Influence of Furfuryl Alcohol Fiber Pre-Treatment on the Moisture Absorption and Mechanical Properties of Flax Fiber Composites

Abstract

1. Introduction

2. Materials and Methods

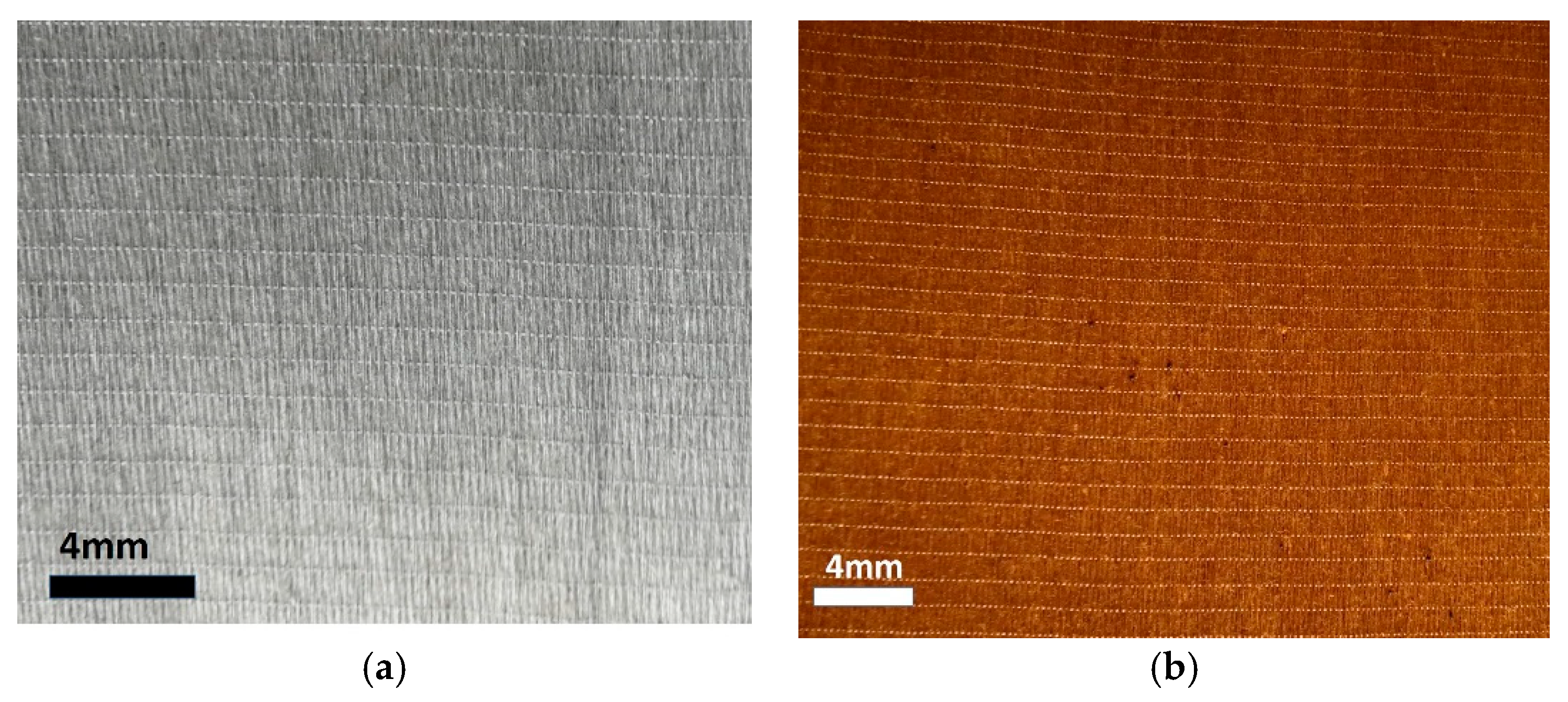

2.1. Bio-Based Epoxy Matrix and Flax Fibers

2.2. Furfuryl Alcohol Treatment on Flax Fibers

2.3. Composite Manufacturing

2.4. Water Absorption

2.5. Mechanical Tests on Composites

2.6. Tensile Tests on Flax Fiber Bundles (Yarns)

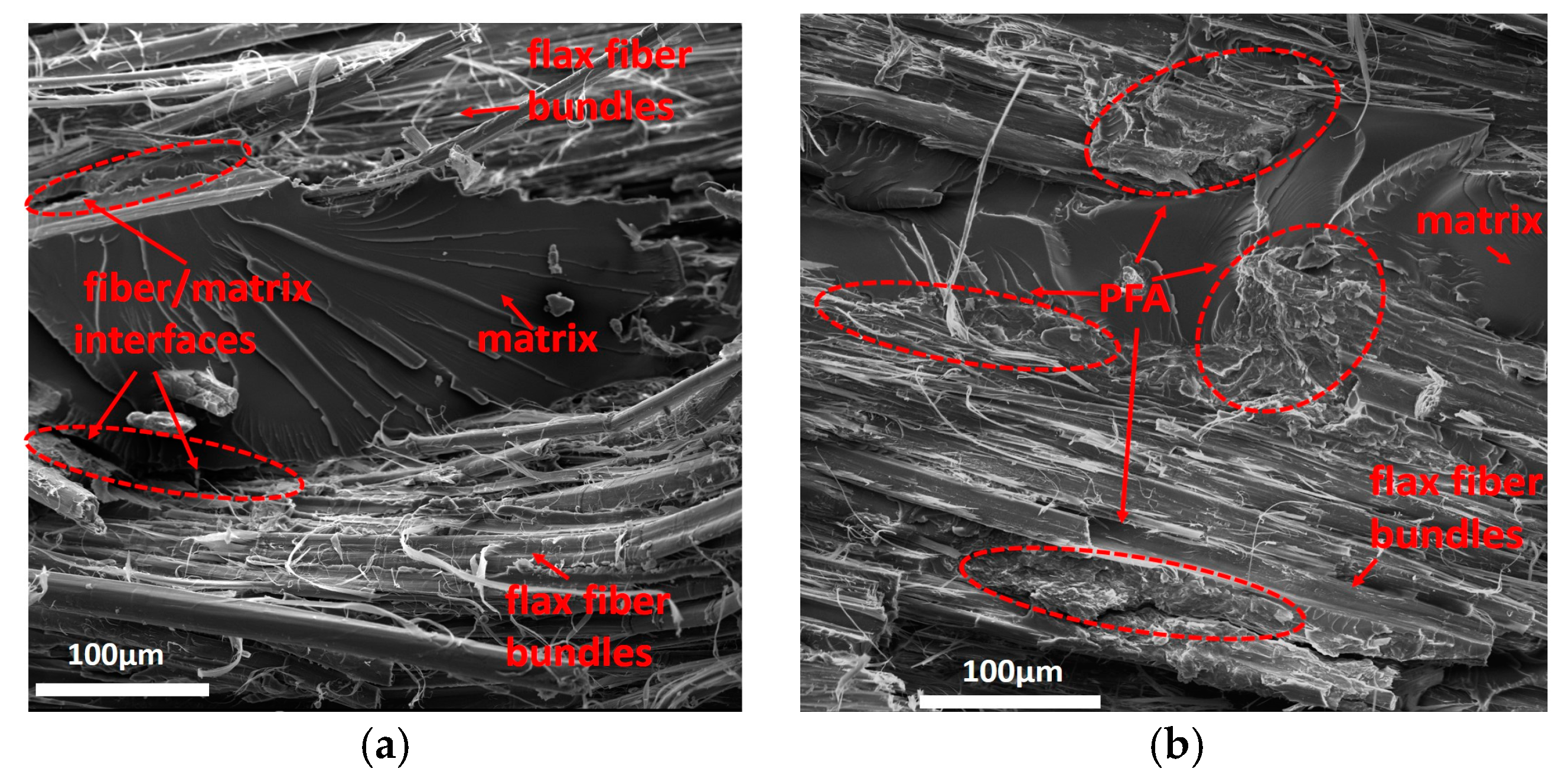

2.7. Scanning Electron Microscope (SEM)

2.8. Fourier Transform Infrared Spectroscopy (FTIR)

3. Results

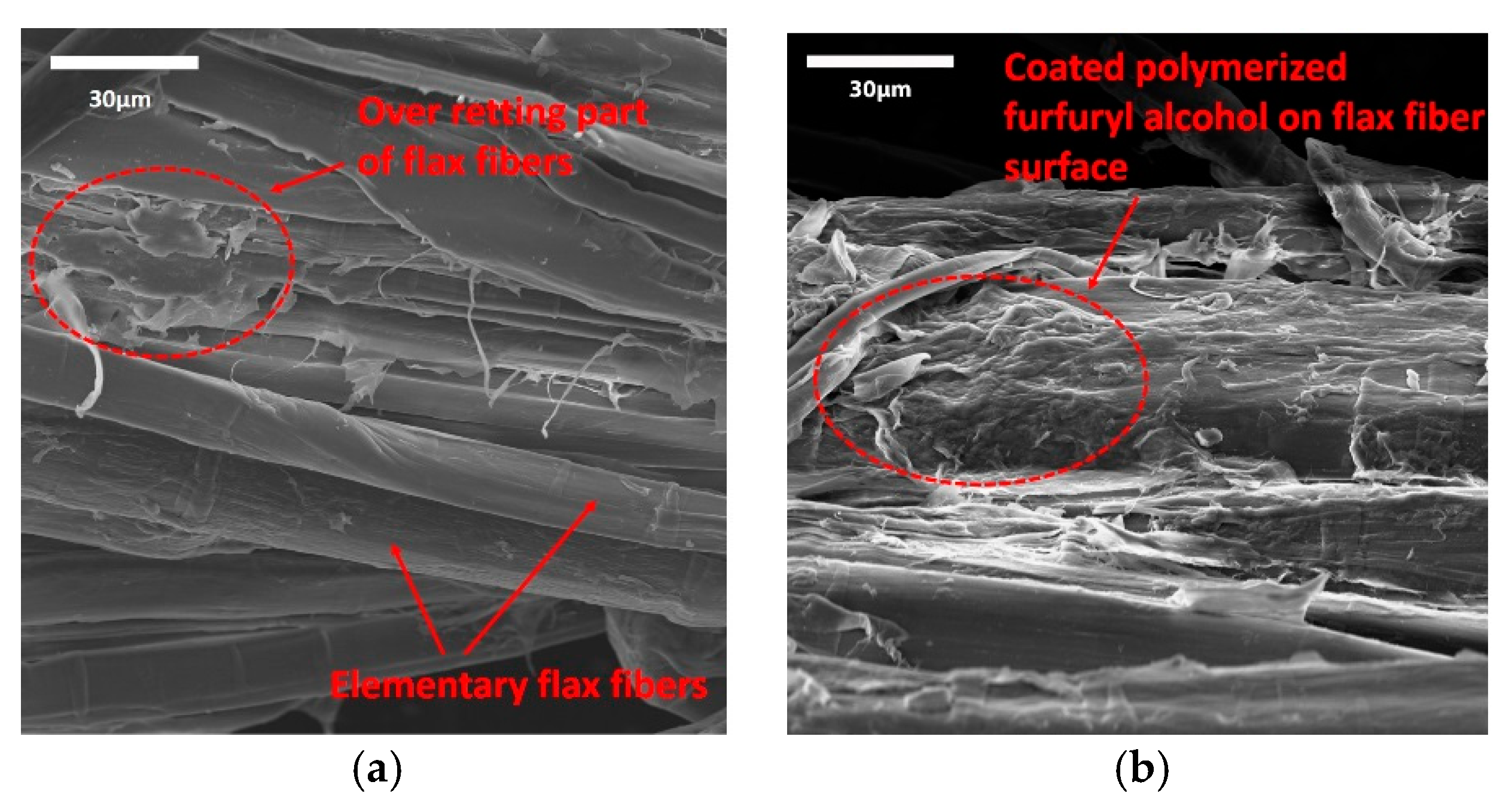

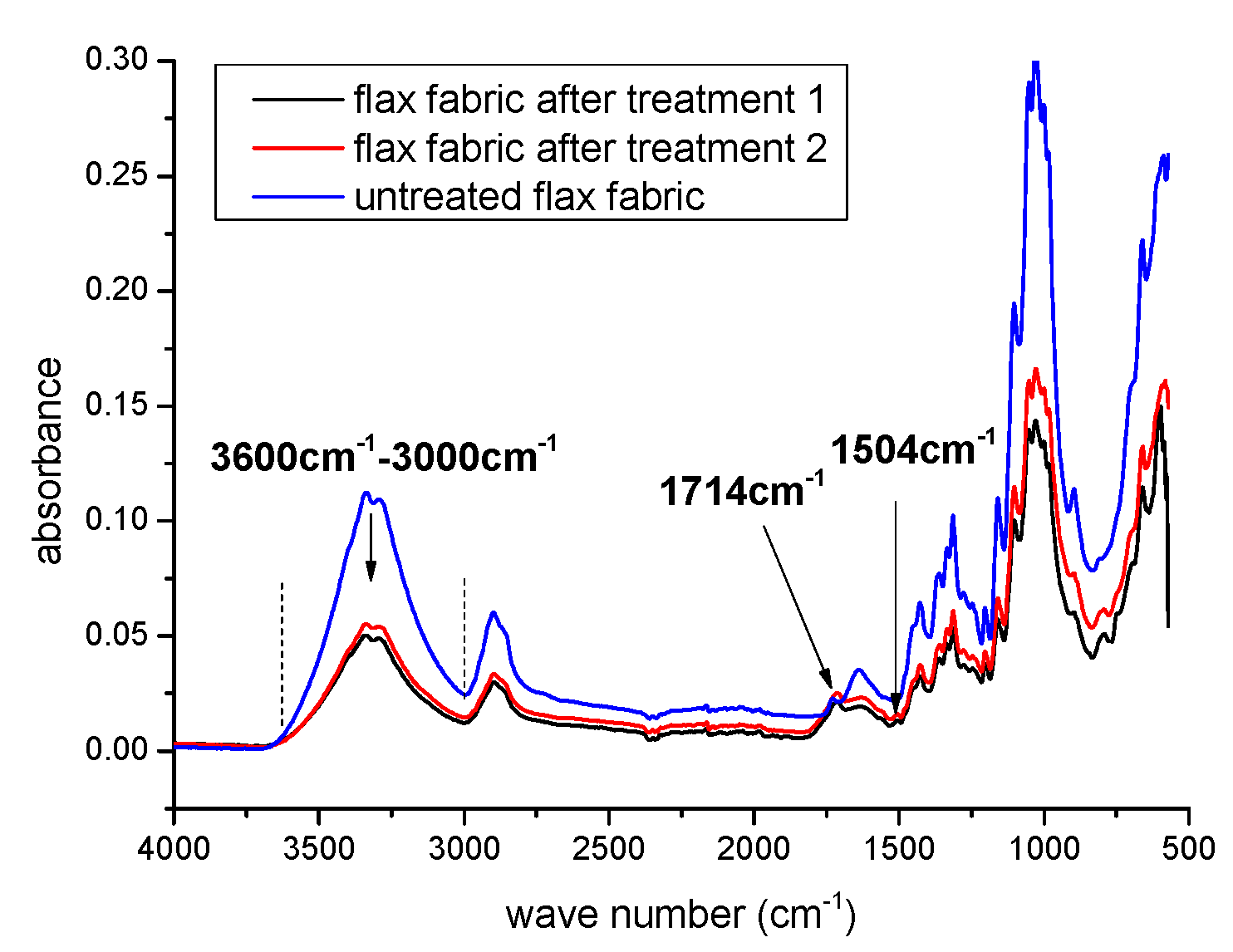

3.1. Characterization of FA Treatment

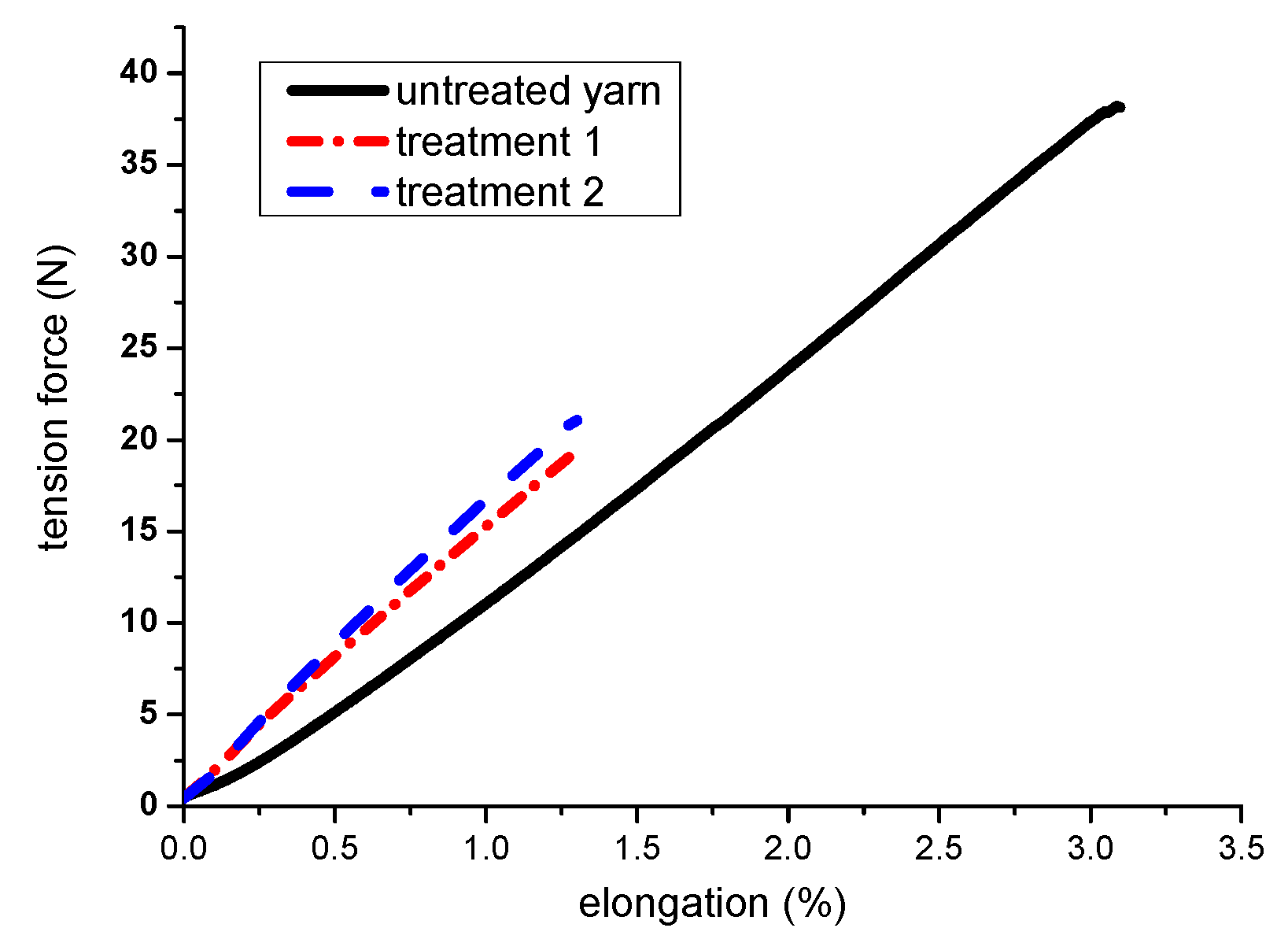

3.2. Tensile Tests on Flax Fiber Bundles

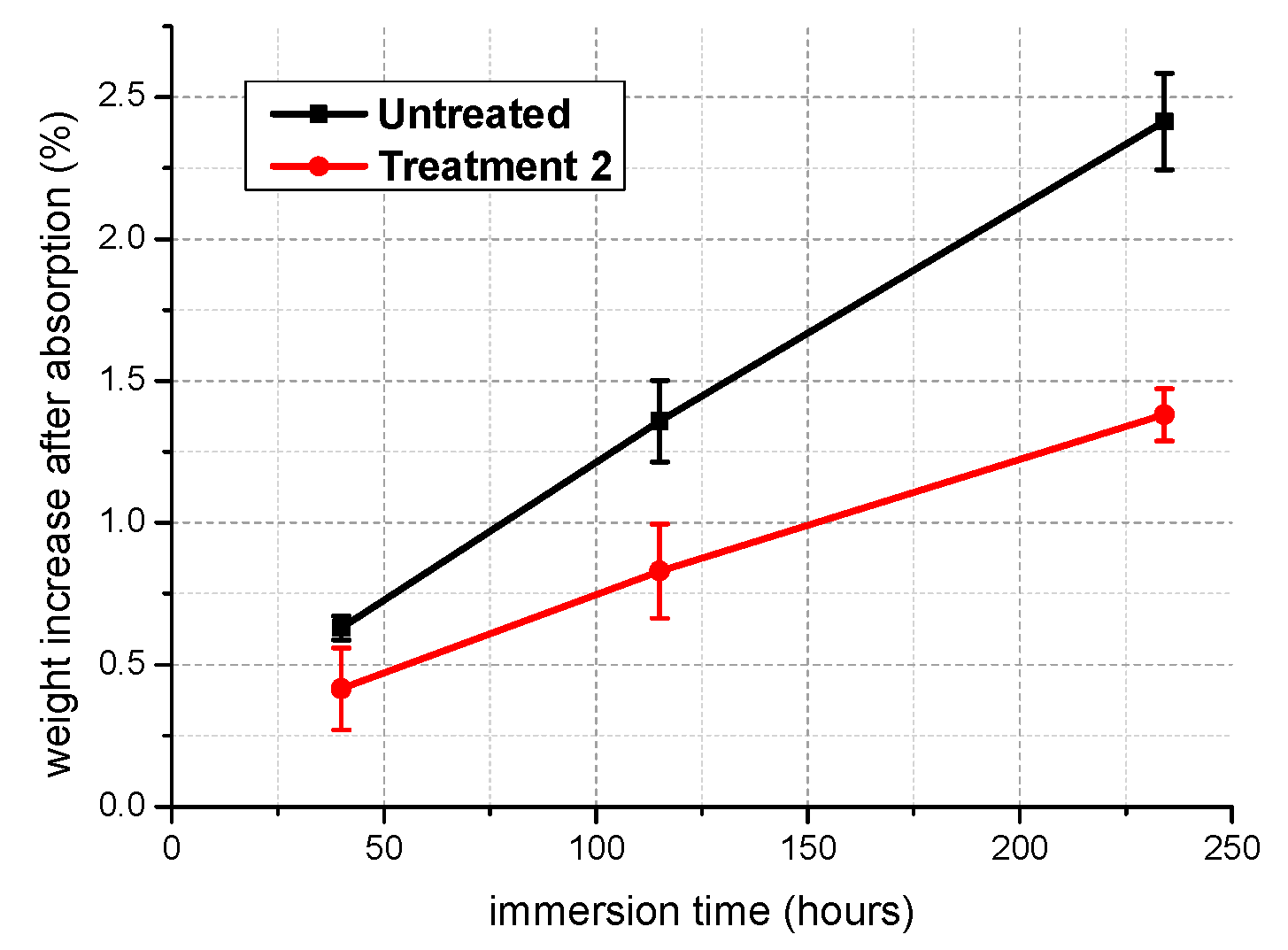

3.3. Moisture Absorption Tests

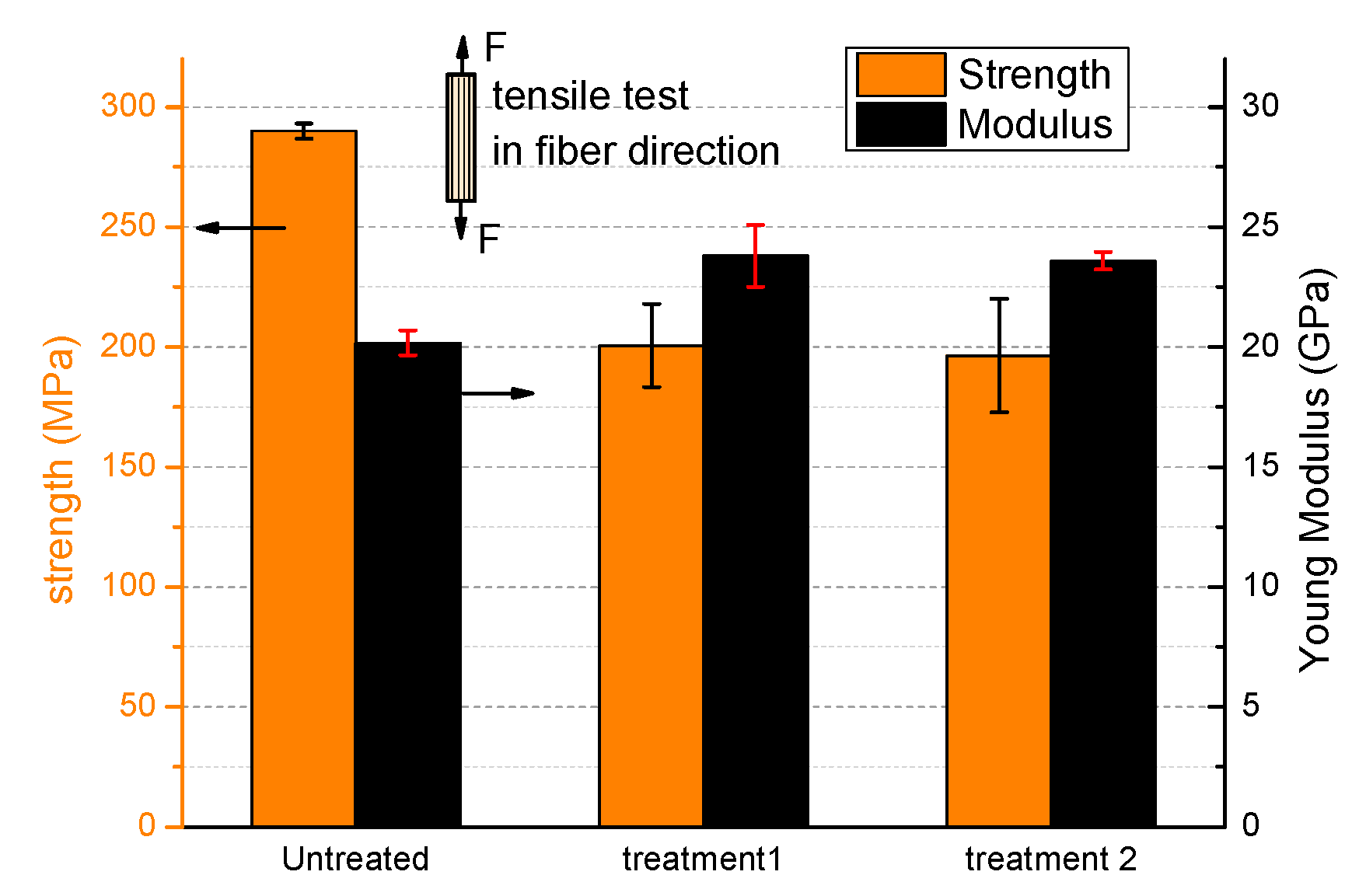

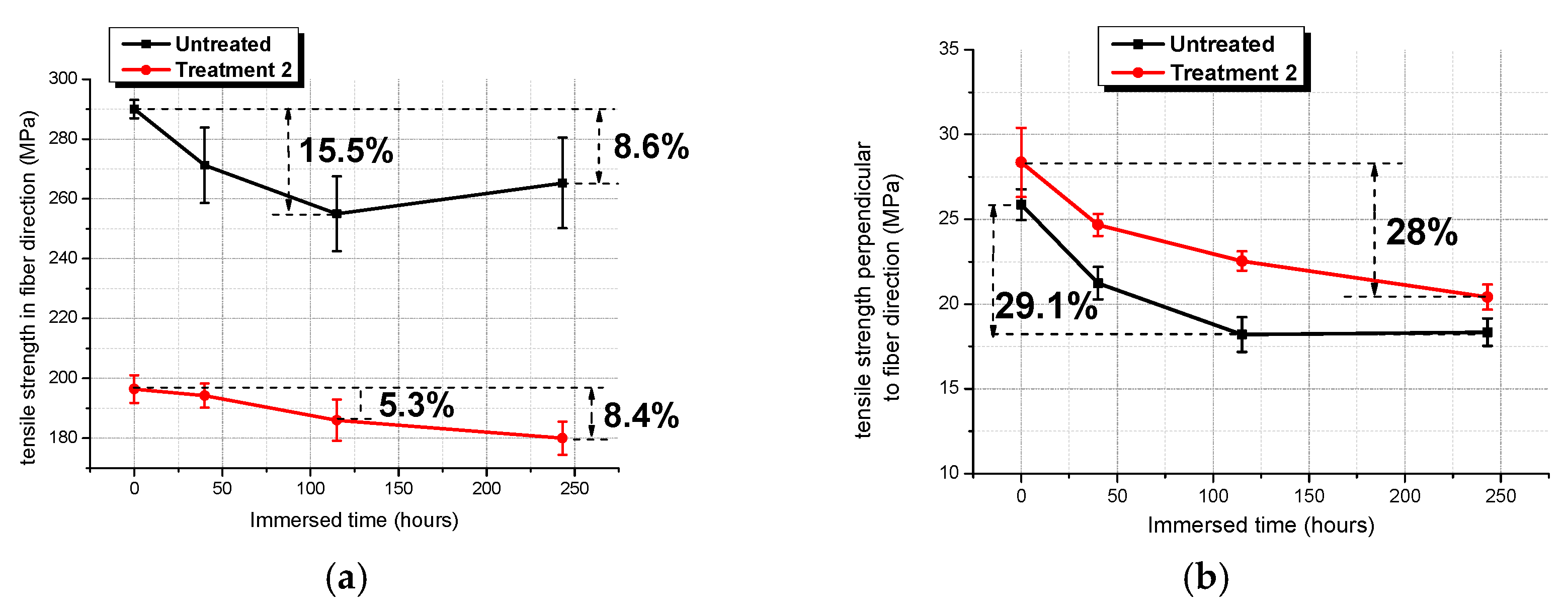

3.4. Tensile Tests on Flax Fiber Composites

4. Discussion

4.1. Influence of FA Treatment on the Mechanical Properties of Composites

4.2. Influence of FA Treatment on the Moisture Absorption of Composites

4.3. Influence of FA Treatment on the Retention Properties of Composites after Water Absorption

4.4. Comparison of FA Treatments with Different Heating Cycles

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J. Can flax replace E-glass in structural composites? A small wind turbine blade case study. Compos. Part B Eng. 2013, 52, 172–181. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of Flax Fibre based Textile Reinforcements for Composite Applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural Fibre Reinforced Composite Laminates–A Review. Mater. Today 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.-H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: an overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Shekar, H.S.; Ramachandra, M. Green Composites: A Review. Mater. Today 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr. Polym. 2015, 131, 337–354. [Google Scholar] [CrossRef] [PubMed]

- Hristozov, D.; Wroblewski, L.; Sadeghian, P. Long-term tensile properties of natural fibre-reinforced polymer composites: Comparison of flax and glass fibres. Compos. Part B Eng. 2016, 95, 82–95. [Google Scholar] [CrossRef]

- Cheour, K.; Assarar, M.; Scida, D.; Ayad, R.; Gong, X.-L. Effect of water ageing on the mechanical and damping properties of flax-fibre reinforced composite materials. Compos. Struct. 2016, 152, 259–266. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax–fibres and glass–fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Effect of water ageing on the load-unload cyclic behaviour of flax fibre-reinforced thermoplastic and thermosetting composites. Compos. Struct. 2018, 183, 309–319. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Effect of moisture content on the properties of silanized jute-epoxy composites. Polym. Compos. 1997, 18, 179–184. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Studies on water absorption of bamboo-epoxy composites: Effect of silane treatment of mercerized bamboo. J. Appl. Polym. Sci. 2010, 115, 1846–1852. [Google Scholar] [CrossRef]

- Zahari, W.; Badri, R.; Ardyananta, H.; Kurniawan, D.; Nor, F.M. Mechanical Properties and Water Absorption Behavior of Polypropylene/Ijuk Fiber Composite by Using Silane Treatment. Procedia Manuf. 2015, 2, 573–578. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Abhyankar, H.; Njuguna, J. Effect of Fibre Treatments on Water Absorption and Tensile Properties of Flax/Tannin Composites. In Proceedings of the 19th International Conference on Composite Materials, Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Deka, H.; Misra, M.; Mohanty, A. Renewable resource based “all green composites” from kenaf biofiber and poly(furfuryl alcohol) bioresin. Ind. Crops Prod. 2013, 41, 94–101. [Google Scholar] [CrossRef]

- Choura, M.; Belgacem, N.M.; Gandini, A. Acid-catalyzed polycondensation of furfuryl alcohol: Mechanisms of chromophore formation and cross-linking. Macromolecules 1996, 29, 3839–3850. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Ren, D.; Yu, Y.; Yu, Y. Wood modification with furfuryl alcohol catalysed by a new composite acidic catalyst. Wood Sci. Technol. 2015, 49, 845–856. [Google Scholar] [CrossRef]

- Lande, S.; Westin, M.; Schneider, M. Properties of furfurylated wood. Scand. J. For. Res. 2004, 19, 22–30. [Google Scholar] [CrossRef]

- Nordstierna, L.; Lande, S.; Westin, M.; Karlsson, O.; Furó, I. Towards novel wood-based materials: Chemical bonds between lignin-like model molecules and poly(furfuryl alcohol) studied by NMR. Holzforschung 2008, 62, 267. [Google Scholar] [CrossRef]

- Motaung, T.E.; Gqokoma, Z.; Linganiso, L.Z.; Hato, M.J. The effect of acid content on the poly(furfuryl) alcohol/cellulose composites. Polym. Compos. 2016, 37, 2434–2441. [Google Scholar] [CrossRef]

- Crossley, R.J.; Schubel, P.J.; Stevenson, A.; Moreira, M. The Development and Processing of a Sustainable Fully bio Derived Polyfurfuryl Alcohol Matrix Flax Fibre Prepreg. In Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Saw, S.K.; Purwar, R.; Nandy, S.; Ghose, J.; Sarkhel, G. Fabrication, Characterization, and Evaluation of Luffa cylindrica Fiber Reinforced Epoxy Composites. BioResources 2013, 8. [Google Scholar] [CrossRef]

- BS EN ISO. 62. Plastics–Determination of Water Absorption 1999; American National Standards Institute: New York, NY, USA, 2007.

- ASTM. D3039/D3039M. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Wyman, C.E. Ethanol from lignocellulosic biomass: technology, economics, and opportunities. Bioresour. Technol. 1994, 50, 3–15. [Google Scholar] [CrossRef]

- Marshall, W.E.; Akin, D.E.; Wartelle, L.H.; Annis, P.A. Citric acid treatment of flax, cotton and blended nonwoven mats for copper ion absorption. Ind. Crops Prod. 2007, 26, 8–13. [Google Scholar] [CrossRef]

- Liebig, W.V.; Leopold, C.; Hobbiebrunken, T.; Fiedler, B. New test approach to determine the transverse tensile strength of CFRP with regard to the size effect. Compos. Commun. 2016, 1, 54–59. [Google Scholar] [CrossRef]

- Subramanian, S.; Lesko, J.J.; Reifsnider, K.L.; Stinchcomb, W.W. Characterization of the fiber-matrix interphase and its influence on mechanical properties of unidirectional composites. J. Compos. Mater. 1996, 30, 309–332. [Google Scholar] [CrossRef]

| Treatments | Heating Cycles |

|---|---|

| T1 | 120 °C for 6 h → 150 °C for 4.5 h |

| T2 | 120 °C for 2 h → 150 °C for 7 h |

| Specimen | Testing Machine | Specimen Dimensions (mm) | Strain Measurement | Testing Speed |

|---|---|---|---|---|

| 0° | Zwick 100 kN | 2 × 18 × 250 | Clip-on extensometer | 2 mm/min |

| 90° | Zwick 2.5 kN | 2 × 20 × 110 | Displacement of traverse | 1 mm/min |

| Treatments | Break Force (N) | Strain at Breakage (%) |

|---|---|---|

| untreated | 37.16 ± 2.94 | 2.94 ± 0.43 |

| T1 | 19.76 ± 6.75 | 1.108 ± 0.356 |

| T2 | 20.17 ± 5.49 | 1.171 ± 0.36 |

| Time (h) | 0° Samples | 90° Samples | ||||

|---|---|---|---|---|---|---|

| Untreated | T1 | T2 | Untreated | T1 | T2 | |

| 40 | 0.630 ± 0.042 | 0.405 ± 0.170 | 0.415 ± 0.144 | 1.294 ± 0.209 | 0.569 ± 0.093 | 0.593 ± 0.082 |

| 115 | 1.358 ± 0.144 | - | 0.829 ± 0.166 | 3.199 ± 0.321 | - | 1.311 ± 0.135 |

| 243 | 2.414 ± 0.170 | 1.389 ± 0.119 | 1.380 ± 0.093 | 5.204 ± 0.337 | - | 2.755 ± 0.442 |

| Time (h) | Untreated | T2 | T1 | |||

|---|---|---|---|---|---|---|

| Strength (MPa) | Young Modulus (GPa) | Strength (MPa) | Young Modulus (GPa) | Strength (MPa) | Young Modulus (GPa) | |

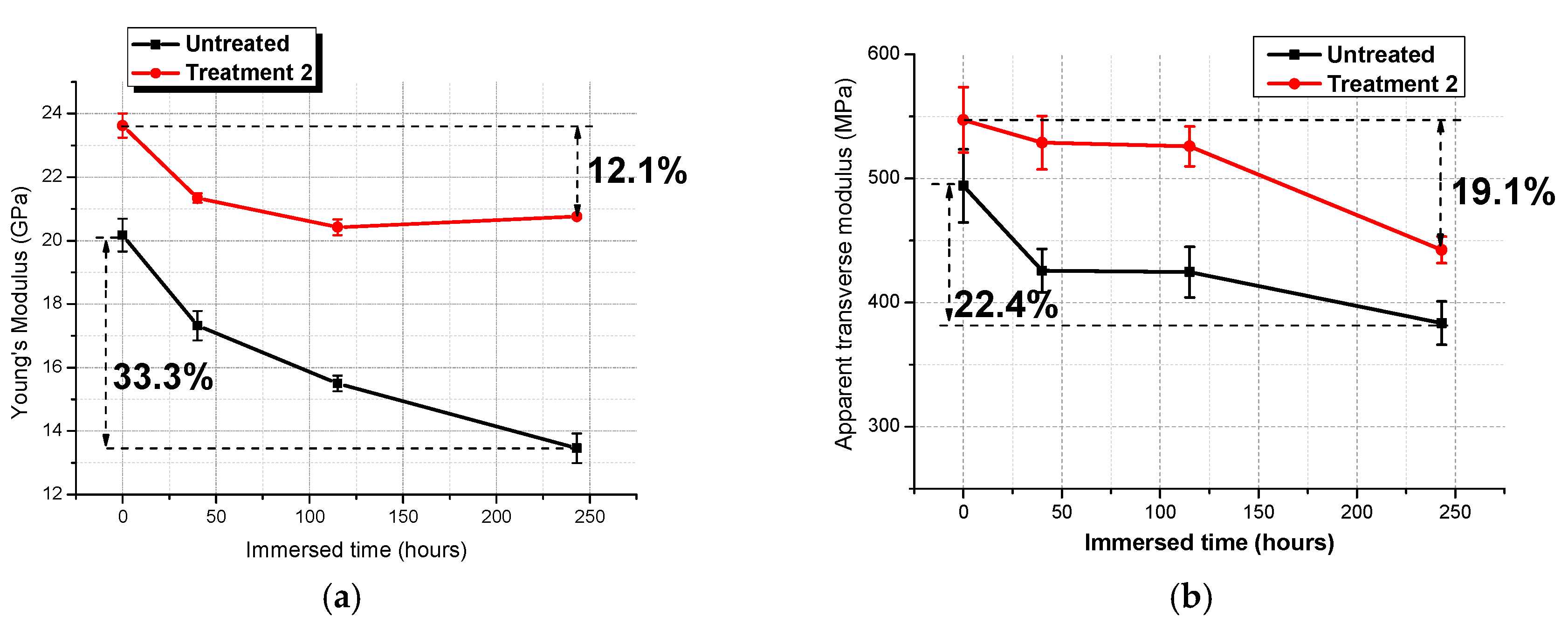

| 0 | 290.00 ± 3.08 | 20.17 ± 0.52 | 196.40 ± 4.62 | 23.62 ± 0.38 | 200.6 ± 17.37 | 23.8 ± 1.33 |

| 40 | 271.20 ± 12.60 | 17.32 ± 0.46 | 194.2 ± 4.02 | 21.34 ± 0.15 | - | - |

| 115 | 255.00 ± 12.59 | 15.50 ± 0.25 | 186.00 ± 6.89 | 20.42 ± 0.25 | - | - |

| 243 | 265.3 ± 15.13 | 13.46 ± 0.47 | 180.00 ± 5.58 | 20.77 ± 0.06 | 180.5 ± 2.38 | 20.4 ± 0.25 |

| Time (h) | Untreated | T2 | T1 | |||

|---|---|---|---|---|---|---|

| Strength (MPa) | Apparent Modulus (GPa) | Strength (MPa) | Apparent Modulus (GPa) | Strength (MPa) | Apparent Modulus (GPa) | |

| 0 | 25.87 ± 0.92 | 0.494 ± 0.029 | 28.36 ± 2.04 | 0.547 ± 0.026 | 27.74 ± 1.71 | 0.545 ± 0.027 |

| 40 | 21.24 ± 0.96 | 0.425 ± 0.017 | 24.67 ± 0.97 | 0.529 ± 0.022 | - | - |

| 115 | 18.20 ± 1.03 | 0.424 ± 0.020 | 22.54 ± 0.58 | 0.526 ± 0.016 | - | - |

| 243 | 18.34 ± 0.81 | 0.383 ± 0.018 | 20.41 ± 0.75 | 0.443 ± 0.011 | 20.15 ± 0.99 | 0.462 ± 0.009 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Fiedler, B. Influence of Furfuryl Alcohol Fiber Pre-Treatment on the Moisture Absorption and Mechanical Properties of Flax Fiber Composites. Fibers 2018, 6, 59. https://doi.org/10.3390/fib6030059

Jia Y, Fiedler B. Influence of Furfuryl Alcohol Fiber Pre-Treatment on the Moisture Absorption and Mechanical Properties of Flax Fiber Composites. Fibers. 2018; 6(3):59. https://doi.org/10.3390/fib6030059

Chicago/Turabian StyleJia, Yunlong, and Bodo Fiedler. 2018. "Influence of Furfuryl Alcohol Fiber Pre-Treatment on the Moisture Absorption and Mechanical Properties of Flax Fiber Composites" Fibers 6, no. 3: 59. https://doi.org/10.3390/fib6030059

APA StyleJia, Y., & Fiedler, B. (2018). Influence of Furfuryl Alcohol Fiber Pre-Treatment on the Moisture Absorption and Mechanical Properties of Flax Fiber Composites. Fibers, 6(3), 59. https://doi.org/10.3390/fib6030059