Heat and Mass Transfer Properties of Sugar Maple Wood Treated by the Thermo-Hygro-Mechanical Densification Process

Abstract

:1. Introduction

2. Materials and Methods

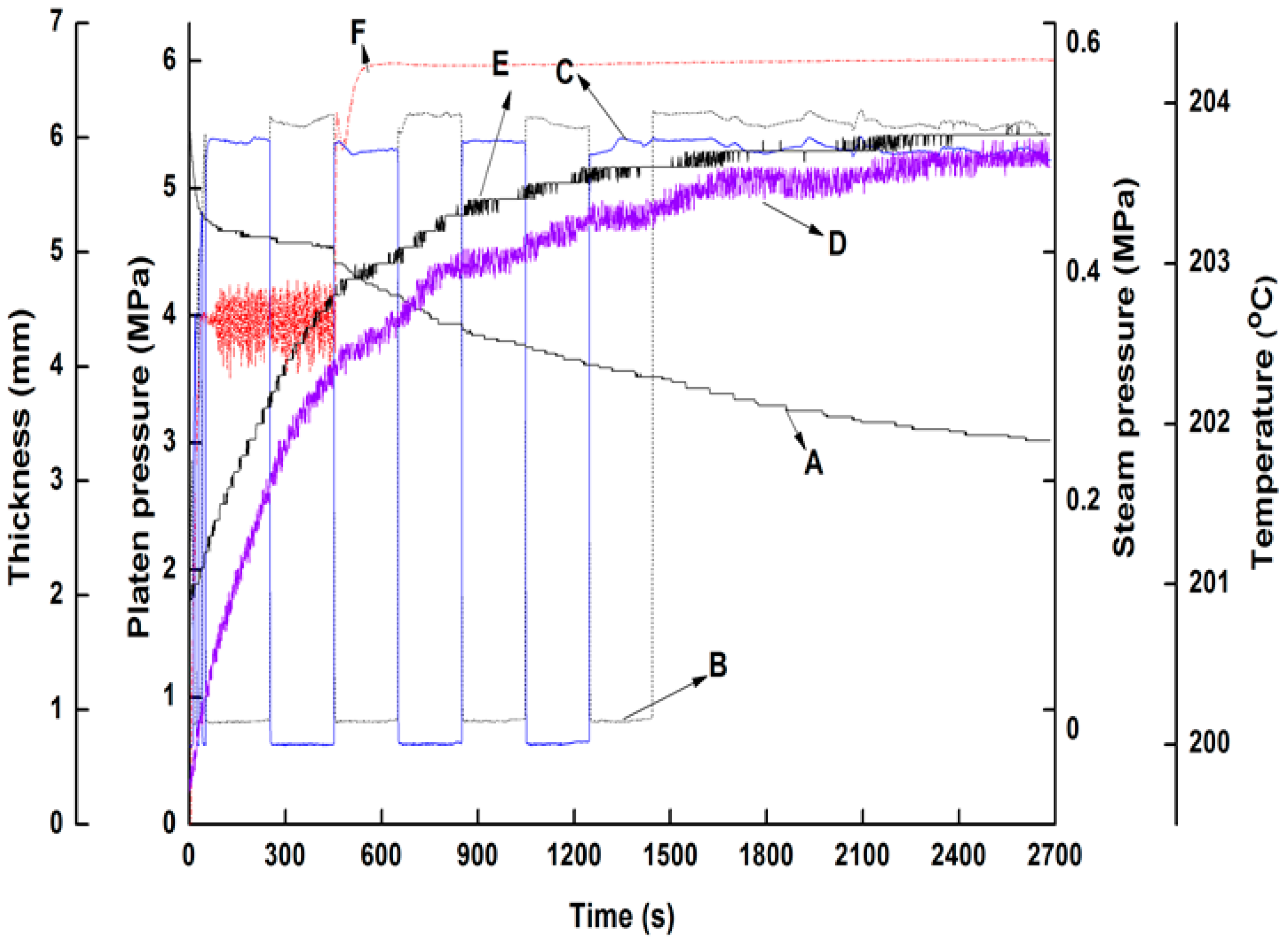

2.1. Thermo-Hygro-Mechanical Densification Process

2.2. Properties Determination—Oven-Dry Average Density

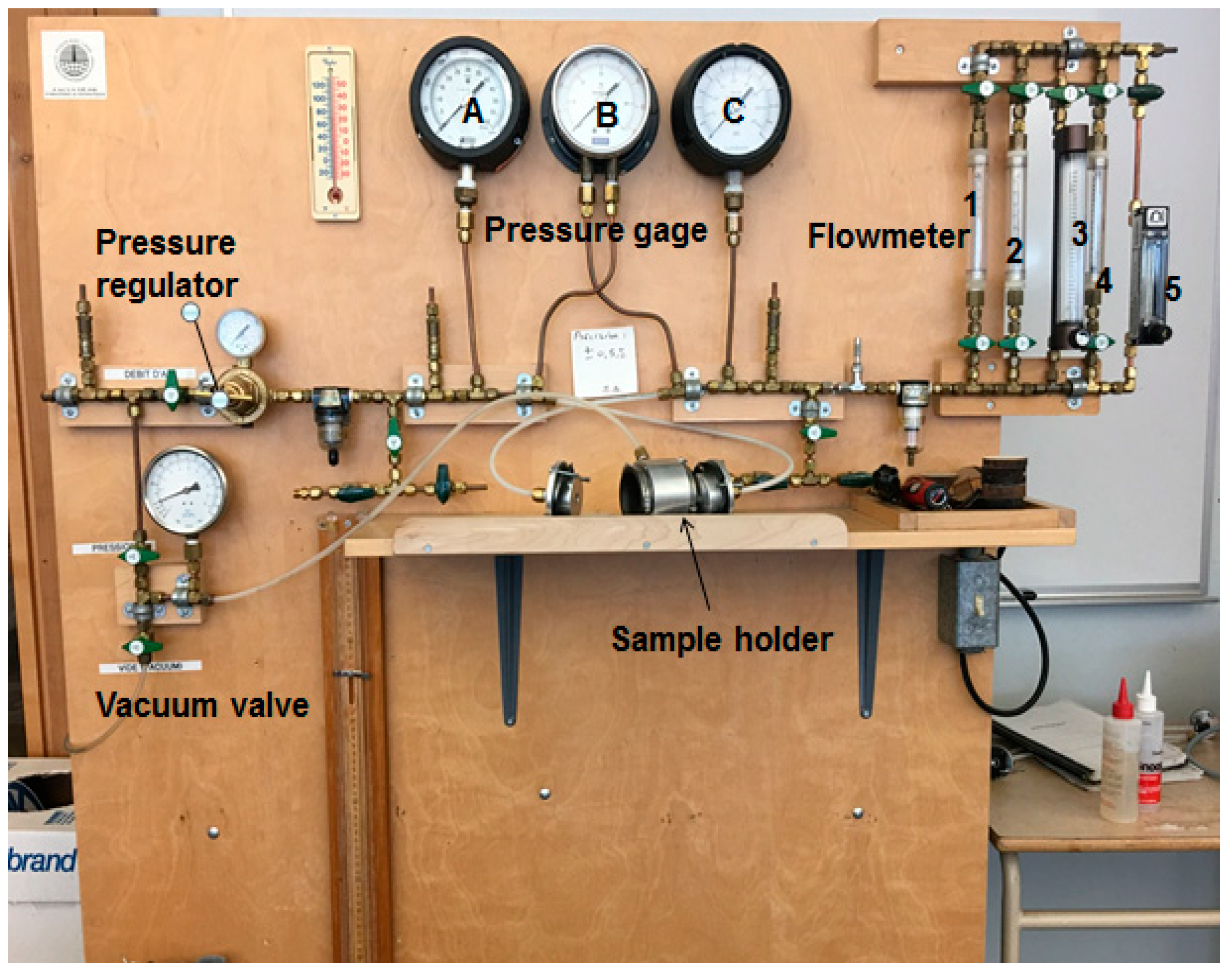

2.3. Permeability Measurement

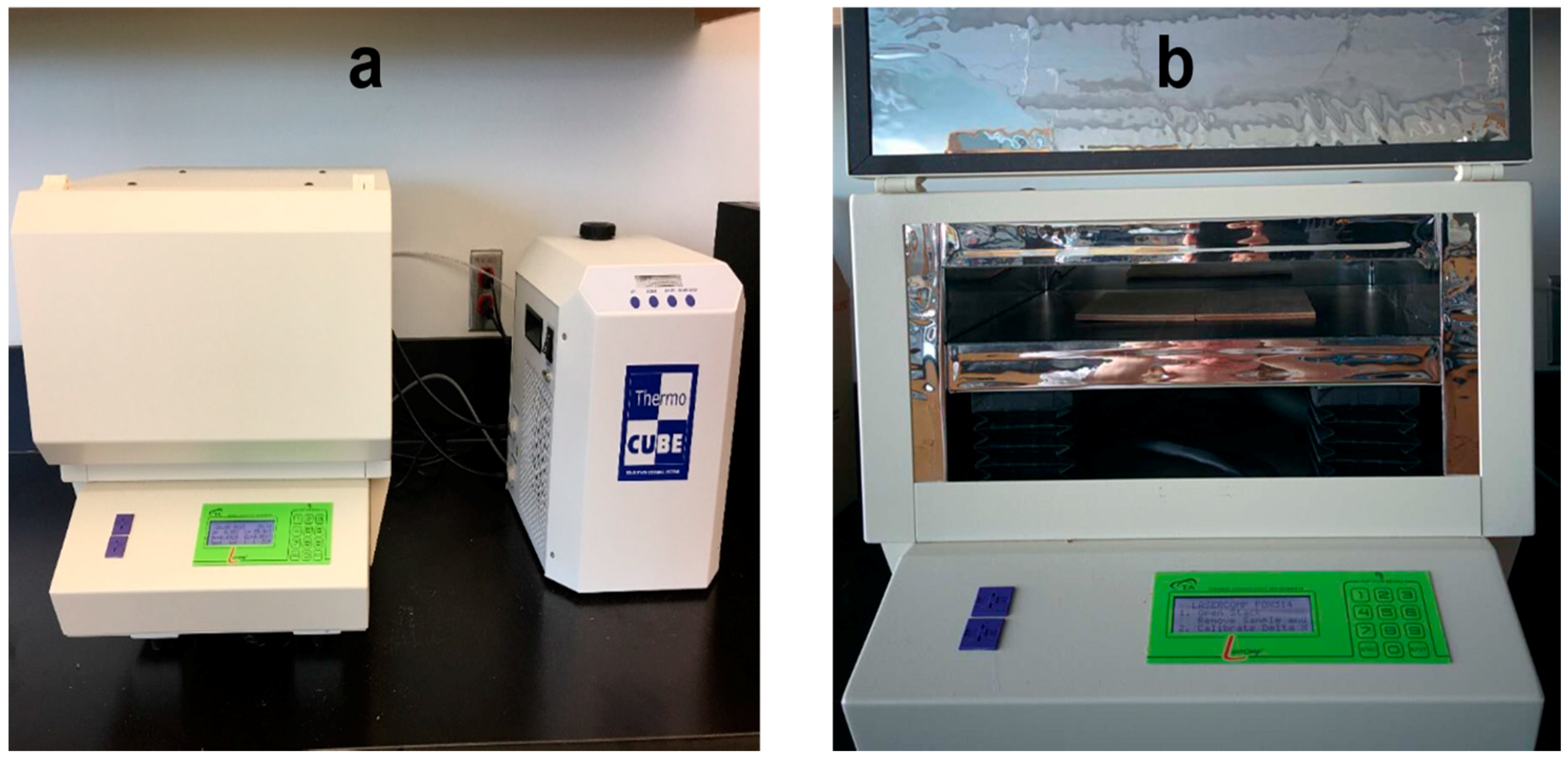

2.4. Thermal Conductivity Measurement

2.5. Statistical Analysis

3. Results

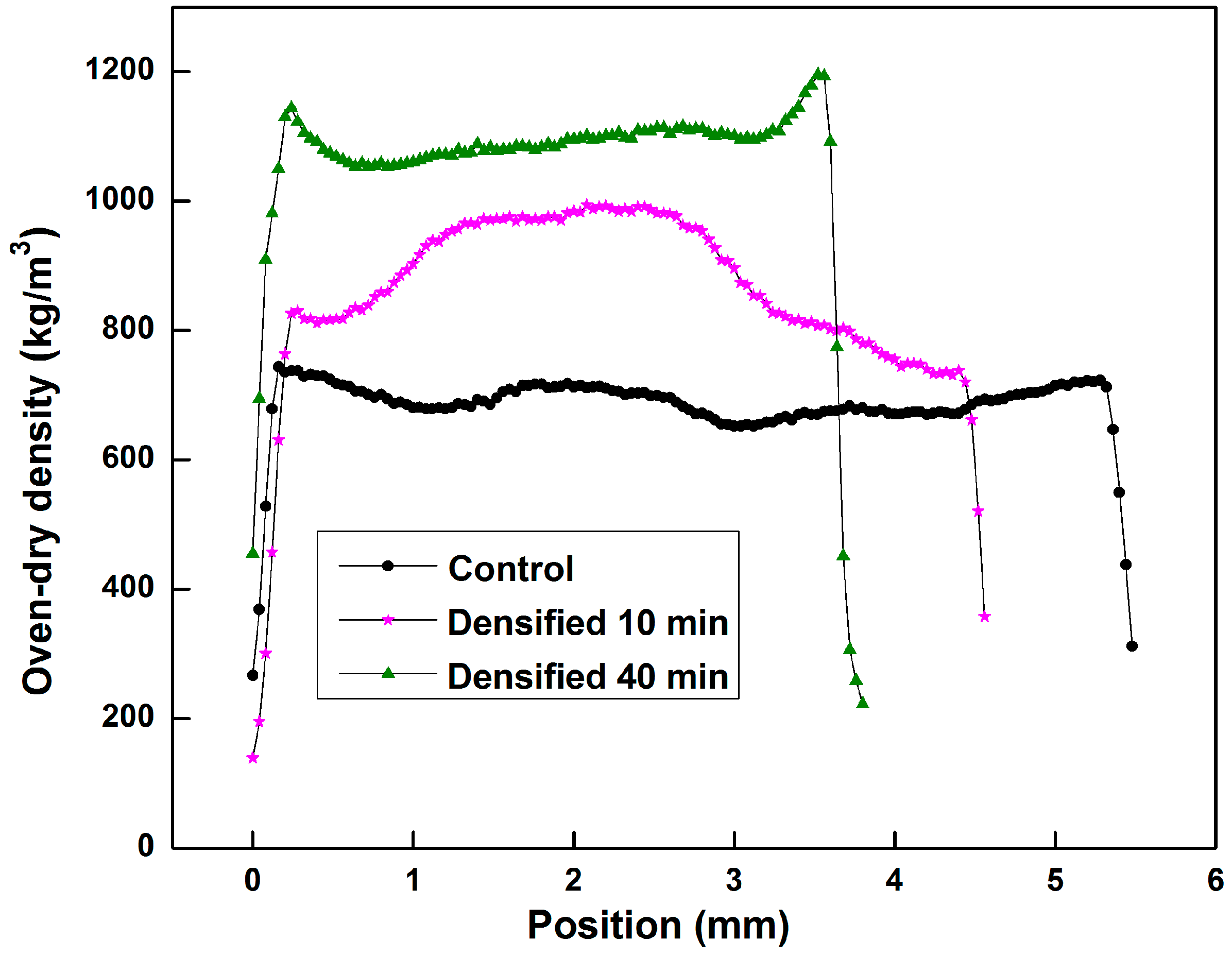

3.1. Density Profile and Oven-Dry Density

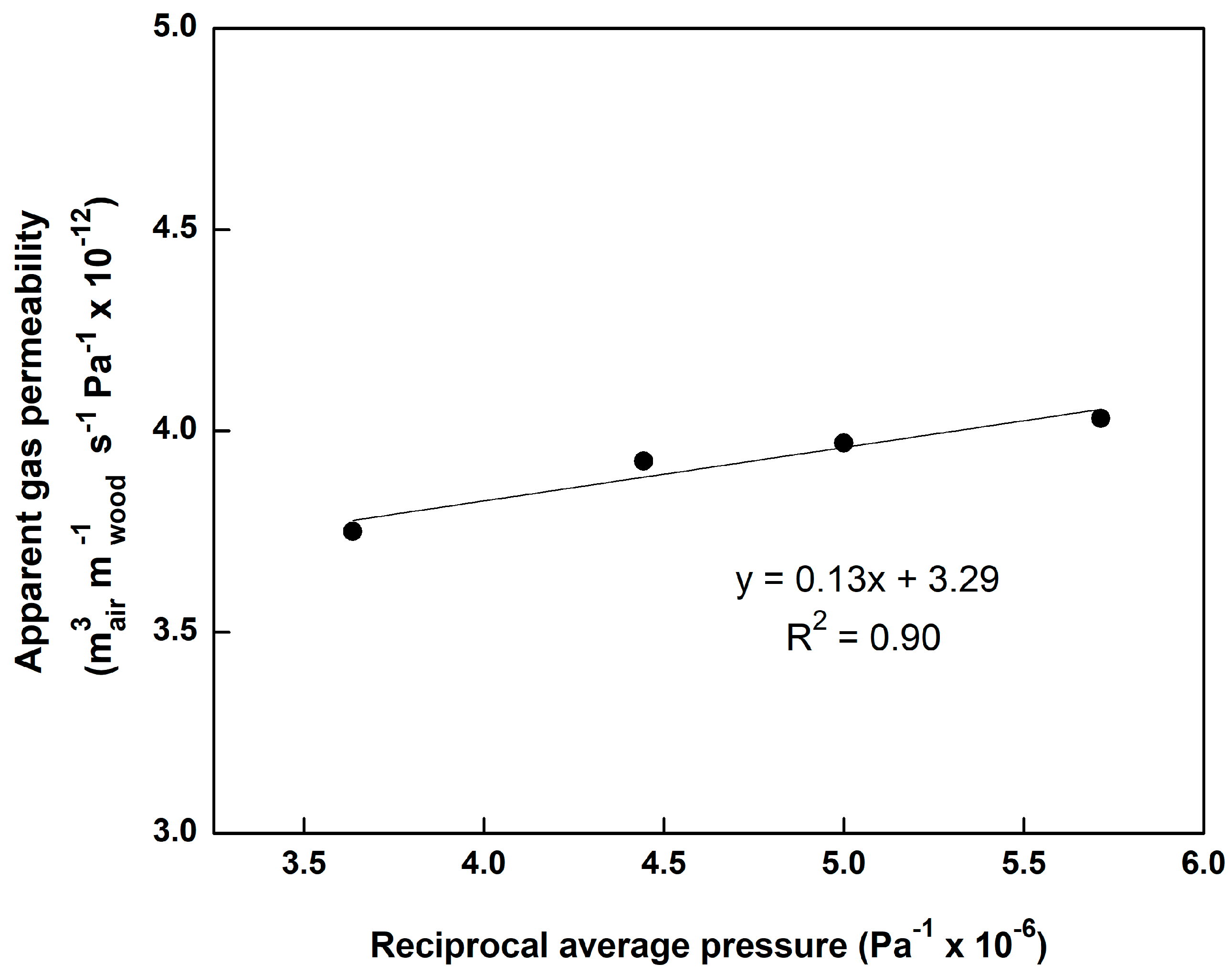

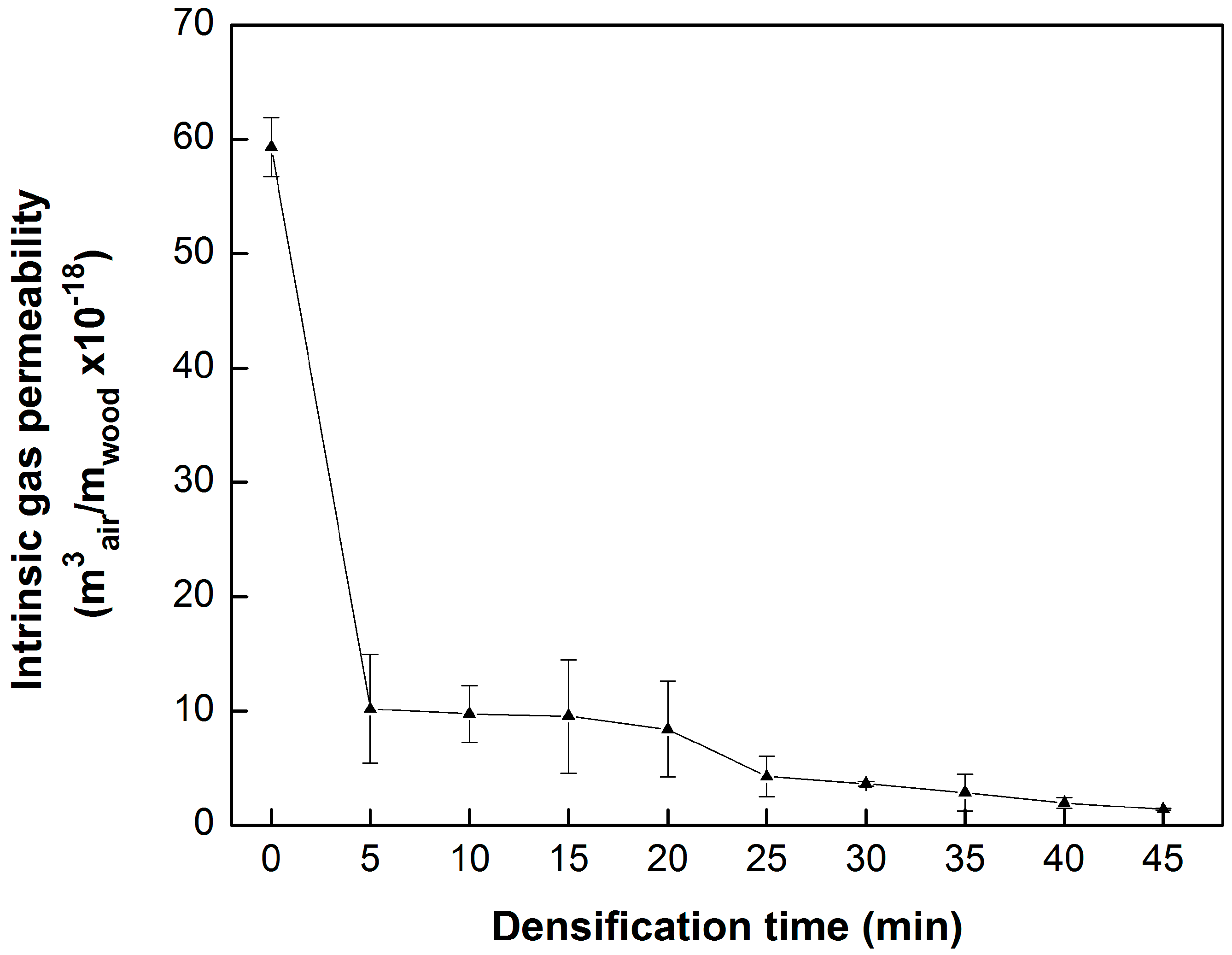

3.2. Gas Permeability

3.3. Thermal Conductivity

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Siau, J.F. Transport Processes in Wood; Springer: Heidelberg, Germany, 1984; ISBN 13:978-3-642-69215-4. [Google Scholar]

- Dai, C.P.; Yu, C.M.; Zhou, X.Y. Heat and mass transfer in wood composite panels during hot pressing. Part II. Modeling void formation and mat permeability. Wood Fiber Sci. 2005, 37, 242–257. [Google Scholar]

- Comstock, G.L. Directional permeability of softwoods. Wood Fiber Sci. 2007, 1, 283–289. [Google Scholar]

- Denisov, O.B.; Anisov, P.P.; Zuban, P.E. Untersuchung der permeabilität von spanvliesen. Holztechnologie 1975, 16, 10–14. [Google Scholar]

- Hata, T.; Kawai, S.; Ebihara, T.; Sasaki, H. Production of particleboards with steam-injection press. Press V. Effects of particle geometry on temperature behaviors in particle mats and on air permeabilities of boards. Mokuzai Galdcaishi 1993, 39, 161–168. [Google Scholar]

- Von Haas, G.; Steffen, A.; Frühwald, A. Permeability of fibre, particle and strand mats for gas. Holz Roh Werkst. 1998, 56, 386–392. [Google Scholar]

- Lihra, T.; Cloutier, A.; Zhang, S.Y. Longitudinal and transverse permeability of balsam fir wetwood and normal heartwood. Wood Fiber Sci. 2000, 32, 164–178. [Google Scholar]

- García, R.A.; Cloutier, A. Characterization of heat and mass transfer in the mat during the hot pressing of MDF panels. Wood Fiber Sci. 2005, 37, 23–41. [Google Scholar]

- Defo, M.; Cloutier, A.; Fortin, Y. Modeling vacuum-contact drying of wood: The water potential approach. Dry. Technol. 2000, 18, 1737–1778. [Google Scholar] [CrossRef]

- Thömen, H. Modeling the Physical Processes in Natural Fiber Composites during Batch and Continuous Pressing. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, May 2000. [Google Scholar]

- Gu, H.M.; Zink-Sharp, A. Geometric model for softwood transverse thermal conductivity. Part I. Wood Fiber Sci. 2005, 37, 699–711. [Google Scholar]

- Simpson, W.; TenWolde, A. Physical properties and moisture relations of wood. In Wood Handbook: Wood as an Engineering Material; Ross, R.J., Ed.; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; pp. 3–17. [Google Scholar]

- Troppová, E.; Švehlík, M.; Tippner, J.; Wimmer, R. Influence of temperature and moisture content on the thermal conductivity of wood-based fibreboards. Mater. Struct. 2015, 48, 4077–4083. [Google Scholar] [CrossRef]

- Griffiths, E.; Kaye, G.W.C. The measurement of thermal conductivity. Proc. R. Soc. A 1923, 104, 71–98. [Google Scholar] [CrossRef]

- MacLean, J.D. Thermal conductivity of wood. Heat. Pip. Air Cond. 1941, 13, 380–391. [Google Scholar]

- Suleiman, B.M.; Larfeldt, J.; Leckner, B.; Gustavsson, M. Thermal conductivity and diffusivity of wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Haselein, C.R. Numerical Simulation of Pressing Wood-Fiber Composites. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, January 1998. [Google Scholar]

- De Moura, L.F.; Hernández, R.E. Evaluation of varnish coating performance for two surfacing methods on sugar maple wood. Wood Fiber Sci. 2005, 37, 355–366. [Google Scholar]

- Fang, C.H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Fu, Q.; Cloutier, A.; Laghdir, A. Optimization of the thermo-hygromechanical (THM) process for sugar maple wood densification. BioResources 2016, 11, 8844–8859. [Google Scholar] [CrossRef]

- Siau, J.F. Wood: Influence of Moisture on Physical Properties; Department of Wood Science and Forest Products, Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1995; ISBN 13:9780962218101-10:0962218103. [Google Scholar]

- Fu, Q.; Cloutier, A.; Laghdir, A. Effects of heat and steam on the mechanical properties and dimensional stability of thermo-hygromechanically densified sugar maple wood. BioResources 2017, 12, 9212–9226. [Google Scholar] [CrossRef]

- Finnish ThermoWood Association. ThermoWood Handbook; Finnish ThermoWood Association: Helsinki, Finland, 2003. [Google Scholar]

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F Value | p Value | Remarks |

|---|---|---|---|---|---|---|

| Densification time | 280,224.4 | 9 | 31,136.0 | 6.8 | 0.0002 | Significant |

| Treatment Time (min) | Thickness (mm) (n = 3) | Oven-Dry Density (kg/m3) (n = 3) |

|---|---|---|

| 0 | 5.63 (0.11) | 694.3 (4.1) c,* |

| 5 | 4.49 (0.15) | 848.6 (82.8) b |

| 10 | 4.26 (0.04) | 845.4 (76.1) b |

| 15 | 3.81 (0.09) | 917.3 (61.0) a,b |

| 20 | 3.8 (0.10) | 948.3 (106.2) a,b |

| 25 | 3.63 (0.04) | 947.1 (43.5) a,b |

| 30 | 3.6 (0.07) | 952.7 (81.9) a,b |

| 35 | 3.68 (0.06) | 1039.6 (60.6) a |

| 40 | 3.57 (0.09) | 1031.6 (44.2) a |

| 45 | 3.51 (0.08) | 969.5 (65.6) a,b |

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F Value | p Value | Remarks |

|---|---|---|---|---|---|---|

| Densification time (data after logarithmic transformation treatment) | 5.9 | 9 | 0.66 | 22.61 | <0.0001 | Significant |

| Treatment Time (min) | Oven-Dry Density (kg/m3) (n = 3) | Intrinsic Gas Permeability | Intrinsic Gas Permeability (after Logarithm Transformation) |

|---|---|---|---|

| 0 | 694.3 (4.1) c,* | 5.93 × 10−17 (2.57 × 10−18) | −16.23 a,* |

| 5 | 848.6 (82.8) b | 1.02 × 10−17 (4.71 × 10−18) | −17.02 b |

| 10 | 845.4 (76.1) b | 9.74 × 10−18 (2.48 × 10−18) | −17.02 b |

| 15 | 917.3 (61.0) a,b | 9.53 × 10−18 (4.95 × 10−18) | −17.06 b |

| 20 | 948.3 (106.2) a,b | 8.40 × 10−18 (4.19 × 10−18) | −17.12 b,c |

| 25 | 947.1 (43.5) a,b | 4.28 × 10−18 (1.76 × 10−18) | −17.40 c,d |

| 30 | 952.7 (81.9) a,b | 3.63 × 10−18 (2.00 × 10−19) | −17.44 d,e |

| 35 | 1039.6 (60.6) a | 2.87 × 10−18 (1.64× 10−18) | −17.58 d,e,f |

| 40 | 1031.6 (44.2) a | 1.95 × 10−18 (4.8 × 10−19) | −17.72 e,f |

| 45 | 969.5 (65.6) a,b | 1.4 × 10−18 (0.84 × 10−19) | −17.86 f |

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F Value | p Value | Remarks |

|---|---|---|---|---|---|---|

| Densification time | 0.014 | 9 | 0.002 | 38.88 | <0.0001 | Significant |

| Moisture content | 0.001 | 2 | 0.001 | 19.18 | <0.0001 | Significant |

| Densification time * Moisture content | 0.0002 | 18 | 0 | 0.24 | 0.99 |

| Treatment Time (min) | Oven-Dry Density (kg/m3) (n = 3) | Thickness (mm) MC = 0% (n = 4) | Thermal Conductivity (W·m−1·K−1) (MC = 0%) (n = 4) | Thermal Conductivity (W·m−1·K−1) (MC = 6%) (n = 4) | Thermal Conductivity (W·m−1·K−1) (MC = 12%) (n = 4) |

|---|---|---|---|---|---|

| 0 | 694.3 (4.1) c,* | 5.43 (0.11) | 0.124 (0.008) b,* | 0.130 (0.005) b | 0.140 (0.002) a |

| 5 | 848.6 (82.8) b | 4.42 (0.19) | 0.097 (0.006) c,d,e,f,g,h | 0.102 (0.005) c,d,e,f | 0.106 (0.006) c |

| 10 | 845.4 (76.1) b | 4.08 (0.24) | 0.095 (0.009) d,e,f,g,h | 0.098 (0.010) c,d,e,f,g,h | 0.103 (0.009) c,d,e |

| 15 | 917.3 (61.0) a,b | 3.78 (0.10) | 0.096 (0.009) c,d,e,f,g,h | 0.099 (0.009) c,d,e,f,g | 0.105 (0.008) c,d |

| 20 | 948.3 (106.2) a,b | 3.75 (0.16) | 0.094 (0.005) e,f,g,h | 0.096 (0.005) c,d,e,f,g,h | 0.101 (0.005) c,d,e,f,g |

| 25 | 947.1 (43.5) a,b | 3.62 (0.15) | 0.092 (0.008) e,f,g,h | 0.094 (0.007) d,e,f,g,h | 0.099 (0.008) c,d,e,f,g |

| 30 | 952.7 (81.9) a,b | 3.60 (0.10) | 0.091 (0.004) f,g,h | 0.094 (0.002) d,e,f,g,h | 0.099 (0.002) c,d,e,f,g |

| 35 | 1039.6 (60.6) a | 3.63 (0.09) | 0.090 (0.002) g,h | 0.093 (0.002) e,f,g,h | 0.099 (0.004) c,d,e,f,g |

| 40 | 1031.6 (44.2) a | 3.56 (0.12) | 0.095 (0.005) d,e,f,g,h | 0.097 (0.005) c,d,e,f,g,h | 0.100 (0.006) c,d,e,f,g |

| 45 | 969.5 (65.6) a,b | 3.44 (0.06) | 0.088 (0.007) h | 0.093 (0.004) e,f,g,h | 0.096 (0.005) c,d,e,f,g,h |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Q.; Cloutier, A.; Laghdir, A. Heat and Mass Transfer Properties of Sugar Maple Wood Treated by the Thermo-Hygro-Mechanical Densification Process. Fibers 2018, 6, 51. https://doi.org/10.3390/fib6030051

Fu Q, Cloutier A, Laghdir A. Heat and Mass Transfer Properties of Sugar Maple Wood Treated by the Thermo-Hygro-Mechanical Densification Process. Fibers. 2018; 6(3):51. https://doi.org/10.3390/fib6030051

Chicago/Turabian StyleFu, Qilan, Alain Cloutier, and Aziz Laghdir. 2018. "Heat and Mass Transfer Properties of Sugar Maple Wood Treated by the Thermo-Hygro-Mechanical Densification Process" Fibers 6, no. 3: 51. https://doi.org/10.3390/fib6030051

APA StyleFu, Q., Cloutier, A., & Laghdir, A. (2018). Heat and Mass Transfer Properties of Sugar Maple Wood Treated by the Thermo-Hygro-Mechanical Densification Process. Fibers, 6(3), 51. https://doi.org/10.3390/fib6030051