Abstract

Increased loading rates on fasteners may be caused by high ground accelerations as a consequence of e.g., nuclear explosions, earthquakes or car collisions. It was concluded by Hoehler et al. (2006) that fasteners under rapid loading rates show an increased ultimate resistance in the concrete dominant failure modes or the ultimate resistance is at least as large as under quasi-static loading. Due to the increased demand on using fasteners in steel fiber reinforced concrete (SFRC), it is intended to show how the ultimate concrete cone capacity of fasteners changes under higher than quasi-static loading rate in normal plain concrete (PC) and in SFRC. This paper presents the results of an extensive experimental program carried out on single fasteners loaded in tension in normal plain concrete and in SFRC. The test series were conducted using a servo-hydraulic loading cylinder. The tests were performed in displacement control with a programmed ramp speed of 1, 100, 1000, and 3500 mm/min. This corresponded to calculated initial loading rates ranging between 0.4 and 1600 kN/s. The results of the tension tests clearly show that the rate-dependent behavior of fasteners in SFRC with 30 and 50 kg/m3 hooked-end-type fibers fits well to the previously reported rate-dependent concrete cone behavior in normal plain concrete. Additionally, a positive influence of the fibers on the concrete cone capacity is clearly visible.

1. Introduction and Motivation

Impact loads acting on concrete structures or on structural components are of common occurrence. Examples for that include nuclear explosions, earthquakes and collision of vehicles. Engineering structures may be subjected to functional impact loads such as pile driving. As a part of the whole, fasteners in safety relevant applications may also be subjected to high loading rates and high impact loads over their service life.

It is well known that concrete shows strong rate-dependent behavior. Concrete, even if unloaded, always shows micro-cracking, mainly at the matrix-to-particle interfaces [1]. Under loading, the cracks propagate and a tensile failure occurs after the cracks exceed a critical crack length i.e., after excessive cracking. The crack growth rate is affected by the loading rate. In order to reach a critical crack size, at which the concrete fails, a certain amount of time is required. In the case of static tests and at very low loading rates i.e., sustained loads, the cracks can extend to zones in the concrete where the concrete tensile strength and/or the bond is the lowest [2]. Under low loading rates, the opening crack has enough time to follow the path of minimum resistance. If concrete is subjected to high loading rates, the fracture takes places within a very short time span (milliseconds). Therefore, the cracks are not always able to propagate into the zones with lowest resistance. Instead, the cracks will extend to concrete fracture areas with higher strengths e.g., due to crossing aggregates. This, however, requires more energy and consequently the resistance under increased and impact loads must be higher. The ultimate strain under impact loads is also greater than for static loads [2]. As aforementioned, under high loading rates, the crack cannot find the weakest path, and therefore the cracking will develop at various sections involving greater fracture areas. Crack branching may also take place, and therefore the sum of the ultimate strain is expected to be higher [2]. Another aspect that dominates the structural response at very high loading rates e.g., impact is structural inertia.

The available studies on the rate-dependent behavior of concrete emphasizes the influence of loading rate on the ultimate capacity, crack pattern and the failure mode of concrete. Three effects govern the rate-dependent concrete behavior: (1) creep of bulk material between the opening cracks, which effect dominates at very slow strain rates < 10−8 s−1, i.e., sustained loads, (2) rate dependency related to the crack initiation at moderate strain rates 10−5–101 s−1, and (3) the activation of structural inertia forces at very high strain rates > 101 s−1 (impact load) [3,4]. However, in the latter case, the rate dependency cannot be neglected.

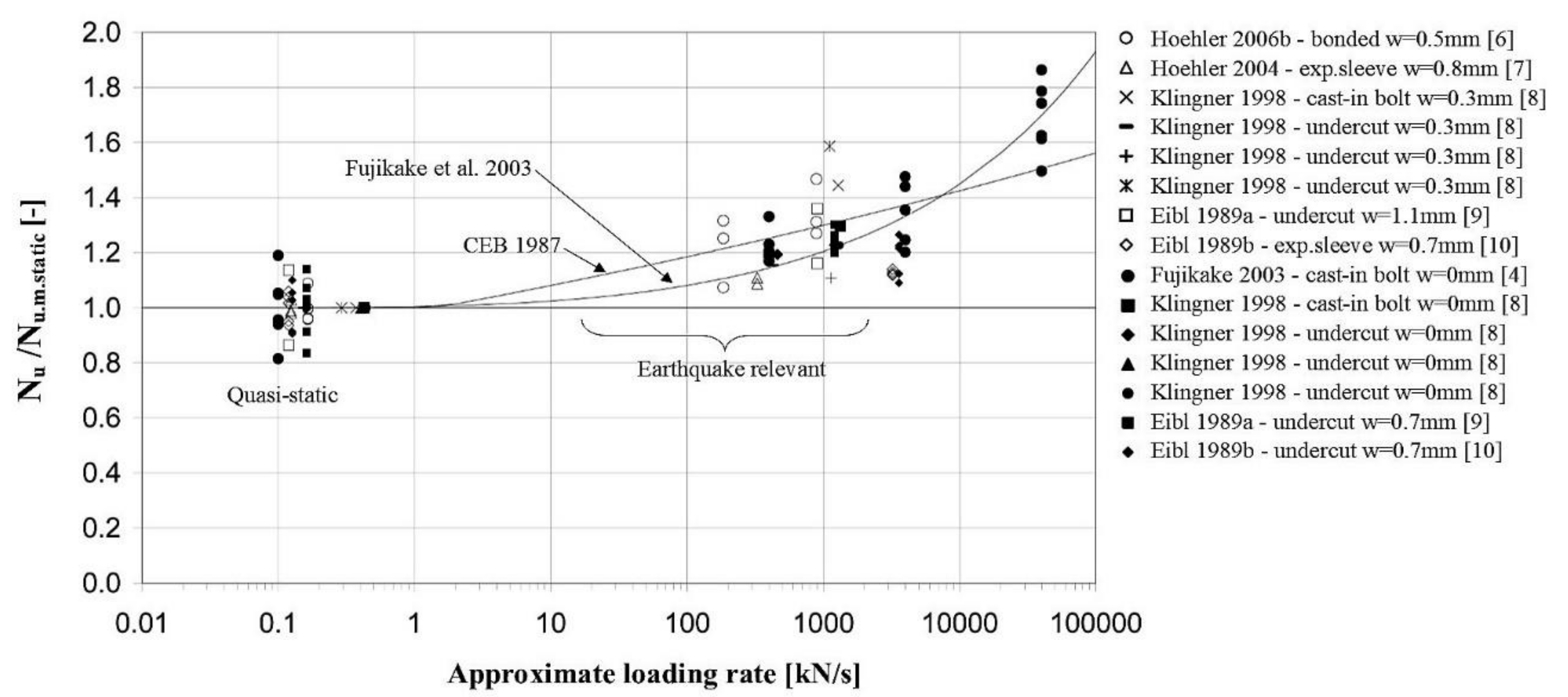

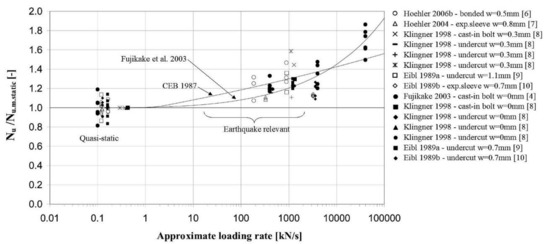

The rate-dependent concrete behavior also applies for fasteners failing by concrete cone failure ([3,5,6,7,8,9,10,11]). Based on the available results regarding the rate-dependent behavior of fasteners in the case of concrete breakout failure, Hoehler et al. [6] concluded that the ultimate capacity of fasteners is at least as high when subjected to rapid loading rate, as under quasi-static loading. Since this data set includes test results carried out using various fastener types (undercut anchors, metal expansion anchors, bonded anchors ([5,6,7,8,9,10,11]), it can be assumed that the observed increase of the capacity is independent of the type of anchor and concrete strength, provided concrete cone failure occurs. In the earthquake-relevant loading range (5 × 10−3–5 × 10−1 s−1), the highest reported dynamic increase factor is 1.6 and approximately 1.2 on average compared to the static reference value (Figure 1). At loading rates higher than 3000 kN/s, only limited experimental data are available (Fujikake, 2003 [5]). The highest reported loading rate was approximately 50,000 kN/s which corresponded to an increase of about 70%.

Figure 1.

Influence of loading rate on the load-bearing behavior of fasteners in the case of concrete breakout failure, Reproduced with permission from [6]. Hoehler, M.S. Behavior and Testing of Fastenings to Concrete for use in Seismic Applications. Ph.D. Thesis, Institut für Werkstoffe im Bauwesen, Universität Stuttgart, Stuttgart, Germany, 2006.

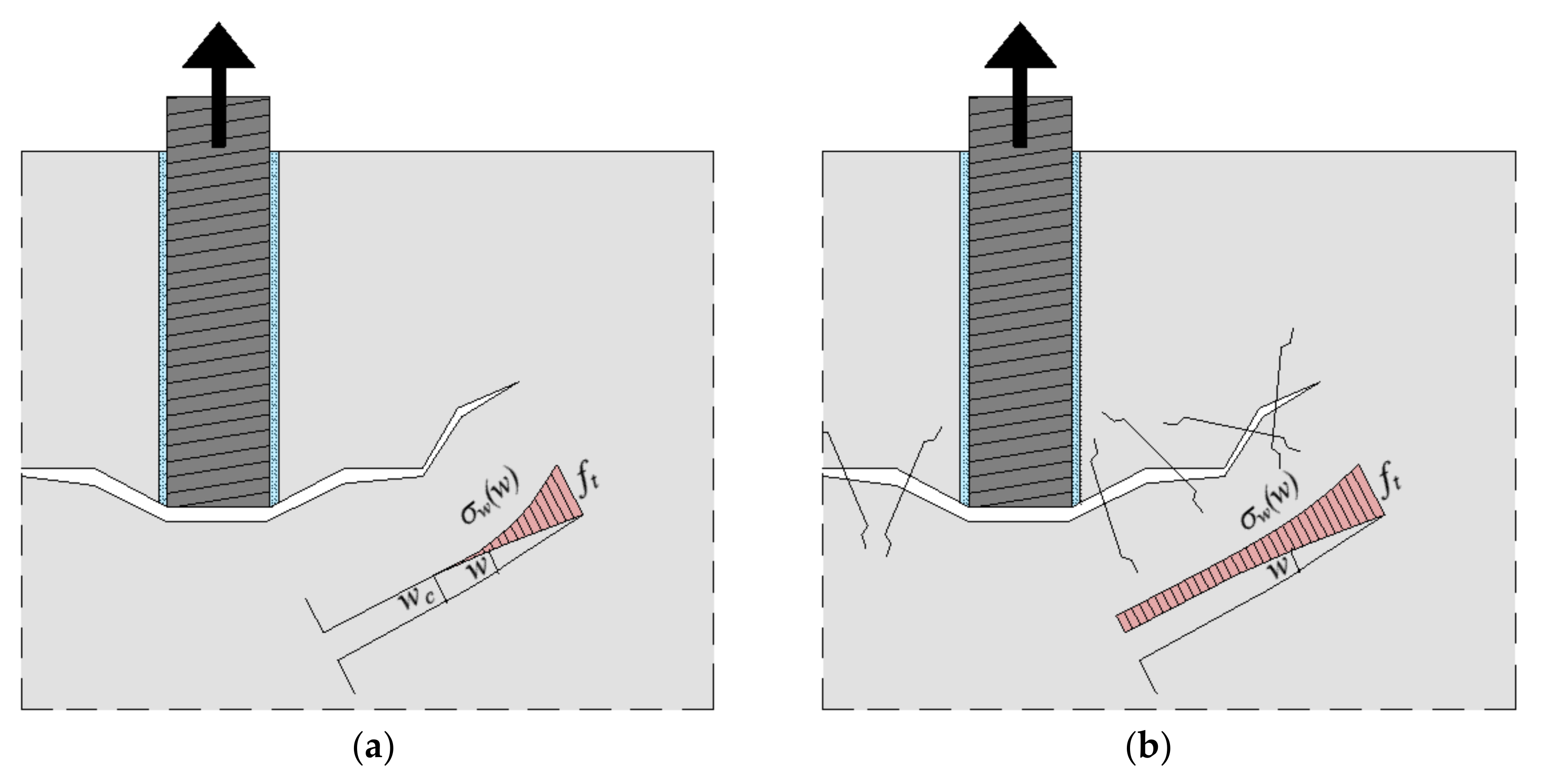

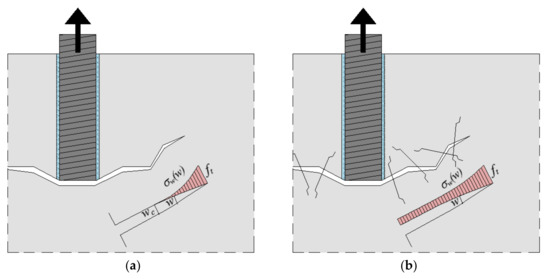

In engineering structures, which are likely to be subjected to increased loading rates and impact loads, the use of e.g., steel fiber reinforced concrete (SFRC) and high-performance fiber reinforced cementitious composites (HPFRCC) has become a good alternative for construction material due to their better mechanical and physical properties. There is extensive research available in the field of SFRC for structural and non-structural applications, which confirms the beneficial effects including higher fracture energy, limited crack widths, higher impact and abrasion resistance, and increased durability compared to plain concrete [12,13,14,15,16]. However, there is only little research available on the load-bearing behavior of fasteners, which are installed in base materials other than plain concrete such as SFRC [17,18,19,20,21,22]. The evaluation of results from the literature shows that with the right choice of installation parameter combinations, the fiber content has a positive effect on the load-displacement behavior of the anchorages, in general, and a better utilization of fastening systems can be attained due to the more ductile behavior and due to the crack bridging mechanism of the SFRC (Figure 2). However, no studies were found in the literature that focus on the load-displacement behavior of fasteners installed in SFRC subjected to higher than quasi-static or impact tension loading rates.

Figure 2.

Crack propagation in the anchoring zone of an anchor in (a) plain concrete and (b) in SFRC.

The aim of this study is, therefore, to investigate the behavior of single fasteners in SFRC under increased loading rates. The performed experimental study includes tension tests on single fasteners with four different loading rates ranging between 0.4 and 1600 kN/s in plain concrete and in SFRC with an amount of 30 and 50 kg/m3 hooked-end type fibers, respectively.

2. Experimental Investigations

2.1. Test Program

In this experimental program, a total of 58 tension loading tests were performed on single bonded fasteners at the Institute of Construction Materials, University of Stuttgart. The investigated parameters were the loading rate and the amount of fibers dispersed in the concrete. For the experiments, concrete specimens with 0, 30 and 50 kg/m3 fiber content were cast. The designated loading rates were 0, 100, 1000, and 3500 mm/min. The embedment depth of the fasteners and the diameter were selected such that other failure modes than concrete cone failure were not decisive. The calculated failure load corresponding to bond failure and steel failure load were significantly higher than the estimated ultimate concrete cone breakout failure load. The embedment depth was kept at hef = 70 mm uniformly and the edge distance was greater than the critical edge distance (1.5 hef). The test program and the test parameters are tabulated in Table 1. In general, four to five tests were performed in each test series. The nomenclature is given for the tests as (T tension loading; desired loading rate in mm/min; fiber content in kg/m3; and test number).

Table 1.

Test program: tension loading tests on single fasteners in NSC and in SFRC. Displ.: Displacement control.

2.2. Test Specimen

Plain and steel fiber reinforced concrete members with 30 and 50 kg/m3 steel fiber content served as base material for the tests according to the test program given in Table 1. The geometry of the concrete specimens enabled the formation of the full size concrete breakout bodies without influencing the neighboring fasteners. The concrete mix used for the experiments is given in Table 2. The production of the normal plain concrete and SFRC test members were carried out in three steps in order to ensure that the same basic mix is used for the SFRC members with 30 and 50 kg/m3 fiber dosage. First, the plain concrete members using the basic mix were cast (0 kg/m3). Second, the 30 kg/m3 amount of steel fibers was added to the fresh basic mix. The fibers were dispersed uniformly to the freshly mixed basic concrete mix, and to ensure the lump-free state of fibers in the mixture the mixer was rotated at full speed continuously for approximately 3 to 5 min. The SFRC specimens with 30 kg/m3 fiber content were cast, subsequently. Then, the second step was repeated by adding the required amount of steel fibers to obtain 50 kg/m3 steel fiber into the mix. To improve the workability of concrete, the amount of superplasticizer was increased from 1.93 to 2.54 (M% of cement) after increasing the fiber amount to 50 kg/m3. The compaction was performed by using an internal vibrator. The above-described technological steps enabled the direct comparison of the results in plain concrete and in SFRC.

Table 2.

Concrete mix and concrete mechanical properties. Cem.: Cement; Aggr.: Aggregate; Compr.: Compressive; Flex.: Flexural.

Note that in order to ensure a sufficient bond between the cement matrix and the fibers, the maximum aggregate size (Dmax) should not exceed one-third of the fiber length. The maximum aggregate size of the mix was Dmax = 8 mm and the hooked-end type fibers (nominal tensile strength 1200 N/mm2) with nominal wire diameter of d = 0.75 mm and nominal fiber length of Lfiber = 35 mm (HE 75/35 ArcelorMittal) were used [23].

The compressive strength of the test specimens was measured on concrete cubes with a side length of a = 150 mm according to DIN EN 12390-15 [24]. The measured mean concrete cube compressive strength fcc of the test specimen is given in Table 2. The flexural tensile strength (modulus of rupture) of concrete was measured by three-point bending tests according to the recommendations given by RILEM TC 162-TDF [25] on concrete specimens of size 70 cm × 15 cm × 15 cm. The flexural tensile strength values are given in Table 2.

2.3. Tested Fasteners and Test Setup

A shock-approved injection type adhesive system was used for the tension tests. The adhesive system consisted of an epoxy mortar with a mean bond strength of ca. τ = 35 N/mm2 and a steel component, namely 12.9 threaded rod (fu.nom = 1200 N/mm2) of size M16. The fasteners were installed according to the corresponding Manufacturer’s Printed Installation Instructions (MPII). Cylindrical holes were drilled perpendicular to the concrete surface. After drilling, the holes were cleaned according to the MPII and the fasteners were installed. After the prescribed curing time, the fixtures were positioned on the fasteners and subsequently the tests were carried out with quasi-static or increased loading rate according to the test program (Table 1).

In the quasi-static monotonic tests with a loading rate of 1 mm/min, the load was applied under the control of the servo-hydraulic cylinder displacement while continuously measuring the load and the displacement of the anchor. The ultimate load was reached in approximately 1 to 4 min, which corresponds to the loading rate recommended for the static tests of fasteners according to ETAG Annex A [26]. These test series are considered as reference tests for the series with increased loading rates in the corresponding concrete mixes. For the tests with increased loading rate, the testing cylinder was actuated at the corresponding rate namely 100 mm/min, 1000 mm/min and 3500 mm/min.

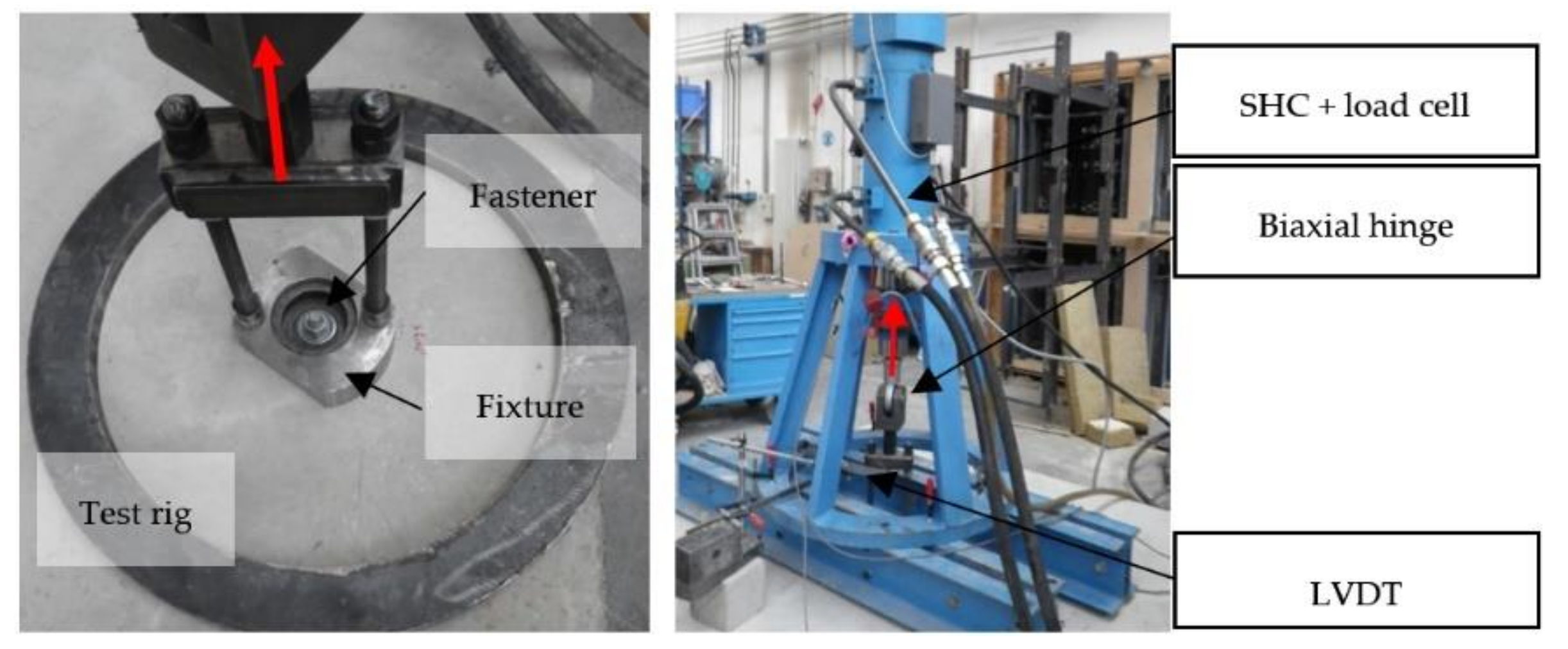

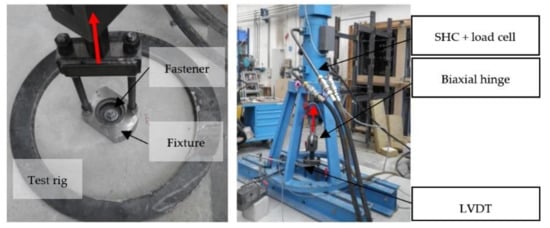

The test setup consisted of a tension test rig with adequate spacing to allow the formation of an unrestricted concrete cone, a servo-hydraulic cylinder with a built-in calibrated load cell and a displacement transducer. The tension load was applied to the anchors through the fixture. The loading fixture was connected to a biaxial hinge to transfer the centric tension load from the hydraulic cylinder to the fastener. The tension load applied to the fastener; the displacement of the servo-hydraulic cylinder and the vertical anchor displacement were measured and recorded continuously during all tests. The vertical anchor displacement was measured at the anchor top by means of Linear Variable Displacement Transformer (LVDT). The test setup used for the tension tests is depicted in Figure 3. Note that the cylinder displacement and the vertical anchor displacement are not necessarily equal due to the non-perfect alignment and steel elongations of the different steel parts. By measuring the anchor displacement directly on the anchor top, the displacement due to the steel elongation in the force flow can be neglected in the evaluation of the results.

Figure 3.

Typical test setup used for the tension tests on single anchors.

3. Test Results

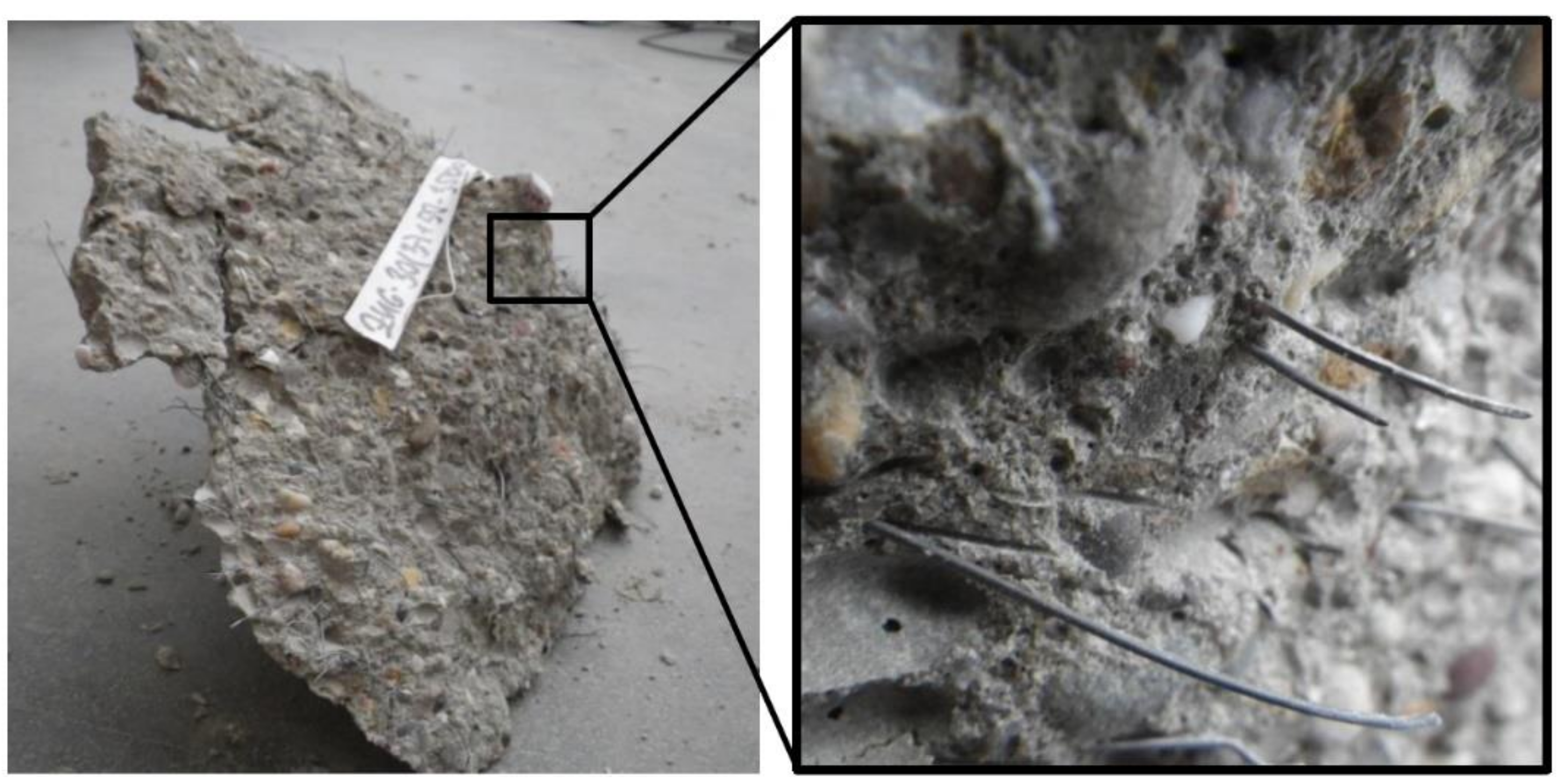

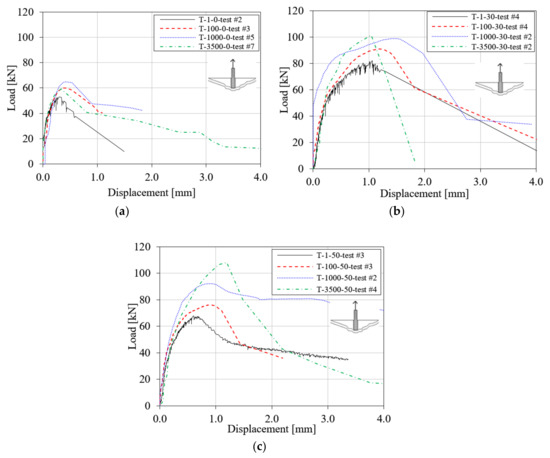

In this section, the results of the experiments are presented. The ultimate load of each executed test, the mean value of the ultimate loads with the corresponding coefficient of variation (CoV) of the particular test series and the mean displacements at ultimate loads are given in Table 3. The percentage increase in the mean failure loads for the tests with increased loading rates to the corresponding tests with quasi-static loading rates for each base material are also given in Table 3. In all tests, concrete cone failure mode was observed. The typical concrete cone breakout body is shown in Figure 4. The comparison of load-displacement curves of the tension tests is shown in Figure 5. Each graph presents the results of the test series in one particular base material, namely in normal plain concrete, in SFRC with 30 kg/m3 and in SFRC with 50 kg/m3 fiber content. Note that only the representative load-displacement curves of the tension tests at different loading rates are given.

Table 3.

Test results: tension loading tests on single fasteners in NSC and in SFRC. Displ.: Displacement; w.r.t.ref.: with respect to reference.

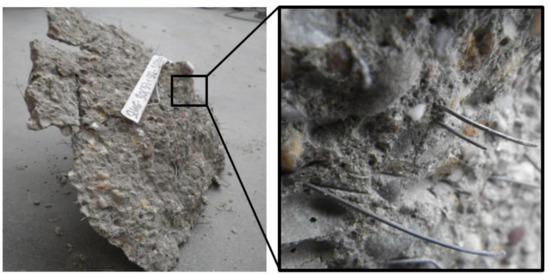

Figure 4.

Typical concrete cone failure mode in SFRC, Test ID: T-3500-50-test #4.

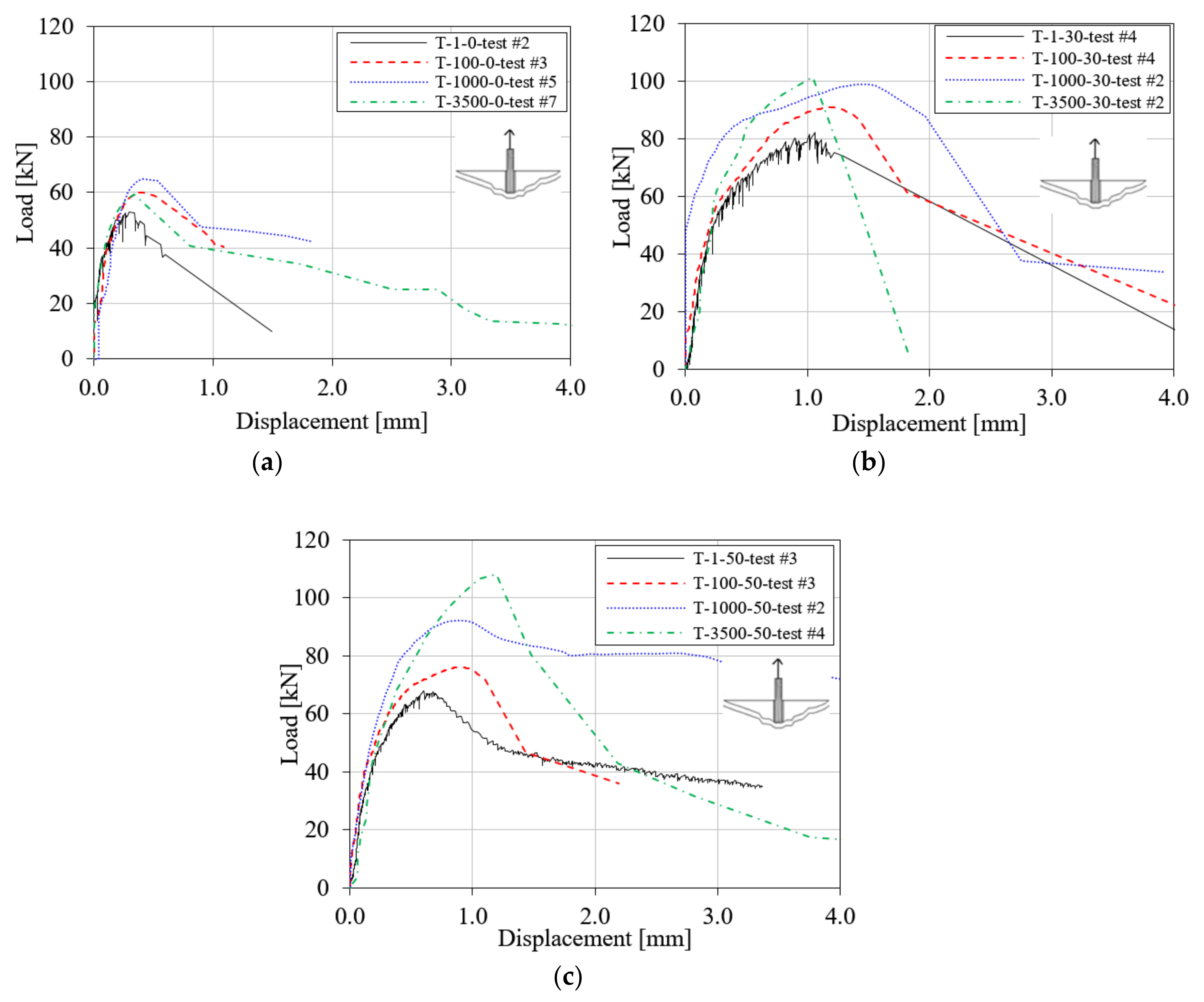

Figure 5.

Representative load-displacement curves of the tension tests at different loading rates (a) in normal plain concrete, (b) in SFRC with 30 kg/m3 steel fiber content and (c) in SFRC with 50 kg/m3 steel fiber content.

The positive influence of fiber content on the load-displacement behavior of tension-loaded single anchors was observed at all loading rates. At all displacement rates, not only the ultimate loads but also the displacement at ultimate load increased by adding fibers to the concrete (Table 3). The mean ultimate concrete cone capacity under quasi-static loading increased by 50% and 35% by adding 30 and 50 kg/m3 to the concrete mix, respectively. This can be attributed to the scatter of the concrete cone failure and to the actual number of fibers intercepted by the concrete cone. These results highlight the fact that SFRC is quite an inhomogeneous material and that the fiber distribution as well as fiber orientation plays a major role in governing the behavior of the anchorages. At displacement rates (100–1000–3500 mm/min), a similar relative increase of the ultimate concrete cone capacity in normal plain concrete and in SFRC was observed. By adding 30 and 50 kg/m3 fiber to the concrete, the increase due to fiber addition was 43% and 31% at 100 mm/min, 47% and 37% at 1000 mm/min and 45% and 53% at 3500 mm/min displacement rate, respectively. However, it was also observed that compared to the basic mix without fibers, the increase in the ultimate load was less in the case of 50 kg/m3 than 30 kg/m3 steel fiber content at displacement rates of 1 to 1000 mm/min. Similar to the results with the quasi-static loading rate, this can be attributed to the scatter of the test results.

By increasing the loading rate, the mean concrete cone capacity increases in all concrete mixes, in general. In normal plain concrete, the concrete cone capacity shows a relative increase of 22–23% at loading rates of 480 kN/s to 1500 kN/s. In SFRC, a similar relative increase of the ultimate concrete cone capacity was observed. In SFRC with 30 kg/m3 steel fiber content, an 18–21% increase was measured at 550 kN/s to 1600 kN/s loading rates. The results by adding 50 kg/m3 steel fibers to the concrete mix show a slightly higher rate dependency, namely 25% at 530 kN/s and 37% at 1500 kN/s.

4. Discussion

4.1. Influence of Steel Fiber Reinforcement

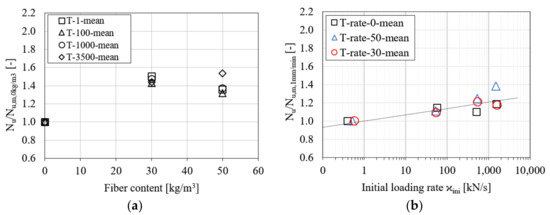

The concrete cone capacity of the single fasteners loaded in tension was improved by adding steel fibers to the basic mix and by increasing the loading rate. The observed increase fits well to the tendency reported by Nilforoush et al. in Reference [20]. The increase due to fiber addition can be attributed to the fact that the fibers intercepted by the fracture surface provide additional resistance and contribute to the load-bearing capacity. The ultimate loads and the displacement at ultimate load increased at all loading rates. Since the steel fibers increase the fracture energy of the concrete [13], it is intuitive that if a sufficient amount of fiber intercepts the fracture surface, the concrete breakout capacity increases. After the crack initiation in SFRC, the overbridging fibers are able to transmit tensile stresses over the crack into the surrounding concrete, which leads to an optimized stress-redistribution and results in better performance. The positive influence of 30 and 50 kg/m3 fiber content on the ultimate concrete cone capacity is shown in Figure 6a.

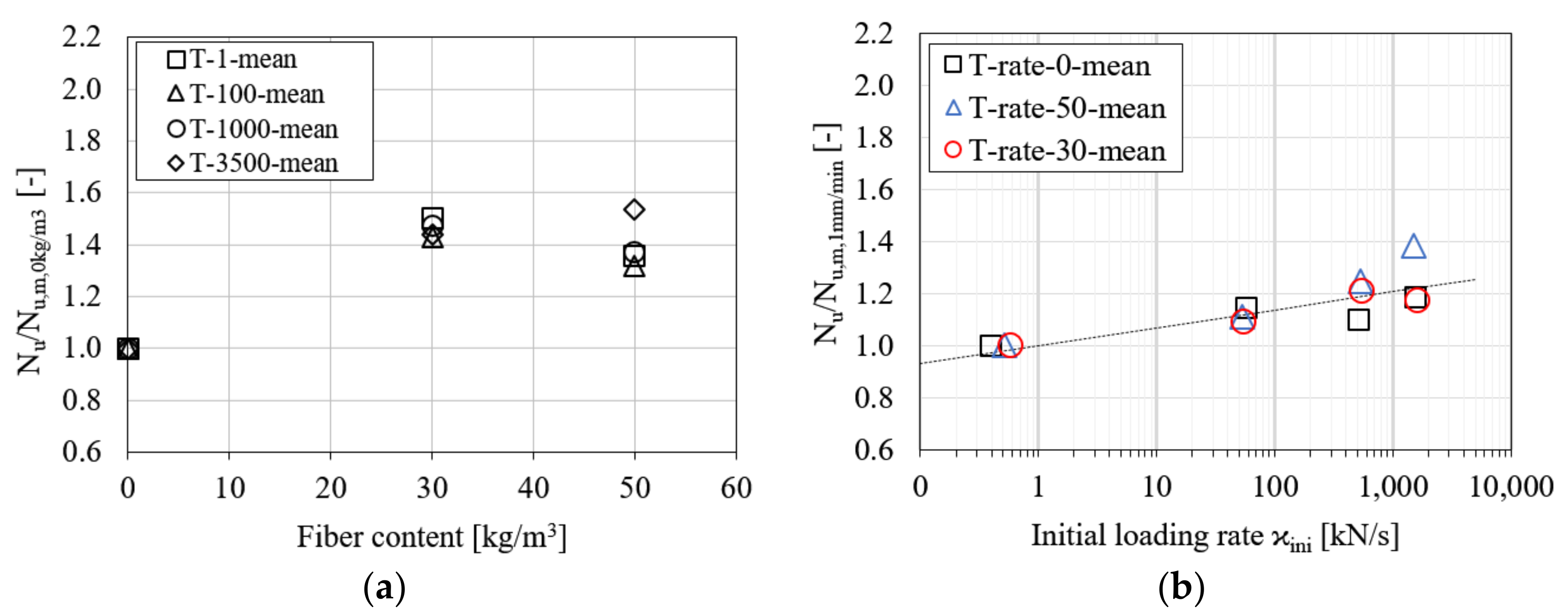

Figure 6.

(a) Influence of fiber content on the ultimate concrete cone resistance of fasteners; (b) influence of loading rate on the ultimate concrete cone resistance of fasteners.

4.2. Influence of Loading Rate

The better performance of the fasteners at increased loading rates in both plain concrete and in SFRC can be explained by the rate-dependent concrete behavior, which applies for fasteners when the decisive failure mode under tension loading is concrete cone failure. The results of tension tests on single fasteners clearly show that the rate-dependent behavior of fasteners in SFRC with hooked-end fibers fits well with the previously reported rate-dependent concrete cone behavior in normal plain concrete [3,5,6] (see Figure 6b).

The observed increase in the ultimate concrete cone capacity at 3500 mm/min ramp speed (calc. 1500 kN/s initial loading rate) in normal plain concrete is 22.6% and in SFRC the increase ranges between 18% and 37%. Based on the presented results, the dynamic increase factor (DIF), which represents the ratio between the dynamic and quasi-static ultimate load at moderate loading rates, can be approximated by the following function: DIF(Nu) = 1 + [ln(κini)]/300, where κini is the initial loading velocity measured as (0.5Nu/t0.5Nu). The test results, on which the proposed equation is based on, show a rather small scatter (see Table 3). According to the experience, the scatter of the concrete cone failure load of fasteners may reach 15% in PC, which is accounted for in Reference [27]. Note that the scatter of the ultimate loads was calculated for each executed test series. Only in one case, (+50 kg/m3 SFRC, loading rate 100 mm/min) the calculated CoV was 17%. Note that the proposed DIF(Nu) is valid only for the experimentally covered loading rate range, namely up to 1500 kN/s. At higher loading rates, the activation of the structural inertia forces shall lead to the progressive increase of the concrete cone capacity. This loading rate range is beyond the scope of this current experimental study.

The concrete cone capacity of tension-loaded fasteners is mainly dependent on the concrete fracture energy, concrete tensile strength and on the embedment depth of the anchor [27]. Therefore, it is intuitive that the findings on the rate dependency of the fracture energy and tensile strength measured on SFRC flexural members can be applied to the concrete tensile failure governed failure modes in fastening technology, such as concrete cone failure of fasteners loaded in tension.

It was concluded by Ulzurrun and Zanuy [28] that the pullout of the smooth straight fibers from the concrete matrix is primarily governed by the bond stress-slip mechanism. However, this does not apply for the hooked-end type fibers, where a significant part of the pullout strength of the fibers is provided by the end anchorage (mechanical interlock). In the case of the pullout of hooked-end type fibers from the matrix, first the plastic hinge formation of the curved hook sections will occur. This is, however, less rate-sensitive than the concrete mechanical properties in SFRC. This explains that the observed rate dependence of the concrete cone failure load of fasteners in SFRC is comparable with the rate dependence in plain concrete, provided that the same concrete basic mix and installation parameters for the fasteners are used.

It is believed that at very high loading rates (impact loads), fasteners installed in SFRC exhibit the same dynamic increase factor as those installed in plain concrete. This can be explained by the fact that at very high loading rates, the influence of structural inertia on the response becomes dominant and this influence is much larger than the influence of the crack growth rate, which is dominant at moderate high loading rates [3]. This aspect is currently being investigated by the authors and will be presented in another paper.

5. Conclusions

In this paper, the results of an experimental program on the investigation of the concrete cone capacity of tension-loaded fasteners under quasi-static and moderately high loading rates in normal and steel fiber reinforced concrete are reported. Based on the results, the following concluding remarks were made:

The beneficial effect of the presence of steel fibers in the concrete on concrete cone capacity of anchors was shown. Compared to the measured concrete cone capacity in normal plain concrete, the increase of concrete cone capacity in SFRC (30 kg/m3 and 50 kg/m3) was 22% to 37% under quasi-static loading. The results fit well with the findings of Reference [20]. Based on the results, it seems reasonable to introduce a modification factor that accounts for the beneficial effect of the presence of steel fibers in the concrete and which is proportional to the amount of steel fibers dispersed into the concrete. However, due to the contradictory results reported in References [17,18], the beneficial effect of steel fibers in the concrete on the concrete cone capacity of fasteners must be addressed in further studies with particular emphasis on the installation parameters (embedment depth, steel fiber length, steel diameter, bond strength etc.). Further research and the systematic investigation of the above parameters is necessary for design recommendations for the use of fasteners in SFRC. This is currently being done by the authors and will be presented in another paper.

The concrete cone capacity increases linearly as a function of the increasing loading rate in semi log. Scale. The observed mean dynamic increase factor was 1.2 at ca. 1500 kN/s loading rate. This relative dynamic increase factor seems to be valid if fasteners fail by concrete cone in normal plain concrete as well as in steel fiber reinforced concrete. This corresponds well to the experimentally shown dynamic increase factors in Reference [5] as well as to the numerically predicted rate-dependent concrete cone behavior [3]. Although the shown experimental data cover the loading rate up to moderately high loading rates, a progressive increase of the resistance due to structural inertia forces is expected to be valid for both normal and steel fiber reinforced concrete when subjected to very high loading rates. However, further experiments are required at high loading rates on the concrete cone behavior to verify the above assumptions.

The pull-out tests failing by concrete cone have also shown the increase of the ultimate displacement when subjected to increased loading rates. The relative increase of the ultimate displacement in normal plain concrete was 33% when subjected to ca. 1500 kN/s. The increase of the ultimate displacement was slightly higher, 36% and 68% in SFRC with 30 kg/m3 and 50 kg/m3 steel fiber content.

Author Contributions

M.T.; B.B. and A.S. conceived and designed the experiments; M.T. and B.B. performed the experiments and analyzed the data; M.T.; B.B. and A.S. wrote the paper.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Stroeven, P. Some Aspects of the Micromechanics of Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, February 1973. [Google Scholar]

- Reinhardt, H.W. Concrete under impact loading Tensile strength and Bond. HERON 1982, 27, 1982. [Google Scholar]

- Ozbolt, J.; Rah, K.K.; Mestrovic, D. Influence of loading rate on concrete cone failure. Int. J. Fract. 2006, 139, 239–252. [Google Scholar] [CrossRef]

- Ozbolt, J.; Sharma, A.; Reinhardt, H.W. Dynamic fracture of concrete—Compact tension specimen. Int. J. Solids Struct. 2011, 48, 1534–1543. [Google Scholar] [CrossRef]

- Fujikake, K.; Nakayama, J.; Sato, H.; Mindess, S.; Ishibashi, T. Chemically Bonded Anchors Subjected to Rapid Pullout Loading. ACI Mater. J. 2003, 100, 246–252. [Google Scholar]

- Hoehler, M.S. Behavior and Testing of Fastenings to Concrete for use in Seismic Applications. Ph.D.Thesis, Institut für Werkstoffe im Bauwesen, Universität Stuttgart, Stuttgart, Germany, 2006. [Google Scholar]

- Hoehler, M.S. Influence of earthquake relevant tensile loading rates on fastener failure mode. Institut für Werkstoffe im Bauwesen, Universität Stuttgart, Stuttgart, Germany, 2006. Report, Not published. [Google Scholar]

- Hoehler, M.S. Tension Cycling of Fasteners at High Load Levels (Extension of Series A2 to HIGH Load Rates): Series A4–Test Report; Institut für Werkstoffe im Bauwesen, Universität Stuttgart: Stuttgart, Germany, 2004. [Google Scholar]

- Klingner, R.E.; Hallowell, J.M.; Lotze, D.; Park, H.-G.; Rodriguez, M.; Zhang, Y.-G. Anchor Bolt Behavior and Strength during Earthquakes; NUREG/CR-5434; Prepared at University of Texas at Austin, Prepared for U.S. Nuclear Regulatory Commission: Washington, DC, USA, 1998. [Google Scholar]

- Eibl, J.; Keintzel, E. Zur Beanspruchung von Befestigungsmitteln bei Dynamischen Lasten (On the Dynamic Loading of Fastenings); Institut für Massivbau und Baustofftechnologie, Universität Karlsruhe: Karlsruhe, Germany, 1989. (In German) [Google Scholar]

- Eibl, J.; Keintzel, E. Verhalten von Dübeln unter Hoher Stoß- und Wechselbeanspruchung (Behavior of Anchors under High Speed Impact and Reversed Cyclic Loads); Institut für Massivbau und Baustofftechnologie, Universität Karlsruhe: Karlsruhe, Germany, 1989. (In German) [Google Scholar]

- Balaguru, P.N.; Shah, S.P. Fiber-Reinforced Cement Composites; McGraw-Hill: New York, NY, USA, 1992; ISBN 0070564000. [Google Scholar]

- Mechtcherine, V. Rissbeherrschung durch Faserbewehrung, Beherrschung von Rissen in Beton. In Proceedings of the 7 Symposium Baustoffe und Bauwerkserhaltung, Karlsruher Institut für Technologie, Karlsruhe, Germany, 23 March 2010; Müller, H., Nolting, U., Haist, M., Eds.; KIT Scientific Publishing: Karlsruhe, Germany, 2010; pp. 83–94. [Google Scholar]

- Døssland, Ä.L. Fibre Reinforcement in Load Carrying Concrete Structures. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, February 2008. [Google Scholar]

- Schulz, M. Stahlfasern: Eigenschaften und Wirkungsweisen. Beton-Düsseldorf 2000, 50, 382–387. [Google Scholar]

- Naaman, A.E.; Reinhardt, H.W. International Workshop Series on High Performance Fiber Reinforced Cement Composites (HPFRCC): History and Evaluation. In Proceedings of the 7th RILEM Workshop on High Performance Fiber Reinforced Cement Composites, Stuttgart, Germany, 1–3 June 2015; Department of Construction Materials, University of Stuttgart: Stuttgart, Germany, 2015; pp. 3–10, ISBN 978-2-35158-145-2. [Google Scholar]

- Klug, Y.; Holschemacher, K.; Wittmann, F. Tragverhalten von Befestigungselementen in Stahlfaserbeton. In Faserbeton; König, G., Holschemacher, K., Dehn, K., Eds.; Bauwerk Verlag: Berlin, Germany, 2002; pp. 89–105. ISBN 3-89932-019-0. [Google Scholar]

- Kurz, C.; Thiele, C.; Schnell, J.; Reuter, M.; Vitt, G. Tragverhalten von Dübeln in Stahlfaserbeton. Bautechnik 2012, 89, 545–552. [Google Scholar] [CrossRef]

- Coventry, K.; Richardson, A.; Intyre, C.M.; Aresh, B. Pullout Performance of Chemical Anchor Bolts in Fibre Concrete. In Proceedings of the Fibre Concrete 2011–6th International Conference, Czech Technical University, Prague, Czech Republic, 8–9 September 2011. [Google Scholar]

- Nilforoush, R.; Nilsson, M.; Elfgren, L. Experimental evaluation of tensile behaviour of single cast-in-place anchor bolts in plain and steel fibre-reinforced normal- and high-strength concrete. Eng. Struct. 2017, 147, 195–206. [Google Scholar] [CrossRef]

- Bokor, B.; Tóth, M.; Sharma, A. Influence of steel fiber content on the load-bearing capacity of anchorages in concrete. In Proceedings of the 3rd International Symposium on Connections between Steel and Concrete, Stuttgart, Germany, 27–29 September 2017; Sharma, A., Hofmann, J., Eds.; Institute of Construction Materials, University of Stuttgart: Stuttgart, Germany, 2017; pp. 1258–1269, ISBN 978-3-945773-06-2. [Google Scholar]

- Bokor, B.; Tóth, M.; Sharma, A.; Hofmann, J. Zugtragfähigkeit von Befestigungen in stahlfaserverstärkten Betonen—Experimentelle Untersuchungen, “Neues aus der Befestigungstechnik“. In Proceedings of the 5th Jahrestagung des DAfStb, TU Kaiserslautern, Kaiserslautern, Germany, 20–21 September 2017. [Google Scholar]

- Technical Data Sheet: Hooked-End Steel Fibers HE 75/35, ArcelorMittal. Available online: http://ds.arcelormittal.com/wiresolutions/steelfibres/products/hooked_end_fibres_he/language/EN (accessed on 7 April 2017).

- DIN EN 12390-1:2012-12. Prüfung von Festbeton—Teil 1: Form, Maße und Andere Anforderungen für Probekörper und Formen; Deutsche Fassung EN 12390-1:2012; DIN Deutsches Institut für Normung e. V., Beuth Verlag GmbH: Berlin, Germany, 2012. [Google Scholar]

- Vandewalle, L.; Nemegeer, D.; Balazs, L.; Di Prisco, M. Recommendations of RILEM TC 162-TDF: Test and design methods for steel fibre reinforced concrete: Bending test. Mater. Struct. 2002, 35, 579–582. [Google Scholar]

- Annex A: Details of Tests. In ETAG 001 Guideline for European Technical Approval of Metal Anchors for Use in Concrete; Edition 1997; EOTA: Brussels, Belgium, 2013.

- Eligehausen, R.; Mallée, R.; Silva, J.F. Anchorage in Concrete Construction; Ernst & Sohn: Berlin, Germany, 2006; ISBN 978-3-433-01143-0. [Google Scholar]

- Ulzurrun, G.; Zanuy, C. Flexural response of SFRC under impact loading. Constr. Build. Mater. 2017, 134, 397–411. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).