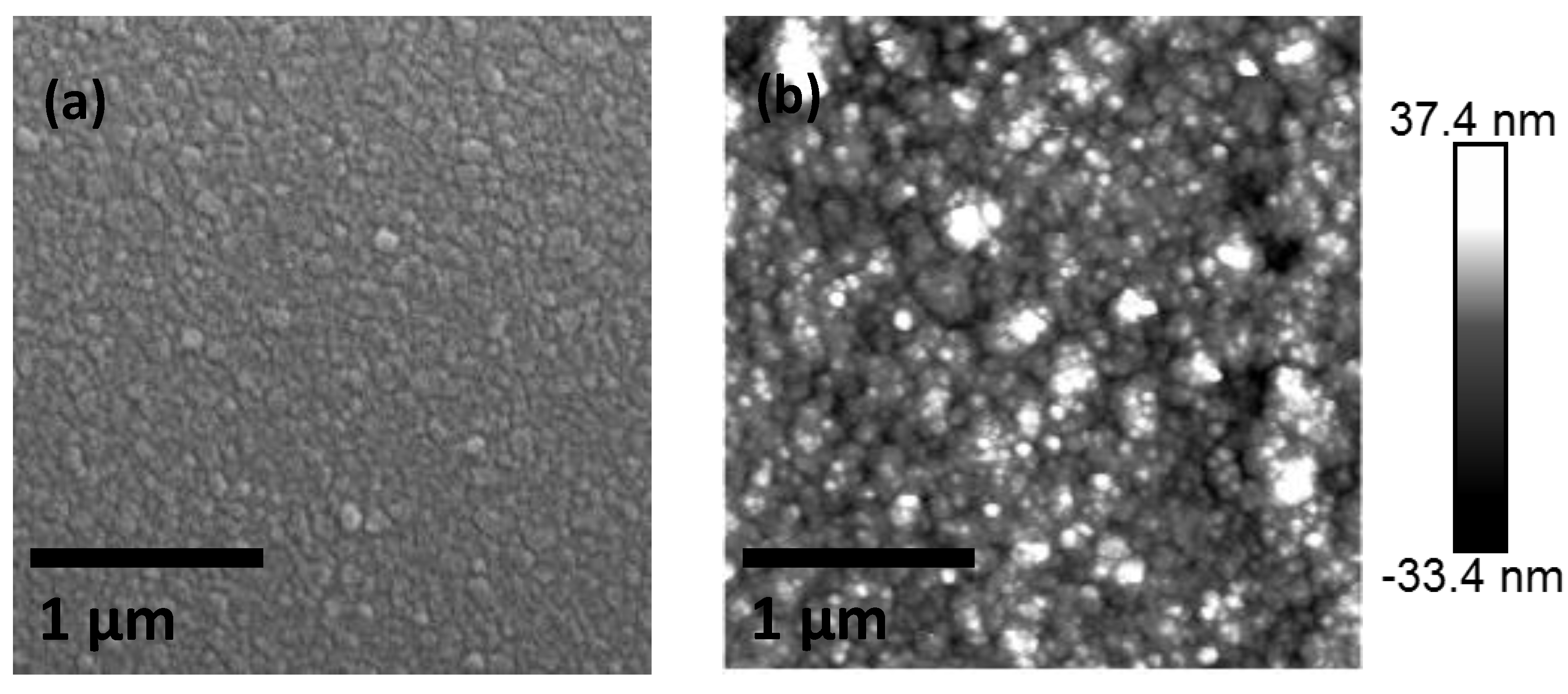

3.3. Atomic Force Microscopy

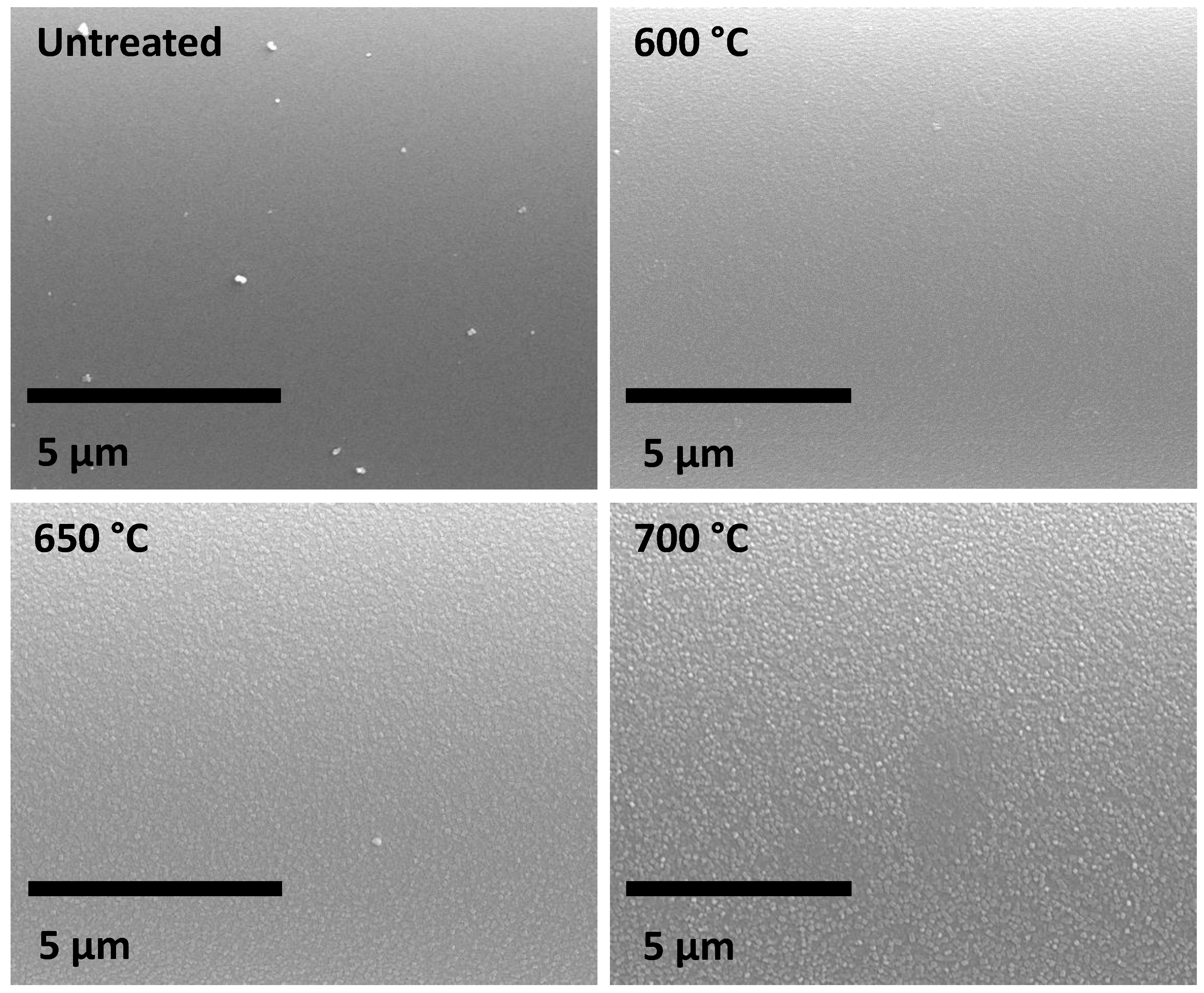

3.4. Scanning Electron Microscopy

3.4.1. Fibre Surfaces

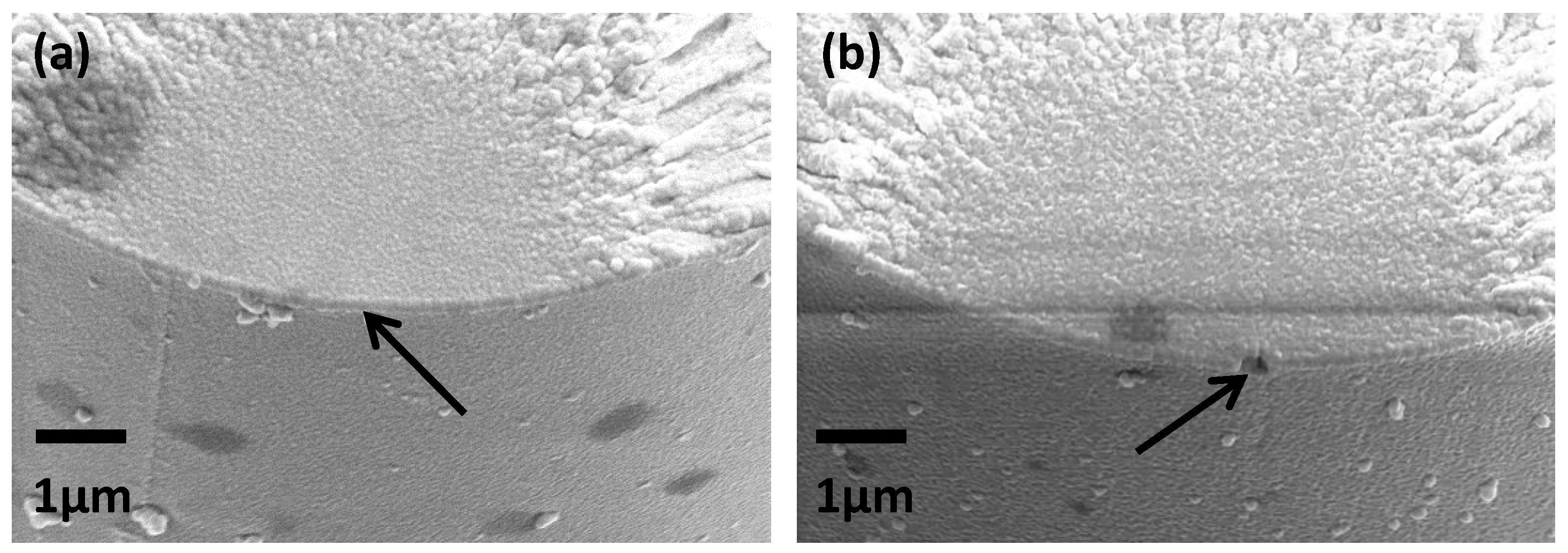

3.4.2. Fracture Surfaces

4. Discussion

4.1. Chemical Surface Changes

4.2. Physical Surface Changes

4.2.1. Possibility of Phase Separation

4.2.2. Effects Relating to Water

4.3. Fibre Strength Loss and Fracture Behaviour

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, H.; Watson, J.C. Continuous Glass Fibers for Reinforcement. Encycl. Glas. Sci. Technol. Hist. Cult. 2016, in press. [Google Scholar]

- Job, S.; Leeke, G.A.; Mativenga, P.T.; Oliveux, O.; Pickering, S.J.; Shuaib, N.A. Composites recycling: Where are we now? Composites UK Ltd. 2016, 1–11. [Google Scholar]

- Pickering, S.J. Recycling technologies for thermoset composite materials—current status. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Kennerley, J.R.; Fenwick, N.J.; Pickering, S.J.; Rudd, C.D. The properties of glass fibers recycled from the thermal processing of scrap thermoset composites. J. Vinyl Addit. Technol. 1997, 3, 58–63. [Google Scholar] [CrossRef]

- Kennerley, J.R.; Kelly, R.M.; Fenwick, N.J.; Pickering, S.J.; Rudd, C.D. The characterisation and reuse of glass fibres recycled from scrap composites by the action of a fluidised bed process. Compos. Part A Appl. Sci. Manuf. 1998, 29A, 839–845. [Google Scholar] [CrossRef]

- Jenkins, P.G.; Yang, L.; Liggat, J.J.; Thomason, J.L. Investigation of the strength loss of glass fibre after thermal conditioning. J. Mater. Sci. 2015, 50, 1050–1057. [Google Scholar] [CrossRef]

- Thomason, J.L.; Yang, L.; Meier, R. The properties of glass fibres after conditioning at composite recycling temperatures. Compos. Part A Appl. Sci. Manuf. 2014, 61, 201–208. [Google Scholar] [CrossRef]

- Feih, S.; Boiocchi, E.; Mathys, Z.; et al. Mechanical properties of thermally-treated and recycled glass fibres. Compos. Part B Eng. 2011, 42, 350–358. [Google Scholar] [CrossRef]

- Thomason, J.L.; Jenkins, P.G.; Yang, L. Glass fibre strength—A review with relation to composite recycling. Fibers 2016, 4, 18. [Google Scholar] [CrossRef]

- Sakka, S. Effect of reheating on strength of glass fibers. Bull. Inst. Chem. Res. 1957, 34, 316–320. [Google Scholar]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. A. Math. Phys. Eng. Sci 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Thomas, W.F. An investigation of the factors likely to affect the strength and properties of glass fibres. Phys. Chem. Glas. 1960, 1, 4–18. [Google Scholar]

- Cameron, N.M. The effect of environment and temperature on the strength of E-glass fibres. Part 2. Heating and ageing. Glas Technol. 1968, 9, 121–130. [Google Scholar]

- Yang, L.; Thomason, J.L. Effect of silane coupling agent on mechanical performance of glass fibre. J. Mater. Sci. 2012, 48, 1947–1954. [Google Scholar] [CrossRef]

- Lund, M.D.; Yue, Y. Fractography and tensile strength of glass wool fibres. J. Ceram. Soc. Jpn. 2008, 116, 841–845. [Google Scholar] [CrossRef]

- Nichols, D.; Hercules, D.M.; Peek, R.C.; Vaughan, D.J. Application of x-ray photoelectron spectroscopy to the study of fiberglass surfaces. Appl. Spectrosc. 1974, 28, 219–222. [Google Scholar] [CrossRef]

- Korwin-Edson, M.L.; Hofmann, D.A.; McGinnis, P.B. Strength of high performance glass reinforcement fiber. Int. J. Appl. Glas. Sci. 2012, 3, 107–121. [Google Scholar] [CrossRef]

- Kennedy, C.R.; Bradt, R.C.; Rindone, G.E. Fracture mechanics of binary sodium silicate glasses. In Fracture Mechanics of Ceramics; Bradt, R.C., Evans, A.C., Hasselman, D.P.H., Lange, F.F., Eds.; Springer: Boston, MA, USA, 1974; Volume 2, pp. 883–893. [Google Scholar]

- Freiman, S.W. The Fracture of glass: Past, present, and future. Int. J. Appl. Glas. Sci. 2012, 3, 89–106. [Google Scholar] [CrossRef]

- El Achari, A.; Ghenaim, A.; Wolff, V.; Caze, C.; Carlier, E. Topographic study of glass fibers by atomic force microscopy. Text. Res. J. 1996, 66, 483–490. [Google Scholar] [CrossRef]

- Radlein, E.; Frischat, G.H. Atomic force microscopy as a tool to correlate nanostructure to properties of glasses. J. Non Cryst. Solids 1997, 222, 69–82. [Google Scholar] [CrossRef]

- Gupta, P.K.; Inniss, D.; Kurkjian, C.R.; Zhong, Q. Nanoscale roughness of oxide glass surfaces. J. Non Cryst. Solids 2000, 262, 200–206. [Google Scholar] [CrossRef]

- Mellott, N.P.; Pantano, C.G. A mechanism of corrosion-induced roughening of glass surfaces. Int. J. Appl. Glas. Sci. 2013, 4, 274–279. [Google Scholar] [CrossRef]

- Aslanova, M.S.; Shaina, Z.I. Influence of phase separation on physical and chemical properties of heat-treated fibers. In Phase-Separation Phenom. Glas. Proc. first All-Union Symp. Phase-Separation Phenom; Porai-Koshits, E.A., Ed.; Glas: Leningrad, Russia, 1968; pp. 168–171. [Google Scholar]

- Kreidl, N.J.; Maklad, M.S. Effect of water content on phase separation in soda-silica glasses. J. Am. Ceram. Soc. 1969, 52, 508–509. [Google Scholar] [CrossRef]

- Wheaton, B.R.; Clare, A.G. Evaluation of phase separation in glasses with the use of atomic force microscopy. J. Non Cryst. Solids 2007, 353, 4767–4778. [Google Scholar] [CrossRef]

- Dalmas, D.; Lelarge, A.; Vandembroucq, D. Quantitative AFM analysis of phase separated borosilicate glass surfaces. J. Non Cryst. Solids 2007, 353, 4672–4680. [Google Scholar] [CrossRef]

- Zheng, W.; Lin, M.; Cheng, J. Effect of phase separation on the crystallization and properties of lithium aluminosilicate glass-ceramics. Glass Phys. Chem. 2013, 39, 142–149. [Google Scholar] [CrossRef]

- Varshneya, A.K. Fundamentals of Inorganic Glasses; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Carman, L.A.; Pantano, C.G. Water-vapor adsorption on calcium-boroaluminosilicate glass fibers. J. Non Cryst. Solids. 1990, 120, 40–46. [Google Scholar] [CrossRef]

- Nishioka, G.M.; Schramke, J.A. Desorption of water from glass fibers. In Mol. Charact. Compos. Interfaces; Ishida, H., Kumar, G., Eds.; Plenum Press: New York, NY, USA, 1985; pp. 387–400. [Google Scholar]

- Nishioka, G.M. Adsorption/desorption of water on glass fiber surfaces. J. Non Cryst. Solids 1990, 120, 34–39. [Google Scholar] [CrossRef]

- Oehler, A.; Tomozawa, M. Water diffusion into silica glass at a low temperature under high water vapor pressure. J. Non Cryst. Solids 2004, 347, 211–219l. [Google Scholar] [CrossRef]

- Amma, S.I.; Kim, S.H.; Pantano, C.G. Analysis of water and hydroxyl species in soda lime glass surfaces using Attenuated Total Reflection (ATR)-Ir spectroscopy. J. Am Ceram. Soc. 2016, 99, 128–134. [Google Scholar] [CrossRef]

- Lezzi, P.J.; Xiao, Q.R.; Tomozawa, M.; et al. Strength increase of silica glass fibers by surface stress relaxation: A new mechanical strengthening method. J. Non Cryst. Solids 2013, 379, 95–106. [Google Scholar] [CrossRef]

- Martin, D.M.; Akinc, M.; Oh, S.M. Effect of forming and aging atmospheres on e-glass strength. J. Am. Ceram. Soc. 1978, 61, 308–311. [Google Scholar] [CrossRef]

- Li, H.; Tomozawa, M. Mechanical strength increase of abraded silica glass by high pressure water vapor treatment. J. Non Cryst. Solids 1994, 168, 287–292. [Google Scholar] [CrossRef]

- Wiederhorn, S.M.; Yi, F.; LaVan, D.; Richter, L.J.; Fett, T.; Hoffmann, M.J. Volume expansion caused by water penetration into silica glass. J. Am. Ceram. Soc. 2015, 98, 78–87. [Google Scholar] [CrossRef]

- Irwin, G.R. Fracture. In Elast. Plast.; Flugge, S., Ed.; Springer: Heidelberg, Germany, 1958; pp. 551–590. [Google Scholar]

- Feih, S.; Mouritz, A.P.; Case, S.W. Determining the mechanism controlling glass fibre strength loss during thermal recycling of waste composites. Compos. Part A Appl. Sci. Manuf. 2015, 76, 255–261. [Google Scholar] [CrossRef]

- Jaras, A.C.; Norman, B.J. The measurement of glass fibre strength in composites from studies of their fracture surfaces. J. Mater. Sci. 1983, 18, 2459–2465. [Google Scholar] [CrossRef]

| Treatment temperature (°C) | Element Atomic % | |||||

|---|---|---|---|---|---|---|

| Si | O | Ca | Al | Mg | Na | |

| 20 | 18.97 | 70.27 | 5.36 | 3.94 | 1.13 | 0.31 |

| 450 | 18.94 | 67.55 | 5.60 | 3.62 | 2.66 | 1.27 |

| 500 | 19.72 | 67.7 | 5.56 | 4.56 | 1.34 | 1.12 |

| 600 | 19.26 | 67.84 | 6.14 | 4.42 | 1.66 | 0.67 |

| Sample | Fracture Surfaces Available | Type 1 | Type 2 | Type 3 |

|---|---|---|---|---|

| Surface flaw data | No. | No visible origin | Visible origin | Internal pore |

| Continuous E-glass | 19 | 15 | 4 | 0 |

| Treatment Temperature (°C) | Measured Avg. Strength (GPa) | Avg. zmin (nm) | Calculated Strength (GPa) | Calculated Strength (GPa) |

|---|---|---|---|---|

| Y = 1.12 | Y = 1.29 | |||

| 200 | 1.42 | −8.5 | 5.0 | 4.3 |

| 300 | 1.31 | −22.2 | 3.1 | 2.7 |

| 400–450 | 1.12 | −11.9 | 4.2 | 3.7 |

| 500 | 0.83 | −14.8 | 3.8 | 3.3 |

| 600 | 0.66 | −21.4 | 3.1 | 2.7 |

| 700 | 0.31 | −31.7 | 2.6 | 2.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jenkins, P.G.; Yang, L.; Thomason, J.L.; Chen, X.; Watts, J.F.; Hinder, S.J. Investigation of Chemical and Physical Surface Changes of Thermally Conditioned Glass Fibres. Fibers 2019, 7, 7. https://doi.org/10.3390/fib7010007

Jenkins PG, Yang L, Thomason JL, Chen X, Watts JF, Hinder SJ. Investigation of Chemical and Physical Surface Changes of Thermally Conditioned Glass Fibres. Fibers. 2019; 7(1):7. https://doi.org/10.3390/fib7010007

Chicago/Turabian StyleJenkins, Peter G, Liu Yang, James L Thomason, Xinyong Chen, John F Watts, and Steven J Hinder. 2019. "Investigation of Chemical and Physical Surface Changes of Thermally Conditioned Glass Fibres" Fibers 7, no. 1: 7. https://doi.org/10.3390/fib7010007

APA StyleJenkins, P. G., Yang, L., Thomason, J. L., Chen, X., Watts, J. F., & Hinder, S. J. (2019). Investigation of Chemical and Physical Surface Changes of Thermally Conditioned Glass Fibres. Fibers, 7(1), 7. https://doi.org/10.3390/fib7010007