Abstract

In this study, a fabric was manufactured consisting of 50% pineapple, 25% jute and 25% cotton fibers by weight, to make composites using polypropylene (PP) as a matrix material. We used compression molding technique, which kept 30% of the fabric content by total weight as the composite. The tensile strength (TS), tensile modulus (TM), elongation break (Eb%), bending strength (BS) and bending modulus (BM) were investigated. From analyzed data, it was found that the composite values of TS, TM, Eb%, BS and BM were 58 MPa, 867 MPa, 22.38%, 42 MPa and 495 MPa, respectively. The TS, TM, Eb%, BS and BM of the neat polypropylene sheet were 28 MPa, 338 MPa, 75%, 20 MPa and 230 MPa, respectively. Due to fabric reinforcement, composite values for TS, TM, BS and BM increased 107%, 156%, 110% and 115%, respectively in comparison with a polypropylene sheet. A water absorption test was performed by dipping the composite samples in deionized water and it was noticed that water absorption was lower for PP-based composites. For investigating the effect of alkali, we sunk the composites in a solution containing 3%, 5% and 7% sodium hydroxide alkali solutions by weight, for 60 min after which their mechanical properties were investigated. A degradation test was carried out by putting the samples in soil for six months and it was noticed that the mechanical properties of fabric/PP composites degraded slowly.

1. Introduction

Fabricating composites by using natural fibers has been of great interest because natural fiber is biodegradable and environment friendly [1,2,3,4,5,6,7,8,9,10,11,12,13,14]. Composites are inexpensive and also not harmful to the environment. The advantages of fiber reinforced materials (FRM) over unreinforced ones are well known, and their characteristics are useful in many fields, and as such, they are used for many applications. FRM are widely used in aerospace [15] and construction [16] applications. Moreover net [17] or long [18] continuous fiber reinforced composites are used in medical science. Nowadays, the most used fibers to reinforce composites are synthetic, but the results obtained with natural fibers are promising [19]. Synthetic fiber reinforced polymers are expensive and have an environmental impact. Natural fibers which are cellulose-based are replacing synthetic fibers as they resolve this issue. This is the reason that the interest of using natural fibers in combination with thermoplastic material is increasing day by day, especially for high volume and low cost applications. Natural fibers have inherent properties of polarity and hydrophilicity, which can be removed by using non-polar thermoplastic material. These properties are not considered when they are not harmful to the environment [20,21,22,23].

Scientists and engineers are paying more attention to replacing synthetic fibers with natural fibers that have analogous physical and mechanical properties. Various other matters should be kept in consideration while choosing raw materials such as cost, environmental impact, hygiene, flexibility, ease of collection and be availability, which are directly related to the suitability of natural fibers [24,25,26,27]. Being a renewable resource, natural fibers provide a long lasting solution, beside the economical and hygienic benefits. Moreover, the processing of natural fibers is cost effective and provides good mechanical and physical properties [28,29,30,31,32,33].

Pineapple leaf fiber (PALF) is a waste material in the agriculture sector which is cultivated widely in Asia across the world. Very few tropical fruits are as essential as pineapple (Ananas comosus). Pineapple fruit has an important commercial value, and the leaves of pineapple are waste material which yields natural fibers [34]. It is chemically composed of 70–82% holocellulose, 5–12% lignin and 1.1% ash. It has excellent mechanical properties due to the higher percentage of hollocellulose. This is why it can be implemented in fabricating of reinforced polymer composites [35,36]. Cotton is an important natural fiber and produced in many parts of the Asian continent such as China, India, Pakistan, Bangladesh etc. Among these countries, China is the biggest cotton producer. Cotton fiber is comprised of 94% cellulose. There are various factors on which the strength of cotton fiber is dependent like fiber structure, microfibril orientation, molecular weight of cellulose chains, the crystalline structure perfection and the convolution angle of microfibrils [37]. Another important natural fiber is jute fiber which is mostly produced in Bangladesh, India, China, Uzbekistan, Bhutan, Vietnam and Thailand. About 93% of the world’s jute fiber is produced in Bangladesh and India. Clothes, ropes, bags, floor mats etc., are made from jute fiber. Moreover, it can be used as a good reinforcing agent with hydrophobic matrix material like polypropylene, polyethylene, low density polyethylene, and unsaturated polyester resin, etc. It provides advantages such as being light weight, cost effective, low density. Also it has having high availability, a high tensile modulus and low elongation at break [3,38]. Jute fibers are comprised of 82–85% hollocellulose, of which 58–63% is alpha-cellulose, which is responsible for the excellent mechanical properties of jute fiber [8]. For these reasons, to fabricate a lightweight and inexpensive composite, pineapple leaf, jute and cotton fibers were selected.

The most vital part of a composite are the matrix materials. As a matrix material, polypropylene has been extensively used with natural fibers in composite preparation [2,3,4,5,6,7,8]. Polypropylene (PP) is an amorphous thermoplastic polymer and is extensively used as an engineering thermoplastic material for its various important characteristics such as its dimensional stability, transparency, high heat distortion temperature, flame resistance and high impact strength. PP can also be used for filling, reinforcing and blending. PP composites with natural fiber are becoming more promising each day [9,39,40,41,42,43,44].

In this study, the mechanical and degradation properties of a fabric reinforced PP-based partially biodegradable composite were evaluated. Water uptake profiles and the effect of alkali on composite were also investigated.

2. Materials and Methods

2.1. Materials

A plain structure bleached fabric (consisting of 50% pineapple, 25% jute and 25% cotton) was made at the Bangladesh Jute Research Institute (BJRI), Dhaka, Bangladesh. The thread count in the vertical (warp) and horizontal (weft) directions of the fabric were 52 and 40 in one square inch. Figure 1 shows the weaved fabric. The granules of PP were bought from Polyolefin Company Limited, Singapore. The symbolic expression of PP is (C3H6)n. Alkali (NaOH) was purchased from the local market of Dhaka, Bangladesh.

Figure 1.

Fabric.

2.2. Fabrication of Fabric-Reinforced PP-Based Composites

The granules of polypropylene were placed inside of two plates of a heat press machine (Carver, INC, USA Model 3856) for making PP sheets. The heat press machine was used at a temperature of 180 °C for 5 min and a load of 2000 kg. The sheets were cooled inside the heat press machine. For composite fabrication, the prepared PP sheet and fabric were cut into the desired size. Composites were fabricated by sandwiching fabric between two sheets of PP and using the method as discussed for making PP sheets [2]. The fabric percentage of the composites was 30% by weight. The prepared composites were then packed in polyethylene bags.

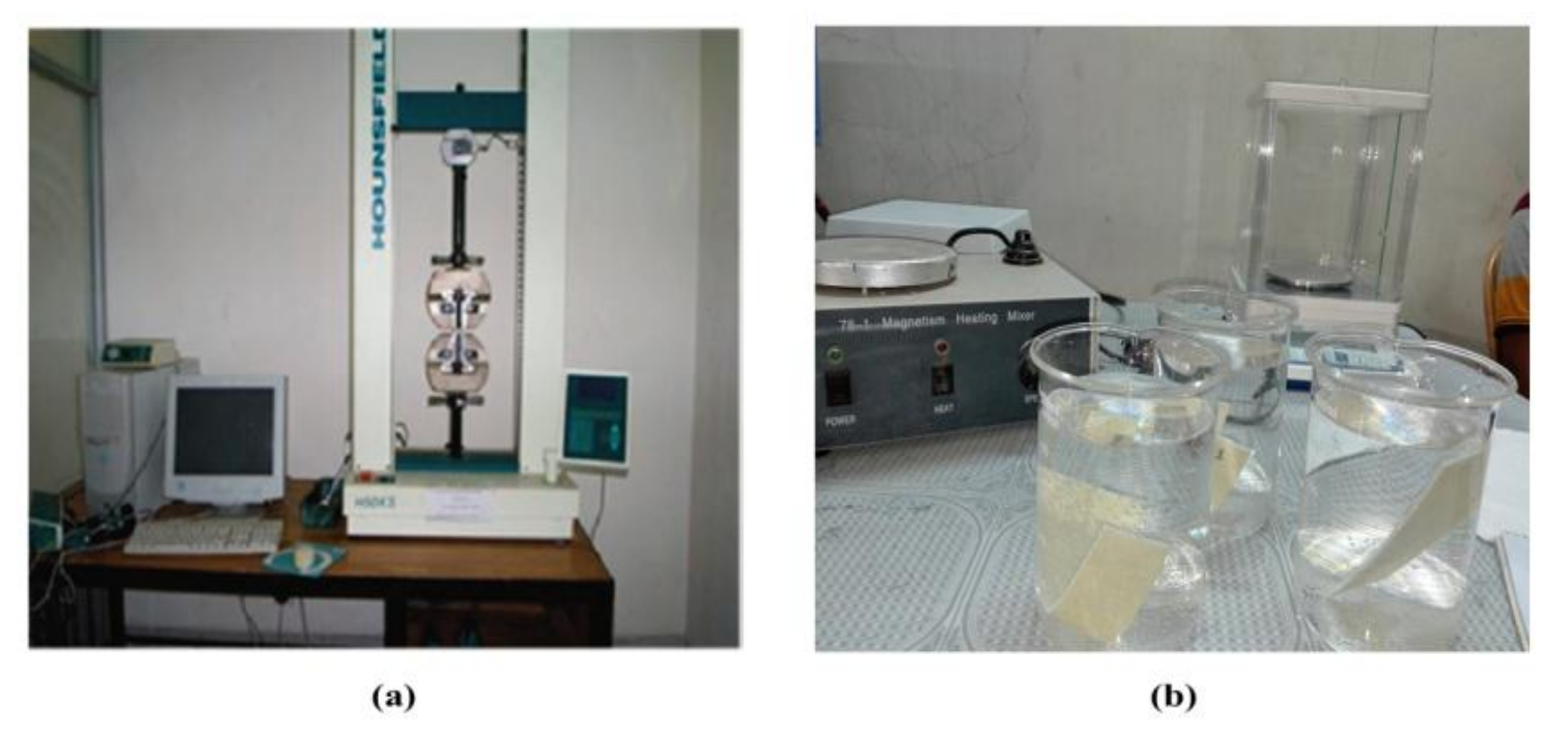

2.3. Mechanical Properties of Composites

The tensile and bending properties of the composites were measured according to the European standard (ISO/DIS 527-1:2010) by using the Hounsfield series S testing machine (UK) with an initial separation of clamp of 20 mm and a loading force of 10 mm/min. The dimensions of fabric/PP composites were (60 × 10 × 1.60) mm3. The test samples were conditioned at 25 °C and 50% relative humidity for three days prior to testing. The mechanical tests were carried out according to the vertical (warp) direction. The average of the results for at least five samples was taken for all the test values.

2.4. Water Absorption Profile of the Composites

Water absorption test of the fabric/PP composite was performed according to ASTM D-570. Water absorption tests were carried out on three samples (sample-1, sample-2 and sample-3) of the fabric/PP composite (Figure 2). Samples of the composite were weighed and dipped in beakers containing 500 mL of deionized water at room temperature (25 °C) for 1 h. Then after the time interval the samples were brought out of the beaker, wiped by using tissue paper and re-weighed. In this case, it showed no uptake after 40 min, so we carried out the test up to 1 h [14]. The water absorption percentage was determined by:

Water absorption (%) = [(Wet weight − Dry weight)/Dry weight] × 100

Figure 2.

(a) Universal testing machine (UTM) and (b) water uptake (%) test.

2.5. Effect of Alkali

The alkali treatment was performed to investigate the effect of alkali on the composites. The composites were treated with aqueous solution of 3%, 5% and 7% sodium hydroxide (NaOH) for 24 h [2]. The samples were taken out of the solution after 24 h and washed in water to remove the remaining sodium hydroxide. Then the samples were dried at 70 °C for 1 h and their mechanical properties were evaluated.

2.6. Soil Degradation Test of the Composites

Soil degradation tests of the composite provided information on the mechanical properties of the composites retained after a certain time period of contact with. The degradation test of the fabric/PP composites was conducted for up to 24 weeks in soil. Composite samples were placed in soil for different periods of time. After a three week interval, samples were brought out carefully. Then cleaned with distilled water and dehydrated at 105 °C for 6 h, reposed at room temperature (25 °C) for 24 h and then the tensile and bending properties were measured [8].

3. Results and Discussion

3.1. Mechanical Properties of Composites

The tensile and bending property values of the PP matrix and fabric/PP composites are represented in Table 1 and Table 2. From the tables, the tensile strength (TS), tensile modulus (TM), elongation at break (Eb%), bending strength (BS) and bending modulus (BM) of the PP sheet were found to be 28 MPa, 338 MPa, 75%, 20 MPa and 230 MPa respectively. TS, TM, BS and BM for the fabric/PP composites were found to be 58, 867, 42 and 483 MPa respectively. Pineapple leaf, cotton & jute fiber based PP composites gained a 107% increase in TS and a 110% increase in BS over that of the matrix PP. It was also observed that TM and BM improved by 156% and 115% respectively over that of the matrix material PP. By analyzing the values, it was found that 30 wt% fabric/PP composite exhibited improved mechanical properties (TS, TM, BS and BM). But Eb% was reduced drastically compared to PP. Motaleb et al. stated that the TS, TM, Eb%, BS and BM of PALF/PP composite (30% fiber content) were 61 MPa, 1096 MPa, 14.05%, 31 MPa and 420 MPa, respectively [14]. Compared with the present study, reduced mechanical properties were observed due to the addition of jute and cotton fiber. When jute and cotton fiber were added with the pineapple fiber, the stress was transferred among pineapple, jute and cotton fiber instead of only pineapple fiber, thus, stress was reduced for matrix PP. Which is the cause of the change in mechanical properties. The better mechanical properties in this study came mainly from the sandwich structure, where the core layer (fabric) contributed a lot to the mechanical properties. From this investigation, it was clear that pineapple leaf, cotton and jute fiber based PP composites achieved more than double the mechanical property values over the matrix material alone. The content of cellulose in pineapple, jute and cotton fiber gave an advantage in this case [2].

Table 1.

Tensile properties of polypropylene (PP) and fabric/PP composites.

Table 2.

Bending properties of polypropylene (PP) and fabric/PP composites.

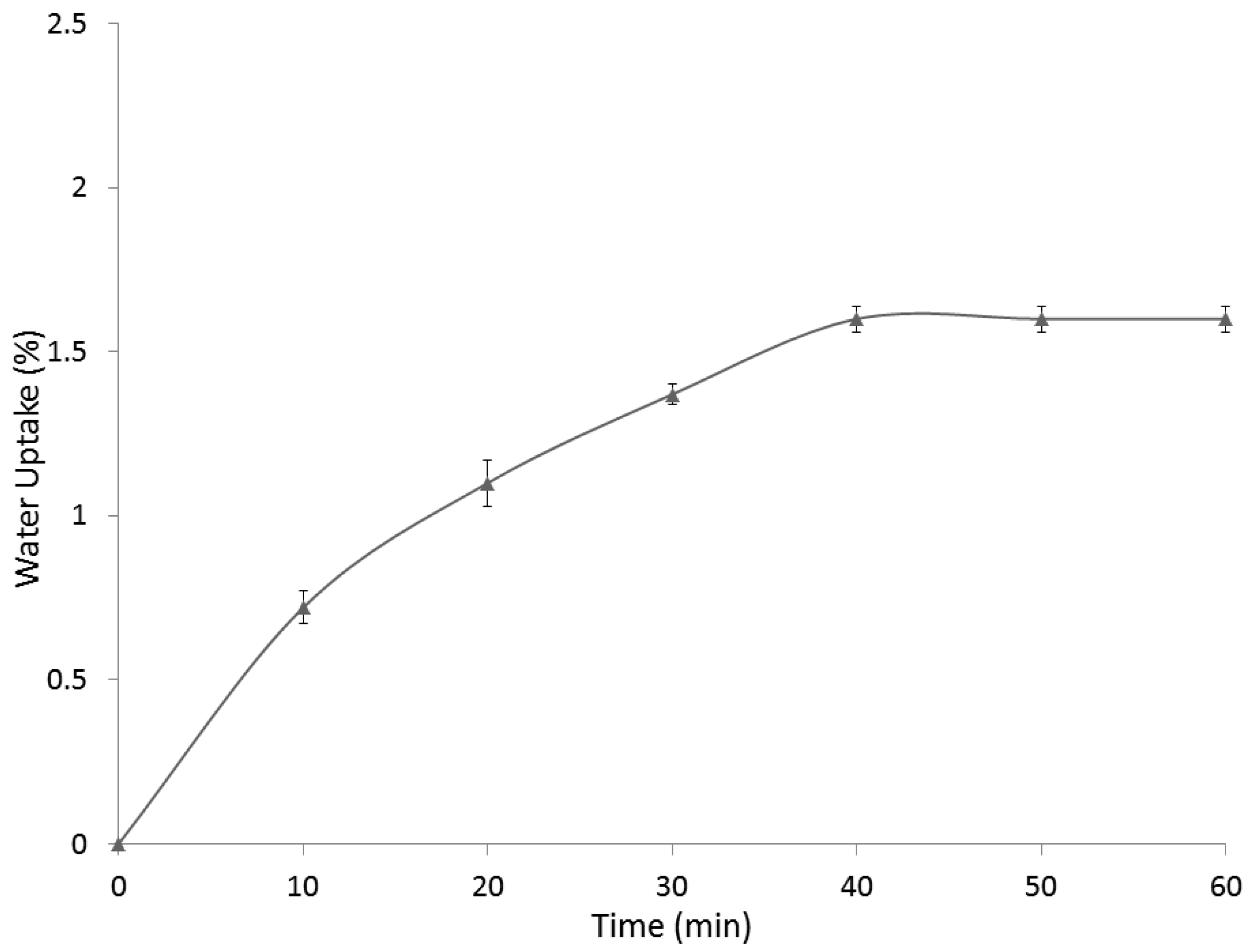

3.2. Water Absorption Profile of the Composites

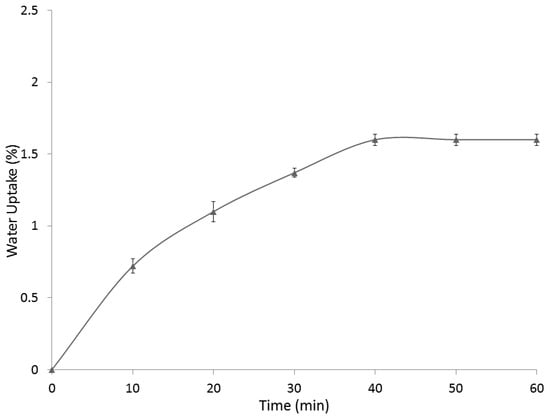

The water absorption test allowed divulging the water absorbing behavior of the composite. The results of water absorption tests of the three samples of the fabric/PP composites are depicted in Figure 3, against the time of soaking in water at room temperature. With an increase of soaking time, the level of water absorption increased up to 40 min, as shown in the graph, after which no further water absorption occurred [45]. It was found that the fabric/PP composite absorbed 1.6% water. Motaleb et al. reported that PALF/PP composite (30% fiber content) absorbed no further water after 50 min and that the water uptake percentage was 1.46% [14]. Little variation was noticed for the fabric/pp composite due to its different fiber composition.

Figure 3.

Water uptake % of fabric/PP composites.

Water absorption can be described by hydroxyl (–OH) groups that are present in the fiber cellulose resulting in the strong hydrophilic nature of fabric [46]. Polypropylene is strongly hydrophobic in nature [3] and resists water penetration when fabricating composites by sandwiching the fabric in between polypropylene sheets. Water was absorbed by the cut edge of the composite and this resulted in lower fabric/PP composite water uptake values.

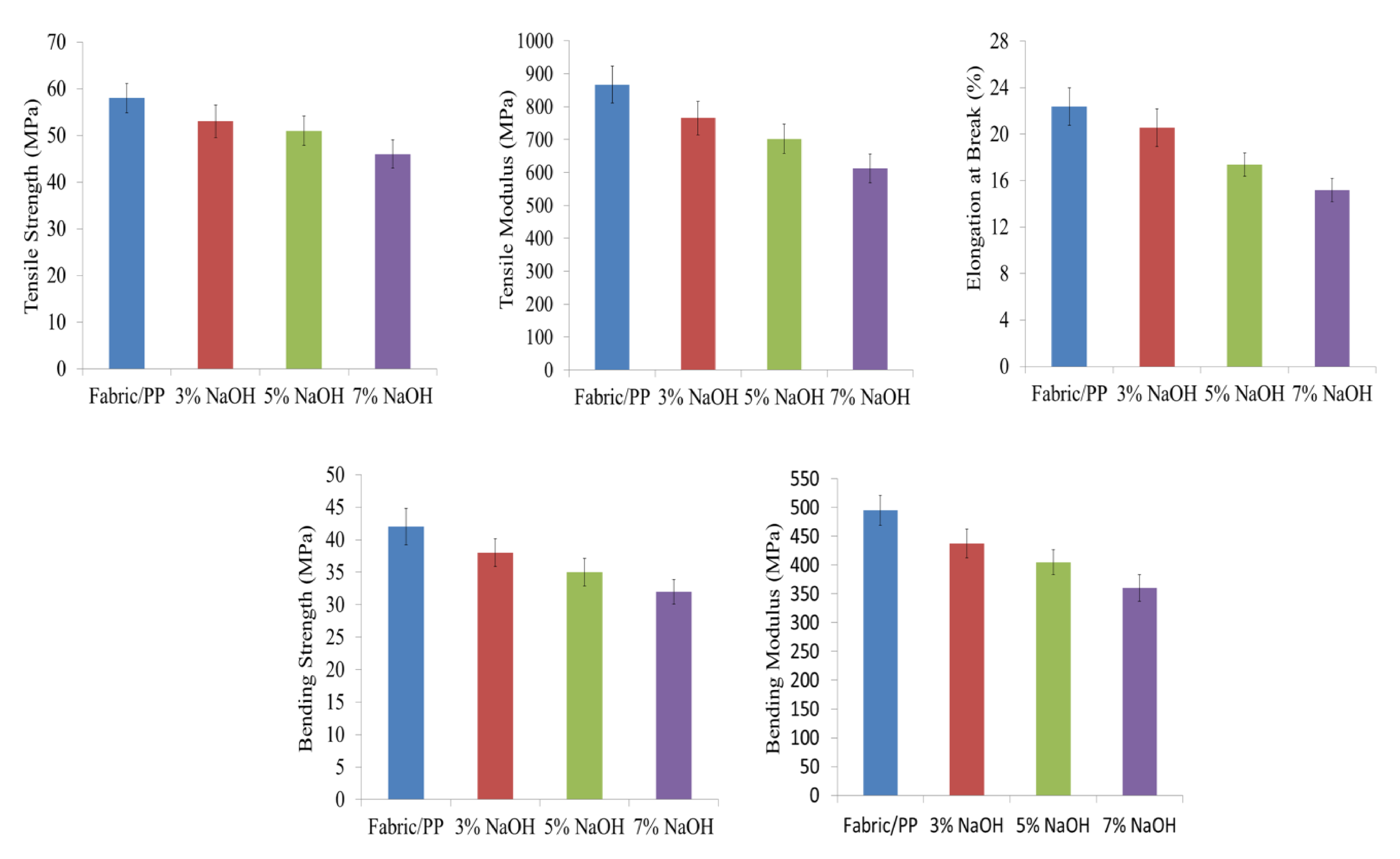

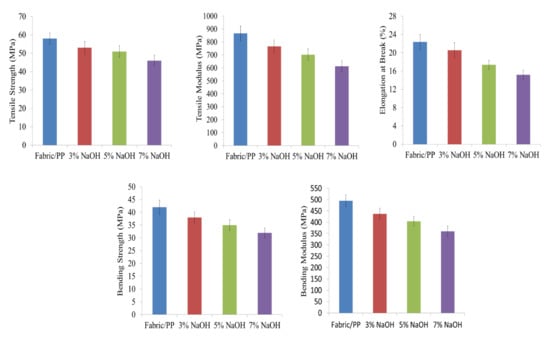

3.3. Effect of Alkali

The effect of alkali (3%, 5% and 7% NaOH) on composites was tested at room temperature for 24 h. Tensile strength (TS), tensile modulus (TM), elongation at break (Eb%), bending strength (BS) and bending modulus (BM) values are shown in Figure 4. It was found that the mechanical properties of fabric/PP composites decreased for all conditions under the study. In this study, the mechanical properties of the composites decreased significantly when the composites were treated in 7% NaOH solution as shown in the figures. In particular, after 24 h of 7% alkali treatment, fabric/PP composite values decreased by 21%, 29%, 32%, 23% and 27% of TS, TM, Eb%, BS and BM respectively.

Figure 4.

Effect of alkali on the mechanical properties of the composites.

When natural fiber was alkali treated, which contains cellulose, crystal structure of fibers, the mechanical properties increased greatly. On the other hand, when the natural fiber reinforced composites were treated with alkali, there was some variation in the mechanical properties [47].

The change in mechanical properties can be well explained by the help of mercerization. It may be that the fabric lost its strength over time. Due to mercerization, the breaking tendency of composites was increased [2].

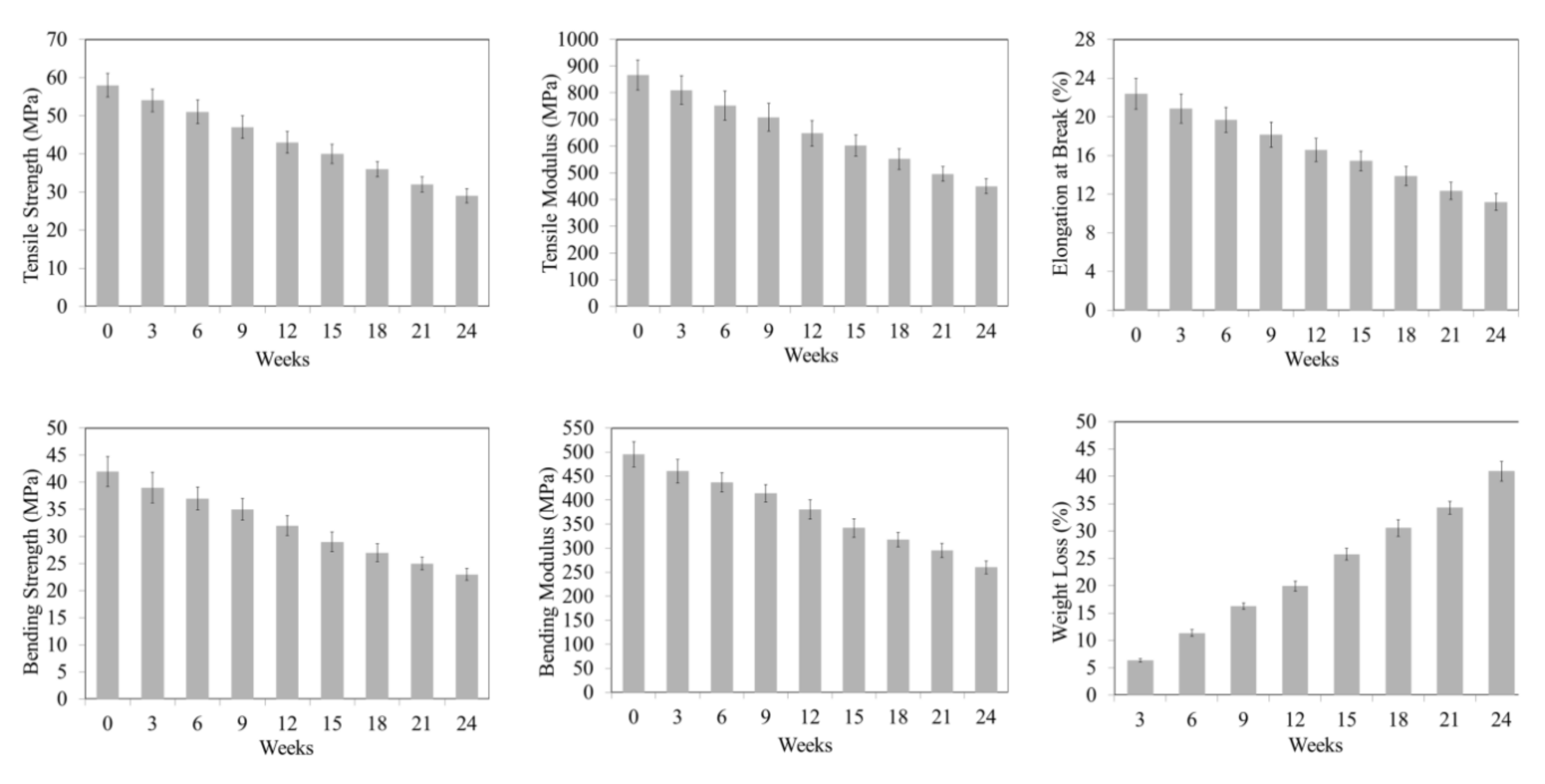

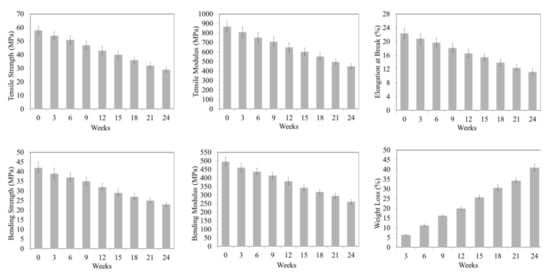

3.4. Soil Degradation Test of the Composites

The degradation tests on the composites were carried out in soil at ambient conditions for up to 24 weeks. Tensile strength (TS), tensile modulus (TM) and elongation at break (Eb%) values are shown in Figure 5. From the figures, it can be seen that the TS, TM and Eb% of the fabric/PP composites decreased slowly with time. Fabric/PP composites consumed almost 50%, 48% and 49% of their TS, TM and Eb% respectively after 24 weeks of soil degradation. Similarly, decreased values of bending strength (BS) and bending modulus (BM) were also observed, and the results are depicted in Figure 5. Results revealed that soil degraded 45% and 47% of the initial BS and BM values of the fabric/PP composites respectively, after 24 weeks. It was also observed that, fabric/PP composites lost almost 41% of their mass after 24 weeks. For being a cellulose based natural biodegradable fiber, pineapple leaf, cotton and jute absorbs water within a few minutes, which indicates its strong hydrophilic nature. Cellulose has a strong aptitude to degrade in soil [48]. PP is strongly hydrophobic in nature. During the soil-degradation tests, the penetration of water occurred from the cut edges of the composites and degraded the cellulose resulting in significantly reduced mechanical properties. S. Nahar et al. stated that 40%, 46%, 36% and 35% of the TS, TM, BS and BM, respectively, were lost after a 24 week soil degradation test of natural fiber (jute fiber) reinforced pp based composite (50% fiber weight) [8]. Analyzing these values, no significant change of tensile properties are seen due to soil degradation test after 24 weeks. But some change of bending properties were happened because of different fiber percentage and composition of fabric/PP composite.

Figure 5.

Soil degradation test of the composites.

4. Conclusions

Fabric-reinforced polypropylene-based composites were successfully prepared and characterized. Increased mechanical properties of the composites were seen compared with the matrix material. The TS and TM of the fabric/PP composites were found to be 58 MPa and 867 MPa respectively, compared with the PP matrix, a 107% and 156% increase of TS and TM was noticed. For the fabric/PP composites, BS and BM were found to be 42 MPa and 495 MPa respectively, which was 110% and 115% higher than those of the matrix material. Little variation was noticed in the water uptake, whereas reduced mechanical properties were observed, due to the addition of jute and cotton fiber compared with a 30 wt% PALF/PP composite [14]. Alkali reduced the mechanical properties of fabric/PP composites. Degradation testing of the fabric/PP composites were carried out for 6 months in soil and it was observed that composites retained about 50% of their original mechanical properties. Further research is needed in order to compare synthetic and natural fiber reinforced composites in order to improve knowledge on the topic.

Author Contributions

Conceptualization, M.B.H. and S.; methodology, M.B.H. and S.; validation, A.B.M.H.A. and H.M.; formal analysis, M.B.H. and A.N.; investigation, M.B.H. and A.N.; writing—original draft preparation, M.B.H.; writing—review and editing, M.B.H. and S.; supervision, S.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sahadat Hossain, M.D.; Sarwaruddin Chowdhury, A.M.; Khan, R.A. Effect of disaccharide, gamma radiation and temperature on the physico-mechanical properties of jute fabrics reinforced unsaturated polyester resin-based composite. Radiat. Eff. Defects Solids 2017, 172, 517–530. [Google Scholar] [CrossRef]

- Hoque, M.B.; Sahadat Hossain, M.D.; Nahid, A.M.; Solaiman, B.; Khan, A.R. Fabrication and characterization of pineapple fibre-reinforced polypropylene based composites. Nano Hybrids Compos. 2018, 21, 31–42. [Google Scholar] [CrossRef]

- Sahadat Hossain, M.D.; Uddin, M.B.; Razzak, M.D.; Sarwaruddin Chowdhury, A.M.; Khan, R.A. Fabrication and characterization of jute fabrics reinforced polypropylene-based composites: Effects of ionizing radiation and disaccharide (sucrose). Radiat. Eff. Defects Solids 2017, 172, 904–914. [Google Scholar] [CrossRef]

- Wu, L.-P.; Kang, W.-L.; Chen, Y.; Zhang, X.; Lin, X.-H.; Chen, L.-Y.; Gai, Y.-G. Structures and properties of low-shrinkage polypropylene composites. J. Ap. Polym. Sci. 2016, 134, 44275. [Google Scholar] [CrossRef]

- Uawongsuwan, P.; Yang, Y.; Hamada, H. Long jute fiber-reinforced polypropylene composite: Effects of jute fiber bundle and glass fiber hybridization. J. App. Polym. Sci. 2014, 132, 41819. [Google Scholar] [CrossRef]

- Varshney, D.; Debnath, K.; Singh, I. Mechanical characterization of polypropylene (PP) and polyethylene (PE) based natural fiber reinforced composites. Int. J. Surf. Eng. 2014, 4, 16–23. [Google Scholar]

- Nuruzzaman Khan, M.D.; Roy, J.K.; Akter, N.; Zaman, H.U.; Islam, T.; Khan, R.A. Production and properties of short jute and short e-glass fiber reinforced polypropylene-based composites. Open J. Compos. Mater. 2012, 2, 40–47. [Google Scholar] [CrossRef]

- Nahar, S.; Khan, R.A.; Dey, K.; Sarker, B.; Das, A.K.; Ghoshal, S. Comparative studies of mechanical and interfacial properties between jute and bamboo fiber- Reinforced polypropylene-based composites. J. Thermoplast. Compos. Mater. 2012, 25, 15–32. [Google Scholar] [CrossRef]

- Khan, M.A.; Hinrichsen, G.; Drzal, L.T. Influence of noble coupling agents on mechanical properties of jute reinforced polypropylene composites. J. Mater. Sci. Lett. 2001, 20, 1711–1713. [Google Scholar] [CrossRef]

- Kasim, A.N.; Selamat, M.Z.; Daud, M.A.M.; Yaakob, M.Y.; Putra, A.; Sivakumar, D. Mechanical properties of polypropylene composites reinforced with alkaline treated pineapple leaf fibre from Josapine cultivar. Int. J. Automotive Mech. Eng. IJAME 2016, 1, 3157–3167. [Google Scholar] [CrossRef]

- Kasim, A.N.; Selamat, M.Z.; Aznan, N.; Sahadan, S.N.; Daud, M.A.M.; Jumaidin, R.; Salleh, S. Effect of pineapple leaf fiber loading on the mechanical properties of pineapple leaf fiber–polypropylene composite. J. Teknologi 2015, 77, 117–123. [Google Scholar] [CrossRef]

- Ranganathan, N.; Oksman, K.; Nayak, S.K.; Sain, M. Regenerated cellulose fibers as impact modifier in long jute fiber reinforced polypropylene composites: Effect on mechanical properties, morphology, and fiber breakage. J. App. Polym. Sci. 2014, 132, 41301. [Google Scholar] [CrossRef]

- Berhanu, T.; Kumar, P.; Singh, I. Mechanical behaviour of jute fibre reinforced polypropylene composites. In Proceedings of the 5 th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Assam, India, 12–14 December 2014. [Google Scholar]

- Motaleb, K.Z.M.A.; Islam, S.; Hoque, M.B. Improvement of physicomechanical properties of pineapple leaf fiber reinforced composite. Int. J. Biomater. 2018. [Google Scholar] [CrossRef] [PubMed]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Lau, K.-T.; Hung, P.-Y.; Zhu, M.H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Sfondrini, M.F.; Cacciafesta, V.; Scribante, A. Shear bond strength of fibre-reinforced composite nets using two different adhesive systems. Eur. J. Orthod. 2011, 33, 66–70. [Google Scholar] [CrossRef]

- Cacciafesta, V.; Sfondrini, M.F.; Lena, A.; Scribante, A.; Vallittu, P.K.; Lassila, L.V. Flexural strengths of fiber-reinforced composites polymerized with conventional light-curing and additional postcuring. Am. J. Orthod. Dentofac. Orthop. 2007, 132, 524–527. [Google Scholar] [CrossRef]

- Lei, W.; Fang, C.; Zhou, X.; Li, Y.; Pu, M. Polyurethane elastomer composites reinforced with waste natural cellulosic fibers from office paper in thermal properties. Carbohydr. Polym. 2018, 197, 385–394. [Google Scholar] [CrossRef]

- Anand, R.S.; Daniel, F.C.; Rodney, E.J.; Roger, M.R. Renewable agricultural fibers as reinforcing fillers in plastics: Mechanical properties of kenaf fibers–polypropylene composites. Ind. Eng. Chem. Res. 1995, 34, 1889–1896. [Google Scholar]

- Ma, C.M.; Tseng, H.; Wu, H. Blocked diisocyanate polyester-toughened novolak-type phenolic resin: Synthesis, characterization, and properties of composites. J. Appl. Polym. Sci. 1998, 69, 1119–1127. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Chemical modification of henequen fibers with an organosilane coupling agent. Compos. Part B 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers and Biocomposites; Taylor & Francis, CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-Gonzalez, A. A study of the mechanical properties of short natural-fiber reinforced composites. Compos. Part B Eng. 2005, 36, 597–608. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: Effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Yuan, X. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. J. Reinf. Plast. Compos. 2012, 31, 425–437. [Google Scholar] [CrossRef]

- Liu, Q.; Stuart, T.; Hughes, M.; Sharma, H.S.S.; Lyons, G. Structural biocomposites from flax-part II: The use of PEG and PVA as interfacial compatibilising agents. Compos. Part A Appl. Sci. Manuf. 2017, 38, 1403–1413. [Google Scholar] [CrossRef]

- Carus, L.S.M. Targets for bio-based composites and natural fibres. JEC Compos. Mag. 2011, 8, 31. [Google Scholar]

- Mohanty, K.; Misra, M.; Drzal, L.T. Natural Fibres, Biopolymers and Biocomposites; Taylor & Francis, CRC Press: Oxfordshire, UK, 2005. [Google Scholar]

- Satyanarayana, K.G.; Pillai, S.K.G.; Pai, B.C.; Sukumaran, K. Lignocellulosic fibre reinforced polymer composite. In Handbook of Ceramic and Composites; Cheremisinoff, N.P., Ed.; Marcel Dekker: New York, NY, USA, 1990. [Google Scholar]

- Satyanarayana, K.G.; Sukumaran, K.; Mukherjee, P.S.; Pavithran, C.; Pillai, S.K.G. Natural fibre-polymer composites. Cem. Concr. Compos. 1990, 12, 117–136. [Google Scholar] [CrossRef]

- Arib, R.M.N.; Sapuan, S.M.; Hamdan, M.A.M.M.; Paridah, M.T.; Zaman, H.M.D.K. A literature review of pineapple fibre reinforced polymer composites. Polym. Polym. Compos. 2004, 12, 341–348. [Google Scholar] [CrossRef]

- Pavithran, C.; Mukherjee, P.S.; Brahmakumar, M.; Damodaran, A.D. Impact properties of natural fibre composites. J. Mater. Sci. Lett. 1987, 6, 882–884. [Google Scholar] [CrossRef]

- Mishra, S.; Misra, M.; Tripathy, S.S.; Nayak, S.K.; Mohanty, A.K. Potentiality of pineapple leaf fibre as reinforcement in PALF-polyester composite: Surface modification and mechanical performance. J. Reinf. Plast. Compos. 2001, 20, 321–334. [Google Scholar] [CrossRef]

- Harzallah, O.; Benzina, H.; Drean, J.-Y. Physical and mechanical properties of cotton fibers: Single-fiber failure. 2009, 80, 1093–2013. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Khan, R.A.; Khan, M.A.; Sultana, S.; Noor, F.G. Mechanical, degradation, and interfacial properties of synthetic degradable fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 29, 466–476. [Google Scholar] [CrossRef]

- Garcia, M.; Vliet, G.V.; Jain, S.; Zyl, W.E.V.; Boukamp, B. Polypropylene/SiO2 nano composites with improved mechanical properties. Rev. Adv. Mater. Sci. 2004, 6, 169–175. [Google Scholar]

- Karmaker, A.C.; Hinrichsen, G. Processing and characterization of jute fiber reinforced thermoplastic polymers. Polym. Plast. Technol. Eng. 1999, 30, 609–621. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. J. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Wambua, P.; Ivan, J.; Verport, I. Natural fibers: Can they replace glass in fiber reinforced plastics. J. Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Czvikovszky, T. Reactive recycling of multiphase polymer systems. Nucl. Instrum. Methods Phys. Res. B 1995, 105, 233–237. [Google Scholar] [CrossRef]

- Zhu, J.; Abhyankar, H.; Njuguna, J. Effect of fibre treatment on water absorption and tensile properties of flax/tannin composites. In Proceedings of the 11th International Conference on Manufacturing Research (ICMR2013), Bedford, UK, 19–20 September 2013; pp. 387–392. [Google Scholar]

- Kumar, B.; Lin, S.T. Redox state of iron and its related effects in the CaOP2O5- Fe2O3 glasses. J. Am. Ceram. Soc. 1991, 74, 226–229. [Google Scholar] [CrossRef]

- Ray, D.; Sarker, B.K.; Rana, A.K.; Bose, N.R. Effect of alkali treated jute fibres on composite properties. Bull. Mater. Sci. 2001, 24, 129–135. [Google Scholar] [CrossRef]

- Khan, R.A.; Parsons, A.J.; Jones, I.A.; Walker, G.S.; Rudd, C.D. Surface teatment of phosphate glass fibers using 2-Hydroxyethyl methacrylate: Fabrication of poly(caprolactone)-based composites. J. Appl. Polym. Sci. 2009, 111, 246–254. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).